SMA TCS 500-SC Maintenance manual

EN

Accessories for Central Inverters

TRANSFORMER COMPACT STATION 500SC / 630SC /

800SC / 900SC / 1000SC / 1250SC /1600SC / 1800SC

Maintenance manual

TCS-CP-WH-en-10 | 98-508610 | Version 1.0

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Qualifications of Skilled Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Personal Protective Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Overview of Maintenance-Relevant Components . . . . . . . . . . . . . . . . 9

3.2 Maintenance Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Disconnecting from and Reconnecting to Voltage Sources . . 15

4.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Disconnecting the Low Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Disconnecting the Medium Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Disconnecting the Control Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Reconnecting the Medium Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Reconnecting the Low Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7 Reconnecting the Control Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 Maintenance After Disconnection. . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Checking Tightness of Enclosure Openings. . . . . . . . . . . . . . . . . . . . 18

5.2 Checking LV/HRC Fuses for Discolouration . . . . . . . . . . . . . . . . . . . 18

5.3 Checking the AC Circuit Breaker for Functionality. . . . . . . . . . . . . . . 19

5.4 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4.1 Torque List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4.2 Checking Torque of Screw Connections . . . . . . . . . . . . . . . . . . . . . 19

5.5 Checking That Interlocking Works. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Maintenance when Medium Voltage, Low Voltage and

Control Voltage Is Present. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Checking that Transformer Fan Works . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Checking Exterior of Steel Station for Damage. . . . . . . . . . . . . . . . . 21

Maintenance manual TCS-CP-WH-en-10 3

Table of Contents SMA Solar Technology AG

7 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 TCS-CP-WH-en-10 Maintenance manual

SMA Solar Technology AG 1 Information on this Document

1 Information on this Document

Validity

This document is valid for the following device types:

• TCS-500-SC

• TCS-630-SC

• TCS-800-SC

• TCS-900-SC

• TCS-1000-SC

• TCS-1250-SC

• TCS-1600-SC

• TCS-1800-SC

• TCS-500-SC-ES

• TCS-630-SC-ES

• TCS-800-SC-ES

• TCS-1000-SC-ES

• TCS-1250-SC-ES

• TCS-1600-SC-ES

• TCS-500-SC-RO

• TCS-630-SC-RO

• TCS-800-SC-RO

• TCS-900-SC-RO

• TCS-1000-SC-RO

• TCS-1250-SC-RO

• TCS-1600-SC-RO

• TCS-1800-SC-RO

• TCS-500-SC-IN

• TCS-630-SC-IN

• TCS-800-SC-IN

• TCS-900-SC-IN

• TCS-1000-SC-IN

• TCS-1250-SC-IN

• TCS-1600-SC-IN

• TCS-1800-SC-IN

• TCS-500-SC-CZ

• TCS-630-SC-CZ

• TCS-800-SC-CZ

• TCS-1000-SC-CZ

• TCS-1250-SC-CZ

• TCS-1600-SC-CZ

• TCS-500-SC-BG

• TCS-630-SC-BG

• TCS-800-SC-BG

• TCS-900-SC-BG

• TCS-1000-SC-BG

• TCS-1250-SC-BG

• TCS-1600-SC-BG

• TCS-1800-SC-BG

• TCS-500-SC-UK

• TCS-630-SC-UK

• TCS-800-SC-UK

• TCS-1000-SC-UK

• TCS-1250-SC-UK

• TCS-1600-SC-UK

• TCS-500-SC-GR

• TCS-630-SC-GR

• TCS-800-SC-GR

• TCS-900-SC-GR

• TCS-1000-SC-GR

• TCS-1250-SC-GR

• TCS-1600-SC-GR

• TCS-1800-SC-GR

• TCS-500-SC-IT

• TCS-630-SC-IT

• TCS-800-SC-IT

• TCS-900-SC-IT

• TCS-1000-SC-IT

• TCS-1250-SC-IT

• TCS-1600-SC-IT

• TCS-1800-SC-IT

• TCS-500-SC-FR

• TCS-630-SC-FR

• TCS-800-SC-FR

• TCS-1000-SC-FR

• TCS-1250-SC-FR

• TCS-1600-SC-FR

• TCS-500-SC-AU

• TCS-630-SC-AU

• TCS-800-SC-AU

• TCS-1000-SC-AU

• TCS-1250-SC-AU

• TCS-1600-SC-AU

• TCS-500-SC-ZA

• TCS-630-SC-ZA

• TCS-800-SC-ZA

• TCS-900-SC-ZA

• TCS-1000-SC-ZA

• TCS-1250-SC-ZA

• TCS-1600-SC-ZA

• TCS-1800-SC-ZA

• TCS-500-SC-EX

• TCS-630-SC-EX

• TCS-800-SC-EX

• TCS-900-SC-EX

• TCS-1000-SC-EX

• TCS-1250-SC-EX

• TCS-1600-SC-EX

• TCS-1800-SC-EX

Maintenance manual TCS-CP-WH-en-10 5

1 Information on this Document SMA Solar Technology AG

%"/(&3

8"3/*/(

$"65*0/

/05*$&

Target Group

This manual is intended for skilled persons. Only persons with the appropriate skills are allowed to

perform the tasks described in this manual (see Section2.2 "Qualifications of Skilled Persons",

page8).

Additional Information

For additional information on third-party components, please contact the relevant manufacturer.

A maintenance report is enclosed with each Transformer Compact Station. The maintenance report

describes the pending maintenance work and the maintenance interval recommended by

SMA Solar Technology AG.

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury

Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury

Indicates a situation which, if not avoided, could result in property

damage

Information that is important for a specific topic or goal, but is not

safety-relevant

☐ Indicates an essential requirement for achieving a specific goal

☑ Desired result

✖A problem that might occur

Abbreviations

Abbreviation Designation Explanation

AC Alternating Current MV Medium Voltage PV Photovoltaics -

6 TCS-CP-WH-en-10 Maintenance manual

SMA Solar Technology AG 2 Safety

2 Safety

2.1 Safety Precautions

Electric Shock

High voltages are present in the Transformer Compact Station. Failure to adhere to the safety

messages will lead to death or serious injuries as a result of electric shock.

• All work must be carried out as described in this manual. Observe all safety precautions.

Observe all safety precautions included in this document and the documentation of the

components.

• Do not touch any live components of the Transformer Compact Station or the medium-voltage

grid. Comply with all applicable safety regulations for handling electrical installations and the

medium-voltage grid.

• When electrical work is being carried out, a second person must be present at all times. In the

event of an unforeseen accident involving electricity, this person must be able to switch off the

electricity supply and provide assistance.

In the event of an earth fault, remember that plant components which are presumed earthed may still

be live. Failure to adhere to the safety messages will lead to death or serious injuries as a result of

electric shock.

• Ensure that no voltage is present before touching any part of the plant.

• Wear personal protective equipment.

Operating a damaged Transformer Compact Station can lead to hazardous situations that result in

death or serious injuries due to electric shock.

• Operate the Transformer Compact Station only if it is in safe and good working order.

• Regularly check the Transformer Compact Station for visible damage.

• Operate the Transformer Compact Station only if there is no visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

Environmental Hazard

Ensure that escape routes are not blocked.

• The escape routes must be dimensioned sothat the persons working on the

Transformer Compact Station can escape quickly in dangerous situations.

• Escape routes must not be blocked.

• The minimum passage width of the escape route must comply with national standards.

In Germany, the minimum passage width is 800 mm.

Moisture and dust penetration can damage the Transformer Compact Station.

• Do not open the low-voltage area of the Transformer Compact Station if it is raining.

• Only perform maintenance in a dry and dust-free environment.

Maintenance manual TCS-CP-WH-en-10 7

2 Safety SMA Solar Technology AG

Mechanical Hazards

Failure to observe the torque specifications reduces the ampacity of the screw connections. This can

cause components to overheat and catch fire. Adhere to the torque specifications in the circuit

diagram and documentation.

• Observe the specified torque.

• Contact the SMA Service Line if torque specifications are not given.

Storing Documentation

This documentation must be accessible to service and maintenance personnel at all times.

• Keep this documentation within the immediate vicinity of the Transformer Compact Station.

Warning Signs

Warning signs must be clearly legible at all times.

• Replace warning signs if damaged.

• Clean warning signs if dirty.

2.2 Qualifications of Skilled Persons

The work described in this document must be performed by skilled persons only. Skilled persons must

have the following qualifications:

• Knowledge of how a Transformer Compact Station works and is operated

• Training in how to deal with dangers and risks associated with operating and maintaining

electrical devices and plants

• Training in the maintenance of electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of and compliance with this document and the component documents with all the

safety precautions

• Authorisation to connect and disconnect medium-voltage sources if maintenance activities are

required for medium-voltage components

2.3 Personal Protective Equipment

After the control voltage, low voltage or medium voltage has been switched on, personal protective

equipment is required for all work performed. The protective equipment must comply with Directive

89/686/EEC. Any protective equipment that is stipulated by law or otherwise required must also be

used.

8 TCS-CP-WH-en-10 Maintenance manual

SMA Solar Technology AG 3 Maintenance Schedule

3 Maintenance Schedule

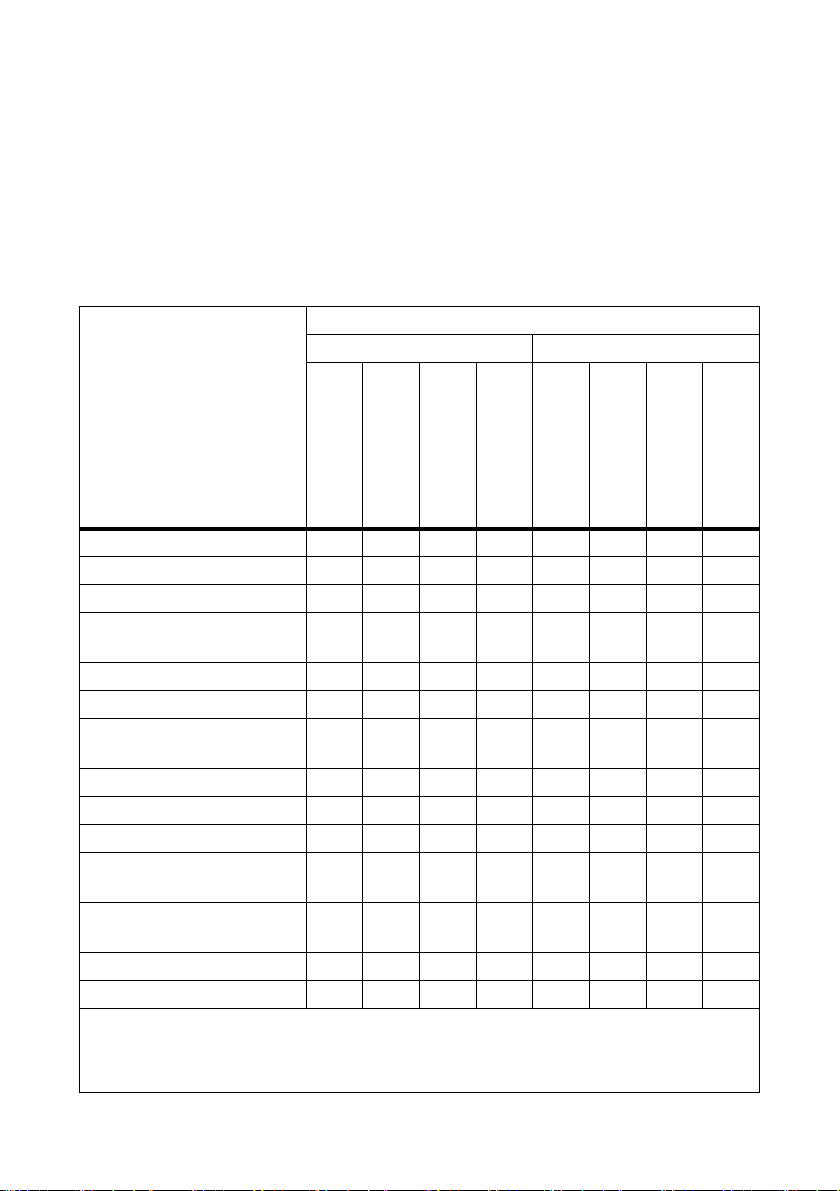

3.1 Overview of Maintenance-Relevant Components

Ma int ena nce of the Tra nsf orm er C omp act Sta tio n depe nds on t he c ountry option and the components

used. In the following table, depending on the country option, you can determine:

• for which component maintenance must be carried out,

• for which component maintenance must be carried out if option is present.

Component Country option

Concrete station Steel station

TCS-DE (V.2)/CZ/ES

BG/RO/UK

TCS-DE (V.1)

TCS-FR

TCS-IT

TCS-EX

TCS-AU/ZA/IN

TCS-DE

TCS-GR

Concrete station x x x x ‒ ‒ ‒ ‒

Steel station ‒ ‒ ‒ ‒ x x x x

Enclosure openings x x x x ‒ ‒ ‒ ‒

LV/HRC fuse

switch-disconnector

AC circuit breaker ooxooooo

Low-voltage meter (GSE) ‒‒‒x‒‒‒‒

Transformer for auxiliary power

supply

Interlocking ‒‒xo‒‒‒‒

Station sub-distribution xxxxxxxx

Medium-voltage transformer x x x x x x x x

Contact thermometer of

medium-voltage transformer

Medium-voltage transformer

protection device

MV transformer fan ‒ o ‒ o o ‒ o x

Medium-voltage switchgear oooooooo

x Maintenance must be carried out

o Maintenance must be carried out if option exists

‒ Maintenance not required

xx‒xxxxx

oooooooo

oooooooo

oooooooo

Maintenance manual TCS-CP-WH-en-10 9

Loading...

Loading...