Page 1

Instructions Manual

CMVANILLA – CMVERTIGO - CMZOOM

Page 2

INDEX

RECOMMENDATIONS AND SUGGESTIONS ..................................................................................................................... 3

CHARACTERISTICS ............................................................................................................................................................. 4

INSTALLATION...................................................................................................................................................................... 8

USE ...................................................................................................................................................................................... 19

MAINTENANCE ................................................................................................................................................................... 21

EN

2

2

Page 3

2°

RECOMMENDATIONS AND SUGGESTIONS

The Instructions for Use apply to several versions of this appliance. Accordingly, you may find

descriptions of individual features that do not apply to you r specific appliance.

INSTALLATION

• The manufacturer will not be held liable for any damages resulting from incorrect or improper

installation.

• The minimum safety distance between the cooker top and the extractor hood is 650 mm (some

models can be installed at a lower height, please refer to the paragraphs on working dimensions

and installation).

• Check that the mains voltage corresponds to that indicated on the rating plate fixed to the inside of

the hood.

• For Class I appliances, check that the domestic po wer supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum diameter 120 mm. The route

of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces,

etc.).

• If the extractor is used in conjunction with non-electrical appliances (e.g. gas burning appliances), a

sufficient degree of aeration must be guaranteed in the room in order to prevent the backflow of

exhaust gas. The kitchen must have an opening communicating directly with the open air in order

to guarantee the entry of clean air. When the cooker hood is used in conjunction with appliances

supplied with energy other than electric, the negative pressure in the room must not exceed 0,04

mbar to prevent fumes being drawn back into the room b y the cooker hood.

• In the event of damage to the power cable, it must be replaced by the manufacturer or by the

technical service department, in order to prevent an y risks.

“WARNING: Failure to install the screws or fixing devic e in accordance with these instructions may

result in electrical hazards.”

USE

• The extractor hood has been designed ex clusively for domestic use to eliminate kitchen smells.

• Never use the hood for purposes other than for wh ich it has been designed.

• Never leave high naked flames under the hood wh en it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that it does not

engulf the sides.

• Deep fat fryers must be continuously monitor ed during use: overheated oil can burst into flames.

• Do not flambè under the range hood; risk of fire

• This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appli ance by a person responsible for their safety.

• Children should be supervised to ensure that they d o not play with the appliance.

• “WARNING: Accessible parts may become hot when used with coo king appliances.”.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance

work.

• Clean and/or replace the Filters after the specified ti me period (Fire hazard).

• Clean the hood using a damp cloth and a neutral liq uid detergent.

The symbol on the product or on its packaging indicates that this product may not be treated as household waste. Instead it

shall be handed over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product

is disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more detailed information about recycling of this product,

please contact your local city office, your household waste disposal service or the shop where you purchased the product.

EN

3

3

Page 4

CHARACTERISTICS

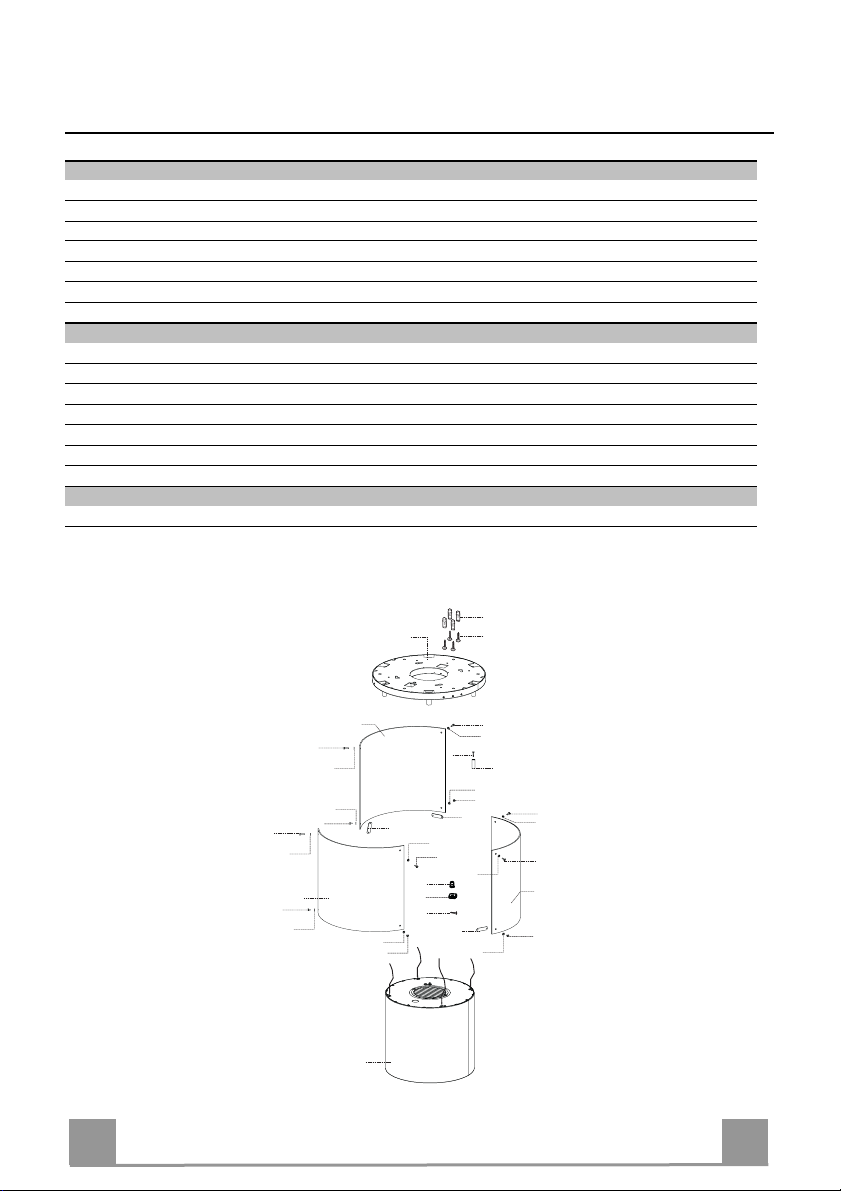

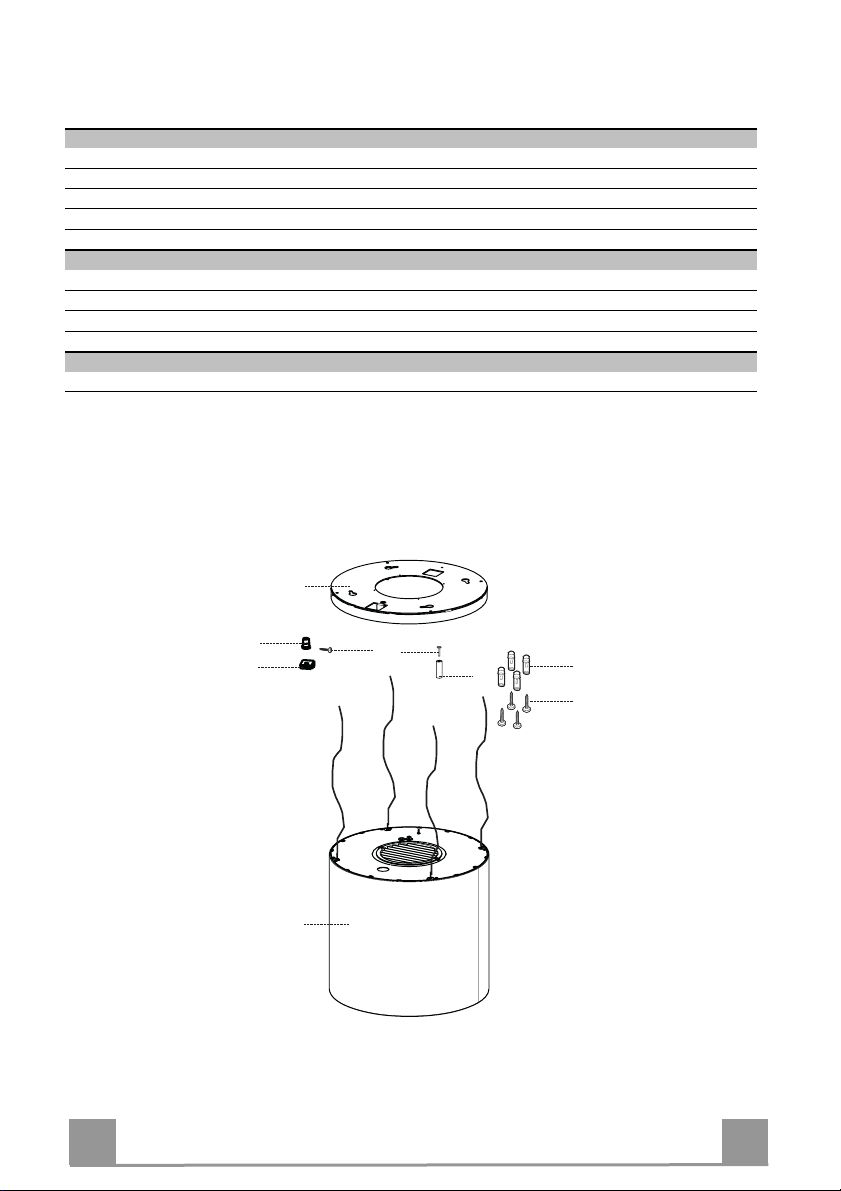

Components (Chic-Vanilla models)

Ref. Q.ty Product Components

1 1 Hood Canopy complete with: Controls, Light, Filters, Motor.

2 1 Hood support Plate (with lamp holder).

3 1 Power supply cable lock

4 1 Cable raceway

5 3 Glass

6 3 Glass fixing plates

14 1 Pawl

Ref. Q.ty Installation Components

11 4 Wall plugs ø 10

12h 4 Screws M5 x 70

12c 1 Screws 2.9 x 9.5

12d 6 Screws M4 x 20

12e 6 Screws M4 x 10

12g 1 Screws for pawl

22 12 Rubber washers

Q.ty Documentation

1 Instruction Manual

CHIC / VANILLA (30 Kg)

11

12h

2

EN

5

12d

22

22

12e

12d

22

5

12e

22

6

22

12e

1

12d

22

12g

14

22

12e

6

22

12d

4

3

12c

6

12d

22

12d

22

5

12e

22

4

4

Page 5

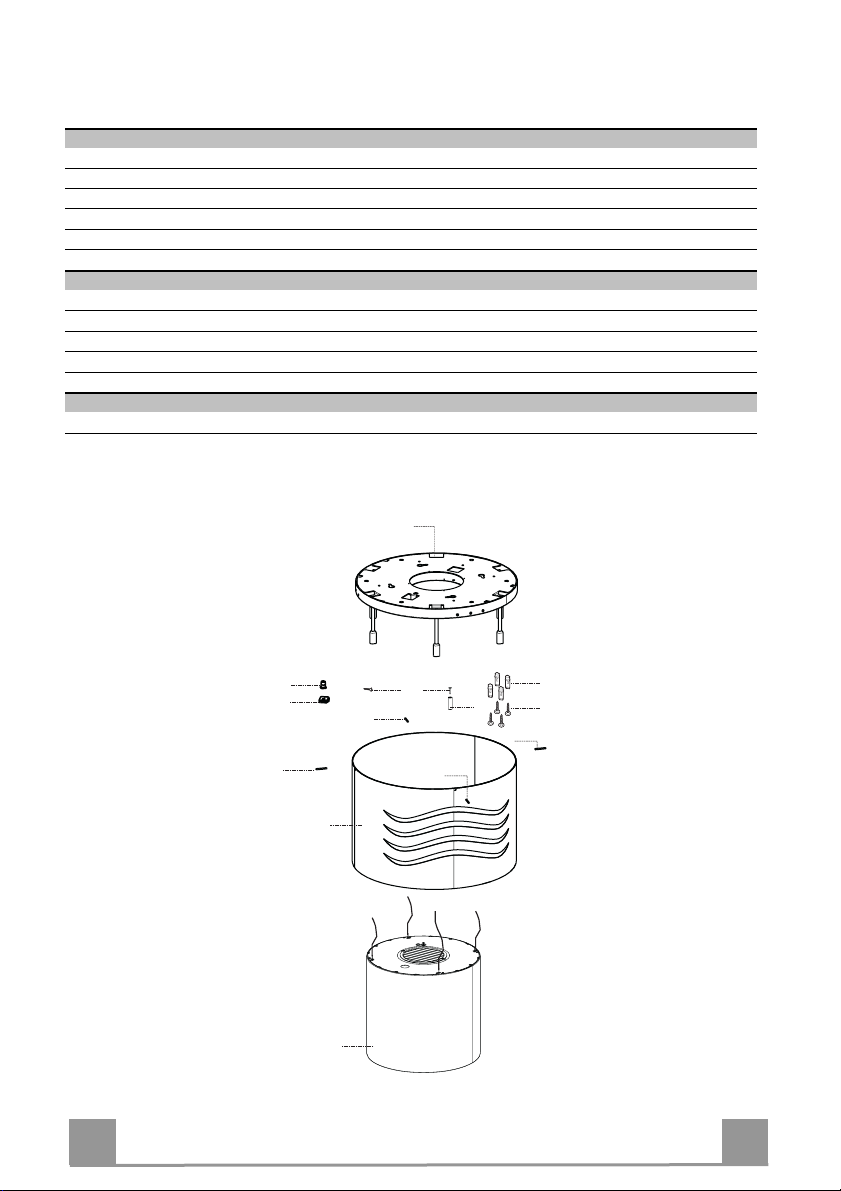

Components (Vertigo model)

Ref. Q.ty Product Components

1 1 Hood Canopy complete with: Controls, Light, Filters, Motor.

2 1 Hood support Plate (with lamp holder)

3 1 Power supply cable lock

4 1 Cable raceway

5 1 Glass or Panels the other material

14 1 Pawl

Ref. Q.ty Installation Components

11 4 Wall plugs ø 10

12h 4 Screws M5 x 70

12c 1 Screws 2.9 x 9.5

12d 4 Chrome plated glass fixing Pin/Screw

12g 1 Screw for pawl

Q.ty Documentation

1 Instruction Manual

VERTIGO (20 Kg)

2

EN

12d

4

3

12c

12g

12d

5

1

14

12d

11

12h

12d

5

5

Page 6

Components (Zoom model)

Ref. Q.ty Product Components

1 1 Hood Canopy complete with: Controls, Light, Filters, Motor.

2 1 Hood support plate.

3 1 Power supply cable lock

4 1 Cable raceway

14 1 Pawl

Ref. Q.ty Installation Components

11 4 Wall plugs ø 10

12h 4 Screws M5 x 70

12c 1 Screws 2.9 x 9.5

12g 1 Screws for pawl

Q.ty Documentation

1 Instruction Manual

ZOOM (15 Kg)

2

EN

4

3

12c

12g

14

1

11

12h

6

6

Page 7

Dimensions

EN

7

7

Page 8

INSTALLATION

This hood is designed to be mounted on the ceiling/on a shelf, above a free-standing Hob (min. 650

mm), in:

• Ducting version: Evacuation to the outside.

• Recirculation version: Internal recirculation.

Warning: The F-Light hood is a system comprising hood + lamp, so that two separate electrical

The Zoom model is not fitted with a lamp.

• Preparing for installation

• Drilling the Ceiling/Shelf and Fixing the support plate

• Connections

• Fitting the hood body

• Functional Check

• Disposal of Packaging

wiring systems must be provided, one for the hood and one for the lamp.

Sequence of operations - Installation

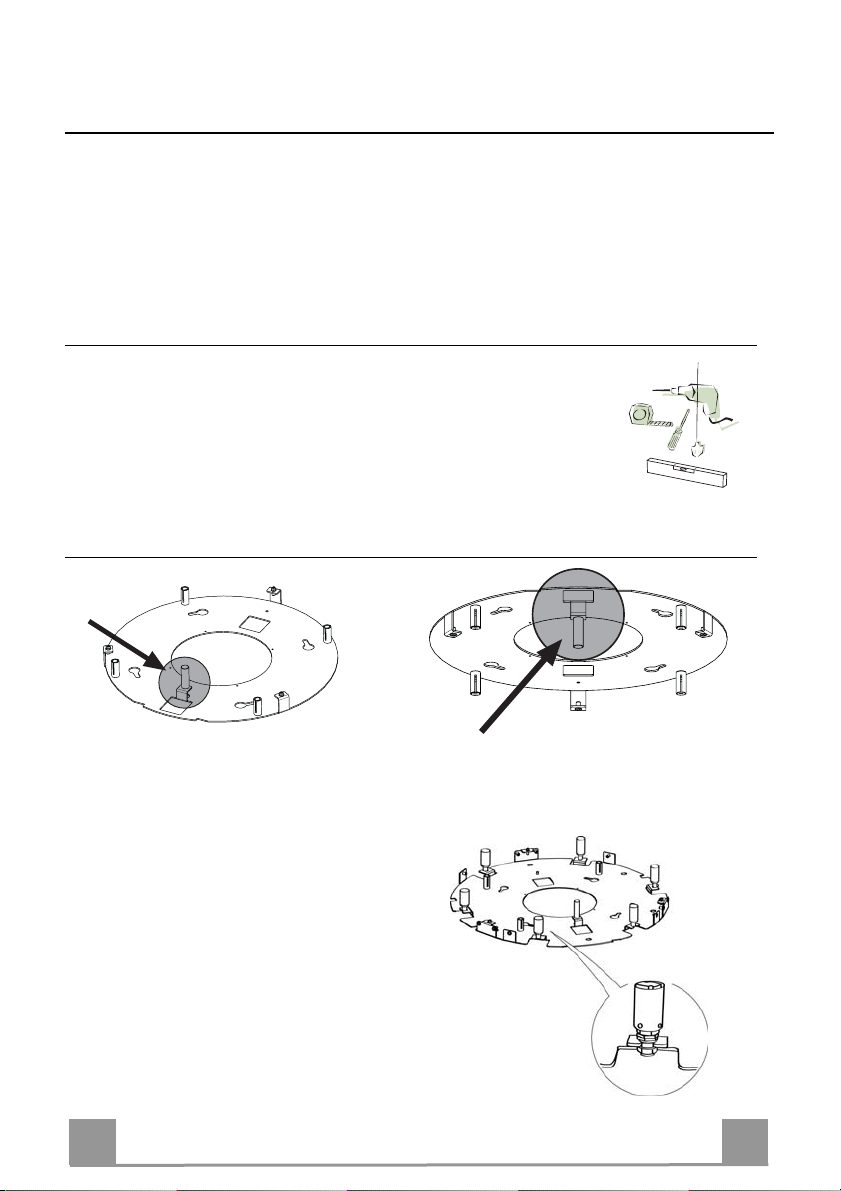

Fitting the Limiter pawl

• Unfasten the 3 screw that join the parts of the Plate (of different shapes and/or sizes) using

the wrench provided.

• Take the Pawl and fix it to the plate on the bracket in the position indicated in the figure,

using the screw provided.

• Take the bulb holders and slot them onto the

brackets provided, which can be seen by

their fork-shaped ends.

Warning: the clamps used to fix the wires

must not be cut.

• Tighten the Screw fixing the bulb holders to

the bracket, in such a way as to hold the

latter between the 2 washers.

EN

8

8

Page 9

Ceiling/Shelf drilling and Plate Fixing

CEILING/SHELF DRILLING

• Use a plumb-line and mark the centre of the cooking hob on the Support Ceiling/Shelf.

• Rest the plate against the ceiling/shelf, taking care to keep the limit pawl that has just been

fitted in a position facing the installer and the cooking hob (the limit pawl must not be confused with the other 4 used to fix the steel cables that move the Hood).

• Mark on the ceiling the centres of the holes in the plate.

• Drill the following points:

• Ceilings in solid concrete: As per concrete plugs used.

• Ceilings in hollow bricks with 20 mm resistance thickness: Drill a hole ø 10 mm (insert

Plugs 11 supplied immediately).

• Ceilings with Wood Beams: As per Wood Screws used (not supplied).

• Wooden shelf, with a resistant thickness of 15 mm: drill a hole ø 7 mm.

• Feeding the electric supply cable: drill a hole ø 10 mm.

Warning: there will be two lines to be connected: a direct electric line for the hood power

supply and another line with a switch for the lamp. This does not apply to Zoom model.

• Air Outlet (Ducting Version): according to the diameter of the connection to the external

ducting pipe.

• Insert two screws, crossing them and leaving 4-5 mm from the ceiling:

• for solid concrete, concrete plugs, not provided.

• for hollow bricks with approx. 20 mm resistance thickness, screws 12h, provided.

• for wooden beams, wood screws, not provided.

• for wooden shelves, screws with washers and nuts, not provided.

EN

9

9

Page 10

2

1

1

2

FIXING THE PLATE

• Lift up the fixing plate, taking care to ensure that the limit pawl

is positioned frontally.

• Fit the slots onto the two screws previously inserted in the

ceiling, and turn until they are at the centre of the adjustment

slot.

• Tighten the two screws completely and screw in the other two

provided; before locking the screws completely it is possible to

make adjustments by turning the piece, making sure that the

screws do not come out of the adjustment slot.

• The unit must be securely fastened both due to the weight of

the Hood and the stress caused by occasional sideways pressure on the Appliance when in position. Once the unit has been

fixed, make sure that the plate is stable.

• In all cases where the Ceiling is not sufficiently strong at the

point of suspension, the Installation technician must strengthen

it with suitable plates and counterplates, anchored to

structurally sound elements.

EN

1

10

Page 11

CONNECTING HOOD-PLATE CABLES

N.B. Before continuing with installation it is necessary to move the hood to a height

of at least 650 mm from the cooker hob, using a support or the assistance of another person.

This is essential, as the hood cables must necessarily be connected to the plate

fitted to the ceiling without the weight of the hood bearing on the structure.

• The cable fixing system is made up of 3 parts:

• Threaded Pawls (a) already mounted on the ceiling plate.

• Cable clamp screws (b) provided.

• Safety knobs (c) provided.

a

b

c

• Pass the cables connected to the hood canopy into the respective holes in the plate

cover, after dismantling

• Insert the cable

raceway 4 in the

opening on the

plate cover and

pass the hood

power supply

cable through it.

4

EN

1

11

Page 12

• Attention to the direction of the plate

fixed to the ceiling (the limit pawl on

the plate fastened to the ceiling has a

corresponding hole on the plate cover

and on the hood canopy).

B

• Insert the cables into the safety knobs (c)

with the thread at the top.

C

• Insert the cables into the cable clamp

screws (b)

EN

1

12

Page 13

• Pass the cables through the slots in the threaded pawls (a)

and screw the cable locking screws (b) to the pawls themselves.

• When the operation has been

completed the result must be as

shown in the figure for all 4 cables.

• At this point we have all 4 cables connected to the plate

Bring the cables under tension by pushing them upwards so that they slide inside the cable clamp screw and slide out

of the slot in the threaded pawl.

This is possible because the cable clamp

screw has a system that, if mounted

properly, allows the cables to slide inside it in one direction only, and prevents it from sliding in the other direction.

Attention, the cables all have the same

length to facilitate the operation of the

final level. The front left cable must not

be slacker than the others.

EN

1

13

Page 14

• At this point it is possible to connect up the hood, and the lamp if there is one, to the power

supply using the respective power cables.

• Close the plate cover using the 3

screws removed previously and the

wrench provided

• At this point the Hood is suspended.

EN

1

14

Page 15

Connections

AIR OUTLET - DUCTING VERSION

To install the hood in the ducting version, please refer to the

instructions provided in the ducting kit specific to the hood.

AIR OUTLET – RECIRCULATION VERSION

• Open the lighting unit by pulling on the notch provided.

• Remove the grease filter.

• Make sure that the Activated charcoal odour filter has been

fitted.

EN

1

15

Page 16

LEVELLING THE HOOD

• The hood mobile unit must be levelled to allow

the movement to operate properly.

• The hood is levelled by adjusting the safety pawls.

• Rest a spirit level on the hood.

• When the safety knobs are pressed upwards,

movement of the hood is “unlocked”. By inserting or extracting the cable from the cable

clamp screw it is possible to make adjustments that allow the mobile hood body to be

levelled.

• Once the hood has been set level, the safety

knobs must be tightened again.

Warning:

• Please check that all 4 cables are stretched.

• Please check that all 4 cables were not damaged during installation.

• It must be remembered that the minimum distance between the hood and the cooking

hob must be 650mm.

• The mobile unit (hood canopy) must have a maximum stroke of 900 mm in case of

recirculation version and in the case of the ducting kit of 750mm.

EN

1

16

Page 17

FIXING THE POWER SUPPLY CABLE

• Wind the power cable around its axis so that it

forms a spiral from the mobile body to the plate in

the ceiling.

• It is important to do this to prevent the wire come

out from the hood body during the closing of the

hood

X

L

• Take the cable clamp 3 provided.

• Insert the Power cable in the Cable

clamp 3 and screw it to the plate using one of the Screws 12c provided.

Finally, check that the power supply cable is properly locked, checking that when the mobile

unit rises up towards the ceiling, it positions itself over the mobile unit and does not come out

from the edge of the hood.

The length of the Power Cable “L” must be equal to the stroke “X” plus 50mm for the Recirculation Version and 200 mm for the Ducting Version.

L = X + 50 mm Recirculation version

L = X + 200 mm Ducting version

EN

1

17

Page 18

FITTING THE GLASS – CHIC-VANILLA MODELS

• Take the lamps and insert them in the lamp holders.

• They do not have to be screwed in, but simply inserted

all the way.

• Fix the glass 5 to the plate using the screws 12d and

washers 22 in the top part.

• Fix the glass elements together at the bottom using the

glass fixing plates 6 with screws 12e and washers 22.

2

12d

22

5

12e

22

6

12d

22

12e

22

FITTING THE GLASS – VERTIGO-KALEIDOS-LUXIA MOD-

ELS

• Take the lamps and insert them in the lamp holders.

• They do not have to be screwed in, but simply inserted

all the way.

• Fix the glass (or other material) 5 to the plate using the

fixing knobs 12d.

Electrical connection

• Connect the Hood to the Mains Power Supply, inserting

a bipolar switch with a contact aperture of at least 3

mm.

• Open the lighting unit by pulling on the catch provided

• Remove the Filter, pushing it towards the back of the

unit and at the same time pulling downward.

• Make sure that the Power cable has been properly inserted into the Suction fan socket

• Replace the Grease filter and then the lighting unit.

2

12d

5

12d

12d

5

5

EN

1

18

Page 19

USE

Control panel

L T1

Button Function Display

L Turns the lights On/Off.

T1 Hood Down

Press for 2 seconds to raise the Hood.

Press briefly to turn the Motor On/Off.

Hood Up

Press once: The Hood lowers.

Press a second time: The Hood Stops.

When the movement has been completed

the motor turns on at Speed two.

On/Off

Off/Off

Warning: The Hood controls only control the Hood functions. The Lighting unit has a completely separate power supply and a separate switch.

The electronic control system recognises and signals two types of fault.

Led T1

Current absorption threshold exceeded:

Slow flashing

Rapid flashing

If an overload condition occurs, the fault is signalled by LED T1 on the

keyboard flashing once every 2 seconds. Check that nothing is blocking

normal hood movements.

The signal remains active until a new hood open/close command is given.

Hood opening safety microswitch tripped:

If the safety microswitch trips, the fault is signalled by LED T1 on the

keyboard flashing quickly (once every 250 ms). This means that the hood

has passed the microswitch…….. Call Technical Assistance!

You can continue to use the hood’s light and motor functions while this

fault is active. Whenever the motor is on, LED T1 will continue to flash,

indicating that the fault is still present.

EN

1

19

Page 20

REMOTE CONTROL

The appliance can be controlled using a remote control

powered by a 1.5 V carbon-zinc alkaline batteries of the

standard LR03-AAA type (not included).

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper

manner.

Control panel

Button Function Display

Turns the Motor On/Off. -

Hood Closed:

- Press the button briefly to start lowering the hood

- It will stop when the button is pressed again.

When the movement has been completed the motor will start at speed 2.

Hood Open:

- Press and hold for 2 seconds to activat e raising of the hood, which stops when it reaches the stop.

- Press (briefly) to stop the movement (before the stop is reached).

- Press again briefly to turn the motor on/off.

- Press and hold for 2 seconds to start raisin g of the hood.

- If the motor is on, it will first stop the motor and then start the m ovement.

Decreases the speed of the Motor. -

Increases the speed of the Motor. -

INTENSIVE

- This can only be activated with the hood lowered and when the delay or 24h functions are not active.

- Activates Intensive speed from any other speed.

To disable it, simply press the same button a gain or turn the motor off.

- Intensive speed is timed to run for 10 minutes. At the end of the 10 minutes the system will automati

cally return to the speed that was set before.

Press briefly for the Delay Function:

Can only be activated if the Intensive or 24h function is not active.

Activates and deactivates total sh utdown of the hood (motor+lights) after 30 minutes:

To disable the Delay, simply press the button again or turn the motor off.

Press and hold for 2 sec. for the 24H Function:

Can only be activated if the Intensive or Delay function is not active.

Activates and deactivates the 24H function for 10 minutes every hour, for 24 hours. After this time it is

deactivated.

Turns the Hood lights On/Off.

EN

-

-

The led on the motor

button (on the hood

controls) will flash

once a second.

The led on the motor

button (on the hood

controls) will flash

once every 0.5 seconds.

The led on the motor

button (on the hood

controls) will flash

once every 2 seconds.

2

20

Page 21

A

B

MAINTENANCE

Grease filter

The filter must be cleaned every 2 months of operation, or more

frequently for particularly heavy usage, and can be washed in a

dishwasher.

CLEANING METAL SELF- SUPPORTING GREASE FILTER

• Open the lighting unit by pulling on the nocth.

• Remove the filter one by one pushing it towards the back side

of the hood unit and simultaneously pulling downwards.

• Any kind of bending of the filter has to be avoided when washing it. Before fitting it again into the hood make sure that it is

completely dry.

• When fitting the filter into the hood pay attention that they are

mounted in correct position the handle facing outwards.

• Replace the lighting unit.

Activated Charcoal Filter (Recirculation Version)

This cannot be washed or regenerated, and must be changed approximately once every 4 months, or more frequently in the case

of particularly intensive use.

CHANGING

• Open the light unit.

• Remove grease filter.

• Remove the saturated Activated Charcoal Filters, as indicated

(A).

• Fit the new Filters, as indicated (B).

• Fit the anti-grease filter and the Light Unit back into position.

EN

2

21

Page 22

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the snap-on lamp cover by levering it from under the

metal ring, supporting it with one hand.

• Remove the halogen lamp from the lamp holder by pulling

gently.

• Replace the lamp with a new one of the same type, making

sure that you insert the two pins properly into the housings on

the lamp holder.

• Replace the snap-on lamp cover.

Lighting Unit Lamps

Vanilla

Vertigo

Attention: Bulbs are not provided.

G9 -- Energy Saving 9W

EN

2

22

Page 23

Additional information for the installation technician

• Open the lighting unit by pulling on the notch provided.

• Apply the label, indicated the type of lighting, on the Hood as indicated in the figure

(Rif.A).

B

A

Procedure to be used in case of malfunction on the movement

• Check that the fuse is properly inserted and that it has not burned out, for replacing the

fuse open the lighting unit and unscrew the fuser holder and replace it with one having

the same characteristics (Rif.B)

• Check that the hood canopy is fitted level (the use of a spirit level is recommended).

• Check that the four cables are all at the same tension. The front left cable must not be

slacker than the others.

If even these operations do not solve the problem contact the Technical Assistance.

EN

2

23

Page 24

991.0266.243_ver1

Loading...

Loading...