Page 1

Dear Customer,

Thank you for having purchased one of our products.

We are certain that this new, modern, functional and practical appliance, built with the very

highest quality materials, will meet your requirements in the best possible way. This appliance is

easy to use. It is, however, important to thoroughly read the instructions in this handbook in order

to obtain the best results.

These instructions are only valid for the countries of destination, the identification symbols of

which are indicated on the cover of the instruction manual and on the appliance itself.

The manufacturer shall not be held responsible for any damages to persons or property

caused by incorrect installation or use of the appliance.

The Manufacturer shall not be held responsible for any inaccuracies in this handbook due to printing or

transcription errors; the designs in the figures are purely indicative. The Manufacturer also reserves the right

to make any modifications to the products as may be considered necessary or useful, also in the interests

of the user, without jeopardizing the main functional and safety features of the products themselves.

COD. 01101SM - 22.04.2004

INSTRUCTIONS AND ADVICE FOR THE

USE, INSTALLATION AND MAINTENANCE

OF OUR BUILT-IN ELECTRIC HOB

SMEG S.p.A.

Via Circonvallazione Nord, 36

42016 GUASTALLA- ITALIA

TIPO: PAZ04

MOD.: SA435X - 1

Page 2

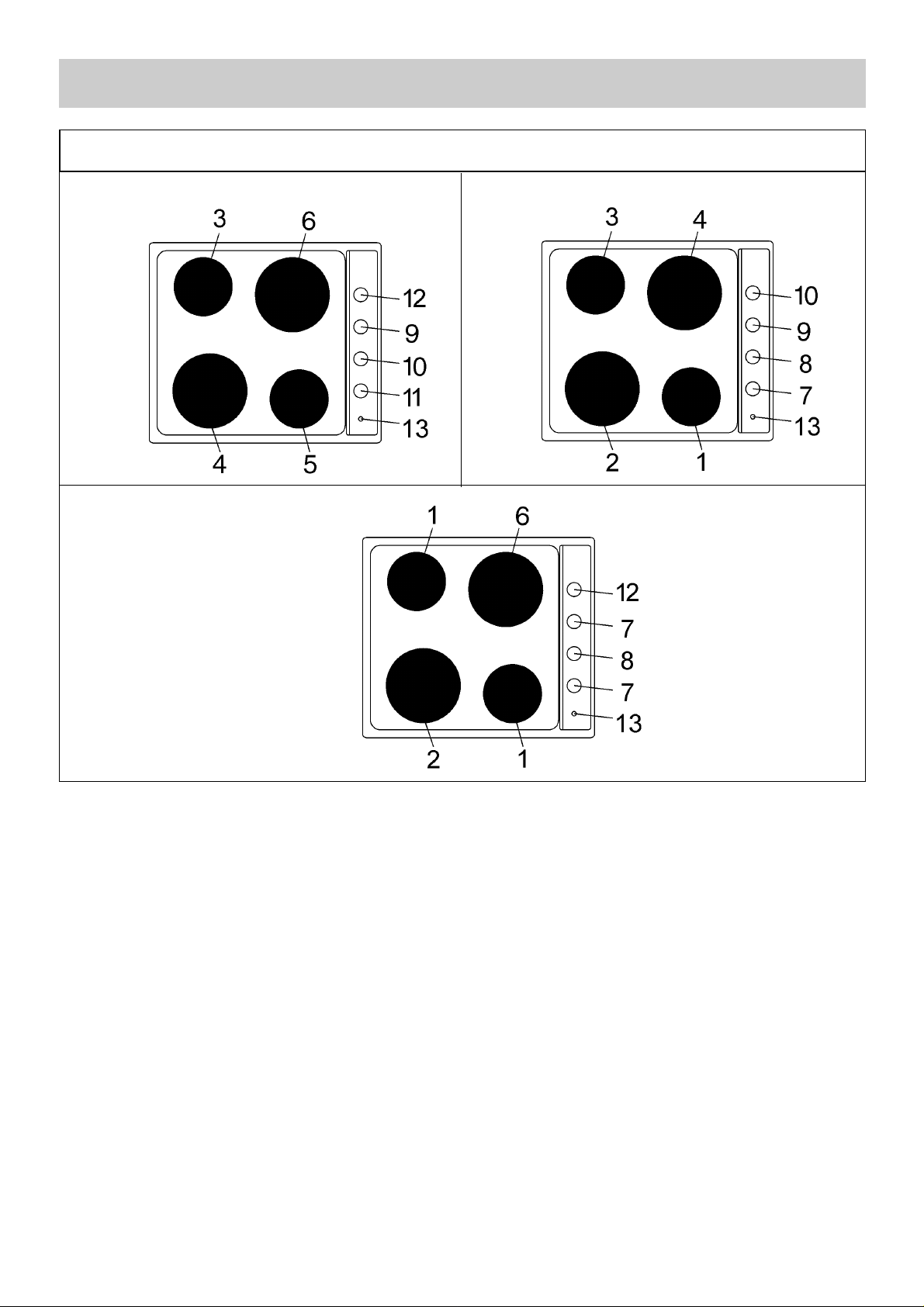

2

1 Normal plate Ø 145 of 1000 W

2 Normal plate Ø 180 of 1500 W

3 Rapid plate Ø 145 of 1500 W

4 Rapid plate Ø 180 of 2000 W

5 Thermostat plate Ø 145 of 1500 W

6 Thermostat plate Ø 180 of 2000 W

7 Control knob for electric plate n° 1

8 Control knob for electric plate n° 2

9 Control knob for electric plate n° 3

10 Control knob for electric plate n° 4

11 Control knob for electric plate n° 5

12 Control knob for electric plate n° 6

13 Warning light indicating that one or more plates are operating

DESCRIPTION OF THE HOT PLATES

TYPE: PAZ04

Page 3

3

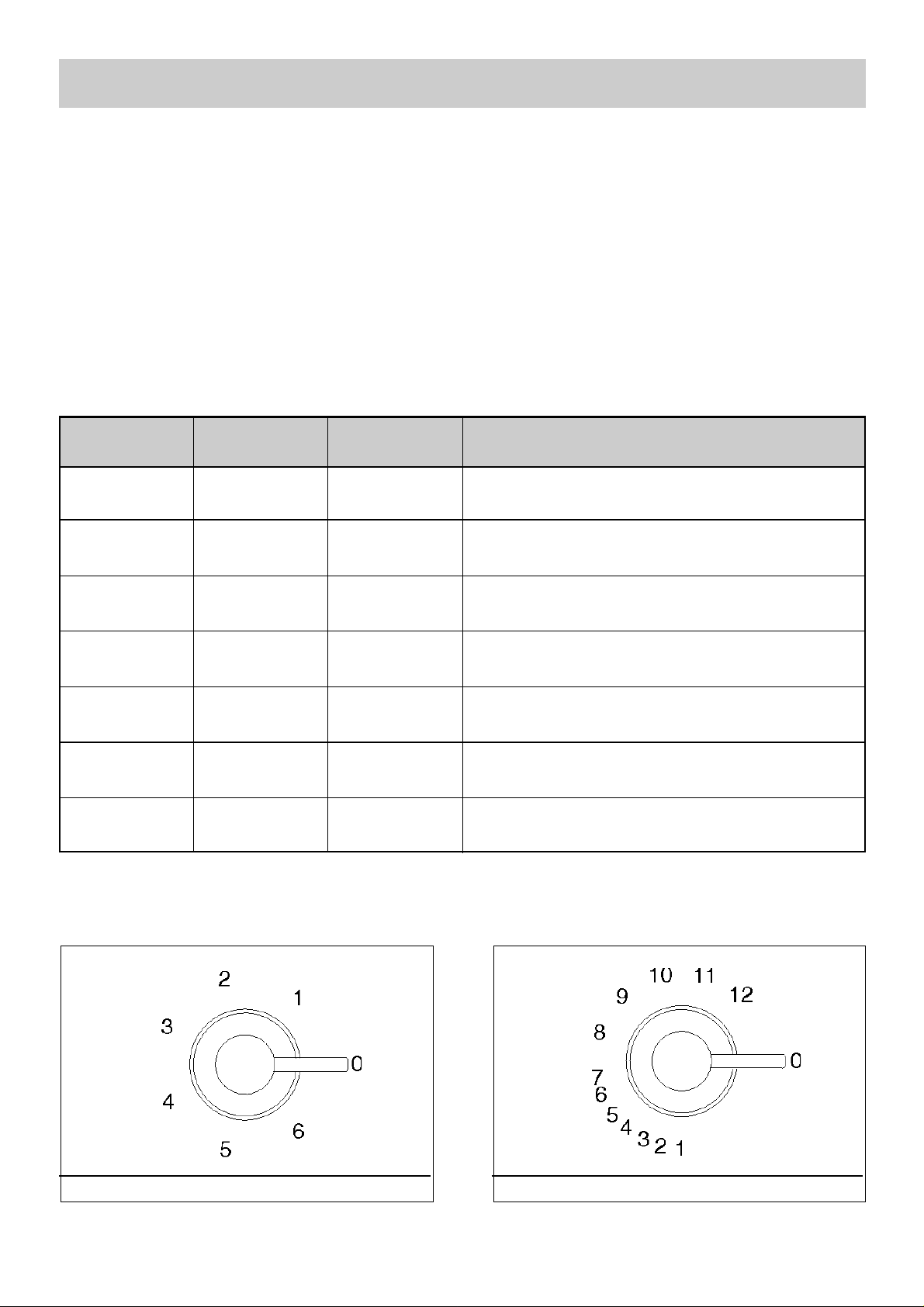

USE

1) SWITCHING ON THE ELECTRIC

PLATES

The hobs may be equipped with three types of

electric plates: normal, thermostat and rapid plates

indicated by a red mark. The normal plates and the

rapid plates are controlled by a 7 - position switch

(see fig. 1). The thermostat plates are controlled by

12 - position switch (see fig. 2).

Switch on the plates by turning the knob to the

required position.

A diagram is screen-printed on the front panel. This

diagram indicates to which electric plate the knob in

question corresponds (see fig. 1 - 2).

A red warning light will come on to indicate that the

plate has been ignited.

2) HOW TO USE THE ELECTRIC

PLATES

A purely indicative plate regulation chart is given

below.

FIG. 1 FIG. 2

0Off

1 1 Weak

2 1 - 4 Low

3 4 - 8 Slow

4 8 - 10 Medium

5 10 - 12 Strong

6 12 High

NORMAL AND THERMOSTAT HEAT POSSIBLE COOKING

RAPID PLATE PLATE INTENSITY PROCESSES

TABLE

To dissolve butter, chocolate, etc.. To heat small

amounts of liquid.

To heat larger amounts of liquid. To prepare cremes

and suces requiring long slow cooking times.

To thaw frozen foods and prepare stews, heat to boiling

point or simmer.

To heat foods to boiling point. To brown delicate meats

and fish.

For escalopes and steaks. To simmer large amounts

of food.

To bring large amounts of liquid to the boil. For frying.

Page 4

IMPORTANT:

Always disconnect the appliance from the

electricity main before carrying out any cleaning

operation.

3) HOTPLATE

If you want to preserve the surface clean and bright,

periodically wash the hot plate with lukewarm soapy

water.

Following this, all parts should be thoroughly rinsed

and dried. Never wash them while they are still

warm and never use abrasive powders.

Do not allow vinegar, coffee, milk, salted water,

lemon or tomato juice from remaining in contact with

the enamelled surfaces for long periods of time.

WARNINGS:

- Correctly preserve the plate after use by

treating it with special products, easily

available on the market. This will keep the

surface of the plate clean and bright. The

operation will also prevent the formation of

rust.

- Any liquid overflowed the pans, must be

always remove with a rag.

- Don’t use steam jets for the equipment

cleaning.

4

USE

WARNINGS:

When the plate is switched on for the first time, or

if it has remained unused for a long period, it

should be dried for 30 minutes on switch position

n° 1. This will eliminate any moisture that may have

been absorbed by the insulating material.

To correctly use the appliance, remember:

- To place a pan on the plate before switching it on.

- To always use pans with flat and very thick

bottoms (see fig. 3).

- To never use pans that are smaller than the

plate diameters.

- To dry the bottom of the pan before placing it on

the plate.

- Never leave the appliance unattended when the

plates are being used. Particularly make sure that

the pan handles are safely positioned and keep

a check on foods requiring oil and grease to

cook, since these products can easily catch

fire.

- The plates will remain hot for a ÿperiod of time

after use. Never touch them with the hands or

other objects in order to prevent burns.

- Immediately disconnect the appliance from the

electricity main if cracks are noted on the

surfaces of the plates.

- Correctly preserve the plate after use by treating

it with special products, easily available on the

market. This will keep the surface of the plate

clean and bright. The operation will also prevent

the formation of rust.

FIG. 3

CLEANING

Page 5

5

INSTALLATION

Installation and maintenance must only be

carried out by a qualified technician.

Incorrect installation could cause damage to

persons, property and animals for which the

manufacturer cannot be held responsible.

Check that the appliance is in a good condition

after having removed the outer packaging and

internal wrappings from around the various loose

parts. If in doubt, do not use the appliance and

contact qualified personnel.

Never leave the packaging materials

(cardboard, bags, polystyrene foam, staples,

etc.) within children's reach since they could

become a potential source of danger.

4) INSTALLING

Installation in accordance with local

regulations.

The cut-out size for this appliance is 473 x 553

see fig. 4.

Remember that the cabinet can only withstand a

temperature of 120° C.

If a wood is installed above the hob, please look at

the hood manufacturer instructions regarding the

minimum distance between hood and hob (fig. 5).

5) FIXING THE HOB

The hob has a special seal which prevents liquids

from getting into the cabinet. Strictly comply with

the following instructions in order to correctly apply

this seal:

- Detach the seals from their backing, checking

that the transparent protection still adheres to the

seal itself.

- Overturn the hob and correctly position seal “E”

(fig. 6) under the edge of the hob itself, so that

the outer part of the seal ÿperfectly matches the

outer edge of the hob. The ends of the strips

must fit together without overlapping.

- Evenly and securely fix the seal to the hob,

pressing it into place with the fingers.

- Remove the strip of protective paper from the

seal. Fit the hooks into their relative housings in

the unit and set the hob into the hole in the

cabinet. Lock it in place with the fixing screws

“G” (see fig. 7).

Barrier installation

CAUTION: THE UNDERSIDE SURFACE OF THE

COOKING HOB CAN REACH A TEMPERATURE

EXCEEDING 95°C DURING NORMAL USE. IF

AFTER INSTALLATION THE UNDERSIDE

SURFACE IS ACCESSIBLE THROUGH UNDERBENCH CUPBOARD DOORS AND THE LIKE, IT

IS ESSENTIAL THAT A RIGID BARRIER IS

INSTALLED SO THAT SUCH ACCESS IS

RESTRICTED. IN ORDER TO AVOID A HAZARD

THE BARRIER MUST BE OF LOW THERMAL

CONDUCTIVITY MATERIAL (eg wood)

INSTALLED ACCORDING TO THE FOLLOWING

INSTRUCTIONS.

The barrier must have at least 28 Ø 70mm

holes cut into it. The barrier should be

positioned directly under the cooking hob at

least 50mm away from the base of the unit. The

barrier should extend for at least the total

width of the cooking hob (600mm) and should

extend back for the total width of the

cupboard. The following drawing illustrates a

typical installation.

6) ELECTRICAL CONNECTION

The manufacturer cannot be responsible for the

missing earthing of the appliance.

Electrical connection must be carried out in

compliance with local regulations.

This appliance must be connected directly to

the mains supply.

FIG. 4 FIG. 4/A FIG. 5 FIG. 6

FIG. 7

Page 6

6

CONVERSIONS

Disconnect the appliance from the mains supply

prior to any conversions being carried out.

7) CHANGING THE TYPE OF POWER

SUPPLY

Although they leave our factory preset for singlephase connection, certain appliances may by

converted to the threephase system.

Comply with the following instructions:

a) Remove the hotplate from the top of the cabinet,

overturn it, unscrew screw "Z" and remove under

part (see fig. 8).

b) Shift connecting plate on terminal according to

the following chart. This chart is also affixed to the

hob.

c) Insert a supply cable of adequate section (see

chart par. 9) through core hitch on the terminal

board.

d) Connect the phase and earth wires to the relative

terminal board.

e) Fix the supply cable in place using clamp.

f) Refit the hotplate, complying with the above

instructions in reverse.

FIG. 8 FIG. 9

Page 7

7

SERVICING

Always disconnect the appliance from the

electricity main before proceeding with any

servicing operation.

8) REPLACING THE ELECTRICAL

COMPONENTS

For access to the various parts, remove the hotplate

from the top of the cabinet. Then overturn it, unscrew

screw “Z” and remove under part. (see fig. 8).

After these actions is possible to work on the

plates, commutators, clamps and input cable.

N.B. In case of substitution of the input cable,

the installer must keep the “earth” conductor

longer than “live” ones, and must respect the

cautions in paragraph “Electrical connection”.

To reassemble the appliance repeat the inverse

process.

9) TECHNICAL CHARACTERISTICS OF

THE ELECTRICAL COMPONENTS

To facilitate the job of the installer we present a

scheme with the characteristics of the components.

POWER OF ELECTRICAL COMPONENTS DENOMINATIONS W

Normal plate Ø 145 mm – 7 positions with the protector 1000

Normal plate Ø 180 mm – 7 positions with the protector 1500

Rapid plate Ø 145 mm – 7 positions 1500

Rapid plate Ø 180 mm – 7 positions 2000

Thermostat plate Ø 145 mm – 12 positions 1500

Thermostat plate Ø 180 mm – 12 positions 2000

Denominations W

TYPE AND SECTION OF THE POWER CABLES

Rubber

H05 RR-F

Polycroropene 3 X 2.5 mm

2

(*) 5 X 1.5 mm2(*) 4 X 1.5 mm2(*)

H05 RN-F

Single phase Three phase Three phase

Cable type

power 230 - 240 V ~ power 400 - 415 V 3N~ power 400 - 415 V 2N~

(*) keeping in mind the contemporaneousness factor

Page 8

VOLTAGE 240 V~

FREQUENCY 50/60 Hz

TOT. RATING 7000 W

MODEL WITH

2 RAPID PLATES + 2 THERMOSTAT PLATES

VOLTAGE 240 V~

FREQUENCY 50/60 Hz

TOT. RATING 6000 W

MODEL WITH

2 RAPID PLATES + 2 NORMAL PLATES (with protector)

VOLTAGE 240 V~

FREQUENCY 50/60 Hz

TOT. RATING 5500 W

MODEL WITH

3 NORMAL PLATES (with protector) + 1 THERMOSTAT PLATE

8

TECHNICAL DATA

Loading...

Loading...