Sloan Foot Pedal Flushometer User Manual

Code No. 0816488

Rev. 0 (08/08)

INSTALLATION INSTRUCTIONS FOR

FOOT PEDAL ACTIVATED WATER CLOSET AND URINAL FLUSHOMETERS

LIMITED WARRANTY

Sloan Valve Company warrants its Sloan Flushometers to be made of first class materials, free from defects of material or workmanship under normal use and to perform the

service for which they are intended in a thoroughly reliable and efficient manner when properly installed and serviced, for a period of three years (1 year for special finishes)

from date of purchase. During this period, Sloan Valve Company will, at its option, repair or replace any part or parts which prove to be thus defective if returned to Sloan

Valve Company, at customer’s cost, and this shall be the sole remedy available under this warranty. No claims will be allowed for labor, transportation or other incidental

costs. This warranty extends only to persons or organizations who purchase Sloan Valve Company’s products directly from Sloan Valve Company for purpose of resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY RESPONSIBLE

FOR ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

PRIOR TO INSTALLATION

Before installing the Sloan Flushometer, be sure the items listed below are

installed. Also, refer to the rough-in diagrams on Page 2.

• Closet/urinal fixture

• Drain line

• Water supply line

• Drill holes in wall for foot pedal actuator and water inlet to fixture

Due to code restrictions and installation practices, the Crown Naval 313

INT’L is for International use only.

Important:

• INSTALL ALL PLUMBING IN ACCORDANCE WITH APPLICABLE CODES

AND REGULATIONS.

• WATER SUPPLY LINES MUST BE SIZED TO PROVIDE AN ADEQUATE

VOLUME OF WATER FOR EACH FIXTURE.

• FLUSH ALL WATER LINES PRIOR TO MAKING CONNECTIONS.

Most Low Consumption water closets (1.6 gallon/6.0 liter) require a

minimum flowing pressure of 25 psi (172 kPa).

The Sloan Flushometer is designed to operate with 15 to 100 psi (104 to

689 kPa) of water pressure. THE MINIMUM PRESSURE REQUIRED TO THE

VALVE IS DETERMINED BY THE TYPE OF FIXTURE SELECTED. Consult

fixture manufacturer for minimum pressure requirements.

Most Low Consumption water closets (1.6 gpf/6.0 Lpf) require a minimum

flowing pressure of 25 psi (172 kPa).

Protect the Chrome or Special finish of this Flushometer — DO NOT USE

TOOTHED TOOLS TO INSTALL OR SERVICE THE VALVE. Also, see "Care and

Cleaning" section of this manual.

IMPORTANT: EXCEPT FOR CONTROL STOP INLET, DO NOT USE PIPE

SEALANT OR PLUMBING GREASE ON ANY VALVE COMPONENT OR

COUPLING!

TOOLS REQUIRED FOR INSTALLATION

• Straight blade screwdriver for stop adjustment (exposed models only)

• Sloan A-50 Super-Wrench™, Sloan A-109 Plier Wrench or smooth jawed

spud wrench

• Hole saw for foot pedal actuator and water inlet to fixture

• 1/16” hex wrench for supply flange (exposed models only)

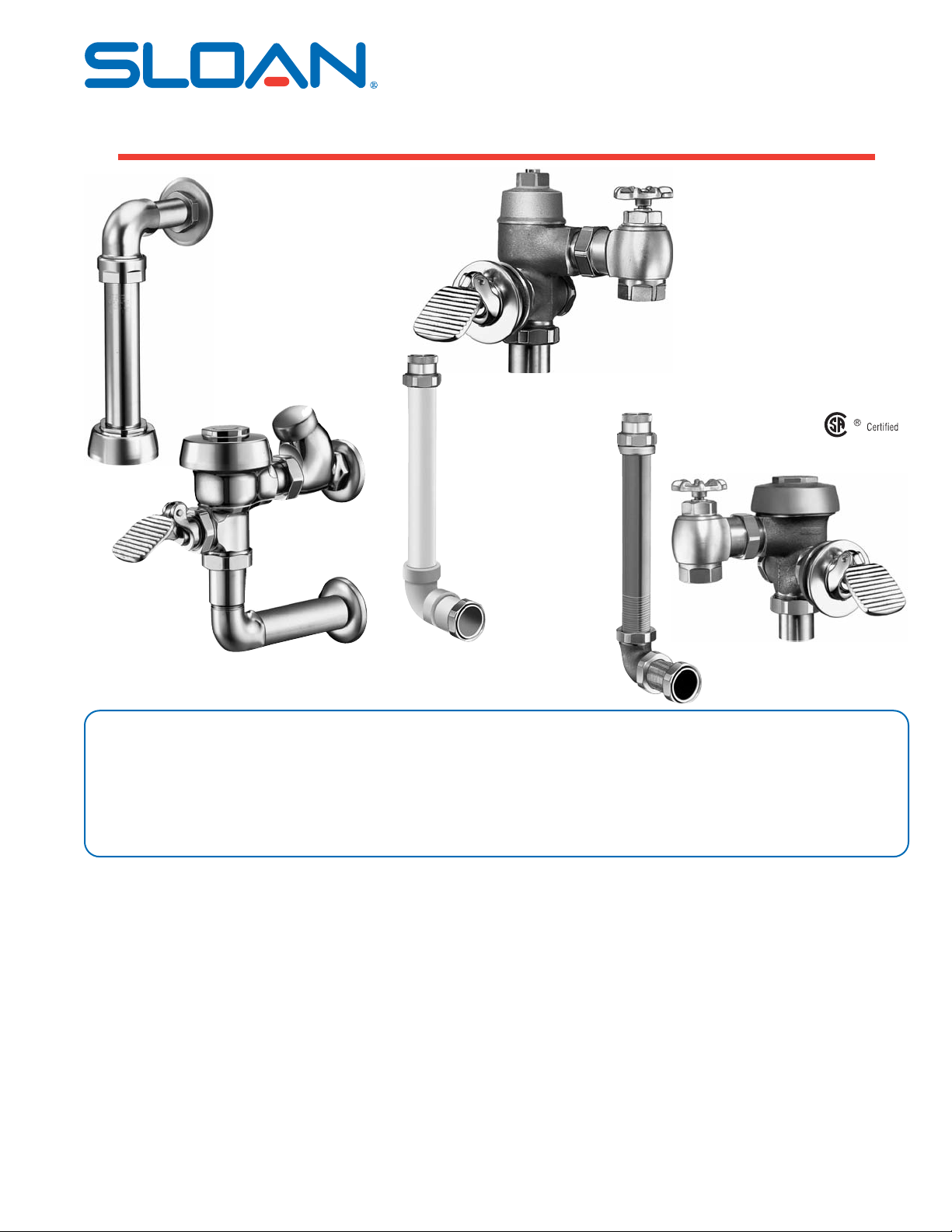

Royal 310

Exposed Model Shown

Royal, Regal, and

Crown Naval

Models 310, 312, 313, 313 INT’L,

318, 320, 323 and 343

Exposed and Concealed

Foot Pedal Activated

Closet and Urinal

Flushometer Valves

Royal 313

Concealed Model Shown

Crown Naval 313 INT’L

Concealed Model Shown

Made in the U.S.A.

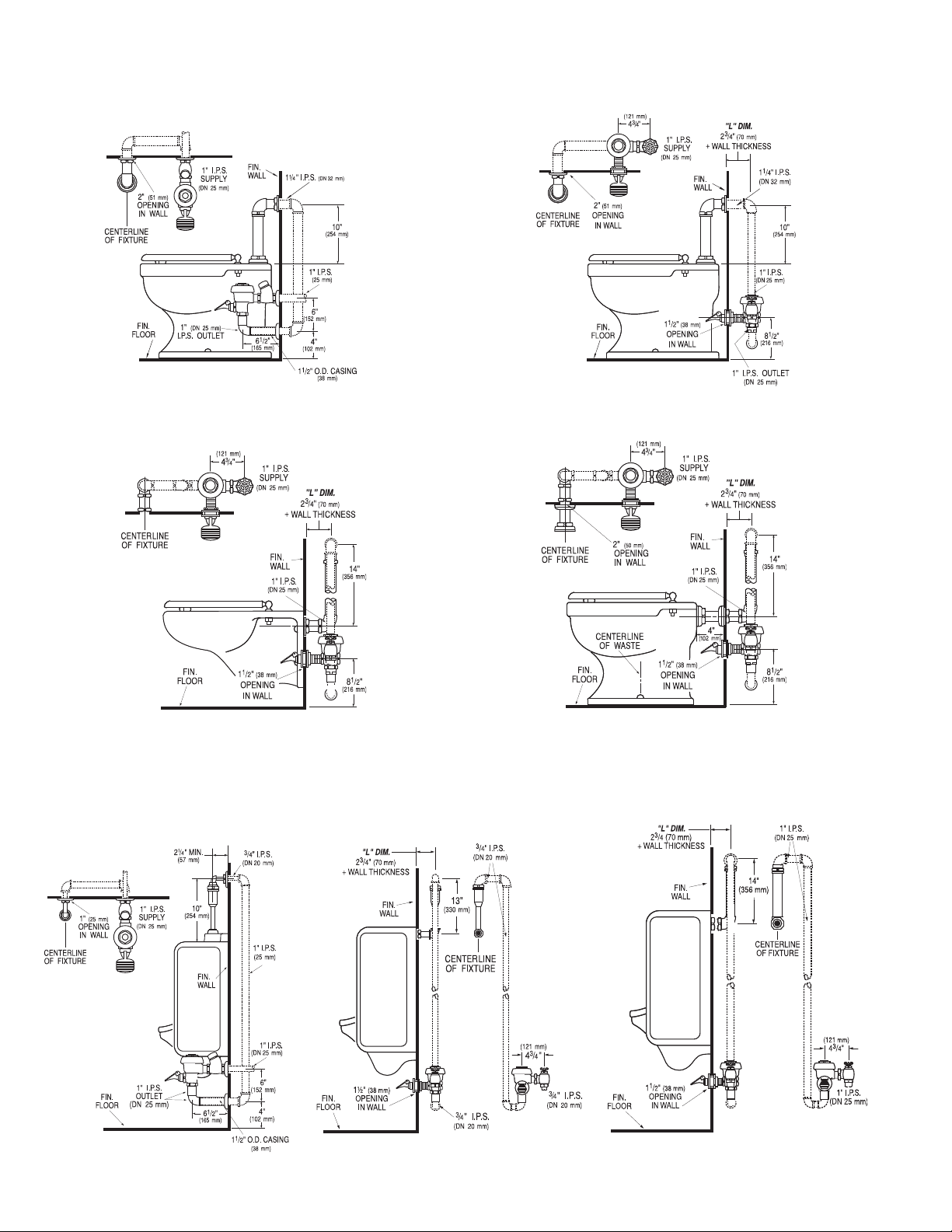

WATER CLOSET ROUGH-IN

2

URINAL ROUGH-IN

Model 310 — Water Saver (3.5 gpf/13.2 Lpf)

Model 310-1.6 Low Consumption (1.6 gpf/6.0 Lpf)

Model 312 — Water Saver (3.5 gpf/13.2 Lpf)

Model 312-1.6 Low Consumption (1.6 gpf/6.0 Lpf)

Model 313 — Water Saver (3.5 gpf/13.2 Lpf)

Model 313-1.6 Low Consumption (1.6 gpf/6.0 Lpf)

Model 318 — Water Saver (3.5 gpf/13.2 Lpf)

Model 318-1.6 Low Consumption (1.6 gpf/6.0 Lpf)

Model 320 — Water Saver (1.5 gpf/5.7 Lpf)

Model 320-1.0 Low Consumption (1.0 gpf/3.8 Lpf)

Model 323 — Water Saver (1.5 gpf/5.7 Lpf)

Model 323-1.0 Low Consumption (1.0 gpf/3.8 Lpf)

Model 343 — Water Saver (1.5 gpf/5.7 Lpf)

Model 343-1.0 Low Consumption (1.0 gpf/3.8 Lpf)

Note: Flush Connections shown in dotted lines not included

Note: Flush Connections shown in dotted lines not included

3

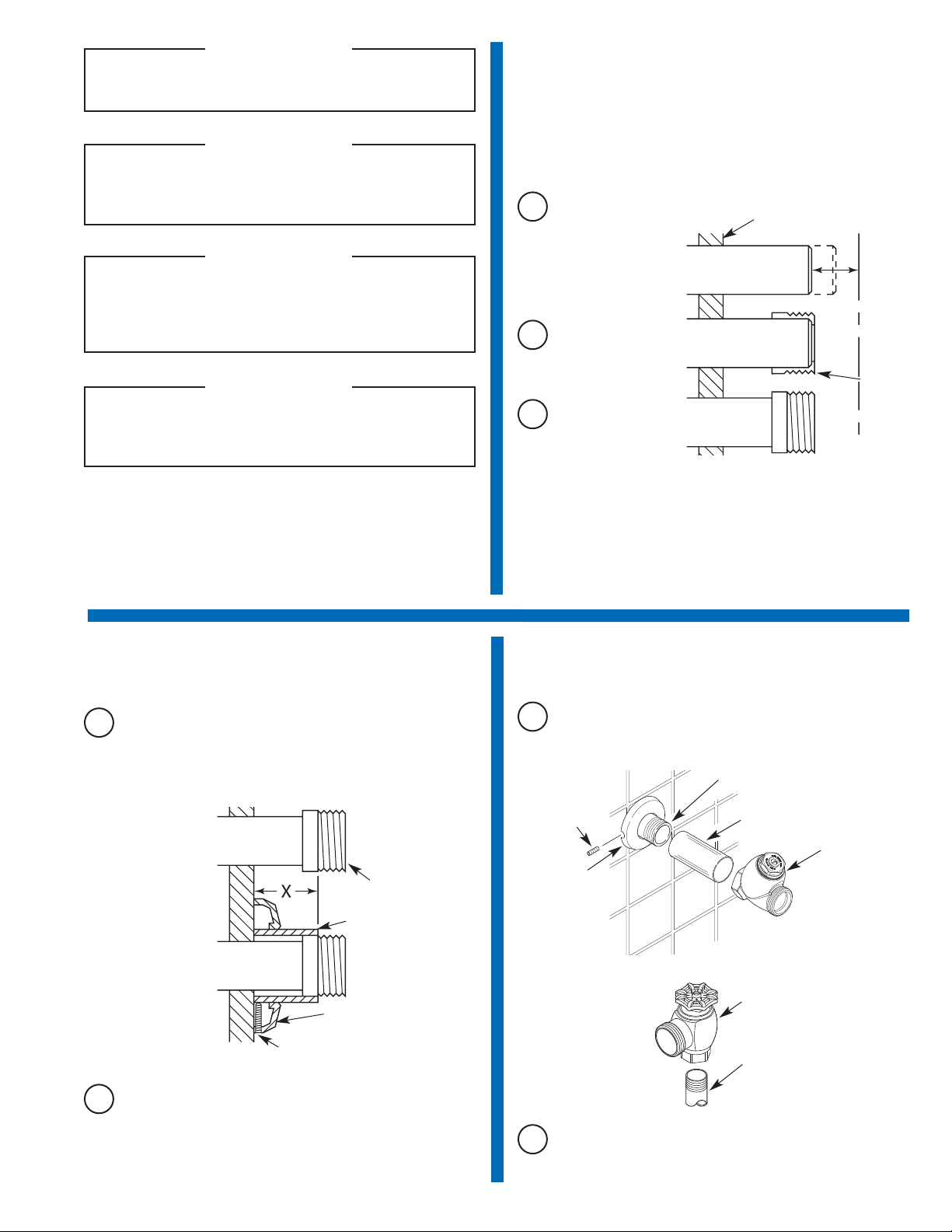

1

Install Optional Sweat Solder

Adapter (only if your supply pipe

does not have a male thread)

2

Install Cover Tube and Wall Flange

to supply pipe

With the exception of Control Stop Inlet, DO NOT use pipe

sealant or plumbing grease on any valve component or

coupling!

!!! IMPORTANT !!!

Protect the chrome or special finish of Sloan Flushometers —

DO NOT USE toothed tools to install or service these valves.

Use a Sloan A-50 Super-Wrench™, Sloan A-109 Plier Wrench

or smooth jawed spud wrench to secure all couplings. Also

see “Care and Cleaning” section of this manual.

!!! IMPORTANT !!!

This product contains mechanical and/or electrical

components that are subject to normal wear. These

components should be checked on a regular basis and

replaced as needed to maintain the valve’s performance.

!!! IMPORTANT !!!

If you have questions about how to install your Sloan

Flushometer, consult your local Sloan Representative or call

Sloan Installation Engineering Department at:

1-888-SLOAN-14 (1-888-756-2614) OR 1-847-233-2016

A

Measure from finished

wall to C/L of Fixture

Spud. Cut pipe 1¼"

(32 mm) shorter than

this measurement.

Chamfer O.D. and I.D.

of water supply pipe.

WATER SUPPLY PIPE

FINISHED WALL

1-1/4”

(32 mm)

C/L OF

FIXTURE

SPUD

SWEAT

SOLDER

ADAPTER

B

Slide Threaded Adapter

fully onto pipe.

C

Sweat solder the

Adapter to pipe.

Thread Control Stop onto supply pipe. Tighten with a wrench until

outlet is positioned as required.

WATER

SUPPLY PIPE

SWEAT

SOLDER ADAPTER

COVER TUBE

WALL

FLANGE

SET SCREW

A

Measure from finished wall to first thread of Adapter or threaded

supply pipe (dimension “X”). Cut Cover Tube to this length.

B

Slide Cover Tube over pipe. Slide Wall Flange over Cover Tube

until against wall.

A

Tighten Set Screw with a 1/16” hex wrench. For Exposed

Flushometers — DO NOT install Vandal Resistant Stop Cap at this

time.

B

3

Install Control Stop

CONCEALED

EXPOSED

SET

SCREW

SUPPLY

FLANGE

IRON PIPE NIPPLE OR COPPER PIPE

WITH SWEAT SOLDER ADAPTER

COVERING

TUBE

BAK-CHEK

®

CONTROL

STOP

BAK-CHEK

®

CONTROL STOP

IRON PIPE NIPPLE OR

COPPER PIPE WITH

SWEAT SOLDER

ADAPTER

Never open Control Stop to where the flow from the valve

exceeds the flow capability of the fixture. In the event of a

valve failure, the fixture must be able to accommodate a

continuous flow from the valve.

!!! IMPORTANT !!!

Loading...

Loading...