Page 1

EN

Wind Power Inverters

WINDY BOY 3000TL / 3600TL / 4000TL / 5000TL

Installation Manual

WB3-5TL-21-IA-en-10 | IMEN-WB3-5TL-21 | Version 1.0

Page 2

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information about this document . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Skills of Qualified Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

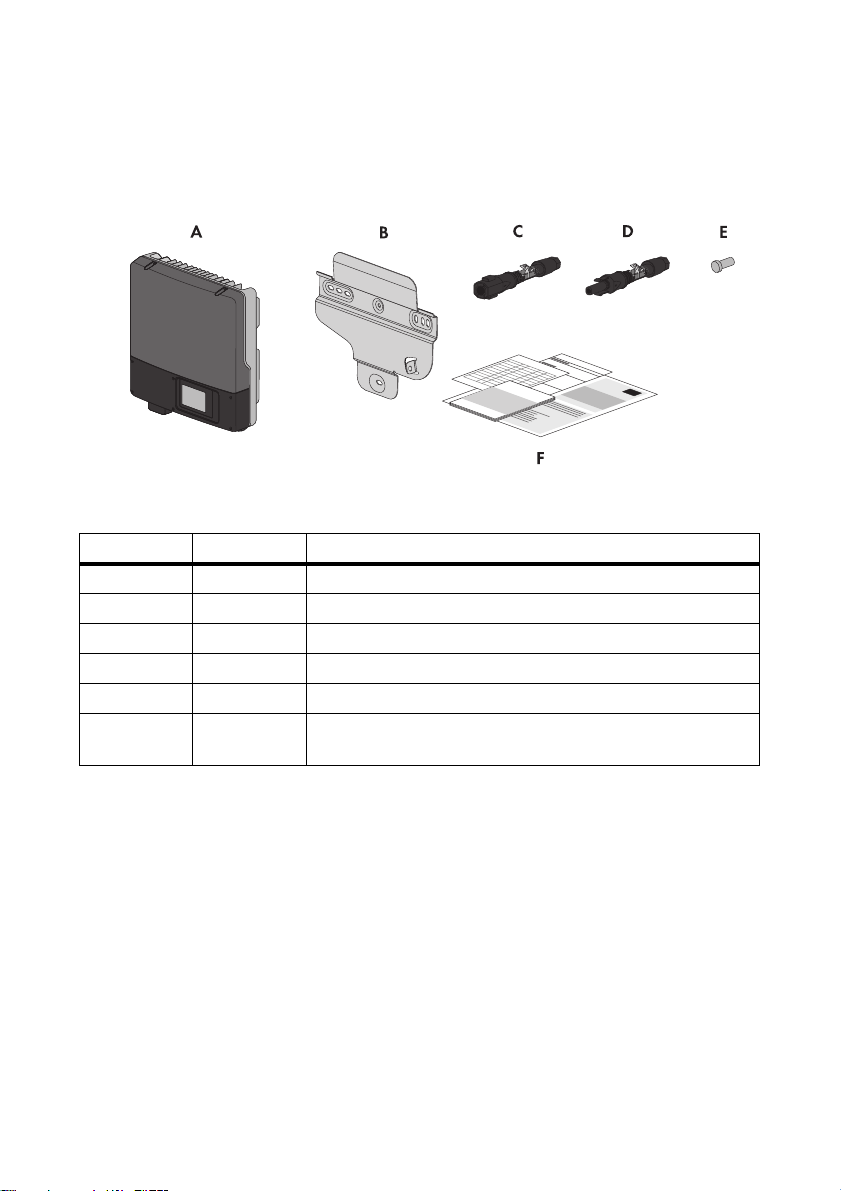

3 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Windy Boy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Bluetooth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Slot for Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.6 Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.7 Slot for Multi-Function Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.8 Grid Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.9 Varistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.10 SMA Grid Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Selecting the Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Mounting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1 Safety during Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Overview of the Connection Area. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2.1 View from Below . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2.2 Interior View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation Manual WB3-5TL-21-IA-en-10 3

Page 4

Table of Contents SMA Solar Technology AG

6.3 AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.1 Conditions for the AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.2 Connecting the Inverter to the Power Distribution Grid . . . . . . . . . . 31

6.3.3 Additional Grounding of the Enclosure . . . . . . . . . . . . . . . . . . . . . . 34

6.4 DC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.1 Connecting the Connection Cables to DC Connectors . . . . . . . . . . 35

6.4.2 Bridging the DC Inputs on the Inverter. . . . . . . . . . . . . . . . . . . . . . . 37

6.4.3 Connecting the Rectifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7 Initial Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Configuring the Country Data Set . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3 Setting the NetID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4 Commissioning the Inverter for the First Time. . . . . . . . . . . . . . . . . . . 46

7.5 For Italy Only: Starting the Self-Test. . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.5.1 Abortion of the Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.5.2 Restarting the Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Changing the Display Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.2 Changing the Plant Password and Plant Time . . . . . . . . . . . . . . . . . . 50

8.3 Adapting the Polynomial Curve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.4 Setting the Deactivation Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.5 Changing the DC Critical Voltage for Feed-in to the

Power Distribution Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.6 Connecting the Inverter to Sunny Portal. . . . . . . . . . . . . . . . . . . . . . . 53

8.7 Setting the Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9 Disconnecting the Inverter from Voltage Sources . . . . . . . . . . 54

10 Recommissioning the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4 WB3-5TL-21-IA-en-10 Installation Manual

Page 5

SMA Solar Technology AG Table of Contents

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.1 LED Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.2 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.2.1 Event Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

11.2.2 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

11.3 Cleaning the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

11.4 Checking the Small Wind Turbine System for Ground Faults . . . . . . 71

11.5 Checking the Function of the Varistors. . . . . . . . . . . . . . . . . . . . . . . . 72

11.6 Replacing the Varistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

12 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.1 Disassembling the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

12.2 Packing the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.3 Disposing of the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

13 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.1 DC/AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.1.1 Windy Boy 3000TL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

13.1.2 Windy Boy 3600TL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13.1.3 Windy Boy 4000TL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13.1.4 Windy Boy 5000TL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13.2 General Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.3 Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.4 Climatic Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.5 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.6 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.7 Grounding Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.8 Data Storage Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

13.9 Multi-Function relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

15 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Installation Manual WB3-5TL-21-IA-en-10 5

Page 6

Table of Contents SMA Solar Technology AG

6 WB3-5TL-21-IA-en-10 Installation Manual

Page 7

SMA Solar Technology AG 1 Information about this document

1 Information about this document

Validity

This document is valid for the following device types as of firmware version 2.10:

• WB 3000TL-21

• WB 3600TL-21

• WB 4000TL-21

• WB 5000TL-21

Target Group

This document is intended for qualified persons. Only qualified personnel with the appropriate skills

are allowed to perform the tasks described in this document (see Section2.2 "Skills of Qualified

Persons", page11).

Additional Information

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

Miniature Circuit-Breaker Technical information

Measured Values and Parameters Technical description

®

SMA Bluetooth ‒ SMA Bluetooth

in Practice

®

SMA Bluetooth

Wireless Technology Technical description

Wireless Technology

Technical information

Installation Manual WB3-5TL-21-IA-en-10 7

Page 8

1 Information about this document SMA Solar Technology AG

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury

Indicates a hazardous situation which, if not avoided, can result in death

or serious injury

Indicates a hazardous situation which, if not avoided, can result in minor

or moderate injury

Indicates a situation which, if not avoided, could result in property damage

Information that is important for a specific topic or goal, but is not

safety-relevant

☐ Indicates an essential requirement for achieving a specific goal

☑ Desired result

✖ A problem that could occur

Typographies

Typography Use Example

bold •Display messages

• Parameters

• Connections

•Elements on an interface

text

• Elements to be selected

• Elements to be entered

[Button] • Button on a user interface • Select

• Select the Set country

standard parameter and

adjust the required

country data set.

[Device selection].

8 WB3-5TL-21-IA-en-10 Installation Manual

Page 9

SMA Solar Technology AG 1 Information about this document

Nomenclature

Complete designation Designation in this document

Torque Torque

Electronic Solar Switch ESS

Small wind turbine system Small wind turbine system, plant

®

SMA Bluetooth

Wireless Technology Bluetooth

Windy Boy Inverter, product

Abbreviations

Abbreviations Designation Explanation

AC Alternating Current ‒

DC Direct Current ‒

EC European Community ‒

EMC Electromagnetic Compatibility ‒

LED Light-Emitting Diode ‒

MSL Mean Sea Level ‒

NetID Network Identification Identification number for

SMA Bluetooth network

PC Personal Computer ‒

PE Protective Earth Protective conductor

SWTS Small Wind Turbine System ‒

VDE Verband der Elektrotechnik Elektronik

Informationstechnik e.V.

Association for Electrical, Electronic

and Information Technologies

Installation Manual WB3-5TL-21-IA-en-10 9

Page 10

2 Safety SMA Solar Technology AG

Windy Boy Protection Box

Windy Boy

power

distribution grid

Small Wind

Turbine System

Load resistor

2 Safety

2.1 Intended Use

The Windy Boy is a transformerless wind power inverter that converts the rectified alternating current

of a small wind turbine system or other energy converters based on permanent magnet electric

generators into alternating current suitable for the grid and feeds this energy into the power

distribution grid or stand-alone grid.

Figure1: Principle of a small wind turbine system with Windy Boy

The Windy Boy is suitable for indoor and outdoor use.

The Windy Boy may only be used with small wind turbine systems or with energy converters based

on permanent magnet electric generators (e.g. water energy plants, CHP plants, diesel generators).

The small wind turbine system or energy converter must be suitable for use with the Windy Boy and

ap pro ved by t he s mal l wi nd t urb ine sys tem or e ner gy c onv ert er m anuf act ure r. S MA S ola r Te chn olo gy

recommends operating Windy Boy together with a small wind turbine system without neutral

grounding.

The Windy Boy must not be connected to a direct current supply grid.

An overvoltage protection must be installed between the Windy Boy and the rectifier to limit the direct

vo lta ge. Use onl y an ove rvo lta ge p rot ect ion tha t is design ed f or the maximum power of the small wind

turbine system. SMA Solar Technology recommends using the Windy Boy Protection Box of type

50 0-1 1. I f you ar e no t using the Windy B oy P rot ect ion Box of t ype 500-11, you must install a capacity

of at least 120 μF between the Windy Boy and the rectifier. A low DC voltage ripple has a positive

effect on the electrical endurance of the inverter.

All components must remain within their permitted operating ranges at all times.

Alternative uses of the Windy Boy not expressly recommended by SMA Solar Technology AG are

not permitted.

The Windy Boy must not be connected in parallel with other inverters on the DC side.

10 WB3-5TL-21-IA-en-10 Installation Manual

Page 11

SMA Solar Technology AG 2 Safety

For safety reasons, it is not permitted to modify the product or install components that are not explicitly

recommended or distributed by SMA Solar Technology AG for this product.

Before carrying out work on the inverter and before the ESS can be removed, the small wind turbine

system must always be stopped and secured against restart. Disconnecting the inverter and removing

the ESS while the small wind turbine system is running can cause damage to the small wind turbine

system and the inverter due to the resulting rapid discharge.

• Do not mount the Windy Boy on flammable construction materials.

• Do not mount the Windy Boy near areas containing highly flammable materials.

• Do not mount the Windy Boy in potentially explosive areas.

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

2.2 Skills of Qualified Persons

The tasks described in this document must be performed by qualified persons only. Qualified persons

must have the following skills:

• Knowledge of how an inverter works and is operated

• Training in how to deal with the dangers and risks associated with installing and using electrical

devices and plants

• Training in the installation and commissioning of electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this document and all safety precautions

2.3 Safety Precautions

Electric Shock

High voltages that can cause fatal electric shocks when touched are present in the live components

of the inverter.

• Prior to pe rforming any work on the inver ter, d isconnec t it from any voltage sou rce as described

in this document (see Section 9).

Burn Hazards

Some parts of the enclosure can become hot during operation.

• Do not touch any parts other than the lower enclosure lid of the inverter during operation.

Electrostatic Discharge

By touching electronic components, you can damage or even destroy the inverter through electrostatic

discharge (ESD).

• Ground yourself before touching any components.

Installation Manual WB3-5TL-21-IA-en-10 11

Page 12

3 Scope of Delivery SMA Solar Technology AG

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

specialty retailer if the scope of delivery is incomplete or damaged.

Figure2: Components included in the scope of delivery

Position Quantity Description

A1Inverter

B 1 Wall mounting bracket

C4Positive DC connector

D4Negative DC connector

E8Sealing plug

F 1 Installation manual, user manual, document set with explanations

and certificates, supplementary sheet with the default settings

12 WB3-5TL-21-IA-en-10 Installation Manual

Page 13

SMA Solar Technology AG 4 Product Description

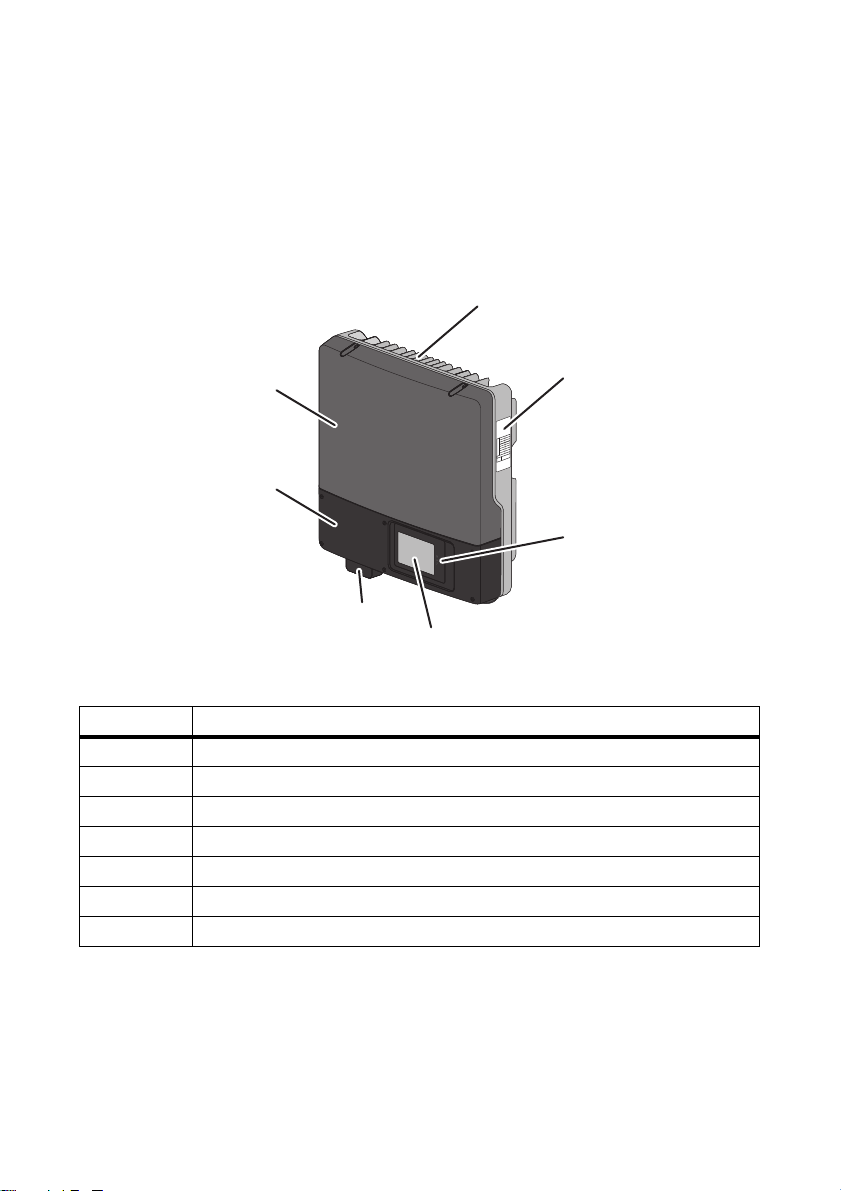

A

B

C

D

E

F

G

4 Product Description

4.1 Windy Boy

The Windy Boy is a transformerless wind power inverter that converts the alternating current of a small

wind turbine system into alternating current suitable for the grid and feeds this energy into the power

distribution grid or stand-alone grid.

Figure3: Design of the Windy Boy

Position Description

A Cooling fins

B Type label

CLEDs

DDisplay

E Electronic Solar Switch (ESS)

FLower enclosure lid

G Upper enclosure lid

Installation Manual WB3-5TL-21-IA-en-10 13

Page 14

4 Product Description SMA Solar Technology AG

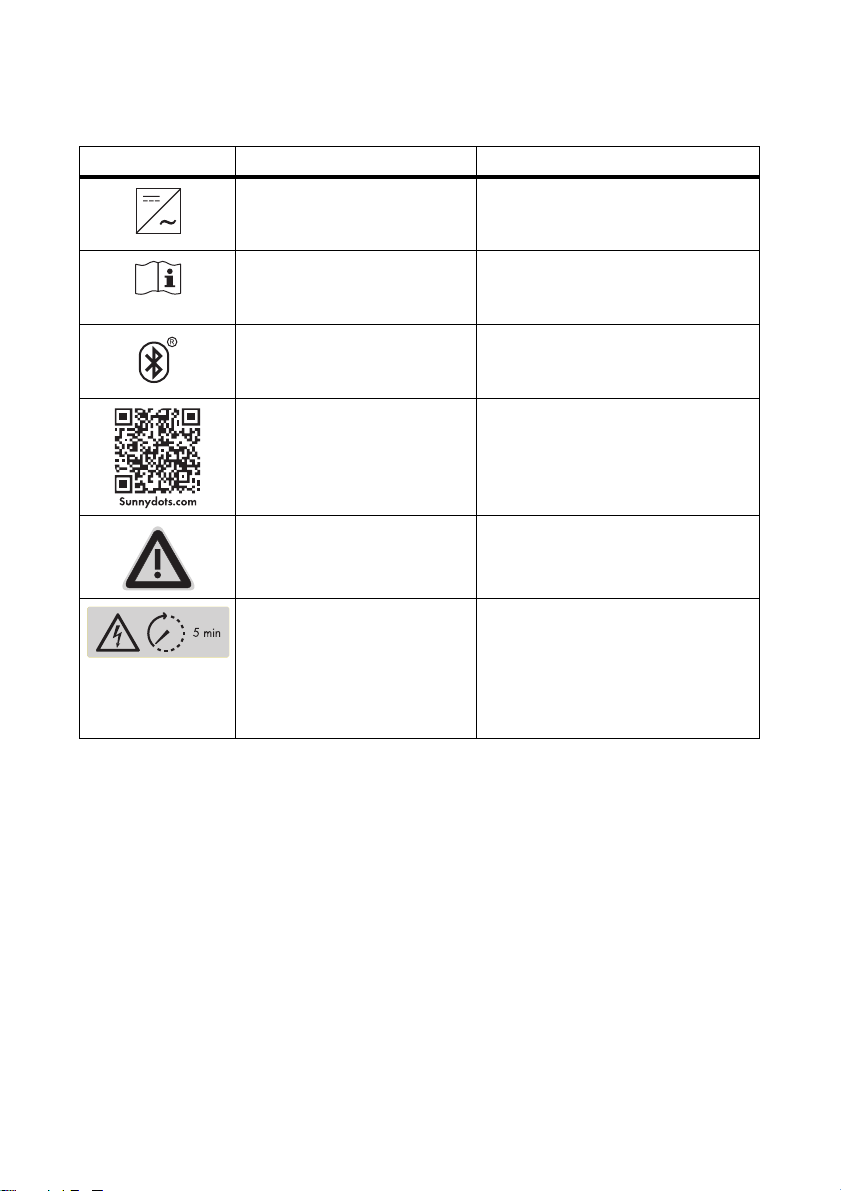

Symbols on the inverter

Symbol Description Explanation

Inverter This symbol defines the function of the

green LED. The green LED indicates the

operating state of the inverter.

Observe documentation This symbol defines the function of the

red LED. The red LED indicates an error.

Read this document to remedy the error.

Bluetooth This symbol defines the function of the

bl ue L ED. The blu e LE D in dic ate s th at the

Bluetooth communication is enabled.

QR Code

®

Danger If a second protective conductor is

The QR Code® refers to the SMA bonus

program (for information on this, see

www.SMA-Bonus.com).

required, also ground the enclosure (see

Section 6.3.3).

Danger to life due to high

voltages in the inverter; observe

waiting time.

High voltages that can cause fatal

electric shocks are present in the live

components of the inverter. Disconnect

the inverter from any voltage sources

before performing any work on it

(see Section 9).

14 WB3-5TL-21-IA-en-10 Installation Manual

Page 15

SMA Solar Technology AG 4 Product Description

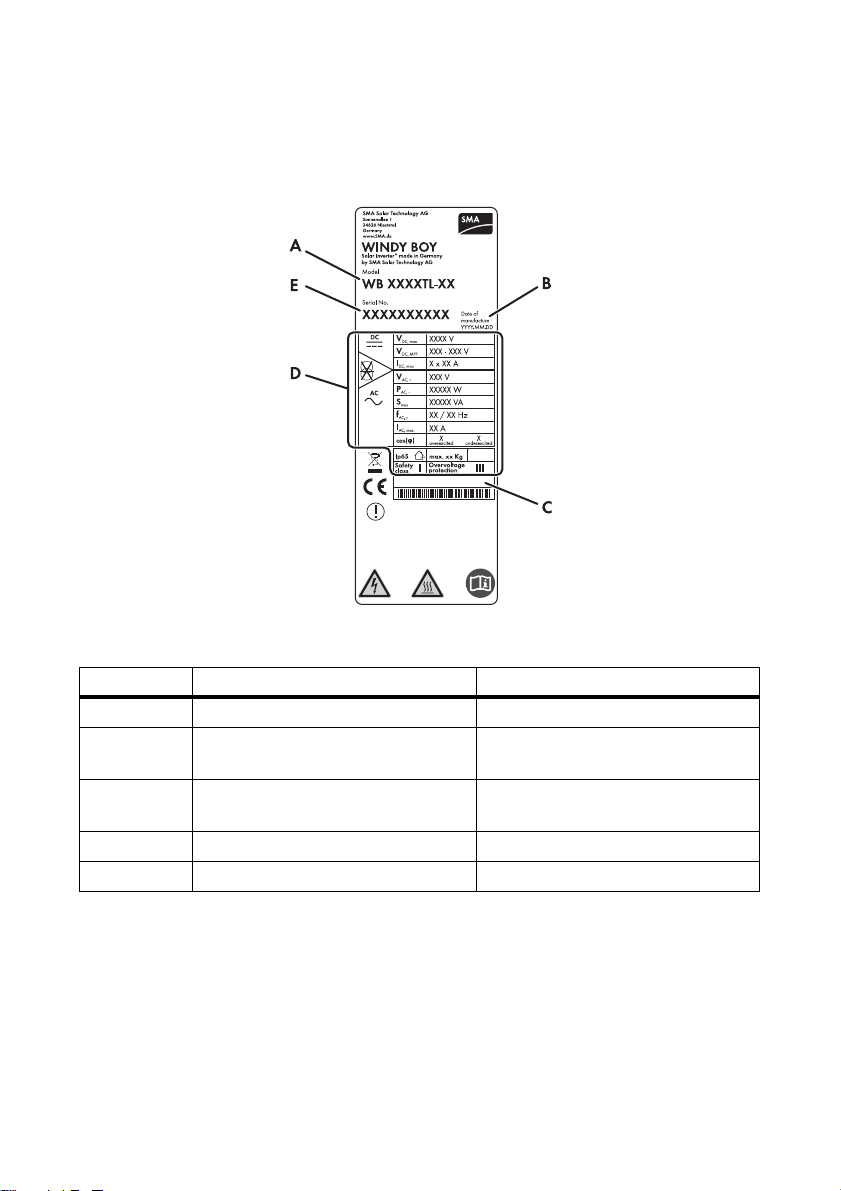

4.2 Type Label

The type label provides a unique identification of the inverter. The type label is on the right-hand side

of the enclosure.

Figure4: Layout of the type label

Position Description Explanation

A Model Inverter device type

BDate of manufacture Inverter manufacture date

(year-month-day)

C Additional information Field for additional information, e.g.

standard information

D Device-specific characteristics ‒

E Serial No. Inverter serial number

You will require the information on the type label to use the inverter safely and when seeking customer

support from the SMA Service Line. The type label must be permanently affixed to the inverter.

Installation Manual WB3-5TL-21-IA-en-10 15

Page 16

4 Product Description SMA Solar Technology AG

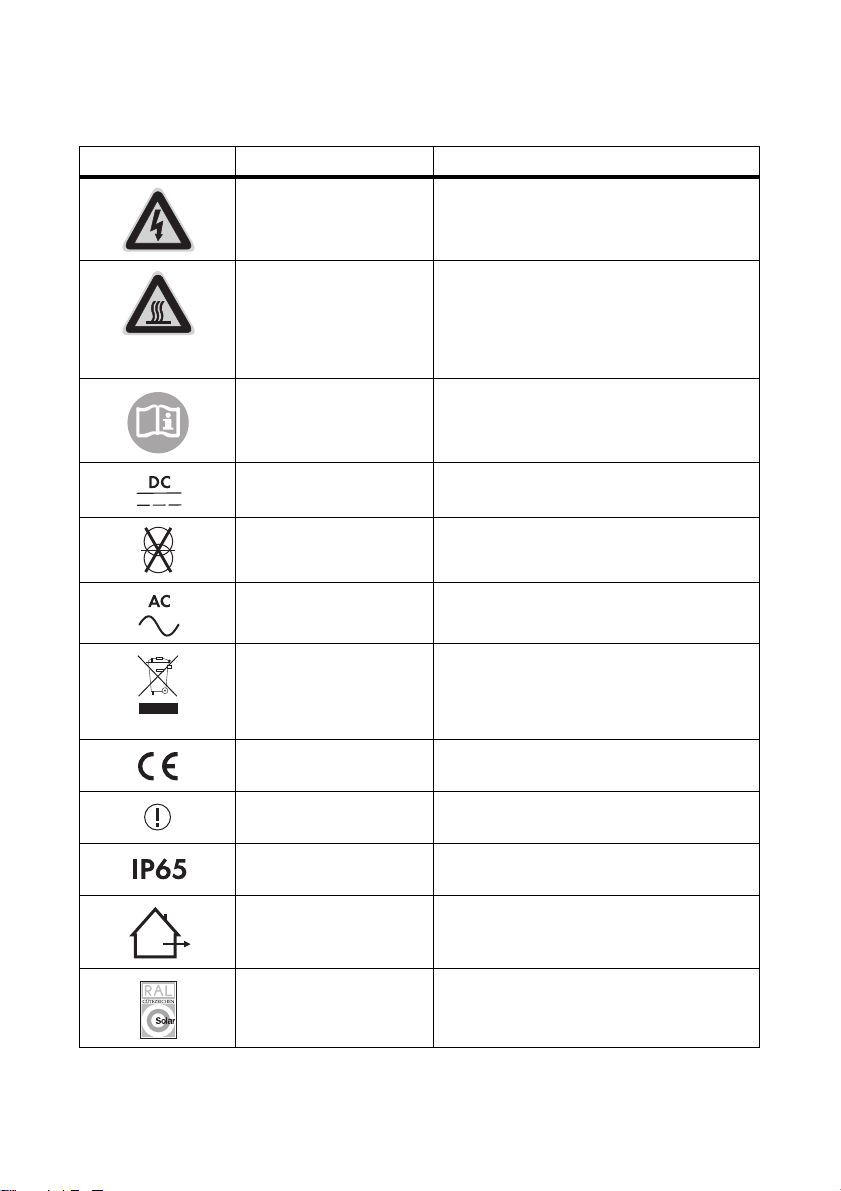

Symbols on the type label

Symbol Description Explanation

Danger to life due to high

voltages.

The product operates at high voltages.

All work on the inverter must be carried out by

qualified persons only.

Risk of burns from hot

surfaces

The product can become hot during operation.

Avoid contact during operation. Allow the

product to cool down sufficiently before

carrying out any work. Wear personal

protective equipment such as safety gloves.

Observe documentation Observe all documentation that is supplied

with the product.

DC Direct current

Without transformer The product does not have a transformer.

AC Alternating current

WEEE designation Do not dispose of the product together with the

household waste but in accordance with the

locally applicable disposal regulations for

electronic waste.

CE marking The product complies with the requirements of

the applicable EC directives.

Device class ID The product is equipped with a wireless

component and complies with device class 2.

Degree of protection The product is protected against dust intrusion

and water jets from any angle.

Outdoor The product is suitable for outdoor installation.

RAL quality mark for solar

products

The product complies with the requirements of

the German Institute for Quality Assurance

and Certification.

16 WB3-5TL-21-IA-en-10 Installation Manual

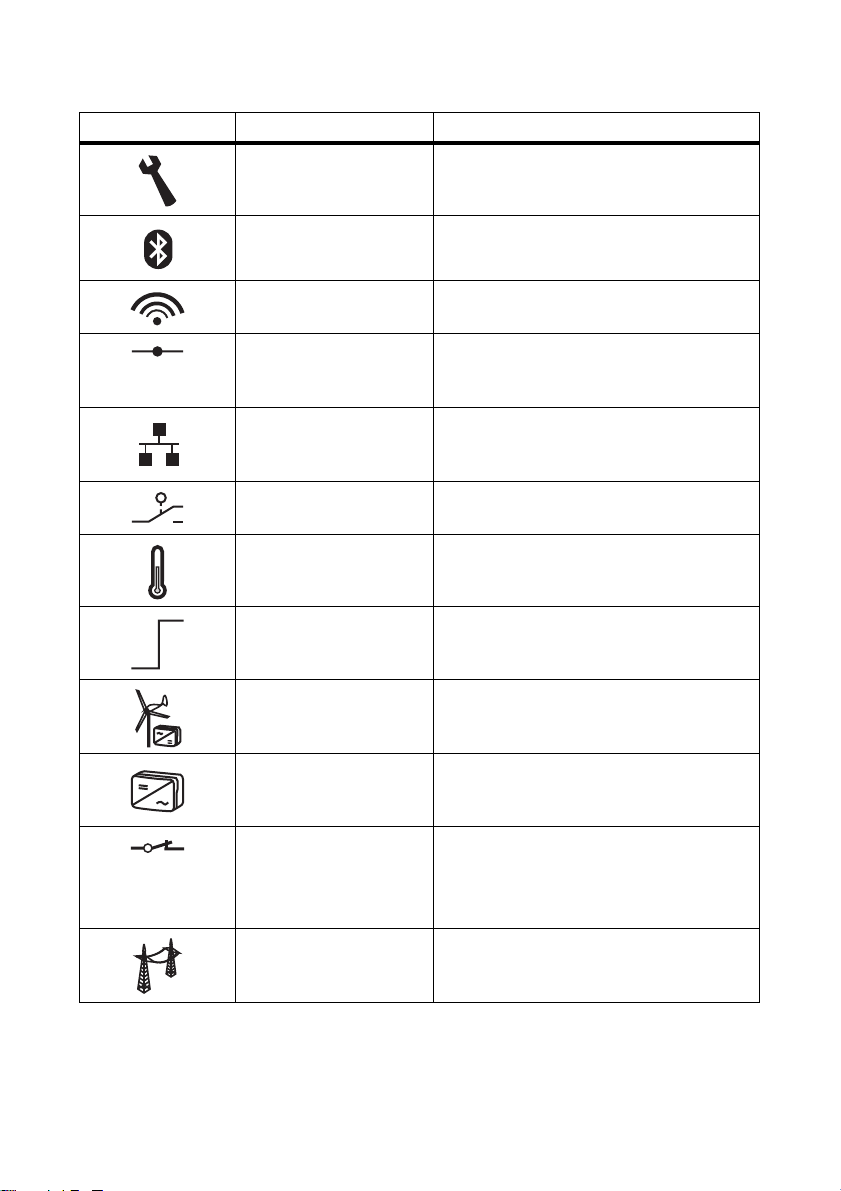

Page 17

SMA Solar Technology AG 4 Product Description

Symbol Description Explanation

Certified safety The product is VDE-tested and complies with

the requirements of the German Equipment

and Product Safety Act.

C-Tick The product complies with the requirements of

the applicable Australian EMC standards.

4.3 Display

The display shows the current operating data of the inverter (e.g. current power, daily energy, total

energy) as well as events or errors. The power and energy are displayed as bars in the diagram.

There is a slot for an SD card on the left edge of the display enclosure. You can use the SD card to

carry out an inverter firmware update, for example (for information on firmware updates with an

SD card see the technical description "Firmware Update with SD Card" at www.SMA-Solar.com).

Figure5: Display layout (example)

Position Description Explanation

A Power Current power

B Day Daily energy

C Total Displays the total amount of energy fed in up until now

D Active functions The different symbols indicate which functions for

communication, grid management or temperature

derating are enabled or active.

Installation Manual WB3-5TL-21-IA-en-10 17

Page 18

4 Product Description SMA Solar Technology AG

Position Description Explanation

E Line conductor Indicates which line conductor the displayed values are

assigned to.

F Event number relating to the

power distribution grid

G Output voltage/

output current

H Event number relating to the

Event number of errors relating to the power distribution

grid

Displays output voltage and output current of a line

conductor in alternation

Event number of errors relating to the inverter

inverter

IInput voltage/

input current

K Event number relating to the

small wind turbine system

Displays input voltage and input current of one input in

alternation

Event number of errors relating to the small wind turbine

system

L Text line Displays the event message or error message

M Power and yield curve Changes in power over the last 16 feed-in hours or the

energy yields over the last 16 days

• In order to switch between the displays, tap once

on the enclosure lid

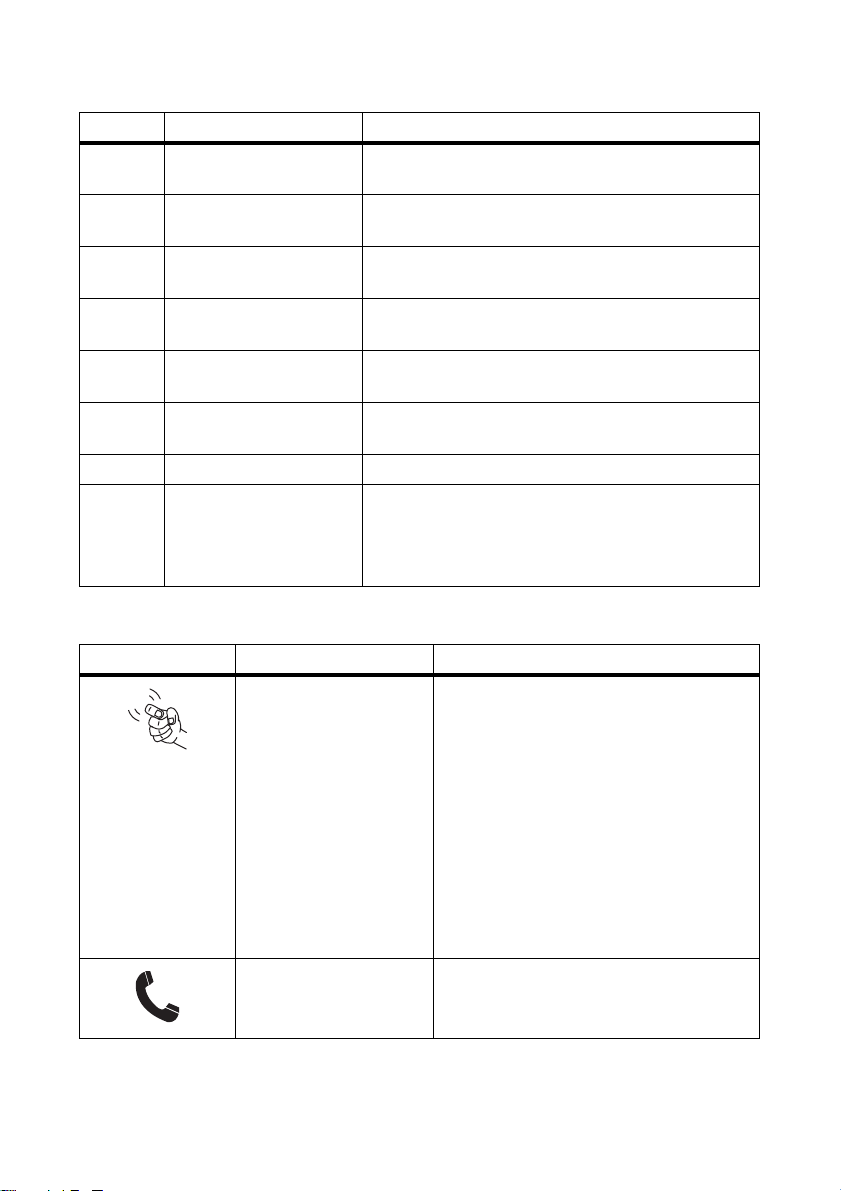

Symbols on the display

Symbol Description Explanation

Tapping You can operate the display by tapping on the

enclosure lid:

• Tapping once: to activate the backlight,

to scroll to the next text line, to switch

between the power graphs of the last

16 feed-in hours and the energy yields of

the last 16 days.

• Tapping twice: the display shows, in

succession, the firmware version, the

serial number or designation of the

inverter, NetID, the configured country

data set and display language.

Telephone receiver Indicates that an error cannot be rectified on

site

• Contact the SMA Service Line.

18 WB3-5TL-21-IA-en-10 Installation Manual

Page 19

SMA Solar Technology AG 4 Product Description

Symbol Description Explanation

Wrench Indicates that an error can be rectified on site

Bluetooth Indicates that an active Bluetooth conne cti on is

established

Bluetooth connection

quality

Indicates the quality of the Bluetooth

connection to other Bluetooth devices

Speedwire If a Speedwire data module is installed in the

inverter, this symbol indicates that there is a

connection to a network.

Webconnect function If a Webconnect data module is installed in the

inverter, this symbol indicates that it is possible

to connect to the Sunny Portal.

Multi-function relay Indicates that the multi-function relay is active

Thermometer Indicates that the power of the inverter is

limited due to excessive temperature

Power limitation Indicates that the external active power

limitation via the plant control is active

Small wind turbine system

‒

with rectifier

Inverter ‒

Grid relay A closed grid r elay i ndicates that t he inv erter is

feeding into the power distribution grid.

An open grid relay shows that the inverter is

disconnected from the power distribution grid.

Power distribution grid ‒

Installation Manual WB3-5TL-21-IA-en-10 19

Page 20

4 Product Description SMA Solar Technology AG

4.4 Bluetooth

The inverter is equipped as standard with a Bluetooth interface and can communicate with special

SMA communication products or other inverters (for information on supported products, see

www.SMA-Solar.com).

If you would like to communicate via Bluetooth, you can protect the inverter with one plant password

for the user and one plant password for the installer.

All inverters are delivered with a standard plant password for the user (0000) and a standard plant

password for the installer (1111). To protect the plant from unauthorized access, you must change

the plant passwords using Sunny Explorer (for information on changing the plant password, refer to

the Sunny Explorer help).

If you do not wish to communicate via Bluetooth, deactivate the Bluetooth communication

(see Section7.3 "Setting the NetID", page45).

4.5 Slot for Communication Interface

The inverter can optionally be fitted with an extra communication interface (e.g. RS485).

This communication interface enables the inverter to communicate with special SMA communication

products (for information on supported products, see www.SMA-Solar.com). The communication

interface can be retrofitted or installed by default with the respective order.

Depending on the type of communication, RS485, Bluetooth, or Speedwire, the parameters and

messages are displayed differently on the communication products.

Example: How the country data set parameter is displayed

• For communication with RS485: CntrySet parameter

• For communication with Bluetooth or Speedwire: Set country standard parameter

4.6 Operating Parameters

Various operating parameters control the functionality of the inverter. You can only adjust all

operating parameters of the inverter, excluding the country data set, using an SMA communication

product (see Section 8.7). You can adjust the country data set before commissioning or within the first

ten feed-in hours via two rotary switches in the inverter (see Section 7.2).

20 WB3-5TL-21-IA-en-10 Installation Manual

Page 21

SMA Solar Technology AG 4 Product Description

4.7 Slot for Multi-Function Interface

The inverter has a slot for a multi-function interface. This slot is designed to connect a simple

multi-function relay, an SMA Power Control Module, or a fan retrofit kit. The multi-function interface

can be retrofitted or installed by default with the respective order.

Multi-Function Relay

You can configure the multi-function relay for various operating modes. The multi-function relay is

used, for example, to switch error indicators on or off (for information on installation and

configuration, see installation manual of the multi-function relay).

SMA Power Control Module

The SMA Power Control Module enables the inverter to implement grid management and is equipped

with an additional multi-function relay (for information on installation and configuration, see the

SMA Power Control Module installation manual).

Fan Retrofit Kit

The fan retrofit kit is used for additional inverter cooling at high ambient temperatures and also has a

multi-function relay (for information on installation and configuration, see the fan retrofit kit installation

manual). The fan retrofit kit and the SMA Power Control Module cannot be operated in parallel.

4.8 Grid Management

The inverter is equipped with grid management functions.

Depending on the requirements of the grid operator, you can activate and configure the functions

(e.g. provision of reactive power, active power limitation) via operating parameters (for information

on the functions and operating parameters, see the Technical Description "Measured Values and

Parameters" at www.SMA-Solar.com).

4.9 Varistors

Varistors are voltage-dependent resistors that protect the inverters against overvoltage. The inverter is

equipped with thermally monitored varistors.

Varistors can become worn and lose their protective function with age or repeated strain as a result

of overvoltage. The inverter detects if one of the varistors is defective and displays an error message.

The varistors are specially manufactured for use in the inverter and are not commercially available.

You must order new varistors directly from SMA Solar Technology AG.

Installation Manual WB3-5TL-21-IA-en-10 21

Page 22

4 Product Description SMA Solar Technology AG

4.10 SMA Grid Guard

SMA Grid Guard acts as an automatic disconnection device between a grid-parallel generator

(e.g. a PV plant or small wind turbine system) and the power distribution grid.

Furthermore, SMA Grid Guard is a grid monitoring concept which detects errors by permanently

monitoring grid impedance, line voltage and power frequency. For example, SMA Grid Guard

detects when a stand-alone grid is formed and immediately disconnects the inverter from the power

distribution grid.

In some countries, the connection conditions require a device which protects grid-relevant operating

parameters against unpermitted changes. SMA Grid Guard assumes this function and protects the

setting of the country data set after the first 10 feed-in hours. After the first 10 feed-in hours the country

data set can only be changed using a communication product and after a personal access code has

been entered, the SMA Grid Guard code. You can obtain the SMA Grid Guard code from

SMA Solar Technology AG (for application for the SMA Grid Guard code, see certificate

"Application for SMA Grid Guard-Code" at www.SMA-Solar.com).

22 WB3-5TL-21-IA-en-10 Installation Manual

Page 23

SMA Solar Technology AG 5 Mounting

5 Mounting

5.1 Selecting the Mounting Location

Requirements for the mounting location:

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

• Do not mount the inverter on flammable construction materials.

• Do not mount the inverter in areas where highly flammable materials are stored.

• Do not mount the inverter in a potentially explosive atmosphere.

☐ The mounting location must be inaccessible to children.

☐ A solid foundation must be available for mounting, e.g. concrete or masonry. When mounted

on plasterboard or similar materials in a living area, the inverter will develop audible vibrations

during operation, which could be considered disturbing.

☐ The mounting location must be suitable for the weight and dimensions of the inverter

(see Section13 "Technical Data", page77).

☐ The mounting location must be easily and safely accessible at all times without the use of

additional aids being necessary, e.g., scaffolding or lifting platforms. Non-fulfillment of these

criteria may restrict servicing.

☐ The mounting location must not be exposed to direct solar irradiation. Direct solar irradiation

can overheat the inverter. As a result, the inverter reduces its power output.

☐ Climatic conditions must be met (see Section13 "Technical Data", page77).

☐ The ambient temperature must be below 40°C to ensure the optimal operation of the inverter.

Installation Manual WB3-5TL-21-IA-en-10 23

Page 24

5 Mounting SMA Solar Technology AG

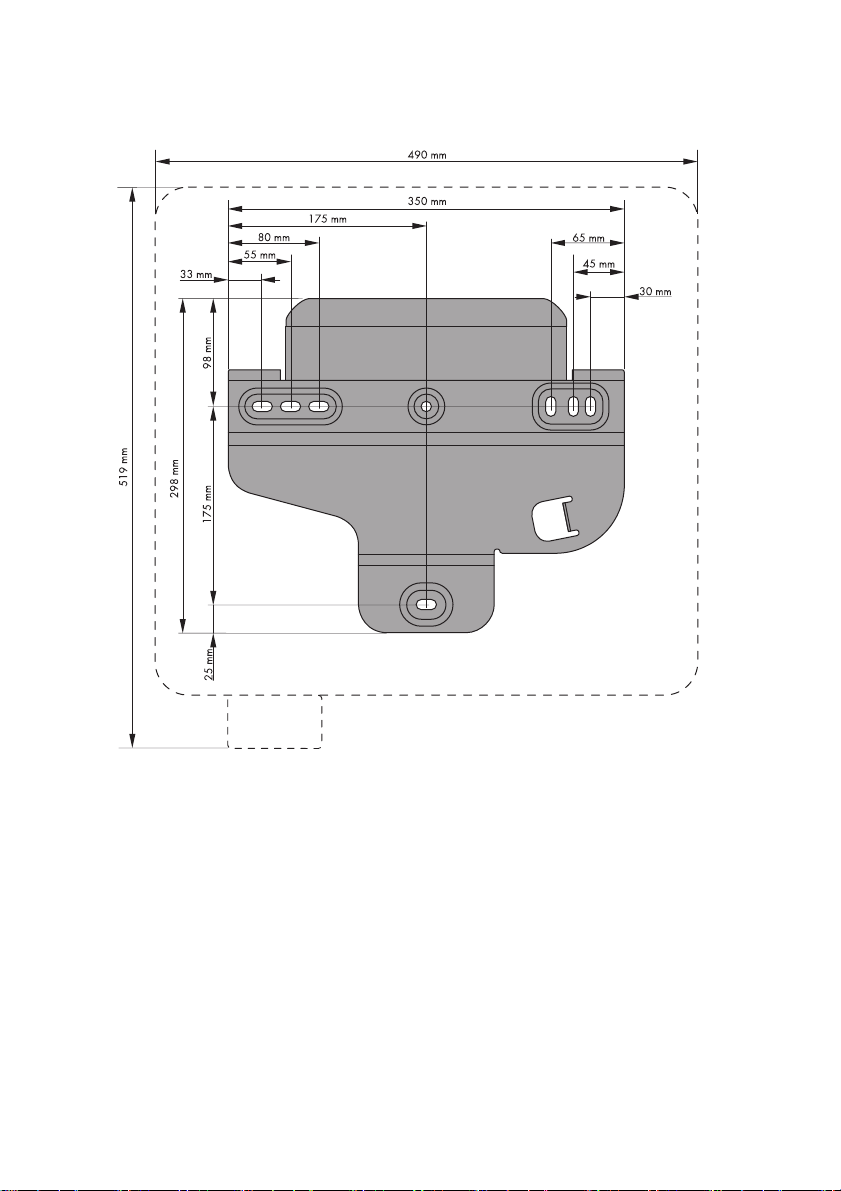

Dimensions for wall mounting:

Figure6: Wall mounting bracket dimensioning

24 WB3-5TL-21-IA-en-10 Installation Manual

Page 25

SMA Solar Technology AG 5 Mounting

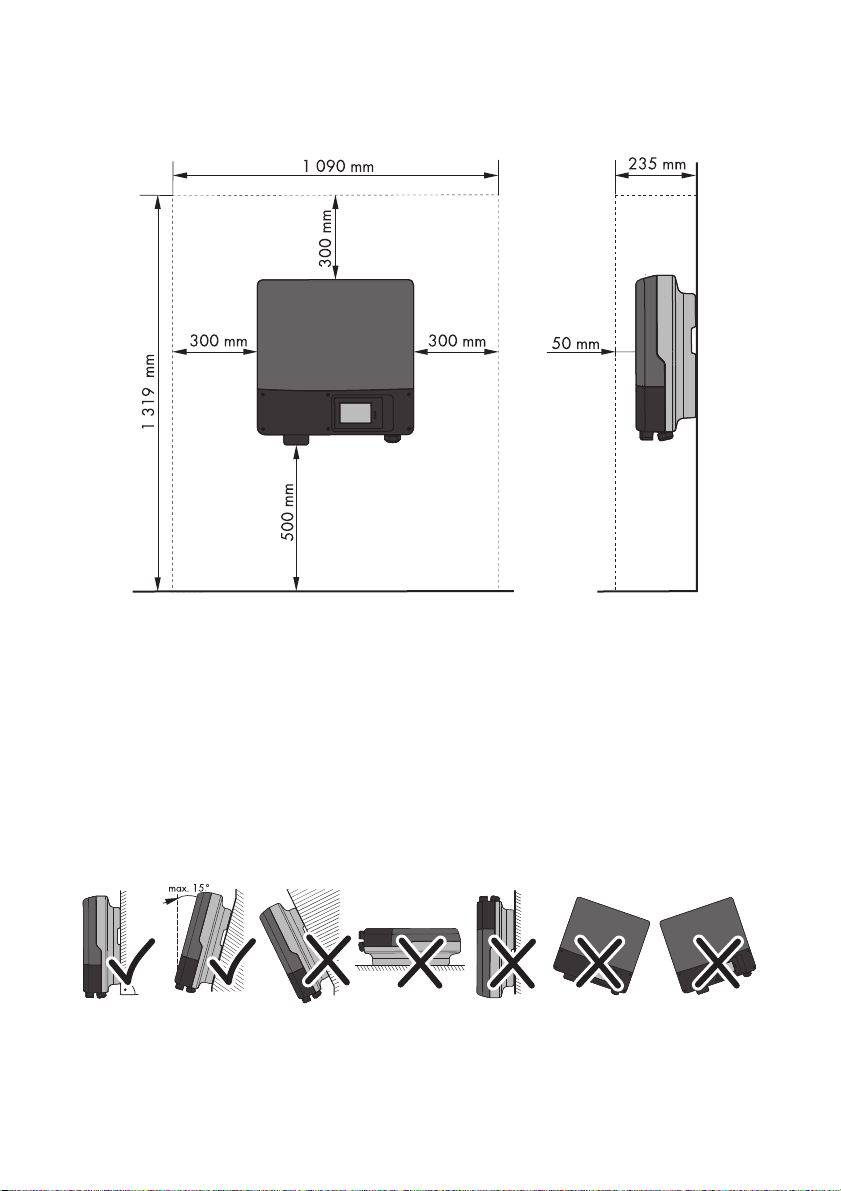

Observe recommended clearances:

Figure7: Recommended clearances

• Observe minimum clearances to the walls as well as to other inverters or objects.

This ensures adequate heat dissipation and sufficient space to remove the ESS.

• If multiple inverters are mounted in areas with high ambient temperatures, increase the

clearances between the inverters and ensure sufficient fresh-air supply.

☑ This prevents a reduction in inverter power as a result of high temperatures (for details

on temperature derating, see the Technical Information "Temperature Derating"

at www.SMA-Solar.com).

Observe permitted mounting position:

Figure8: Permitted and prohibited mounting positions

Installation Manual WB3-5TL-21-IA-en-10 25

Page 26

5 Mounting SMA Solar Technology AG

• Mount t he inv erter in a pe rmitt ed mou nting posit ion. T he dis play should be mounted at eye level.

☑ Mounting the inverter in a permissible position will ensure that no moisture can penetr ate the

inverter.

☑ By mounting the device at eye level, display messages and LED signals can be read without

difficulty.

5.2 Mounting the Inverter

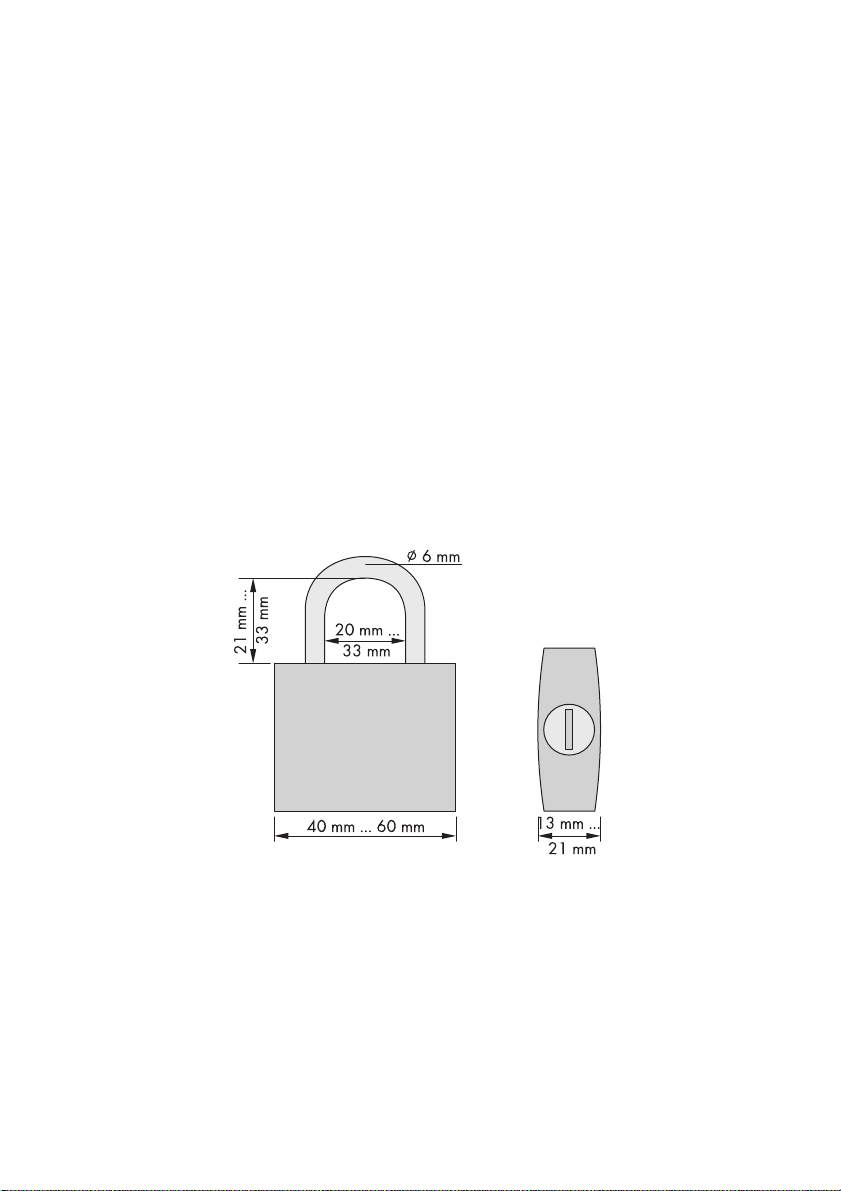

Anti-theft device:

You can protect the inverter from theft with a padlock. The padlock locks the inverter to the wall

mounting bracket.

The device must meet the following requirements:

☐ The material must be resistant to corrosion.

☐ The lock shackle must be hardened.

☐The lock cylinder must be secured.

☐ If it is mounted outdoors, the padlock must be weather-proof.

☐ The function must be guaranteed for the electrical endurance of the inverter.

Figure9: Dimensions of the padlock for the anti-theft device

Additionally required mounting material (not included in the scope of delivery):

☐ 3 screws (minimum diameter 6 mm) that are suitable for the foundation

☐ 3 washers (minimum external diameter 18 mm) that are suitable for the screws

☐ 3 screw anchors that are suitable for the foundation

☐ If the inverter is to be protected against theft, 1 padlock

1. Ensure that there are no lines laid in the wall which could be damaged when drilling.

26 WB3-5TL-21-IA-en-10 Installation Manual

Page 27

SMA Solar Technology AG 5 Mounting

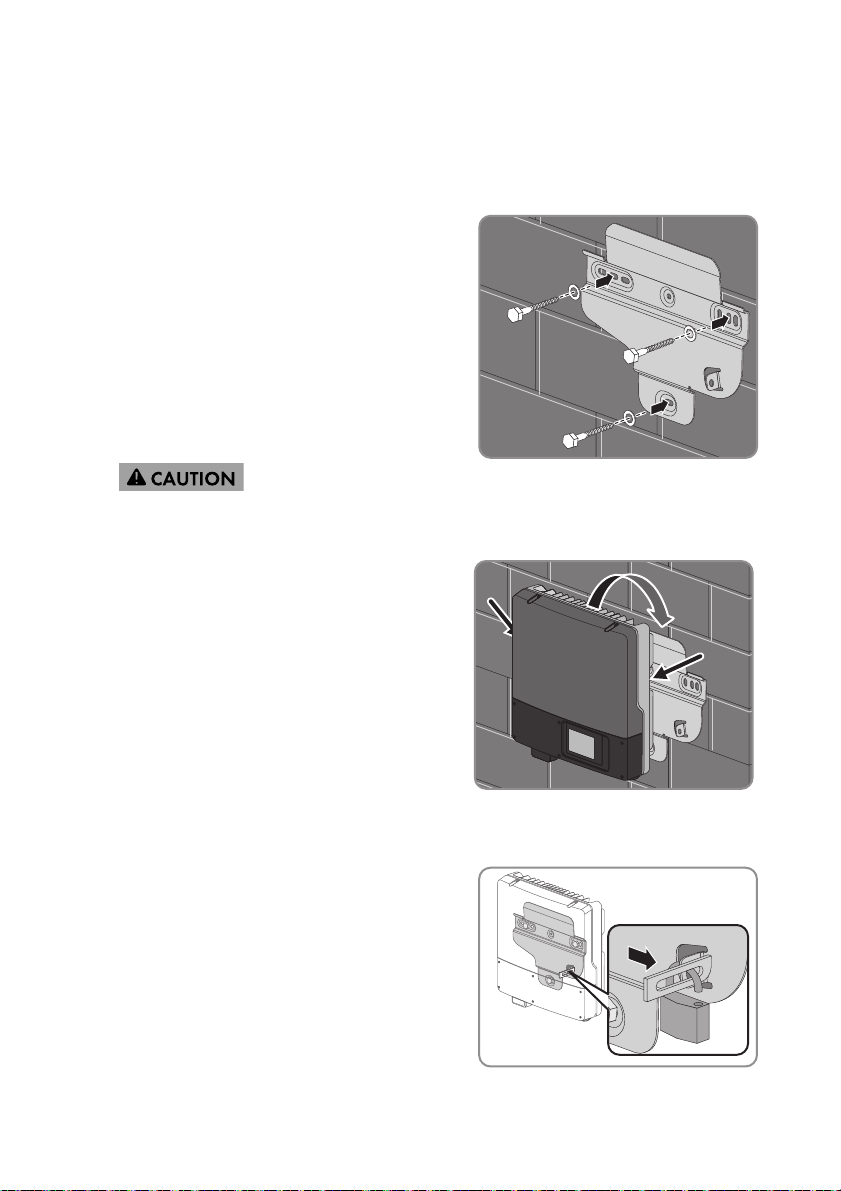

2. Mark the position of the drill holes using the wall mounting bracket. Use at least two holes on

the left-hand and right-hand side and the lower hole in the wall mounting bracket.

Tip: When mounting on a post, use the upper and lower central holes.

3. Drill the holes and insert the screw anchors.

4. Secure the wall mounting bracket horizontally to

the wall using screws and washers.

5.

Risk of injury when hanging the inverter in the wall mounting bracket

• Keep in mind the weight of the inverter (see Section13 "Technical Data", page77).

• Hang the inverter in the wall mounting

bracket. Use the recessed grips at the side

and transport the inverter in a horizontal

position.

6. Ensure that the inverter is securely seated.

7. To protect the inverter from theft, attach a padlock:

• Place the shackle of the padlock through the

metal lug on the wall mounting bracket and

through the lug on the rear of the inverter.

As you do so, move the shackle outward from

the center of the inverter.

• Close the shackle.

Installation Manual WB3-5TL-21-IA-en-10 27

Page 28

6 Electrical Connection SMA Solar Technology AG

A B

C

D

6 Electrical Connection

6.1 Safety during Electrical Connection

Electric Shock

High voltages that can cause fatal electric shocks when touched are present in the live components

of the inverter.

• Prior to pe rforming any work on the inver ter, d isconnec t it from any voltage sou rce as described

in this document (see Section 9).

Electrostatic Discharge

Touching electronic components can cause damage to or destroy the inverter through electrostatic

discharge.

• Ground yourself before touching any components.

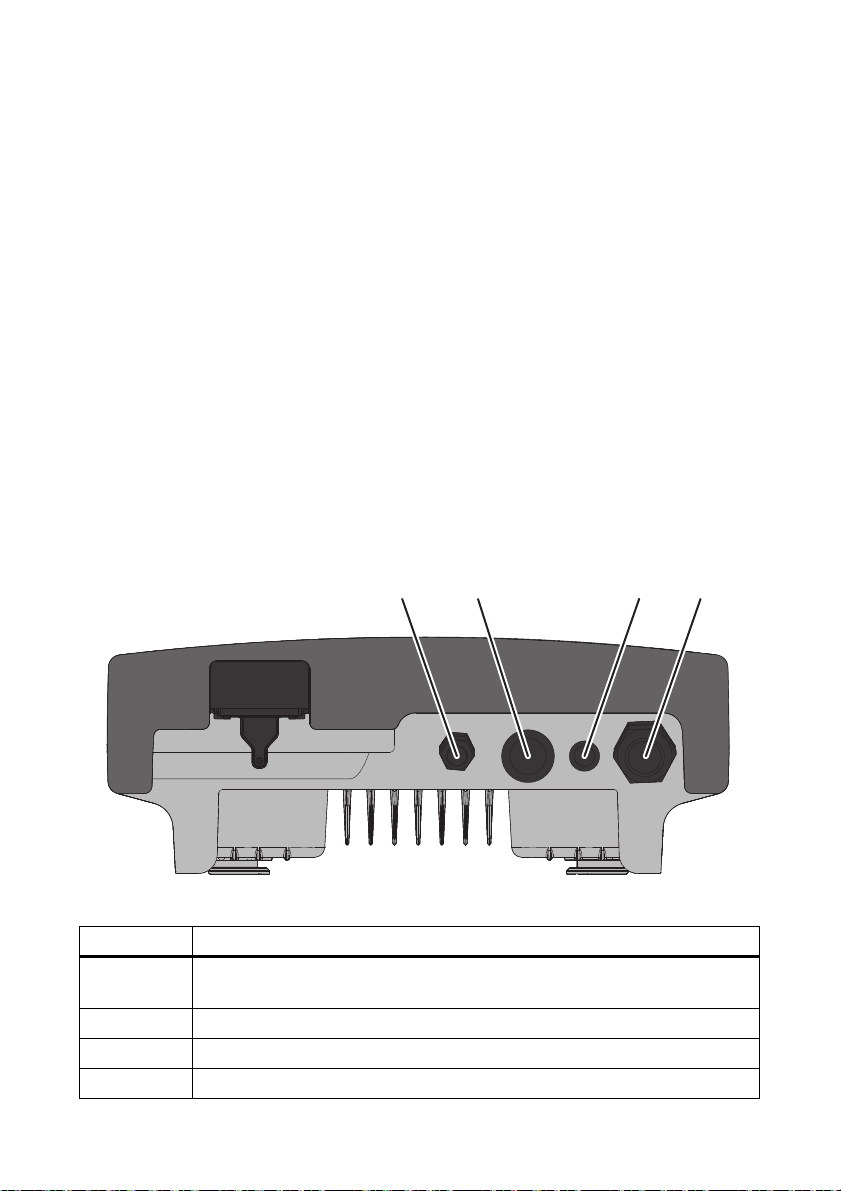

6.2 Overview of the Connection Area

6.2.1 View from Below

Figure10: Enclosure openings at the bottom of the inverter

Position Description

A Cable gland M20x1.5 for connection to the multi-function interface or connection

of the fan retrofit kit

B Enclosure opening with filler-plug for connection to the communication interface

C Enclosure opening with filler-plug for connection to the communication interface

D Cable gland M32x1.5 for connection to the power distribution grid

28 WB3-5TL-21-IA-en-10 Installation Manual

Page 29

SMA Solar Technology AG 6 Electrical Connection

B

A CDEF

G

H

6.2.2 Interior View

Figure11: Connection areas in the interior of the inverter

Position Description

A 2 positive and 2 negative DC connectors, input A

B Jack for plugging in the ESS

C 2 positive and 2 negative DC connectors, input B

D Jack for connecting the multi-function interface

E Jack for connecting the communication interface

F Connecting terminal plate for connecting the AC cable

G Installation location for retrofitted fan

H Ground terminal for additional grounding of the inverter

6.3 AC Connection

6.3.1 Conditions for the AC Connection

Cable requirements:

☐ External diameter: 12 mm to 21 mm

☐ Maximum wire size: maximal 10 mm²

☐ Stripping length: 12 mm

Installation Manual WB3-5TL-21-IA-en-10 29

Page 30

6 Electrical Connection SMA Solar Technology AG

☐ The cable must be dimensioned in accordance with the local and national directives for the

dimensioning of cables. The requirements for the minimum wire size derive from these directives.

Influencing factors for cable dimensioning are, among others, the following: nominal AC

current, type of cable, routing method, cable bundling, ambient temperature, and maximum

desired line losses.

Switch-disconnector and cable protection:

Damage to the inverter due to the use of screw-type fuses as load disconnection units

Screw-type fuses (e.g. DIAZED fuses or NEOZED fuses) are not switch-disconnectors

• Do not use screw-type fuses as load disconnection units.

• Use a switch-disconnector or miniature circuit-breaker as a load disconnection unit

(for information and examples for designing, see the Technical Information "Miniature

Circuit-Breaker" at www.SMA-Solar.com).

• In plants with multiple inverters, protect every inverter with a separate miniature circuit-breaker.

Observe the maximum permissible fuse protection (see Section13 "Technical Data", page77).

That prevents residual voltage being present at the corresponding cable after disconnection.

• Loads installed between the inverter and the miniature circuit-breaker must be protected

separately.

Residual-current device:

• If an external residual-current device is prescribed, install a residual-current device that trips at

a residual current of 100 mA or higher (for information on choice of residual-current devices,

see the Technical Information "Criteria for Selecting a Residual-Current Device" at

www.SMA-Solar.com).

Protective conductor monitoring:

The inverter is equipped with protective conductor monitoring that detects if the protective conductor

is not connected and if this is the case, disconnects the inverter from the power distribution grid.

Depending on the installation site and grounding system, it may be advisable to deactivate the

protective conductor monitoring. Ask your grid operator or SMA Solar Technology AG to advise.

• To ensure safety according to IEC 62109 when the protective conductor monitoring is

deactivated, connect a protective conductor to the connecting terminal plate for the AC cable

(minimum cross-section: 10 mm², copper wire).

or

Connect a second protective conductor with the same wire size as the original protective

conductor (see Section6.3.3 "Additional Grounding of the Enclosure", page34). This prevents

touch current if the original protective conductor fails.

Connection of a second protective conductor

In some countries a second protective conductor is required as a matter of principle.

In each case, observe the local applicable regulations.

30 WB3-5TL-21-IA-en-10 Installation Manual

Page 31

SMA Solar Technology AG 6 Electrical Connection

1

2

6.3.2 Connecting the Inverter to the Power Distribution Grid

Requirements:

☐ The connection requirements of the grid operator must be met.

☐ The line voltage must be within the permissible range. The exact operating range of the inverter

is specified in the operating parameters (see the Technical Description "Measured Values and

Parameters" at www.SMA-Solar.com).

1. Stop the small wind turbine system and secure against restart.

2. Disconnect the miniature circuit-breaker and secure against re-connection.

3. Remove the ESS.

4. Loosen all six screws of the lower enclosure lid

us ing an Allen ke y (AF 3) and remov e the enclosur e

lid.

5. Flip the display up to have more space to make the

connection. Loosen the screw on the display to do

this.

☑ The display clicks into place.

Installation Manual WB3-5TL-21-IA-en-10 31

Page 32

6 Electrical Connection SMA Solar Technology AG

6. If the diameter of the AC cable is between 15 mm and 21 mm, remove the insert from the seal

in the AC cable gland:

• Unscrew the swivel nut of the AC cable gland.

• Remove the insert in the seal of the AC cable

gland.

• Screw the swivel nut a little way onto the AC cable gland. Do not fully tighten the swivel nut.

7. Strip the AC cable insulation.

8. Shorten L and N by 5 mm each.

9. Strip 12 mm of the L, N, and PE insulation each.

10. Route the AC cable into the inverter through the cable gland. If necessary, slightly loosen the

swivel nut of the cable gland.

11. Push the safety levers of the connecting terminal

plate for the AC cable right up to the stop.

12. Connect the AC cable to the connecting terminal plate for the AC cable:

• Connect PE to the terminal.

•Connect N to the N terminal.

•Connect L to the L terminal.

32 WB3-5TL-21-IA-en-10 Installation Manual

Page 33

SMA Solar Technology AG 6 Electrical Connection

13.

Danger of crushing when safety levers snap shut

The safety levers close by snapping down fast and hard.

• Only press the safety levers on the terminals

down with your thumb. Do not grasp the

entire connecting terminal plate for the AC

cable and do not place your fingers under

the safety levers.

14. If the display is still raised, lower it again.

15. Fasten the screw on the display hand-tight.

16. Retighten the swivel nut of the AC cable gland.

Installation Manual WB3-5TL-21-IA-en-10 33

Page 34

6 Electrical Connection SMA Solar Technology AG

6.3.3 Additional Grounding of the Enclosure

If a second protective conductor or equipotential bonding is required locally, you can also ground

the enclosure. This prevents touch current if the original protective conductor fails.

Cable requirement:

☐ Maximum grounding cable cross-section: 10 mm²

1. Strip the grounding cable insulation.

2. Loosen the screws using an Allen key (AF 4), until

the grounding cable can be led under the clamping

bracket.

3. Feed the grounding cable under the clamping

bracket. Set the protective conductor to the left.

4. Tighten the clamping bracket with the screw and

conical spring washer (torque: 6 Nm). The teeth of

the conical spring washer must face the clamping

bracket.

34 WB3-5TL-21-IA-en-10 Installation Manual

Page 35

SMA Solar Technology AG 6 Electrical Connection

+

6.4 DC Connection

6.4.1 Connecting the Connection Cables to DC Connectors

Figure12: DC connectors

Position Description

A Negative DC connector

B Positive DC connector

Required material (not included in the scope of delivery):

☐ 2 PV1-F cables for connecting the rectifier (maximum length: 30 m)

☐ 2 PV1-F cables for bridging the DC inputs on the inverter (length: 25 cm to 35 cm)

Cable requirements:

☐ External diameter: 5 mm to 8 mm

☐ Wire size: 2.5 mm² to 6 mm²

Assigning the PV1-F cables to the DC connectors:

• Connect one PV1-F cable for connecting the rectifier to a positive DC connector.

• Connect one PV1-F cable for connecting the rectifier to a negative DC connector.

• Connect each end of the PV1-F cable for bridging the DC inputs to a positive DC connector.

• Connect each end of the PV1-F cable for bridging the DC inputs to a negative DC connector.

Connect each connection cable to the appropriate DC connector according to the following

procedure.

1. Strip the insulation of the cable by 12 mm.

2. Lead the stripped cable all the way into the DC

connector. Ensure that the stripped cable and the

DC connector have the same polarity.

Installation Manual WB3-5TL-21-IA-en-10 35

Page 36

6 Electrical Connection SMA Solar Technology AG

+

+

+

1

2

+

1

2

3. Press the clamping bracket down.

☑ The clamping bracket snaps audibly into place.

☑ The stranded wire can be seen inside the

clamping bracket chamber.

✖ The stranded wire cannot be seen in the chamber.

The cable is not positioned correctly.

• Loosen the clamping bracket. To do so, insert

a screwdriver (blade width: 3.5 mm) into the

clamping bracket and lever it out.

• Remove the cable and start again from step

2.

4. Push the swivel nut up to the thread and tighten

(torque: 2 Nm).

36 WB3-5TL-21-IA-en-10 Installation Manual

Page 37

SMA Solar Technology AG 6 Electrical Connection

6.4.2 Bridging the DC Inputs on the Inverter

Requirements:

☐ A negative connection cable to bridge the DC inputs on the inverter must be equipped with

two negative DC connectors.

☐ A positive connection cable to bridge the DC inputs on the inverter must be equipped with

two positive DC connectors.

Bridge the two rear DC connectors of input A with the two rear DC connectors of input B according

to the following procedure.

1. Stop the small wind turbine system and secure against restart.

2. Disconnect the miniature circuit-breaker and secure against re-connection.

3. If the ESS is plugged in, remove the ESS.

4. Re mov e th e fi lle r-p lug s fr om t he r ear DC c onn ect ors

of both inputs on the inverter.

5. Connect the positive DC connectors of input A with

the positive DC connectors of input B.

Installation Manual WB3-5TL-21-IA-en-10 37

Page 38

6 Electrical Connection SMA Solar Technology AG

6. Connect the negative DC connectors of input A with

the negative DC connectors of input B.

6.4.3 Connecting the Rectifier

Requirements:

☐ The rear DC inputs on the inverter must be bridged.

☐ The positive connection cable of the rectifier must be fitted with a positive DC connector.

☐ The negative connection cable of the rectifier must be fitted with a negative DC connector.

Destruction of the inverter due to overvoltage

If the ope n-c irc uit vol tag e of the pla nt e xce eds the max imu m in put vol tag e of the inv ert er, the inv ert er

can be destroyed by overvoltage.

• Install overvoltage protection between the inverter and the rectifier.

• If the open-circuit voltage of the plant exceeds the maximum input voltage of the inverter,

do not connect any DC cables to the inverter and check the design of the plant.

38 WB3-5TL-21-IA-en-10 Installation Manual

Page 39

SMA Solar Technology AG 6 Electrical Connection

1. Re move the fille r-plug s from the front DC connector s

of both inputs on the inverter.

2. Check the connection cables of the rectifier for ground faults (see Section 11.4).

3. Connect the rectifier to the inverter:

• Connect the positive connection cable to the

front positive DC connector of input A on the

inverter.

• Connect the negative connection cable to the

front negative DC connector of input A on the

inverter.

☑ The DC connectors click audibly into place.

Installation Manual WB3-5TL-21-IA-en-10 39

Page 40

6 Electrical Connection SMA Solar Technology AG

+

1

2

+

+

4.

Damage to the inverter due to moisture penetration

The inverter is only properly sealed when all the unused DC inputs are sealed with DC

connectors and sealing plugs.

•Do NOT insert the sealing plugs DIRECTLY into the DC inputs on the inverter.

• For unused DC connectors, push down the

clamping bracket and push the swivel nut up

to the thread.

• Insert the sealing plug into the DC connector.

• Tighten the DC connector (torque: 2 Nm).

• Insert the DC connectors with sealing plugs

into the corresponding DC inputs on the

inverter.

☑ The DC connectors click audibly into

place.

5. Ensure that all DC connectors are securely in place.

40 WB3-5TL-21-IA-en-10 Installation Manual

Page 41

SMA Solar Technology AG 6 Electrical Connection

1

2

3

4

5

6

6. Place the lower enclosure lid with the 6 screws on

the enclosure and secure with screw 6. Then tighten

all screws with an Allen key (AF 3) in the order

1 to 6 (torque: 2 Nm).

7. Securely plug in the ESS. The ESS must be aligned

parallel to and flush with the enclosure.

Installation Manual WB3-5TL-21-IA-en-10 41

Page 42

7 Initial Start-Up SMA Solar Technology AG

7 Initial Start-Up

7.1 Procedure

Before you can commission the inverter, you must check various settings and if necessary make

changes. This section describes the procedure for initial start-up and provides an overview of the steps

that must always be performed in the given sequence.

Procedure See

1. Check the country data set configuration of the inverter. Type label or

supplementary sheet

with default settings

2. If the country data set is not correctly configured for your country or

purpose, adjust the desired country data set and the associated

display language.

3. If the inverter will communicate with several Bluetooth devices, or if

Bluetooth will not be used as a type of communication, configure

NetID.

4. Commission the inverter for the first time and start a self-test, if

required.

7.2 Configuring the Country Data Set

There is a display language assigned to each country data set. Configure the country data set with

the associated display language so it is appropriate for your country or purpose. If the display

language is not your desired language, you can change the display language after commissioning

(see Section 8.1).

Section 7.2

Section 7.3

Section 7.4 and

Section 7.5

Country data set must be correctly configured

If you configure a country data set that is not valid for your country or purpose, it can cause a

disturbance in the plant and lead to problems with the grid operator. When selecting the

country data set always observe the locally valid standards and directives, as well as the

characteristics of the plant (e.g. dimensions of the plant, grid-connection point, etc.).

• If you are not sure which country data set is valid for your country or purpose, contact

your grid operator and ask which country data set should be configured.

1. Ensure that the inverter is disconnected from voltage sources and t he l owe r en clos ure lid is o pen .

42 WB3-5TL-21-IA-en-10 Installation Manual

Page 43

SMA Solar Technology AG 7 Initial Start-Up

B

A

2. Using a slotted screwdriver (blade width: 2.5 mm),

set rotary switches A and B to the country data set

that is valid for your country or purpose.

☑ The inverter will adopt the setting up to five minutes after commissioning.

Rotary switch positions

Rotary switch A Rotary switch B Country data set Display language

0 0 Default setting Default setting

1 0 VDE0126-1-1 German

1 2 VDE-AR-N4105* German

1 4 VDE-AR-N4105-MP** German

1 6 VDE-AR-N4105-HP*** German

1 8 VDE0126-1-1 French

1 9 VDE0126-1-177/UTE French

2 0 VDE0126-1-1 Italian

2 8 AS4777.3 English

3 1 CEI 0-21 intern**** Italian

3 2 CEI 0-21 extern***** Italian

4 0 RD1663-A Spanish

4 1 RD1663/661-A Spanish

48PPC Greek

49PPC English

5 1 KEMCO501/2009 English

5 2 KEMCO501/2009 Korean

5 8 G83/1-1 English

5AG 59/2 English

6 0 EN50438 German

6 1 EN50438 English

6 2 EN50438 French

6 3 EN50438 Italian

Installation Manual WB3-5TL-21-IA-en-10 43

Page 44

7 Initial Start-Up SMA Solar Technology AG

Rotary switch A Rotary switch B Country data set Display language

6 4 EN50438 Spanish

6 5 EN50438 Greek

6 6 EN50438 Czech

6 7 EN50438 Portuguese

6 8 EN50438 Bulgarian

6 9 EN50438 Polish

7 0 EN50438-CZ Czech

7 1 EN50438-CZ English

7 2 EN50438-CZ German

74PPDS Czech

75PPDS English

76PPDS German

7 8 C10/11 French

7 9 C10/11 English

7 A C10/11 German

7 B C10/11 Dutch

A C SI4777-2 English

B 8 IEC61727/MEA English

B C IEC61727/PEA English

C0Other standardEnglish

C 1 Other standard German

C 2 Other standard French

C3Other standardSpanish

C 4 Other standard Italian

C 5 Other standard Greek

C6Other standardCzech

D 0 Island mode 60 Hz English

D 1 Island mode 60 Hz German

D 2 Island mode 60 Hz French

D 3 Island mode 60 Hz Spanish

D 4 Island mode 60 Hz Italian

D 5 Island mode 60 Hz Greek

44 WB3-5TL-21-IA-en-10 Installation Manual

Page 45

SMA Solar Technology AG 7 Initial Start-Up

C

Rotary switch A Rotary switch B Country data set Display language

D 6 Island mode 60 Hz Czech

E 0 Island mode 50 Hz English

E 1 Island mode 50 Hz German

E 2 Island mode 50 Hz French

E 3 Island mode 50 Hz Spanish

E 4 Island mode 50 Hz Italian

* setting in accordance with VDE-AR-N 4105 for plants ≤ 3.68 kVA (Germany)

** setting in accordance with VDE-AR-N 4105 for plants from 3.68 kVA to 13.8 kVA (Germany)

*** setting in accordance with VDE-AR-N 4105 for plants > 13.8 kVA (Germany)

**** planned setting in accordance with CEI 0-21 for plants ≤ 6 kVA (Italy)

***** planned setting according to CEI 0-21 for plants with external grid and plant protection > 6 kVA (Italy)

7.3 Setting the NetID

By default, the NetID is set to 1 for all SMA inverters and SMA communication products with

Bluetooth. If your plant consists of an inverter and a maximum of one further Bluetooth device

(e.g. computer with Bluetooth or SMA communication product), you can leave the NetID set to 1.

You must change the NetID in the following cases:

• If your plant consists of an inverter and two further Bluetooth devices (e.g. computer with

Bluetooth or SMA communication product) or of several inverters, you need to change the

NetID of your plant. This enables you to communicate with several Bluetooth devices.

• If another plant with Bluetooth is loc ated wi thi n 50 0 m of y our plant, you mus t ch ange th e Ne tID

of your plant. This will help to separate both plants from each other.

• If you do not want to communicate using Bluetooth, deactivate the Bluetooth communication on

your inverter. This protects your plant from unauthorized access.

All Bluetooth devices in a plant must have the same NetID. Before commissioning, you can set a new

NetID in the inverter by using rotary switch C. The setting will be adopted up to five minutes after

commissioning.

Figure13: Positions of rotary switch C

Installation Manual WB3-5TL-21-IA-en-10 45

Page 46

7 Initial Start-Up SMA Solar Technology AG

C

C

Position Explanation

0 Communication via Bluetooth is disabled.

1 Communication via Bluetooth with a maximum of one other Bluetooth device

2 to F NetID for communication via Bluetooth with several Bluetooth devices

1. Ensure that the inverter is disconnected from voltage sources and t he l owe r en clos ure lid is o pen .

2. Determine a free NetID using the Sunny Explorer software (see the documentation for the

Sunny Explorer software).

3. To con fig ure a ne w Ne tID , set th e ro tar y sw itc h C to

the determined NetID using a slotted screwdriver

(blade width: 2.5 mm).

4. To deactivate the communication via Bluetooth, set

the rotary switch C to the position 0 using a slotted

screwdriver (blade width: 2.5 mm). This protects

your plant from unauthorized access.

☑ The inverter will adopt the setting up to five minutes after commissioning.

7.4 Commissioning the Inverter for the First Time

When commissioning the inverter for the first time, proceed as follows.

Requirements:

☐ The AC miniature circuit-breaker must be correctly rated.

☐ Overvoltage protection must be installed between the inverter and the rectifier.

☐ The inverter must be correctly mounted and closed.

☐ All cables must be correctly connected.

☐ Unused DC inputs must be sealed using the corresponding DC connectors and sealing plugs.

☐ The country data set must be configured according to the country or purpose.

☐ The ESS must be securely plugged in.

46 WB3-5TL-21-IA-en-10 Installation Manual

Page 47

SMA Solar Technology AG 7 Initial Start-Up

1. Switch on the miniature circuit-breaker.

2. If the multi-function relay is used, switch on the load supply voltage.

3. Start the small wind turbine system.

☑ The start phase begins.

☑ The green LED is lit and the display shows, in succession, the device type, the firmware

version, the se rial n umber or designat ion of the in verte r, the NetID , and t he spe cifie d coun try

data set and display language.

✖ Green LED flashing?

Possible cause of error: The DC input voltage is still too low, or the inverter is monitoring the

power distribution grid.

• If the DC input voltage is sufficiently high and the grid start-up conditions are met, the

inverter starts to operate.

✖ The red LED is lit and an error message and event number appear in the display?

• Eliminate the fault (see Section11 "Troubleshooting", page59).

4. Configure the inverter (see Section 8).

7.5 For Italy Only: Starting the Self-Test

The self-test is only valid for inverters that are configured with the country data set

CEI0-21 Int/CEI 0-21 Intern and were commissioned in Italy.

The Italian standard requires that all inverters feeding into the power distribution grid are equipped

with a self-test function in accordanc e with CEI 0-21. During the self-test, the inverter will consecutively

check the reaction times for overvoltage, undervoltage, maximum frequency and minimum frequency.

The self-test changes the upper and lower trip-limit values for each pr otective funct ion on a lin ear ba sis

for frequency monitoring and voltage monitoring. As soon as the measured value exceeds the

permitted trip-limit value, the inverter disconnects from the power distribution grid. In this way, the

inverter determines the reaction time up to disconnection and checks itself.

After the self-test has been completed, the inverter automatically switches back to the feed-in

operation, resets the original calibration values and connects to the power distribution grid.

Requirements:

☐ Configured country data set: CEI0-21Int/CEI 0-21 Intern or amended country data set

trimmed/Special setting based on one of the country data sets mentioned above.

☐ A report for entering the test results must be available.

☐ The inverter must be in operation and in the start phase.

Installation Manual WB3-5TL-21-IA-en-10 47

Page 48

7 Initial Start-Up SMA Solar Technology AG

1. As soon as the configured country data set appears in the display, tap once on the display

within ten seconds.

☑ A message informing you that the self-test has started is shown in the display:

Avvio Autotest.

✖The message Avvio Autotest is not shown in the display?

Ten seconds have passed and the self-test has not started.

• Restart the self-test (see Section 7.5.2).

2. Tap on the display within 20 seconds and enter the test results that follow into the test report.

☑ The self-test starts.

☑ The inverter displays the results of the individual tests for overvoltage, undervoltage,

maximum frequency and minimum frequency. The results are displayed three times in

succession for ten seconds each.

Example: Display messages for overvoltage test

•Test name: Autotest Vac Max

• Current line voltage: Vac Max 245,0 V

• Disconnection value: Valore di soglia 233,0 V

•Calibration value: Valore die taratura 276,0 V

• Reaction time: Tempo die intervento 0,08 s

7.5.1 Abortion of the Self-Test

If, during the self-test, an unexpected disconnection requirement occurs, the self-test is aborted.

The same applies if the DC voltage is so low that the feed-in cannot be continued.

• A message informing you that the self-test has been aborted is shown in the display for ten

seconds: Autotest interroto.

• Restart the self-test (see Section 7.5.2).

7.5.2 Restarting the Self-Test

1. Stop the small wind turbine system and secure against restart.

2. Disconnect the miniature circuit-breaker and secure against re-connection.

3. If the multi-function relay is used, switch off the load supply voltage, if necessary.

4. Remove the ESS from the inverter for five minutes and then plug it in again.

5. Commission the inverter again (see section 7.4).

☑ The inverter is once again in the start phase and you can start the self-test (see Section 7.5).

48 WB3-5TL-21-IA-en-10 Installation Manual

Page 49

SMA Solar Technology AG 8 Configuration

B

A

8 Configuration

8.1 Changing the Display Language

If the language associated with the country data set is not your desired language, you can change

the display language according to the following procedure.

1. Disconnect the inverter and open the lower enclosure lid (see Section 9).

2. Set the rotary switch A to 0 using a slotted

screwdriver (blade width: 2.5 mm). This ensures

that the country data set remains unchanged.

3. Set the rotary switch B to the desired language

using a slotted screwdriver (blade width: 2.5 mm):

Position Display language

0 Default setting

1English

2 German

3French

4Spanish

5Italian

6 Greek

7Czech

8Korean

9Portuguese

ADutch

BSlovenian

CBulgarian

DPolish

4. Re-commission the inverter (see Section 10).

☑ The inverter will adopt the setting up to five minutes after commissioning.

Installation Manual WB3-5TL-21-IA-en-10 49

Page 50

8 Configuration SMA Solar Technology AG

8.2 Changing the Plant Password and Plant Time

Requirements:

☐A computer with Bluetooth interface must be available.

☐ Sunny Explorer must be installed on the PC or laptop.

☐ The plant must be logged in to Sunny Explorer.

• Change the standard plant password (see Sunny Explorer help). This protects your plant from

unauthorized access.

• Change the plant time (see Sunny Explorer help).

8.3 Adapting the Polynomial Curve

The polynomial curve is a programmable power curve depending on the DC input voltage.

By adapting the polynomial curve of the inverter to the plant being used, you can optimize the energy

yield of the plant. To do so, you need the power-voltage characteristic curve for the plant being used.

Request the characteristic curve from the manufacturer of the plant.

To set the polynomial curve of the inverter, you must calculate the coefficients of the polynomial curve

using the Windy Boy Setup Tool. You can adjust the calculated coefficients with the Sunny Explorer

and transfer them to the inverter.

Requirements:

☐ A PC or laptop with Bluetooth interface must be available.

☐ Windy Boy Setup Tool, as of software version 1.05 and Sunny Explorer, as of software version

1.02, must be installed on the computer (for installation file see www.SMA-Solar.com).

☐ The plant must be logged in to Sunny Explorer.

☐ Power-voltage characteristic curve for the small wind turbine system must be available.

☐ AC line voltage or a DC voltage of at least 150 VDC must be present at the inverter.

Procedure:

• Calculate values for polynomial curve with Windy Boy Setup Tool

• Adjust calculated values for polynomial curve with Sunny Explorer

Calculating values for polynomial curve with Windy Boy Setup Tool

1. Open the Windy Boy Setup Tool.

2. Select [Device selection].

3. Select the inverter in the Device type list

4. If the default inverter parameters have been changed, manually enter the adjusted values of the

parameters in the appropriate fields (see the documentation for the Windy Boy Setup Tools).

5. Adjust the polynomial curve (power characteristic curve) (see the documentation for the Windy

Boy Setup Tool). In doing so, display the polynomial curve as monotonically increasing.

6. Note the values for the parameters Wind_a0, Wind_a1, Wind_a2, and Wind_a3.

50 WB3-5TL-21-IA-en-10 Installation Manual

Page 51

SMA Solar Technology AG 8 Configuration

Adjusting calculated values for polynomial curve with Sunny Explorer

1. Log in to Sunny Explorer as Installer (see Sunny Explorer help).

2. Select the parameter Constant deviation of power calculation and set the noted values for

parameter Wind_a0.

3. Select the parameter Coefficient of power calculation based on Udc and set the noted

values for parameter Wind_a1.

4. Select the parameter Coefficient of power calculation based on Udc^2 and set the noted

values for the parameter Wind_a2.

5. Select the parameter Coefficient of power calculation based on Udc^3 and set the noted

values for the parameter Wind_a3.

6. Save setting.

8.4 Setting the Deactivation Delay

The deactivation delay is the amount of time that must pass from the moment the DC feed-in conditions

are no longer met until the moment the inverter disconnects itself from the power distribution grid.

Requirement:

☐ A communication product that is appropriate for the type of communication used must be

available.

1. Select the parameter Deactivation delay or T-Stop and set the desired value.

2. Save setting.

Installation Manual WB3-5TL-21-IA-en-10 51

Page 52

8 Configuration SMA Solar Technology AG

8.5 Changing the DC Critical Voltage for Feed-in to the Power Distribution Grid

It is possible to change the default setting for the critical voltage to end and/or start feed-in.

Requirement:

☐ A communication product that is appropriate for the type of communication used must be

available.

Changing the critical voltage to end feed-ing

If the de fault value s for ending fee d-in a re not in the range of the set polynomial curve, you must adjust

the critical voltages to the zero-crossing of the power-voltage characteristic curve with the x axis. By

doing so, you achieve optimum start-up behavior for the plant.

Figure14: Power-voltage characteristic curve of a small wind turbine system indicating the default value for

1. Select the parameter Critical voltage to end feed-in or Upv-Stop and set the desired value.

2. Save setting.

52 WB3-5TL-21-IA-en-10 Installation Manual

critical voltage to end feed-in and the zero-crossing of the curve with the x axis (example)

Page 53

SMA Solar Technology AG 8 Configuration

Changing the critical voltage to start feed-in

If it is intended that feed-in to the power distribution grid and stress of the plant are not to start until

there is higher DC voltage, change the DC default values as described below.

1. To change the default value for the DC input, select the parameter Critical voltage to start

feed-in or A.VStr and set the desired value.

2. Save setting.

8.6 Connecting the Inverter to Sunny Portal

If the inverter is equipped with the Webconnect data module, you can connect the inverter to the

Sunny Portal.

Requirements:

☐ The inverter must be equipped with the Webconnect data module.

☐ The inverter must be connected to a network with Internet connection.

• Connect the inverter to Sunny Portal and register in the Sunny Portal (see the user manual of

Webconnect plants in the Sunny Portal)

8.7 Setting the Operating Parameters

Requirements:

☐ A communication product that is appropriate for the type of communication used must be

available.

☐ The changes to the grid-relevant parameters must be approved by the responsible grid

operator.

☐ For changing the grid-relevant parameters, an SMA Grid Guard code must be available

(see certificate "Application for SMA Grid Guard-Code" at www.SMA-Solar.com).

1. Access the user interface of the communication product and log in as "Installer".

2. If required, enter the SMA Grid Guard code.

3. Select and set the desired parameter.

4. Save setting.

Installation Manual WB3-5TL-21-IA-en-10 53

Page 54

9 Disconnecting the Inverter from Voltage Sources SMA Solar Technology AG

9 Disconnecting the Inverter from Voltage Sources

Destruction of the measuring device due to overvoltage

•Only use measuring devices with a DC input voltage range up to at least 1,000 V.

1. Stop the small wind turbine system and secure against restart.

2. Disconnect the miniature circuit-breaker and secure against re-connection.

3. If the multi-function relay is used, switch off the load supply voltage.

4. Remove the ESS.

5. Wait until the LEDs, display and if necessary, the load connected to the multi-function relay,

are switched off.

6. Use a current probe to make sure no current is

present in the DC cables.

7.

Danger to life due to high voltages

The capacitors in the inverter require five minutes to discharge.

• Wait five minutes before opening the enclosure lid.

8. Loosen all six screws of the lower enclosure lid

us ing an Allen ke y (AF 3) and remov e the enclosur e

lid.

54 WB3-5TL-21-IA-en-10 Installation Manual

Page 55

SMA Solar Technology AG 9 Disconnecting the Inverter from Voltage Sources

2

9. Unlock and disconnect all DC connectors. To do

this, insert a screwdriver into one of the side slots

(blade width: 3.5 mm) and pull the DC connectors

straight down. Do NOT PULL ON THE CABLE

while doing this.

10. Ensure that no voltage is present on the DC inputs

using a suitable measuring device.

11. Ensure that no voltage is present on the AC

connecting terminal plate between L and N using a

suitable measuring device. Insert the test probe

(maximum diameter: 2 mm) in each round opening

of the terminal.

Installation Manual WB3-5TL-21-IA-en-10 55

Page 56

9 Disconnecting the Inverter from Voltage Sources SMA Solar Technology AG

1

2

12. Ensure that no voltage is present on the AC

connecting terminal plate between L and PE using a

suitable measuring device. Insert the test probe

(maximum diameter: 2 mm) in each round opening

of the terminal.

13. Flip the display up to have more space to make the

measurement. Loosen the screw on the display to

do this.

☑ The display clicks into place.

14. Ensure that no voltage is present between all

terminals of the multi-function relay and PE of the

AC connecting terminal plate.

15.

Electrostatic discharges can damage the inverter

The internal components of the inverter can be irreparably damaged by electrostatic discharge.

• Ground yourself before touching any components.

56 WB3-5TL-21-IA-en-10 Installation Manual

Page 57

SMA Solar Technology AG 10 Recommissioning the Inverter

10 Recommissioning the Inverter

If you have disconnected the inverter from voltage sources (e.g. for configuration purposes) and want

to re-commission it, proceed as follows.

Requirements:

☐ The AC miniature circuit-breaker must be correctly rated.

☐ A rectifier and overvoltage protection must be installed between the inverter and the plant.

☐ The inverter must be correctly mounted.

1. Connect the rectifier to the inverter:

• Connect the positive connection cable to the

front positive DC connector of input A on the

inverter.

• Connect the negative connection cable to the

front negative DC connector of input A on the

inverter.

☑ The DC connectors click audibly into place.

2. Seal all unused DC inputs using the DC connectors

with sealing plugs.

Installation Manual WB3-5TL-21-IA-en-10 57

Page 58

10 Recommissioning the Inverter SMA Solar Technology AG

1

2

3

4

5

6

3. Place the lower enclosure lid with the 6 screws on

the enclosure and secure with screw 6. Then tighten

all screws with an Allen key (AF 3) in the order 1 to

6 (torque: 2 Nm).

4. Securely plug in the ESS. The ESS must be aligned

parallel to and flush with the enclosure.

5. Switch on the miniature circuit-breaker.

6. Start the small wind turbine system.

☑ The green LED is lit and the display shows the device type, the firmware version, the NetID,

the configured country data set and the display language.

✖ Green LED flashing?

Possible cause of error: The DC input voltage is still too low, or the inverter is monitoring the

power distribution grid.

• If the DC input voltage is sufficiently high and the grid start-up conditions are met, the

inverter starts to operate.

✖ The red LED is lit and an error message and event number appear in the display?

• Eliminate the fault (see Section11 "Troubleshooting", page59).

58 WB3-5TL-21-IA-en-10 Installation Manual

Page 59

SMA Solar Technology AG 11 Troubleshooting

11 Troubleshooting

11.1 LED Signals

The LEDs indicate the operating state of the inverter.

LED Status Explanation

Green Is lit Operation

In case of an event, the event message is shown in the display

(see Section 11.2.1).

Fl ash ing The r equ ire men ts f or t he c onn ect ion to th e po wer dis tri buti on g rid hav e no t

been met.

In case of an event, the event message is shown in the display

(see Section 11.2.1).

Red Is lit Error