Page 1

Rev. 01

Man. WD1050

Pag. 1 - 40

The machine must only be installed, serviced and repaired by

authorized personnel.

The warranty could become void if the machine is used in a way

that Fails to Conform to the instructions given by SMEG.

19 390 2191 01

02/03/2011

Rev.

Date

READ THE INSTRUCTIONS MANUAL CAREFULLY

Failure to read the manual, misunderstandings or incorrect interpretation of the

instructions herein may result in damage to the appliance. Moreover, such action may

also become a source of danger for the user and considerably lower the performances

of the machine.

The manufacturer declines all liability for use of the machine

differing from that described in this manual.

The text and illustrations in this manual are for informative purposes only. The

contents and appliance described herein may be liable to modification without prior

notice. In no case may SMEG be held liable for any direct or indirect damages deriving

from or in relation to use of this manual.

Page 2

Rev. 01

Man. WD1050

Pag. 2 - 40

Information or Assistance for products from the

SMEG Instruments Division

If so, please contact us from 8 a.m. until 6 p.m. at the following numbers and

addresses:

www.smeg-instrumens.com

instruments@smeg.it

Fax +39 0522 821 592

Tel +39 0522 8211

Our Sales Office staff will give you all the info you require about prices and

offers. You can also view our entire production range in our web site along with any

innovations.

Our Technical Assistance Office staff can tell you how to operate your appliance

in the correct way or put you in contact with your nearest Authorized Assistance

Centre if necessary.

International customers, please contact your local SMEG distributor.

Page 3

Rev. 01

Man. WD1050

Pag. 3 - 40

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................................ 5

2. SYMBOLS LEGEND .......................................................................................... 6

3. GENERAL RECOMMENDATIONS ..................................................................... 6

4. GENERAL SPECIFICATIONS ............................................................................ 8

4.1. TECHNICAL FEATURES ................................ ............................................................. 8

4.2. LIFTING AND HANDLING ............................................................................................ 9

4.3. DOOR LOCKING SYSTEM .......................................................................................... 9

4.4. MANUAL DOOR UNLOCKING ................................................................................... 10

5. INSTALLATION ............................................................................................... 11

5.1. POSITIONING ........................................................................................................... 11

5.2. LEVELLING ............................................................................................................... 11

5.3. CONNECTION TO WATER MAINS ............................................................................ 12

5.4. WATER SUPPLY ....................................................................................................... 13

5.5. NON PRESSURIZED DEMINERALIZED WATER CONNECTION ................................ 14

5.6. WATER DRAIN CONNECTION .................................................................................. 15

5.7. ELECTRICAL CONNECTION ..................................................................................... 16

6. DESCRIPTION OF CONTROLS ....................................................................... 17

6.1. SETUP DESCRIPTION .............................................................................................. 18

6.2. WASHING PROGRAMME SETTINGS ........................................................................ 20

6.3. THERMAL DISINFECTION IN ACCORDANCE WITH THE PARAMETER "A0" ............. 20

6.4. PROGRAMMES DESCRIPTION ................................................................................ 22

6.5. MACHINE RUNNING ................................................................................................. 23

6.6. RESIN WASHING PHASE ................................ ......................................................... 24

6.7. RESIN REGENERATION PHASE ............................................................................... 24

6.8. PROGRAMME TERMINATION .................................................................................. 24

6.9. IN PROGRESS PROGRAMME INTERRUPTION ........................................................ 24

6.10. RESET PROCEDURE.............................................................................................. 24

6.11. DATE AND TIME SETUP ......................................................................................... 25

6.12. DEMI WATER SETTING .......................................................................................... 26

6.13. PRINTER ................................................................................................................ 26

6.14. PRINTER LANGUAGE ............................................................................................. 27

7. OPERATING INSTRUCTIONS ......................................................................... 28

7.1. USE OF THE WATER SOFTENER ............................................................................. 28

7.2. USE OF THE DETERGENT AND NEUTRALIZING AGENT ......................................... 29

7.3. DETERGENT AND NEUTRALIZING AGENT RECOMMENDED BY SMEG .................. 29

8. ALARMS .......................................................................................................... 31

9. CLEANING AND MAINTENANCE .................................................................... 34

9.1. RECOMMENDATIONS AND GENERAL ADVICE ........................................................ 34

9.2. IF THE INSTRUMENT WASHER IS NOT USED FOR A LONG PERIOD OF TIME ........ 37

9.3. REUSE OF THE INSTRUMENT WASHER AFTER A LONG PERIOD OF INACTIVITY . 37

9.4. TROUBLESHOOTING ............................................................................................... 37

Page 4

Rev. 01

Man. WD1050

Pag. 4 - 40

10. ROUTINE CHECKS ................................................................ ......................... 39

10.1. DAYLY .................................................................................................................... 39

10.2. WEEKLY ................................................................................................................. 39

10.3. HALF YEARLY ........................................................................................................ 39

10.4. YEARLY .................................................................................................................. 39

11. WD1050 DIMENSIONS .................................................................................... 40

Page 5

Rev. 01

Man. WD1050

Pag. 5 - 40

The instrument washer complies with all the requisites established by

the current safety standards governing electrical equipment. Technical

inspections must only be made by specialized and authorized

personnel.

BESIDES VOIDING THE WARRANTY, REPAIRS MADE BY

UNAUTHORIZED PERSONNEL MAY REPRESENT A DANGER

HAZARD FOR THE USER.

1. INTRODUCTION

This manual is an integral part of the machine.

It must be kept in a good condition and ready to hand for the entire life cycle of the

machine. We advise you to carefully read this manual and all the instructions it

contains before using the appliance.

This appliance conforms to the EEC Directive 2007/47 currently in force.

The appliance has been made in order to:

- wash Surgical and Dental Instruments with Thermal Disinfection1;

- the appliance cannot be used to sterilize instruments or any other device.

All other uses are considered improper.

The manufacturer declines all liability for uses differing from those indicated.

The manufacturer declines all responsibility for any possible damage caused by

the washing of instruments whose manufacturers have not authorized to be

automatically decontaminated.

1

Treatment in the Instrument Washer can never be a substitute for sterilizing. Disinfection in the instrument

washer is carried out to reduce the risks sustained by the persons who handle surgical instruments when

preparing them for sterilization and to guarantee a better successive sterilization process.

Page 6

Rev. 01

Man. WD1050

Pag. 6 - 40

Carefully read the paragraph.

Attention, Danger, see the manual.

Attention, hot surface.

~

Alternating current.

CE mark, notified body: IMQ.

At the end of life the product should be sent to disposal facilities for the recovery and

recycling.

Never use solvents such as alcohol or turpentine in the appliance as

they could cause an explosion. Never put instruments dirtied with ash,

wax or paint in the appliance.

2. SYMBOLS LEGEND

3. GENERAL RECOMMENDATIONS

Do not rest or sit on the open door of the instrument washer as this could cause the

appliance to overturn and thus represent a danger hazard for persons. The

maximum weight loaded onto the open door, including the weight of the instrument

trolley, must never exceed 30kg.

Page 7

Rev. 01

Man. WD1050

Pag. 7 - 40

Only open the door after the washing cycle has terminated.

If you open the door while a programme is in progress, hot water, steam

and other liquids will spill out and may injure the user. Only authorized

and well-informed personnel are allowed to use the machine.

Never ever touch the heating element immediately after a washing cycle has

terminated.

The heating element could become slightly darkened during use of the instrument

washer, even to a localized extent. This should be considered normal as it depends

on the operating mode and does not impair the way the appliance works.

At the end of its working life, the appliance must be rendered unusable. Cut off the

power flex after having removed the plug from the power socket. The appliance

must then be consigned to an authorized disposal center.

If the appliance operates in a faulty way, unplug it from the electricity main, shut off

the water cock and contact your nearest authorized Assistance Center.

Page 8

Rev. 01

Man. WD1050

Pag. 8 - 40

MODELS

WD1050

WD1050-3

WD1050-1

ELECTRIC POWER SUPPLY

VERSION

Triphase 400V

Trifase 230V

Monophase 230V

TYPE OF VOLTAGE

[tolerated variation 10%]

400V 3/N/E

230V 3/PE

230V 1/N/PE

FREQUENCY [H Z]

50

POWER RATING [KW]

7 kW

7 kW

2,8 kW

AUTOMATIC SWITCH ON

MACHINE

In 16 A 3P+N 400V

Icn 4500 A

In 20A 3P 400V Icn

6000 A

In 16 A P+N 230V

Icn 4500 A

WATER SUPPLY

TYPE OF WATER

COLD WATER

DEMINERALISED WATER

PRESSURE [BAR ]

2 – 5

2 – 5

TYPE OF CONNECTION

3/4"

3/4"

MAX HARDNESS [°F] /

CONDUCTIVITY[S/CM ]

42°F

Max 20μS

IRON [PPM] FE MAX

< 0.5

DRAIN

FROM FLOOR LEVEL (on which machine is placed)

HEIGHT [MM]

Min 650 - Max 800

DIAMETER [MM]

Min 40

DIMENSIONS

HEIGHT

850

DEPTH

670

WIDTH

600

NET WEIGHT [KG]

65

Material used

Washing chamber AISI 316L

External cladding AISI 304

ENVIRONMENTAL CONDITIONS

USE

Indoor

ALTITUDE

Up to 1000m

TEMPERATURE

From 5°C to 40°C

RELATIVE HUMIDITY

80% for temperatures up to 31°C with linear diminution down to 50%

at the temperature of 40°C

INSTALLATION CATEGORY

II

CLASS TO WHICH

APPLIANCE BELONGS

IIb (in compliance with the classification criteria established by DIRECTIVE

2007/47)

POLLUTION DEGREE

2

4. GENERAL SPECIFICATIONS

4.1. TECHNICAL FEATURES

Page 9

Rev. 01

Man. WD1050

Pag. 9 - 40

Before it leaves the factory, the base of the machine is fixed to a pallet

which is then used to lift and transport the machine itself.

The machine must be handled with a fork-lift truck or transpallet.

Do not use appliances damaged by transport! Consult your dealer if in

doubt.

The appliance must only be installed and connected by personnel

authorized by the manufacturer.

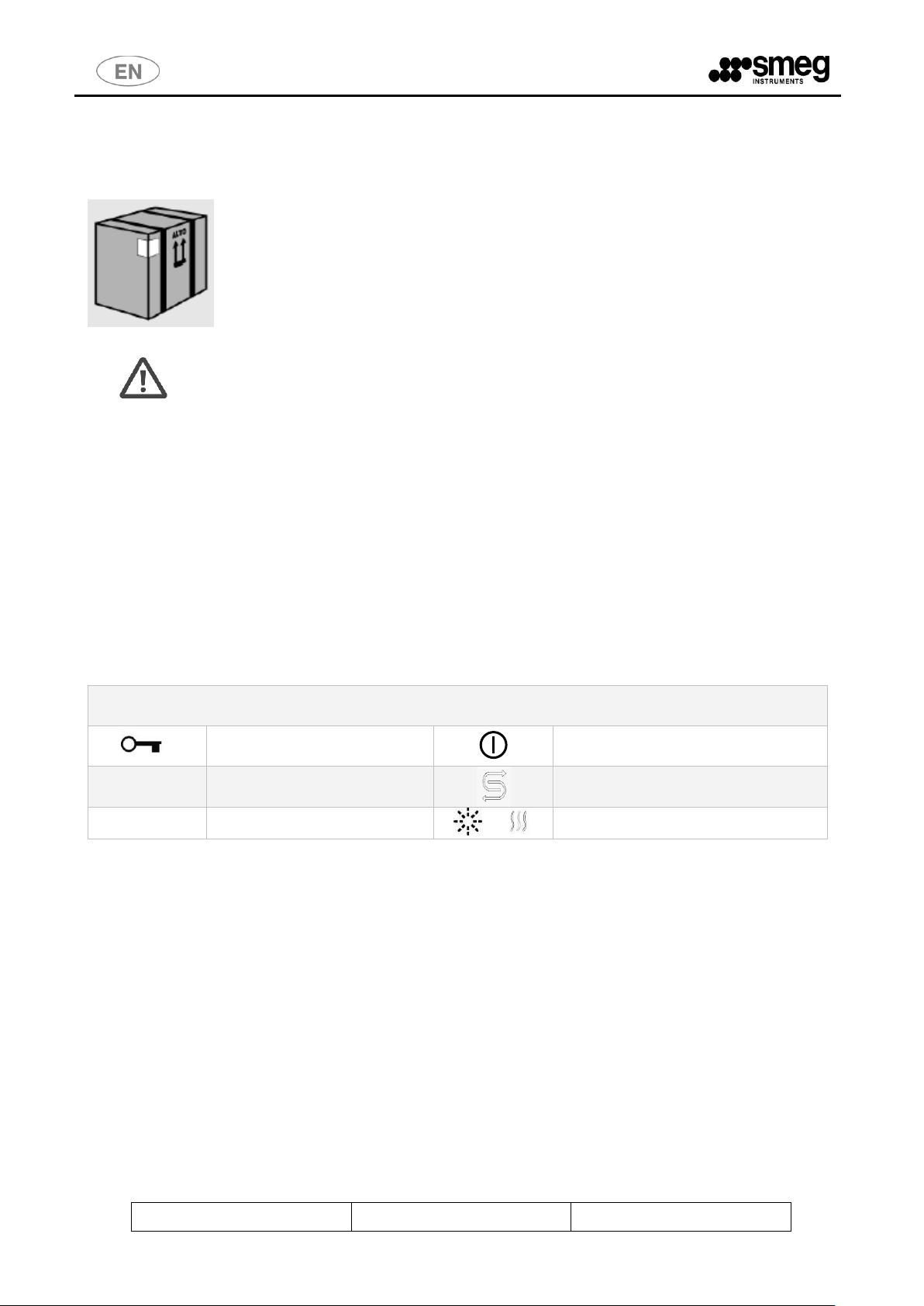

SIGNS ON THE FRONT OF THE MACHINE

Door unlocking

ON / OFF

°C

Temperature

Salt Lack

► ll

START / PAUSE

or

Heating element on

4.2. LIFTING AND HANDLING

4.3. DOOR LOCKING SYSTEM

After unpacking, pay attention to the following:

the machine is equipped with an automatic door locking/unlocking system.

The door is locked. Don‟t force the door, but follow the procedure below.

Connect the machine to the mains supply;

push the ON/OFF button (in order to switch on the machine)

push (and hold) the button with the symbol of the key and after some seconds the

door opens

Page 10

Rev. 01

Man. WD1050

Pag. 10 - 40

fig. 1 – WD1050 front.

In order to open the door without connecting the machine to the mains, the manual

unlocking procedure must be executed. Please, see the following paragraph for further

details.

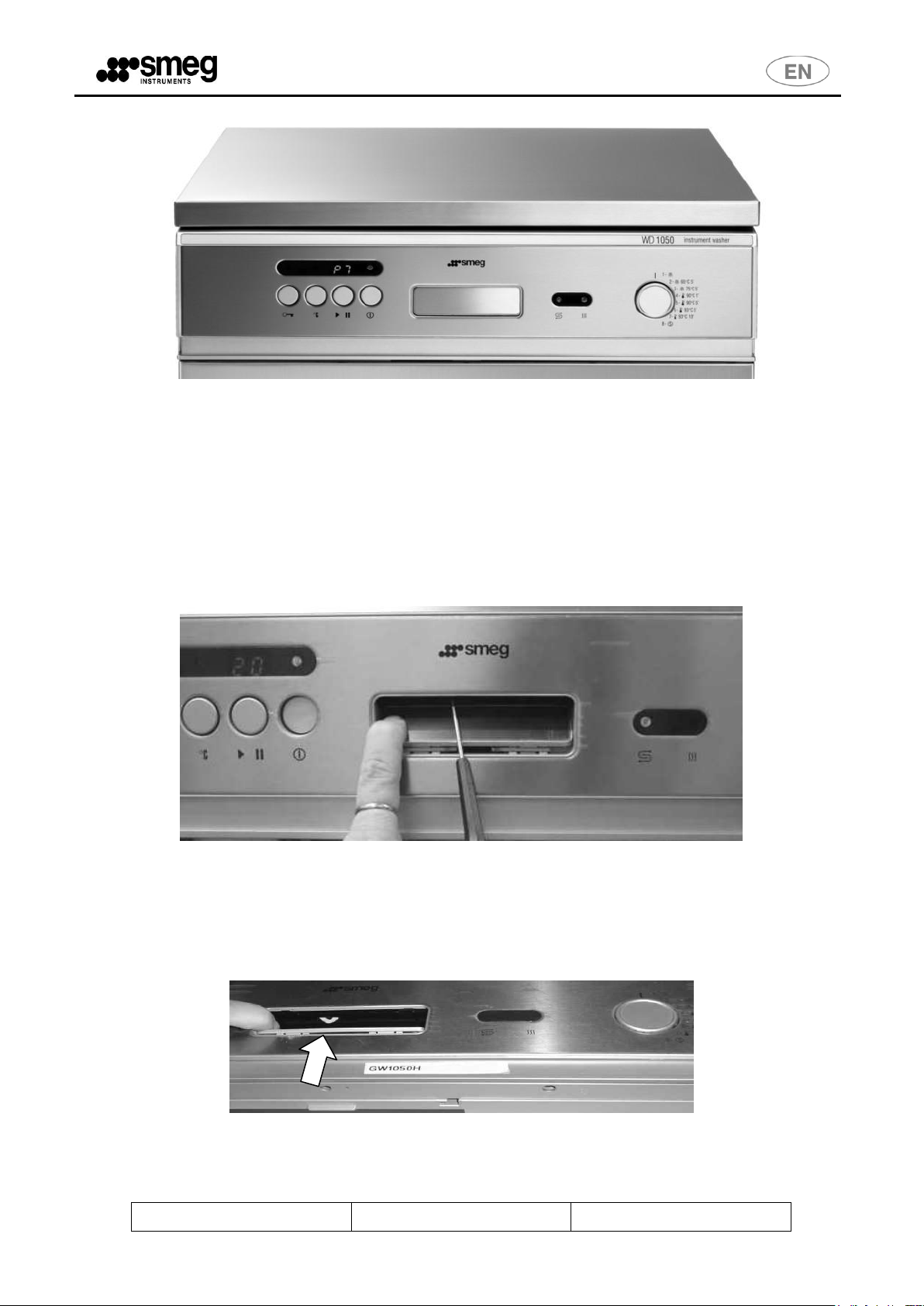

4.4. MANUAL DOOR UNLOCKING

In case of emergency or in case of a power failure the door may be manually opened

inserting a small screwdriver under the handle, as shown on the image.

fig. 2 – WD1050 front. To unlock the door manually: 1 - push the handle opening to access the opening

mechanism, 2 - Force, pushing it from bottom to top, with a small screwdriver the opening mechanism.

Insert the screwdriver carefully into the yellow marked hole till the characteristic

“CLACK” is heard.

Page 11

Rev. 01

Man. WD1050

Pag. 11 - 40

IMPORTANT: The machine must be positioned against the wall

(minimum distance 10 cm) and must be installed by a technician

authorized by the manufacturer.

The technician who installs the machine is responsible for the

appliance operating correctly after it has been installed. He is also

obliged to provide the user with all the information required to use

the machine in the correct way.

All adjustments, servicing and so forth, must be carried out with the

appliance disconnected from the electricity main.

The scratch-proof film must be removed from the external steel

surfaces when the appliance is installed.

IT IS STRICTLY FORBIDDEN FOR UNAUTHORIZED PERSONS TO

USE THE MACHINE.

5. INSTALLATION

5.1. POSITIONING

The side panels of the machine must adhere to the adjacent furniture and care must

be taken to leave space at the rear: it is therefore advisable for the wall at the back to

be made of brickwork or some other impermeable material.

The machine has pipes to supply and drain off the water. These can be positioned

towards the right or left, depending on the installation requirements.

The machine can also be installed under a work top: this operation must be carried out

by specialized personnel.

5.2. LEVELLING

Once the machine has been set in position, it must be levelled until horizontal (2

degrees tolerance allowed) by either screwing in the feet or unscrewing them.

Correct levelling will ensure that the machine operates in the right way.

Page 12

Rev. 01

Man. WD1050

Pag. 12 - 40

WARNING

Make sure that the inlet pressure of the mains water is within the

operating limits: min. 2 bar - max 5 bar.

The water shutoff valves must be accessible

CAUTION

Chemical characteristics of mains water that are not compatible

with a good washing process.

If the water contains more than 0.5 ppm of iron Fe2+/Fe3+ and/or the

hardness of the water is more than 42°F (French degrees), it must be

pre-treated by installing a deferrization and/or softening system

upstream.

5.3. CONNECTION TO WATER MAINS

Prevent the risk of clogging or damage to the appliance: if the water pipe is new or has

remained unused for a long period of time, make sure that the water is limpid and free

from impurities before connecting the machine to the water main.

The pipe is pre-engineered for connection to a cock with 3/4‟‟ gas threaded union on

both ends.

Insert the supplied filters "A" before connecting the other ends of the pipes to their

respective cocks.

It is advisable to allow the water to run in order to drain off any rusty deposits or

sludge if connections are made with new pipes.

In case of blood-stained instruments make sure that the machine is not supplied with

water at temperature higher than 40°C.

Always shut off the water supply cocks when the machine is not being used

Page 13

Rev. 01

Man. WD1050

Pag. 13 - 40

If demineralized water isn't available: don't connect the demi pipe

to the cold or hot water, leave it disconnected and see the

instructions (paragraph "DEMI WATER SETTINGS" 6.12) in order to

set correctly the demi water parameter.

5.4. WATER SUPPLY

The machine is supplied with two water supply pipes that join to a non-return device

inside the machine.

The pipes are designed for connection to cocks with 3/4” gas threaded bushings.

The following pipes (see the picture below) must be connected to water mains:

cold water pipe;

pressurized demineralized water pipe (min. 2 bar - max. 5 bar) – if present.

fig. 3 – Back view of the machine

Page 14

Rev. 01

Man. WD1050

Pag. 14 - 40

If the PAD pump is used, the water supply pressure must be less

than 1 bar.

WARNING

Make sure that the demineralized water pressure is less than or

equal to 1bar. The manufacturer declines every responsibility for

higher pressures.

5.5. NON PRESSURIZED DEMINERALIZED WATER CONNECTION

The connection to a non-pressurized demineralized water supply (e.g. gravity tank) is

possible only by installing the special demineralized water pump, called "PAD5".

The PAD, optional booster pump, ensures the correct inlet water supply pressure

within the pre-set filling time.

This accessory can be fitted on any machine and must be mounted on the back of the

machine.

We advise having the pump installed by a specialized technician, who should follow

the instructions provided.

The manufacturer will accept no responsibility for any possible damage caused

by an incorrect installation performed by an unauthorized technician.

Page 15

Rev. 01

Man. WD1050

Pag. 15 - 40

WARNING

The drain connection must comply with international standards.

Our company will accept no liability for pollution caused by the

machine..

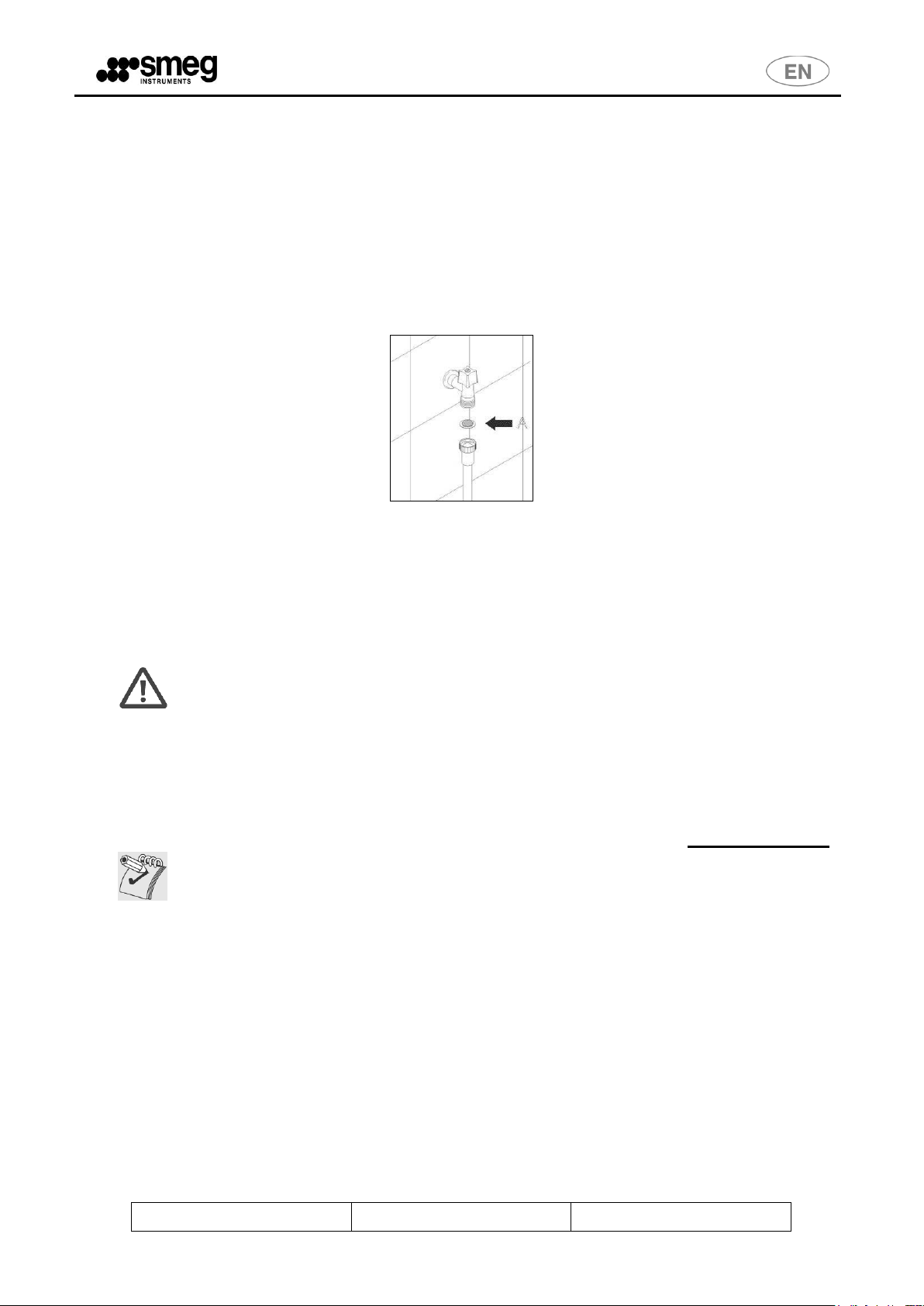

5.6. WATER DRAIN CONNECTION

This machine has just one outlet hose.

The internal diameter of the hose is ½” so it can be connected to any standard ½”

hose adapter.

General rules for installing outlet

The washing water outlet hose must be placed with its curved section hooked onto the

edge of a sink or waste pipe. A drain pipe with siphon should be used.

The following precautions should be observed during installation:

As the water drain temperature may reach about 93°C the end of the outlet hose

must be connected firmly to the drain by using clamps.

The outlet hose must not have any tight bends liable to obstruct the flow;

The end of the outlet hose must not be placed either more than 80cm or less than

65 cm above the surface on which the machine is installed;

The end of the hose must under no circumstances be immersed in water;

The internal diameter of the waste pipe must be at least Ø 40 mm;

We recommend installing a waste pipe of diameter 50 mm;

Don't use waste pipe extensions.

fig. 4 – 65 cm < A < 80 cm

Page 16

Rev. 01

Man. WD1050

Pag. 16 - 40

WARNING

The machine is equipped with a power cable for permanent connection to the

electrical power supply.

A switch (or circuit breaker) shall be prepared as the means for

disconnection:

1. Il must be easily accessible for the user.

2. It shall be in close proximity to the equipment.

3. It shall be marked as the disconnecting device for the equipment.

WARNING

It is essential for the electricity mains to which the machine is connected to

comply with the current standards in force (CEI 64-8/7;V2 standards).

Always make sure that the ground connection is efficient.

Our company declines all liability for damage caused by connection to a

defective socket that fails to ensure a perfect connection to the general earth

conductor, or by a poorly efficient grounding circuit.

5.7. ELECTRICAL CONNECTION

The machine is designed for connection to an electricity main with the following

voltage rating:

WD1050 ~ 230V 3 / N / PE 50Hz.

There is also a single-phase and 230V three-phase "without neutral", with the following

electrical characteristics:

WD1050-1 ~ 230V 1 / N / PE 50Hz.

WD1050-3 ~ 230V 3 / PE 50Hz.

Page 17

Rev. 01

Man. WD1050

Pag. 17 - 40

ID

DESCRIPTION

1

WASHING PROGRAMME SELECTOR

2

RECESSED HANDLE TO OPEN the DOOR

3

ON/OFF KEY

4

START/PAUSE KEY

5

TEMPERATURE DISPLAY KEY

6

DOOR UNLOCKING KEY

7

THERMODISINFECTION PHASE INDICATOR LIGHT

8

TEMPERATURE DISPLAY INDICATOR LIGHT

9

CYCLE INFORMATION DISPLAY

10

“POWER ON” INDICATOR LIGHT

11

“LACK OF SALT” INDICATOR LIGHT

12

"HEATING ON" INDICATOR LIGHT

SYMBOLS ON THE FRONT PANEL

DOOR UNLOCKING

ON/OFF

°C

TEMPERATURE

LACK of SALT

► ll

START / PAUSE

HEATING ELEMENT ON

6. DESCRIPTION OF CONTROLS

All the controls and indicators of the instrument washer are positioned on the front

panel.

Page 18

Rev. 01

Man. WD1050

Pag. 18 - 40

The new "SETUP" functions are accessible via the program selection process, with

similar procedures to those already used for making the date settings (see also the

user manual, paragraph entitled "SETTING THE TIME AND DATE").

6.1. SETUP DESCRIPTION

Note: Hereafter, in parentheses, we refer to the indices used in the figure to identify

the control elements.

Procedure for accessing the machine "SETUP" menu (common to both models

WD1050 and WD2050, accessible only if no other washing program is running):

Press the ON / OFF key (3) to switch the machine on.

Turn the PROGRAM SELECTOR (1) to the "SETUP" of interest (see below).

Press UNLOCK DOOR (6) and hold for 4 seconds to access the setup function.

You will hear a double beep as confirmation.

To increase the setting press TEMPERATURE DISPLAY (5). Do not use this

key if you only want to display the parameter without editing it.

To decrease the setting press START / PAUSE (4). Do not use this key if you

only want to display the parameter without editing it.

TO TERMINATE PROGRAMMING, press UNLOCK DOOR (6) and hold for 4

seconds. The settings will be saved.

TO EXIT THE "SETUP" MODE WITHOUT SAVING any settings you have

edited, do not press UNLOCK DOOR (6) but simply switch off the machine

using the ON / OFF key (3).

Page 19

Rev. 01

Man. WD1050

Pag. 19 - 40

Language

selected

German

French

Spanish

Italian

English

Code

displayed

dE

Fr

ES

It

En

Connection to demineralized water

Present

Absent:

Code displayed

dn

--

Field

setting

Year

month

Day

Hour

Minutes

Seconds

Position

not used

Position

not used

Position

selector

1 2 3 4 5 6 7

8

SETUP MENU

"SETUP" menu, functions available:

1. Position 1: relative to detergent dosage by pump P1, to set in ml/liter the

dose of detergent with maximum threshold of 20ml/liter. 1 ml steps

(increase/decrease using keys (5) and (4). Default setting P1: 5 ml/l.

2. Position 2: same as Position 1 for P2, neutralizer. Default setting P2: 3 ml/l.

3. Position 3: same as Position 1 for P3. Default setting P3 and 0 ml/l. Function

not present by default on models WD1050 and WD2050.

4. Position 4: setting for hardness of input water in °F, from 5 to 60 with 5°F

steps. By default, hardness is considered 40°F. This parameter is important for

correct function of the water softener incorporated in the equipment.

5. Position 5: selection for automatic door opening at end of cycle. Default

setting is "ON". The segmented display will show "ON" and "OFF" respectively

to select between the two.

6. Position 6: printer language selecting among the different languages

available, default is English.

7. Position 7: connection to demineralized water, yes/no (default is "yes" on

WD1050, "no" on WD2050, which does not have this function).

8. Position 8: Date-time (setting already made, for the details see the user

manual, paragraph entitled "SETTING THE TIME AND DATE").

With the program selector and using keys (5) and (4) you can access and edit

the following parameters:

Page 20

Rev. 01

Man. WD1050

Pag. 20 - 40

6.2. WASHING PROGRAMME SETTINGS

The instrument washer has a practical display that provides all the information the

user needs to know about the functions programmed.

Consult the following table to select the required programme. It gives the washing

cycle most able to suit the nature of the instruments you need to wash and the degree

of dirt involved.

Once you have found the most suitable washing programme in the table, turn the

PROGRAMME SELECTOR knob and select the desired programme by setting it to the

relative reference number.

The following is an indicative list of the type of washing cycles to which the available

programmes refer:

1. Quick washing programme using cold water.

2. Washing programme at 60°C suitable for plastic ware.

3. Washing programme at 75°C suitable for standard glassware.

4. Washing + disinfection at 90°C for 1‟ (A0 =600).

5. Washing + disinfection at 90°C for 5‟ (A0 =3.000).

6. Washing + disinfection at 93°C for 5‟ (A0 =6.000).

7. Washing + disinfection at 93°C for10‟ (A0 =12.000).

8. Service programme: to test the detergent and neutralizer dispensers and rinse the

washing chamber.

6.3. THERMAL DISINFECTION IN ACCORDANCE WITH THE PARAMETER "A0"

We introduce the "A0 concept" to explain the time/temperature relationship used to

draw up the programmes.

According to EN ISO 15883 and the recommendations of the Robert Koch Institute

(European authority on the subject), an A0 of 600 is considered as the minimum

standard for non-critical medical devices, i.e. for those that only come into contact with

uninjured skin. A further condition required is that microbic contamination must only be

slight and there must be no heat-resistant pathogens present.

An A0 value of 600 can be obtained by maintaining a temperature of 80°C for 10

minutes or 90°C for 1 minute or again, 70°C for 100 minutes.

If the medical devices are contaminated with heat-resistant viruses, such as those of

hepatitis B, the value of A0 must be at least 3000. This can be obtained by

maintaining a temperature of 90°C for 5 minutes.

An A0 value of 3000 is considered the minimum value to apply to all medical devices

considered to be critical.

Programmes that include thermal disinfection have therefore been designed to offer

the following A0 values:

Page 21

Rev. 01

Man. WD1050

Pag. 21 - 40

Temperature – time

A0

90°C 1‟

600

90°C 5‟

3000

93°C 5‟

6000

93°C 10‟

12000

10

80

0

10

T

A

T

The approximated formula to calculate A0 is given as follows:

where:

= holding time in seconds at the disinfection temperature.

= disinfection temperature in Celsius degrees.

Page 22

Rev. 01

Man. WD1050

Pag. 22 - 40

PROGR.

PROGRAMME

NAME

PHASE 0

PHASE 1

PHASE 2

PHASE 3

PHASE 4

CYCLE

TIME

1

PREWASH

RINSING

WITH MAINS

WATER FOR

2‟

- - -

-

6‟

2

WASH 60°C – 5'

RINSING

WITH MAINS

WATER FOR

3‟

WASHING

WITH MAINS

WATER

60°C/3‟ AND

DETERGENT

P1

NEUTRALIZIN

G WITH ACID

AGENT 3‟ – P2

RINSING WITH

MAINS WATER

60°C 2'

-

50‟

3

WASH 75°C – 5'

RINSING

WITH MAINS

WATER FOR

3‟

WASHING

WITH MAINS

WATER

60°C/4‟ AND

DETERGENT

P1

NEUTRALIZIN

G WITH ACID

AGENT 1‟ – P2

RINSING WITH

MAINS WATER

75°C AT 5‟

-

55‟

4

THERMAL

DISINFECTION 90°C

1’ (A0=600)

RINSING

WITH MAINS

WATER FOR

3‟

WASHING

WITH MAINS

WATER

60°C/5‟ AND

DETERGENT

P1

NEUTRALIZIN

G WITH ACID

AGENT 1‟ – P2

THERMAL-

DISINFECTION

WITH DEMI

WATER AT

90°C/1‟

-

55‟

5

THERMAL-

DISINFECTION 90°C

5’ (A0=3000)

RINSING

WITH MAINS

WATER FOR

3‟

WASHING

WITH MAINS

WATER

60°C/3‟ AND

DETERGENT

– P1

NEUTRALIZIN

G WITH ACID

AGENT 1‟ – P2

THERMAL-

DISINFECTION

WITH DEMI

WATER AT

90°C/5‟

-

1h

6

THERMAL-

DISINFECTION 93°C

5’ (A0=6000)

RINSING

WITH MAINS

WATER FOR

3‟

WASHING

WITH MAINS

WATER

65°C/4‟ AND

DETERGENT

P1

NEUTRALIZIN

G WITH ACID

AGENT 1‟ – P2

THERMAL-

DISINFECTION

WITH DEMI

WATER AT

93°C/5‟

-

1h 5‟

7

THERMAL-

DISINFECTION 93°C

10’ (A0=12000)

RINSING

WITH MAINS

WATER FOR

3‟

WASHING

WITH MAINS

WATER

75°C/3‟ AND

DETERGENT

– P1

NEUTRALIZIN

G WITH ACID

AGENT 1‟ – P2

THERMAL-

DISINFECTION

WITH DEMI

WATER AT

93°C/10‟

-

1h 10‟

8

REFRESH*

DETERGENT

DISPENSER

TEST – P1

NEUTRALIZ

ER

DISPENSER

TEST – P2

WASHING

CHAMBER

RINSE (DEMI

WATER)

-

-

6‟

NOTE

Execution times are just as an indication: inlet water temperature or water pressure may

cause them to vary.

*Refresh: This programme must be considered a “service” programme and mus t be used

only to clean the washing chamber.

The given times are approximate and related to the three-phase 400V version. For

the single-phase version the estimated times increase of about 20'÷ 30’.

NOTE

The initial phase, "Phase 0", may be preceded by a phase of resins washing (for the

embedded water softener), the display shows the inscription "Lr".

6.4. PROGRAMMES DESCRIPTION

Page 23

Rev. 01

Man. WD1050

Pag. 23 - 40

The machine is provided with an automatic door locking/unlocking system: to open

the door connect the machine to the mains supply and press the ON/OFF key (3).

The ON/OFF light comes on. At this point, press the key button (6).

WARNING

Never open the door whilst the programme is in progress! Despite the fact that the

machine is provided with devices that immediately turn off the washing pump and

heating element, it is absolutely forbidden to open the door when the machine is

operating.

6.5. MACHINE RUNNING

The symbols used below refer to those that appear at the beginning of the par. 6.

Press the ON/OFF key (3) to power the instrument washer on. The “power on”

indicator light will come on.

The door must be shut before any programme can begin. Once the racks have been

filled with the instruments, shut the door and proceed with the following operations.

To activate a washing cycle, select the required programme (P1, …,P8) using the

knob, then press the START button (4).for a couple of seconds until the characteristic

bip-bip signal is heard.

During the cycle, the display will alternately show the number of the programme

selected and the phase in progress.

The "degrees indicator light" (8) will come on if the temperature key "°C" (5) is

pressed. In this case, the number of the programme in progress and the value of the

temperature in the washing chamber will be displayed alternately.

If you press the temperature key (5) again the corresponding indicator light will come

off and the display will alternately show the number of the programme and phase in

progress.

Page 24

Rev. 01

Man. WD1050

Pag. 24 - 40

WARNING

It may happen that it takes few seconds before the door opens; don’t push the key

furtherly and, please, wait until it opens.

NOTE

At the end of a programme, once the door has been opened, we recommend to make

the drying of the instruments better by pulling the lower basket out of the washing

chamber and then by letting it stay over the door for a few minutes.

6.6. RESIN WASHING PHASE

Message „Lr‟ flashes on the display in alternation with the programme number during

the resin washing phase.

6.7. RESIN REGENERATION PHASE

Message „r-‟ flashes on the display in alternation with the programme number during

the resin regeneration phase.

6.8. PROGRAMME TERMINATION

Message "EP" appears and flashes on the display once the programme has

terminated: therefore, the washing cycle must be considered terminated only when this

message appears. A "beep" signal begins to run and lasts for 5 seconds, after which

the door automatically opens.

Note – delayed automatic door opening

Starting from the software versions installed from March 2011, if the temperature in

the washing chamber exceeds 80°C, the automatic opening does not occur

immediately when “EP” appears: a delay of 10minutes has been introduced, to allow

the temperature in the chamber to decrease gradually.

After 10 minutes the door opens automatically.

During the delay time, the lock can be released, however, by pressing key (6), and

opening the door manually.

6.9. IN PROGRESS PROGRAMME INTERRUPTION

While a programme is running, you may stop it pressing the START/STOP button (4).

The following message appears on the display: “ S1,…, S8”, where the number

indicates the programme in progress.

If the interruption lasts longer than 1 minute, the machine will access an alarm status

and can only continue to operate after it has been RESET.

6.10. RESET PROCEDURE

In the event of an alarm or with the machine not responding to any keys, hold down

together the temperature "°C" (5) and the START key "► ll" (4) for few seconds till the

Page 25

Rev. 01

Man. WD1050

Pag. 25 - 40

characteristic double beep sound is heard. Message „ P-„ will appear on the display and

the RESET procedure will begin.

„E-„ flashes on the display at the end of the RESET phase.

In some circumstances (e.g. when the washing chamber is hot) the RESET procedure

might not be accepted: in such a case open and close the door, then repeat the same

procedure (e.g. after few minutes).

NOTE: In any case, if the RESET procedure does not work, switch OFF and ON the

machine and try again before calling the Technical Assistance.

6.11. DATE AND TIME SETUP

The machine is equipped with a real time clock system. This mainly serves for cycle

tracing purposes (cycle archive).

When needed, this clock system may be set up by means of the following procedure

(available only when no programme is running).

Press the ON/OFF button (3) to switch on the machine (If any alarm appears on

the display at this stage, ignore it).

Turn the programme selector knob (1) to position 8.

Press the Door Open button (6) for 4 seconds to enter the setup function

According to the position of the programme selector knob the following

parameters can be set/modified:

o Position 1: YEAR [00-99]

o Position 2: MONTH [01-12]

o Position 3: DATE [01-XX] XX is calculated according to the month and

year.

o Position 4: hour [00-23]

o Position 5: minutes [00-59]

o Position 6: Seconds [00-59]

o Position 7:inactive position - Display Flashing

o Position 8: inactive position – Display Flashing

To increase a value press "°C" (5)

Page 26

Rev. 01

Man. WD1050

Pag. 26 - 40

NOTE

If demi water is not available don't connect the demi water pipe to cold

or hot water, leave it disconnected.

The demi water circuit inside the machine don't pass through the built in

softener, so the demi water connection must be used only for

demineralised water.

To decrease a value press "► ll" (4)

To terminate, turn the programme selector knob (1) to position 8 and press the

Door Open button (6) for 4 seconds.

The new DATE and TIME is now installed.

6.12. DEMI WATER SETTING

Demi water may be used when required by the machine (thermodisinfection phases)

and available.

When the machine is in stand-by, i.e. when no cycle is running, to set the demi water

parameter proceed as follows:

Press the ON/OFF button (3) to switch on the machine;

Turn the programme selector knob (1) to position 7;

Press the Door Open button (6) for 4 seconds to enter the demi water setup

mode;

On the display, it may appear "OE" when the demi water has been already set

or „–‟ when it has not been set yet;

To set the demi water (demineralised water available), press "°C " (5);

To delete this setting (demineralised water not available), press "► ll" (4);

To terminate, turn the programme selector knob to position 7 and press the

Door Open button (6) for 4 seconds.

6.13. PRINTER

On the WD1050 a serial port (RS232) is available as a standard feature (see picture

below) and to which the SMEG printer, named “WD-PRINTE” with code 901783, may

be connected. The SMEG printer is capable of printing out the following data:

Serial Number of the WD1050 "Serial Number"

Number of cycles carried out "Cycle N."

Date and Time

Page 27

Rev. 01

Man. WD1050

Pag. 27 - 40

Program Number indicating Thermal Disinfection Temperature and holding time

(for example 93°C 10‟)

Detergent control

o "Inflow Detergents P1 Deter" - for the detergent;

o "Inflow Detergents P2 Neutr" - for the neutralizing agent;

Temperature control

o „TL1‟: indicates the temperature measured inside the washing chamber.

It is the main temperature of the cycle;

o „TLC‟: indicates the control temperature as requested by the EN15883

standard;

o „Target T‟: stands for the target temperature value of the phase

Heating element

o „Res ON‟: indicates that the heating element is on;

o „Res OFF‟: indicates that the heating element is off;

Starting Time of the Cycle

Process of each Phase

End of Cycle time

Eventual errors if Cycle terminates incorrectly.

„A0‟: stands for the thermal disinfection effectiveness;

In the picture below is shown the serial port (WD1050 back view), which the printer

must be connected to.

fig. 5 – WD1050 back – RS232 PORT (printer connection).

6.14. PRINTER LANGUAGE

How to set the printer language:

Switch on the machine.

Turn the programme selector knob to position 6.

Press the Door Open button ("key" button) for 4 seconds to enter into the setup

function.

On the display appears "Lx" – "L" stands for language - "x" is a number: "0" for

Italian, "1" for English.

To increase "x" value press °C.

Page 28

Rev. 01

Man. WD1050

Pag. 28 - 40

ATTENTION

When the instruments washer is used for the first time, pour 1Kg coarse salt in the

reservoir and some water till the rim. Each time the reservoir is filled, make sure that

the cap is tightened with care. The mixture of water and detergent must not penetrate

into the salt reservoir as this would impair the regeneration system. Besides, a salt

leakage in the washing chamber may damage the instruments and the tank. In this

case, the warranty would become void.

Only use regenerating salt for instrument washers. Do not use kitchen salt.

Do not use edible salt as it contains insoluble substances which would damage the

softening system over a period of time.

For each salt loading in the reservoir, perform a prewash (Pr.1) before starting a

To decrease "x" value press ► ll.

To terminate (programme selector knob to position 6) press the Door Open

button for 4 seconds. The new Printer Language setup is now saved.

7. OPERATING INSTRUCTIONS

After the instrument washer has been correctly installed, it must be prepared for

operation in the following way:

Pour in regenerating salt (only if necessary, i.e. with water harder than 10°F);

Add detergent and neutralizing agent.

7.1. USE OF THE WATER SOFTENER

The lime content in the water (index of water hardness) is responsible for the whitish

marks on dry instruments, which tend to become opaque as time goes by. The

instrument washer has an automatic water softener which uses a specific regenerating

salt to remove the hardening substances from the water.

fig. 6 – Regenerating salt for the water softener.

When water of medium hardness is used, new salt must be added after every 20

washes or so. The softener reservoir can hold about 1 kg of coarse salt. This reservoir

is situated on the bottom of the instrument washer. After having removed the bottom

rack, unscrew the plug from the reservoir by turning it in the anti-clockwise direction

and pour in salt using the funnel supplied with the appliance.

Before screwing the plug back on, remove any residues of salt from around the

opening.

Page 29

Rev. 01

Man. WD1050

Pag. 29 - 40

washing programme.

WARNING

Make sure that you do not mistake salt packages for ones containing

detergent: detergent would damage the water softener if it were to be poured

into the reservoir

7.2. USE OF THE DETERGENT AND NEUTRALIZING AGENT

The machine is equipped with two peristaltic pumps, which are situated at the rear of

the machine.

Pump P1 liquid detergent (neutral or lightly alkaline): To dose the liquid detergent:

it must be used whenever it is possible.

Pump P2 (neutralizing acid): To dose the liquid neutralising agent

Pump 3: optional.

With the exception of the Soaking programme, the pump will add an adequate dose of

detergent before each wash. Neutralizing agent for the rinsing phase is automati cally

added when required.

Only use specific detergents for instrument washers. It is important to use a good

quality detergent if optimum washing results are to be obtained.

Keep the packs of detergent securely closed and in a dry place to prevent the

formation of lumps which could compromise the washing results. After the packs have

been opened, they must not be kept for too long as the detergent loses its efficacy.

Periodically check the level of the products inside the tanks, thus avoiding to

accomplish some programs without the detergent or the neutralizing agent which is

very important to obtain good washing results.

During the installation and whenever the detergent tank is empty you must execute Pr.

Nr.8 to charge the liquid into the peristaltic pumps.

7.3. DETERGENT AND NEUTRALIZING AGENT RECOMMENDED BY SMEG

There are essentially two kinds of detergents available for disinfection cycles of

instruments:

Low alkalinity liquid detergent (DENTAL NE);

Lightly acid neutralizing liquid agent (DENTAL AC).

Alkaline detergent is fitted to process stainless steel instruments. After the

thermodisinfection phase with this kind of detergent, it occurs a rinsing phase with an

acid neutralizing agent.

Page 30

Rev. 01

Man. WD1050

Pag. 30 - 40

WARNING

Do not use powder detergents to wash transmission instruments like turbinetype handpieces or contra-angles: this operation may cause serious damages

to internal mechanisms and corrode the titanium surfaces.

Smeg will accept no liability for damages caused by this behaviour.

WARNING

Even when in liquid form, the addition of detergent to the neutralizing agent

reservoir will impair washing efficiency

HANDLE WITH CARE DETERGENTS JERRICANS

We recommend the use of protective gloves for any transactions racking, topping and

insertion of suction lance.

FIRST AID MEASURES IN CASE OF CONTACT WITH DETERGENTS

Take off contaminated clothing and store them in a safe place.

Contact with skin or eyes: rinse immediately with plenty of water. Apply a sterile

dressing. Consult your doctor

Ingestion: Rinse mouth with water. Consult your doctor immediately.

SAFETY DATA SHEET DETERGENTS

It is recommended to keep SAFETY DATA SHEET DETERGENTS near the place

where the detergents are stored, in easily accessible location.

DISPOSAL of any remaining product: consult the manufacturer, under "

INFORMATION ON DISPOSAL ".

If you lose the cards may be required SMEG S.p.A.

instruments@smeg.it

Low alkalinity liquid detergents are recommended to process delicate instruments like

titanium turbine-type dental handpieces, contra-angles and so on. They work well with

stainless steel instruments too.

Page 31

Rev. 01

Man. WD1050

Pag. 31 - 40

Alarm ID

Description

Action

1

Water is not being heated.

Check the condition of the safety

thermostat. Call the Technical

Assistance Service if the fault

persists.

2

The temperature difference between TL1 and TC

is greater than 2°C.

Repeat the cycle: It could be a

temporary alarm.

4

TL1 measures a temperature greater than target

temperature.

Repeat the cycle: It could be a

temporary alarm.

5

TL1 probe is "open".

Call the Technical Assistance Service.

10

TCL probe is "open".

Call the Technical Assistance Service.

11

Lack of cold water.

This alarm is active during the loading

phase.

It intervenes when the relative turbine

does not count any impulses for 30

seconds and the state of the pressure

switch does not change.

Check the water supply:

. cock and connection pipe

open/closed

. solenoid valve input

. mains water pressure

. the state of the pressure switch

. turbine operation

8. ALARMS

All the alarm situations are quitted by means of the RESET procedure (see par. 6.10).

There may arise two types of alarm: fatal or not fatal.

In the first case, the message on the display is „AF‟ followed by the alarm number.

In the second case, the message is ‟A-„ followed by the alarm number.

The instrument washer is equipped with the following alarms.

Page 32

Rev. 01

Man. WD1050

Pag. 32 - 40

Alarm ID

Description

Action

13

Lack of demi water.

This alarm is active during the loading

phase.

Check if the demi water parameter is

correctly set (par. 6.12).

The alarm intervenes when the demi

turbine does not count any impulses

for 30 seconds and the state of the

pressure switch does not change.

Check the demineralized water

supply:

. cock open/closed

. tank/can empty

. solenoid valve input

. when the tank is loaded, check water

input into the tub;

. connection pipe

. connection/program correspondence

. turbine

17

Water load time incorrect.

Check the water supply (cock

open/closed, water pressure,

connection pipe, etc.)

19

Demi water time exceeded.

The machine took too much time to

load the demineralized water. Check

the input pressure. For the Technical

Assistance: increase the loading

timeout (with the WD-TRACE) see

"Extra Loading Time" menu. The

extra-time has a maximum of 180

seconds.

20

Water load system fault.

Check the water supply (cock

open/closed, water pressure,

connection pipe, etc.).

22

Water flowmeter does not correctly measure.

Check the water supply (cock

open/closed, water pressure,

connection pipe, etc.)

Repeat the cycle.

23

Not enough water.

Check the water supply (cock

open/closed, water pressure,

connection pipe, etc.).

24

No water inside.

Check the water supply (cock

open/closed, water pressure,

connection pipe, etc.).

25

Low water pressure for the washing pump.

(Foam presence in washing chamber).

Check the type of detergent used.

Repeat the cycle.

29

No drain.

Make sure that the drain pipe is

positioned as indicated in the manual.

30

Water safety level.

Repeat the cycle. Call the Technical

Assistance Service if the fault

persists.

31

Water safety level fault.

Repeat the cycle. Call the Technical

Assistance Service if the fault

persists.

32

Water in chamber - backwater.

Make a Reset cycle. Repeat the cycle.

Call the Technical Assistance Service

if the fault persists.

Page 33

Rev. 01

Man. WD1050

Pag. 33 - 40

Alarm ID

Description

Action

33

Lack of water in the steam condenser.

Indicates that there is no water in the

steam condenser when there should

be due to sprayer nozzle activation.

Make sure the solenoid valve input to

the condenser activates and operates

correctly. Also make sure that the

drain pump does not remain activated

permanently.

34

Condenser drainage failed.

Intervenes if "SLC" (work level sensor

of the condenser) does not deactivate

after 120 seconds from drain pump

activation.

Make sure the drain pump operates

correctly. Also make sure that the

condenser drain respects the

recommended values and it not

obstructed.

Replace the level sensor, if necessary.

35

Condenser level switch failed

This alarm intervenes when the level

switch does not work: check the

electrical connections.

Call the Technical Assistance Service

36

Condenser draining pump failed.

Check if the condenser draining hose

has been correctly installed.

Call the Technical Assistance Service

52

Door electrically open.

Make sure that the door is properly

closed before beginning a cycle.

Check the conditions of the microswitches related to the closure. Call

the Technical Assistance Service if

the fault persists.

54

Door mechanically open.

Make sure that the door is properly

closed before beginning a cycle.

Check the conditions of the microswitches related to the closure. Call

the Technical Assistance Service if

the fault persists.

56

Doorlock fault.

Make sure that the door is properly

closed before beginning a cycle. Call

the Technical Assistance Service if

the fault persists.

68

Empty container P1

Check that there is some alkaline

detergent in the container or that the

level sensor is working correctly.

69

Empty container P2

Check that there is some acid in the

container or that the level sensor is

working correctly.

70

Empty container P3

Check that there is some disinfectant

in the container or that the level

sensor is working correctly.

73

Cycle Archive fault.

Error inside the microprocessor.

Call the Technical Assistance Service

if the fault persists.

Page 34

Rev. 01

Man. WD1050

Pag. 34 - 40

Alarm ID

Description

Action

75

Low Salt

Fill the softener‟s salt reservoir

(plug in tub).

77

Initial temperature inside the chamber greater

than 45°C; prewash phase must be carried out at

a temperature lower than 45°C.

The alarm appears (if the relative

option has been selected) if the

temperature of the water entering in

the first phase exceeds 45°C.

78

Microprocessor fault; this may happen under

some circumstances (i.e. voltage drops).

Error inside the microprocessor.

Call the Technical Assistance Service

if the fault persists.

81

Demi water inlet fault.

Check the water supply (cock

open/closed, water pressure,

connection pipe, etc.)

Repeat the cycle.

82

Doorlock solenoid fault

Repeat the cycle. Call the Technical

Assistance Service if the fault

persists.

94

Unstable temperature

It might be a temporary failure.

Check the probes in the sump.

ELECTRICITY MAINS – WATER SUPPLY

Disconnect the machine from the electricity mains and shut the water cock before

proceeding with any of the operations described below.

FREE SPACE

To work in the correct way, you must also ensure that there is a free room of about

one square meter in front of the machine.

It is absolutely essential to use cables of the HT 105°C or H05V2-K type if

damaged cables must be replaced.

DETERGENTS

Be especially careful when handling detergents, to read the security requirements in

par. Errore. L'origine riferimento non è stata trovata..

9. CLEANING AND MAINTENANCE

9.1. RECOMMENDATIONS AND GENERAL ADVICE

General cleaning

The external surfaces and door frame of the instrument washer must be cleaned at

regular intervals with a soft cloth soaked in water or a normal detergent for steel

surfaces.

The door seals must be cleaned with a damp sponge.

It is advisable to clean off any dirt that may have accumulated in the washing chamber

or on the seals every so often (once or twice a year) using a soft cloth and water.

How to clean the water inlet filter

Page 35

Rev. 01

Man. WD1050

Pag. 35 - 40

Water inlet filter A installed at the cock outlet must be periodically cleaned. First shut

off the supply cock, then unscrew the end of the water fill plug, remove the filter A and

clean it delicately under running water. Fit filter A back in its housing and carefully

retighten the water fill pipe.

fig. 7 – inlet filter "A"

How to clean the spray arms

The spray arms can be easily removed so that the nozzles can be periodically

cleaned to prevent clogging. Wash them under running water and then fit them back in

their housings. Make sure that their circular movement is not hindered in any way.

Page 36

Rev. 01

Man. WD1050

Pag. 36 - 40

How to clean the filter unit

The filtering unit consists of a circular filter with a filter cone, a micro filter and a

coarse filter. To ensure efficient operation of the machine it is extremely important to

keep the filters clean. They must be inspected frequently to remove deposits which

may adversely affect operation.

fig. 8 – Filter unit.

Coarse filter

To remove the coarse filter, press the tabs and pull upwards (see fig. 8 - panel 19).

Clean the filter and then reposition it.

Micro filter

This is located below the coarse filter (see panel 20). Check and clean whenever

inspecting the coarse filter.

For a perfect clean, use a brush and hot water.

Circular filter

To remove this filter:

press the tabs on the coarse filter and turn counterclockwise.

without pressing the tabs, raise the entire unit (i.e. filter, filter cone, coarse filter and

micro filter) (see panel 22).

When cleaning this filter it is worth also cleaning the others.

Page 37

Rev. 01

Man. WD1050

Pag. 37 - 40

Recommendations for correct maintenance

The filters should be cleaned under running water using a hard brush.

It is essential to clean the filters carefully according to the instructions given above:

the instrument washer will be unable to operate if the filters are clogged.

Fit the filters back in their housings with care, to prevent the washing pump from

being damaged.

9.2. IF THE INSTRUMENT WASHER IS NOT USED FOR A LONG PERIOD OF TIME

Follow the recommendations:

Carry out the soaking programme twice consecutively.

Remove the plug from the power socket.

Leave the door slightly open to prevent unpleasant odors from forming inside the

washing chamber.

Shut off the water cock.

9.3. REUSE OF THE INSTRUMENT WASHER AFTER A LONG PERIOD OF

INACTIVITY

Make sure that there are no rust or sludge deposits in the pipes. If this is the case,

allow water to run from the supply cock for a few minutes.

Plug the machine into the electricity main.

Re-connect the water supply hose and turn on the cock.

9.4. TROUBLESHOOTING

Slight faults can sometimes be eliminated by the user with the aid of the following

instructions.

1. If the programme fails to start, make sure that:

the instrument washer is connected to the electricity main;

the instrument washer is being powered;

the water cock is open;

the door of the instrument washer has been closed properly.

2. If water stagnates in the instrument washer, make sure that:

the drain plug is not bent;

the drain trap is not clogged;

the filters of the instrument washer are not clogged.

3. If the instruments are not cleaned properly, make sure that:

an adequate amount of detergent has been added;

there is regenerating salt in the relative reservoir;

the instruments have been positioned correctly;

the programme is suitable for the type and degree of dirt on the instruments;

all the filters are clean and correctly seated;

the holes in the water spray arms are not clogged;

Page 38

Rev. 01

Man. WD1050

Pag. 38 - 40

WARNING

Repairs to the appliance by unauthorized personnel are not covered by the warranty

and are at the user’s charge.

nothing is preventing the spray arms from turning.

4. If the instruments fail to dry or remain opaque, make sure that:

there is neutralizing agent in the relative container;

the neutralizing agent dispenser has been regulated in the correct way;

the detergent used is of good quality and has not lost its characteristics (e.g. owing

to incorrect storage, pack left open, etc.).

5. If the instruments are streaked, stained… make sure that:

the amount of neutralizing agent dispensed is not excessive.

6. If there are visible traces of rust in the washing chamber

The washing chamber is made of corrosion-proof steel, thus rust stains are due to

external factors (pieces of rust from the water pipes, etc.). Specific products are

available in the shops to eliminate these stains..

Make sure that the detergent dosage is correct. Some detergents can be more

corrosive than others.

Make sure that the salt reservoir plug is firmly closed and that the water softener

system has been correctly regulated.

Contact your nearest authorized technical assistance center if the faults persist

after compliance with the instructions given above.

Page 39

Rev. 01

Man. WD1050

Pag. 39 - 40

WARNING

In no case may SMEG be held liable for any direct or indirect damages deriving from

or in relation to inobservance of the above described checks.

10. ROUTINE CHECKS

10.1. DAYLY

a) control the detergent and neutralizing agent level: fill it up, if necessary.

b) check the sprinklers movement and their cleanliness.

10.2. WEEKLY

a) clean the sump filter.

b) perform Pr.4 without any load to clean and disinfect the washing chamber.

10.3. HALF YEARLY

c) check the status of the electrovalves filters: clean them if necessary, by making

hot water flow backwards;

d) check the tubes status.

10.4. YEARLY

At the end of the warranty period and over the successive years, call the nearest

Smeg authorized assistance centre in order to execute a complete check-up of the

machine.

Page 40

Rev. 01

Man. WD1050

Pag. 40 - 40

MACHINE DIMENSIONS [mm]

A

670 B 600 E 600 F 30

G

850

HYDRAULIC DISCHARGE

CONNECTIONS [mm]

H max

500

I (drain

height)

650 I 800

OPTIONAL DEMI TANK [mm]

L

1000 L 1200

DEMI TANK

The "demi water tank" is optional. Can be prepared if pressurized demineralized water is not

present in the plant (2bar <p_demi <5 bar). The tank must be properly positioned and used

with the accessory "PAD5".

Demineralized water helps to achieve a better washing.

IMPORTANT

If demineralized water isn't available: don't connect the demi pipe to the cold or

hot water, leave it disconnected and see the instructions (paragraph "DEMI

WATER SETTINGS" 6.12) in order to set correctly the demi water parameter.

11. WD1050 DIMENSIONS

Legenda

"cd" – condenser drain.

"d" – drain.

"cw" – cold water (tap water).

"dw" – demi water.

NOTE: the hydraulic connections can be arranged also on the left side of the machine, always taking into

account the maximum distance specified by the product, "H".

Loading...

Loading...