Sloan EW-72000 Installaton

Code No. 0816545

Rev. 1 (03/07)

INSTALLATION INSTRUCTIONS FOR DOUBLE AND TRIPLE STATION

SENSOR ACTIVATED SOLID SURFACE LAVATORY SYSTEMS

LIMITED WARRANTY

Sloan Valve Company warrants its Optima EW-70000 Series Lavatory Systems to be made of first class materials, free from defects of material or workmanship under normal use and to perform the service for which they are intended in a thoroughly reliable and efficient manner when properly installed and serviced, for a period of three years (1 year for special finishes) from date of purchase. During this period, Sloan Valve Company will, at its option, repair or replace

any part or parts which prove to be thus defective if returned to Sloan Valve Company, at customer’s cost, and this shall be the sole remedy available under

this warranty. No claims will be allowed for labor, transportation or other incidental costs. This warranty extends only to persons or organizations who purchase Sloan Valve Company’s products directly from Sloan Valve Company for purpose of resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY

RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

EW-72000

Double Station

Sensor Activated

Solid Surface Lavatory System

EW-73000

Triple Station

Sensor Activated

Solid Surface Lavatory System

EW-72000-xx-SD Model Shown

EW-73000-xx-SD Model Shown

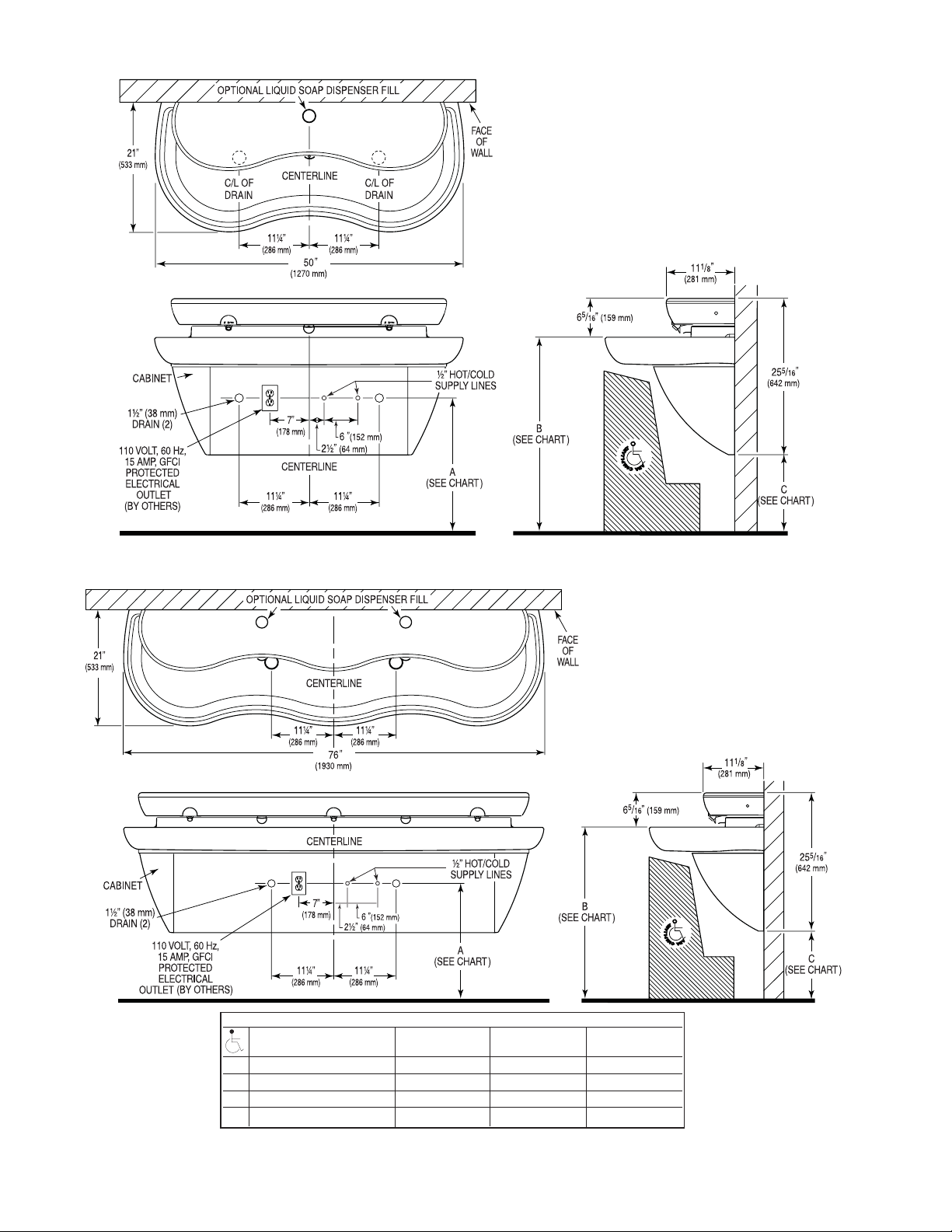

LAVATORY SYSTEM ROUGH-IN

MODEL EW-72000

Double Station Lavatory System

Flow Rate: 0.5 gpm/1.9 Lpm Max. Spray

Lavatory System Weight (Packaged):

Approximately 145 Lbs/65 Kg

2

MODEL EW-73000

Triple Station Lavatory System

Flow Rate: 0.5 gpm/1.9 Lpm Max. Spray

Lavatory System Weight (Packaged):

Approximately 170 Lbs/80 Kg

VARIABLE MOUNTING HEIGHT CHART

DIMENSION T.A.S. † T.A.S. † A.D.A.

DESCRIPTION AGES 4-10 AGES 11-15 STANDARD

A ROUGH-IN 20-1/2” (521 mm) 22-1/2” (572 mm) 24” (610 mm)

B RECOMMENDED RIM HEIGHT 29-7/8” (759 mm) 31-7/8” (810 mm) 33 (838 mm)

C FLOOR CLEARANCE 10-7/8” (276 mm) 12-7/8” (327 mm) 14” (356 mm)

D NOMINAL FRAME HEIGHT ‡ 25-1/8” (638 mm) 27-1/8 (689 mm) 28-1/4” (718 mm)

† When no mirror is required above the basin.

For T.A.S. compliant installations requiring a mirror above the basin, use ELS-72000

products.

‡ Refer to Step 3.

PRIOR TO INSTALLATION

Prior to installing the Sloan Optima EW-70000 Series Lavatory System,

install the items listed below. Also, refer to the appropriate rough-in

diagram on Page 2.

• Install electrical receptacle(s) for plug-in transformer(s) — 120 VAC,

2 amp service for each ETF-233 (24 VAC, 35 VA) plug-in transformer

used.

• Hot and cold water supply lines or tempered water supply line (If there

is no tempered water supply, install thermostatic mixing valve

between hot and cold water supply)

• Drain lines

Important:

• ADEQUATE STRUCTURAL SUPPORT IN OR BEHIND THE WALL IS

REQUIRED. REFER TO THE APPROPRIATE ROUGH-IN DIAGRAM ON

PAGE 2 FOR DRY WEIGHT OF SINK. STRUCTURAL SUPPORT

MUST HAVE A MINIMUM PULLOUT RATING OF 1000 POUNDS

(450 Kg) FOR EACH FASTENER.

• ALL ELECTRICAL WIRING SHOULD BE INSTALLED IN ACCORDANCE

WITH NATIONAL/LOCAL CODES AND REGULATIONS.

• ALL PLUMBING SHOULD BE INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES AND REGULATIONS.

• A 24 VAC STEP-DOWN TRANSFORMER MUST BE USED FOR

HARDWIRE APPLICATIONS.

• USE APPROPRIATE PRECAUTIONS WHILE CONNECTING

TRANSFORMER TO 120 VAC POWER SOURCE.

• DO NOT PLUG TRANSFORMER INTO POWER SOURCE (RECEPTACLE)

UNTIL ALL WIRING IS COMPLETED. PERMANENT DAMAGE TO THE

TRANSFORMER AND CIRCUIT CONTROL MODULE WILL RESULT IF

24 VAC WIRES TOUCH EACH OTHER OR SHORT WHEN POWER

SUPPLY IS ACTIVE.

• BEFORE CONNECTING FLEX HOSES TO SUPPLY STOPS, FLUSH ALL

WATER LINES UNTIL WATER IS CLEAR.

TOOLS REQUIRED FOR INSTALLATION

• Electric drill for drilling anchor holes.

• Standard sockets and open end wrench set for installing anchoring

fasteners and connecting water lines.

• Pipe wrench for installing drain lines.

• Phillips and straight blade screwdrivers.

SINK LOCATION

Determine the appropriate wall location for the Lavatory System.

Consider that hot and cold water supply lines, drain lines, and an

electrical source (receptacle or wiring depending on type of transformer

used) will be required. Compare the physical dimensions of the Lavatory

System to the space available for the installation. If wall is not load

bearing, a carrier may be required behind the wall. Refer to the

appropriate Rough-in diagram on Page 2 for Lavatory System

dimensions.

Prior to Lavatory System installation, electric wiring, water supply and

drain must be installed.

1

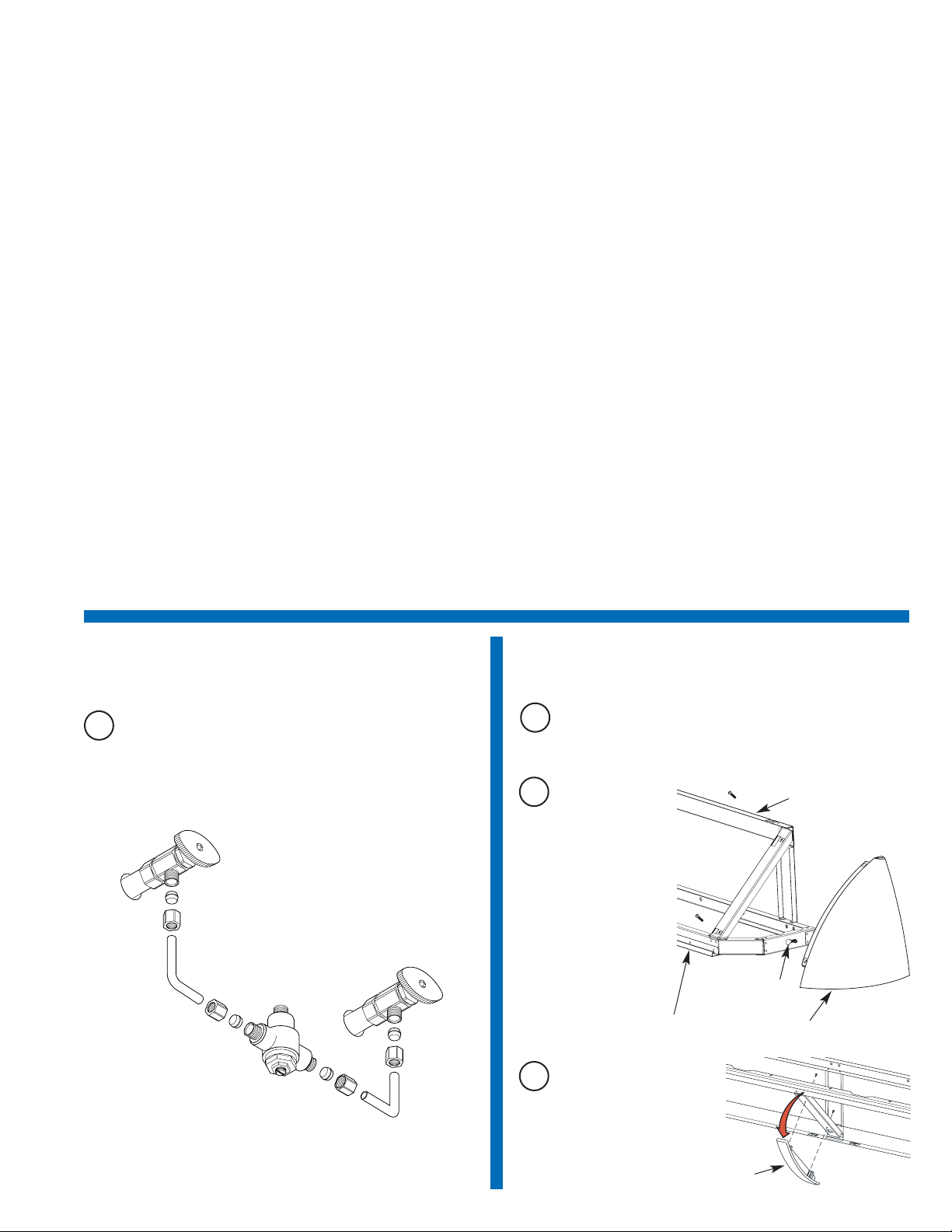

Install Thermostatic Mixing Valve

A

If there is no tempered water supply, install Thermostatic Mixing

Valve between hot and cold water supply.

3

2

Remove End Caps from Frame

Bottom Backside of Frame

Front of Frame

End Cap (2)

Enlarged Hole and

Slot in Frame

A

Loosen (do not remove) screws on inside of frame.

C

For triple station sinks,

remove the Front Panel

Support.

B

Remove both End

Caps by removing

the two outer screws

on each Cap. Slide

Cap forward in slot

and pull it out

through enlarged

hole in Frame.

Front Panel Support

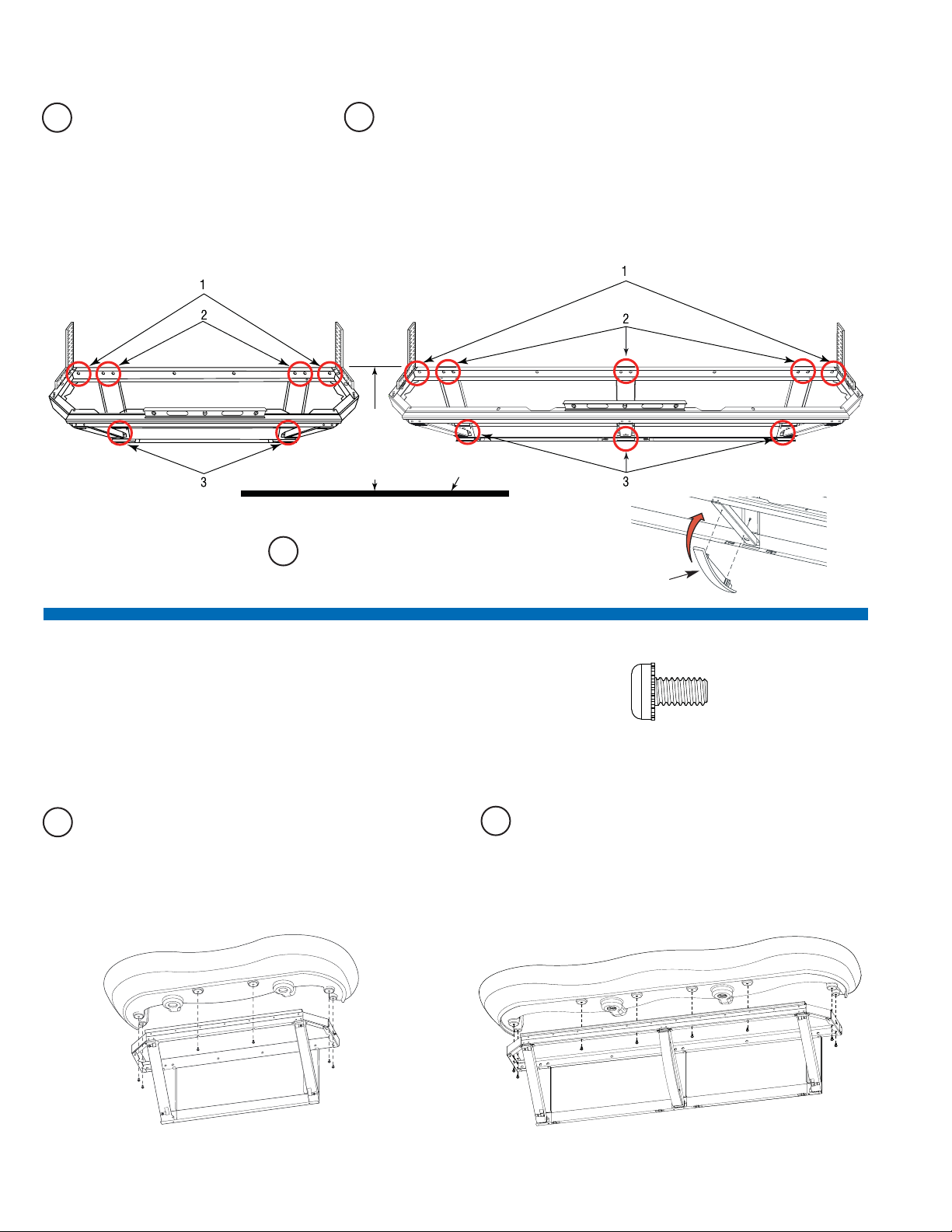

4

Mount Basin to Frame

A

Mount Basin to Frame using 1/4”-20 x 1/2” SEMS fasteners.

B

If desired, apply caulk between Basin and wall.

3

Mount Frame to Wall

4

Triple StationDouble Station

1/4”-20 x 1/2” Pan Head Screw (SEMS)

(Actual Size)

Note: If desired, Grid Strainers may be installed prior to mounting

Basin to the Frame. Refer to Step 5.

Triple Station

Double Station

FINISHED FLOOR

D

(See VARIABLE

MOUNTING

HEIGHT CHART

On Page 2)

C

For triple station sinks, reinstall the Front Panel

Support.

A

If desired, apply adhesive to back

surfaces of Frame.

B

Mount Frame to wall using 3/8" fasteners with 1000 lb min

pull out strength in the following locations:

1. Each hole in the extreme outer corners of top support

2. One of either of the two holes in the top position of each upright

3. The lower hole location in each upright

Fasteners may be optionally applied to any of the remaining mounting hole locations.

Level Frame in both directions before tightening fasteners securely.

Front Panel Support

Loading...

Loading...