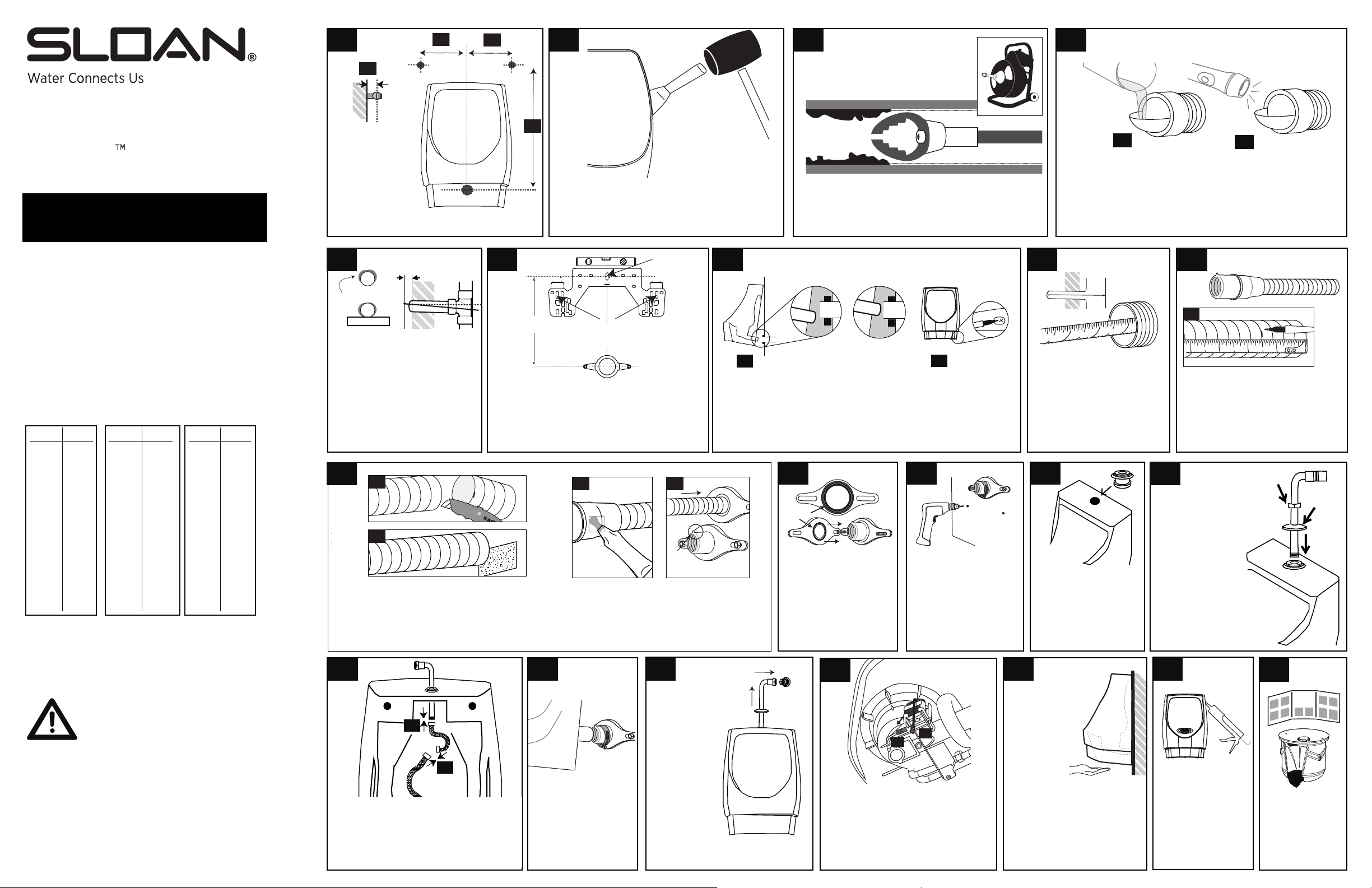

Sloan HYB-1000-RET Installation Manual

1

1

2

3

4

A

A

2

43

®

HYB-1000-RET

RETROFIT HYBRID URINAL

with Jetrinse Solution Technology

INSTALLATION INSTRUCTIONS

BEFORE STARTING INSTALLATION:

•

IMPORTANT Do not install on copper DWV

due to copper’s susceptibility to corrosion.

Check rough-in height to achieve 24” rim height

•

(17” rim height for ADA).

•

Check slope. Downhill slope, per code, is essential

because waterfree urinals depend on gravity flow.

•

Check DWV material. Suitable materials include

cast iron, PVC, ABS and galvanized steel.

•

Shut o water supply and remove flush valve and

vacuum breakers.

TUBE CUTTING CHART

•

Measure drain nipple depth (inches) to find trim

length (inches)

13 7/8” or more DO NOT CUT

•

3 3/4” or less DO NOT USE TUBE

•

OR LESS TRIM

13 ¾" ¼"

13 ½ ½

13 ¼ ¾

13 1

12 ¾ 1¼

12 ½ 1½

12 ¼ 1¾

12 2

11 ¾ 2¼

11 ½ 2½

11 ¼ 2¾

11 3

10 ¾ 3 ¼

10 ½ 3 ½

CUSTOMER CARE

1-800-982-5839

customer.service@sloanvalve.com

OR LESS TRIM

10 ¼" 3 ¾"

10 4

9 ¾ 4 ¼

9 ½ 4 ½

9 ¼ 4 ¾

9 5

8 ¾ 5 ¼

8 ½ 5 ½

8 ¼ 5 ¾

8 6

7 ¾ 6 ¼

7 ½ 6 ½

7 ¼ 6 ¾

7 7

OR LESS TRIM

6 ¾"

6 ½

6 ¼

6

5 ¾

5 ½

5 ¼

5

4 ¾

4 ½

4 ¼

4

7 ¼ "

7 ½

7 ¾

8

8 ¼

8 ½

8 ¾

9

9 ¼

9 ½

9 ¾

10

C

Confirm existing

supply stop and

drainline fall

within these

ranges:

A. 41/4” to 51/4”

1/2” to 351/2”

B. 28

1/8” to 3”

C. 2

5

Cut away wall

Lift drain line & brace

with mending plate

Adjust drain to achieve pitch

1/2” to 3/4”*

only if standing water is present

(code requires 1/4” drop per

foot of drain line for proper

pitch). Seal wall according to

code. IMPORTANT Nipple must

not extend more than 3/4” past

finished wall.

9

B

C

B. Cut the tube at the groove using a

sharp utility knife to ensure a square,

flat cut.

C. Clean burrs from the cut end by

using emery paper.

14

B

Use utility knife to cut caulk then use a putty

knife and mallet to remove the bowl. Remove

hanger brackets, scrape o caulk, and clean the

wall. Ensure the threads on the control stop are

brushed clean.

6

21 ½”

Measure and mark the rough-in if in-wall

carrier is not used. Use a 5/16” masonry bit to

drill hole, then install the hanger bracket with

one plastic anchor and screw. Level the bracket

then mark, drill and install two additional

plastic anchors and screws.

Install additional

screws here

D

LUBRICANT

D. Apply lubricant to the outside of the

rubber bushing and ribbed inside area.

E. Insert tube and bushing IMPORTANT

Be sure arrow tab is at the 12:00 position

Install plastic

anchor and

screw here

E

Arrow

tab UP

.

and lip seats against flange.

15

16

2" side cutter blade

IMPORTANT: Use a drain machine to remove

build-up inside pipes. Clean up to 25 feet deep

then flush with water to remove cutting debris.

Never install on copper DWV.

7

INCORRECT

Not centered

A

A. Hang bowl on the bracket and check tail pipe alignment, then

remove the bowl and adjust the bracket as needed. Re-hang

and re-check bowl alignment with the drain line. Tail pipe should

align with center of drain line. B. Mark anchor holes then remove

bowl without moving hanger bracket.

10

Seal

Place the seal into the

flange with ribs facing

out. Install the flange

with washers and hex

nuts, but do not over

tighten.

CORRECT

Centered

B

11

Drill holes

with 5/16” masonry bit

for the lower anchor

screws and insert

plastic anchors. Install

hose clamp with screw

at bottom, but do not

tighten.

from step 7B

17

A. Clean Face of drain nipple.

B. Install the clear inspection disc with the compression nut.

C. Slowly pour water into the drain.

D. Use a flashlight to check the pitch/slope no water

should be present in the inspection disc or nipple.

E. Remove disc and nut after inspection.

8

10

11

1 2

Determine the drain nipple

length by measuring the

distance between the back

of the sanitary tee (or elbow)

the front edge of the

nipple.

12

With urinal on the floor,

insert rubber grommet

into the hole located at

the top of the urinal.

Be sure the larger

diameter side is facing

up and fully seated.

18

C

8

9

A

D

1234

A. Find the drain nipple depth on

the Tube Cutting Chart (left).

Measure and mark the specified

trim length on the insert tube at

the nearest 1/4” groove.

13

Slide coupling nut

with threads facing

up and escutcheon

plate onto supply

assembly as shown,

then push threaded

end through

grommet so end is

accessible from

backside of urinal.

NOTE Use soap or

excess lubricant from

step 9D to ease

insertion.

19

coupling

nut

20

escutcheon

plate

CAUTION After removing any urinal from the

drain line, it’s normal for certain naturally occurring,

but potentially hazardous sewer gases to escape

through the opening until the waterless cartridge

is installed properly into the waterless urinal. If you

removing the urinal from the wall, temporarily wedge paper towels or a

rag into the drain hole to reduce any outflow of sewer gases, and remove

per towels or rag prior to completing the urinal or cartridge

the pa

installation. Never smoke, have an open flame, or place your nose or

mouth near open drain lines or waterless urinal housings into which

a car tridge is not yet pro perly installed. You also can wear a breathing

mask when removing or installing any waterless urinal or cartridge to

reduce potential exposure to any such gases.

www.SloanValve.com

The information in this document is subject to change without notice.

© 2016 Sloan Valve Company All rights reserved.

Code No. 0816682 (01-16 Rev 1)

need to leave an open drain line unattended after

A

B

A. Securely connect the female end of the

loose braided hose to the end of the

supply assembly. B. Connect the male end

to the braided hose on the Hybrid Jetrinse

assembly on the urinal. NOTE Ensure that

these connections are tight and leak-free.

Hang the bowl

inserting tailpipe into

bushing, and tighten

hose clamp. Install 2

lower anchor screws

with washers.

Rotate and

raise the

supply

assembly and

insert into

supply stop.

Tighten

coupling nut

securely. Do

NOT turn on

water yet.

A

B

Connect battery A to wire B. After 1

minute turn on water at supply stop

and confirm there are no connection

leaks.

Wave hand under

IR switch to

activate test

rinse and

ensure there

is no standing

water in

housing. System will

operate automatically

every 72 hours from

battery activation. NOTE

System will pause for 2

minutes after 2 manual

rinse activations.

Caulk the bowl

to the wall if

there is good

flow and no

leaks or standing

water in housing.

CARTRI DGE

INSTRUCTIO NS

Install cartridge

per the cartridge

instruction sheet.

Loading...

Loading...