Page 1

SUNNY TRIPOWER

STP50-40-BE-en-12 | Version 1.2ENGLISH

Operating manual

SUNNY TRIPOWER CORE1

Page 2

Legal Provisions

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-122

Legal Provisions

The information contained in these documents is property of SMA Solar Technology AG. Any

publication, whether in whole or in part, requires prior written approval by SMA Solar Technology

AG. Internal reproduction used solely for the purpose of product evaluation or other proper use is

allowed and does not require prior approval.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Software licenses

The licenses for the used software modules can be called up on the user interface of the product.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. Missing designations do not

mean that a product or brand is not a registered trademark.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

Email: info@SMA.de

Status: 12/11/2017

Copyright © 2017 SMA Solar Technology AG. All rights reserved.

Page 3

Table of Contents

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 3

Table of Contents

1 Information on this Document................................................. 6

1.1 Validity........................................................................................................................ 6

1.2 Target Group.............................................................................................................. 6

1.3 Structure...................................................................................................................... 6

1.4 Types of warning message........................................................................................ 6

1.5 Symbols ...................................................................................................................... 7

1.6 Typographies.............................................................................................................. 7

1.7 Nomenclature............................................................................................................. 7

1.8 Additional Information ............................................................................................... 7

2 Safety ........................................................................................ 9

2.1 Intended Use .............................................................................................................. 9

2.2 Safety Information...................................................................................................... 9

3 Scope of Delivery ..................................................................... 12

4 Product Overview .................................................................... 13

4.1 Product Description .................................................................................................... 13

4.2 Interfaces and Functions ............................................................................................ 15

5 Mounting................................................................................... 18

5.1 Requirements for Mounting ....................................................................................... 18

5.2 Mounting the Inverter................................................................................................. 21

6 Electrical Connection ................................................................ 24

6.1 Safety during Electrical Connection.......................................................................... 24

6.2 Overview of the Connection Area ............................................................................ 25

6.3 AC Connection........................................................................................................... 25

6.3.1 Requirements for the AC Connection......................................... 25

6.3.2 Connecting the Inverter to the Utility Grid................................. 27

6.4 DC Connection........................................................................................................... 29

6.4.1 Requirements for the DC Connection......................................... 29

6.4.2 Assembling the DC Connectors ................................................. 29

6.4.3 Connecting the PV Array ............................................................ 31

6.4.4 Disassembling the DC Connectors............................................. 34

6.5 Connecting the Multifunction Relay .......................................................................... 35

6.5.1 Procedure for connecting the multifunction relay...................... 35

6.5.2 Operating Modes of the Multifunction Relay ........................... 36

6.5.3 Connection Options.................................................................... 36

Page 4

Table of Contents

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-124

6.5.4 Connection to the Multifunction Relay....................................... 40

6.6 Connecting the Network Cables............................................................................... 42

7 Commissioning ......................................................................... 44

7.1 Commissioning Procedure ......................................................................................... 44

7.2 Commissioning the Inverter........................................................................................ 44

7.3 Starting the Self-Test (For Italy Only) ........................................................................ 45

7.4 Selecting a configuration option ............................................................................... 46

8 Using the Inverter User Interface............................................ 50

8.1 Establishing a connection to the user interface ........................................................ 50

8.1.1 Establishing a direct connection via WLAN.............................. 50

8.1.2 Establishing a Connection via WLAN in the Local Network.... 51

8.1.3 Establishing a Connection via Ethernet in the local network.... 52

8.2 Logging In and Out of the User Interface................................................................. 53

8.3 Start Page Design of the User Interface.................................................................... 55

8.4 Displaying and Downloading the Stored Data........................................................ 57

8.5 Changing the Password............................................................................................. 58

9 Configuration of the Inverter................................................... 59

9.1 Changing Operating Parameters.............................................................................. 59

9.2 Starting the Installation Assistant............................................................................... 60

9.3 Configuring the Country Data Set............................................................................. 61

9.4 Changing the Operating Mode of the Multifunction Relay .................................... 61

9.5 Configuring the Modbus Function............................................................................. 62

9.6 Setting the Tripping Threshold of the Residual-Current Device................................ 63

9.7 Configuring Feed-In Management............................................................................ 63

9.8 Setting SMA OptiTrac Global Peak ......................................................................... 64

9.9 Activating the Receipt of Control Signals (Only for Italy)........................................ 64

9.10 Activating String-Failure Detection............................................................................ 65

9.11 Saving the Configuration in a File............................................................................. 65

9.12 Adopting a Configuration from a File....................................................................... 65

9.13 Switching the Dynamic Power Display Off............................................................... 66

9.14 Switching WLAN On and Off................................................................................... 66

9.15 Activate WPS Function............................................................................................... 67

10 Disconnecting the Inverter from Voltage Sources................. 69

11 Cleaning the Inverter ............................................................... 71

12 Troubleshooting........................................................................ 72

12.1 Event Messages ......................................................................................................... 72

Page 5

Table of Contents

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 5

12.2 LED Signals................................................................................................................. 85

12.3 Forgotten Password.................................................................................................... 86

12.4 Checking the PV System for Ground Faults.............................................................. 87

12.5 Updating the Firmware.............................................................................................. 90

13 Decommissioning the Inverter................................................. 92

14 Technical Data .......................................................................... 96

15 Accessories ...............................................................................101

16 Contact ......................................................................................102

17 EU Declaration of Conformity .................................................104

Page 6

1 Information on this Document

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-126

1 Information on this Document

1.1 Validity

This document is valid for the following device types:

• STP 50-40 (Sunny Tripower CORE1)

1.2 Target Group

This document is intended for qualified persons and end users. Only qualified persons are allowed

to perform the activities marked in this document with a warning symbol and the caption

"Qualifiedperson". Tasks that do not require any particular qualification are not marked and can

also be performed by end users. Qualified persons must have the following skills:

• Knowledge of how an inverter works and is operated

• Training in the installation and commissioning of electrical devices and installations

• Knowledge of all applicable laws, standards and directives

• Knowledge of and compliance with this document and all safety information

• Training in how to deal with the dangers and risks associated with installing, repairing and

using electrical devices and installations

1.3 Structure

This document describes the mounting, installation, commissioning, configuration, operation,

troubleshooting and decommissioning of the product as well as the operation of the product user

interface.

You will find the latest version of this document and further information on the product in PDF format

at www.SMA-Solar.com.

1.4 Types of warning message

DANGER

Safety information that, if not avoided, will result in death or serious injury.

WARNING

Safety information that, if not avoided, could result in death or serious injury.

CAUTION

Safety information that, if not avoided, can result in minor or moderate injury.

NOTICE

Safety information that, if not avoided, can result in property damage.

Page 7

1 Information on this Document

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 7

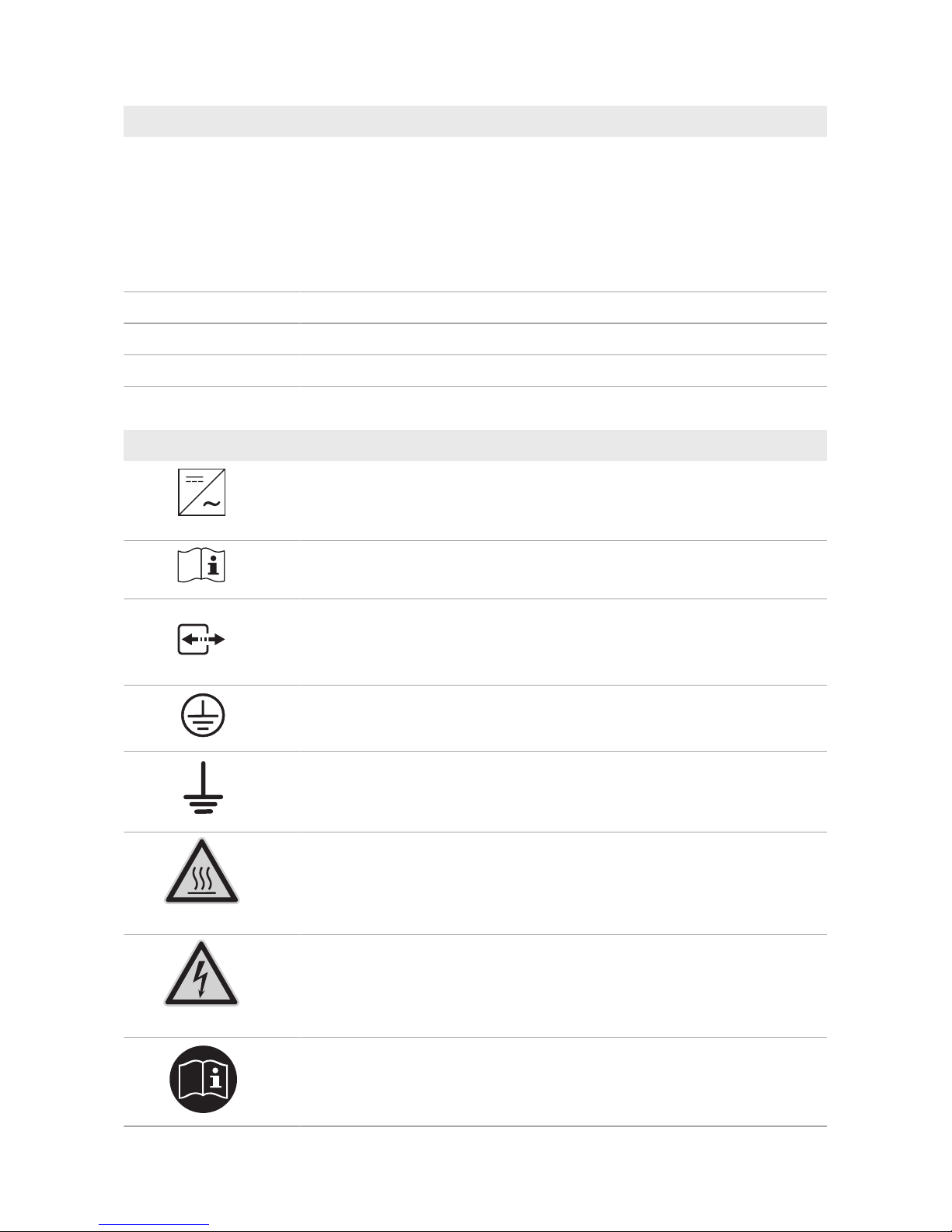

1.5 Symbols

Symbol Explanation

Information that is important for a specific topic or goal, but is not

safety-relevant

☐

Indicates a requirement for meeting a specific goal

☑

Desired result

✖

A problem that might occur

Sections describing activities to be performed by qualified persons

only

1.6 Typographies

Typography Use Example

bold

• Terminals

• Slots

• Parameters

• Elements on the user interface

• Elements to be selected

• Elements to be entered

• The value can be found in

the field Energy.

• Select Settings.

• Enter 10 in the field

Minutes.

>

• Connects several elements to be

selected

• Select Settings > Date.

[Button]

• Button to be selected or pressed

• Select [Next].

1.7 Nomenclature

Complete designation Designation in this document

Sunny Tripower CORE1 Inverter, product

1.8 Additional Information

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

"Parameters and Measured Values"

Overview of All Inverter Operating Parameters and Their Configura-

tion Options

Technical Information

Page 8

1 Information on this Document

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-128

Document title Document type

"Webconnect Systems in SunnyPortal"

Registration in SunnyPortal and setting or changing operating pa-

rameters of the inverter

User Manual

"SMAModbus® Interface"

Information on the commissioning and configuration of the SMA

Modbus interface

Technical Information

"SunSpec® Modbus® Interface"

Information on the commissioning and configuration of the SunSpec

Modbus interface

Technical Information

"Efficiency and Derating"

Efficiency and Derating Behavior of the SunnyBoy, SunnyTripower

and SunnyMiniCentral Inverters

Technical Information

Page 9

2 Safety

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 9

2 Safety

2.1 Intended Use

The SunnyTripower is a transformerless PV inverter, with 6 MPPtrackers, that converts the direct

current of the PV array to grid-compliant, three-phase current and feeds it into the utility grid.

The product is suitable for indoor and outdoor use.

The product must only be operated with PV arrays of protection class II in accordance with

IEC61730, application class A. The PV modules must be compatible with this product.

The product is not equipped with a transformer and therefore has no galvanic isolation. The

product must not be operated with PV modules whose outputs are grounded. This can cause the

product to be destroyed. The product may be operated with PV modules whose frame is grounded.

PV modules with a high capacity to ground must only be used if their coupling capacity does not

exceed 12.6μF (for information on how to calculate the coupling capacity, see the Technical

Information "Leading Leakage Currents" at www.SMA-Solar.com).

All components must remain within their permitted operating ranges and their installation

requirements at all times.

The product must only be used in countries for which it is approved or released by SMA Solar

Technology AG and the grid operator.

The product is also approved for the Australian market and may be used in Australia. If DRM

support is specified, the inverter may only be used in conjunction with a Demand Response

Enabling Device (DRED). This ensures that the inverter implements the commands from the grid

operator for active power limitation at all times. The inverter and the Demand Response Enabling

Device (DRED) must be connected in the same network and the inverter Modbus interface must be

activated and the TCP server set.

Use this product only in accordance with the information provided in the enclosed documentation

and with the locally applicable standards and directives. Any other application may cause

personal injury or property damage.

Alterations to the product, e.g. changes or modifications, are only permitted with the express written

permission of SMA Solar Technology AG. Unauthorized alterations will void guarantee and

warranty claims and in most cases terminate the operating license. SMA Solar Technology AG

shall not be held liable for any damage caused by such changes.

Any use of the product other than that described in the Intended Use section does not qualify as the

intended use.

The enclosed documentation is an integral part of this product. Keep the documentation in a

convenient place for future reference and observe all instructions contained therein.

The type label must remain permanently attached to the product.

2.2 Safety Information

This section contains safety information that must be observed at all times when working on or with

the product.

To prevent personal injury and property damage and to ensure long-term operation of the product,

read this section carefully and observe all safety information at all times.

Page 10

2 Safety

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1210

DANGER

Danger to life due to high voltages of the PV array

When exposed to light, the PV array generates dangerous DC voltage, which is present in the

DC conductors and the live components of the inverter. Touching the DC conductors or the live

components can lead to lethal electric shocks. If you disconnect the DC connectors from the

inverter under load, an electric arc may occur leading to electric shock and burns.

• Do not touch non-insulated cable ends.

• Do not touch the DC conductors.

• Do not touch any live components of the inverter.

• Have the inverter mounted, installed and commissioned only by qualified persons with the

appropriate skills.

• If an error occurs, have it rectified by qualified persons only.

• Prior to performing any work on the inverter, disconnect it from all voltage sources as

described in this document.

DANGER

Danger to life due to electric shock

Touching an ungrounded PV module or array frame can cause a lethal electric shock.

• Connect and ground the frame of the PV modules, the array frame and the electrically

conductive surfaces so that there is continuous conduction. Observe the applicable local

regulations.

CAUTION

Risk of burns due to hot enclosure parts

The enclosure and the enclosure lid may get hot during operation. The DC load-break switch can

not become hot.

• Do not touch hot surfaces.

• Wait until the inverter has cooled down before touching the enclosure or enclosure lid.

NOTICE

Damage to the enclosure seal in subfreezing conditions

If you open the product when temperatures are below freezing, the enclosure seals can be

damaged. Moisture can penetrate the product then.

• Only open the product if the ambient temperature is not below -5°C.

• If a layer of ice has formed on the enclosure seal when temperatures are below freezing,

remove it prior to opening the product (e.g. by melting the ice with warm air). Observe the

applicable safety regulations.

Page 11

2 Safety

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 11

NOTICE

Damage to the type label due to the use of cleaning agents

• If the inverter is dirty, clean the enclosure, the enclosure lid, the type label and the LEDs with

a damp cloth and clear water only.

Page 12

3 Scope of Delivery

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1212

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

distributor if the scope of delivery is incomplete or damaged.

B C E

F

J

I

A

+

_

G

K

D

H

Figure 1: Components included in the scope of delivery

Position Quantity Designation

A 1 Inverter

B 4 Foot

C 8 Hexagon bolt M8x40

D 8 Washer

E 4 Carrying handle

F 12 Positive DC connector

G 12 Negative DC connector

H 24 Sealing plug for DC connectors

I 1 Cable gland M63 with counter nut

J 1 3-pole terminal block

K 1 Quick Reference Guide

Page 13

4 Product Overview

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 13

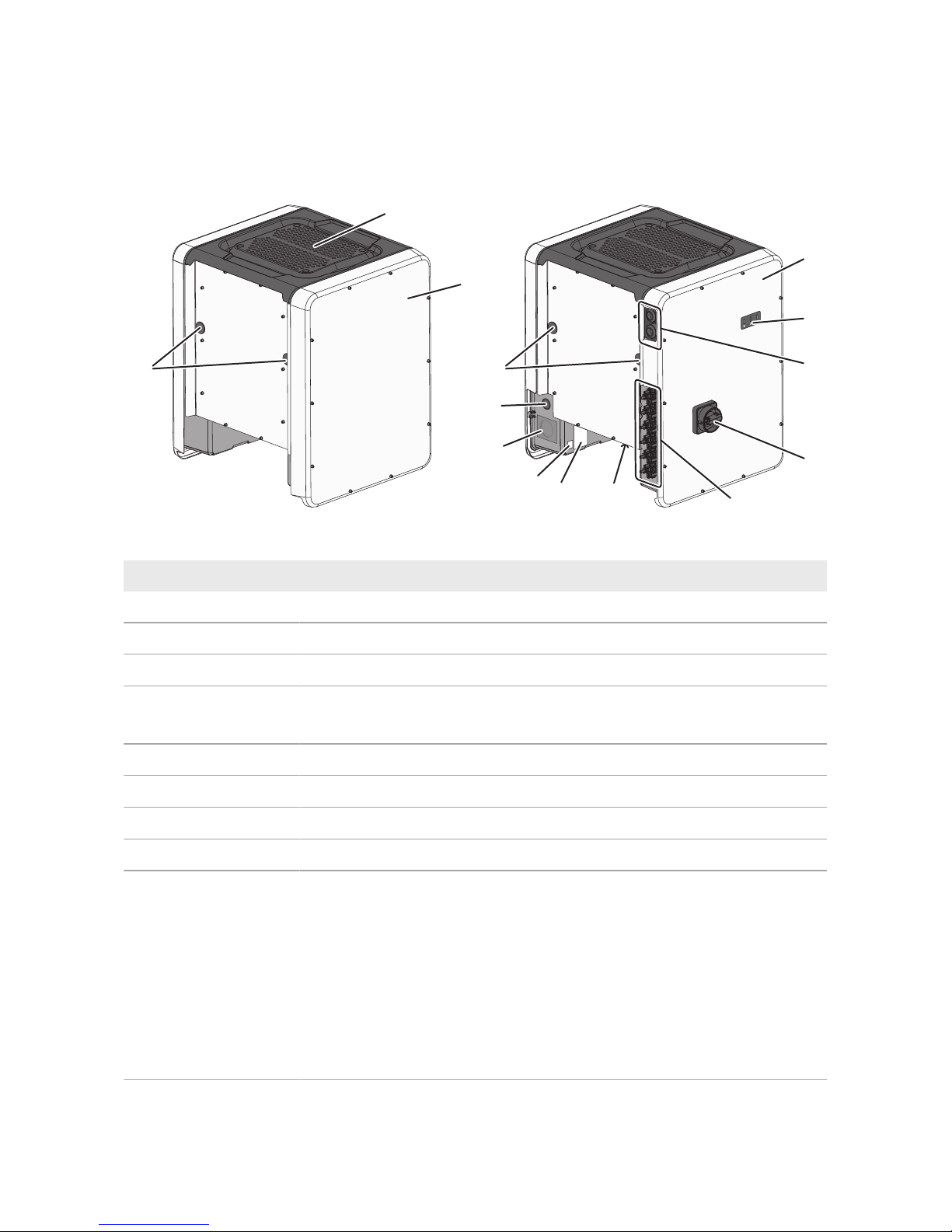

4 Product Overview

4.1 Product Description

A

F

D

M

L

K

G

B

C

E

M

H

I

J

Figure 2: Design of the SunnyTripower

Position Designation

A Cover

B AC Connection Unit

C DC Connection Unit

D LEDs

The LEDs indicate the operating state of the inverter.

E Cable glands for data cables

F DC load-break switch

G DC connector

H Fan bracket with three fans

I Type label

The type label clearly identifies the product. The type label must remain

permanently attached to the product. You will find the following informa-

tion on the type label:

• Device type (Model)

• Serial number (Serial No. or S/N)

• Date of manufacture

• Device-specific characteristics

Page 14

4 Product Overview

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1214

Position Designation

J Additional label with details for registration in SunnyPortal and WLAN

password:

• Identification key (PIC) for registration in Sunny Portal

• Registration ID (RID) for registration in Sunny Portal

• WLAN password (WPA2-PSK) for the direct connection to the user

interface of the inverter via WLAN

K Enclosure opening for AC connection

L Enclosure opening for additional cable

M Enclosure opening for carrying handle

Symbols on the Product and on the Type Label

Symbol Explanation

Inverter

Together with the green LED, this symbol indicates the operating state of

the inverter.

Observe the documentation

Together with the red LED, this symbol indicates an error.

Data transmission

Together with the blue LED, this symbol indicates the status of the network

connection.

Grounding conductor

This symbol indicates the position for connecting a grounding conductor.

Grounding

This symbol indicates the position for the connection of an additional

grounding conductor.

Risk of burns due to hot surfaces

The product can get hot during operation. Avoid contact during operation. Prior to performing any work on the product, allow the product to

cool down sufficiently.

Danger to life due to electric shock

The product operates at high voltages. Prior to performing any work on

the product, disconnect the product from voltage sources. All work on the

product must be carried out by qualified persons only.

Observe the documentation

Observe all documentation supplied with the product.

Page 15

4 Product Overview

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 15

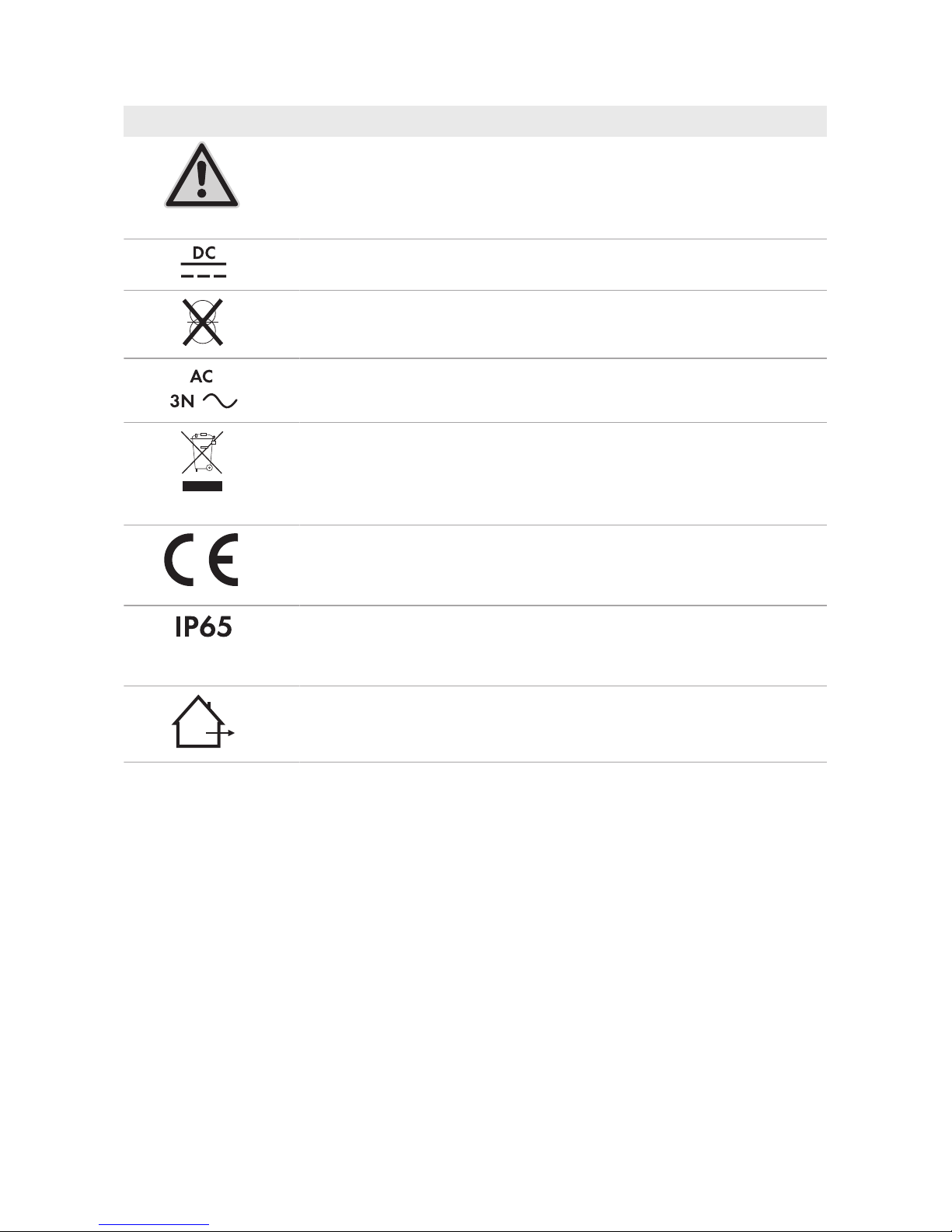

Symbol Explanation

Danger

This symbol indicates that the product must be additionally grounded if

additional grounding or equipotential bonding is required at the installation site.

Direct current

The product is has no galvanic isolation.

Three-phase alternating current with neutral conductor

WEEE designation

Do not dispose of the product together with the household waste but in

accordance with the disposal regulations for electronic waste applicable

at the installation site.

CE marking

The product complies with the requirements of the applicable EU direc-

tives.

Degree of protectionIP65

The product is protected against dust intrusion and water jets from any

angle.

The product is suitable for outdoor installation.

4.2 Interfaces and Functions

The inverter can be equipped or retrofitted with the following interfaces and functions:

User interface for monitoring and configuration

The product is equipped as standard with an integrated webserver, which provides a user interface

for configuring and monitoring the product. The product user interface can be called up via the web

browser if there is an existing connection to an end device (e.g. computer, tablet PC or

smartphone).

SMA Speedwire

The product is equipped with SMASpeedwire as standard. SMASpeedwire is a type of

communication based on the Ethernet standard. SMASpeedwire is designed for a data transfer

rate of 100Mbps and enables optimum communication between Speedwire devices within

systems.

Page 16

4 Product Overview

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1216

SMA Webconnect

The inverter is equipped with a Webconnect function as standard. The Webconnect function

enables direct data transmission between the inverters of a small-scale plant and the Internet portals

SunnyPortal and SunnyPlaces without any additional communication device and for a maximum

of 4 inverters per visualized system. In large-scale PV power plants with more than 4 inverters, there

is the option of establishing data transmission between the inverters and the web-based monitoring

platform SunnyPortal and SunnyPlaces via the SMAClusterController or to distribute the inverters

over several plants. If there is an existing WLAN or Ethernet connection, you can directly access

your visualized system via the web browser on your end device.

WLAN

The product is equipped with a WLAN interface as standard. The inverter is delivered with the

WLAN interface activated as standard. If you do not want to use WLAN, you can deactivate the

WLAN interface.

In addition, the product has a WPS function. The WPS function is for automatically connecting the

product to a network (e.g. via router) and establish a direct connection between the product and

an end device.

Expanding the radio range in the WLAN network

In order to expand the radio range of the inverter in the WLAN network, you can install the

Antenna Extension Kit accessory set in the inverter.

Modbus

The product is equipped with a Modbus interface. The Modbus interface is deactivated by default

and must be configured as needed.

The Modbus interface of the supported SMA products is designed for industrial use – via SCADA

systems, for example – and has the following tasks:

• Remote query of measured values

• Remote setting of operating parameters

• Setpoint specifications for system control

Module slots

The inverter is standard-equipped with two module slots. The module slots are located on the

communication assembly and allow additional modules to be connected (e.g. SMA Sensor

Module). The modules are available as accessories. The installation of two identical modules is not

permissible.

SMA RS485 Module

With the assembly of the RS485 Module, the inverter can communicate with special

SMAcommunication products (Information on assembly and connection see manual of the SMA

RS485 Module). The SMA RS485 Module can be retrofitted.

Grid management services

The product is equipped with service functions for grid management.

Depending on the requirements of the grid operator, you can activate and configure the functions

(e.g. active power limitation) via operating parameters.

Page 17

4 Product Overview

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 17

Antenna Extension Kit

Within the WLAN network, the Antenna Extension Kit enables the radio range of the inverter to be

upgraded (Information on assembly and connection see manual of the Antenna Extension Kit). The

Antenna Extension Kit can be retrofitted.

SMA I/O modules

The SMA I/O Module enables the inverter to perform grid management services (for information

on installation and connection, see the manual of the SMA I/O Module). The SMA I/O Module

can be retrofitted.

SMA Sensor Module

The SMA Sensor Module has different interfaces for connecting various sensors (i.e. temperature

sensor, irradiation sensor, anemometer or energy meter). The SMA Sensor Module converts the

signals of the connected sensors and transmits them to the inverter. The SMA Sensor Module can

be retrofitted.

Multifunction Relay

The inverter is equipped with a multifunction relay as standard. The multifunction relay is an

interface that can be configured for the operating mode used by a particular system.

SMAOptiTracGlobalPeak

SMAOptiTracGlobalPeak is an advancement of SMAOptiTrac and allows the operating point of

the inverter to follow the optimal operating point of the PV array (MPP) precisely at all times. In

addition, with the aid of SMAOptiTracGlobalPeak, the inverter detects several maximum power

points in the available operating range, such as may occur particularly with partially shaded

strings. SMA OptiTrac Global Peak is enabled by default.

String-Failure Detection

The string-failure detection measures the total current of every input and continuously calculates the

mean values for the inputs in question. The total currents are compared with the mean values. If a

total current exceeds or falls short of the mean value by the set tolerance value, an event is

reported. Marginally increased total currents are reliably detected over several query intervals and

distinguished from typical current fluctuations of the PV array. String-failure detection is deactivated

by default and must be activated. In addition, the tolerance value can be set via the user interface

and the mean values read off.

Surge Arrester TypeII

On the AC and DC side, the inverter is equipped with slots for type II surge protection devices. The

surge protection devices limit dangerous overvoltages. The surge protection devices can be

retrofitted.

Page 18

5 Mounting

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1218

5 Mounting

5.1 Requirements for Mounting

Requirements for the Mounting Location:

WARNING

Danger to life due to fire or explosion

Despite careful construction, electrical devices can cause fires.

• Do not mount the product in areas containing highly flammable materials or gases.

• Do not mount the product in potentially explosive atmospheres.

☐ The mounting location must be inaccessible to children.

☐ A solid, flat support surface must be available for mounting.

☐ The mounting location must be suitable for the weight and dimensions of the inverter (see

Section14 "Technical Data", page96).

☐ The mounting location should be freely and safely accessible at all times without the need for

any auxiliary equipment (such as scaffolding or lifting platforms). Non-fulfillment of these

criteria may restrict servicing.

☐ The inverter can be mounted in a position that is directly exposed to solar irradiation. There is,

however, the possibility that the inverter reduces its power output to avoid overheating due to

high temperatures.

☐ The DC load-break switch of the inverter must always be freely accessible.

☐ Climatic conditions must be met (see Section14 "Technical Data", page96).

Page 19

5 Mounting

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 19

Dimensions for mounting:

M8x14/17+1

M8x14/17+1

155

205

155

205

46.2 46.2

112.85

119.17

112.85

119.17

155

205

155

205

79.479.4

395

Figure 3: Position of the anchoring points(Dimensions in mm)

Structural Stability:

☐ When mounting with feet or profile rails, the width of one foot or the profile rail must be at

least 175mm to ensure structural stability.

☐ The inverter must be attached under the following conditions:

– Inclination of the support surface: >3°

– Wind speed (without wind gusts): > 25m/s

– Height of the feet or the profile rail: > 100mm

Page 20

5 Mounting

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1220

☐ When mounting with profile rails, an attachment or fixation by loading is required. When

mounting with profile rail, SMA Solar Technology AG recommends to bolt the profile rail e.g.

to the profile of the module frame or to attach a sheet metal (which can be weighted with

stones or with sandbags) at the profile rails. This will ensure that the inverter is fixed.

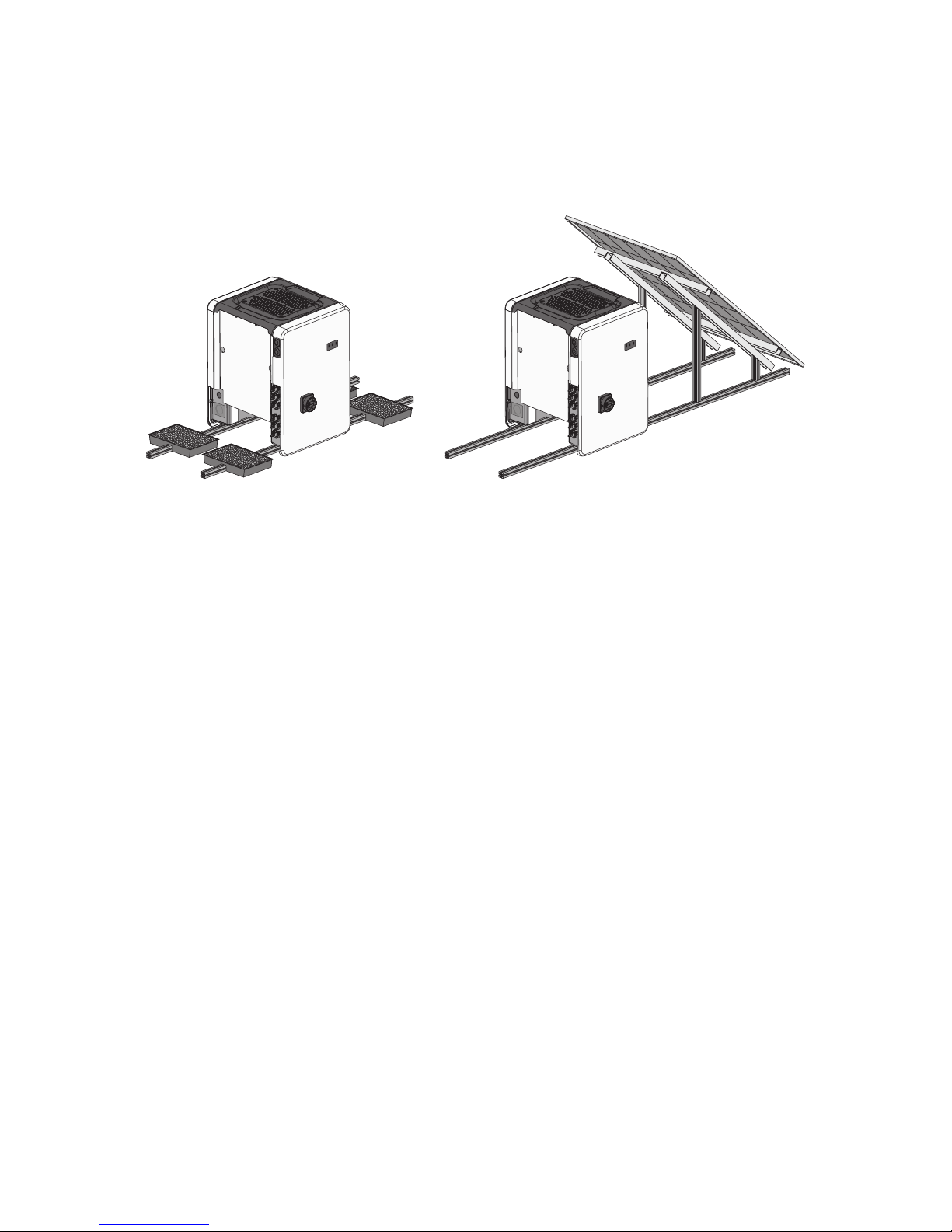

Figure 4: Attachment of the inverters (examples)

Recommended Clearances:

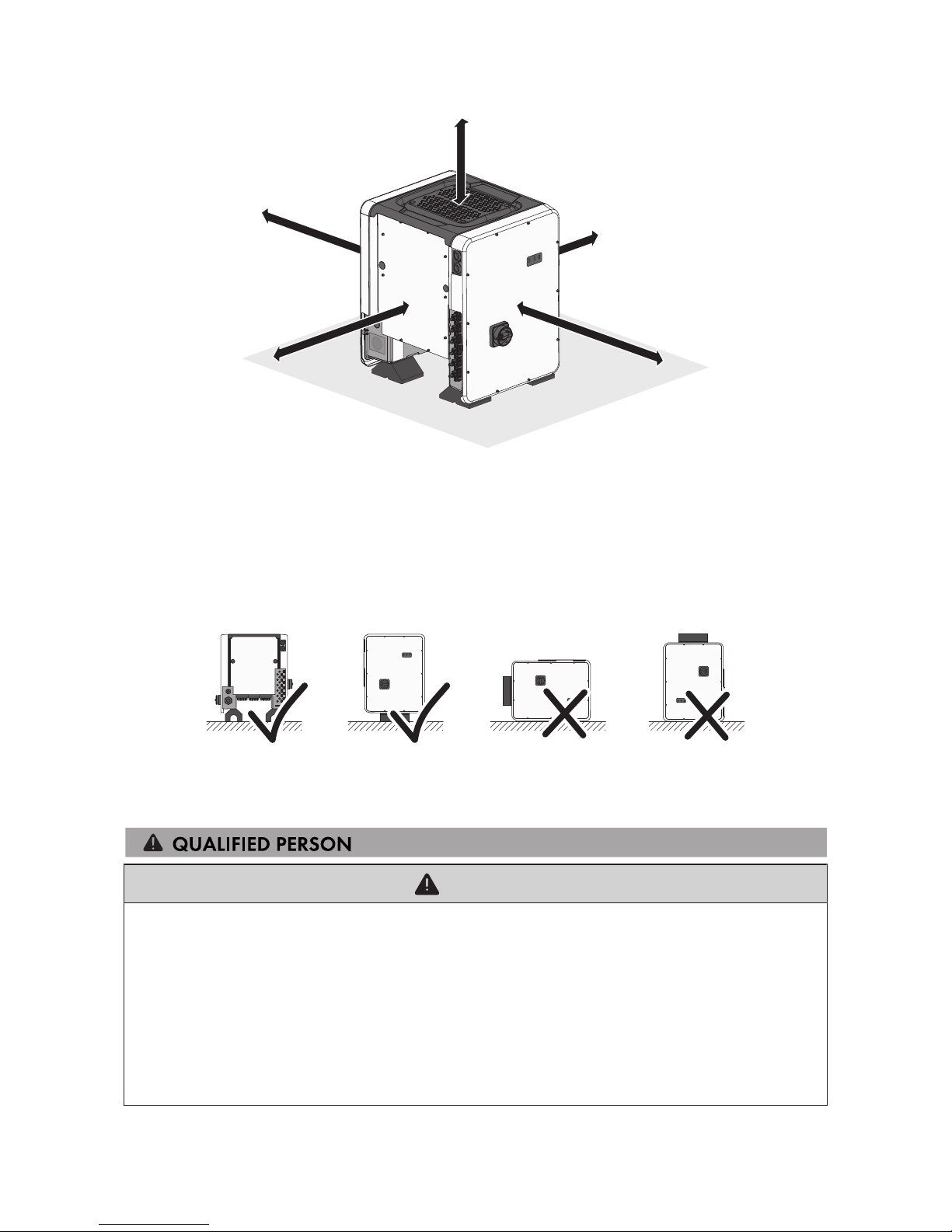

If you maintain the recommended clearances, adequate heat dissipation will be ensured. Thus, you

will prevent power reduction due to excessive temperature.

☐ Maintain the recommended clearances to roof edges, skylights, walls as well as to other

inverters or objects. This ensures that the DC load-break switch on the inverter can be operated

easily and the LED signals can be read without difficulty.

☐ For possible service deployments, SMA Solar Technology AG recommends ensuring sufficient

clearance from walls, other inverters or objects on all four sides of the inverter enclosure. Non-

fulfillment of these criteria may restrict servicing.

☐ If multiple inverters are mounted in areas with high ambient temperatures, increase the

clearances between the inverters and ensure sufficient fresh-air supply.

Page 21

5 Mounting

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 21

1000 (39.37)1000 (39.37)

300

(11.81)

300

(11.81)

900 (35.43)900 (35.43)

1000 (39.37)

100 (3.94)

Figure 5: Recommended clearances(Dimensions in mm)

Permitted and prohibited mounting positions:

☐ The inverter must only be mounted in one of the permitted positions. This will ensure that no

moisture can penetrate the inverter.

☐ The inverter should be mounted in such a way that the LED signals can be read without

difficulty.

Figure 6: Permitted and prohibited mounting positions

5.2 Mounting the Inverter

CAUTION

Risk of injury when lifting the inverter, or if it is dropped

The inverter weighs 84kg. You risk injury if you lift the inverter incorrectly or if it is dropped while

being transported or mounted.

• Carry and lift the inverter upright with the help of several people. For this purpose, take hold

of the carrying handles on the inverter. Always take hold of the two carrying handles

mounted both on each side.

• Take into account the center of gravity of the inverter. The center of gravity is on the side of

the AC connection unit.

Page 22

5 Mounting

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1222

Procedure:

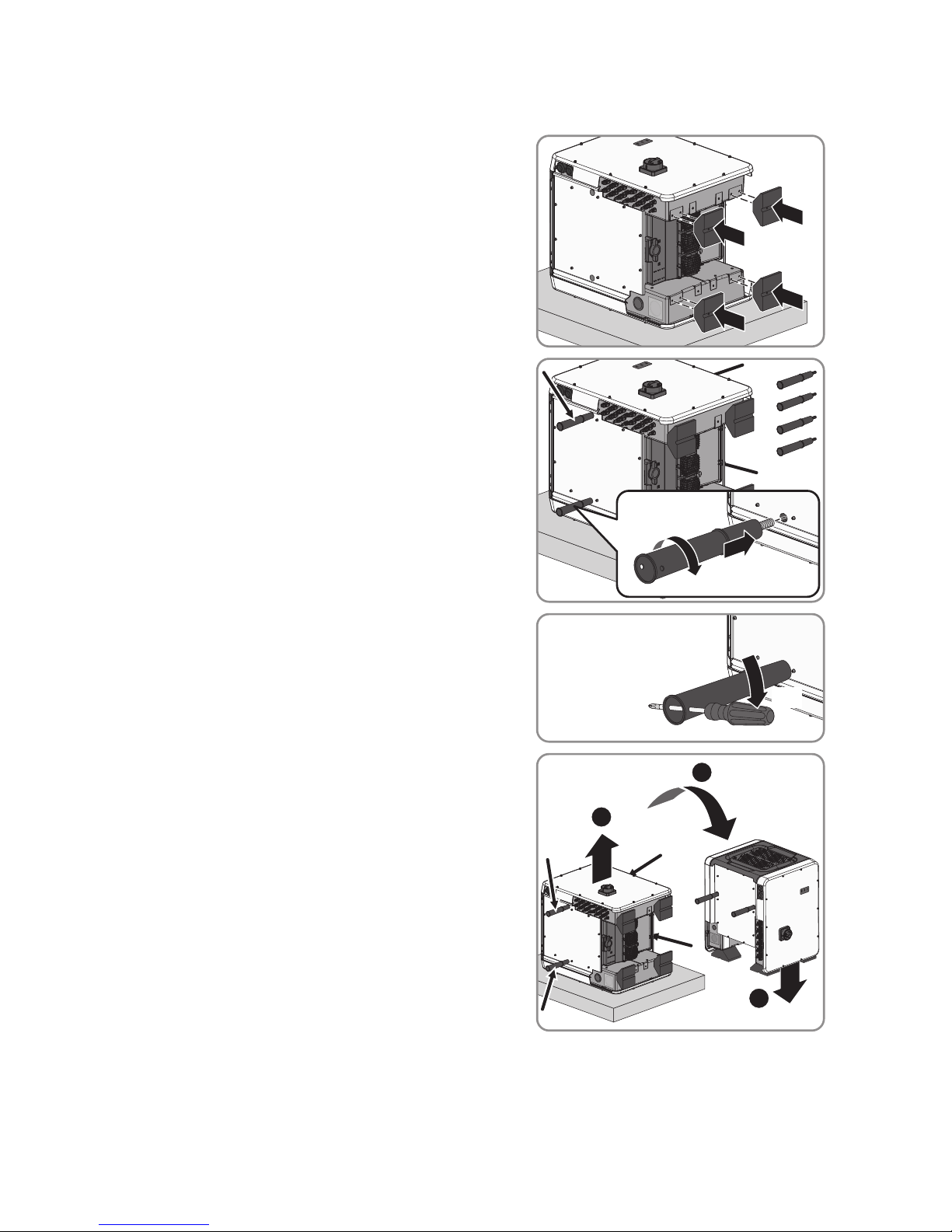

1. Tighten every foot with two M8x40 hexagon screws

and two washers on the two external taps (M8x14)

on the underside of the inverter (torque: 16Nm).

4x

A

_

+

_

+

B

C

D

E

F

2. Screw all four transport handles as far as they will

go into the taps on the right- and left-hand side until

they lie flush with the enclosure. When doing so,

ensure that the transport handles are screwed into

the taps so that they are perfectly straight. If the

transport handles are not screwed in straight, this

can make it more difficult or even impossible to

unscrew them later on and can damage the taps to

the extent that transport handles can no longer be

screwed into them.

A

_

+

_

+

B

C

D

E

F

4x4x

3. Insert a screwdriver into the holes in the transport

handle and turn the screwdriver through 90°. This

ensures that the transport handles are securely

tightened.

90°

4x

4. Remove the inverter from the Euro pallet and

position the inverter at the installation location.

3

1

2

A

_

+

_

+

B

C

D

E

F

5. Make sure that the inverter is stable.

Page 23

5 Mounting

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 23

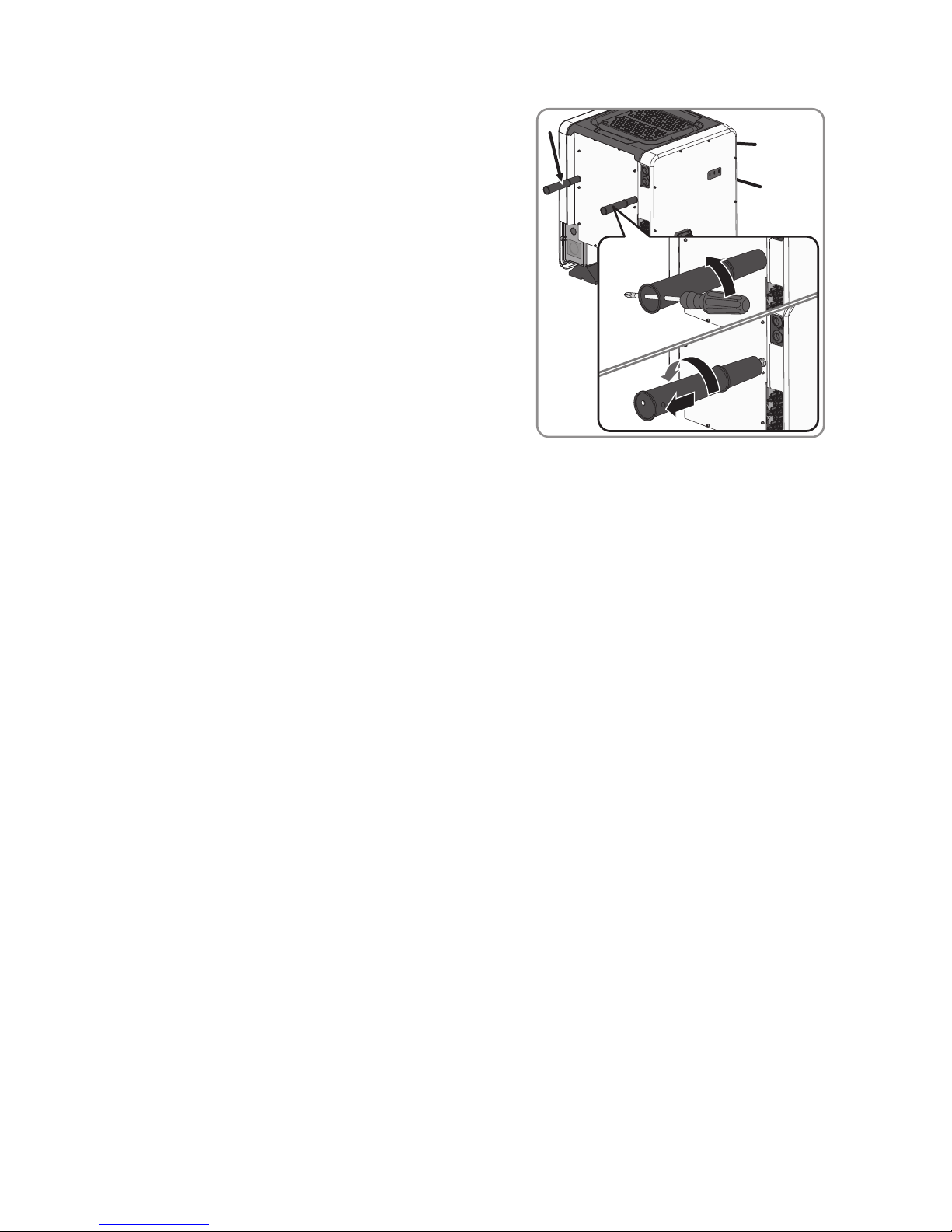

6. Remove all four transport handles from the taps. If

necessary, insert a screwdriver into the holes on the

transport handle and use the screwdriver to remove

the transport handle.

4x4x

Page 24

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1224

6 Electrical Connection

6.1 Safety during Electrical Connection

DANGER

Danger to life due to high voltages of the PV array

When exposed to light, the PV array generates dangerous DC voltage, which is present in the

DC conductors and the live components of the inverter. Touching the DC conductors or the live

components can lead to lethal electric shocks. If you disconnect the DC connectors from the

inverter under load, an electric arc may occur leading to electric shock and burns.

• Do not touch non-insulated cable ends.

• Do not touch the DC conductors.

• Do not touch any live components of the inverter.

• Have the inverter mounted, installed and commissioned only by qualified persons with the

appropriate skills.

• If an error occurs, have it rectified by qualified persons only.

• Prior to performing any work on the inverter, disconnect it from all voltage sources as

described in this document.

NOTICE

Damage to the enclosure seal in subfreezing conditions

If you open the product when temperatures are below freezing, the enclosure seals can be

damaged. Moisture can penetrate the product then.

• Only open the product if the ambient temperature is not below -5°C.

• If a layer of ice has formed on the enclosure seal when temperatures are below freezing,

remove it prior to opening the product (e.g. by melting the ice with warm air). Observe the

applicable safety regulations.

NOTICE

Damage to the inverter due to electrostatic discharge

Touching electronic components can cause damage to or destroy the inverter through

electrostatic discharge.

• Ground yourself before touching any component.

Page 25

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 25

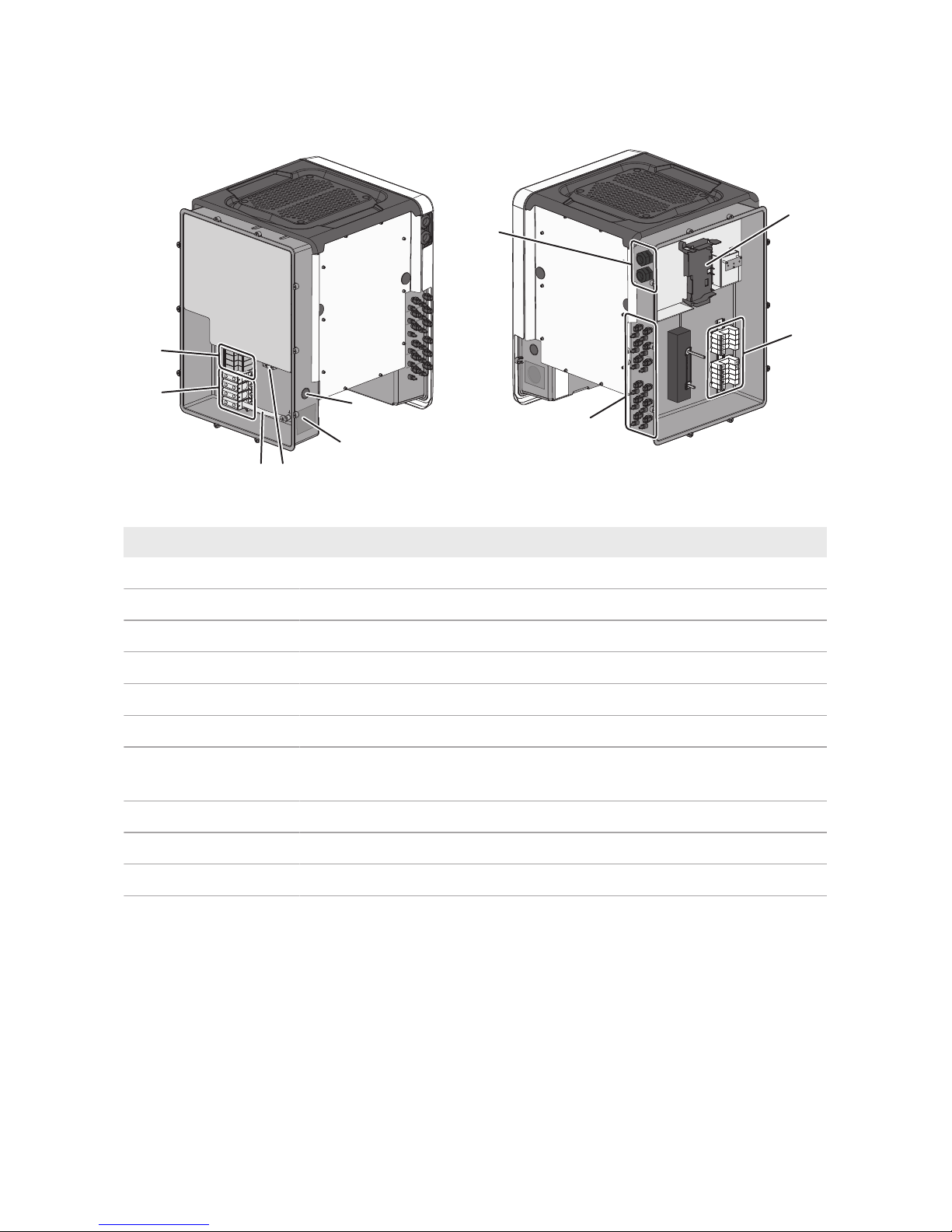

6.2 Overview of the Connection Area

_

+

_

+

A

B

C

D

E

F

A

F

D

E

G

_

+

_

+

I

J

B

H

C

Figure 7: Connection areas of the inverters' AC Connection Unit and DC Connection Unit

Position Designation

A Slots for AC surge protection devices

B Terminal blocks for AC connection

C Bridge between N and enclosure

D Grounding terminal for grounding conductor connection

E Enclosure opening for cable gland M63

F Enclosure opening for additional cable

G Cable glands for network cables and, if needed, for the connection ca-

bles of the AntennaExtensionKit or other data cables

H Positive and negative connectors for DC connection

I Slots for DC surge protection devices

J Communication assembly

6.3 AC Connection

6.3.1 Requirements for the AC Connection

Cable requirements:

☐ The conductors must be made of aluminum or copper.

☐ External diameter: 35mm to 48mm

☐ Conductor cross-section: 35mm² to 120mm²

☐ Insulation stripping length: 30mm

Page 26

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1226

☐ Sheath stripping length: 290mm

☐ The cable must be dimensioned in accordance with the local and national directives for the

dimensioning of cables. The requirements for the minimum wire size derive from these

directives. Examples of factors influencing cable dimensioning are: nominal AC current, type of

cable, routing method, cable bundling, ambient temperature and maximum desired line losses

(for calculation of line losses, see the design software "SunnyDesign" from software

version2.0 at www.SMA-Solar.com).

Overview of the required length of the conductor inside the AC connection unit

300

181

193

Figure 8: Interior view of the AC connection unit with dimensions for the conductors (Dimensions in mm)

Load-break switch and cable protection:

NOTICE

Damage to the inverter due to the use of screw-type fuses as load-break

switches

Screw-type fuses (e.g. DIAZED fuse or NEOZED fuse) are not load-break switches.

• Do not use screw-type fuses as load-break switches.

• Use a load-break switch or circuit breaker as a load disconnection unit (for information and

design examples, see the Technical Information "Circuit Breaker" at www.SMA-Solar.com).

☐ In PV systems with multiple inverters, protect each inverter with a separate three-phase circuit

breaker. Make sure to observe the maximum permissible fuse protection (see Section14

"Technical Data", page96). This will prevent residual voltage being present at the

corresponding cable after disconnection.

☐ Loads installed between the inverter and the circuit breaker must be fused separately.

Page 27

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 27

Residual-current monitoring unit:

☐ If an external residual-current device is required, install a typeB residual-current device that

trips at a residual current of 500mA or higher (for details on selecting a residual-current

device, see the Technical Information ""Criteria for Selecting a Residual-Current Device"" at

www.SMA-Solar.com). Residual-current devices with a tripping threshold <500mA can be

used. The tripping threshold of 300mA must not be undershot.

☐ If a residual-current device with a tripping threshold <500mA is used, you must set the

tripping threshold of the residual-current device in the inverter (see Section9.6, page63).

Overvoltage category:

The inverter can be used in grids of overvoltage categoryIII or lower in accordance with

IEC60664-1. That means that the inverter can be permanently connected to the grid-connection

point of a building. In case of installations with long outdoor cabling routes, additional measures to

reduce overvoltage categoryIV to overvoltage categoryIII are required (see the Technical

Information "Overvoltage Protection" at www.SMA-Solar.com).

6.3.2 Connecting the Inverter to the Utility Grid

Requirements:

☐ The connection requirements of the grid operator must be met.

☐ The grid voltage must be within the permissible range. The exact operating range of the

inverter is specified in the operating parameters.

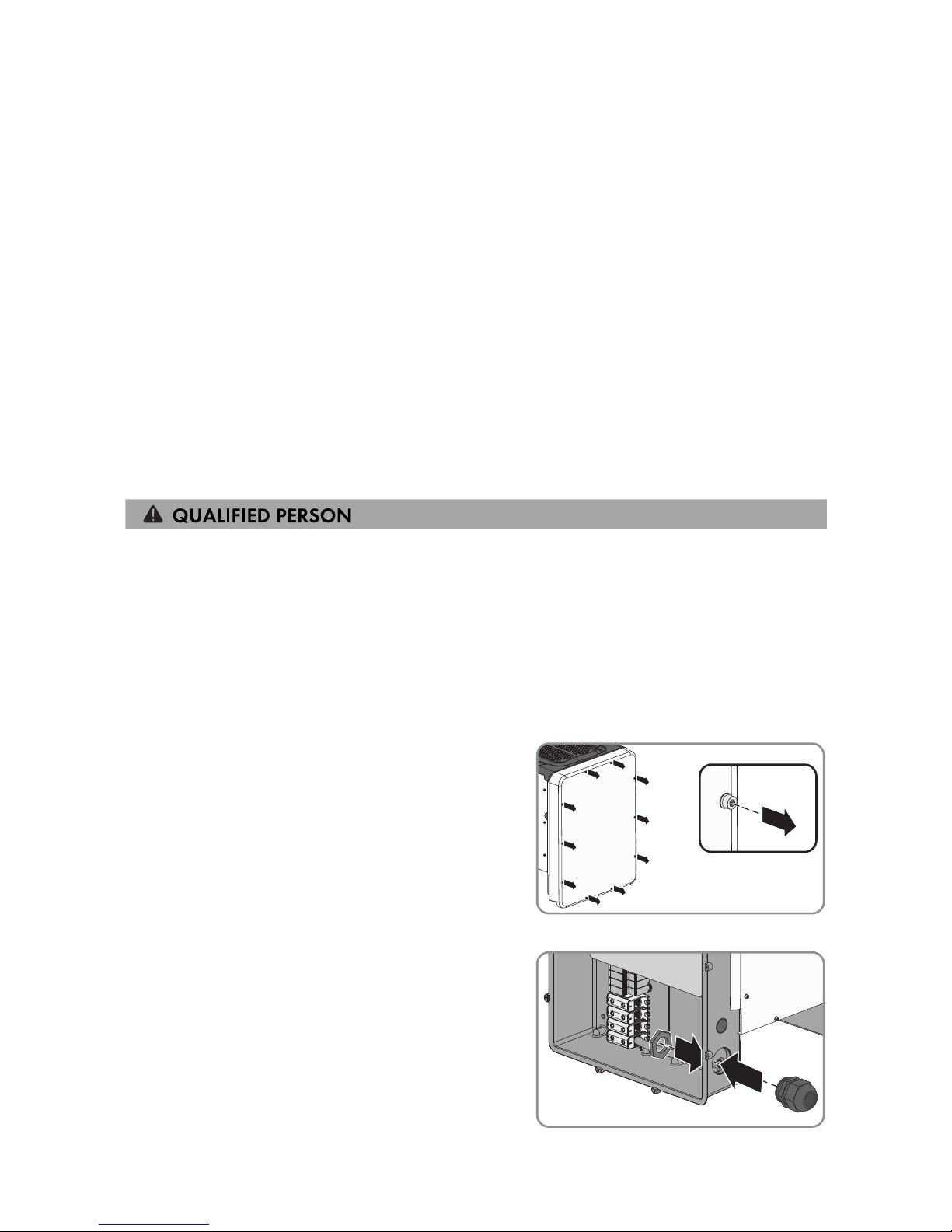

Procedure:

1. Disconnect the circuit breaker from all three line conductors and secure against reconnection.

2. Ensure that the DC load-break switch is in the O position and is secured against reconnection.

3. If the enclosure lid of the AC Connection Unit is

mounted, remove all ten screws of the enclosure lid

using a Torx screwdriver (TX25) and remove the

enclosure lid towards the front.

10x10x

4. Remove the adhesive tape from the enclosure opening for the AC connection.

5. Insert the cable gland M63 into the opening and

screw the counter nut on from the inside.

L1

L2

L3

N

Page 28

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1228

6. Thread the AC cable through the cable gland into the AC Connection Unit. If necessary,

slightly loosen the swivel nut of the cable gland.

7. Dismantle the AC cable.

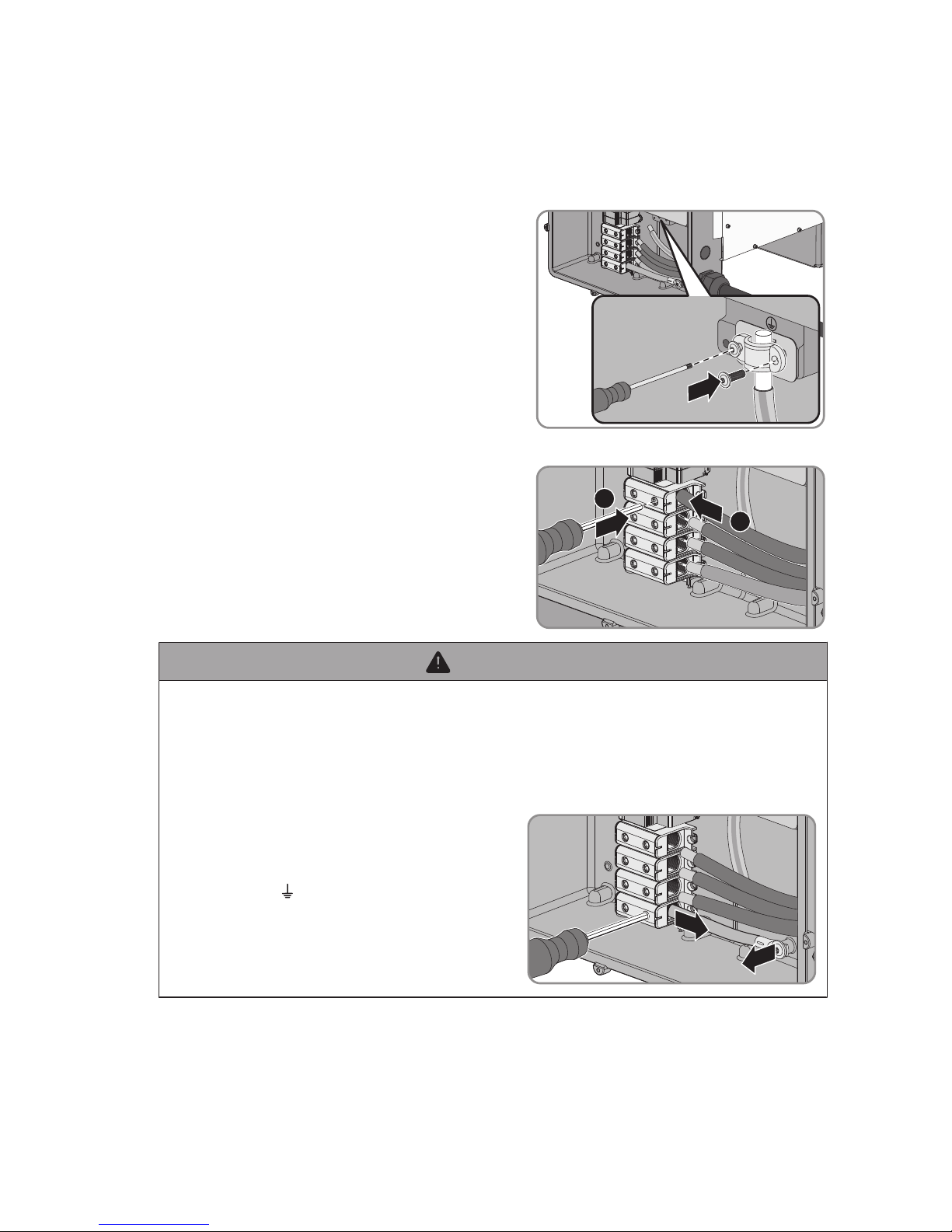

8. Strip off the insulation of L1, L2, L3, N and PE by 30mm.

9. Connect the grounding conductor to the ground

terminal. Use a Torx screwdriver (TX25) to slightly

loosen one of the screws with which the clip and

connection plate are connected to the ground

connection and to completely remove the other

screw. Then place the grounding conductor onto the

connection plate, route the clip via the grounding

conductor and tighten both screws with a Torx

screwdriver (TX25) (torque: 6Nm).

L1

L2

L3

N

10. Ensure that the conductor is on the connection plate.

11. Connect L1, L2, L3 and, if necessary, N to the

terminals according to the label. To do so, position

each conductor as far as they will go into the

corresponding terminal and tighten the screw of the

terminal using a Allen key (AF8) (20Nm torque for

a conductor cross-section of 35mm² to 95mm²;

30Nm torque for a cable cross-section of

120mm²).

2

1

L1

L2

L3

N

12.

WARNING

Danger to life due to electric shock

The inverter is delivered with a bridge between N and the enclosure as standard. The

bridge is absolutely essential if the connection to a utility grid is established without a neutral

conductor.

If the utility grid is connected with a neutral conductor, the bridge must always be removed.

• When N is present and connected to the

corresponding terminal, remove the bridge

installed as standard between N and the

enclosure ( ).

L1

L2

L3

N

13. Ensure that the correct conductors are assigned to all the terminals.

14. Make sure that all conductors are securely in place.

Page 29

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 29

6.4 DC Connection

6.4.1 Requirements for the DC Connection

Requirements for the PV modules per input:

☐ All PV modules must be of the same type.

☐ All PV modules must be aligned and tilted identically.

☐ On the coldest day based on statistical records, the open-circuit voltage of the PV array must

never exceed the maximum input voltage of the inverter.

☐ The same number of series-connected PV modules must be connected to each string.

☐ The maximum input current per string must be maintained and must not exceed the through-

fault current of the DC connectors (see Section14 "Technical Data", page96).

☐ The thresholds for the input voltage and the input current of the inverter must be adhered to

(see Section14 "Technical Data", page96).

☐ The positive connection cables of the PV modules must be equipped with positive DC

connectors (see Section6.4.2, page29).

☐ The negative connection cables of the PV modules must be equipped with the negative DC

connectors (see Section6.4.2, page29).

Use of Y adapters for parallel connection of strings

The Y adapters must not be used to interrupt the DC circuit.

• Do not use the Y adapters in the immediate vicinity of the inverter. The adapters must not

be visible or freely accessible.

• In order to interrupt the DC circuit, always disconnect the inverter as described in this

document (see Section10, page69).

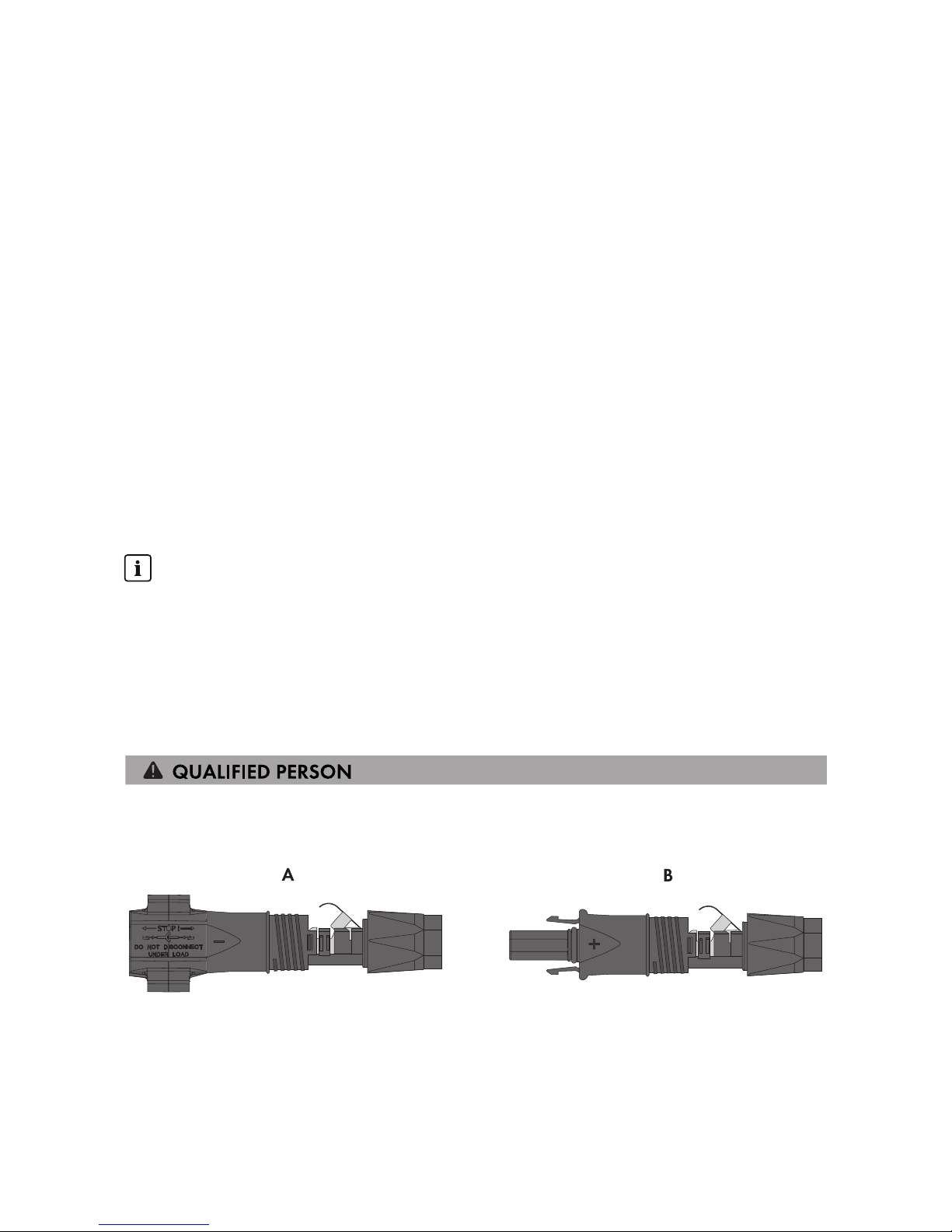

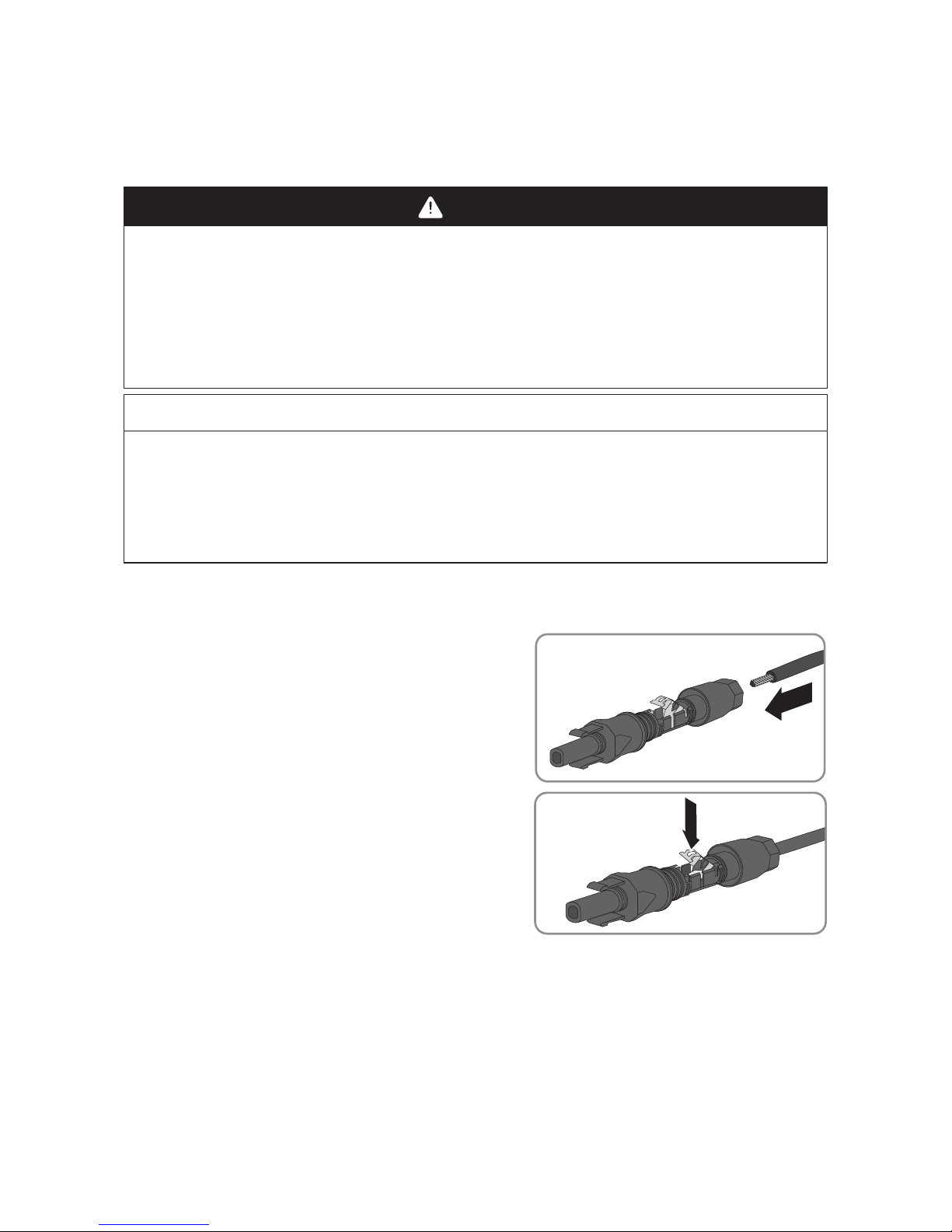

6.4.2 Assembling the DC Connectors

For connection to the inverter, all PV module connection cables must be fitted with the DC

connectors provided. Assemble the DC connectors as described in the following. Be sure to observe

the correct polarity. The DC connectors are marked with the symbols "+" and "−".

Figure 9: Negative (A) and positive (B) DC connectors

Cable requirements:

☐ Cable type: PV1-F, UL-ZKLA, USE2

☐ External diameter: 5mmto8mm

☐ Conductor cross-section: 2.5mm²to6mm²

Page 30

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1230

☐ Qty single wires: minimum7

☐ Nominal voltage: minimum 1000V

☐ Using bootlace ferrules is not allowed.

DANGER

Danger to life due to high voltages on the DC conductors

When exposed to sunlight, the PV array generates dangerous DC voltage which is present in the

DC conductors. Touching the DC conductors can lead to lethal electric shocks.

• Ensure that the inverter is disconnected from all voltage sources.

• Do not touch non-insulated cable ends.

• Do not touch the DC conductors.

NOTICE

Destruction of the inverter due to overvoltage

If the open-circuit voltage of the PV modules exceeds the maximum input voltage of the inverter,

the inverter can be destroyed due to overvoltage.

• If the open-circuit voltage of the PV modules exceeds the maximum input voltage of the

inverter, do not connect any strings to the inverter and check the design of the PV system.

Procedure:

1. Strip 12mm of the cable insulation.

2. Insert the stripped cable into the DC connector up to

the stop. When doing so, ensure that the stripped

cable and the DC connector are of the same

polarity.

+

3. Press the clamping bracket down until it audibly

snaps into place.

+

Page 31

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 31

☑ The stranded wire can be seen inside the

clamping bracket chamber.

+

✖ The stranded wire cannot be seen in the chamber?

The cable is not correctly in place.

• Release the clamping bracket. To do so,

insert a screwdriver (blade width: 3.5mm)

into the clamping bracket and pry the

clamping bracket open.

+

1

2

• Remove the cable and go back to step2.

4. Push the swivel nut up to the thread and tighten

(torque: 2Nm).

+

1

2

6.4.3 Connecting the PV Array

NOTICE

Damage to the inverter due to ground fault on DC side during operation

Due to the transformerless topology of the product, the occurance of ground faults on DC side

during operation can lead to irreparable damage. Damages to the product due to a faulty or

damaged DC installation are not covered by warranty. The product is equipped with a protective

device that checks whether a ground fault is present during the starting sequence. The product is

not protected during operation.

• Ensure that the DC installation is carried out correctly and no ground fault occurs during

operation.

Page 32

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1232

NOTICE

Damage to the DC connectors due the use of contact cleaner of other cleaning

agents

Some contact cleaners or other cleaning agents may contain substances that decompose the

plastic of the DC connectors.

• Do not use contact cleaners or other cleaning agents for cleaning the DC connectors.

NOTICE

Destruction of the inverter due to overvoltage

If the open-circuit voltage of the PV modules exceeds the maximum input voltage of the inverter,

the inverter can be destroyed due to overvoltage.

• If the open-circuit voltage of the PV modules exceeds the maximum input voltage of the

inverter, do not connect any strings to the inverter and check the design of the PV system.

NOTICE

Destruction of the measuring device due to overvoltage

• Only use measuring devices with a DC input voltage range of 1000V or higher.

Procedure:

1. Ensure that the circuit breaker is switched off and that it cannot be reconnected.

2. Set the DC load-break switch of the inverter to

position O.

O

3. Secure the DC load-break switch against

reconnection using a padlock.

O

4. Measure the PV array voltage. Ensure that the maximum input voltage of the inverter is

adhered to and that there is no ground fault in the PV array.

Page 33

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 33

5. Check whether the DC connectors have the correct polarity.

If the DC connector is equipped with a DC cable of the wrong polarity, the DC connector must

be reassembled. The DC cable must always have the same polarity as the DC connector.

6. Ensure that the open-circuit voltage of the PV array does not exceed the maximum input

voltage.

7. Connect the assembled DC connectors to the

inverter.

_

+

_

+

A

B

C

D

☑ The DC connectors snap into place.

8. Ensure that all DC connectors are securely in place.

Page 34

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1234

9.

NOTICE

Damage to the inverter due to moisture ingress

If the electrical connection is not made immediately after the installation, the inverter is not

sealed and moisture can penetrate the inverter. The inverter is only sealed if the DC

connectors are connected to the inverter with the DC conductors or with sealing plugs.

If the electrical connection is to be carried out at a later time, close the DC inputs on the

inverter with DC connectors and sealing plugs as described below.

• Do not insert the sealing plugs directly into the DC inputs on the inverter.

• For unused DC connectors, push down the clamping bracket and push the swivel nut

up to the thread.

• Insert the sealing plug into the DC connector.

• Insert the DC connectors with sealing plugs

into the corresponding DC inputs on the

inverter.

_

+

_

+

A

B

C

☑ The DC connectors snap into place.

• Ensure that the DC connectors with sealing plugs are securely in place.

6.4.4 Disassembling the DC Connectors

To disassemble the DC connectors (e.g. due to faulty assembly), proceed as follows.

DANGER

Danger to life due to high voltages on the DC conductors

When exposed to sunlight, the PV array generates dangerous DC voltage which is present in the

DC conductors. Touching the DC conductors can lead to lethal electric shocks.

• Ensure that the inverter is disconnected from all voltage sources.

• Do not touch non-insulated cable ends.

• Do not touch the DC conductors.

Page 35

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 35

Procedure:

1. Release and remove all DC connectors. To do this,

insert a flat-blade screwdriver or an angled

screwdriver (blade width 3.5mm) into one of the

slide slots and pull the DC connectors out in a

downward direction. Do not pull on the cable.

1

2

2. Remove the DC connector swivel nut.

+

3. Unlock the DC connector. To do this, insert a flatblade screwdriver (blade width: 3.5mm) into the

side catch mechanism and pry the catch mechanism

open.

+

1

2

3

4. Carefully pull the DC connector apart.

5. Release the clamping bracket. To do so, insert a flatblade screwdriver (blade width: 3.5mm) into the

clamping bracket and pry the clamping bracket

open.

+

1

2

6. Remove the cable.

6.5 Connecting the Multifunction Relay

6.5.1 Procedure for connecting the multifunction relay

Procedure See

1. Select for which operating mode you would like to use the

multifunction relay.

Section6.5.2, page36

Page 36

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1236

Procedure See

2. Connect to the multifunction relay according to the operating mode and the associated connection variant.

Section6.5.3, page36

and Section6.5.4,

page40

3. After commissioning the inverter, change the operating

mode of the multifunction relay, if necessary.

Section9.4, page61

6.5.2 Operating Modes of the Multifunction Relay

Operating mode of multifunction relay (Mlt.OpMode)

Description

Fault indication (FltInd)

The multifunction relay controls a display device (e.g. a warning

light) which, depending on the type of connection, signals either an

error or the undisturbed operation of the inverter.

Self-consumption (SelfCsmp)

The multifunction relay switches loads on or off, depending on the

power production of the PV system.

Control via communication (ComCtl)

The multifunction relay switches loads on or off according to commands transmitted by a communication product.

Battery bank (BatCha)

The multifunction relay controls the charging of the batteries depending on the power production of the PV system.

Fan control (FanCtl)

The multifunction relay controls an external fan, depending on the

temperature of the inverter.

Switching status grid relay (GriSwCpy)

The local grid operator may require that a signal is transmitted as

soon as the inverter connects to the utility grid. The multifunction relay can be used to trigger this signal.

6.5.3 Connection Options

The connection procedures vary, depending on the operating mode.

Operating mode Connection option

Fault indication (FltInd)

Using the Multifunction Relay as a Fault Indicator Contact

Self-consumption (SelfCsmp)

Controlling loads via the multifunction relay or charging batteries depending on the power production of the PV system

Control via communication (ComCtl)

Controlling loads via the multifunction relay or charging batteries depending on the power production of the PV system

Battery bank (BatCha)

Controlling loads via the multifunction relay or charging batteries depending on the power production of the PV system

Page 37

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 37

Operating mode Connection option

Fan control (FanCtl)

Connecting the external fan (see fan documentation)

Switching status grid relay (GriSwCpy)

Reporting the switching status of the grid relay

Page 38

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1238

Using the Multifunction Relay as a Fault Indicator Contact

You can use the multifunction relay as a fault indicator contact and have an error or smooth

operation of the inverter displayed or signaled via a suitable display device. You can connect

multiple inverters to one fault indicator or operation indicator, as needed.

B F

1

2

3

B F

1

2

3

B F

1

2

3

B F

1

2

3

B F

1

2

3

B F

1

2

3

= =

Light on

Grounding,

if applicable

Trouble-free

operation (B)

Error (F)

Operation message

Error message

Fuse

Light on

Error in the

inverter

Inverter

in operation

Inverter

in operation

Fuse

max. 30 V

DC

Figure 10: Circuit diagram with multiple inverters for connection to an operation indicator and circuit diagram

for connection to a fault indicator (example)

Page 39

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 39

Controlling loads via the multifunction relay or charging batteries depending on

the power production of the PV system

The multifunction relay can control loads or charge batteries power-dependently. To enable this

function, you must connect a contactor (K1) to the multifunction relay. The contactor (K1) switches

the operating current for the load on or off. If you want batteries to be charged depending on the

available power, the contactor activates or deactivates the charging of the batteries.

B F

K1

3

1

=

=

max. 30 V

DC

Fuse

Figure 11: Wiring diagram for connection for controlling a load or for the power-dependent charging of the

batteries

Page 40

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1240

Reporting the switching status of the grid relay

The multifunction relay can trip a signal to the grid operator as soon as the inverter connects to the

utility grid. To enable this function, the multifunction relays of all inverters must be connected in

parallel.

1 kΩ

B F

1

2

3

B F

1

2

3

B F

1

2

3

=

Signal to

grid operator

Inverter 1:

Grid relay closed

Inverter

Grid relay open

2:

Inverter

Grid relay open

n:

max. 30 V

DC

Figure 12: Wiring diagram for signaling the switching status of the grid relay (example)

6.5.4 Connection to the Multifunction Relay

Requirement:

☐ The technical requirements of the multifunction relay must be met (see Section14 "Technical

Data", page96).

Cable requirements:

• Conductor cross-section: 0.2mm² to 1.5mm²

• The cable type and cable-laying method must be appropriate for the application and location.

Page 41

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 41

Procedure:

1.

DANGER

Danger to life due to high voltages

• Disconnect the inverter from all voltage sources (see Section10, page69).

2. If the enclosure lid of the DC Connection Unit is

closed, remove it as follows: Unscrew all ten screws

with a Torx screwdriver (TX25) and remove the

enclosure lid carefully forward.

10x10x

3. Set the screws and the enclosure lid aside and store safely.

4. Remove the swivel nut from the cable gland for the communication cable.

5. Remove the two-hole cable support sleeve from the cable gland and insert the cable into the

enclosure opening of the two-hole cable support sleeve.

6. Press the two-hole cable support sleeve with the cable into the cable gland and guide the

cable to the communication assembly in the DC Connection Unit. Ensure that any unused

enclosure openings of the two-hole cable support sleeve are sealed with sealing plugs.

7. Strip 9mm of the cable insulation at maximum.

8. Connect the cable to the 3-pole terminal block

according to the circuit diagram, depending on the

operating mode (see Section6.5.3, page36).

Ensure that the conductors are plugged completely

into the terminal points up to their insulation.

1

2

3

9. Stick the 3-pole terminal block with the connected

conductors into the MFR slot on the communication

assembly in the inverter.

X2

Max. 30V DC

USB

M2

FCC ID: SVF-KP20

IC: 9440A-KP20

ANT.

SPS

B

A

X1

M1

MFRBAT

Max. 30V DC

USB

MFRBAT

10. Ensure that the terminal block is securely in place.

11. Ensure that all conductors are correctly connected.

12. Ensure that the conductors sit securely in the terminal points. Tip: To release the conductors,

open the terminal points using a suitable tool.

13. Tighten the swivel nut on the cable gland hand-tight.

Page 42

6 Electrical Connection

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1242

6.6 Connecting the Network Cables

DANGER

Danger to life due to electric shock

Overvoltages (e.g. in the case of a flash of lightning) can be further conducted into the building

and to other connected devices in the same network via the network cable if there is no

overvoltage protection.

• Ensure that all devices in the same network are integrated in the existing overvoltage

protection.

• When laying the network cable outdoors, attention must be given to suitable overvoltage

protection at the network cable transition from the inverter outdoors to the network inside the

building.

• The Ethernet interface of the inverter is classified as "TNV-1" and offers protection against

overvoltages up to 1.5kV.

Additionally required material (not included in the scope of delivery):

☐ Network cables

☐ Where required: Field-assembly RJ45 connector.

Cable requirements:

The cable length and quality affect the quality of the signal. Observe the following cable

requirements.

☐ Cable type: 100BaseTx

☐ Cable category: Cat5, Cat5e, Cat6, Cat6a or Cat7

☐ Plug type: RJ45 of Cat5, Cat5e, Cat6 or Cat6a

☐ Shielding: SF/UTP, S/UTP, SF/FTP or S/FTP

☐ Number of insulated conductor pairs and insulated conductor cross-section: at least 2 x 2 x

0.22 mm²

☐ Maximum cable length between two nodes when using patch cables: 50m

☐ Maximum cable length between two nodes when using installation cables: 100m

☐ UV-resistant for outdoor use

Procedure:

1.

DANGER

Danger to life due to electric shock

• Disconnect the inverter from all voltage sources (see Section10, page69).

Page 43

6 Electrical Connection

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 43

2. If the enclosure lid of the DC Connection Unit is

closed, remove it as follows: Unscrew all ten screws

with a Torx screwdriver (TX25) and remove the

enclosure lid carefully forward.

10x10x

3. Set the screws and the enclosure lid aside and store safely.

4. Remove the swivel nut from the cable gland for the communication cable.

5. Thread the swivel nut over the network cable.

6. Remove the two-hole cable support sleeve from the cable gland.

7. Remove the sealing plug from one of the enclosure openings of the two-hole cable support

sleeve and insert the network cable into the enclosure opening.

8. Press the two-hole cable support sleeve with the cable into the cable gland and guide the

network cable to the communication assembly in the DC Connection Unit. Ensure that any

unused enclosure openings of the two-hole cable support sleeve are sealed with sealing plugs.

9. When using a self-assembly network cable, assemble the RJ45 connector and connect to the

network cable (see connector documentation).

10. Put the RJ45 plug of the cable into one of the

network sockets of the communication assembly.

X2

Max. 30V DC

USB

M2

FCC ID: SVF-KP20

IC: 9440A-KP20

ANT.

SPS

B

A

11. Ensure that the RJ45 plug is securely in place by pulling slightly on the cable.

12. Tighten the swivel nut on the cable gland hand-tight. This will secure the network cable in

place.

13. If the inverter is installed outdoors, install overvoltage protection for all components in the

network.

14. If you would like to integrate the inverter into a local network, connect the other end of the

network cable to the local network (e.g. via a router).

Page 44

7 Commissioning

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1244

7 Commissioning

7.1 Commissioning Procedure

This section describes the commissioning procedure and gives an overview of the steps you must

perform in the prescribed order.

Procedure See

1. Commission the inverter. Section7.2, page44

2. Establish a connection to the user interface of the inverter.

There are various connection options to choose from for

this:

• Direct connection via WLAN

• Connection via WLAN in the local network

• Connection via Ethernet in the local network

Section8.1, page50

3. Log into the user interface. Section8.2, page53

4. Select the inverter configuration option. Please note that

the SMAGridGuard code (a charge is levied for this

code) for changing the grid-relevant parameters must be

available after completion of the first ten feed-in hours or

installation assistant (see "Application for the

SMAGridGuard code" available at www.SMA-Solar.com).

Section7.4, page46

5. Ensure that the country data set has been configured correctly.

Section9.3, page61

6. For PV systems in Italy: Start the self-test. Section7.3, page45

7. Make further inverter settings as needed. Section9, page59

7.2 Commissioning the Inverter

Requirements:

☐ The AC circuit breaker must be correctly rated and mounted.

☐ The inverter must be correctly mounted.

☐ All cables must be correctly connected.

☐ Unused enclosure openings must be sealed tightly with sealing plugs.

Page 45

7 Commissioning

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 45

Procedure:

1. Position the enclosure lid of the AC connection unit

on the AC connection unit and first tighten the

upper-left and lower-right screws, and then the

remaining screws crosswise using a Torx screwdriver

(TX25) (torque: 6Nm).

2

1

10x10x

2. Position the enclosure lid of the DC connection unit on the DC connection unit and first tighten

the upper-left and lower-right screws, and then the remaining screws crosswise using a Torx

screwdriver (TX25) (torque: 6Nm).

3. Turn the DC load-break switch of the inverter to

position I. To do so, first remove the padlock.

I

4. Switch on the AC circuit breaker.

☑ All three LEDs light up. The start-up phase begins.

☑ All three LEDs go out again after approximately 90seconds.

☑ Depending on the available power, the green LED pulses or is continuously illuminated. The

inverter is feeding in.

✖ The green LED is still flashing?

The conditions for activating feed-in operation are not yet met.

• As soon as the conditions for feed-in operation are met, the inverter starts with feed-in

operation and, depending on the available power, the green LED will light up

continuously or it will pulse.

✖ The red LED is glowing?

An event has occurred.

• Find out which event has occurred and, if necessary, initiate countermeasures.

7.3 Starting the Self-Test (For Italy Only)

The self-test is only required for inverters to be commissioned in Italy. The Italian standard requires

that all inverters feeding into the utility grid are equipped with a self-test function in accordance with

CEI0-21. During the self-test, the inverter will consecutively check the reaction times for

overvoltage, undervoltage, maximum frequency and minimum frequency.

Page 46

7 Commissioning

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1246

The self-test changes the upper and lower disconnection values for each protective function on a

linear basis for frequency monitoring and voltage monitoring. As soon as the measured value

exceeds the permitted disconnection threshold, the inverter disconnects from the utility grid. In this

way, the inverter determines the reaction time and checks itself.

After the self-test has been completed, the inverter automatically switches back to feed-in operation,

resets the original disconnection conditions and connects to the utility grid. The test takes

approximately threeminutes.

Requirements:

☐ The country data set of the inverter must be set to CEI 0-21 internal.

Procedure:

1. Select the menu Device Configuration.

2. Select [Settings].

3. Select [Starting the Self-Test] in the subsequent context menu.

4. Observe the instructions shown in the dialog and save the report of the self-test, if necessary.

7.4 Selecting a configuration option

After you have logged onto the user interface as Installer, the Configuring the Inverter page

opens.

A

E

B

D

C

Figure 13: Layout of the Configuring the Inverter page

Position Designation Description

A Device information Provides the following information:

• Device name

• Inverter serial number

• Inverter firmware version

Page 47

7 Commissioning

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 47

Position Designation Description

B User information Provides brief information on the listed configuration

options

C Skip configuration Offers the option of skipping the inverter configura-

tion and go directly to the user interface (not recommended)

D Checkbox Allows you to choose not to have the displayed page

displayed again when the user interface is called up

again

E Configuration options Provides a selection of the various configuration op-

tions

Procedure:

On the Configuring the Inverter page, different configuration options are available to choose

from. Select one of the options and proceed for the selected option as described below. SMA

Solar Technology AG recommends carrying out the configuration with the installation assistant. This

way, you ensure that all relevant parameters are set for optimal inverter operation.

• Adoption of configuration from a file

• Configuration with the installation assistant (recommended)

• Manual configuration

Accepting the settings

Saving the made settings is indicated by an hourglass symbol on the user interface. If the DC

voltage is sufficient, the data is transferred directly to the inverter and accepted. If the DC

voltage is too low (e.g. in the evening), the settings are saved, but they cannot be directly

transferred to or accepted by the inverter. As long as the inverter has not yet received and

accepted the settings, the hourglass symbol will continue to be displayed on the user interface.

The settings will be accepted when there is sufficient DC voltage applied and the inverter

restarts. As soon as the hourglass symbol appears on the user interface, the settings have been

saved. The settings will not be lost. You can log off of the user interface and leave the system.

Adopting the Configuration from a File

You can adopt the inverter configuration from a file. To do this, there must be an inverter

configuration saved to a file.

Procedure:

1. Select the configuration option Adopting configuration from a file.

2. Select [Browse...] and select the desired file.

3. Select [Import file].

Page 48

7 Commissioning

SMA Solar Technology AG

Operating manualSTP50-40-BE-en-1248

Configuring the Installation Assistant (Recommended)

A

C

B

Figure 14: Layout of the installation assistant (example)

Position Designation Description

A Configuration steps Overview of the installation assistant steps. The number of

steps depends on the type of device and the additionally

installed modules. The current step is highlighted in blue.

B User information Information about the current configuration step and the

setting options of the configuration step.

C Configuration field You can make settings in this field.

Procedure:

1. Select the configuration option Configuration with Installation Assistant.

☑ The installation assistant will open.

2. Follow the installation assistant steps and make the settings appropriate for your system.

3. For every setting made in a step, select [Save and next].

☑ In the last step, all made settings are listed in a summary.

4. To save the settings to a file, select [Export a summary] and save the file on your computer,

tablet PC or smartphone.

5. To correct settings you made, select [Back], navigate to the desired step, correct settings and

select [Save and continue].

6. Once all settings are correct, select [Next] in the summary.

☑ The start page of the user interface opens.

Manual configuration

You can configure the inverter manually by setting the desired parameters.

Page 49

7 Commissioning

SMA Solar Technology AG

Operating manual STP50-40-BE-en-12 49

Procedure:

1. Select the configuration option Manual Configuration.

☑ The Device Parameters menu on the user interface will open and all available

parameter groups of the inverter will be displayed.

2. Select [Edit parameters].

3. Select the desired parameter group.

☑ All available parameters of the parameter group will be displayed.

4. Set the desired parameters.