Page 1

Installation Manual

SMA POWER CONTROL MODULE (PWCMOD)

PCONTROLMOD-IA-en-15 | Version 1.5 ENGLISH

Page 2

Legal Provisions SMA Solar Technology AG

Legal Provisions

The information contained in this document is the property of SMA Solar Technology AG. Publishing

its content, either partially or in full, requires the written permission of SMA Solar Technology AG.

Any internal company copying of the document for the purposes of evaluating the product or its

correct implementation is allowed and does not require permission.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does

not mean that a product or symbol is not trademarked.

The BLUETOOTH

and any use of these marks by SMA Solar Technology AG is under license.

Modbus® is a registered trademark of Schneider Electric and is licensed by the Modbus

Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

®

Phillips

and Pozidriv® are registered trademarks of Phillips Screw Company.

®

Torx

is a registered trademark of Acument Global Technologies, Inc.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2014 SMA Solar Technology AG. All rights reserved.

®

word mark and logos are registered trademarks owned by Bluetooth SIG, Inc.

2 PCONTROLMOD-IA-en-15 Installation Manual

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Target Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Further Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Typographies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7 Display of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.8 Figures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Supported Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 SMA Power Control Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Multifunction Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Mounting Position and Cable Route . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Cable Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Installation of the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3.1 Installing the Module in the Sunny Boy Smart Energy . . . . . . . . . . . 15

5.3.2 Installing the Module in the Sunny Tripower / Sunny Boy. . . . . . . . 17

5.4 Preparing the Enclosure Opening on the Inverter . . . . . . . . . . . . . . . 18

5.5 Preparing the Connection Cables for Connection to

Multi-Pole Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.6 Connecting the Ripple Control Receiver . . . . . . . . . . . . . . . . . . . . . . 19

5.7 Using the Ripple Control Receiver Signal for Additional Inverters. . . 23

Installation Manual PCONTROLMOD-IA-en-15 3

Page 4

Table of Contents SMA Solar Technology AG

5.8 Multifunction Relay Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.8.1 Connection Options for the Multifunction Relay . . . . . . . . . . . . . . . 24

5.8.2 Connecting the Remote Terminal to the Multifunction Relay . . . . . . 28

6 Configuring the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Information on Module Configuration. . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Setting the Operating Mode Active Power Limitation or Remote

Shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 Setting the Operating Mode of the Multifunction Relay . . . . . . . . . . 31

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.1 Removing the Module from the Sunny Boy Smart Energy. . . . . . . . . 33

8.2 Removing the Module from the Sunny Tripower / Sunny Boy. . . . . . 35

8.3 Disposing of the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4 PCONTROLMOD-IA-en-15 Installation Manual

Page 5

SMA Solar Technology AG 1 Information on this Document

1 Information on this Document

1.1 Validity

This d ocumen t is valid for de vice ty pe "PWCMOD-10" (SMA Power Control Module) from hardware

version A1.

1.2 Target Group

The tasks described in this document must be performed by qualified persons only. Qualified persons

must have the following skills:

• Training in the installation and commissioning of electrical devices and installations

• Knowledge of how to deal with the dangers and risks associated with installing and using

electrical devices and installations

• Knowledge of all applicable standards and directives

• Knowledge of how an inverter works and is operated

• Knowledge of and compliance with this document, including all safety information

1.3 Further Information

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

Firmware Update with SD Card Technical Description

Measured Values and Parameters Technical Description

1.4 Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in death

or serious injury

Indicates a hazardous situation which, if not avoided, can result in death

or serious injury

Indicates a hazardous situation which, if not avoided, can result in minor

or moderate injury

Indicates a situation which, if not avoided, can result in property damage

Information that is important for a specific topic or goal, but is not

safety-relevant

☐ Indicates a requirement for meeting a specific goal

☑ Desired result

✖ A problem that might occur

Installation Manual PCONTROLMOD-IA-en-15 5

Page 6

1 Information on this Document SMA Solar Technology AG

1.5 Typographies

Typography Use Example

Bold • Display texts

• Elements on a user interface

• Connections

• Elements to be selected

• Elements to be entered

> • Connects several elements to

be selected

[Button/Key] • Button or key to be selected or

pressed

• The value can be found in the

field Energy.

• Select Settings.

• Enter the value 10 in the field

Minutes.

• Select Settings > Date.

• Select [Next].

1.6 Nomenclature

Complete designation Designation in this document

SMA Power Control Module Module

Sunny WebBox with

BLUETOOTH

PV system System

®

Wireless Technology

Sunny WebBox with BLUETOOTH

1.7 Display of Parameters

Depending on the type of communication (e.g. RS485, BLUETOOTH or Speedwire/Webconnect),

the parameters are displayed differently in the communication products. This document uses both

methods of displaying parameters.

Example: Display of the parameter for setting the operating mode of the multifunction

relay

• For communication via RS485: parameter Mlt.OpMode

• For communication via BLUETOOTH or Speedwire/Webconnect: parameter Operating

mode of multifunction relay

1.8 Figures

The figures in this document have been created for inverters of type Sunny Tripower and may deviate

slightly in some cases for inverters of type Sunny Boy.

6 PCONTROLMOD-IA-en-15 Installation Manual

Page 7

SMA Solar Technology AG 2 Safety

2 Safety

2.1 Intended Use

The SMA Power Control Module is a multifunction interface which enables grid management services

to be implemented for one inverter. In addition, the module is equipped with a multifunction relay.

The module is available as a retrofit kit or is pre-installed in the inverter.

The module must only be used with the supported products.

The inverter still complies with the standard after the product has been installed.

For safety reasons, it is not permitted to modify the product or install components that are not explicitly

recommended or distributed by SMA Solar Technology AG for this product.

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

2.2 Safety Information

This section contains safety information that must be observed at all times when working on or with

the product. To prevent personal injury and property damage and to ensure long-term operation of

the product, read this section carefully and observe all safety information at all times.

Danger to life due to electric shock when opening the inverter

High voltages are present in the live components of the inverter. Touching live components results

in death or serious injury.

• Prior to performing any work on the inverter, always disconnect the inverter from voltage

sources on the AC and DC sides (see inverter manual). Observe the waiting time to allow the

capacitors to discharge.

Risk of burns due to hot enclosure parts

Some parts of the inverter enclosure can get hot during operation. Touching these enclosure parts

can result in burn injuries.

• During operation, do not touch any parts other than the lower enclosure lid of the inverter.

Damage to the inverter due to electrostatic discharge

The internal components of the inverter can be irreparably damaged by electrostatic discharge.

• Ground yourself before touching any inverter component.

Installation Manual PCONTROLMOD-IA-en-15 7

Page 8

2 Safety SMA Solar Technology AG

2.3 Supported Products

SMA Inverters

The module must only be installed in the following inverters from the indicated inverter firmware

version:

Sunny Boy From inverter firmware version

SB 2500TLST-21

SB 3000TLST-21

SB 3000TL-21

SB 3600TL-21

SB 4000TL-21

SB 5000TL-21

SB 6000TL-21

SB 3600SE-10

SB 5000SE-10

Sunny Tripower From inverter firmware version

STP 8000TL-10

STP10000TL-10

STP 12000TL-10

STP 15000TL-10

STP 17000TL-10

STP 20000TL-30

STP 25000TL-30

STP 15000TLHE-10

STP 20000TLHE-10

STP 15000TLEE-10

STP 20000TLEE-10

* If the firmware version of the inverter is lower than specified i n th e ta ble, you mus t up dat e th e in ver ter fir mwar e to the version

indicated or higher. For information on performing the firmware update, refer to the Technical Description "Firmware

Update with SD Card" at www.SMA-Solar.com.

2.55.23.R*

2.55.03.R*

2.4.30.R

2.50*

2.60.03.R*

2.51*

Additional SMA Products

The module can be configured with the following communication products:

• Sunny Explorer from software version 1.06*

• Sunny WebBox with BLUETOOTH from firmware version 1.03

• Sunny WebBox from firmware version 1.0

• SMA Cluster Controller from firmware version 1.0

* Inverters of type SB xx00SE-10 are supported from Sunny Explorer software version 1.07.03.

8 PCONTROLMOD-IA-en-15 Installation Manual

Page 9

SMA Solar Technology AG 3 Scope of Delivery

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

distributor if the delivery is incomplete or damaged.

Scope of delivery differs according to order option

If you have ordered the module separately from the inverter, the scope of delivery of the retrofit

kit includes the components shown below. If you have ordered the inverter together with the

module, the module will be pre-installed in the inverter upon delivery.

Figure1: Components included in the scope of delivery

Position Quantity Designation

A 1 SMA Power Control Module

B 2 Cable gland with single-hole seal

C2 Counter nut

D2 Two-hole seal

E 2 Three-pole plug

F 2 Six-pole plug

G 1 Installation manual

Installation Manual PCONTROLMOD-IA-en-15 9

Page 10

4 Product Description SMA Solar Technology AG

4 Product Description

4.1 SMA Power Control Module

The SMA Power Control Module is a multifunction interface which enables grid management services

to be implemented for one inverter. In addition, the module is equipped with a multifunction relay.

For the implementation of grid management services, the module rec eiv es the sp eci fic ati ons of t he g rid

operator via a ripple control receiver. In total, there are 16 setting possibilities or entry combinations.

The module can implement the following grid management services:

• Active power limitation in staged intervals of 0%, 30%, 60% and 100% of the agreed

connected active power

• For systems with a maximum power output of 6 kW and only in conjunction with inverters of

type SB xx00TL-21, SB xx00TLST-21, SB xx00SE-10:

– Remote shutdown within 50 ms

– Narrowing of the frequency limits to between 49.5 Hz and 50.5 Hz

The multifunction relay can be used for the following functions, for example:

• as fault indicator or operation signaling contact

• to control an external load or charge batteries

• to report the switching status of the grid relay (report start of grid feed-in to grid operator)

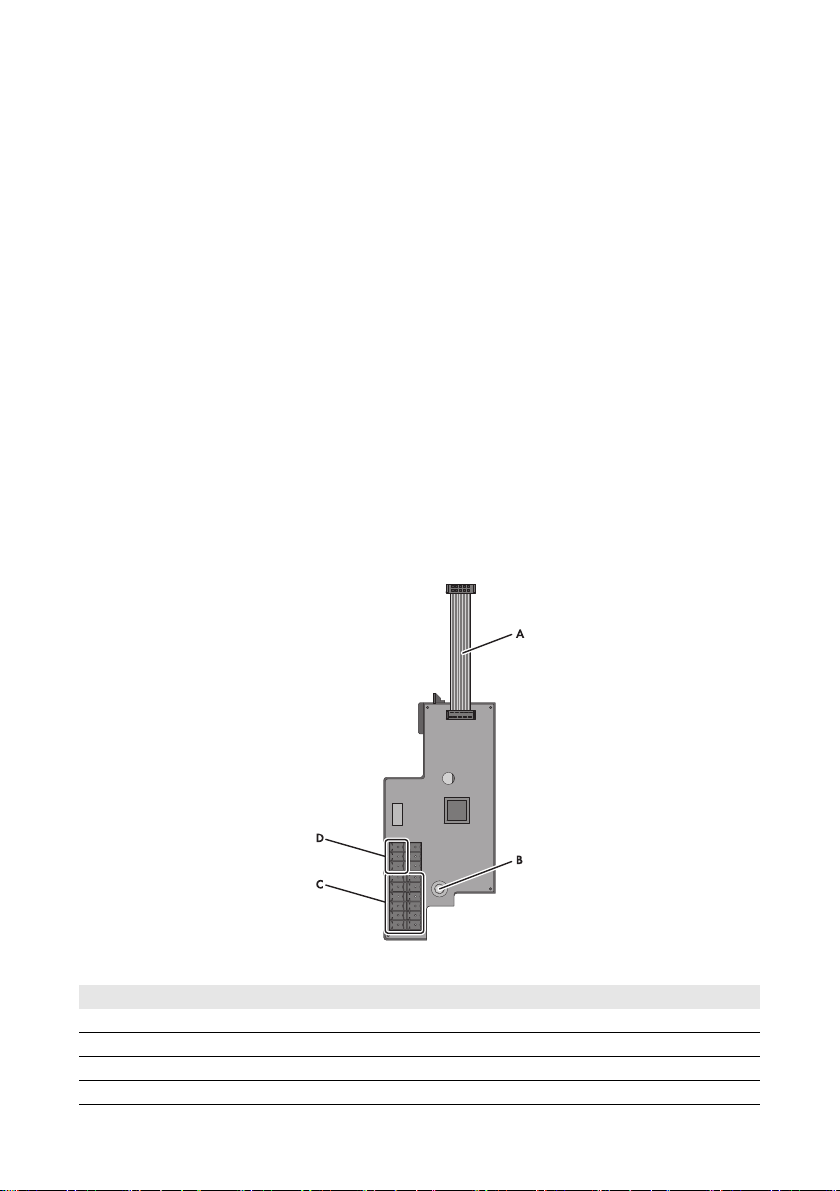

Figure2: Design of the SMA Power Control Module

Position Designation

ARibbon cable

B Screw for attaching the module in the inverter

C Terminals for ripple control receiver

D Multifunction relay terminal

10 PCONTROLMOD-IA-en-15 Installation Manual

Page 11

SMA Solar Technology AG 4 Product Description

4.2 Type Label

The type label clearly identifies the product. The type label is located on the back of the product.

You can read off the following data from the type label:

• Device type (Type)

•Serial number

• Hardware version (Version)

• Device-specific characteristics

Yo u wi ll r equ ire the inf ormatio n on the typ e la bel to u se t he p roduct safely and when seeking customer

support from the SMA Service Line. The type label must remain permanently attached to the product.

4.3 Multifunction Relay

Error message required by standard

In some countries, signaling of errors is required by standards, e.g. IEC 62109-2.

This requirement can be met in one of two ways:

• Operate the multifunction relay in the operating mode Fault indication (FltInd) and

connect a display to the multifunction relay that signals an error or the undisturbed

operation of the inverter.

• Activate the error alarm in Sunny Portal (see the Sunny Portal user manual at

www.SunnyPortal.com for information on receiving error alarms via Sunny Portal).

This requires the inverter to be registered on Sunny Portal.

You can use the multifunction relay for various purposes:

Operating mode of

multifunction relay

(Mlt.OpMod)

Fault indication (FltInd) The multifunction relay controls a display device which,

Self-consumption

(SelfCsmp)

Control via communication

(ComCtl)

Battery bank (BatCha) The multifunction relay controls the charging of external batteries

Installation Manual PCONTROLMOD-IA-en-15 11

Description

de pen din g on the t ype of c onn ect ion , signal s ei the r an err or o r th e

undisturbed operation of the inverter.

This operating mode is set by default.

The multifunction relay switches the loads on or off depending on

the amount of power available from the PV array. If a battery is

integrated in the system, the multifunction relay will still switch the

lo ads on o r of f de pen din g on t he a mou nt o f po wer avai lab le f rom

the PV array, not from the battery.

The multifunction relay switches loads on and off according to

commands transmitted by a communication product.

depending on the amount of power available from the system.

Page 12

4 Product Description SMA Solar Technology AG

Operating mode of

Description

multifunction relay

(Mlt.OpMod)

Fan control (FanCtl) The multifunction relay controls an external fan depending on the

temperature of the inverter.

If the temperature of the inverter is 5°C higher than a specific

threshold set in the inverter, the fan starts automatically. If the

temperature of the inverter is 10°C below the set threshold, the

fan stops automatically.

Switching status grid relay

(GriSwCpy)

The multifunction relay switches simultaneously with the grid relay

of the inverter and transmits a signal to the grid operator.

Depending on the intended application of the multifunction relay, the procedure for connection will

vary (see Section5.8.1 "Connection Options for the Multifunction Relay", page24).

After commissioning, you must set the operating mode of the multifunction relay via a communication

product and, if necessary, make further settings relating to the operating mode (see Section6.3

"Setting the Operating Mode of the Multifunction Relay", page31).

12 PCONTROLMOD-IA-en-15 Installation Manual

Page 13

SMA Solar Technology AG 5 Electrical Connection

5 Electrical Connection

5.1 Mounting Position and Cable Route

Mounting Position and Cable Route in the Sunny Boy Smart Energy

Fi gure 3: Mou nting posit ion an d cable r oute i n the S unny Boy S mart Energy with the enclosu re lid open a nd the

display flipped up

Position Designation

AInverter display (flipped up)

B Mounting position of the module

C Cable route to the module

D Cable gland M20 x 1.5

Installation Manual PCONTROLMOD-IA-en-15 13

Page 14

5 Electrical Connection SMA Solar Technology AG

Mounting Position and Cable Route in the Sunny Tripower / Sunny Boy

Figure4: Mounting position and cable route in the Sunny Tripower / Sunny Boy with the lower enclosure lid

open and the display flipped up

Position Designation

AInverter display (flipped up)

B Mounting position of the module

C Cable route to the module

D Cable gland M20 x 1.5

5.2 Cable Requirements

☐ UV-resistant for outdoor use

☐ Cable diameter when using a single-hole seal (one cable per cable gland): 5 mm to 13 mm

☐ Cable diameter when using a two-hole cable seal (two cables per cable gland): 6.0 mm

☐ Conductor cross-section: 0.5 mm

2

to 1.5 mm

☐ Maximum cable length: 100 m

☐ Required number of insulated conductors for connecting the ripple control receiver: at least five

☐ Required number of insulated conductors for connecting to the multifunction relay: at least two

Common connection cable

You can use one connection cable with at least seven insulated conductors to connect both the

ripple control receiver and the multifunction relay.

14 PCONTROLMOD-IA-en-15 Installation Manual

2

Page 15

SMA Solar Technology AG 5 Electrical Connection

5.3 Installation of the Module

5.3.1 Installing the Module in the Sunny Boy Smart Energy

Procedure:

1.

Danger to life due to electric shock when opening the inverter

High voltages are present in the live components of the inverter. Touching live components

results in death or serious injury.

• Disconnect the inverter from all voltage sources on the AC and DC sides and open it

(see inverter manual). Observe the waiting time to allow the capacitors to discharge.

2. Remove the display:

• Flip the display up.

• Remove the plug of the display ribbon cable

from the pin connector on the display

assembly.

• Flip the display down.

• Press the right-hand retainer outwards.

• Pull the display out of the right-hand retainer.

• Pull the display out of the left-hand retainer.

• Set the display aside in a safe place.

Installation Manual PCONTROLMOD-IA-en-15 15

Page 16

5 Electrical Connection SMA Solar Technology AG

3. Insert the ribbon cable of the module into the pin

connector on the display assembly.

4. Insert the module into the inverter. Insert the

left-hand key on the module into the hole in the

plastic retainer for the display assembly.

5. Use an Allen key (AF 3) to fasten the screw to the

module (torque: 1.5 Nm)

6. Install the display:

• (1) Plug the ribbon cable plug into the pin

connector on the display assembly.

• (2) Push the display into the right-hand retainer.

• (3) Push the display into the left-hand retainer.

16 PCONTROLMOD-IA-en-15 Installation Manual

Page 17

SMA Solar Technology AG 5 Electrical Connection

5.3.2 Installing the Module in the Sunny Tripower / Sunny Boy

Requirement:

☐ The firmware version of the inverter is supported (see Section2.3 "Supported Products",

page8). If necessary, update the inverter firmware (see the Technical Description "Firmware

Update with SD Card" at www.SMA-Solar.com).

Procedure:

1.

Danger to life due to electric shock when opening the inverter

High voltages are present in the live components of the inverter. Touching live components

results in death or serious injury.

• Disconnect the inverter from all voltage sources on the AC and DC sides and open it

(see the inverter manual). Observe the waiting time to allow the capacitors to discharge.

2. Loosen the screw of the display and flip the display up until it snaps into place.

3. If another communication interface is installed at the mounting location of the module,

disassemble it (see the installation manual of the communication interface).

4. Position the module in the inverter and lead the

ribbon cable upwards behind the display. The key

on the rear edge of the m odule m ust fit into the hole

in the plastic retainer in the inverter.

5. Use an Allen key (AF 3) to fasten the screw to the

module (torque: 1.5 Nm)

6. Flip the display down.

7. Insert the r ibb on c abl e in to th e le ft pi n co nne cto r on

the display of the inverter.

Installation Manual PCONTROLMOD-IA-en-15 17

Page 18

5 Electrical Connection SMA Solar Technology AG

5.4 Preparing the Enclosure Opening on the Inverter

Displayed graphics

Using example illustrations, this section shows only the preparation of the enclosure openings

on the inverter Sunny Tripower. However, the same method is used to connect to the module in

all inverters. Only the inverter environment is different.

Procedure:

1. Prepare the cable gland:

• If the enclosure opening of the inverter is sealed

with a filler plug, push the filler plug out of the

enclosure opening.

• If the enclosure opening of the inverter is sealed

with a cable gland installed in reversed

manner, loosen the external counter nut and

remove the cable gland.

2. Insert the cable gland from the outside and tighten

it with the counter nut from the inside.

3. If two cables must be led through the cable gland, press out the single-hole seal and replace

with a two-hole seal. Make sure that the enclosure opening of the inverter is tightly sealed.

18 PCONTROLMOD-IA-en-15 Installation Manual

Page 19

SMA Solar Technology AG

5.5 Preparing the Connection Cables for Connection to Multi-Pole Plugs

Always proceed as follows to prepare connection cables for connection to multi-pole plugs.

Procedure:

1. Trim 4 cm of the cable sheath at the end of the connection cable to be attached to the multi-pole

plug.

2. Trim unused insulated conductors flush with the cable sheath.

3. Strip off the conductor insulation by 6 mm.

5.6 Connecting the Ripple Control Receiver

Additionally required material (not included in the scope of delivery):

☐ One ripple control receiver with four outputs (see figure 5)

☐ One or two connection cables (see Section5.2 "Cable Requirements", page14)

Requirements:

☐ The connection cable must have been prepared for connection to the multi-pole plug (see

Section5.5 "Preparing the Connection Cables for Connection to Multi-Pole Plugs", page19).

☐ The enclosure opening on the inverter must be prepared (see Section5.4 "Preparing the

Enclosure Opening on the Inverter", page18).

Duplicate terminals for ripple control receiver

The ripple control receiver can be connected either to pins 1 to 5 or to pins 14 to 18.

The pins 1/18, 2/17, 3/16, 4/15 and 5/14 are each bridged so that a loop through of the

ripple control receiver signals is possible.

Figure5: Pin assignment of the module at the ripple control receiver terminals

Installation Manual PCONTROLMOD-IA-en-15 19

Page 20

5 Electrical Connection SMA Solar Technology AG

Pin Signal

Pin 5 / Pin 14 + 12 V

Pin 4 / Pin 15 D4

Pin 3 / Pin 16 D3

Pin 2 / Pin 17 D2

Pin 1 / Pin 18 D1

Functions of Signals D1 to D4 in Operating Mode Remote Shutdown

(Default Settings for Italy)

D1 D2 D3*

D4* Function

Closed Closed Open/Closed Open/Closed No specification

Open Closed Open/Closed Open/Closed Remote shutdown

Closed Open Open/Closed Open/Closed Narrowing of

frequency limits

Open Open Open/Closed Open/Closed Remote shutdown

* The signals D3 and D4 are not evaluated in the operating mode Remote shutdown.

20 PCONTROLMOD-IA-en-15 Installation Manual

Page 21

SMA Solar Technology AG 5 Electrical Connection

Value

-1%***

communication product

D1: 0| D2: 0| D3: 0| D4: 1 100%

Open Closed Open Open D1: 0| D2: 1| D3: 0| D4: 0 30%

Open Open Open Open D1: 0| D2: 0| D3: 0| D4: 0**

Closed Open Open Open D1: 1| D2: 0| D3: 0| D4: 0 0%

Digital input D1 Digital input D2 Digital input D3 Digital input D4 Display in the

Functions of Signals D1 to D4 in Operating Mode Active Power Limitation (Default Settings for Germany)

Installation Manual PCONTROLMOD-IA-en-15 21

Open Open Closed Open D1: 0| D2: 0| D3: 1| D4: 0 60%

Closed Closed Open Open D1: 1| D2: 1| D3: 0| D4: 0 -1%***

Open Closed Closed Open D1: 0| D2: 1| D3: 1| D4: 0 -1%***

Closed Open Closed Open D1: 1| D2: 0| D3: 1| D4: 0 -1%***

Open Open Open Open/Closed*

Closed Closed Closed Open D1: 1| D2: 1| D3: 1| D4: 0 -1%***

Closed Open Open Closed D1: 1| D2: 0| D3: 0| D4: 1 -1%***

Open Closed Open Closed D1: 0| D2: 1| D3: 0| D4: 1 -1%***

Closed Closed Open Closed D1: 1| D2: 1| D3: 0| D4: 1 -1%***

Open Open Closed Closed D1: 0| D2: 0| D3: 1| D4: 1 -1%***

Closed Open Closed Closed D1: 1| D2: 0| D3: 1| D4: 1 -1%***

Open Closed Closed Closed D1: 0| D2: 1| D3: 1| D4: 1 -1%***

Closed Closed Closed Closed D1: 1| D2: 1| D3: 1| D4: 1 -1%***

* Depending on the number of inputs of the ripple control receiver to be connected

Instantaneous value.

** When using the Sunny WebBox with RS485 communication, observe the following: If there is no signal, the value D0 is displayed for the parameter PCM-DigInStt under

*** The value "-1%" blocks the entry combination.

Page 22

5 Electrical Connection SMA Solar Technology AG

Procedure:

1.

Danger to life due to electric shock from faulty connection of the ripple control

receiver

In the event of faulty connection of the connection cable to the ripple control receiver, grid

voltage may be present in the module.

• Do not connect the insulated conductors of the connection cable to the line conductors of

the ripple control receiver.

• When connecting, ensure that no bridge is being used in the ripple control receiver.

2. Connect the connection cable to the ripple control receiver (see ripple control receiver manual).

Trim the unused insulated conductors up to the cable sheath and note the conductor colors.

Ripple control receiver

signal

Insulated conductor color Module

pin assignment

+ 12 V Pin 5 / Pin 14

D4 Pin 4 / Pin 15

D3 Pin 3 / Pin 16

D2 Pin 2 / Pin 17

D1 Pin 1 / Pin 18

3. Insert the connection cable through the seal and cable gland into the inverter.

4. Connect the connection cable to the six-pole plug as follows:

• Release the required conductor inlets of the plug using a screwdriver.

• Insert the insulated conductors into the conductor inlets. Make sure that the noted conductor

colors correspond to the pin assignment of the module.

5. Insert the six-pole plug into the terminal of the module. Observe the pin assignment.

6. Fasten the swivel nut hand-tight to the cable gland.

Ensure that the cable is securely in place and that

the enclosure opening of the inverter is tightly

sealed.

7. Flip down the display and fasten the screw hand-tight.

8. Close and commission the inverter (see inverter manual).

22 PCONTROLMOD-IA-en-15 Installation Manual

Page 23

SMA Solar Technology AG 5 Electrical Connection

5.7 Using the Ripple Control Receiver Signal for Additional Inverters

Additionally required material (not included in the scope of delivery):

☐ One connection cable for each additional inverter (see Section5.2 "Cable Requirements",

page14)

Requirements:

☐ The module must be installed in all inverters (see Section5.3 "Installation of the Module",

page15).

☐ The ripple control receiver must be connected to one of the modules (see Section5.6

"Connecting the Ripple Control Receiver", page19).

☐ The required enclosure openings on all inverters must be prepared (see Section5.4 "Preparing

the Enclosure Opening on the Inverter", page18).

☐ Both ends of the connection cable must be prepared for connection to a multi-pole plug

(see Section5.5 "Preparing the Connection Cables for Connection to Multi-Pole Plugs",

page19).

Possible to connect a maximum of five modules in parallel

You can use the signal from one ripple control receiver for a maximum of five inverters with

modules.

Figure6: Cabling for transmission of the signal from the ripple control receiver (example)

Installation Manual PCONTROLMOD-IA-en-15 23

Page 24

5 Electrical Connection SMA Solar Technology AG

Procedure:

1. Insert one end of the cable in inverter 1 and the other end in inverter 2. Each cable must be

routed through the seal and the cable gland of the inverter.

2. Connect a six-pole plug to each end of the cable as follows:

• Release the required conductor inlets of the plug using a screwdriver.

• Insert the insulated conductors into the conductor inlets. Make sure that the noted conductor

colors correspond to the pin assignment of the module.

3. In inverter 1, connect the six-pole plug to the free terminal for the ripple control receiver.

Observe the pin assignment.

4. In inverter 2, connect the six-pole plug to one of the terminals for the ripple control receiver.

Observe the pin assignment.

5. Fasten the swivel nut of the cable gland on both inverters hand-tight. Ensure that the cable is

securely in place and that the enclosure opening of the inverter is tightly sealed.

6. On both inverters, flip down the display and fasten the display screw hand-tight.

7. Close and commission both inverters (see inverter manual).

5.8 Multifunction Relay Connection

5.8.1 Connection Options for the Multifunction Relay

Depending on the required purpose of the multifunction relay, you can choose between the following

connection options (see Section4.3 "Multifunction Relay", page11):

Operating mode of

multifunction relay

(Mlt.OpMod)

Fault indication (FltInd) Using the multifunction relay as fault indicator contact

Self-consumption

(SelfCsmp)

Control via communication

(ComCtl)

Battery bank (BatCha) Controlling loads or charging batteries in a power-dependent

Fan control (FanCtl) Connecting the external fan (see fan documentation)

Switching status grid relay

(GriSwCpy)

24 PCONTROLMOD-IA-en-15 Installation Manual

Connection option

Controlling loads or charging batteries in a power-dependent

way via the multifunction relay

Controlling loads or charging batteries in a power-dependent

way via the multifunction relay

way via the multifunction relay

Reporting the switching status of the grid relay

Page 25

SMA Solar Technology AG 5 Electrical Connection

Using the Multifunction Relay as a Fault Indicator Contact or Operation Signaling

Contact

You can use the multifunction relay as a fault indicator contact for displaying or reporting inverter

errors. This requires a parallel connection. Alternatively, you can choose to have the undisturbed

operation displayed or reported. This requires a series connection. You can connect several inverters

to one fau lt in dic ato r co nta ct or ope rat ion sign ali ng c ont act . Yo u must connect the mu ltifunctio n rela ys

of several inverters in parallel.

Figure7: Wiring diagram with several inverters for connection of an operation signaling contact and wiring

Installation Manual PCONTROLMOD-IA-en-15 25

diagram for connection of a fault indicator contact (example)

Page 26

5 Electrical Connection SMA Solar Technology AG

Controlling loads or charging external batteries in a power-dependent way via

the multifunction relay

Loads can be controlled and external batteries charged in a power-dependent way via the

multifunction relay. To enable this function, a contactor (K1) must be connected to the multifunction

relay. The contactor (K1) switches the operating current for the load on or off. If you want external

batteries to be charged depending on the available power, the contactor serves to activate or

deactivate the charging of the batteries.

Figure8: Wiring diagram for connection to control a load or for the power-dependent charging of the batteries

26 PCONTROLMOD-IA-en-15 Installation Manual

Page 27

SMA Solar Technology AG 5 Electrical Connection

Reporting the Switching Status of the Grid Relay

The multifunction relay can trip a signal to the grid operator as soon as the first inverter connects to

the utility grid. To enable this function, you must switch the multifunction relays of all connected

inverters in parallel.

Figure9: Wiring diagram for reporting the switching status of the grid relay (example)

Installation Manual PCONTROLMOD-IA-en-15 27

Page 28

5 Electrical Connection SMA Solar Technology AG

5.8.2 Connecting the Remote Terminal to the Multifunction Relay

Requirements:

☐ You must select the connection option depending on the desired function of the multifunction

relay (see Section5.8.1 "Connection Options for the Multifunction Relay", page24).

☐ The technical requirements of the multifunction relay must be met (see Section9 "Technical

Data", page36).

☐ The enclosure opening on the inverter must be prepared (see Section5.4, page18).

☐ The connection cable must have been prepared for connection to the multi-pole plug

(see Section5.5, page19).

☐ Only use contactors which meet the connection requirements of the multifunction relay

(see Section9 "Technical Data", page36).

Destruction of the multifunction relay as a result of excessive contact load

• Observe the maximum switching voltage and maximum switching current (see Section9

"Technical Data", page36).

•Only use suitable contactors (see Section9 "Technical Data", page36).

Figure10: Pin assignment of the module at the multifunction relay terminal

Pin Signal Explanation

9NCBack contact

8NOFront contact

7 CO Change-over contact

28 PCONTROLMOD-IA-en-15 Installation Manual

Page 29

SMA Solar Technology AG 5 Electrical Connection

Procedure:

1. Connect the connection cable to the remote terminal (see the remote terminal manual). Trim the

unused insulated conductors up to the cable sheath and note down the conductor colors.

2. Insert the connection cable through the seal and cable gland into the inverter.

3. Connect the connection cable to the three-pole plug as follows:

• Release the required conductor inlets of the plug using a screwdriver.

• Insert the insulated conductors into the conductor inlets. Make sure that the noted conductor

colors correspond to the pin assignment of the module.

4. Connect the three-pole plug to the multifunction relay terminal of the module. Observe the pin

assignment.

5. Fasten the swivel nut hand-tight to the cable gland.

Ensure that the cable is securely in place and that

the enclosure opening of the inverter is tightly

sealed.

6. Flip down the display and fasten the screw hand-tight.

7. Close and commission the inverter (see inverter manual).

8. Use a communication product to set the operating mode of the multifunction relay (see

communication product manual).

9. If available, switch on the external supply voltage of the multifunction relay.

Installation Manual PCONTROLMOD-IA-en-15 29

Page 30

6 Configuring the Module SMA Solar Technology AG

6 Configuring the Module

6.1 Information on Module Configuration

Active power reduction to one of the 16 values set is realized within five seconds in the inverter.

Grid disconnection is possible within two seconds. In order to block an entry combination, the value

−1% mu st b e se t in the c omm uni cat ion pro duc t (s ee ta ble on p age 21) . Thi s en abl es u nas sig ned ent ry

combinations to be blocked.

If the grid operator does not permit the inverter to still feed in a low amount of active power when

limited to 0%, you must set the following parameter for grid disconnection. Setting this parameter

additionally opens the grid relays at a command of 0%. As a result, the inverter disconnects from the

utility grid and grid feed-in is no longer possible. Depending on the type of communication and the

communication product used, the parameter name may vary:

Type of

communication

BLUETOOTH,

Speedwire/

Webconnect

RS485 P-GriSwOpnZerW Yes/No

When the parameter is activated (Yes), the inverter disconnects from the utility grid when the signal

"0%" is issued. When the parameter is deactivated (No), the inverter continues to feed in with

minimum power when the signal "0%" is issued.

You can set the operating mode of the multifunction relay by means of a communication product

(for a detailed description of the operating parameters, see the Technical Description "Measured

Values and Parameters" at www.SMA-Solar.com).

Parameter name Setting

Equipment & device control system > Configuration

of feed-in management > Grid disconnection at 0%

or 0W setpoint, configuration of feed-in

management

Yes/No

6.2 Setting the Operating Mode Active Power Limitation or Remote Shutdown

Depending on the o rdered cou ntry op tion, the o perati ng mode Active power limitation or Remote

shutdown is activated by default.

Procedure:

• If you wish to use the operating mode Active power limitation, select the parameter

Operating mode of Power Control Module/PCM-OpMode and set it to the value Active

power limitation/ModWMax.

• If you wish to use the operating mode Remote shutdown, select the parameter Operating

mode of Power Control Module/PCM-OpMode and set it to the value Remote

shutdown/ModRemOff.

30 PCONTROLMOD-IA-en-15 Installation Manual

Page 31

SMA Solar Technology AG 6 Configuring the Module

6.3 Setting the Operating Mode of the Multifunction Relay

Procedure:

• Set the operating mode of the multifunction relay.

• If one of the following operating modes is used, you will need to carry out further settings for

the operating mode:

– Self-consumption/SelfCsmp

– Control via communication/ComCtl

– Battery bank/BatCha

Setting the Operating Mode of the Multifunction Relay

By default, the multifunction relay is set to activate a fault indicator if an error occurs. If you wish to

use the multifunction relay for another purpose, you will need to set the operating mode.

• Select the parameter Operating mode of multifunction relay/Mlt.OpMode and set the

desired operating mode (see Section4.3 "Multifunction Relay", page11).

Settings for Operating Mode Self-Consumption/SelfCsmp

• S et t he p owe r th res hol d fr om w hic h a l oad is t o be swi tch ed o n. S ele ct t he p ara met er Minimum

On time for MFR self-consumption/Mlt.MinOnPwr and set the desired power.

• Set the minimum time for which the power must exceed the set threshold in order to switch on

the load. Select the parameter Minimum On power for MFR self-consumption/

Mlt.MinOnPwr and set the desired minimum time.

• Set the minimum duration for which the load remains switched on. Select the parameter

Minimum On time for MFR self-consumption/Mlt.MinOnTmm and set the minimum

duration.

Settings for Operating Mode Control via Communication/ComCtl

• Set the status of the multifunction relay where it is to be controlled via a communication product.

Select the parameter Status of MFR with control via communication/MltComCtl.Sw and

set the status.

Settings for Operating Mode Battery bank/BatCha

• Set the power threshold from which the battery is to be charged. Select the parameter

Minimum on-power of MFR battery bank/Mlt.BatCha.Pwr and set the desired power.

• Set the minimum time which must elapse after charging the battery before it can be charged

again. Select the parameter Minimum On power for MFR battery bank/

Mlt.BatCha.Tmm and set the minimum time.

Installation Manual PCONTROLMOD-IA-en-15 31

Page 32

7 Troubleshooting SMA Solar Technology AG

7 Troubleshooting

Problem Cause and corrective measures

The inverter with module is not displayed in

Sunny Explorer.

The inverter with module has not been

commissioned.

Corrective measure:

• Commission the inverter with module

(see inverter manual).

The module is not properly connected.

Corrective measure:

•Ensure that the module is correctly

connected (see Section5 "Electrical

Connection", page13).

The firmware version of the inverter is not

supported (see Section2.3 "Supported

Products", page8).

Corrective measure:

• Update the inverter firmware (see inverter

manual).

The software version of Sunny Explorer is older

than version 1.06.

Corrective measure:

• Download Sunny Explorer from software

version 1.06 at www.SMA-Solar.com.

32 PCONTROLMOD-IA-en-15 Installation Manual

Page 33

SMA Solar Technology AG 8 Decommissioning

8 Decommissioning

8.1 Removing the Module from the Sunny Boy Smart Energy

Procedure:

1.

Danger to life due to electric shock when opening the inverter

High voltages are present in the live components of the inverter. Touching live components

results in death or serious injury.

• Disconnect the inverter from all voltage sources on the AC and DC sides and open it

(see inverter manual). Observe the waiting time to allow the capacitors to discharge.

2. Remove the display:

• Flip the display up.

• Remove the plug of the display ribbon cable

from the pin connector on the display

assembly.

• Flip the display down.

• (1) Press the right-hand retainer outwards.

• (2) Pull the display out of the right-hand

retainer.

• (3) Pull the display out of the left-hand retainer.

• Set the display aside in a safe place.

Installation Manual PCONTROLMOD-IA-en-15 33

Page 34

8 Decommissioning SMA Solar Technology AG

3. Remove the plug of the module ribbon cable from

the pin connector on the display assembly.

4. Loosen the screw on the module and remove the module from the inverter.

5. Install the display:

• (1) Plug the ribbon cable plug into the pin

connector on the display assembly.

• (2) Push the display into the right-hand retainer.

• (3)Push the display into the left-hand retainer.

6. Close the inverter (see inverter manual).

34 PCONTROLMOD-IA-en-15 Installation Manual

Page 35

SMA Solar Technology AG 8 Decommissioning

8.2 Removing the Module from the Sunny Tripower / Sunny Boy

Procedure:

1.

Danger to life due to electric shock when opening the inverter

High voltages are present in the live components of the inverter. Touching live components

results in death or serious injury.

• Disconnect the inverter from all voltage sources on the AC and DC sides and open it

(see inverter manual). Observe the waiting time to allow the capacitors to discharge.

2. Press the left-hand and right-hand lock hooks

outwards and remove the ribbon cable plug from

the left-hand pin connector on the inverter display.

3. Loosen the display screw and flip the display up.

4. Remove the plug for the ripple control receiver and/or multifunction relay from the module.

5. Open the cable gland(s) and remove the connection cables for the ripple control receiver and/

or multifunction relay from the inverter.

6. Seal the enclosure opening of the inverter using a filler plug. Make sure that the enclosure

opening of the inverter is tightly sealed.

7. Remove the module from the interface slot.

8. Flip down the display and fasten the screw hand-tight.

9. Close the inverter (see inverter manual).

8.3 Disposing of the Module

• Dispose of the module in accordance with the disposal regulations for electronic waste

applicable at the installation site.

Installation Manual PCONTROLMOD-IA-en-15 35

Page 36

9 Technical Data SMA Solar Technology AG

9 Technical Data

Connections

Ripple control receiver 4 digital inputs

Multifunction relay Relay output

Voltage Supply

Voltage supply via inverter

Ambient Conditions during Operation

Ambient temperature − 25°C to +85°C

Relative humidity, non-condensing 4% to 100%

Maximum height above mean sea level 3,000 m

Ambient Conditions for Storage/Transport

Ambient temperature − 40°C to +70°C

Relative humidity, non-condensing 10% to 95%

Maximum height above mean sea level 3,000 m

General Data

Dimensions (width x height x depth) 58 mm x 115 mm x 31 mm

Weight 49 g

Mounting location in the inverter

Degree of protection*

Required degree of protection of the inverter IP54

Maximum number of modules switched in

parallel

* in accordance with IEC 60529

IP20

5

Multifunction Relay

Maximum DC switching voltage 30 V

Maximum DC switching current 1.0 A

Terminal Three-pole plug

Minimum electrical endurance when the

100,000 switching cycles

maximum switching voltage and maximum

switching current are complied with

36 PCONTROLMOD-IA-en-15 Installation Manual

Page 37

SMA Solar Technology AG 10 Contact

10 Contact

If you have technical problems concerning our products, please contact the SMA Service Line.

We require the following information in order to provide you with the necessary assistance:

•Inverter

– Serial number

– Firmware version (tap the inverter display twice or see Sunny Portal or Sunny Explorer)

– Special country-specific settings (if applicable)

•Module

– Serial number

– Hardware version

– Application of the multifunction relay

• Communication product (e.g. Sunny Explorer)

–Type

– Serial number or software version

• Detailed description of the problem

Australia SMA Australia Pty Ltd.

Sydney

Belgien/

Belgique/

België

Brasil Vide España (Espanha)

Česko SMA Central & Eastern Europe

Chile Ver España

Danmark Se Deutschland (Tyskland)

Installation Manual PCONTROLMOD-IA-en-15 37

SMA Benelux BVBA/SPRL

Mechelen

s.r.o.

Praha

Toll free for

Australia:

International: +61 2 9491 4200

+32 15 286 730

+420 235 010 417

1800 SMA AUS

(1800 762 287)

Page 38

10 Contact SMA Solar Technology AG

Deutschland SMA Solar Technology AG

Niestetal

España SMA Ibérica Tecnología Solar,

S.L.U.

Barcelona

France SMA France S.A.S.

Lyon

India SMA Solar India Pvt. Ltd.

Mumbai

Italia SMA Italia S.r.l.

Milano

Κύπρος/

Kıbrıs

Luxemburg/

Luxembourg

Βλέπε Ελλάδα/

Bkz. Ελλάδα (Yunanistan)

Siehe Belgien

Voir Belgique

Magyarország lásd Česko (Csehország)

Nederland zie Belgien (België)

Österreich Siehe Deutschland

Perú Ver España

Polska Patrz Česko (Czechy)

Medium Power Solutions

Wechselrichter:

Kommunikation:

+49 561 9522-1499

+49 561 9522-2499

SMA Online Service Center:

www.SMA.de/Service

Hybrid Energy Solutions

Sunny Island: +49 561 9522-399

PV-Diesel

+49 561 9522-3199

Hybridsysteme:

Power Plant Solutions

Sunny Central: +49 561 9522-299

Llamada gratuita en

900 14 22 22

España:

Internacional: +34 902 14 24 24

Medium Power Solutions

Onduleurs :

Communication :

+33 472 09 04 40

+33 472 09 04 41

Hybrid Energy Solutions

Sunny Island : +33 472 09 04 42

Power Plant Solutions

Sunny Central : +33 472 09 04 43

+91 22 61713888

+39 02 8934-7299

38 PCONTROLMOD-IA-en-15 Installation Manual

Page 39

SMA Solar Technology AG 10 Contact

Portugal SMA Solar Technology Portugal,

Unipessoal Lda

Lisboa

România Vezi Česko (Cehia)

Schweiz Siehe Deutschland

Slovensko pozri Česko (Česká republika)

South Africa SMA Solar Technology

South Africa Pty Ltd.

Centurion (Pretoria)

United

Kingdom

Ελλάδα SMA Hellas AE

България Вижте Ελλάδα (Гърция)

대한민국 SMA Technology Korea Co., Ltd.서울+82 2 508-8599

+971 2 234-6177 SMA Middle East LLC

SMA Solar UK Ltd.

Milton Keynes

Αθήνα

SMA Solar (Thailand) Co., Ltd. +66 2 670 6999

Gratuito em

Portugal:

Internacional: +351 2 12 37 78 60

08600 SUNNY

(08600 78669)

International: +27 (12) 643 1785

+44 1908 304899

801 222 9 222

International: +30 212 222 9 222

800 20 89 87

!

Other

countries

Installation Manual PCONTROLMOD-IA-en-15 39

International SMA Service Line

Niestetal

Toll free worldwide: 00800 SMA SERVICE

(+800 762 7378423)

Page 40

SMA Solar Technology

www.SMA-Solar.com

Loading...

Loading...