Page 1

Windy Boy 1100

Windy Boy 1700

Inverter for Wind Energy Power Plants

Operating Instructions Version 1.0 WB11_17-11:FE4205

TBE-WB11-17

Page 2

Page 3

SMA Technologie AG Revision History

Revision History

Document number Changes Author

WB11_17-11:FE4205 First issue Welzel

Operating Instructions WB11_17-11:FE4205 Page 3

Page 4

SMA Technologie AG

Page 4 WB11_17-11:FE4205 Operating Instructions

Page 5

SMA Technologie AG Explanation of Symbols used in this Document

Explanation of Symbols used in this Document

This symbol indicates information that is essential for a trouble-free

and safe operation of the product. Please read these sections carefully in order to avoid any damages of the equipment and for optimal personal protection.

This symbol indicates information that is required for the optimal operation of

the product. Read these sections carefully in order to ensure an optimal operation of the product and all its features.

This symbol indicates an example.

Operating Instructions WB11_17-11:FE4205 Page 5

Page 6

Legal Restrictions SMA Technologie AG

Liability exclusion

The information contained in this documentation are the property of SMA Technologie AG. No part of this

documentation may be published without written permission from SMA Technologie AG. A reproduction for

internal purposes for the evaluation of the product or an appropriate application is permitted and does not

require authorization.

All information are based on our "General Terms and Conditions of Delivery of SMA Technologie AG”.

The content of this documentation is reviewed continuously and adjusted, if necessary. SMA Technologie

AG provides this documentation without exclusion of deviations and without warranty of completeness. You

will find the current version on the Internet at www.SMA.de or can obtain it via the usual sales channels.

Warranty or liability claims for all kinds are excluded in case of damages due to:

• Inappropriate use of the product

• Operation of the product in an improper environment

• Operation of the product without considering the relevant safety regulations

• Non-fulfillment of the warnings or safety instructions described in the documentation for the product

• Operation of the product under faulty conditions concerning security and protection

• Arbitrary changing of the product or the provided software

• Failure of the product due to interference of connected or contiguous devices out of legal limit values

• Disasters and force majeure

Software Licensing

The use of the provided software by SMA Technologie AG is subject to the following conditions:

The software may be reproduced for internal purposes and installed on any number of computers. Provided

source codes can be changed and adjusted on the company’s own authority according to the internal

purpose. Driver may be ported to other operating systems as well. No part of the source codes may be

published without written permission of SMA Technologie AG. Sublicensing of the software is not

acceptable.

Liability limitation: SMA Technologie AG disclaims liability for any direct or indirect consequential damages

arising from the use of the software produced by SMA Technologie AG. The same applies for the provision

and/or non-provision of support.

Provided software not produced by SMA Technologie AG is subject to the respective licensing and liability

agreements of the manufacturer.

Trademarks

All brand and product names used herein are trademarks or registered trademarks of their respective

holders, although they may not be specifically designated as such.

SMA Technologie AG

Hannoversche Strasse 1-5

34266 Niestetal

Germany

Tel. (+49) 5 61 95 22 – 0

Fax (+49) 5 61 95 22 – 100

www.SMA.de

E-Mail: info@SMA.de

© 2005 SMA Technologie AG. All rights reserved.

Page 6 WB11_17-11:FE4205 Operating Instructions

Page 7

SMA Technologie AG Table of Contents

Table of Contents

1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Appropriate usage of the Windy Boy . . . . . . . . . . . . . . . . . . .13

3.2 Device construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.3 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3.1 Normal operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3.2 Critical, faulty operation . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3.3 Non-critical, faulty operation . . . . . . . . . . . . . . . . . . . . . .18

3.3.4 Description of the operational status . . . . . . . . . . . . . . . .19

3.4 Messages in the optional display . . . . . . . . . . . . . . . . . . . . . .26

4 Setting the display language . . . . . . . . . . . . . . . . . . 29

5 Turbine operation . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5.2 Characteristic curve function. . . . . . . . . . . . . . . . . . . . . . . . . .31

5.3 Characteristic curve operation in "Turbine" operating mode . . .34

5.4 General setting example . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6 Maintenance and care. . . . . . . . . . . . . . . . . . . . . . . 37

7 Expansions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Sunny Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.2 Sunny Data via Powerline . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.3 Sunny Data over RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

7.4 Sunny Data over RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

7.5 Sunny Beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

7.6 Sunny Data Control over Sunny Beam . . . . . . . . . . . . . . . . . .42

7.7 Sunny Boy Control Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.8 Sunny Boy Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.9 Sunny Boy Control Plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7.10 Sunny Data Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7.11 Sunny WebBox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.12 Sunny Portal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.13 Sunny TV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

8 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1 Windy Boy 1100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8.1.1 DC connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

8.1.2 Grid connection data . . . . . . . . . . . . . . . . . . . . . . . . . . .48

8.1.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

8.2 Windy Boy 1700. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

8.2.1 DC connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Operating Instructions WB11_17-11:FE4205 Page 7

Page 8

Table of Contents SMA Technologie AG

8.2.2 Grid connection data . . . . . . . . . . . . . . . . . . . . . . . . . . .51

8.2.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9 General information. . . . . . . . . . . . . . . . . . . . . . . . . 53

9.1 Measurement channels and messages. . . . . . . . . . . . . . . . . . .53

9.1.1 Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

9.1.2 Windy Boy operating parameters . . . . . . . . . . . . . . . . . .55

9.2 Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

9.3 Declaration of conformity (CE) . . . . . . . . . . . . . . . . . . . . . . .61

9.4 Import certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

10 Stand-alone systems. . . . . . . . . . . . . . . . . . . . . . . . . 63

11 Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Page 8 WB11_17-11:FE4205 Operating Instructions

Page 9

SMA Technologie AG Introduction

1 Introduction

The installation of the Windy Boy 1100 / 1700 may only be done

by qualified technicians. The installer must be approved by the

utility company. Please read the installation guide carefully before

you begin with the installation. The installation of utility interactive

power sources must be compliant with all applicable regulations of

the utility company and with all applicable regulations and

standards.

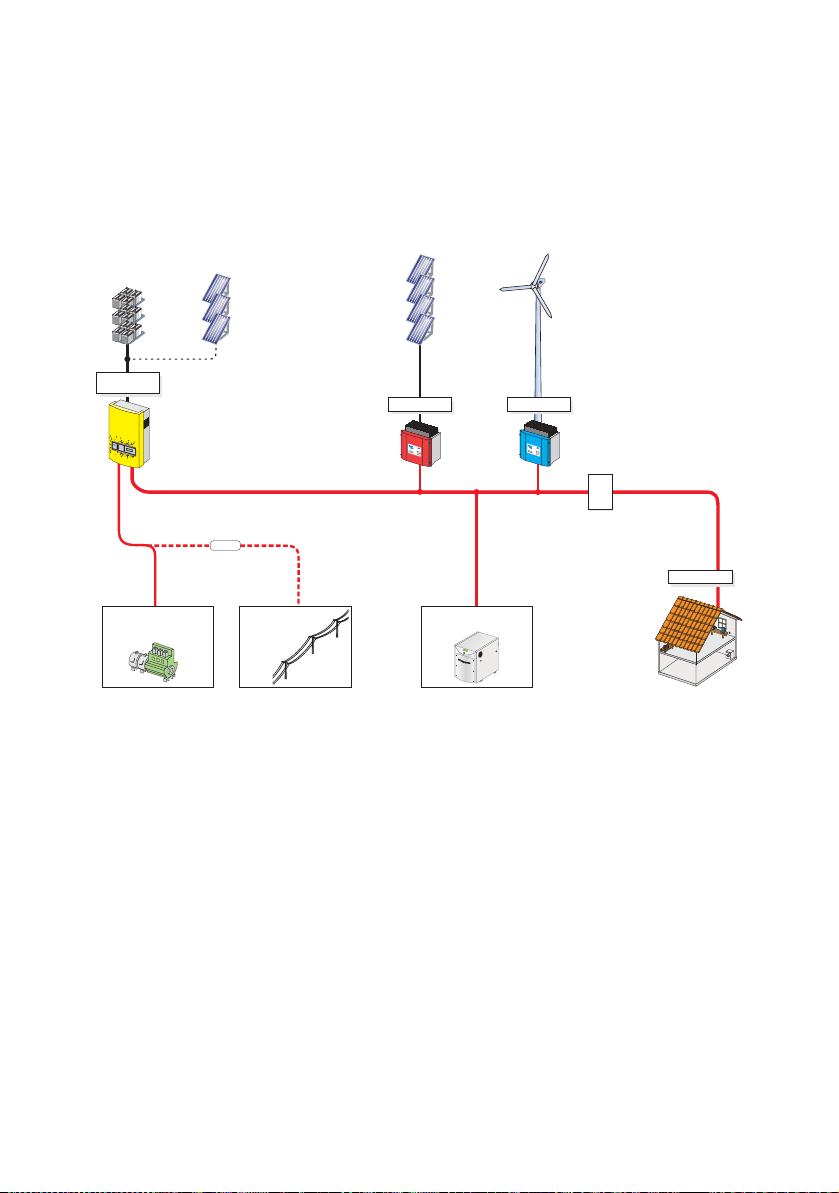

The Windy Boy inverters make it possible to operate small wind turbines as grid-connected systems. Grid-connected means that the energy generated by the wind turbine

can be fed directly into an existing house power grid, a stand-alone power system,

or the mains grid.

To this end, the inverter converts the direct current (DC) from permanent-magnet wind

turbines, which varies with speed, into grid-compatible alternating current (AC). The

inverter requires the constant presence of mains-grid voltage!

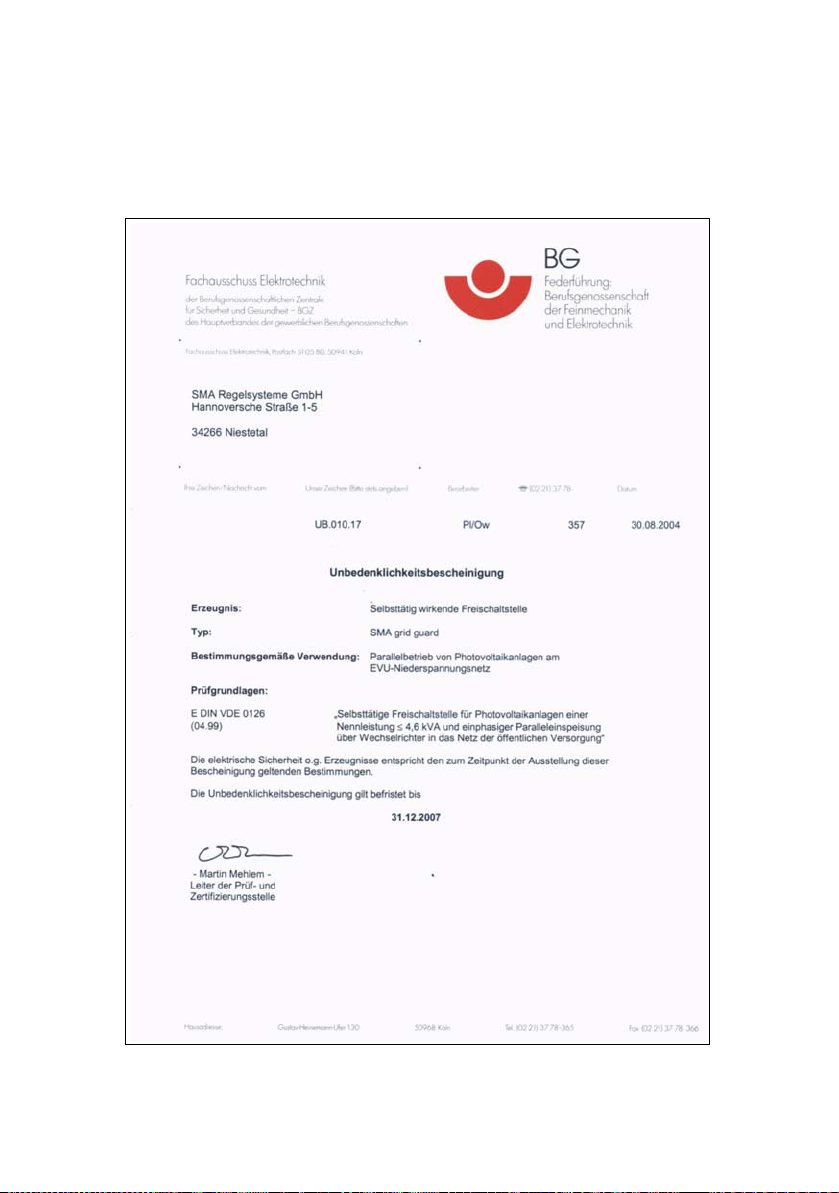

The Windy Boy complies with all the VDEW (Verband der Elektrizitätswirtschaft –

German Electricity Industry Association) regulations for the connection and parallel

operation of electrical power units to the low-voltage grid of the electricity supply

company. This also encompasses the regulations of the German Professional Association for Precision Engineering and Electro technology relating to "Automatic switching of electrical power units" (SMA grid guard) and/or DIN VDE 0126. In addition

to this, the Windy Boy conforms to the electromagnetic tolerance regulations and the

low-voltage regulations of the relevant combined European norms, as confirmed in

the CE conformity declaration (9.3 "Declaration of conformity (CE)” (page 61)).

The documentation provided here covers all such topics that are of interest when operating the Windy Boy inverters. In addition to explanations of the operational methods of the device and detailed technical data, advice as to data capture and analysis

is also provided.

Information relating to the installation and commissioning of the Windy Boy should

be taken from the installation instructions delivered with the device. The Windy Boy

inverter has a special operation mode for wind turbines which allows performance

adjustment to the characteristic curve of the generator. In this way you will obtain

maximum yields from your wind turbine.

A wide input voltage range, high efficiency and a freely configurable output characteristic curve with the highest level of reliability are only some of the properties that

are useful for your grid-connected system, or in a stand-alone system when combined

with the Sunny Island.

Operating instructions WB11_17-11:FE4205 Page 9

Page 10

Introduction SMA Technologie AG

The Windy Boy is compatible with all SMA communication products (RS232, RS485,

Powerline, Wireless, Display), providing numerous possibilities for diagnosis, data visualization and remote maintenance of your small wind turbine system.

For stand-alone systems, that use the Sunny Island: Please configure your

Windy Boy according to the specifications in the Sunny Island manual.

Configuration of the V/I properties of the Windy Boy with respect to your wind

turbine: the parameters U

Start, UDCWindStart and UDCWindMax must be

PV

configured to guarantee optimum operation of your Windy Boy with your wind

turbine. The configuration process is described in chapter 5 "Turbine operation” (page 31).

Apart from the parameter settings, the Windy Boy is identical to the Sunny Boy photovoltaic inverter and can therefore also be used as a PV inverter. Please download

the Sunny Boy manual from www.SMA.de. If you are planning to use the Windy Boy

in a photovoltaic system please contact us on the SMA hotline.

Page 10 WB11_17-11:FE4205 Operating instructions

Page 11

SMA Technologie AG Safety Information

2 Safety Information

Opening of the device, and any

•electrical installation,

•repair or

•modification

Betrieb

Photovoltaik-Stringwechselrichter

Operation

Photovoltaic string

Erdschluss

in

verter

Earth

F

ault

Störung

Failure

The temperature of individual parts of the case of the Windy Boy in particular the temperature of the heatsink - can reach over 60 °C

in normal operation. There is the danger of burn injury when these

parts are touched!

The Windy Boy contains an independent mains disconnection device, the "SMA

grid guard". It ensures that the Windy Boy complies with the VDEW (Verband

der Elektrizitätswirtschaft – German Electricity Industry Association) regulations for the connection and parallel operation of electrical power units to the

low-voltage grid of the electricity supply company (EVU) and with DIN VDE

0126, which forms a part of these regulations.

of the Windy Boy may only be performed

by qualified electrical personnel. Even

when no external voltage is present, the

device can still contain high voltages and

the danger of electrical shock.

Operating instructions WB11_17-11:FE4205 Page 11

Page 12

Safety Information SMA Technologie AG

Page 12 WB11_17-11:FE4205 Operating instructions

Page 13

SMA Technologie AG Unit description

3 Unit description

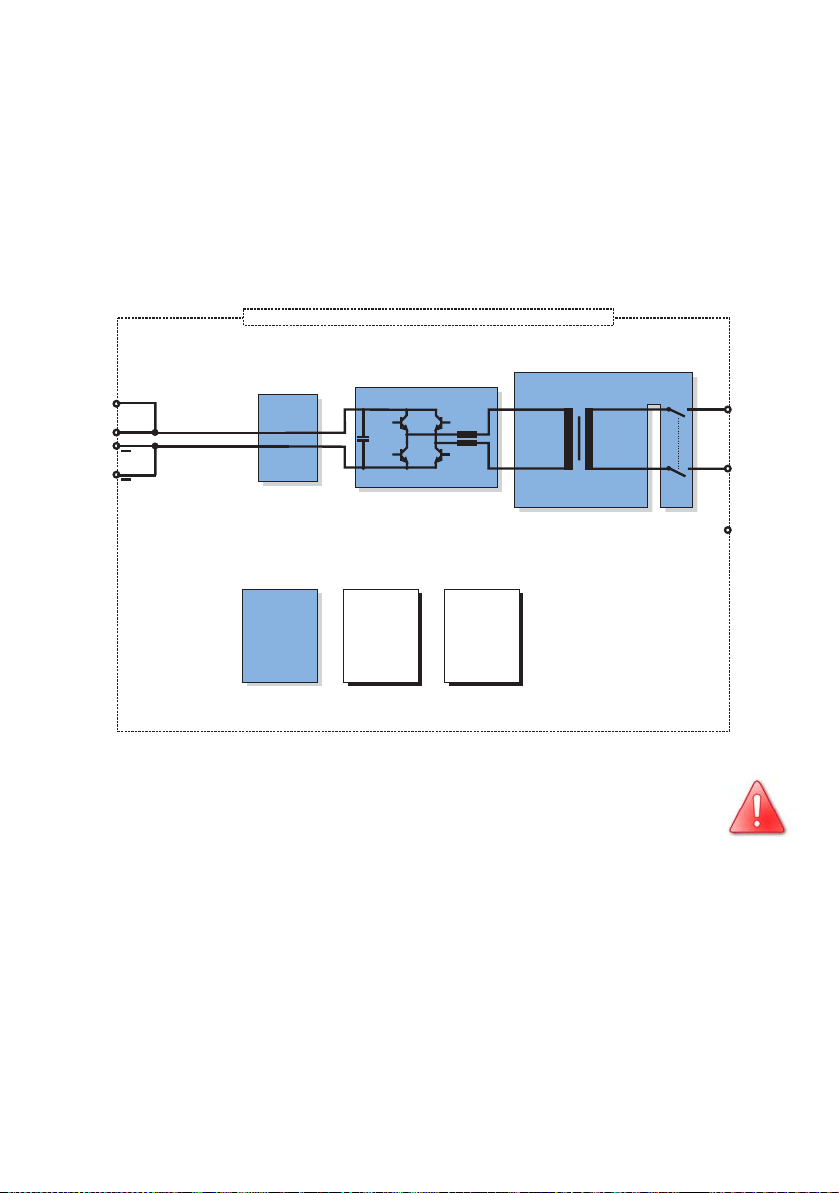

3.1 Appropriate usage of the Windy Boy

The Windy Boy is designed for the conversion of DC voltage from a wind turbine

(permanent magnet generator) into AC voltage for feeding into the public mains grid.

The technical data is described in more detail in chapter 8 "Technical data”

(page 47).

Overvoltage protection

Windy

Boy

Net

z

w

e

c

h

G

s

e

r

i

l

d

r

i

c

t

i

h

e

t

d

e

r

i

n

f

ü

ve

r

r

W

te

r

i

n

f

d

o

e

r

n

w

e

r

i

n

g

d

i

e

t

a

u

n

r

b

l

a

i

n

g

e

e

s

Control unit

Control unit

n

Wind

Generator

Converter

Rectifier

Windy Boy

Public mains grid

Many wind turbine manufacturers offer an extra over-voltage protection module.

These components prevent the destruction of the downstream inverter in the case of

overvoltage.

Overvoltage can occur under the following conditions:

• High turbine rotation speeds under strong wind conditions

• An increase in turbine rotation speed caused by load-shedding when the inverter

is disconnected from the mains grid e.g. in the case of mains interference or power outage.

The overvoltage protection system has the following tasks:

• When a pre-defined voltage is reached, the inverter is disconnected from the generator and a short-circuit slows the generator and/or brings it to a standstill.

• Some devices reduce the turbine rotation speed, and thus the generator output

voltage, by switching in a resistor assembly (Dumpload). The electrical energy generated by the turbine is then converted to heat.

In grid-connected systems, we recommend the use of one of the electronic protection

mechanisms described here. Please note that overvoltage on the inverter can lead to

destruction of the device. In addition to this, you lose the right to all warranty claims

- even if the maximum input voltage of the inverter is only exceeded for a short time.

Operating instructions WB11_17-11:FE4205 Page 13

Page 14

Unit description SMA Technologie AG

The electronic protection systems described here are preferable to mechanical solutions (pitch control, "turning out of the wind") in every case.

Any other use of the Windy Boy leads to loss of the right to all warranty claims.

The presence of excessive input voltage can lead to irreparable

damage! Immediately disconnect the DC input of the Windy Boy.

When the Windy Boy receives an excessive DC input voltage, it automatically

disconnects from the mains network and no longer feeds power into the grid.

When the Windy Boy is in operation, you must always first disconnect the AC

voltage (mains supply) and only then should you disconnect the DC voltage

from the Windy Boy!

Page 14 WB11_17-11:FE4205 Operating instructions

Page 15

SMA Technologie AG Unit description

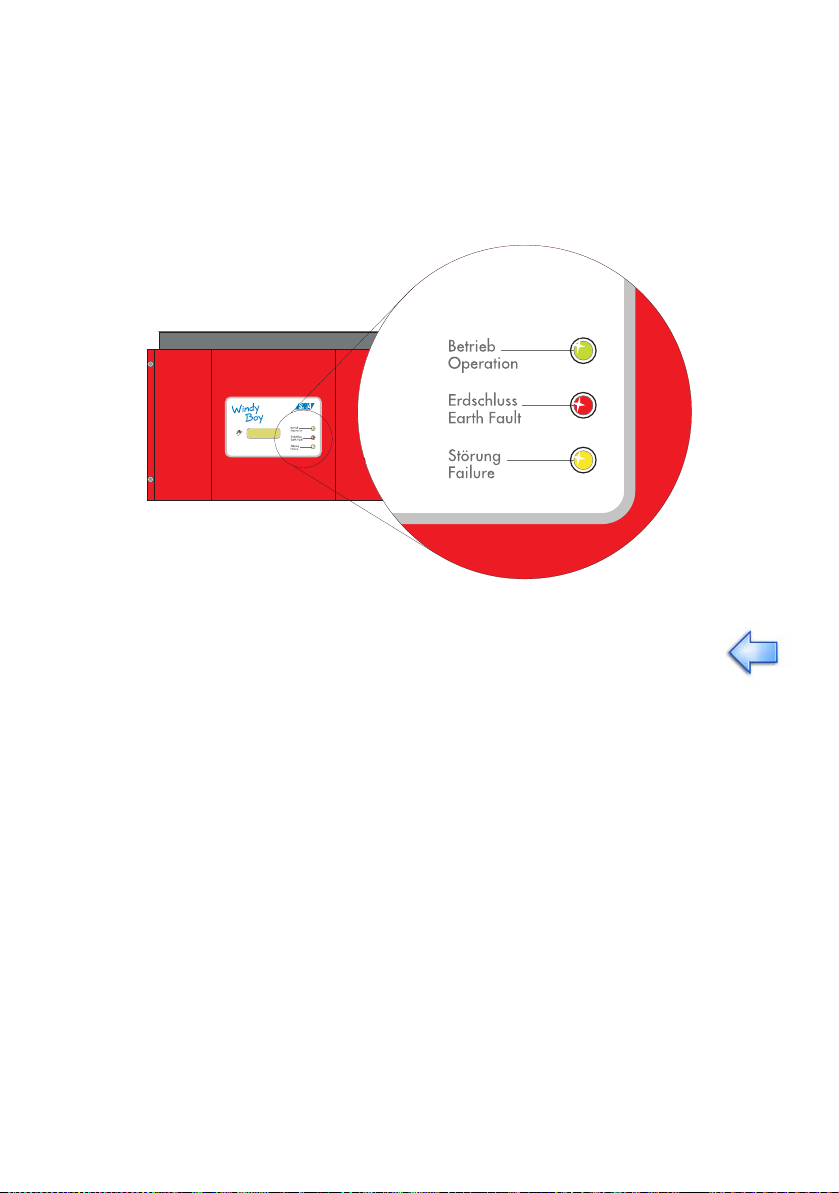

3.2 Device construction

An attractive, functional design is one of the major design objectives of the entire

Windy Boy product range. In its basic configuration, the Windy Boy has the proven

status display consisting of three LEDs. An extra display can be provided already installed or can be retrofitted.

As long as it is installed and commissioned according to the technical specifications,

the Windy Boy can be operated without any further modification or configuration.

The device parameters can however be modified, if required.

Windy Boy 1100/1700 Enclosure IP65 (outside installation possible)

SMA grid guard

Transformer

Optional

display

(IP65)

Bridge

Optional

communi-

cation

interface

RS232

RS485

Powerline

Radio

+

+

DC input with 2x2 DC connectors

Characteristic

wind curve

Overvoltage

protection:

Thermally

monitored

varistors

An extra communications interface is required for ideal adaptation of the Windy Boy to suit the particular wind turbine being

used, and this can also be used for reporting operation data. For

further details, please refer to chapter 7 "Expansions” (page 39).

L

N

AC plug

PE

Operating instructions WB11_17-11:FE4205 Page 15

Page 16

Unit description SMA Technologie AG

All DC connections and connections for the mains grid, as well as any optional communications connections are to be found on the underside of the Windy Boy. Each of

the + and - DC connections are internally connected in parallel within the Windy Boy.

Plug connector for DC

+

Plug connector for DC -

Opening for optional communication

via RS232, RS485 or Radio (for PG16)

AC plug for the

mains supply connection

Page 16 WB11_17-11:FE4205 Operating instructions

Page 17

SMA Technologie AG Unit description

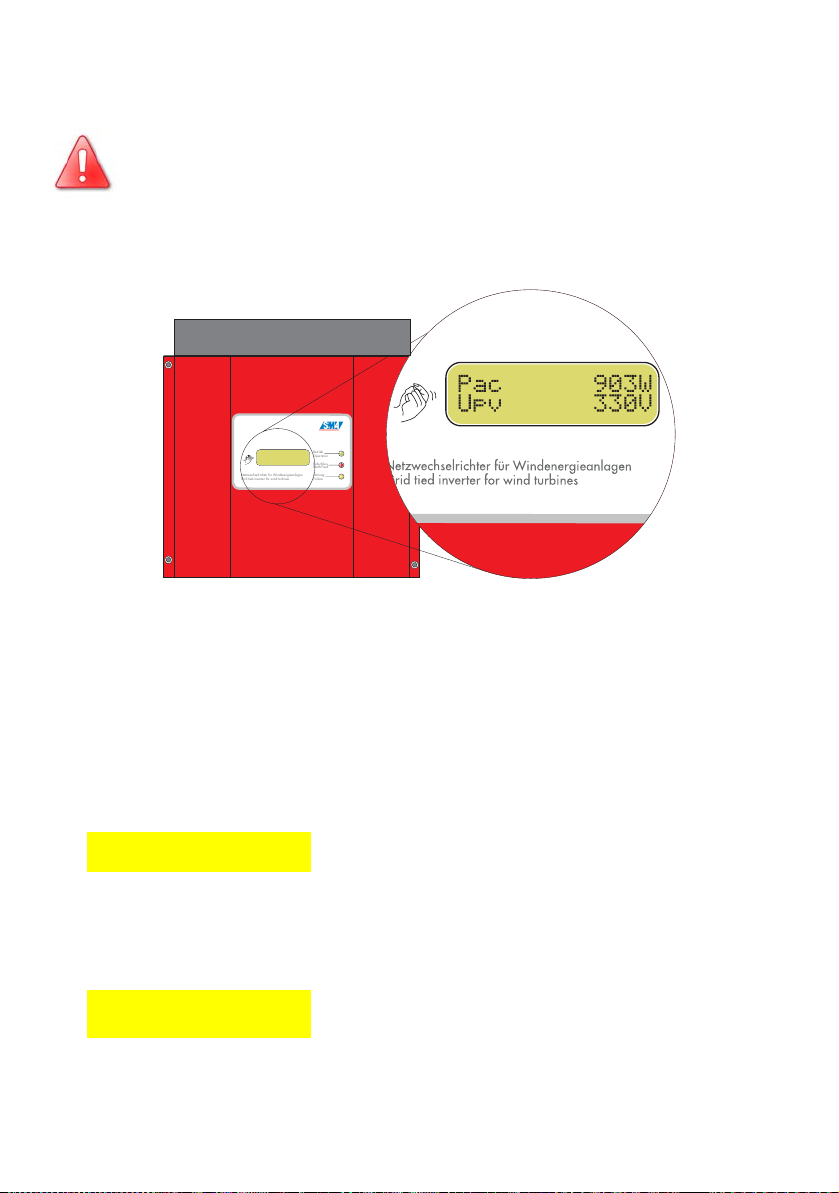

3.3 Operating modes

The operational status is displayed using three light-emitting diodes (LEDs) in the cover of the Windy Boy. To allow the device to signal its operational status via the integrated LEDs, the Windy Boy must be connected to the DC side of the system. There

must be enough wind energy present, so that the Windy Boy has adequate DC voltage.

Pac 903W

Upv 330V

Netzwechselrichter für Windenergieanlagen

Grid tied inverter for wind turbines

Especially in the first year of operation, the operator of the system should

check this display under different wind speeds.

A complete description of the possible displays can be found in chapter 3.3.4 "Description of the operational status” (page 19). These can be split into three categories:

3.3.1 Normal operation

As long as the green control LED is on, or blinking, the Windy Boy is operating normally. The simultaneous illumination of all three LEDs is also an indication of normal

operation ("Initialization"). All other displays are a sign of abnormal operation.

Operating instructions WB11_17-11:FE4205 Page 17

Page 18

Unit description SMA Technologie AG

3.3.2 Critical, faulty operation

A comprehensive safety concept limits the number of critical conditions that can occur

to a single situation:

Input voltage exceeds the permitted value

This is indicated by the following blink-code on the yellow LED:

The yellow LED

illuminates 4 times

LED on

LED off

3s 1s1s 1s 1s

5s

The message is repeated 3 times

and then begins again.

The yellow fault LED illuminates for 5 seconds when the fault occurs, and then begins

displaying the blink code of: 3 seconds off and then 4 times briefly on. This code is

displayed three times in succession. If the fault is still present, the fault display starts

again from the beginning.

The presence of excessive input voltage can lead to irreparable

damage! Immediately disconnect the DC input of the Windy Boy.

12

34

When the Windy Boy receives an excessive DC input voltage, it automatically

disconnects from the mains network and no longer feeds power into the grid.

When the Windy Boy is in operation, you must always first disconnect the AC

voltage (mains supply) and only then should you disconnect the DC voltage

from the Windy Boy!

3.3.3 Non-critical, faulty operation

All other fault codes indicate some form of faulty operation, which are not usually

dangerous to people or equipment, but which should nevertheless be investigated

and corrected.

Despite all precautions, it is possible that other faults may occur that cannot be displayed (e.g. failure of the status display). In order to recognize such faults, the operator of the system should use the explanations in chapter 3.3.4 "Description of the

operational status” (page 19) to check the plausibility of the displayed status.

Further detailed diagnoses are possible using the communication options detailed in

chapter 7 "Expansions” (page 39).

Page 18 WB11_17-11:FE4205 Operating instructions

Page 19

SMA Technologie AG Unit description

3.3.4 Description of the operational status

No (or low) input voltage

The Windy Boy is in Standby mode. This

situation occurs when the input perfor-

All LEDs are off.

Initialization

All LEDs are on.

mance is too low for feeding the mains

grid (DC input voltage < approx. 80 V)

and for satisfying the on-board power requirements.

The on-board computer of the Windy

Boy is presently in the initialization process. The DC input voltage of the Windy

Boy lies between approx. 80 V and approx. 120 V. The power is adequate for

the on-board power requirements but insufficient for mains-grid feed-in or for

data transmission.

Working mode

The Windy Boy has successfully passed

the measurement electronics and SMA

Green LED is on.

Operating instructions WB11_17-11:FE4205 Page 19

grid guard self-tests and has begun feedin operation.

The Windy Boy is working normally and

is feeding electricity into the mains grid.

It is converting the DC voltage from the

wind turbine according to the V/I characteristic curve defined by <U

WindStart> and <UDCWindMax>

<U

DC

Start>,

PV

(chapter 5 “Turbine operation" on

page 31).

Page 20

Unit description SMA Technologie AG

Stop

The Windy Boy is in Stop mode. Among

other functions, the measurement elec-

1s

Green LED blinks 3

times per second.

tronics are calibrated and then finally,

the device switches to "Waiting" mode.

The "Stop" mode can also be manually

set by the system operator via the Sunny

Boy Control or the Sunny Data PC program. In this case, the Windy Boy remains in "Stop" mode until a new

operating mode ("MPP mode", "Turbine

mode") has been set.

Maintenance, grid monitoring

The Windy Boy checks if the initial conditions necessary for feeding the mains

1s

The green LED blinks

once per second.

supply are satisfied (e.g. start voltage)

and then begins monitoring the mains

network.

Derating

The temperature monitoring of the

1s

The green LED turns off

briefly once per second.

Windy Boy has reduced the output performance to prevent the device from

overheating. If this occurs often, then this

is an indication of inadequate heat dissipation.

To avoid unnecessary reductions in

yield, in this case it should be checked if

the Windy Boy can be mounted in a better position with better ventilation.

Page 20 WB11_17-11:FE4205 Operating instructions

Page 21

SMA Technologie AG Unit description

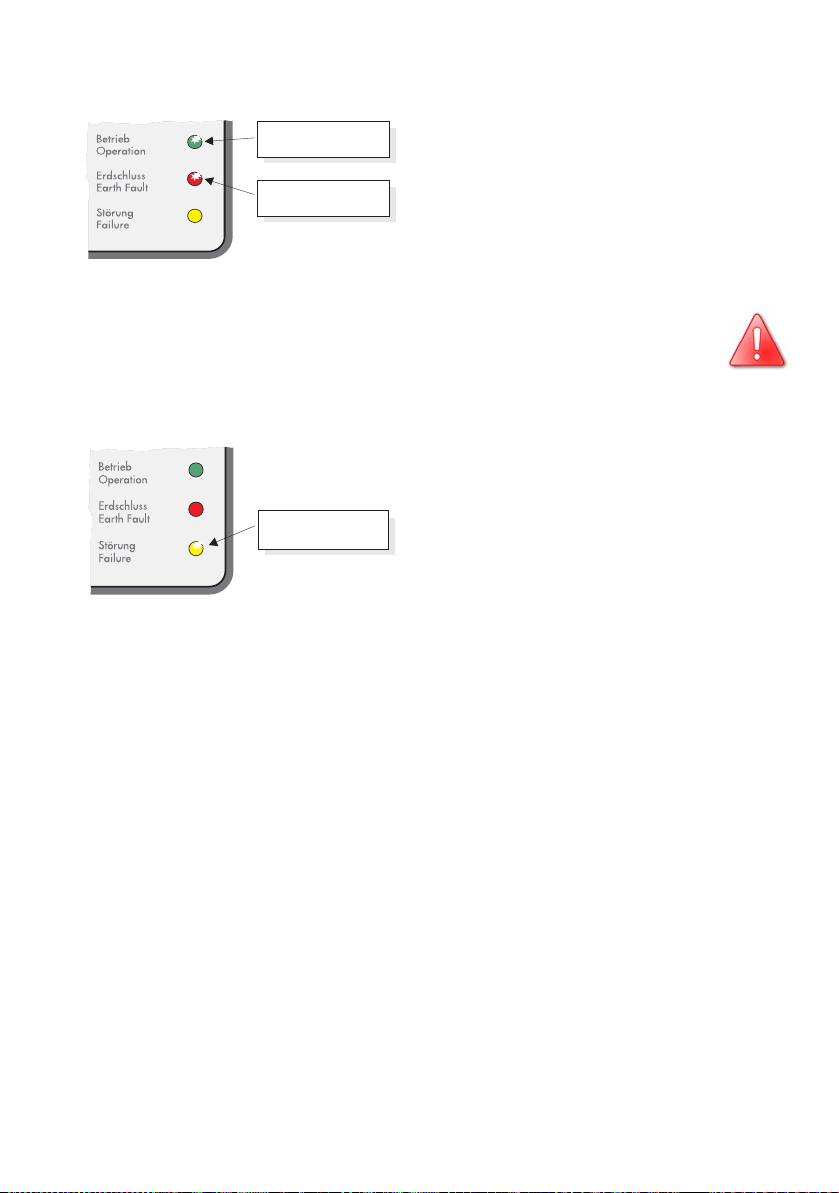

Defective varistor or insulation fault

The green LED blinks

once per second.

The red LED is

continuously on.

Consult trained electrical personnel to correct the fault. You should

also read about this issue in the "Installation manual".

The red LED of the Windy Boy illuminates

continuously. A ground fault exists or

one of the thermally monitored varistors

on the DC input is defective as a result of

overvoltage.

Constant operational limiting

This message is displayed if a fault develops in the grid monitoring and/or the independent disconnection device (SMA

The yellow LED is

continuously on.

grid guard). The Sunny Boy has detected

a fault in the SMA grid guard during an

internal test and has disabled the mains

supply feed-in.

This usually indicates a fault that cannot

be corrected on site. Please consult the

manufacturer (chapter 11 "Contact”

(page 65)) and discuss further action to

solve the problem with them.

Operating instructions WB11_17-11:FE4205 Page 21

Page 22

Unit description SMA Technologie AG

Mains supply fault

The yellow LED

illuminates 2 times

LED on

LED off

12

3s 1s

5s

The message is repeated 3 times

and then begins again.

The yellow fault LED illuminates for 5 seconds when the fault occurs, and then begins

displaying the blink code of: 3 seconds off and then 2 times briefly on. This code is

displayed three times in succession. If the fault is still present, the fault display starts

again from the beginning.

The Windy Boy indicates a mains supply fault with this message, which can have the

following causes:

• Low mains supply voltage (VAC < "Vac-Min")

• High mains supply voltage (VAC > "Vac-Max")

• Low mains supply frequency (fAC < "Fac-Min")

• High mains supply frequency (fAC > "Fac-Max")

• A change in mains supply frequency ("dFac")

Check if a general mains supply dropout has occurred (check the operation of other

mains supply devices), and check if the fuse of the feed-in connection of the Windy

Boy is intact.

If none of these faults can be found, then the mains supply connection of the Windy Boy must be checked by qualified electrical personnel.

Page 22 WB11_17-11:FE4205 Operating instructions

Page 23

SMA Technologie AG Unit description

Mains supply impedance is too high

The yellow LED

illuminates 3 times

LED off

LED on

5s

The message is repeated 3 times

and then begins again.

12

3s 1s

3

The yellow fault LED illuminates for 5 seconds when the fault occurs, and then begins

displaying the blink code of: 3 seconds off and then 3 times briefly on. This code is

displayed three times in succession. If the fault is still present, the fault display starts

again from the beginning.

The Windy Boy has detected a fault relating to an unacceptable impedance in the

mains supply. If the Windy Boy frequently displays this fault during mains monitoring,

the cause can be a mains impedance that is too high. An electrician can usually assist

with this problem by increasing the cross section of the mains connection cable. Other

measures can be taken to correct this problem, but they require the agreement and

cooperation of the electricity supplier.

Operating instructions WB11_17-11:FE4205 Page 23

Page 24

Unit description SMA Technologie AG

Input voltage too high

The yellow LED

illuminates 4 times

LED off

LED on

5s

The message is repeated 3 times

and then begins again.

12

3s 1s1s 1s 1s

The yellow fault LED illuminates for 5 seconds when the fault occurs, and then begins

displaying the blink code of: 3 seconds off and then 4 times briefly on. This code is

displayed three times in succession. If the fault is still present, the fault display starts

again from the beginning.

Immediately disconnect the DC input of the Windy Boy. The presence of excessive input voltage can lead to irreparable damage!

Make sure that the input voltage never exceeds 400 V.

When the Windy Boy receives an excessive DC input voltage, it automatically

disconnects from the mains network and no longer feeds power into the grid.

When the Windy Boy is in operation, you must always first disconnect the AC

voltage (mains supply) and only then should you disconnect the DC voltage

from the Windy Boy!

34

Page 24 WB11_17-11:FE4205 Operating instructions

Page 25

SMA Technologie AG Unit description

Device faults

The yellow LED

illuminates 5 times

LED off

LED on

5s

The message is repeated 3 times

and then begins again.

12

3s 1s1s 1s 1s

The yellow fault LED illuminates for 5 seconds when the fault occurs, and then begins

displaying the blink code of: 3 seconds off and then 5 times briefly on. This code is

displayed three times in succession. If the fault is still present, the fault display starts

again from the beginning.

The Windy Boy is in a condition that prevents it from entering normal operation.

There is possibly a defect in the Windy Boy.

If this often occurs, the device must be checked by qualified electrical personnel.

345

Operating instructions WB11_17-11:FE4205 Page 25

Page 26

Unit description SMA Technologie AG

3.4 Messages in the optional display

If this often occurs, the device must be checked by qualified electrical personnel.

The Windy Boy can be factory fitted with an LCD display in the lid of the case.

Windy

Boy

Betrieb

Pac 903W

Operation

Upv 330V

Erdschluss

Earth

F

Netzwechselrichter für Windenergieanlagen

Grid tied inverter for wind

The display can also be retrofitted (SMA order code, "SB-Display", language specification to be provided when ordering).

ault

Störung

t

urbines

Failure

Switching on the display illumination

The background illumination is switched on by tapping on the lid of the case. Tapping

again switches the display to the next message.

After 2 minutes, the illumination switches off automatically.

Display messages in the startup phase

SunnyBoy 1700

WRxxx

Initialization phase

BFR Version 2.00

SRR Version 2.00

Initialization phase

Page 26 WB11_17-11:FE4205 Operating instructions

The following messages are displayed during the

startup phase of the Windy Boy 1700 and are identical to those in the Windy Boy 1100. Since the

Windy Boy is identically to the Sunny Boy, apart

from the mode of operation, the display shows "Sunny Boy“.

After 6 seconds, the firmware version of the operation control unit (BFR) and the current control unit

(SRR) are displayed.

Page 27

SMA Technologie AG Unit description

Display message during operation

The display shows the most important operational information of the Windy Boy in a

continuous cycle. The following three diagrams serve to clarify the messages. Every

message is displayed for 5 seconds. Then the cycle begins again.

The energy generated today and the current operational status are first displayed.

E-today 3.86

Status Turbine

Energy sum since the last activation, and

the current operational status

Note: The amount of energy shown under "E-today" does not necessarily

reflect the amount of energy produced over the last 24 hours. This is rather the energy produced by the Windy Boy since the last deactivation/activation (wind turbine standstill).

Subsequently, the current feed-in power and the output voltage are displayed.

This is then followed by the total energy produced so

far and the operational hours of the device.

Pac 903W

Vac 195V

Current feed-in power and

AC voltage

E-total 724,4kWh

h-total 512h

Total amount of energy produced and the

total number of operating hours

Fault displays

If an operational fault develops, the display immediately switches to "Disturbance" and the background

illumination is switched on.

The cause of the fault is displayed for 5 seconds in

the second line of the display.

Disturbance

Vac-Bfr

Fault display

If a measured value is responsible for the fault condi-

tion, then the value measured at the time of the fault

is displayed. If another measurement is possible, the

current value is displayed in the second line.

at: 261V

present: 245V

Display of the values measured

during the fault

After another 5 seconds, normal operational information is again displayed.

If the fault is still present, the fault display starts again from the beginning. An overview of the status and fault messages can be found in chapter 9.2 "Fault messages”

(page 58) of this document.

Operating instructions WB11_17-11:FE4205 Page 27

Page 28

Unit description SMA Technologie AG

Faults

ROM

Fault displays

of the Firmware EEPROM

"Fehler ROM" indicates, that the Windy Boy has recognized a fault in the Firmware EEPROM. Contact

SMA to correct the fault.

Special display in the case of excessive DC input voltage

!PV-Overvoltage!

DISCONNECT DC

Overvoltage displays

Immediately disconnect the DC input of the Windy Boy. The presence of excessive input voltage can lead to irreparable damage!

Make sure that the input voltage never exceeds 400 V.

Before placing the device back into operation, the input voltage must be

checked before reconnecting the DC voltage to the Windy Boy! Since the

Windy Boy is identical to the Sunny Boy, apart from the mode of operation,

the display shows "PV" (Photovoltaic) as its input source.

When the Windy Boy receives an excessive DC input voltage, it automatically

disconnects from the mains network and no longer feeds power into the grid.

When the Windy Boy is in operation, you must always first disconnect the AC

voltage (mains supply) and only then should you disconnect the DC voltage

from the Windy Boy.

If an excessive DC input voltage is present on the

Windy Boy, then this is indicated by rapid blinking of

the background illumination and a corresponding

message.

Page 28 WB11_17-11:FE4205 Operating instructions

Page 29

SMA Technologie AG Setting the display language

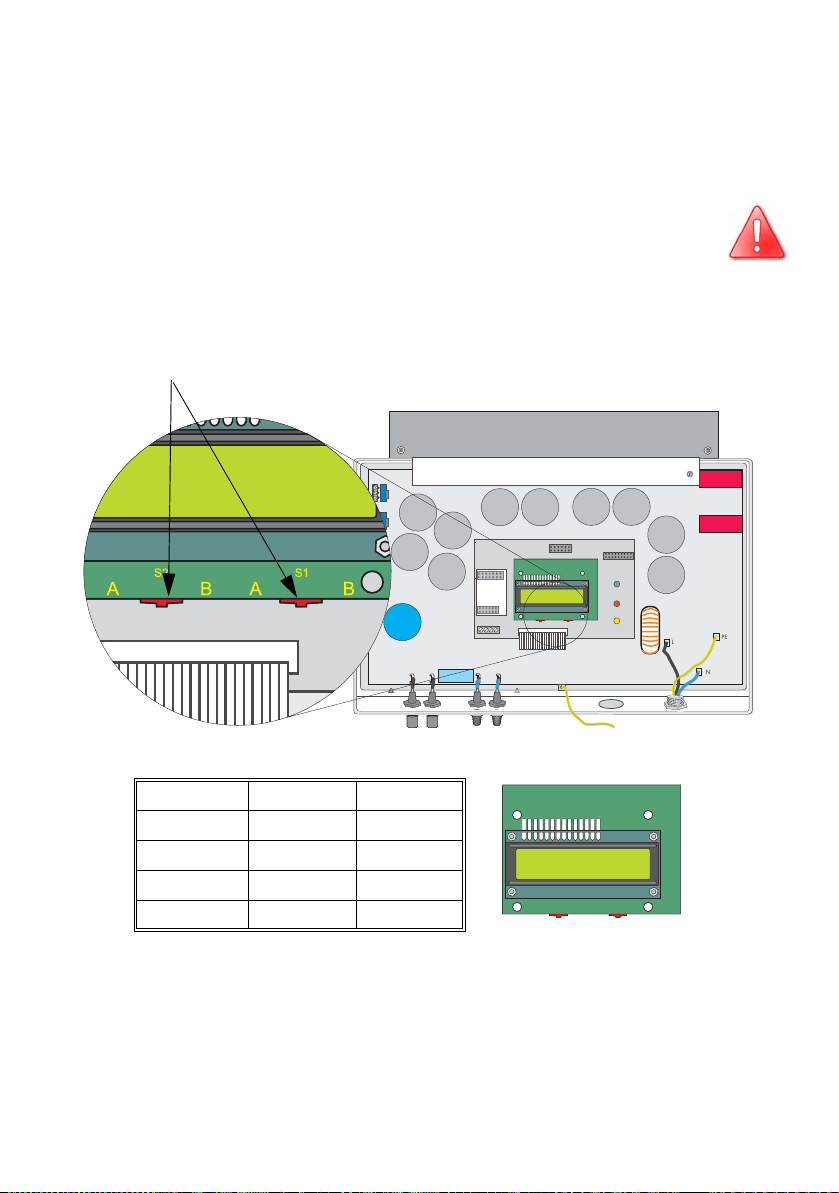

4 Setting the display language

The display language is set using the switches on the underside of the SB-LCD components.

Since the cover must be removed, please ask a qualified electrician

to disconnect the DC and AC connections from the Windy Boy, according to the installation instructions.

Position of the switches for

language configuration

E-Total 124.4kWh

h-Total 512h

S1

S1

AS2AB B

AS2ABB

PE

L

N

Language Switch S2 Switch S1

German B B

English B A

French A B

Spanish A A

Operating instructions WB11_17-11:FE4205 Page 29

E-Total 124.4kWh

h-Total 512h

S2

S1

S2

A

A

S1

AB B

ABB

Page 30

Setting the display language SMA Technologie AG

Page 30 WB11_17-11:FE4205 Operating instructions

Page 31

SMA Technologie AG Turbine operation

5 Turbine operation

5.1 Overview

The Windy Boy is a single phase inverter that converts DC current into AC current

and feeds the energy generated by a wind turbine into an existing mains grid.

The Windy Boy is externally identical to the Sunny Boy inverter for photovoltaic systems.

The Windy Boy inverter has a special operational mode for wind generators however, which allows performance adjustment to the characteristic curves of many different manufacturers' generators ("Turbine" operating mode). In this way maximum

yields can be obtained from your wind turbine.

The mechanical power of the wind turbine is presented to the inverter in the form of

a direct, rotation speed variable DC voltage (RPM) and current intensity (torque).

Most small wind turbines have a so-called permanent magnet generator and a downstream rectifier for converting the variable frequency AC generator voltage into DC

current.

5.2 Characteristic curve function

The "Turbine" operating mode of the Windy Boy uses a programmable power/voltage curve to regulate the input current depending on the generator voltage (V/I characteristic curve).

Every wind generator is designed to have an optimum working point for voltage and

current, at different rotational speeds or wind speeds. This behavior is not linear.

The Windy Boy uses an approximation based on a simple ramp function. The function

can be programmed by the user so that it comes close to the behavior of the wind

generator being used and thus provides power adaptation.

Operating instructions WB11_17-11:FE4205 Page 31

Page 32

Turbine operation SMA Technologie AG

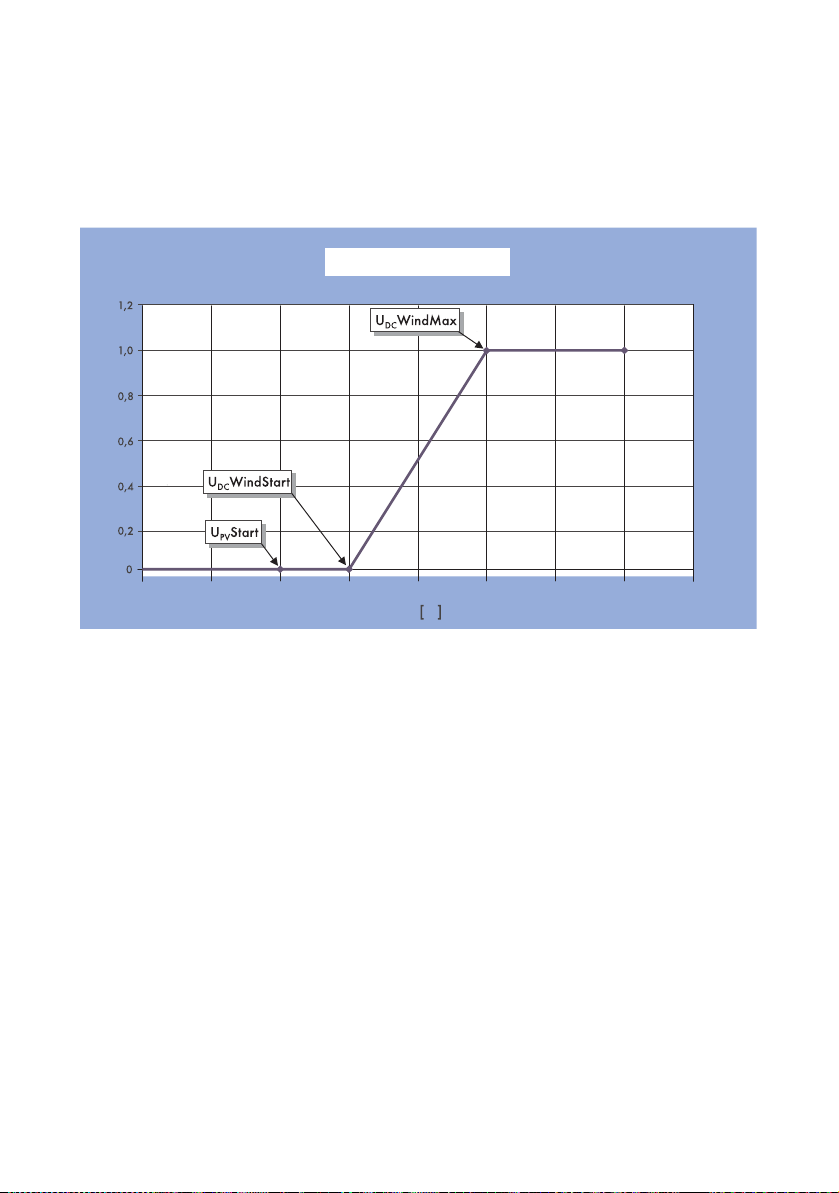

The diagram shows the ramp function of a typical Windy Boy power/voltage curve.

The feed-in AC power depending on the DC input voltage of the inverter is shown

here. The adjustable parameters U

Start, UDCWindStart and UDCWindMax are

PV

used to adapt the power/voltage curve of the Windy Boy to the wind generator being used.

Operating Mode: Turbine

Pac / Pac-max

0

50

100 150 200 250

300

350 400

Vdc V

The correct configuration of the parameters shown in the diagram is absolutely necessary to guarantee optimum operation with wind generators from different manufacturers.

The basic parameters of a Windy Boy (factory settings) are shown in the following

table.

Page 32 WB11_17-11:FE4205 Operating instructions

Page 33

SMA Technologie AG Turbine operation

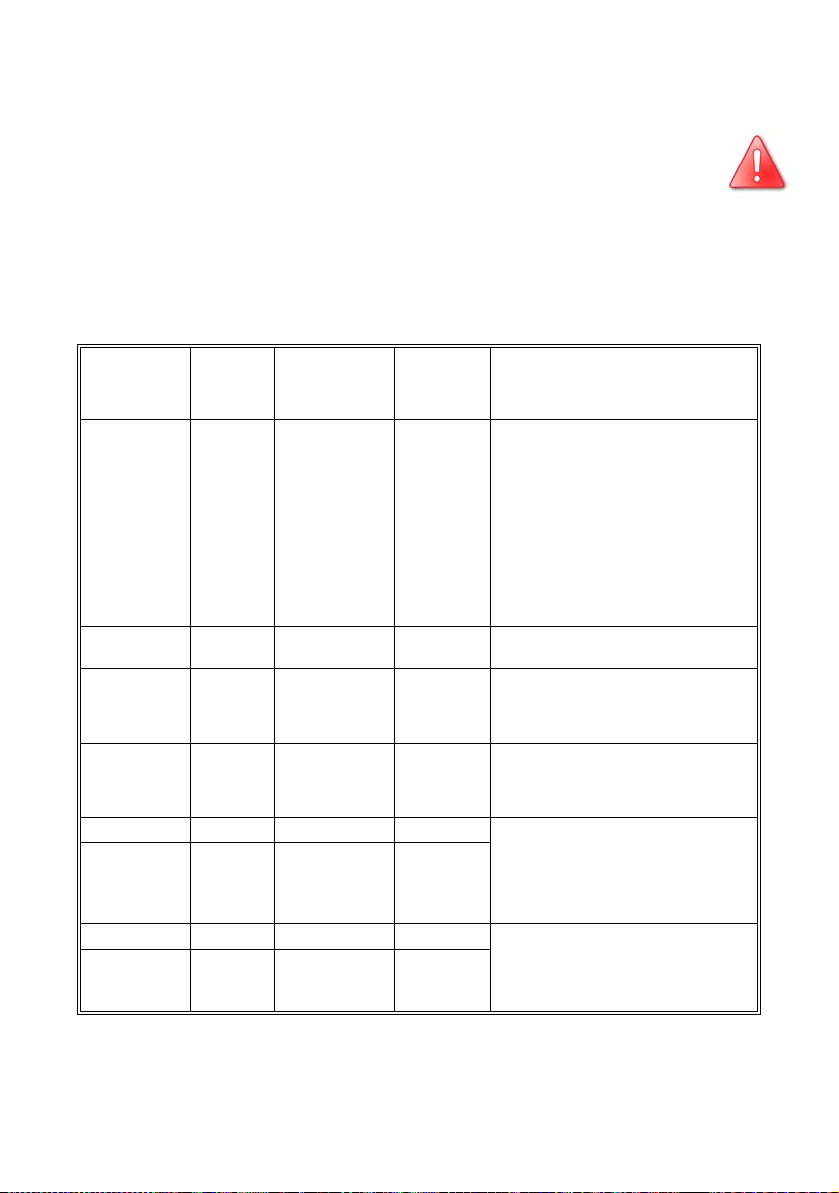

Name WB 1100 WB 1700 Unit Description

Defines the voltage at the

UpvStart

180

(150 ... 400)

180

(150 ... 400)

V

DC

moment when the Windy

Boy is ready to perform a

mains-grid synchronization.

Defines the voltage at the

UdcWindStart

190

(1 ... 800)

190

(1 ... 800)

V

DC

moment when the Windy

Boy is ready to begin feeding power into the mains

grid.

Defines the voltage at the

UdcWindMax

330

(1 ... 800)

330

(1 ... 800)

V

DC

moment when the Windy

Boy begins feeding maximum power into the mains

grid.

Controls a delayed startup

of the characteristic curve,

P-WindRamp

200

(10 ... 2000)

280

(10 ... 2000)

W/sec

only after the Windy Boy

has been switched on. This

avoids the generator being

suddenly presented with a

heavy load.

T-Start

T-Stop

10

(5 ... 300)10(5 ... 300)

2

(1 ... 3600)2(1 ... 3600)

sec

sec

Start Timer Mains synchronization.

Stop Timer Aborting the supply of power and switching

off.

The correct configuration of the parameters above is absolutely necessary to guarantee optimum operation with generators from different manufacturers. Preconditions

for changing the operating parameters are described in chapter 5.4 "General setting

example” (page 35).

To perform the configuration process, the DC input voltage must be greater

than <UpvStart> and the Windy Boy must be connected to the mains grid.

Operating instructions WB11_17-11:FE4205 Page 33

Page 34

Turbine operation SMA Technologie AG

5.3 Characteristic curve operation in "Turbine" opera-

ting mode

Please note: The linear characteristic curve of the Windy Boy only approximates the actual characteristics of a real wind generator. Consult the manufacturer of your wind generator for the typical characteristics of your generator

before changing the characteristic curve parameters.

As soon as the DC input voltage defined in the parameter <UpvStart> is reached, the

inverter begins a number of self tests, measurement processes and synchronizes with

the mains grid. If the self tests are successfully completed, and the DC input voltage

remains above the value defined in <UpvStart> for the time defined in <T-Start>, the

inverter connects to the mains grid.

As soon as the DC input voltage reaches the value defined in <UdcWindStart>, the

inverter begins feeding power into the mains grid. As you can see from the characteristic curve, the power fed into the mains grid rises with the DC input voltage.

As soon as the DC input voltage reaches the value defined in the parameter <UdcWindMax>, the Windy Boy feeds the mains grid with the maximum possible power.

If the input voltage continues to rise, the Windy Boy continues to feed the mains grid

at maximum power.

The characteristic curve ends at the maximum permissible input voltage of the Windy

Boy, which must never be exceeded.

If the wind strength is so low that the DC input voltage falls below <UpvStart>, then

the inverter ceases feeding power into the mains grid for the period defined in <TStop>.

If the DC input voltage increases again, then the Windy Boy will again operate according to the characteristic curve.

If the DC input voltage falls below the internally calculated minimum operating value

of <Umin>, then there is insufficient energy for the on-board electronics and the Windy Boy will switch off.

If the DC input voltage lies between <Umin> and <UpvStart> for the time defined by

<T-Stop>, then the inverter will also switch off.

After the switch-off process, the whole process begins anew.

Only change the operating parameters when you know exactly what you are

doing!

Page 34 WB11_17-11:FE4205 Operating instructions

Page 35

SMA Technologie AG Turbine operation

5.4 General setting example

Please note that the following example only represents a starting point for operating

with a wind generator.

• <UpvStart> is set to the lowest possible value:

This achieves an early switch-on of the Windy Boy.

• <UdcWindStart> is set to the same value of <UpvStart>:

This achieves an early mains grid feed-in. If the wind turbine does not properly

start, or the inverter frequently switches on and off, it is recommended that you

increase <UdcWindStart> in (e.g.) 10 V steps.

• <UdcWindMax> is initially set to approx. 10 % below the maximum MPP voltage

of the Windy Boy:

In this case the slope of the ramp function is relatively flat. The maximum output

power is this only reached with a relatively high DC input voltage, which avoids

"braking" of the wind generator through excessive power consumption. This setting is especially suitable in locations with little or weak wind. Once the properties

of the wind generator are known, then the reduction of the <UdcWindMax> parameter may be necessary, in order to extract the maximum power from the wind

generator even at low DC input voltages (low wind speeds). The ramp function

will then be steeper.

Contact the manufacturer of your wind generator for the typical properties of

your generator (voltage/power characteristic).

• <T-Stop> is set to the maximum value:

Here, the inverter remains connected to the mains grid, even at low DC input voltage levels, and "waits" for the next gust of wind. This delays an early switch-off

of the inverter.

• <T-Start> is set to the minimum value:

This achieves a reduction of the switch-on time (please observe the regulations of

the energy supplier responsible).

Only change the operating parameters when you know exactly what you are

doing!

Operating instructions WB11_17-11:FE4205 Page 35

Page 36

Turbine operation SMA Technologie AG

Page 36 WB11_17-11:FE4205 Operating instructions

Page 37

SMA Technologie AG Maintenance and care

6 Maintenance and care

Because the Windy Boy can be used outdoors in places that are difficult to access,

the Windy Boy has been constructed for low maintenance. To guarantee safe operation, it is usually adequate to check the device visually for damage approximately

every two months. It should also be checked if the red LED is illuminated and, if necessary, remove the fault by referring to chapter 3.3.4 "Description of the operational

status” (page 19).

In the interests of maximum yield, the operator should check, weekly if possible, under various conditions of wind, if the display of the Windy Boy indicates plausible

normal operation (cf. chapter 3.3.4 "Description of the operational status”

(page 19)). Naturally, this information can be obtained by using one of the communication options.

Cleaning of the Windy Boy is only necessary when the heat dissipation is limited by

dirty cooling fins or a dirty space between the Windy Boy and the wall. The dirt

should be carefully removed with an appropriate soft brush or paintbrush.

If the LEDs are so dirty that they can no longer be seen, then they can be cleaned

with a damp cloth. Solvents, abrasives or corrosive liquids must not be used!

Operating instructions WB11_17-11:FE4205 Page 37

Page 38

Maintenance and care SMA Technologie AG

Page 38 WB11_17-11:FE4205 Operating instructions

Page 39

SMA Technologie AG Expansions

7 Expansions

As with all inverters in the Sunny Boy family, the Windy Boy can also be expanded

with a range of communication interfaces. This provides the operator with the possibility of requesting detailed operational data and error messages, for subsequent

analysis on a PC using (e.g.) the free software available from SMA.

The data can currently be transferred in five different ways:

• using Powerline

• using a separate RS485 cable

• using a separate RS232 cable

• using a wireless link (Sunny Beam)

• using a USB-Service-Interface (USBPBS)

The wind turbine can be monitored by the Windy Boy in a number of different ways.

SMA offers a range of products for this purpose, allowing you to install a tailor-made

monitoring system for your system. If you require detailed information about the Windy Boy products, please request the Sunny Family catalogue or visit www.SMA.de.

In the following sections the currently available communications options are schematically described.

7.1 Sunny Data

Sunny Data is a PC program for direct monitoring of

your system. The connection of the Sunny Boys or the

Sunny Mini Centrals with the PC is described in the following sections.

Operating instructions WB11_17-11:FE4205 Page 39

Page 40

Expansions SMA Technologie AG

7.2 Sunny Data via Powerline

"Wireless" communication via the mains power line

(up to 50 Windy Boys)

Prerequisites: The Windy Boys must be equipped with a Powerline Piggy-Back and

the PC must be equipped with an SWR-COM / USB-COM plug modem. The connection of the PC using SWR-COM / USB-COM is described in the SWR-COM / USBCOM documentation.

SWR-COM

socket connector

SWR1100E

Bet

r

Phot

ieb

ovolt

O

pera

Pho

ai

k-S

ti

to

on

t

vo

r

ing

l

ta

w

i

c

e

c

s

tr

hs

i

Er

ng

elr

dschlu

ic

i

nvert

ht

e

r

s

Ear

e

s

r

t

h

F

a

ul

t

S

t

ö

r

u

ng

Fail

u

r

e

SWR1100E

B

etrie

Pho

t

ovolt

Operation

P

ai

h

ot

k-Stri

o

vo

ng

lta

w

ic

e

c

s

t

hs

ri

Er

ng

elri

ds

i

c

n

c

hter

ve

h

l

uss

rt

Eart

er

h

F

a

u

lt

St

ö

r

u

ng

Fai

l

ure

max. 50

SWR1100E

Be

trie

b

Pho

b

tovolt

Ope

P

ai

r

h

at

ot

k-Strin

io

o

n

vo

lt

g

aic

w

e

c

s

t

hs

ri

Er

ng

elr

ds

ic

i

n

chl

hter

ve

u

r

ter

s

Ear

s

t

h

F

a

ul

t

S

t

örun

g

Fai

l

ure

PC with

Sunny Data

Powerline

7.3 Sunny Data over RS232

Communication via a cable

(a single Windy Boy)

Prerequisites: The Windy Boy must be equipped with an RS232 Piggy-Back, the con-

nection to the PC usually occurs directly over the COM1 or COM2 port of the PC.

The installation of the RS232 cable is described in the installation instructions of the

Windy Boy.

PC with

Sunny Data

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operati

0

E

Photovoltaicstringinverter

on

Erdschluss

Earth

F

ault

Störung

Failure

RS232

Page 40 WB11_17-11:FE4205 Operating instructions

Page 41

SMA Technologie AG Expansions

7.4 Sunny Data over RS485

Communication via a cable

(up to 50 Windy Boys)

Prerequisites: All Windy Boys must be equipped with an RS485 Piggy-Back, the con-

nection with the PC usually occurs via an RS485/RS232 interface converter connected to the COM1 or COM2 port or via an RS485/USB interface converter connected

to the USB port. The installation of the RS232 cable is described in the installation

instructions of the Windy Boy.

Interfaceconverter

(RS485/RS232)

i-7520

S

W

R

Betrieb

1

1

Ph

otovol

0

Operation

0

E

Photovolta

t

aik-Str

in

gw

i

c

ec

s

tring

h

s

Erdschluss

elri

i

c

nverter

hte

r

E

arth

F

ault

Stö

rung

Fai

lur

e

S

W

R

1

1

Photovol

0

0

E

Ph

t

aik-Str

otovol

i

ngwechselr

t

aic

s

tri

n

g

i

i

chter

nv

er

t

e

r

max. 50

S

W

Betrieb

Operat

i

on

Er

ds

chl

uss

E

arth

F

ault

Störun

g

Failu

r

e

R

Betrieb

1

1

P

h

otovolt

0

Operation

0

E

Photovoltaic

a

ik-Stri

n

gw

e

chselri

s

tring

Erd

s

i

c

nverter

chluss

hte

r

Earth

F

a

u

lt

Stö

ru

n

g

Fai

lur

e

RS232

PC with

Sunny Data

RS485

Interface-

converter

(RS485/USB)

i-7561

S

W

R

B

1

etrie

1

Ph

b

o

0

t

o

Ope

0

voltaik

E

Photovoltaic

ra

tio

-

String

n

w

echselric

s

tring

E

rds

i

nverter

ch

h

ter

lus

Earth

s

F

au

lt

Störung

Failure

S

W

R

1

1

Photovoltaik-Stringwechselrichter

0

0

E

Photovoltaic

s

trin

g

i

nverter

max. 50

S

W

Bet

r

ieb

Operation

Erdschluss

Earth

F

ault

Störung

Failure

R

Bet

1

ri

1

Ph

eb

o

0

t

ov

Operat

0

olta

E

Ph

i

otovo

k-

i

on

S

t

r

in

lt

gw

ai

c

echsel

s

t

r

i

E

n

rds

g

r

ic

i

n

ch

h

ver

ter

lu

te

s

Earth

s

r

F

a

ult

Störung

Failure

USB

PC with

Sunny Data

RS485

Operating instructions WB11_17-11:FE4205 Page 41

Page 42

Expansions SMA Technologie AG

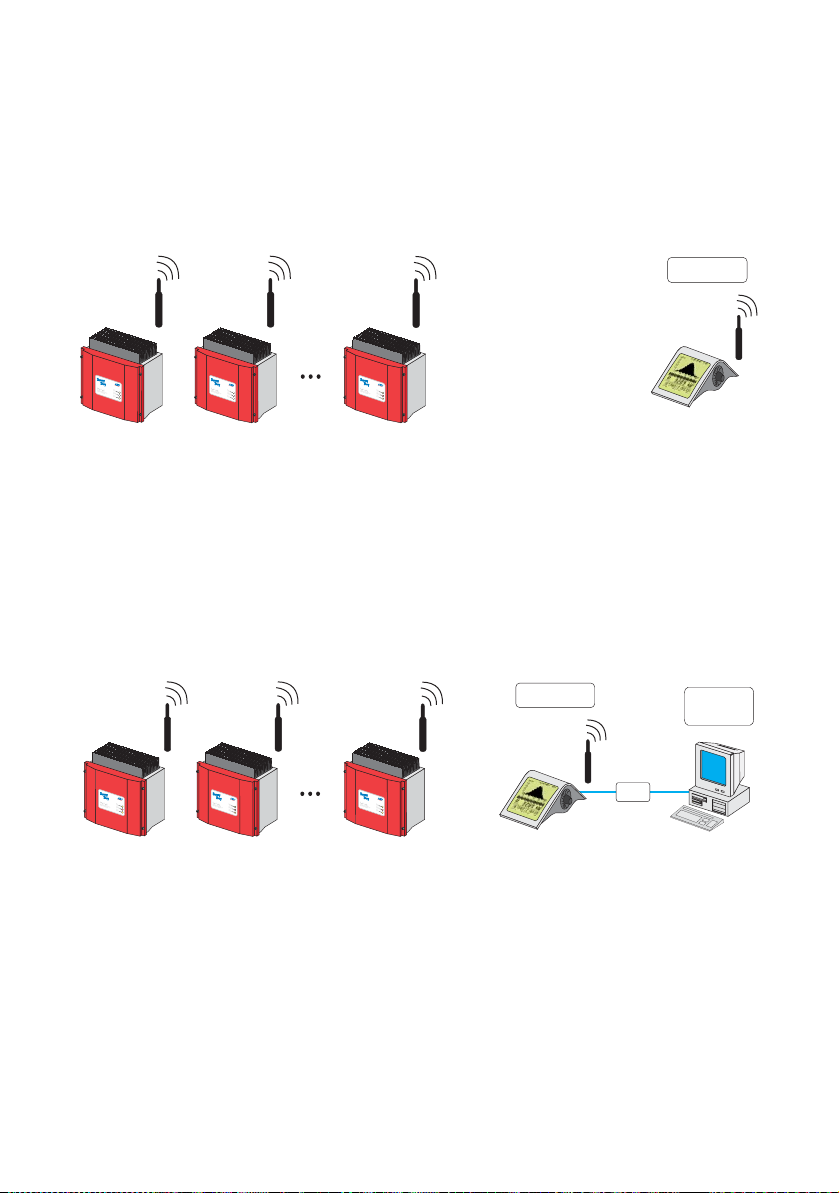

7.5 Sunny Beam

Simple wireless system monitoring for up to 4 Windy Boys.

Prerequisites: The Windy Boys must be equipped with a wireless Piggy-Back and a

Sunny Beam must be present at an appropriate distance. The installation of the wireless Piggy-Back is described in the Sunny Beam user manual.

Sunny Beam

max. 4

S

W

R

Be

1

t

rieb

1

Photov

0

Ope

0

o

E

l

Photov

ta

rat

i

k-Stringwec

ion

o

ltaic

s

tri

h

selricht

Erds

n

g

i

n

ch

v

er

lus

e

r

ter

E

s

art

h

F

aul

t

Störun

g

F

ailure

S

W

R

Betri

1

1

Ph

eb

otov

0

O

0

ol

p

E

e

Pho

ta

rat

i

k

-S

i

t

on

ovol

t

r

i

n

t

g

a

wechs

i

c

s

tr

i

Erdsc

n

e

g

lr

i

i

chter

nv

h

e

lu

rter

s

Eart

s

h

F

aul

t

S

törun

g

F

ailure

S

W

R

Be

1

t

ri

1

Ph

eb

otov

0

O

0

ol

p

E

erati

Pho

ta

i

k

-

t

o

ovol

S

t

n

r

in

t

g

a

wechs

i

c

s

tr

i

E

n

e

rds

g

lr

i

i

chter

nv

ch

e

lu

rter

ss

Eart

h

F

a

u

l

t

S

t

ö

ru

ng

Failure

7.6 Sunny Data Control over Sunny Beam

Communication with a PC over Sunny Beam

(up to 4 Windy Boys)

Prerequisites: All 4 Windy Boys must be equipped with a wireless Piggy-Back and ac-

cessible to Sunny Beam for system monitoring. The Sunny Beam is connected to the

PC via an USB cable. The installation of the wireless Piggy-Backs and the connection

to the PC is described in the Sunny Beam user manual.

Sunny Beam

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operation

0

E

Photovoltaic

s

tring

Erdschluss

i

nverter

Earth

F

ault

Störung

Failure

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechsel

0

Operation

0

E

Photovolt

aic

s

tring

E

rd

richter

schluss

i

nverter

Earth

F

au

l

t

Störung

Failure

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operation

0

E

Photovolt

aic

s

tring

E

rdschluss

i

nverter

Earth

F

ault

Störung

Failure

max. 4

USB

PC with

Sunny Data

Page 42 WB11_17-11:FE4205 Operating instructions

Page 43

SMA Technologie AG Expansions

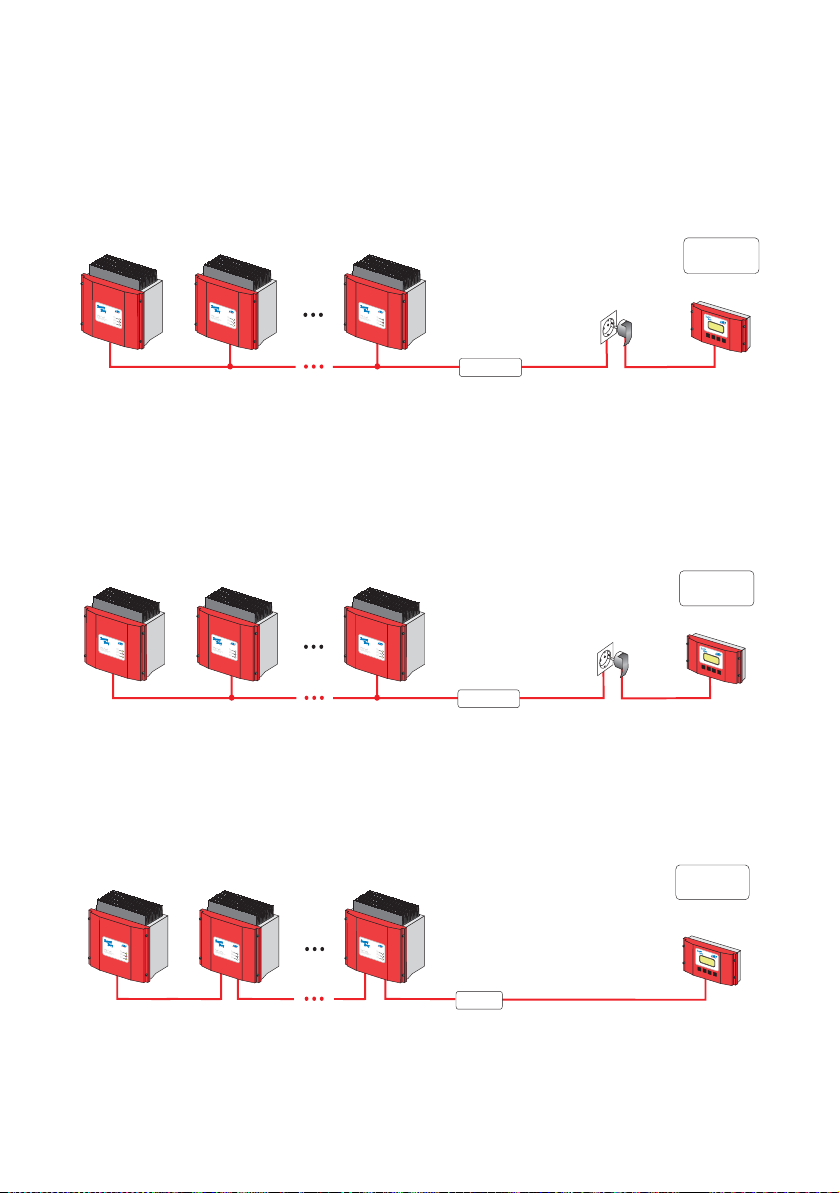

7.7 Sunny Boy Control Light

The simple data logger for PV systems with up to 10 Windy Boys. The connection between the Sunny Boy Control Light and the Windy Boys occurs over Powerline.

Prerequisites: The Windy Boys must be equipped with a Powerline Piggy-Back. The

installation is described in detail in the Sunny Boy Control Light documentation.

Sunny Boy

Control Light

S

W

R

Be

1

t

rie

1

P

h

b

ot

0

o

Ope

0

voltaik-Stri

E

P

rat

hotov

ion

ol

n

taic

gw

ec

s

t

h

rin

s

Erds

el

g

r

i

i

c

n

c

h

v

h

t

erter

lu

e

r

ss

Earth

F

au

l

t

St

ö

r

ung

F

a

i

l

u

re

S

W

R

B

1

etrie

1

Ph

b

otov

0

Ope

0

ol

E

Photovolta

ta

r

at

i

k-Stri

ion

n

g

wech

i

c

s

t

r

sel

i

E

n

rds

g

r

i

i

ch

n

c

v

hlus

t

er

e

r

t

Earth

e

s

r

F

au

l

S

t

ö

rung

F

ail

ure

max. 10

t

S

W

R

B

1

etri

1

Ph

eb

otov

0

Oper

0

ol

E

Photovol

ta

at

i

k-Stri

ion

n

t

g

a

wech

i

c

s

t

r

sel

i

E

n

rds

g

r

i

i

c

n

c

ht

v

hlus

er

e

r

t

Earth

e

s

r

F

aul

t

S

t

ö

rung

F

ail

ure

PAC1273 W

Powerline

7.8 Sunny Boy Control

The simple data logger for systems with up to 50 Windy Boys. The connection between the Sunny Boy Control and the Windy Boys can be achieved as follows:

Powerline - "Wireless" communication via the mains power line

Prerequisites: All the Windy Boys must be equipped with a Powerline Piggy-Back.

Sunny Boy

Control

S

W

R

Be

1

tr

1

Photovoltaik

i

eb

0

Operation

0

E

Photovoltaic

-

Str

i

ngw

e

chselri

s

tring

Erdschluss

i

ch

nverter

t

e

r

Earth

F

ault

St

ö

run

g

Fail

ure

S

W

R

Betrieb

1

1

P

h

o

0

t

o

Operation

0

vo

lt

E

Photovoltaic

aik

-S

tr

in

gw

e

ch

s

tring

se

Erdschluss

lri

i

ch

nverter

ter

E

ar

t

h

S

t

öru

Fail

u

RS485 Communication via a cable

Prerequisites: All Windy Boys must be equipped with an RS485 Piggy-Back, the Sun-

ny Boy Control must be equipped with an RS485 Piggy-Back on the "COM1 - Sunny

Boy" interface.

max. 50

F

ault

n

g

re

S

W

R

Be

1

trieb

1

Photovo

0

Operation

0

l

E

Photovoltaic

taik-Stringwechselrichter

s

tring

Erds

i

nverter

c

hluss

Earth

F

ault

Stör

u

ng

Fai

l

ur

e

PA

C

1

2

7

3

W

Powerline

Sunny Boy

Control

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operation

0

E

Photovoltaic

s

tring

Erdschluss

i

nverter

Earth

F

ault

Störung

Failure

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operation

0

E

Photovoltaic

s

tring

Erdschluss

i

nverter

Earth

Störung

Failure

max. 50

F

ault

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operation

0

E

Photovoltaic

s

tring

Erdschluss

i

nverter

Earth

F

ault

Störung

Failure

PA

C

1

2

7

3

W

RS485

Operating instructions WB11_17-11:FE4205 Page 43

Page 44

Expansions SMA Technologie AG

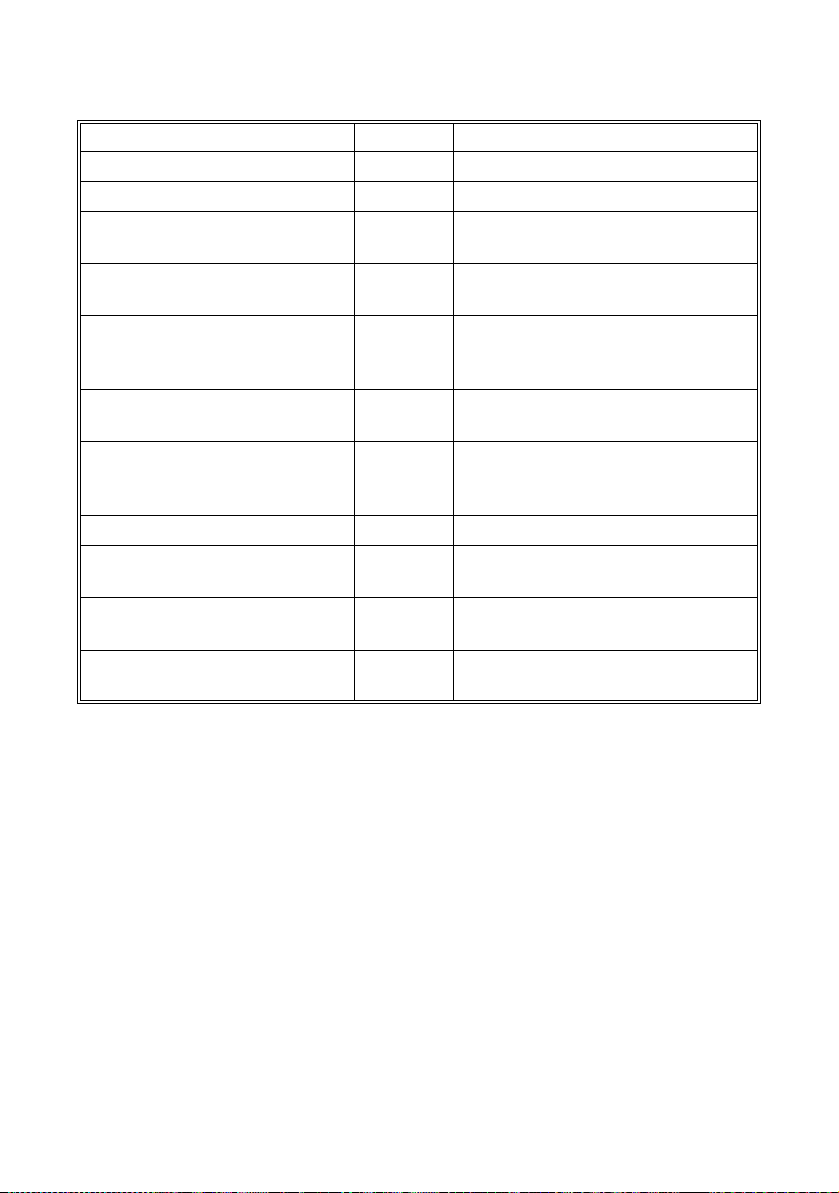

7.9 Sunny Boy Control Plus

The data logger for systems with up to 50 Windy Boys, an additional interface for

connection to PCs or large displays and additional connection possibilities for digital

and analog inputs and outputs.

Prerequisites: See Sunny Boy Control.

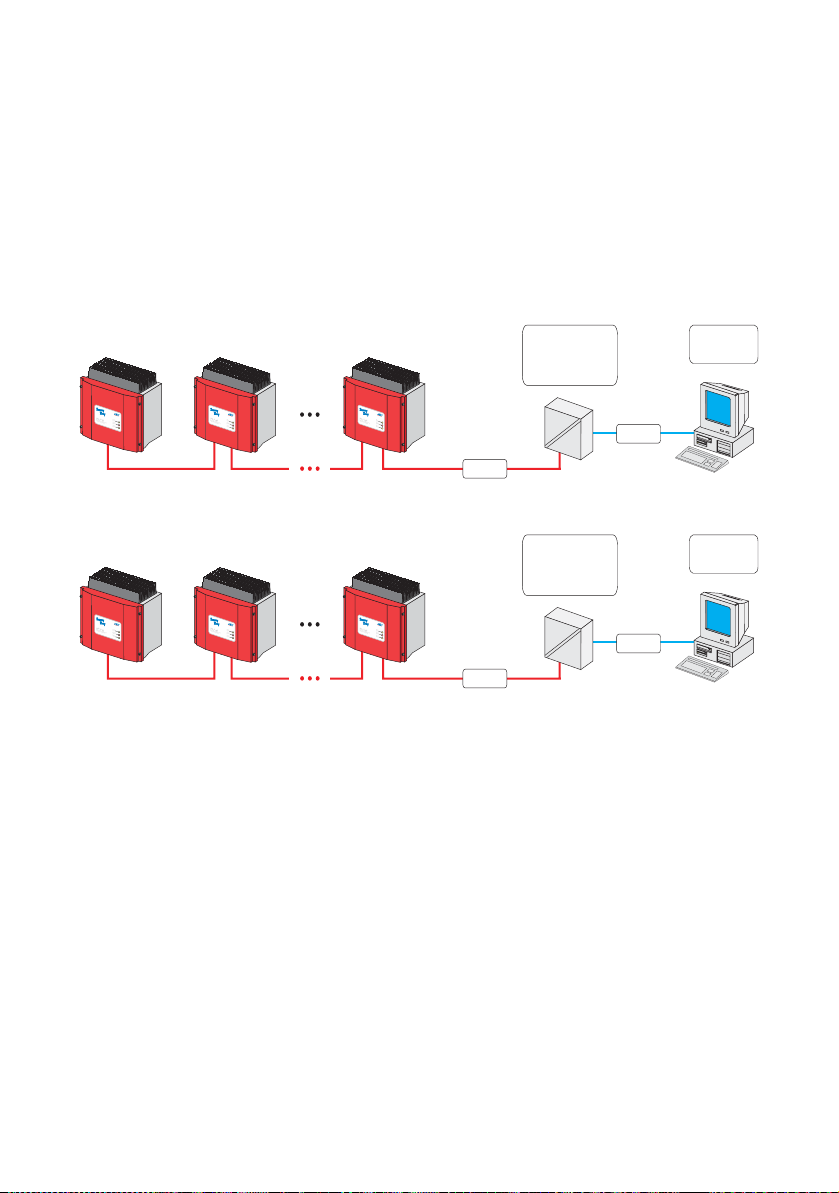

7.10 Sunny Data Control

This is a PC program for system monitoring and visualization on a PC for systems with

a Sunny Boy Control.

Prerequisites: A system with a Sunny Boy Control, Sunny Boy Control Plus or Sunny

Boy Control Light with a connection to a PC.

Connection also

possible via Modem

Visualization

S

W

R

Betrieb

1

1

Ph

ot

0

ovoltaik-Strin

Operation

0

E

Photovoltaic

g

wech

s

tring

s

Erdschluss

elrichte

i

nverter

r

Ear

th

F

ault

Störung

Failur

e

.

.

.

S

W

R

Betrieb

1

1

Photovoltaik-Stringwechselrichter

0

Operation

0

E

Photovoltaic

s

tring

Erdschluss

i

nverter

Earth

F

ault

Störung

Failu

re

S

W

R

Betrieb

1

1

P

hotovolt

0

Operation

0

E

Photovoltaic

aik-Str

i

ngwechselrichter

s

tring

Erdschluss

i

nverter

Earth

F

ault

Störung

Failure

.

.

.

Data evaluation

with Excel

with Sunny Data

Control

Remote Desktop

Internet

presentation

with

SDC-Agent

Internet

presentation

with

SMA-Portal

The connection between the PC and the Sunny Boy

Control can occur via modem if required. Large systems with more than 50 Windy Boys can be monitored

by coupling several Sunny Boy Controls together.

Page 44 WB11_17-11:FE4205 Operating instructions

Page 45

SMA Technologie AG Expansions

7.11 Sunny WebBox

The Sunny WebBox is a versatile inexpensive platform for system visualization directly on a PC or via the Internet using the Sunny Portal. The Sunny WebBox will be available from the 2nd quarter of 2005.

PC via

Telephone

Connection

S

W

R

Betr

1

1

Phot

i

eb

0

o

O

0

v

o

p

l

E

eration

P

t

ai

ho

k

-S

t

o

t

v

r

o

i

ngwechs

l

t

a

i

c

s

t

r

i

Erdsc

ng

e

lricht

i

n

v

h

e

luss

e

r

r

t

E

e

ar

r

th

F

a

ult

Störu

n

g

F

a

i

lu

re

Sunny

.

.

.

RS485

(

RS232*)

Powerline*)

(

(Radio*)

S

W

R

B

1

et

rieb

1

P

hoto

0

Operation

0

v

o

E

l

P

t

ai

h

otovoltaic

k

-

St

rin

gwec

s

tring

h

selrichter

Erdschluss

i

nv

e

rter

E

a

r

th

F

ault

Störung

F

a

il

ure

External

Sensors

WebBox

Memory Card

Hub

LAN

LAN

LAN

Modem

Sunny

Portal

(Internet)

External

Display

PC

S

W

R

B

1

etr

1

Photovoltaik-Stringwechselrichter

ie

b

0

Oper

0

E

Photovoltaic

at

ion

s

tring

Erdschluss

i

nverter

Earth

F

ault

Störung

Failure

* Communication with Sunny WebBox via RS232, Powerline or using

a wireless link will be possible at the end of 2005 or later.

LAN

7.12 Sunny Portal

The Sunny Portal is a high performance interface from

SMA for the monitoring and presentation of your system in the Internet. Details can be obtained from the

Sunny Family catalog or directly under www.SUNNYPORTAL.de.

Operating instructions WB11_17-11:FE4205 Page 45

Page 46

Expansions SMA Technologie AG

7.13 Sunny TV

Sunny TV is an accessory for Windy Boy inverters, which displays the system data

and the current performance on a monitor or video projector. It is suitable for the

presentation of large systems in lobbies and entrance halls as well as in private areas.

Video Projector TV Set

S

S

u

u

n

n

n

n

y

y

T

T

V

Sunny TV

Sunny TV

Pac = 7,450 W

S

W

R

B

1

etrieb

1

P

h

o

0

to

Op

0

v

olt

E

er

P

aik

h

a

o

ti

-

t

on

ov

S

t

r

o

i

n

l

t

gwe

a

i

c

ch

s

tr

sel

i

Er

n

g

d

r

i

sc

i

ch

nv

h

ter

e

luss

rt

Ea

e

r

r

t

h

F

aul

t

St

ör

un

g

F

a

i

lur

e

.

.

.

Pac = 7,450 W

Sunny TV

RS485

(

RS232*)

Powerline*)

(

S

W

R

B

1

etrieb

1

Pho

0

t

ovoltai

O

0

peration

E

Photovoltaic

k

-Stringw

e

chselrich

s

tring

Erdschluss

i

nverter

te

r

Earth

F

ault

Störung

Failur

e

(Radio*)

Video-Out

Configuration

with PC

V

P

P

a

a

c

c

=

=

7

7

,

,

4

4

5

5

0

0

W

W

PC Monitor

S

u

n

n

y

T

V

P

a

c

=

7

,

4

5

0

W

S

u

n

n

y

T

V

S

W

R

Betrieb

1

1

P

h

ot

0

ovoltai

Operation

0

E

Ph

ot

k

-

ovoltaic

S

trin

gwec

s

tring

h

s

Erdschluss

e

lricht

i

nverte

e

r

E

a

r

r

th

F

ault

Störung

Failur

e

* Communication with Sunny TV via RS232, Powerline or using

a wireless link will be possible at the end of 2005 or later.

Page 46 WB11_17-11:FE4205 Operating instructions

Page 47

SMA Technologie AG Technical data

8 Technical data

8.1 Windy Boy 1100

8.1.1 DC connection data

Max. input open circuit voltage U

Input voltage, MPP range U

Nominal DC operating voltage U

Max. input current I

Max. input power P

Recommended generator pow-

er at 5000 full-load hours / year

Recommended generator pow-

er at 2500 full-load hours / year

DC 0

DC

DC nom

DC max

DC max

P

turb max

P

turb max

All-pole isolator on the DC input

side

Overvoltage protection Thermally monitored varistors

DC voltage ripple U

SS

Personal protection Insulation monitoring (Riso > 1 MΩ)

Operating consumption < 5 W (standby)

Reverse polarity protection Short circuit diode

400 V

139 V ... 400 V DC

180 V

10 A

1210 W

800 W

900 W

DC plug connector

< 10 % of the input voltage

Operating instructions WB11_17-11:FE4205 Page 47

Page 48

Technical data SMA Technologie AG

8.1.2 Grid connection data

Nominal output power P

Peak output power P

Nominal output current I

Harmonic distortion of output

current

Operating range, grid voltage U

Operating range, grid frequency

All-pole isolator grid side

ACnom

ACmax

ACnom

THD

AC

f

AC

IAC

1000 W

1100 W

4.4 A

< 4 % (PAC > 0.5 P

198 ... 260 V AC

(180 ... 265 V programmable)

49.8 ... 50.2 Hz / 59.8 ... 60.2 Hz

(45.5 ... 54.5 Hz / 55.5 ... 64.5 Hz

programmable)

Independent disconnection device

(SMA grid guard)

Phase shift angle

(relative to the fundamental

cos Phi 1

wave of the current)

Overvoltage category III

Test voltage (50 Hz)

Test surge voltage

Own consumption in standby

mode

1.4 kV (1 s routine testing / 5 s type

testing)

4 kV (1.2/50 ms)

(serial interface: 6 kV)

0.1 W

ACnom

)

Page 48 WB11_17-11:FE4205 Operating instructions

Page 49

SMA Technologie AG Technical data

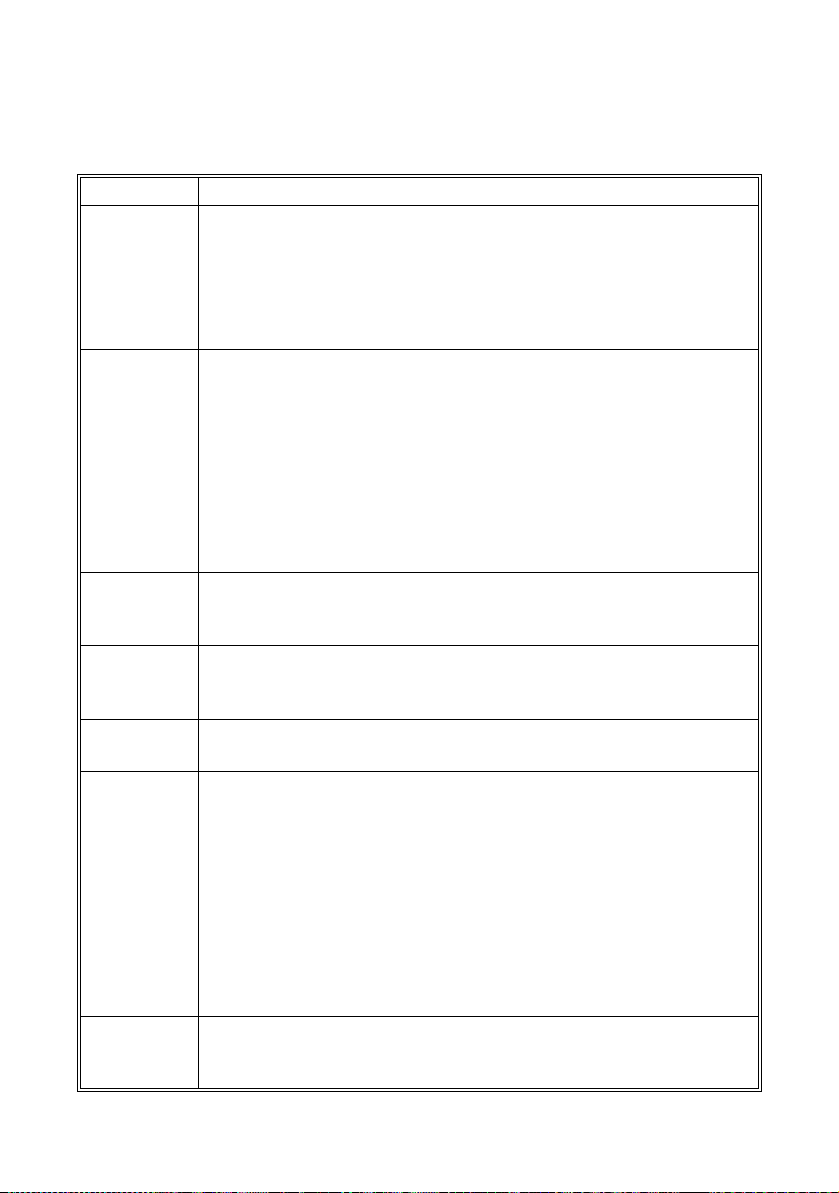

8.1.3 General data

For a detailed description of the device, see chapter 3 "Unit description” (page 13)

of this manual.

General data

Protection type to DIN EN 60529 IP65

External temperature range -25° C to +60° C

Dimensions (w x h x d) 322 mm x 320 mm x 180 mm

Weight 21 kg (approx.)

External interfaces

Data transfer (mains cable) Optional

Data transfer (data cable) Optional, RS232 / RS485

Data transfer (wireless) Optional

Efficiency

Max. efficiency η

max

The efficiency of the Windy Boy is heavily dependent on the DC input voltage. The

lower the input voltage the higher is the efficiency.

> 93,0 %

94

93

92

91

90

89

88

87

Overall efficiency [%]

86

85

84

0

Operating instructions WB11_17-11:FE4205 Page 49

200 400300100 500 700600

Output power [W]

Windy Boy 1100

800 900 1000 1100

Page 50

Technical data SMA Technologie AG

8.2 Windy Boy 1700

8.2.1 DC connection data

Max. input open circuit voltage U

Input voltage, MPP range U

Nominal DC operating voltage U

Max. input current I

Max. input power P

Recommended generator power

at 5000 full-load hours / year

Recommended generator power

at 2500 full-load hours / year

DC 0

DC

DC nom

DC max

DC max

P

turb max

P

turb max

All-pole isolator on

the DC input side

Overvoltage protection Thermally monitored varistors

Voltage ripple U

PP

Personal protection Insulation monitoring (Riso > 1 MΩ)

Operating consumption < 4 W

Reverse polarity protection Short circuit diode

400 V

139 V ... 400 V DC

180 V

12.6 A

1850 W

1240 W

1395 W

DC plug connector

< 4 % of the input voltage

Page 50 WB11_17-11:FE4205 Operating instructions

Page 51

SMA Technologie AG Technical data

8.2.2 Grid connection data

Nominal output power P

Peak output power P

Nominal output current I

ACnom

ACmax

ACnom

1550 W

1700 W

6.5 A

Harmonic distortion of output current (at K

> 0.5 P

P

AC

Unom

< 2 %,

ACnom

)

Operating range, grid voltage V

THD

AC

< 4 %

IAC

198 ... 260 V AC

(180 ... 265 V programmable)

49.8 ... 50.2 Hz / 59.8 ... 60.2 Hz

Operating range, grid frequency f

AC

(45.5 ... 54.5 Hz / 55.5 ... 64.5 Hz

programmable)

All-pole isolator grid side

Independent disconnection device

(SMA grid guard)

Phase shift angle

(relative to the fundamental wave

cos ϕ 1

of the current)

Overvoltage category III

Test voltage (50 Hz)

Test surge voltage

Own consumption in standby

mode

1.4 kV (1 s routine testing / 5 s type

testing)

4 kV (1.2/50 ms)

(serial interface: 6 kV)

0.1 W

Operating instructions WB11_17-11:FE4205 Page 51

Page 52

Technical data SMA Technologie AG

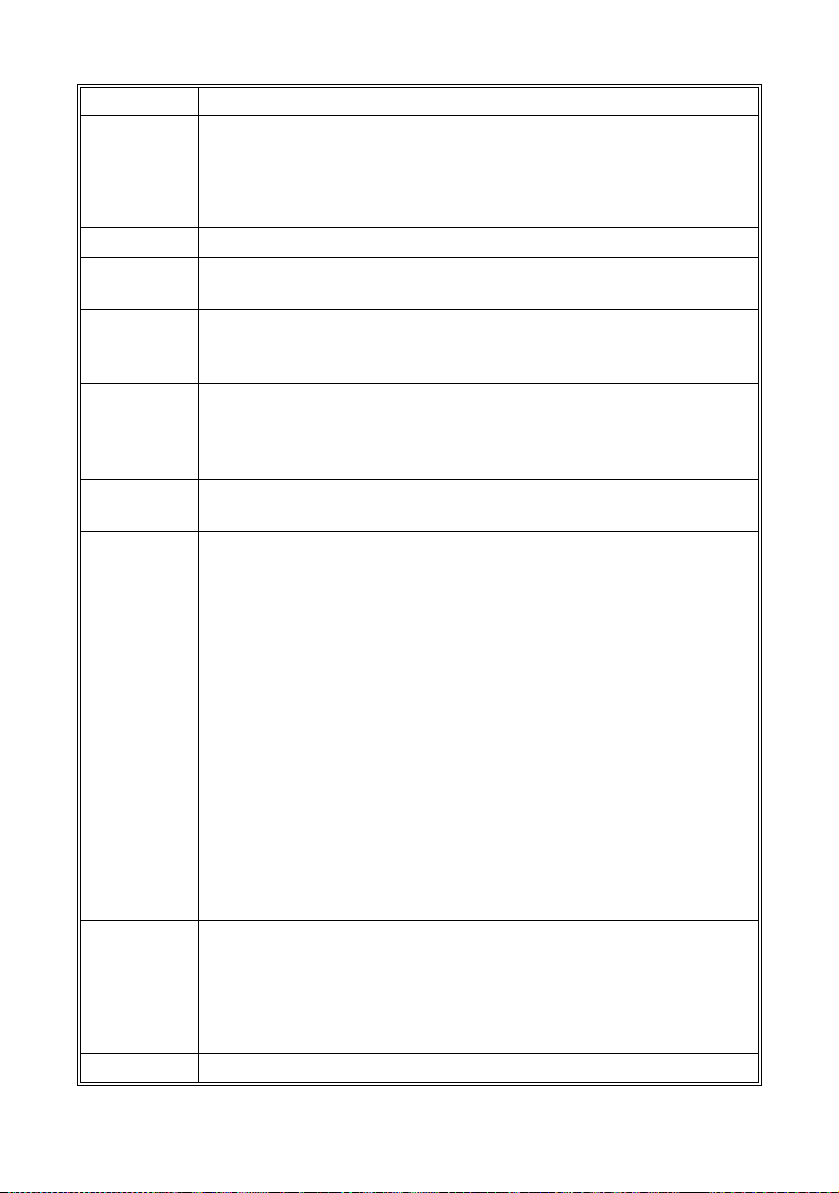

8.2.3 General data

For a detailed description of the device, see chapter 3 "Unit description” (page 13)

of this manual.

General data

Protection type to DIN EN 60529 IP65

Dimensions (w x h x d) 434 mm x 295 mm x 214 mm

Weight 25 kg (approx.)

External interfaces

Data transfer (mains cable) Optional

Data transfer (separate data cable) Optional, RS232 / RS485

Data transfer (wireless) Optional

Efficiency

Max. efficiency η

max

The efficiency of the Windy Boy is heavily dependent on the DC input voltage. The

lower the input voltage, the higher the efficiency.

94

93

92

91

90

89

88

87

Overall efficiency [%]

86

85

84

0

200 400 600

> 93,5 %

Windy Boy 1700

800 1000 1200

1400 1600

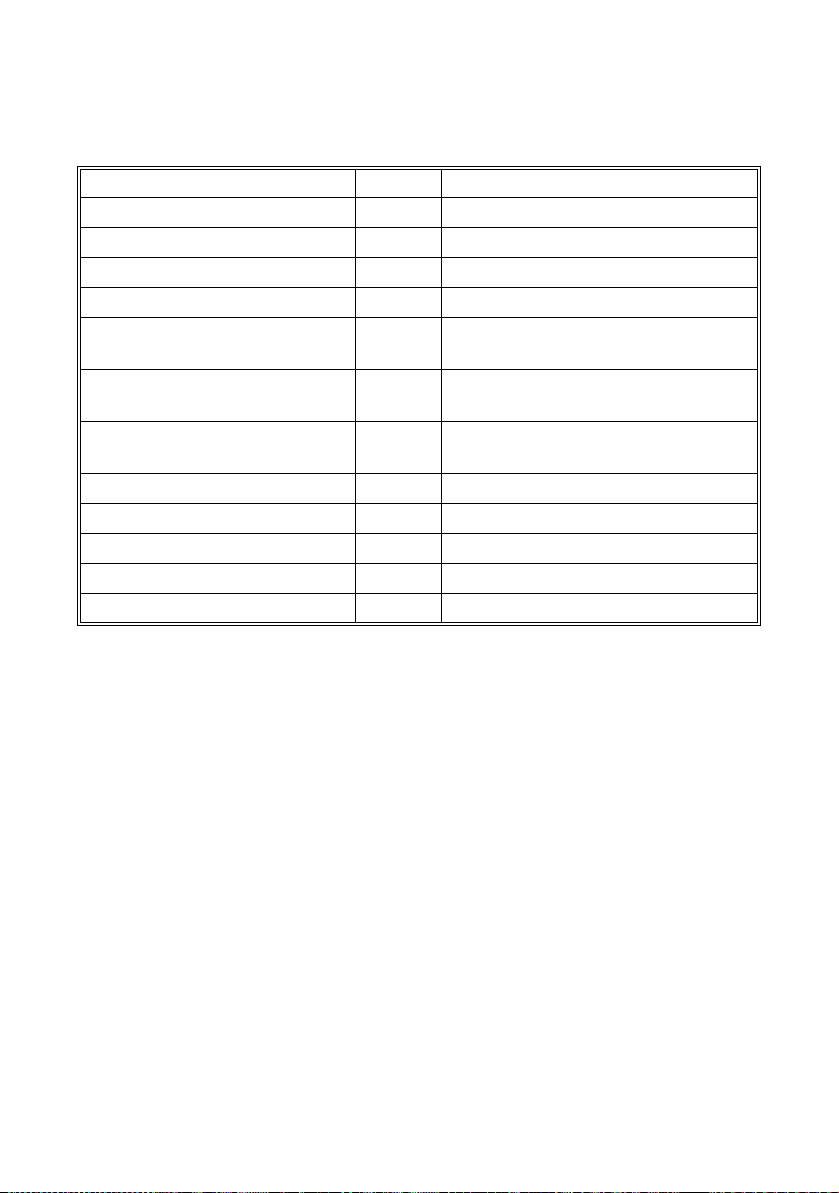

Output power [W]