Page 1

EN

Wind Power Inverter

WINDY BOY 3300 / 3800

Installation Manual

WB33-38-IA-IEN120940 | IME-WB3800 | Version 4.0

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Manual. . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Explanation of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Symbols on the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Symbols on the Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Identifying the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Selecting the Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Mounting the Inverter using the Wall Mounting Bracket . . . . . 18

5 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Overview of the Connection Area . . . . . . . . . . . . . . . . . . . . . . 21

5.2.1 Exterior View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.2 Interior view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation Manual WB33-38-IA-IEN120940 3

Page 4

Table of Contents SMA Solar Technology AG

5.3 Connection to the Electricity Grid (AC). . . . . . . . . . . . . . . . . . . 23

5.3.1 Conditions for AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3.2 Connecting the Inverter to the Electricity Grid (AC) . . . . . . . . . . . . . . . . . . . 25

5.3.3 Connecting Additional Earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4 Setting the Display Language . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5 Connecting the Small Wind Turbine System (DC) . . . . . . . . . . 30

5.5.1 Conditions for DC connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.5.2 Assembling the DC Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5.3 Opening DC Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5.4 Connecting the Small Wind Turbine System (DC). . . . . . . . . . . . . . . . . . . . . 34

5.6 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7 Setting the Grid and Country Parameters . . . . . . . . . . . . . . . . . 36

5.7.1 Setting the Installation Country . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.7.2 Setting to Stand-alone Grid Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.8 Polynomial Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1 Commissioning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2 Display Messages During the Start-up Phase . . . . . . . . . . . . . . 40

6.3 Self-Test in Accordance with DK 5940, Ed. 2.2

(Applies to Italy Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3.1 Starting the Self-Test by Tapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.3.2 Completion of the Self-test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.4 Operating States of the Inverter . . . . . . . . . . . . . . . . . . . . . . . . 46

7 Opening and Closing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.2 Opening the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3 Closing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4 WB33-38-IA-IEN120940 Installation Manual

Page 5

SMA Solar Technology AG Table of Contents

8 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . 52

8.1 Cleaning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.2 Checking Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.2.1 Cleaning the Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.2.2 Checking the Fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2.3 Cleaning the Ventilation Grids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.1 Blink Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.2 Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.3 Red LED is Permanently On . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.3.1 Checking the Small Wind Turbine System for Earth Faults . . . . . . . . . . . . . . 62

9.3.2 Checking the Function of the Varistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.1 Dismantling the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.2 Packing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.3 Storing the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.4 Disposing of the inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.1 DC/AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.1.1 Windy Boy 3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11.1.2 Windy Boy 3800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11.2 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.3 Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.4 Licences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.5 Climatic Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.6 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.7 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11.8 Distribution systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Installation Manual WB33-38-IA-IEN120940 5

Page 6

Table of Contents SMA Solar Technology AG

12 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6 WB33-38-IA-IEN120940 Installation Manual

Page 7

SMA Solar Technology AG Information on this Manual

1 Information on this Manual

1.1 Validity

This manual describes the mounting, installation, commissioning, maintenance and troubleshooting

procedures for the following SMA inverters:

• Windy Boy 3300 (WB 3300, WB 3300-11, WB 3300-IT)

• Windy Boy 3800 (WB 3800, WB 3800-11, WB 3800-IT)

Please store this manual where it will be accessible at all times.

1.2 Target Audience

This manual is for the use of electrically skilled persons. The tasks described in this manual may be

performed by electrically skilled persons only.

1.3 Additional Information

You will find further information on special topics, such as the design of a miniature circuit-breaker or

the description of the operating parameters, in the download area at www.SMA.de/en.

Please refer to the user manual provided for detailed information on operating the inverter.

Installation Manual WB33-38-IA-IEN120940 7

Page 8

Information on this Manual SMA Solar Technology AG

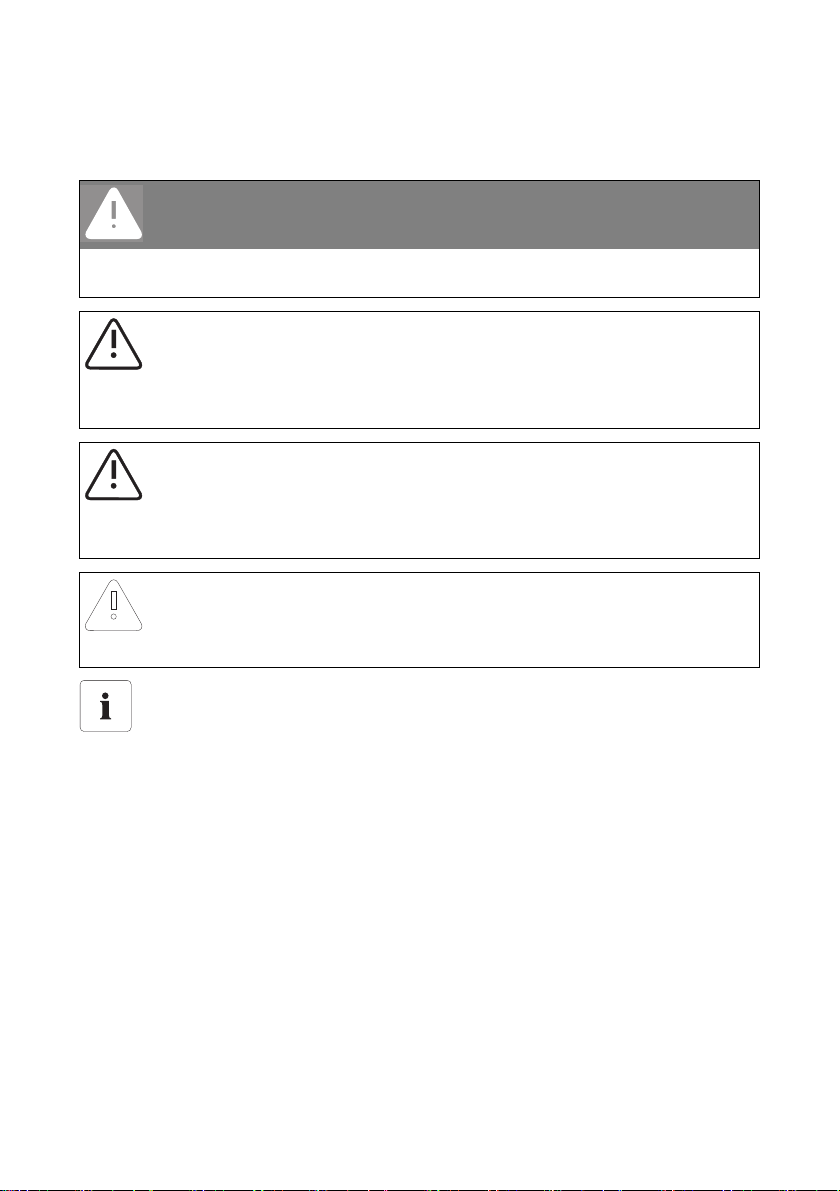

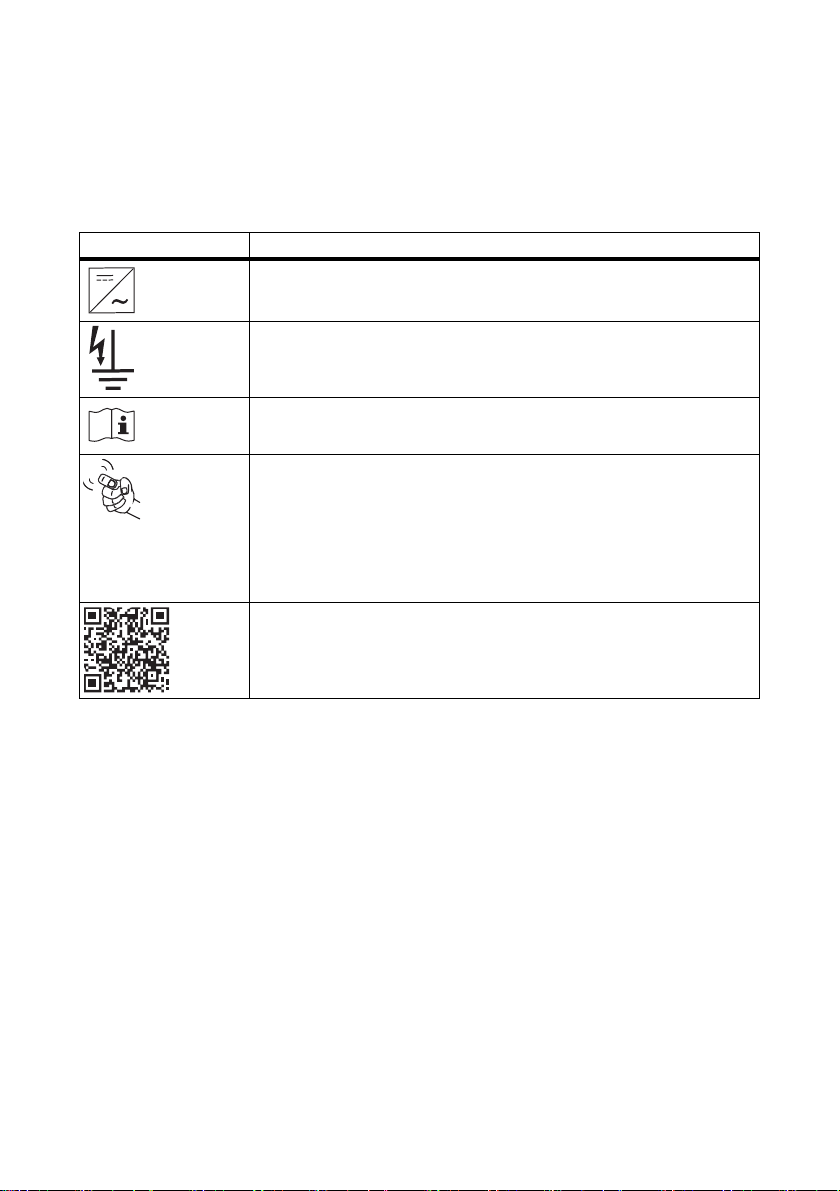

1.4 Symbols Used

The following types of safety precautions and general information are used in this manual:

DANGER!

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE!

NOTICE indicates a situation which, if not avoided, could result in property damage.

Information

Information provides tips that are valuable for the optimal installation and operation of the

product.

☑ This symbol indicates the result of an action.

8 WB33-38-IA-IEN120940 Installation Manual

Page 9

SMA Solar Technology AG Safety

2 Safety

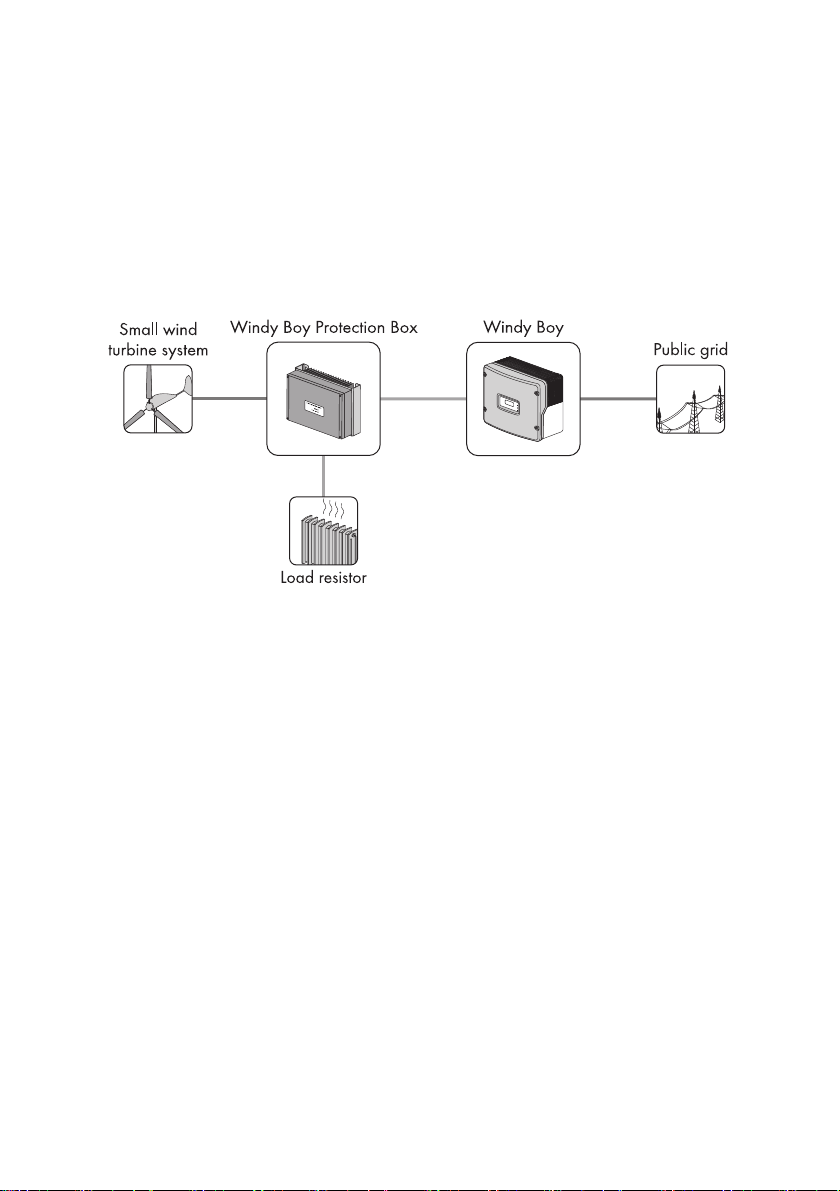

2.1 Intended Use

The Windy Boy is a wind power inverter, which converts the rectified current generated by a small

wind turbine system into AC current and feeds this energy into the electricity grid, domestic network

or the Sunny Island system.

Principle of a small wind turbine system with Windy Boy

In add iti on, the W ind y Bo y can be u sed as inver ter for energy c onverters based on permanent magnet

generators (hydro-power systems, combined heat and power plants, diesel generators, etc.).

The manufacturer of the small wind turbine system or generator must have approved his plant for

operation with this Windy Boy.

For safety reasons, it is not permitted to modify the product or install components that are not explicitly

recommended or distributed by SMA Solar Technology AG.

When designing the PV plant, ensure that the permitted operating range of all components is

complied with at all times. Moreover, make sure that appropriate protective measures are in place to

ensure that the maximum permissible input voltage is not exceeded. SMA Solar Technology AG offers

you the necessary components, such as the Windy Boy Protection Box (overvoltage protection for

wind power inverters including the rectifier).

Installation Manual WB33-38-IA-IEN120940 9

Page 10

Safety SMA Solar Technology AG

2.2 Safety Precautions

DANGER!

Electric shock due to high voltages in the inverter when connecting the device.

Death or serious injuries.

• All work on the inverter must be carried out by a trained electrically skilled person

only.

• Work on the inverter should only be carried out as described in this manual.

• All safety precautions listed here must be observed.

CAUTION!

Risk of burns through contact with the hot enclosure during operation. Burns to

the palm of the hand.

• Do not touch the inverter enclosure during operation.

Problems while performing the described activities

If you hav e pr obl ems whi le p erf orm ing any of t he a cti vit ies des cri bed in t his man ual , pl eas e

contact SMA Solar Technology AG (see Section 13"Contact" (page77)).

10 WB33-38-IA-IEN120940 Installation Manual

Page 11

SMA Solar Technology AG Safety

2.3 Explanation of Symbols

This section gives an explanation of all the symbols found on the inverter and on the type label.

2.3.1 Symbols on the Inverter

Symbol Explanation

Operation display

Indicates the operating state of the inverter.

Earth fault or varistor defective

Read Section 9.3"Red LED is Permanently On" (page62).

Fault or disturbance.

Read Section 9"Troubleshooting" (page56).

You can operate the display by tapping the enclosure lid.

• Single tap: the backlight switches on or the display scrolls to the next

display message.

• Double tap in quick succession*: The inverter shows the display

messages from the start-up phase again (see Section 6.2"Display

Messages During the Start-up Phase" (page40)).

QR-Code®** for SMA bonus programme

You will find information on the SMA bonus programme at

www.SMA-Bonus.com.

* This function is valid as of firmware version 4.00.

** QR-Code is a registered trademark of DENSO WAVE INCORPORATED.

Installation Manual WB33-38-IA-IEN120940 11

Page 12

Safety SMA Solar Technology AG

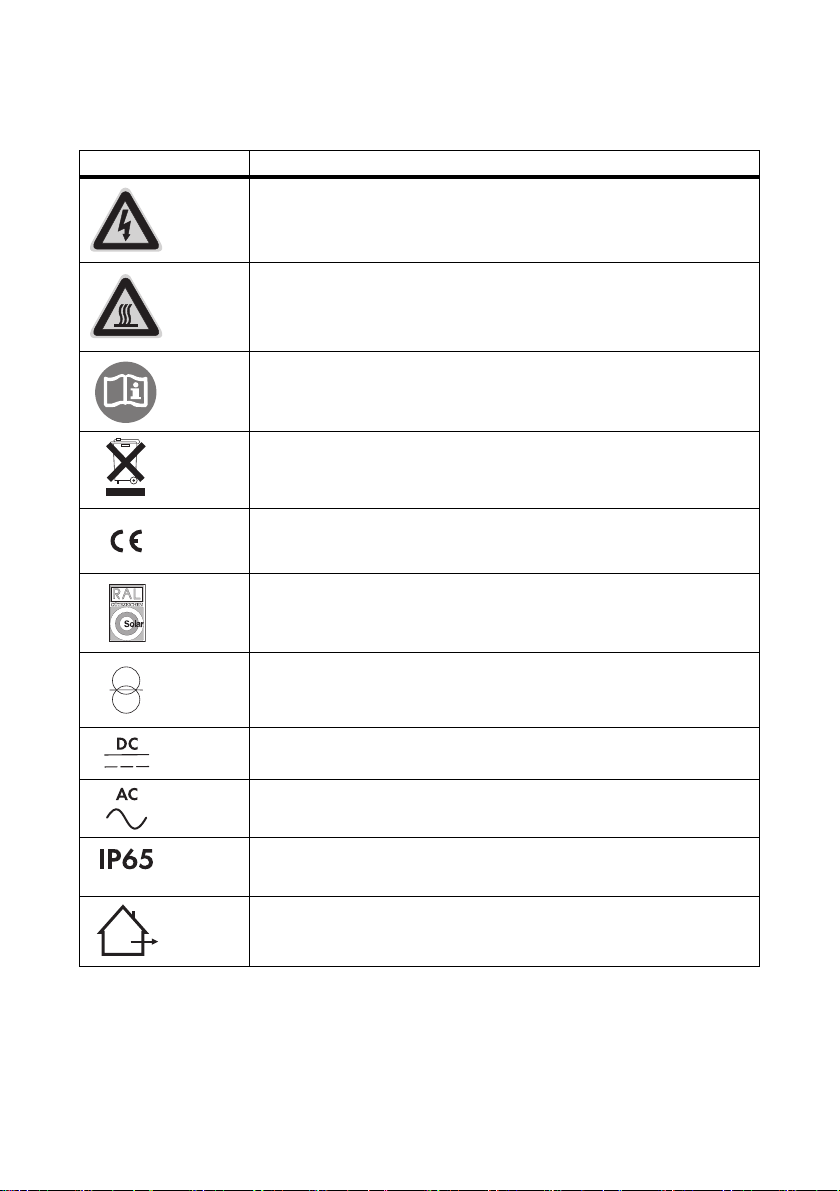

2.3.2 Symbols on the Type Label

Symbol Explanation

Beware of dangerous electrical voltage.

The inverter operates at high voltages. All work on the inverter must be

carried out by a trained electrically skilled person only.

Beware of hot surface.

The inverter can become hot during operation. Avoid contact during

operation.

Observe all documentation that accompanies the inverter.

Th e in ver ter must not be d isp ose d of tog eth er w ith the hous eho ld waste. For

more information on disposal, see Section 10.4"Disposing of the inverter"

(page68).

CE marking

The inverter complies with the requirements of the applicable EC directives.

RAL quality mark for solar products

The inverter complies with the requirements of the German Institute for

Quality Assurance and Labelling.

The inverter has a transformer.

Direct current (DC)

Alternating current (AC)

The inverter is protected against dust intrusion and water jets from any

angle.

The inverter is suitable for outdoor installation.

12 WB33-38-IA-IEN120940 Installation Manual

Page 13

SMA Solar Technology AG Unpacking

3 Unpacking

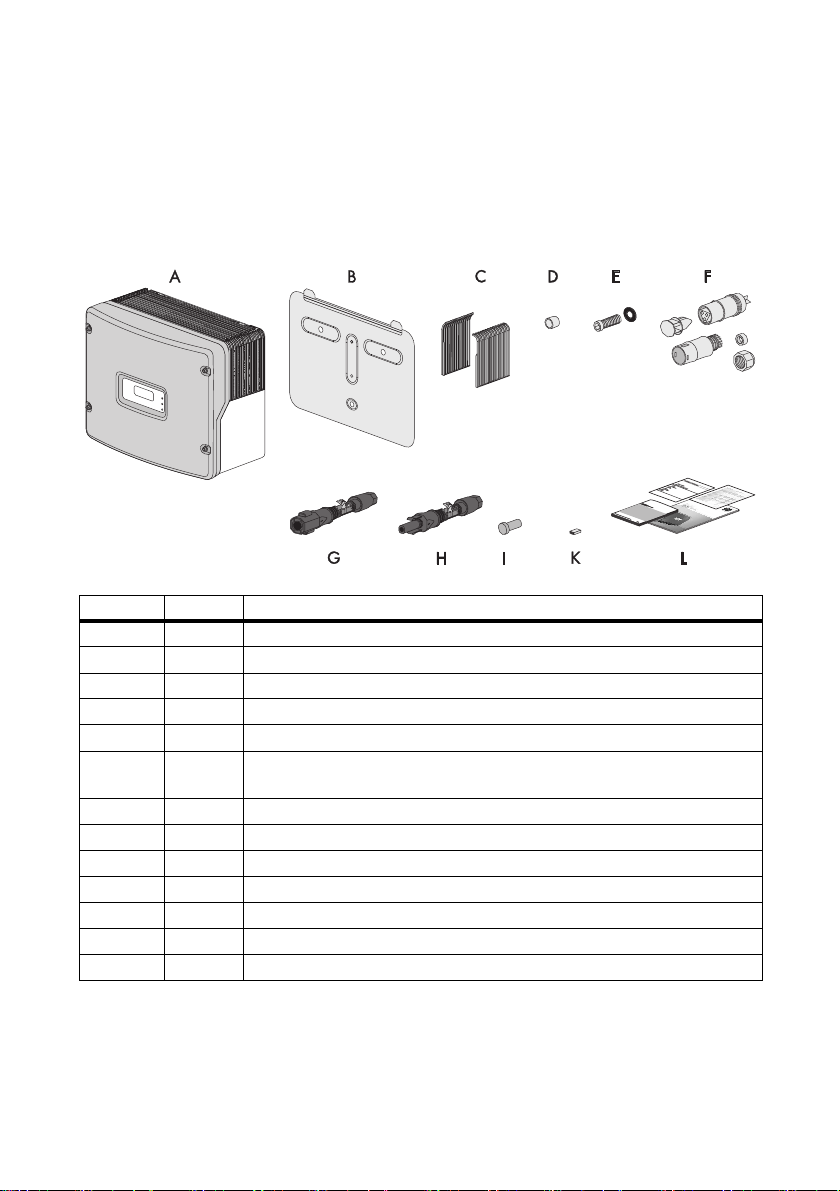

3.1 Scope of Delivery

Check the delivery for completeness and for any visible external damage. Contact your dealer if

anything is damaged or missing.

Object Quantity Description

A1Inverter

B 1 Wall mounting bracket

C 2 Ventilation grid (1 x left, 1 x right)

D 5 Filler-plug for wall mounting (sealing)

E 2 Cheese-head screw (M6)

F 1 AC connection socket: bush insert, protective cap for bush insert,

threaded sleeve, sealing ring, pressure screw

G 6 DC connectors (3 x positive, 3 x negative)*

H 6 Sealing plug for DC connectors

I 1 Jumper for communication / fan test

K 1 Installation manual

L1User manual

M 1 Document set with explanations and certificates

N 1 Supplementary sheet with inverter default settings

* For WB 3300-11 / WB 3800-11 2 ⨯ positive, 2 ⨯ negative

Installation Manual WB33-38-IA-IEN120940 13

Page 14

Unpacking SMA Solar Technology AG

3.2 Identifying the Inverter

You can identify the inverter be means of the type label. The type label is located on the right-hand

side of the enclosure.

On the type label you will find the type (Type / Model) and the serial number (Serial No.) of the

inverter.

14 WB33-38-IA-IEN120940 Installation Manual

Page 15

SMA Solar Technology AG Assembly

4 Assembly

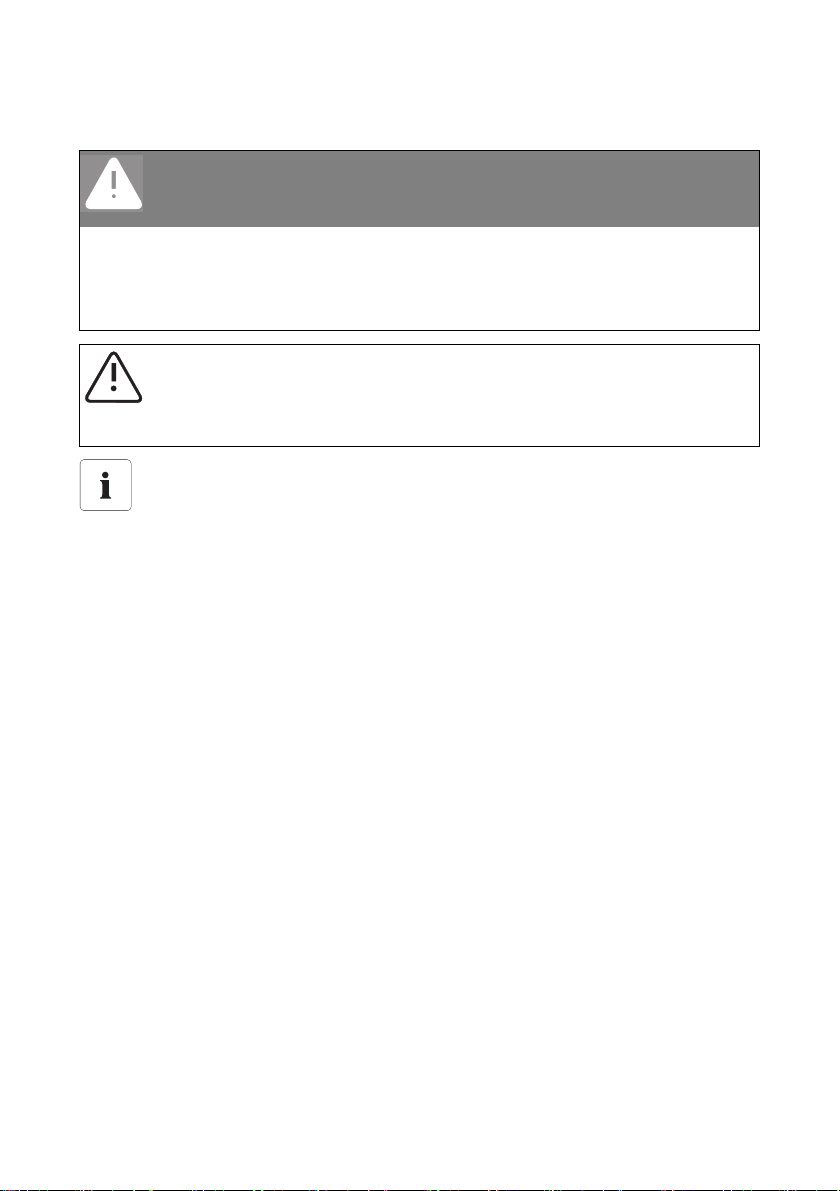

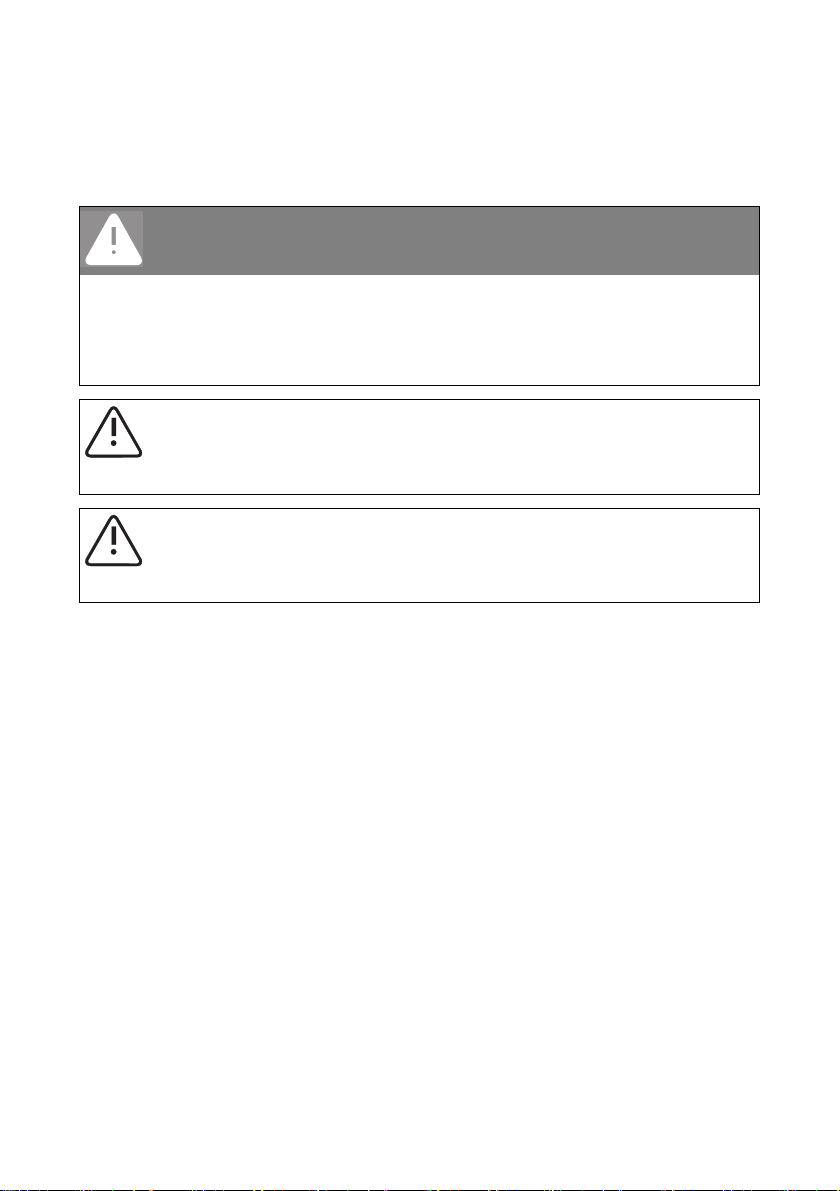

4.1 Safety

DANGER!

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

• Do not mount the inverter on flammable construction materials.

• Do not mount the inverter in areas where highly flammable materials are stored.

• Do not mount the inverter in a potentially explosive atmosphere.

CAUTION!

Risk of burns due to hot enclosure parts

• Do not touch the enclosure during operation.

CAUTION!

Risk of injury due to the heavy weight of the inverter.

• Bear in mind that the inverter weighs approx. 38 kg

Installation Manual WB33-38-IA-IEN120940 15

Page 16

Assembly SMA Solar Technology AG

4.2 Selecting the Mounting Location

Observe the following conditions for mounting:

• The mounting method and location must be suitable for the weight and size of the inverter.

• Mount on a solid surface.

• The mounting location must be clear and safely accessible at all times without the use of

additional aids such as scaffolding or lifting platforms. Non-fulfillment of these criteria may

restrict service friendliness.

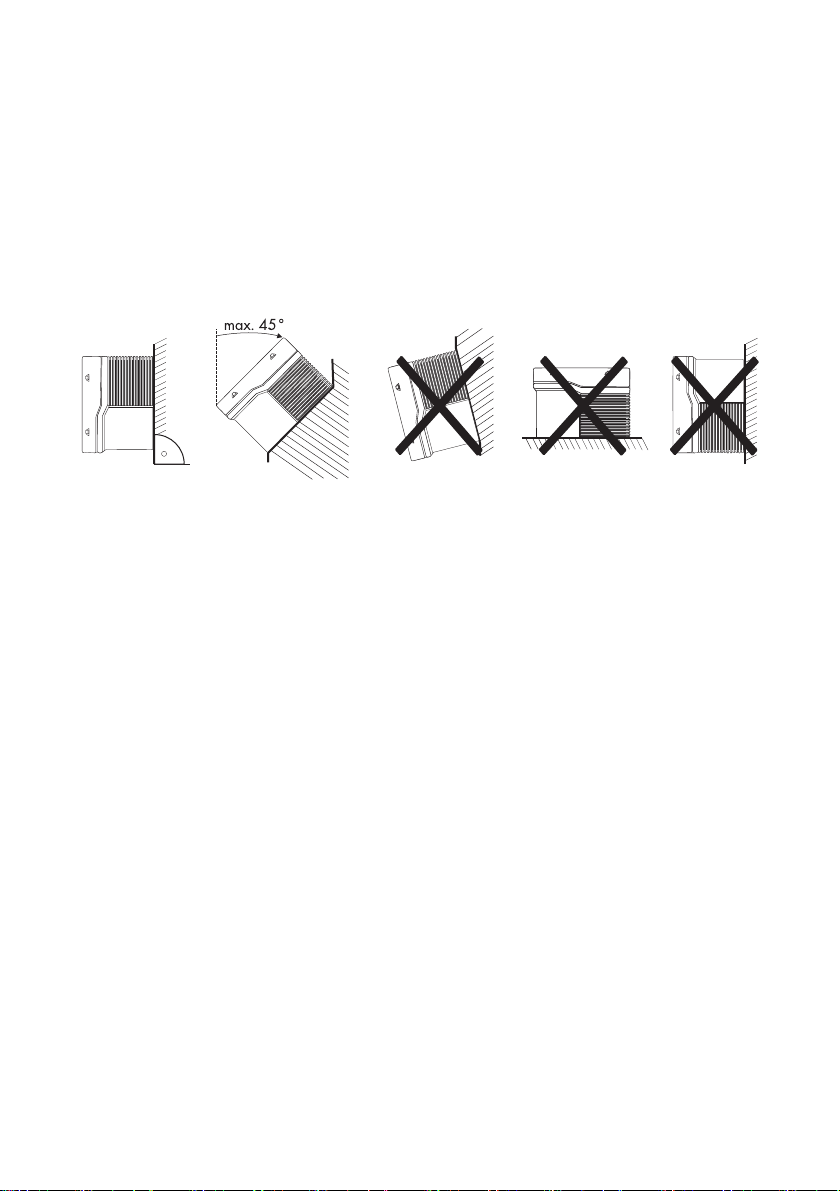

• Mount vertically or tilted backwards by max. 45°.

• Never mount the device with a forward tilt.

• Never mount the device with a sideways tilt.

• Do not mount in a horizontal position.

• The connection area must point downwards.

• Mount at eye level so that operation states can be read.

• The ambient temperature should be below 40°C to ensure optimum operation.

• Do not expose the inverter to direct solar irradiation as this can cause over-heating and hence

power reduction.

• To avoid audible vibrations in living areas, do not mount the unit on plasterboard walls or

similar. The inverter can make noises when in use which may be perceived as a nuisance in

living areas.

16 WB33-38-IA-IEN120940 Installation Manual

Page 17

SMA Solar Technology AG Assembly

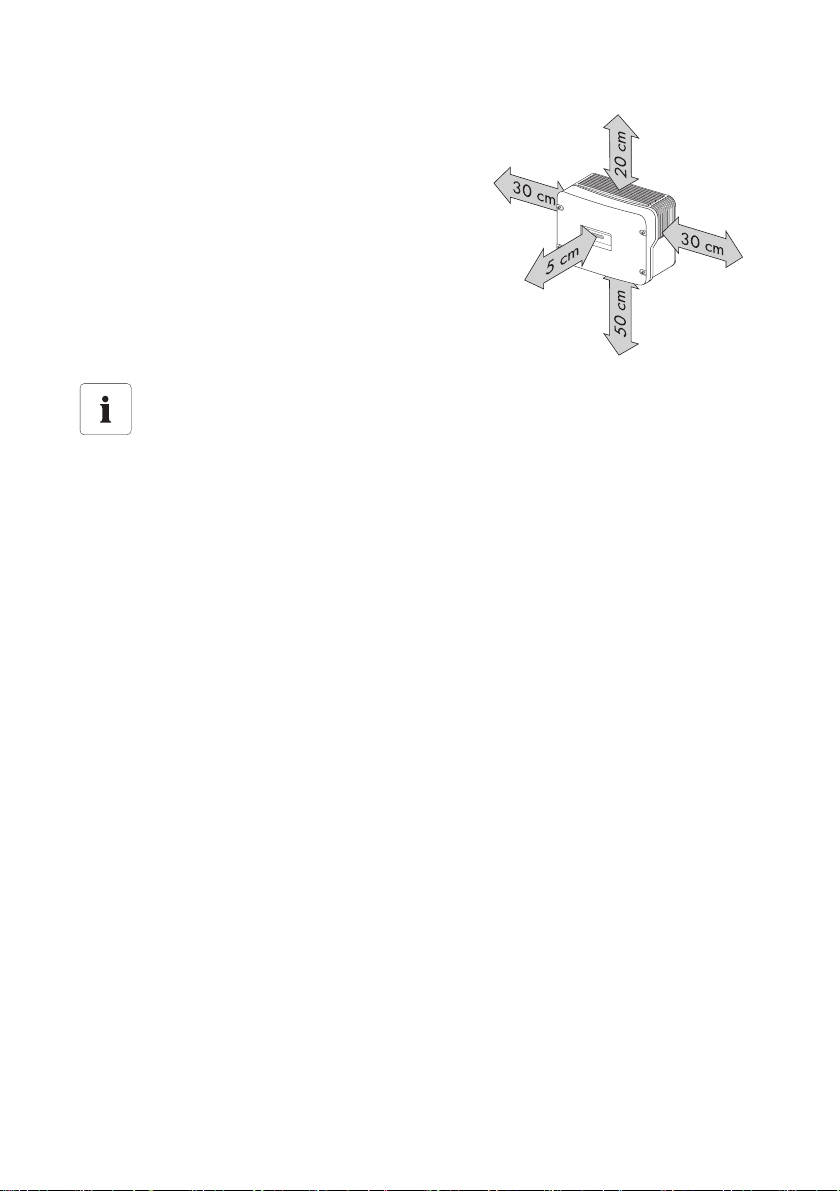

• Observe minimum clearances to walls, other

inverters or objects as shown in the diagram in

order to guarantee adequate heat dissipation.

Multiple inverters installed in areas with high ambient temperatures

If necessary, increase the spacing between the individual inverters. In addition, make sure

there is an adequate fresh-air supply to ensure sufficient cooling of the inverters.

Installation Manual WB33-38-IA-IEN120940 17

Page 18

Assembly SMA Solar Technology AG

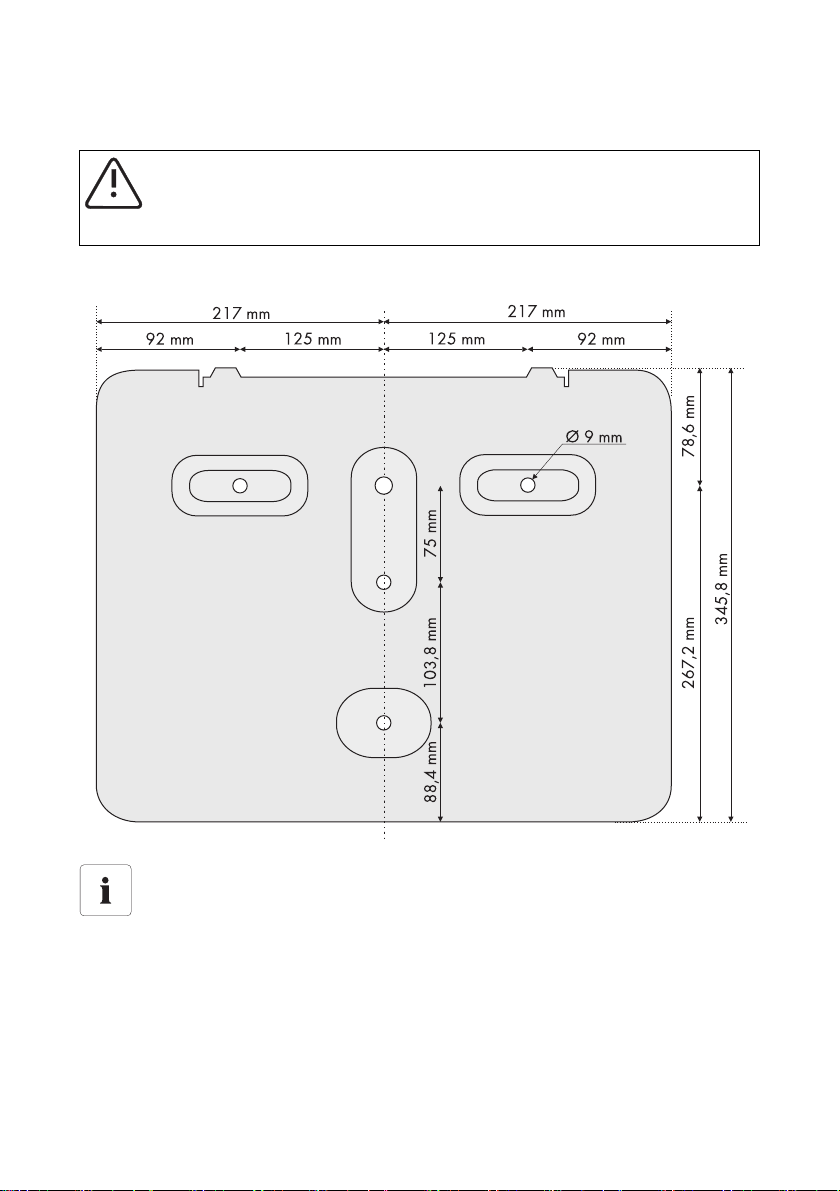

4.3 Mounting the Inverter using the Wall Mounting Bracket

CAUTION!

Risk of injury due to the heavy weight of the inverter.

• Bear in mind that the inverter weighs approx. 38 kg

1. Use the wall mounting bracket as a drilling template and mark the positions of the drill holes.

Mounting material

When mounting the wall mounting bracket, use fastening material suitable for the mounting

surface.

2. Use filler-plugs to fill any unused holes in the wall mounting bracket. Insert the filler-plugs into

the wall mounting bracket from the outside (the side that will later be placed against the wall).

18 WB33-38-IA-IEN120940 Installation Manual

Page 19

SMA Solar Technology AG Assembly

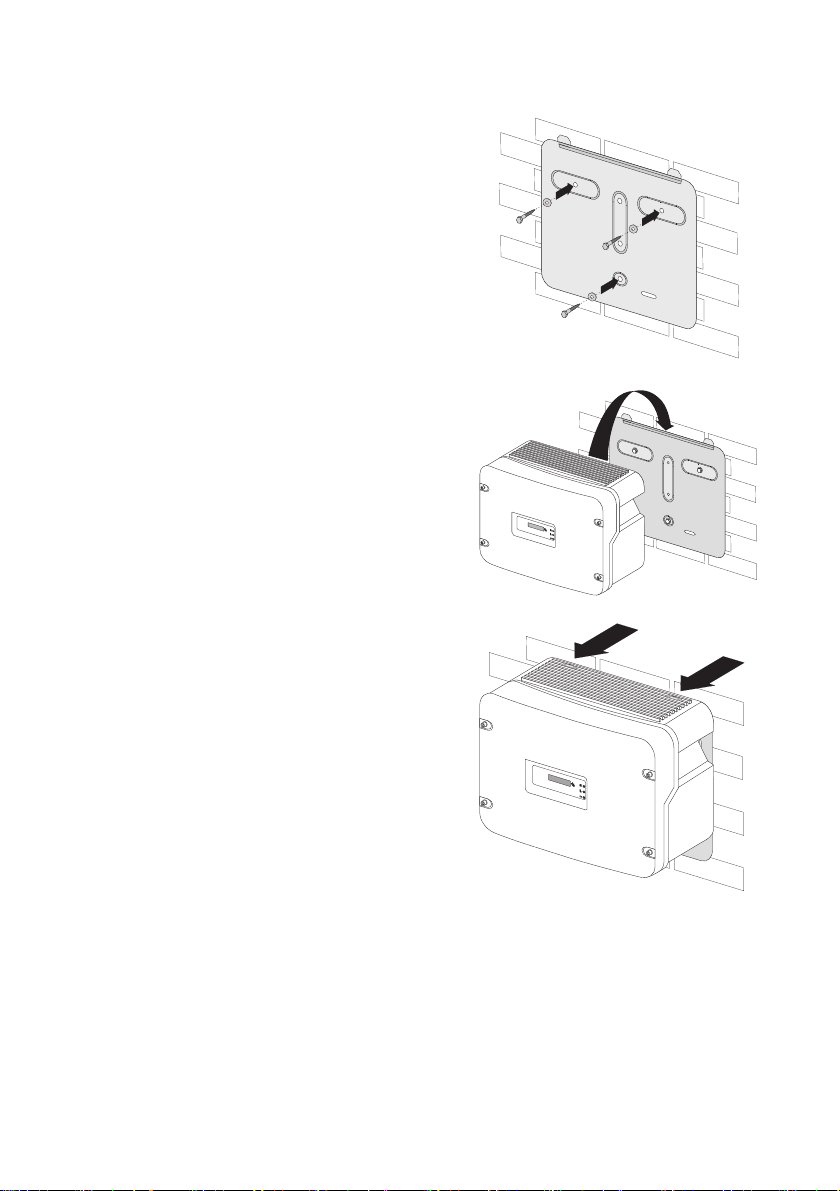

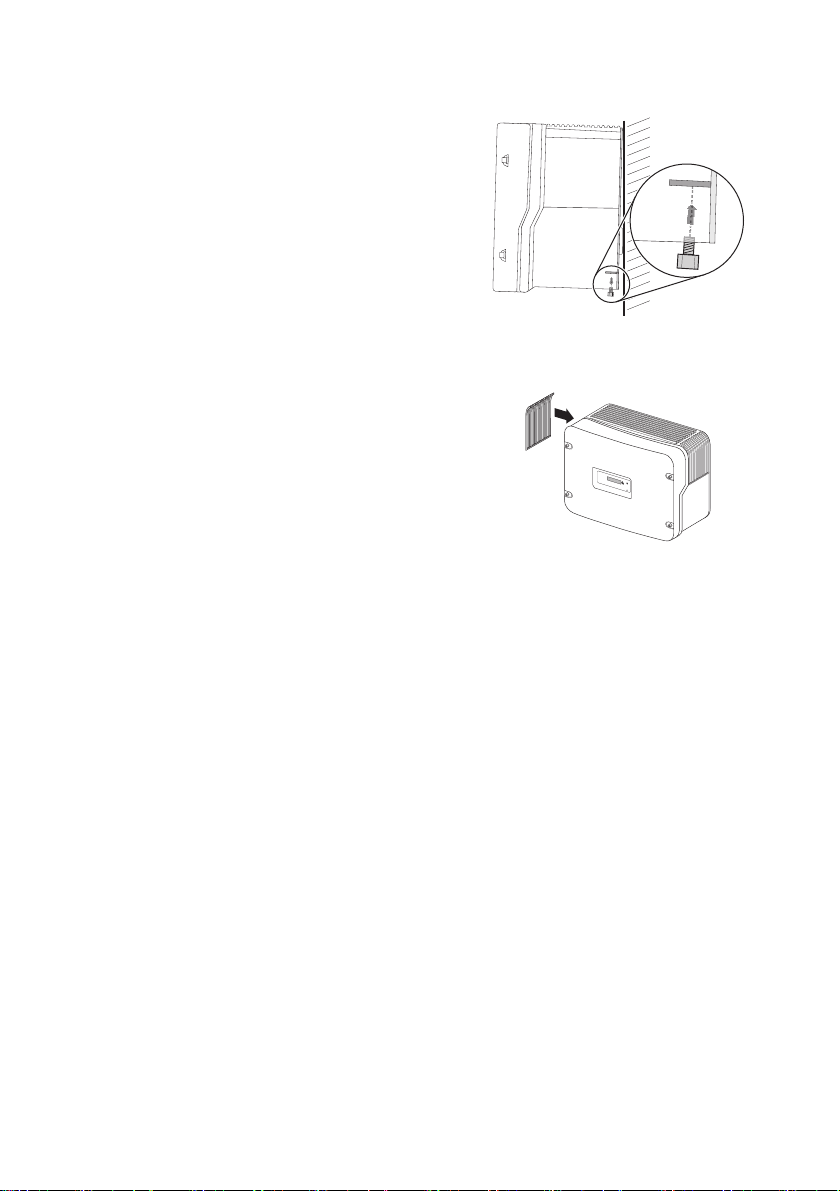

3. Attach the wall mounting bracket to the wall using

suitable screws and washers.

4. Hook t he inverte r by its top mounti ng plates into the

wall mounting bracket with both attachments of the

wall bracket passing through the cutouts on the

inverter.

5. Visual inspection: The inverter is only correctly

mounted when both rear panel attachments slightly

protrude through the cutouts.

Installation Manual WB33-38-IA-IEN120940 19

Page 20

Assembly SMA Solar Technology AG

6. Secure the inverter in position by screwing the

supplied M6 contact screw into the underside of

the enclosure. Use the contact washer provided

with the toothing facing towards the enclosure.

Tighten the screw with a torque of approx. 5 Nm.

7. Check to ensure that the inverter is securely in place. The wall mounting bracket is designed in

such way that the inverter is tilted slightly backwards on a perfectly vertical wall.

8. Attach the ventilation grids provided to the inverter.

To help you identify the sides,

"links/left" or "rechts/right" is printed on the inside

of the ventilation grids.

☑ The inverter is now mounted.

20 WB33-38-IA-IEN120940 Installation Manual

Page 21

SMA Solar Technology AG Electrical Connection

5 Electrical Connection

5.1 Safety

NOTICE!

Electrostatic discharge can damage the inverter

Internal components of the inverter can be irreparably damaged by electrostatic

discharge.

• Earth yourself before touching a component.

5.2 Overview of the Connection Area

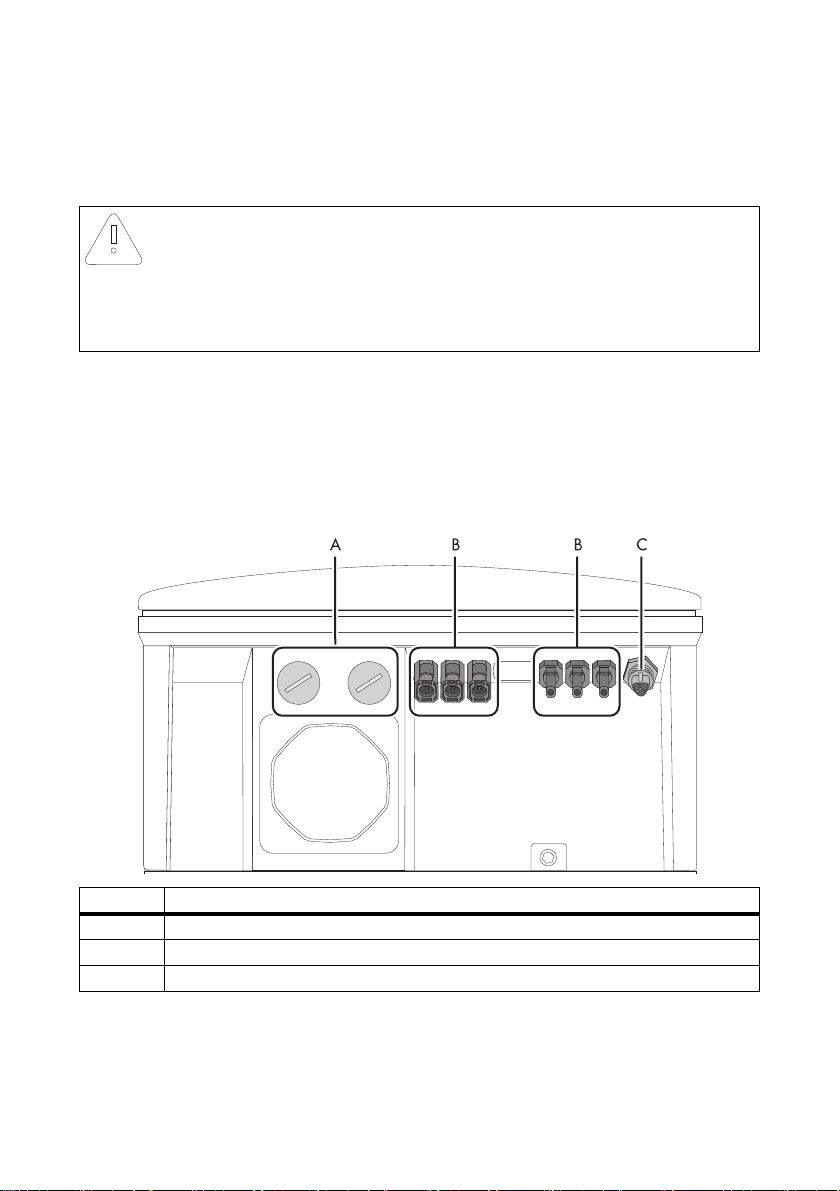

5.2.1 Exterior View

The following figure shows the assignment of the individual connection areas on the underside of the

inverter.

Object Description

A Enclosure openings for communication (with filler-plugs)

B DC connectors for connecting the DC cables*

C AC socket for grid connection

* For WB 3300-11 / WB 3800-11, the inverter is fitted with 2 negative and 2 positive DC connectors.

Installation Manual WB33-38-IA-IEN120940 21

Page 22

Electrical Connection SMA Solar Technology AG

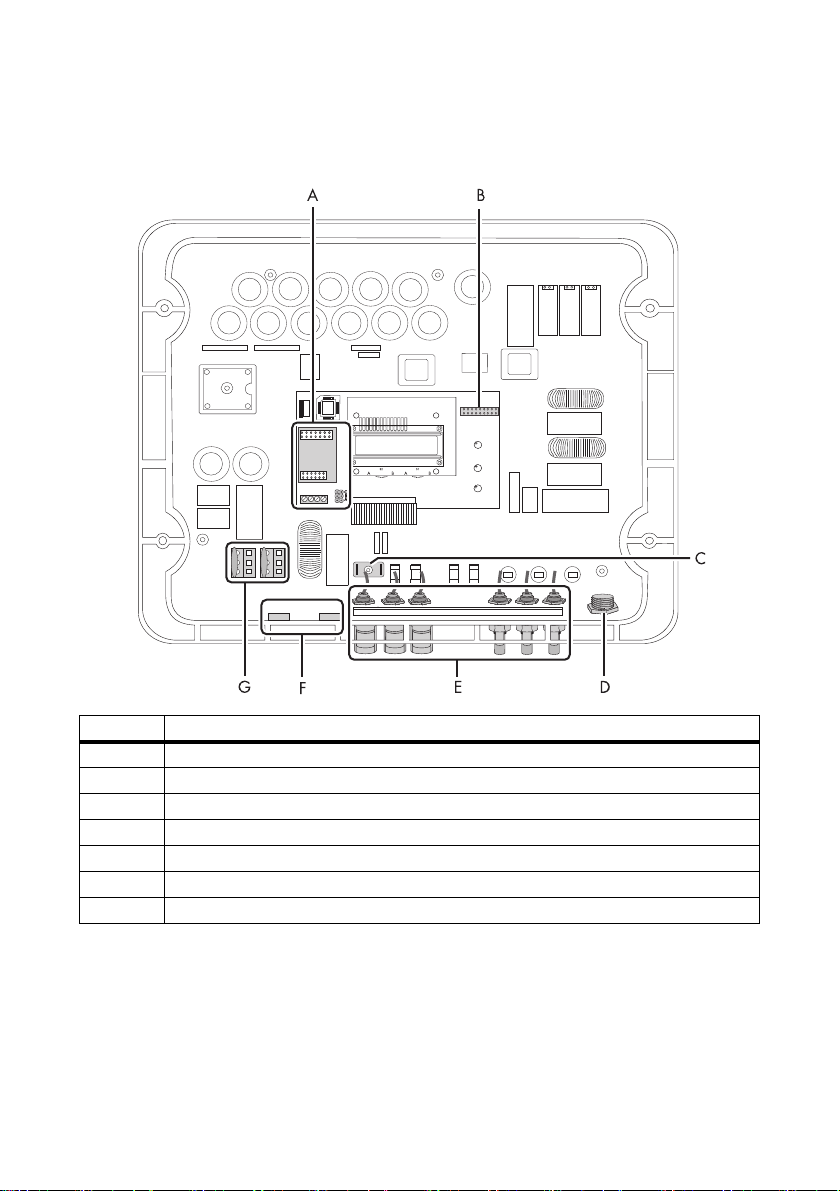

5.2.2 Interior view

The following figure shows the various components and connection areas of the open inverter.

Object Description

A Slot and connection area for communication

B Jumper slot for fan test

C Flat male tab for earthing the cable shield with cable-bound communication

D AC socket for grid connection

E DC connector for connecting the small wind turbine system*

F Enclosure opening with filler-plugs for communication

GVaristors

* For WB 3300-11 / WB 3800-11, the inverter is fitted with 2 negative and 2 positive DC connectors.

22 WB33-38-IA-IEN120940 Installation Manual

Page 23

SMA Solar Technology AG Electrical Connection

5.3 Connection to the Electricity Grid (AC)

5.3.1 Conditions for AC Connection

Connection requirements of the network operator

Always comply with the connection requirements of your network operator.

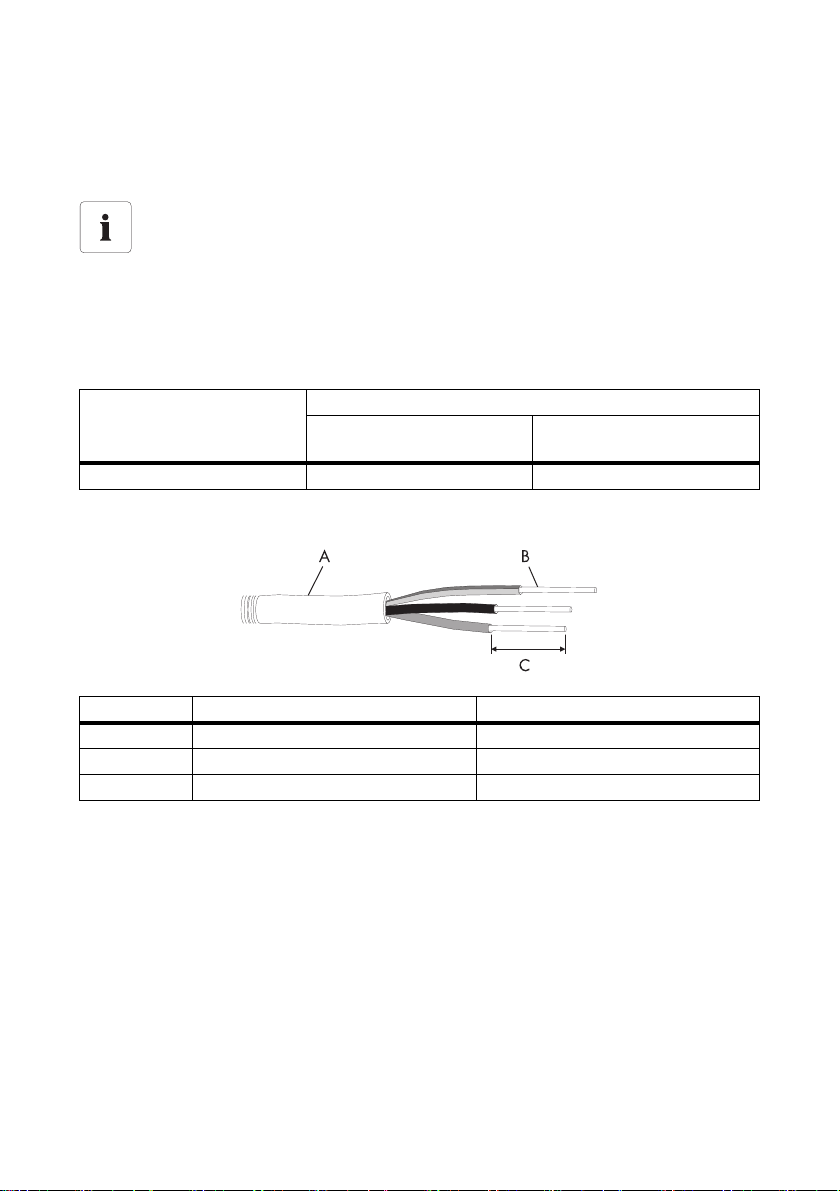

Cable sizing

Use Sunny Design Version 2.0 or higher for sizing the conductor cross-sections

(see Sunny Design program at www.SMA.de/en).

The maximum cable lengths as a function of conductor cross-section are shown in the following table.

Cable cross-section Maximum cable length

WB 3300 / WB 3300-11 /

WB 3300-IT

4 mm² 18.5 m 16 m

Cable requirements

WB 3800 / WB 3800-11 /

WB 3800-IT

Object Description Value

A External diameter 6 mm … 14 mm

B Conductor cross-section 4 mm²

C Stripping length 8 mm

Installation Manual WB33-38-IA-IEN120940 23

Page 24

Electrical Connection SMA Solar Technology AG

Load disconnect unit

You must install a separate miniature circuit-breaker for each inverter in order to ensure that the

inverter can be securely disconnected under load. The maximum permissible fuse protection can be

found in Section 11"Technical Data" (page69).

Detailed information and examples on the design of miniature circuit-breakers are available in the

Technical Information "Miniature circuit-breakers" to be found in the download area of

SMA Solar Technology AG at www.SMA.de/en.

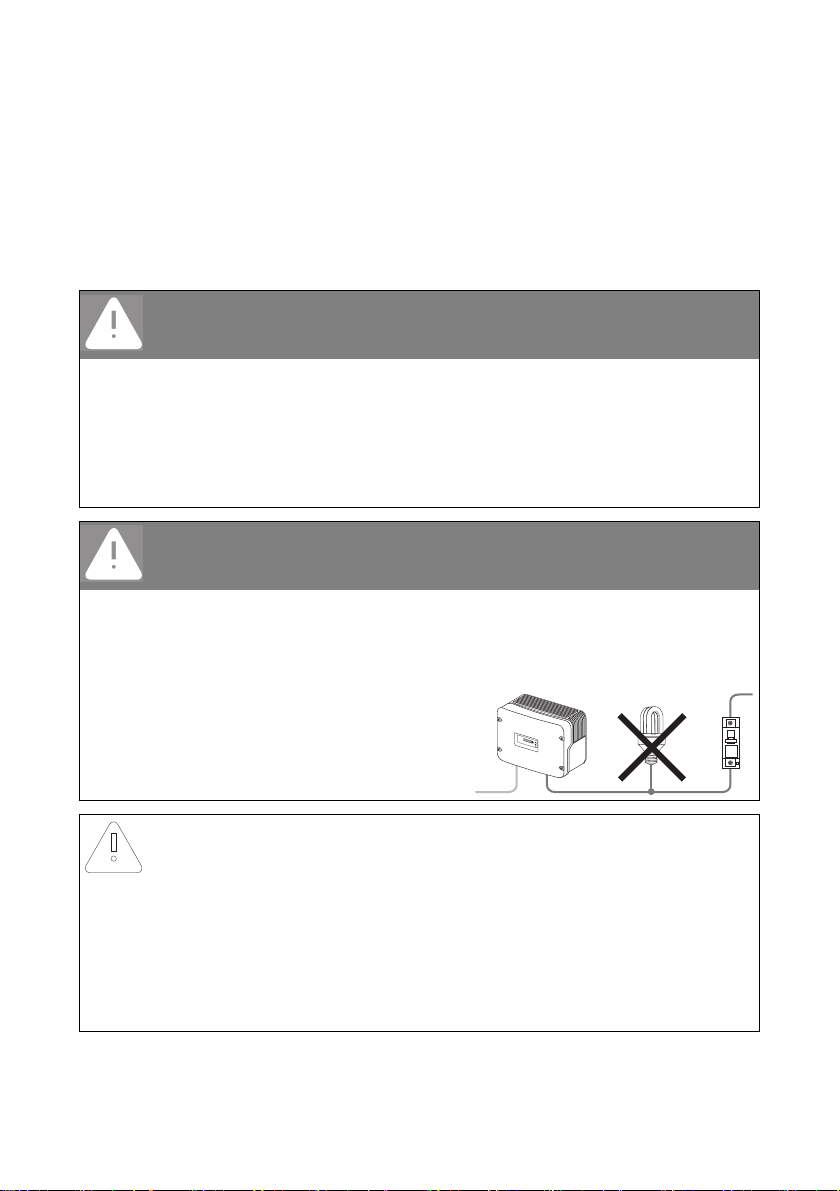

DANGER!

Danger to life by fire.

When more than 1 inverter is connected in parallel to the same miniature circuit-breaker,

the protective function of the miniature circuit-breaker is no longer guaranteed. It can result

in a cable fire or destruction of the inverter.

• Never connect several inverters to the same miniature circuit-breaker.

• Observe the maximum permissible fuse protection of the inverter when selecting the

miniature circuit-breaker.

DANGER!

Danger to life by fire.

When a generator (inverter) and a load are connected to the same miniature circuitbreaker, the protective function of the miniature circuit-breaker is no longer guaranteed.

The currents from the inverter and the grid can accumulate to form overcurrents that are not

detected by the miniature circuit-breaker.

• Never connect the load between the

inverter and the miniature circuit-breaker

without protection.

• Always protect the load separately.

NOTICE!

Damag e to the inverte r due to use of screw-t ype fuses as load disconnection units

A s cre w-t ype fus e, e .g. DIA ZED fus e or NEO ZED fus e, i s no t a s witch-disconnector and thus

may not be used as a load disconnection unit. A screw-type fuse only acts as cable

protection.

Disconnection under load using a screw-type fuse may damage the inverter.

• Use o nly a switch-di sconnecto r or a mi niature circui t-breaker as a l oad dis conne ction

unit.

24 WB33-38-IA-IEN120940 Installation Manual

Page 25

SMA Solar Technology AG Electrical Connection

5.3.2 Connecting the Inverter to the Electricity Grid (AC)

Overview of the AC connection socket

Object Description

A Protective cap for bush insert

BBush insert

C Threaded sleeve with sealing ring for cable diameters from 10 mm … 14 mm

D Sealing ring for cable cross-section from 6 mm … 10 mm

E Pressure screw

Procedure

1. Check that the line voltage is within the permissible voltage range.

The exact operating range of the inverter is specified in the operating parameters. The relevant

document can be found in the download area at www.SMA.de/en, in the "Technical

Description" category of the respective inverter.

2. Disconnect the miniature circuit-breaker and secure against accidental or inadvertent

reconnection.

3. If necessary, replace the sealing ring of the threaded sleeve with the sealing ring provided.

– Pull the sealing ring out of the threaded sleeve.

– Insert the smaller sealing ring.

4. Pass the pressure screw (E) over the AC cable.

Installation Manual WB33-38-IA-IEN120940 25

Page 26

Electrical Connection SMA Solar Technology AG

5. Pass the threaded sleeve (C) with the sealing ring over the AC cable.

6. Bend the AC cable The bending radius must be at

least four times the cable diameter.

7. Shorten the cable.

8. Shorten phase L and neutral conductor

N 4 to 5 mm.

9. Insert the PE conductor (green-yellow) into the

screw terminal with the earth sign on the bush insert

and tighten the screw. The PE conductor must be

longer than the connection wires N and L.

10. Insert neutral conductor N (blue) into screw

terminal N on the bush insert and tighten the screw.

11. Insert phase L (brown or black) into screw terminal

L on the bush insert and tighten the screw.

12. Check that the connection wires are securely

connected.

13. Push the threaded sleeve (C) onto the bush insert

(B) until it audibly snaps into place.

26 WB33-38-IA-IEN120940 Installation Manual

Page 27

SMA Solar Technology AG Electrical Connection

14. Screw the pressure screw (E) tightly onto the threaded sleeve (C). The pressure screw acts as a

seal and to relieve strain.

☑ The AC connection socket is now assembled.

15. Close the bush insert with the protective cap provided if the inverter is not to be connected

immediately.

16. Insert the AC connection socket into the AC socket

on the inverter. If necessary, remove the protective

cap beforehand.

☑ The AC cable is now connected to the inverter.

Installation Manual WB33-38-IA-IEN120940 27

Page 28

Electrical Connection SMA Solar Technology AG

5.3.3 Connecting Additional Earthing

If a second protective conductor, additional earthing or equipotential bonding is required, you can

also earth the inverter on the enclosure.

Overview of additional earthing

Object Description

A Metal bracket on the bottom of the inverter enclosure

B Conical spring washer (included in delivery)

C Terminal lug (M6) with protective conductor

D Washer

E M6x12 cheese-head screw (included in delivery)

Procedure

1. Disconnect the inverter on the AC and DC side as described in Section 7.2"Opening the

Inverter" (page48).

2. Align washer, terminal lug with protective

conductor and conical spring washer on cheesehead screw. The teeth of the conical spring washer

must be facing the metal bracket.

3. Insert the cheese-head screw into the metal bracket

and tighten to a torque of 6 Nm.

4. Check that the contact between the protective conductor and the enclosure is in accordance

with the regulations valid in the country of installation.

28 WB33-38-IA-IEN120940 Installation Manual

Page 29

SMA Solar Technology AG Electrical Connection

5.4 Setting the Display Language

You can set the display language using the rotary switches on the underside of the display assembly

inside the inverter.

For inverters configured to the Italian country standard DK 5940, different switch positions apply. You

can see the standard to which the inverter was set upon delivery on the type label and on the included

supplementary sheet with the default settings. For more information, see the Technical Description

"Operating Parameters" at www.SMA.de/en.

Procedure

1. Open the inverter as described in Section 7.2"Opening the Inverter" (page48).

2. Set the switch to the appropriate language. The

following switch settings apply to all national

standards except for DK 5940:

Language

Rotary switch S2 Rotary switch S1

German B B

English B A

French A B

Spanish A A

The following switch settings apply to inverters that are set to the Italian national standard

DK 5940:

Language

Rotary switch S2 Rotary switch S1

Italian B A

English A A

3. Close the inverter as described in Section 7.3"Closing the Inverter" (page50).

☑ The display language is now set.

Installation Manual WB33-38-IA-IEN120940 29

Page 30

Electrical Connection SMA Solar Technology AG

5.5 Connecting the Small Wind Turbine System (DC)

5.5.1 Conditions for DC connection

• The connection cables of the small wind turbine system must be fitted with connectors.

The DC connectors for the DC connection are included in the delivery.

• The following limit values must not be exceeded at the DC input of the inverter:

Maximum input voltage Maximum input current

500 V 20 A

DANGER!

Risk of lethal electric shock or fire

The maximum possible input current is limited by the connectors used. If the connectors are

overloaded, an electric arc may occur, thus causing a fire risk.

• Ensure that the input current does not exceed the maximum through-fault current of

the connectors used.

NOTICE!

Destruction of the inverter due to overvoltage

If the voltage of the small wind turbine system exceeds the maximum input voltage of the

inverter, the inverter can be destroyed by overvoltage. This will void all warranty claims.

• Install overvoltage protection, e.g. Windy Boy Protection Box, between the small

wind turbine system and the inverter.

30 WB33-38-IA-IEN120940 Installation Manual

Page 31

SMA Solar Technology AG Electrical Connection

5.5.2 Assembling the DC Connectors

For connection to the inverter, all connection cables of the small wind turbine system must be fitted

with the supplied DC connectors.

Assemble the DC connectors as follows. Ensure the connectors have the correct polarity.

The DC connectors are marked with the symbols "+" and " − ".

Cable requirements

• Use a PV1-F cable.

Procedure

1. Insert the stripped cable into the plug up to the stop.

2. Press the clamping bracket down until it audibly

snaps into place.

Installation Manual WB33-38-IA-IEN120940 31

Page 32

Electrical Connection SMA Solar Technology AG

3. Ensure that the cable is correctly positioned:

Result What to do

☑ If the stranded wire is visible in the chamber

• Proceed to step 4.

of the clamping bracket, the cable is

correctly positioned.

☑ If the stranded wire is not visible in the

chamber, the cable is not correctly

positioned.

Release the clamping bracket. Do this by

•

inserting a screwdriver (blade width: 3.5 mm)

into the clamping bracket to lever it open

.

• Remove the cable and go back to step 1.

4. Push the cable gland up to the thread and fasten to a torque of 2 Nm.

☑ The DC connectors are now assembled and can be connected to the inverter as described in

Section 5.5.4"Connecting the Small Wind Turbine System (DC)" (page34).

32 WB33-38-IA-IEN120940 Installation Manual

Page 33

SMA Solar Technology AG Electrical Connection

5.5.3 Opening DC Connectors

1. Unscrew the cable gland.

2. Release the DC connector. To do so, insert a

screwdriver (blade width: 3.5 mm) into the lateral

catch and lever it open.

3. Carefully pull the DC connector apart.

4. Release the clamping bracket. Do this by inserting

a screwdriver (blade width: 3.5 mm) into the

clamping bracket to lever it open.

5. Remove the cable.

☑ The cable is now detached from the DC connector.

Installation Manual WB33-38-IA-IEN120940 33

Page 34

Electrical Connection SMA Solar Technology AG

5.5.4 Connecting the Small Wind Turbine System (DC)

DANGER!

Danger to life due to high voltages in the inverter

• Before connecting the small wind turbine system, ensure that it is not running.

1. Connect the assembled DC connectors to the inverter.

☑ The DC connectors click audibly into position.

To release the DC connectors, see Section 7.2"Opening the Inverter" (page48).

34 WB33-38-IA-IEN120940 Installation Manual

Page 35

SMA Solar Technology AG Electrical Connection

+

1

2

+

+

NOTICE!

Risk of damage to the inverter by moisture penetration

The inverter is only properly sealed when all the unused DC inputs are closed with DC plug

connectors and sealing plugs:

• DO NOT insert the sealing plugs DIRECTLY into the DC inputs on the inverter.

•For unused DC plug connectors, push

down the clamping bracket and push the

swivel nut up to the thread.

• Insert the sealing plug into the

DC connector.

• Tighten the DC connector (torque: 2 Nm).

• Insert the DC plug connectors with sealing

plugs into the corresponding DC inputs on

the inverter.

☑ The DC connectors click audibly into

position.

2. Ensure that all DC connectors are securely in place.

☑ The small wind turbine system is now connected.

You can now commission the inverter as described in Section 6"Commissioning" (page39).

The following connections are optional.

Installation Manual WB33-38-IA-IEN120940 35

Page 36

Electrical Connection SMA Solar Technology AG

5.6 Communication

The inverter is equipped with a slot for communication interfaces which enable it to communicate with

data loggers (e.g., Sunny WebBox) or a PC with appropriate software (e.g., Sunny Explorer).

Refer to the communication interface manual for a detailed wiring diagram and installation

instructions.

The inverter's active power can be limited or the displacement power factor cos φ can be set

externally using the Power Reducer Box by SMA Solar Technology AG. You will find detailed

information on active power limitation and on setting the displacement power factor cos φ in the

technical description "Operating Parameters" at www.SMA.de/en.

5.7 Setting the Grid and Country Parameters

Changing grid-relevant parameters and country parameters

To change grid-relevant parameters, you need a personal access code – the so-called

SMA Grid Guard code. The application form for the personal access code is available in

the download area at www.SMA.de/en, in the "Certificate" category of the respective

inverter.

Confirm the changes to these parameters with your network operator.

A detailed description of the operating parameters for the inverter is available in the download area

at www.SMA.de/en in the category "Technical Description" of the respective inverter.

5.7.1 Setting the Installation Country

Using the "Default" parameter, you can set the country of installation and/or the grid connection

standard valid for that country via a communication product (e.g., Sunny WebBox) or a PC with

corresponding software (e.g., Sunny Data Control or Sunny Explorer). However, this is only required

if the inverter was originally ordered for another country. You can see the standard to which the

inverter was set upon delivery on the type label and on the included supplementary sheet with the

default settings.

36 WB33-38-IA-IEN120940 Installation Manual

Page 37

SMA Solar Technology AG Electrical Connection

5.7.2 Setting to Stand-alone Grid Operation

To operate the inverter in an stand-alone system with Sunny Island, you must set the inverter via the

"Default" parameter to stand-alone grid operation ("OFF-Grid").

There are several ways of setting the inverter to stand-alone grid operation:

• Setting via Sunny WebBox

or

• Setting via Sunny Data Control or Sunny Explorer

DANGER!

Danger to life due to high voltages in the event of electricity grid failure

If you set the inverter to stand-alone grid operation, it does not fulfil any country-specific

standards or guidelines. If grid failure occurs, there will consequently be a danger of

backfeed.

• Neve r operate t he inverter directl y on th e elect ricity gri d when set to stand-alone grid

operation.

Installation Manual WB33-38-IA-IEN120940 37

Page 38

Electrical Connection SMA Solar Technology AG

5.8 Polynomial Curve

The polynomial curve is a programmable power curve which is dependent on the DC input voltage.

By adapting the default polynomial curve to the small wind turbine system being used, you can

optimise the energy output of the system.

To adapt the polynomial curve of the inverter to the wind turbine system being used, you can change

the following parameters on the PC with the "Windy Boy Setup Tool" (www.SMA.de/en):

•Vpv-Start

• UdcWindStart

• Wind_a0 ... Wind_a3

•Pmax

•P-Wind-Ramp

•KP-Wind-Reg

•KI-Wind-Reg

•T-Stop

A description of the operating parameters is available in the download area at www.SMA.de/en in

the category "Technical Description" of the respective inverter.

The inverter regulates its output power according to the generator voltage. The following diagram

shows the function of a typical polynomial curve in a WB 3300 / WB 3300-11 / WB 3800 /

WB 3800-11. Here, the AC power fed in is depicted as a function of the DC input voltage of the

inverter.

38 WB33-38-IA-IEN120940 Installation Manual

Page 39

SMA Solar Technology AG Commissioning

6 Commissioning

6.1 Commissioning the Inverter

1. Check the following requirements before commissioning:

– Correct mounting and connection of the inverter.

– Appropriately sized miniature circuit-breaker.

– Correct earthing of the small wind turbine system in accordance with the instructions of the

manufacturer.

– The rectifier and overvoltage protection (e.g. Windy Boy Protection Box) are installed

between the small wind turbine system and the inverter.

– Unused DC inputs are closed with the corresponding DC connectors and sealing plugs

2. Switch on the miniature circuit-breaker.

3. Commission the small wind turbine system in accordance with the instructions of the

manufacturer.

☑ All 3 LEDs on or flashing: the start-up phase commences.

☑ Green LED on: commissioning successful.

or

☑ Green LED flashing: grid connection conditions have not yet been reached. Wait until the

green LED is permanently on.

or

☑ The red or yellow LED lights up or flashes: a disturbance has occurred. Proceed to step 3.

Object Description

A Green LED: operation

B Red LED: earth fault or varistor

defective

C Yellow LED: disturbance

Self-test in accordance with DK 5940, Ed. 2.2 during initial start-up

(applies to Italy only)

The Italian DK 5940 standard prescribes that an inverter can only operate on the electricity

grid if the disconnection times for overvoltage, undervoltage, minimum frequency and

maximum frequency have been checked.

Start the self-test as described in Section 6.3"Self-Test in Accordance with DK 5940, Ed.

2.2 (Applies to Italy Only)" (page41). The test takes approx. 8 minutes.

4. Read S ection 9"Troubl eshoot ing" (page56) and if n ecessary eliminate the fault or disturbance.

Installation Manual WB33-38-IA-IEN120940 39

Page 40

Commissioning SMA Solar Technology AG

SB xxx

WRxxx

Sunny Boy xxx

WRxx

6.2 Display Messages During the Start-up Phase

• After commissioning, the inverter displays the

device type in the start-up phase.

• A fte r 5 seco nds or a fu rth er tap o n th e enclos ure lid,

the inverter displays the firmware version of the

internal processors.

• A fte r a furt her 5 secon ds o r an other t ap, the inv ert er

displays the configured country standard

(example: "VDE-AR-N4105").

Show display messages again (valid from Firmware Version 4.00)

If you want to view the display messages of the start-up phase again during operation, tap

the enclosure lid twice in quick succession.

40 WB33-38-IA-IEN120940 Installation Manual

Page 41

SMA Solar Technology AG Commissioning

6.3 Self-Test in Accordance with DK 5940, Ed. 2.2 (Applies to Italy Only)

6.3.1 Starting the Self-Test by Tapping

You can start the check of the disconnection times by tapping on the enclosure lid. The prerequisite

for this is that the inverter country setting has been set to Italy (IT/DK5940) or "trimmed". Proceed as

follows for checking the disconnection times:

1. Connect the small wind turbine system to the inverter. The inverter can only initialise once the

small wind turbine system is producing enough power.

2. Connect the inverter on the AC side. To do this, you have to make the AC connection

(AC plug or direct connection) and switch on the circuit-breaker of the grid feed cable

(fuse or miniature circuit-breaker).

3. The inverter is now in the initialisation phase, i.e. all three LEDs are simultaneously on.

Start the self-test immediately after all three LEDs have gone out by tapping on the display of

the inverter.

4. The display queries whether you would like to start

the test sequence. Tap on the display again within

30 seconds to confirm.

Once you have started the test sequence, the inverter

successively checks the disconnection times for overvoltage, undervoltage, maximum frequency and

minimum frequency. During the tests, the values described in Section 6.3.2"Completion of the Selftest" (page42) appear in the display.

Installation Manual WB33-38-IA-IEN120940 41

Page 42

Commissioning SMA Solar Technology AG

6.3.2 Completion of the Self-test

Note the values which are displayed during the self-test. These values must be entered in a test report.

The test results of the individual tests are displayed three times in succession. Each display message

appears for 10 seconds.

During the self-test, the upper and lower disconnection thresholds for each protective function are

subject to linear adjustment with a modification of 0.05 Hz/s and 0.05 Vn/s for the frequency and

voltage monitoring. As soon as the actual measured value exceeds the permitted range (adjusted

disconnection threshold), the inverter disconnects from the electricity grid. In this way, the inverter

determines the reaction time and the self-test is performed.

Overvoltage test

The inverter begins with the overvoltage test. During the

test sequence, the voltage limit applied is shown in the

display of the inverter.

The voltage is reduced step by step until the

disconnection threshold is reached and the inverter

disconnects from the electricity grid.

Once the inverter has disconnected from the electricity grid, the display alternates between the

following values:

•Disconnection value,

•Calibration value,

•Reaction time,

• Current line voltage.

42 WB33-38-IA-IEN120940 Installation Manual

Page 43

SMA Solar Technology AG Commissioning

Undervoltage test

After the overvoltage test, the inverter performs the

undervoltage test. During the test sequence, the current

calibration value of the voltage limit applied is shown in

the display of the inverter.

The voltage is increased step by step until the

disconnection threshold is reached and the inverter

disconnects from the electricity grid.

Once the inverter has disconnected from the electricity grid, the display alternates between the

following values:

•Disconnection value,

•Calibration value,

•Reaction time,

• Current line voltage.

Installation Manual WB33-38-IA-IEN120940 43

Page 44

Commissioning SMA Solar Technology AG

Maximum frequency

In the thi rd s tep , the inv ert er t est s the max imu m fr equ enc y.

During the test sequence, the frequency limit applied is

shown in the display of the inverter.

The frequency is reduced step by step until the

disconnection threshold is reached and the inverter

disconnects from the electricity grid.

Once the inverter has disconnected from the electricity grid, the display alternates between the

following values:

•Disconnection value,

•Calibration value,

•Reaction time,

• Current power frequency.

44 WB33-38-IA-IEN120940 Installation Manual

Page 45

SMA Solar Technology AG Commissioning

Minimum frequency

Finally, the inverter tests the minimum frequency. During

the test sequence, the frequency limit applied is shown in

the display of the inverter.

The frequency is increased step by step until the

disconnection threshold is reached and the inverter

disconnects from the electricity grid.

Once the inverter has disconnected from the electricity grid, the display alternates between the

following values:

•Disconnection value,

•Calibration value,

•Reaction time,

• Current power frequency.

Once the inverter has carried out all four tests, it switches to the "Turbine Mode". The original

calibration values are then reset and the inverter automatically connects to the electricity grid. If you

wish to carry out the test again, you must switch off the inverter, i.e. disconnect it on the AC and DC

sides, and then restart it. You can then restart the self-test as described in Section 6.3.1"Starting the

Self-Test by Tapping" (page41). The inverter restarts the test sequence as described in Section

6.3.2"Completion of the Self-test" (page42).

Installation Manual WB33-38-IA-IEN120940 45

Page 46

Commissioning SMA Solar Technology AG

6.4 Operating States of the Inverter

Start-Up Procedure

Providing that the inverter is supplied with sufficient voltage and power, the three LEDs on the inverter

light up simultaneously, indicating that the start-up process is ongoing.

As soon as the DC input voltage reaches the value configured for the parameter "Vpv-Start", the

inverter triggers several self-tests, measuring procedures and synchronization with the electricity grid.

This operating state is indicated on the inverter by the flashing green LED.

Once the DC input voltage has reached the "Vpv-Start" value for the time configured in "T-Start" and

all the tests have been completed successfully, the inverter connects to the electricity grid and the

green LED comes on permanently. The inverter then switches to characteristic-curve operation, and

regulates the input current according to the generator voltage.

Characteristic-Curve Operation

After the start-up procedure, the inverter switches to characteristic-curve operation and regulates the

input current according to the generator voltage.

The inverter then begins to exert a load on the small wind turbine system, draws power from the system

according to the input voltage present, and then feeds it into the electricity grid. The maximum power

output corresponds to the maximum AC power of the inverter. However, this can be reduced via the

"Pmax" parameter.

Shutdown Procedure

If wind strength is so low that the DC input voltage falls below an internally calculated value, the

inverter stops feeding energy to the electricity grid for the period defined in "T-Stop". As soon as DC

input voltage increases again, the inverter switches back to characteristic-curve operation.

If the DC input voltage remains below an internally calculated value for the time set in "T-Stop", the

inverter will switch off.

If the DC input voltage is no longer sufficient to supply the on-board electronics with power, the

inverter switches off immediately.

46 WB33-38-IA-IEN120940 Installation Manual

Page 47

SMA Solar Technology AG Opening and Closing

7 Opening and Closing

7.1 Safety

DANGER!

Electric shock due to high voltages in the inverter. This can result in death or

serious burns.

Before opening the inverter, observe the following:

• Ensure that no voltage is present on the AC side.

• Ensure that neither voltage nor current is present on the DC side.

NOTICE!

Electrostatic discharge can damage the inverter

The internal components of the inverter can be irreparably damaged by electrostatic

discharge.

• Earth yourself before touching any components inside the inverter.

Installation Manual WB33-38-IA-IEN120940 47

Page 48

Opening and Closing SMA Solar Technology AG

7.2 Opening the Inverter

1. Stop the small wind turbine system and secure against restarting.

2. Disconnect the miniature circuit-breaker and secure against accidental or inadvertent

reconnection.

3. Use a current probe to make sure that no current is

present in the DC cables.

☑ If current is present, check the installation.

4. Release and disconnect all DC connectors. To do

this, insert a flat-blade screwdriver (blade width:

3.5 mm) into one of the side slots and pull the DC

plug connectors straight out. Take care

NOT TO PULL ON THE CABLE.

☑ All DC connectors are now disconnected from the inverter. The inverter is completely

disconnected from the small wind turbine system.

5. Ensure that no voltage is present at the DC connectors on the inverter.

☑If voltage is present, check the installation.

6. Pull out the AC plug.

48 WB33-38-IA-IEN120940 Installation Manual

Page 49

SMA Solar Technology AG Opening and Closing

7. Check whether all LEDs and the display have gone out.

DANGER!

Danger to life due to high voltages in the inverter

The capacitors in the inverter take 15 minutes to discharge.

• Wait 15 minutes before opening the inverter.

8. Loosen the screws of the enclosure lid.

9. Slowly pull the enclosure lid forward and off.

☑ The inverter is now open and de-energised.

Installation Manual WB33-38-IA-IEN120940 49

Page 50

Opening and Closing SMA Solar Technology AG

7.3 Closing the Inverter

1. Attach the enclosure lid using the 4 screws and the

conical spring washers with the toothing facing

toward the enclosure lid. The screws must be

tightened with approximately 6 Nm torque to

ensure that the enclosure is sealed and the lid

properly earthed.

DANGER!

Danger to life due to live enclosure lid

The earthing of the lid is effected by the conical spring washers.

• Attach the conical spring washers for all screws with the toothing facing toward the

enclosure lid.

2. Check the DC connectors for correct polarity and plug them in.

To release the DC connectors see Section 7.2"Opening the Inverter" (page48).

☑ The DC connectors click audibly into position. To release the DC connectors,

see Section 7.2"Opening the Inverter" (page48).

3. Close all unused DC inputs as described in Section 5.5.4"Connecting the Small Wind Turbine

System (DC)" (page34) to ensure that the inverter is properly sealed.

4. Ensure that all DC connectors are securely in place.

50 WB33-38-IA-IEN120940 Installation Manual

Page 51

SMA Solar Technology AG Opening and Closing

5. Connect the AC plug.

6. Switch on the miniature circuit-breaker.

7. Check whether the inverter display and LEDs

indicate a normal operating state

(see Section 6"Commissioning" (page39)).

☑ The inverter is now closed and in operation.

Installation Manual WB33-38-IA-IEN120940 51

Page 52

Maintenance and cleaning SMA Solar Technology AG

8 Maintenance and cleaning

8.1 Cleaning the Inverter

NOTICE!

Damage to the display by use of cleaning agents

• If the inverter is dirty, clean the enclosure lid, the display and the LEDs with clear

water and a cloth only.

8.2 Checking Heat Dissipation

You only need to check the heat dissipation of the inverter if a visual inspection reveals a marked

clogging of the fan guard or the inverter frequently goes into the "Derating" operating state. The

ambient temperature and cooling efficiency determines whether the inverter switches to "Derating".

8.2.1 Cleaning the Fans

If the fan guard is only covered in loose dust, it can be cleaned with a vacuum cleaner. If you do not

achieve satisfactory results with a vacuum cleaner, dismantle the fans for cleaning.

Proceed as follows:

1. Disconnect the inverter on both the DC and AC sides as described in Section 7.2"Opening the

Inverter" (page48).

2. Wait for the fan to stop rotating.

Cleaning the fan guards

3. To dismantle the fan guard:

– Use a screwdriver to press both latches at the

right edge of the fan guard to the right and

dislodge it from the retainer.

– Carefully remove the fan guard.

4. Cl ean the fan g uard wit h a soft bru sh, a paint bru sh,

a cloth or compressed air.

52 WB33-38-IA-IEN120940 Installation Manual

Page 53

SMA Solar Technology AG Maintenance and cleaning

Cleaning the Fans

5. Press the two upper latches towards the rear and

the lower latch towards the front.

6. Remove the fan by pulling it slowly and carefully

downwards.

7. Release and pull out the fan plug inside the inverter.

The fan cables are long enough to let you lift the fan out sufficiently to disconnect the internal

plugs in the inverter.

8. Remove the fan.

9. Clean the fan with a soft brush, a paint brush, or a damp cloth.

NOTICE!

Damage to the fan through use of compressed air

• Do not use compressed air to clean the fan. The fan could be damaged as a result.

10. After cleaning, reassemble everything in reverse order.

11. Check fan operation, as described in the following section.

8.2.2 Checking the Fans

There are two ways to check whether the fan is working:

• Set the "Fan Test" parameter to "1" in the installer mode using Sunny Data Control,

Sunny Explorer or Sunny WebBox.

or

• Plug the provided jumper into the system control board.

Setting Parameters

1. Request an installer password from the SMA Service Line (contact see page 77).

2. Set the "Fan Test" parameter to "1" in the installer mode.

3. Check the air-flow of the fan.

The inverter draws air in from underneath and blows it out at the top left. Listen for any unusual

noise that could indicate incorrect installation or that the fan is defective.

4. After checking the fan, set the "Fan Test" parameter back to "0".

☑ The fan test is now completed.

Installation Manual WB33-38-IA-IEN120940 53

Page 54

Maintenance and cleaning SMA Solar Technology AG

Plugging the Jumper

The inverter recognizes the jumper only after a system restart (i.e. all LEDs must have gone out prior

to restart).

1. Open the inverter as described in Section 7.2"Opening the Inverter" (page48).

2. Plug the provided jumper in the slot on the system control board as shown below.

3. Close the inverter as described in Section 7.3"Closing the Inverter" (page50).

4. Restart the inverter.

5. Check the air-flow of the fan.

The inverter draws air in from underneath and blows it out at the top left. Listen for any unusual

noise that could indicate incorrect installation or that the fan is defective.

6. Remove the jumper. Open and close the inverter as described in Section 7"Opening and

Closing" (page47).

☑ The fan test is now completed.

54 WB33-38-IA-IEN120940 Installation Manual

Page 55

SMA Solar Technology AG Maintenance and cleaning

8.2.3 Cleaning the Ventilation Grids

There are ventilation grids on each side of the inverter. The inverter takes cooling air in from

underneath via the fan and blows it out again through the ventilation grids on the upper left side. To

ensure adequate heat dissipation of the inverter, you only need to clean the left ventilation grid.

Procedure

1. Remove the left ventilation grid.

Insert your finger in the space between the

ventilation grid and the upper part of the enclosure

and remove the ventilation grid laterally.

2. Clean the ventilation grid with a soft brush, a paint

brush or compressed air.

3. Re-attach the ventilation grid to the inverter.

To help you identify the sides, the ventilation grids

are marked on the inside with "rechts/right" and

"links/left".

☑ Cleaning of the ventilation grids is now complete.

NOTICE!

Risk of damage to the inverter through intrusion of insects.

• The ventilation grids must not be removed permanently, because otherwise the

device will not be protected against the intrusion of insects.

Installation Manual WB33-38-IA-IEN120940 55

Page 56

Troubleshooting SMA Solar Technology AG

9 Troubleshooting

If the inverter displays blink codes which differ from those described below, contact the

SMA Service Line.

You will find a description of display messages during operation, status messages and measurement

channels in the user manual provided.

Do not try to carry out any repairs other than those described here. Instead, use

SMA Solar Technology AG's 24-hour replacement service (the inverter will be ready for dispatch at

the freight forwarder within 24 hours) and repair service.

9.1 Blink Codes

Green Red Yellow Status

flashing flashing flashing OK (start-up phase)

permanently on off off OK (feed-in operation)

permanently on off Earth fault or varistor

defective

permanently on OK (initialisation)

flashing rapidly

(3 x per second)

flashing slowly

(1 x per second)

goes off briefly

(approx. 1 x per second)

off off off OK

off off OK (stop)

permanently on off Earth fault or varistor

defective

off off OK (waiting, grid

monitoring)

off off OK (derating)

permanently on off Earth fault or varistor

defective

on / flashing Disturbance

permanently on off Earth fault or varistor

defective

on / flashing Earth fault or varistor

defective and

disturbance

56 WB33-38-IA-IEN120940 Installation Manual

Page 57

SMA Solar Technology AG Troubleshooting

9.2 Error Messages

When a disturban ce occurs, the invert er generat es a me ssage depending on the operating mode and

the type of disturbance detected.

Message Description / Remedial Action

!PV-Overvoltage!

!DISCONNECT DC!

ACVtgRPro The 10-minute-average line voltage is no longer within the permissible

Bfr-Srr Internal measurement comparison fault or hardware defect.

DC Overvoltage

Disconnect the small wind turbine system from the inverter immediately.

1. Stop the small wind turbine system.

2. Disconnect the miniature circuit-breaker.

3. Disconnect the DC connectors.

4. Check the DC voltage:

– If the DC voltage is above the maximum input voltage, check

the plant design.

– If the DC voltage is below the maximum input voltage,

reconnect the small wind turbine system to the inverter as

de scr ibed in Sec tio n 5.5.4 "Co nnectin g th e Small W ind Turb ine

System (DC)" (page34).

If the message is repeated, disconnect the inverter again and contact the

SMA Service Line.

range. This can be caused by one of the following:

• The line voltage at the termination point is too high.

• The grid impedance at the termination point is too high.

The inverter disconnects to assure compliance with the power quality of

the electricity grid.

• Check the line voltage at the termination point of the inverter:

– If, due to the local grid conditions, the line voltage is 253 V or

more, ask the network operator whether the voltage at the feedin point can be adjusted, or whether they will accept an

adjustment of the limiting value of parameter "ACVtgRPro" for

power quality monitoring.

– If the line voltage is permanently within the tolerance range and

this error message is still displayed, contact the SMA Service

Line.

• Contact the SMA Service Line if this disturbance occurs frequently.

Installation Manual WB33-38-IA-IEN120940 57

Page 58

Troubleshooting SMA Solar Technology AG

Message Description / Remedial Action

Derating The "Derating" operating state is a normal operating state which may

occur occasionally and can have several causes.

Once the inverter enters the "Derating" operating state, it will display the

"Derating" warning until the next total shutdown of the device

(when there is not enough wind).

• Check the heat dissipation as described in Section 8.2"Checking

Heat Dissipation" (page52).

dZac-Bfr

dZac-Srr

Sudden changes in grid impedance are outside the permissible range

("Bfr" or "Srr" are internal messages of no relevance for the user).

The inverter disconnects from the electricity grid for safety reasons.

• Check grid impedance and observe how often major deviations

occur.

– If repeated frequency fluctuations occur and this is causing

"dZac-Bfr" or "dZac-Srr" disturbances, ask the network operator

to agree to a modification of the operating parameters

(dZac-Max).

– Discuss any changes to the operating parameter with the

SMA Service Line.

EEPROM Transitional disturbance while data is being written to or read from

EEPROM. The data has no relevance to safe operation.

• This disturbance has no effect on the performance of the inverter.

EEPROM dBh EEPROM data is defective, the inverter has switched off because the loss

of data has disabled important functions of the inverter.

• Contact the SMA Service Line.

EeRestore One of the duplicate records in the EEPROM is defective and has been

restored without loss of data.

• This error message is only for information purposes and has no

effect on the performance of the inverter.

Fac-Bfr

Fac-Srr

FacFast

The power frequency is no longer within the permissible range

("Bfr" or "Srr" is an internal message of no relevance for the user). The

inverter disconnects from the electricity grid for safety reasons.

• If the power frequency is within the tolerance range and the faults

"Fac-Bfr", "Fac-Srr" or "FacFast" are displayed frequently, contact

the SMA Service Line.

Imax Overcurrent on the AC side. This message is displayed when the current

on the AC grid is greater than specified.

• Check the system design and grid conditions.

58 WB33-38-IA-IEN120940 Installation Manual

Page 59

SMA Solar Technology AG Troubleshooting

Message Description / Remedial Action

K1-Close

K1-Open

Error during relay test.

• Contact the SMA Service Line if this disturbance occurs frequently

or several times in a row.

MSD-Zac

MSD-Vac

Internal measurement comparison fault or hardware defect.

• Contact the SMA Service Line if this disturbance occurs frequently.

MSD-Timeout

MSD-Zac

Offset The "Offset" operating state is a normal operating state that occurs prior

to grid monitoring.

If "Offset" is displayed as an error, there is a disturbance in data logging.

• Contact the SMA Service Line if this disturbance occurs frequently.

Riso Th e electric al insulation b etween the smal l wind turb ine sys tem and earth

is faulty. The resistance between the DC plus and/or DC minus

connection and earth is outside the defined limit range.

• Check the insulation of the small wind turbine system.

• Chec k the small wind turbine sy stem for ea rth faults as desc ribed in

Section 9.3.1"Checking the Small Wind Turbine System for Earth

Faults" (page62).

ROM The inverter firmware is faulty.

• Contact the SMA Service Line if this disturbance occurs frequently.

Shutdown Temporary inverter disturbance.

• Contact the SMA Service Line.

Trafo-Temp-F Temperatures in the transformer have excee ded the per missible limit. The

inverter stops feeding into the grid until the temperature reverts to within

the permissible range.

• If this problem recurs, check the heat dissipation of the inverter, as

described in Section 8.2"Checking Heat Dissipation" (page52).

Trafo-Temp-W I f th e transf orm er r eac hes an u nac ceptabl y hi gh t emp erature , th e inverter

stops feeding energy to the grid until the temperature has reverted to

normal and the system can begin feeding into the grid again.

The "Trafo-Temp-W" warning is displayed until the device is completely

disconnected.

• Check the heat dissipation as described in Section 8.2"Checking

Heat Dissipation" (page52).

Installation Manual WB33-38-IA-IEN120940 59

Page 60

Troubleshooting SMA Solar Technology AG

Message Description / Remedial Action

Vac-Bfr

Vac-Srr

The line voltage is no longer within the permissible range ("Bfr" or "Srr" is

an internal message of no relevance for the user). This disturbance can

be caused by any of the following conditions:

• Grid disconnected (miniature circuit-breaker, fuse),

• AC cable is interrupted or

• AC cable is highly resistive.

The inverter disconnects from the electricity grid for safety reasons.

• Check the line voltage and grid connection on the inverter.

• If the line voltage is outside the permissible range because of local

grid conditions, ask the network operator if the voltages can be

adjusted at the feed-in point or if they will accept adjustments to the

values of the monitored operating limits

(operating parameters: Vac-Min and Vac-Max).

• If the line voltage is within the tolerance range, yet "Vac-Bfr" or

"Vac-Srr" faults are still displayed, contact the SMA Service Line.

VpvMax

Vpv-Max

Overvoltage at the DC input. This could damage the inverter.

Disconnect the small wind turbine system from the inverter immediately.

1. Stop the small wind turbine system.

2. Disconnect the miniature circuit-breaker.

3. Remove all DC connectors.

4. Check the DC voltage:

– If the DC voltage is above the maximum input voltage, check

the plant design.

– If the DC voltage is below the maximum input voltage,

reconnect the small wind turbine system to the inverter as

de scr ibed in Sec tio n 5.5.4 "Co nnectin g th e Small W ind Turb ine

System (DC)" (page34).

If the message is repeated, disconnect the inverter again and contact the

SMA Service Line.

Watchdog

Watchdog Srr

Internal disturbance of the program sequence.

• Contact the SMA Service Line if this disturbance occurs frequently.

60 WB33-38-IA-IEN120940 Installation Manual

Page 61

SMA Solar Technology AG Troubleshooting

Message Description / Remedial Action

Zac-Bfr

Zac-Srr

The grid impedance is outside the permissible range. The suffixes

"Bfr" und "Srr" are not relevant.

The inverter disconnects from the electricity grid for safety reasons. The

impedance is made up of both the grid impedance and the impedance

of the inverter AC cables.

• Check the grid impedance and grid connection at the inverter.

• Use an AC cable with an adequate cross-section

(= low impedance) as described in Section 5.3.2"Connecting the

Inverter to the Electricity Grid (AC)" (page25). If required, check

and re-tighten the screws on the AC plugs.

• Check the grid impedance and the AC connection on the inverter.

Use a cable with an adequate cross-section (= low impedance).

Observe the relevant advice in Section 5.3"Connection to the

Electricity Grid (AC)" (page23).

• If this fault recurs, please contact the SMA Service Line.

Installation Manual WB33-38-IA-IEN120940 61

Page 62

Troubleshooting SMA Solar Technology AG

9.3 Red LED is Permanently On

If the red LED is permanently on during operation, this points either to an earth fault in the system or

at least one of the overvoltage protection varistors being defective.

In deliberately earthed systems, the red LED lights up as soon as the inverter has been commissioned.

However, this has no impact on the function of the inverter. Before you check the small wind turbine

system for an earth fault, check whether deliberate earthing has been carried out.

In deliberately earthed small wind turbine systems, check from time to time that the varistors in the

inverter are working properly, since a varistor fault can no longer be displayed.

9.3.1 Checking the Small Wind Turbine System for Earth Faults

DANGER!

Danger to life due to high voltages in the inverter

• Stop the small wind turbine system and secure against restarting.

• Disconnect the miniature circuit-breaker and secure against accidental or inadvertent

reconnection.

1. Wait until LEDs have gone out.

DANGER!

Danger to life due to high voltages in the inverter

The capacitors in the inverter take 15 minutes to discharge.

• Wait 15 minutes before opening the inverter.

2. Use a current probe to make sure no current is

present in the DC cables.

☑ If current is present, check the installation.

62 WB33-38-IA-IEN120940 Installation Manual

Page 63

SMA Solar Technology AG Troubleshooting

3. Release and disconnect all DC connectors. To do

this, insert a flat-blade screwdriver

(blade width: 3.5 mm) into one of the side slots and

pull the DC plug connectors out. Take care

NOT TO PULL ON THE CABLE.

4. Remove the AC connection socket from the inverter.

5. Disconnect L1, L2 and L3 of the small wind turbine system from the Windy Boy Protection Box.

6. Measure the resistance between the phases of the small wind turbine system and the earth

potential:

– Measure the resistance between L1 of the small wind turbine system and the earth potential.

– Measure the resistance between L2 of the small wind turbine system and the earth potential.

– Measure the resistance between L3 of the small wind turbine system and the earth potential.

Result What to do

The measured resistance is virtually infinite.

☑ There is no earth fault in the small wind

turbine system.

There is probably an earth fault in the

Windy Boy Protection Box or in the supply

cables to the inverter.

• Disconnect the Windy Boy Protection Box

from the inverter and measure the

resistance of all connections and the earth

potential.

Installation Manual WB33-38-IA-IEN120940 63

Page 64

Troubleshooting SMA Solar Technology AG

Result What to do

The measured resistance is very small

(< 10 Ω ).

☑ There is an earth fault in the small wind

turbine system.

• Have the installer of the small wind

turbine system eliminate the earth fault

before reconnecting the system to the

inverter.

64 WB33-38-IA-IEN120940 Installation Manual

Page 65

SMA Solar Technology AG Troubleshooting

9.3.2 Checking the Function of the Varistors

Varistors are wear parts. Their functional efficiency diminishes with age or repeated strain as a result

of overvoltages. It is therefore possible that one of the thermally monitored varistors has lost its

protective function.

Position of the varistors

The position of the varistors can be located with the help of the diagram below. Note the

following assignment of the terminals:

• Terminal A: outer terminal

(varistor connection with crimp)

• Terminal B: middle terminal

• Terminal C: outer terminal

(varistor connection without crimp)

You can check the function of the varistors as follows:

1. Open the inverter as described in Section 7.2"Opening the Inverter" (page48).

2. Use a multimeter to check that in each of the

installed varistors there is a conductive connection

between terminals B and C.

Result What to do

There is a conductive connection. There is presumably a different error in the inverter.

1. Close the inverter as described in Section

7.3"Closing the Inverter" (page50).

2. Contact the SMA Service Line.

Installation Manual WB33-38-IA-IEN120940 65

Page 66

Troubleshooting SMA Solar Technology AG

Result What to do

There is no conductive connection.

The respective varistor is defective and must be

replaced.

Varistor failure is generally due to influences that affect

all varistors in a similar manner (temperature, age,

induced overvoltage). SMA Solar Technology AG

recommends that you replace both varistors.

The varistors are specially manufactured for use in the

inverter and are not commercially available. You must

order replacement varistors directly from

SMA Solar Technology AG (see Section 13"Contact"

(page77)).

• For the replacement of the varistors, proceed to

step 3.

NOTICE!

Inverter overvoltage due to faulty varistors. Destruction of the inverter due to

overvoltage

• Procure replacement varistors immediately and replace the defective varistors.

• In systems with a high risk of overvoltage, do not operate inverters with faulty

varistors or no varistors at all.

3. Insert the special insertion tool into the openings of

the terminal contacts (1).

☑ This releases the terminals.

If you have not received an insertion tool to operate

the terminals together with the replacement

varistors, contact SMA Solar Technology AG.

Alternatively, the individual terminal contacts can

be operated using a screwdriver with blade width

3.5 mm.

4. Remove the varistor (2).

5. Insert the new varistor (3).

When installing the new varistor, the pole with the

small loop (crimp) must be mounted in terminal

A (3).

6. Close the inverter as described in Section

7.3"Closing the Inverter" (page50).

☑ Testing and replacement of the varistors is now complete.

66 WB33-38-IA-IEN120940 Installation Manual

Page 67

SMA Solar Technology AG Decommissioning

10 Decommissioning

10.1 Dismantling the Inverter