Sloan EW-62050 Installation Manual

Code No. 0816836

Rev. 0 (07/09)

INSTALLATION INSTRUCTIONS FOR DOUBLE AND TRIPLE STATION

SENSOR ACTIVATED SOLID SURFACE LAVATORY SYSTEMS

LIMITED WARRANTY

Sloan Valve Company warrants its EW-60000 Series Lavatory Systems to be made of first class materials, free from defects of material or workmanship

under normal use and to perform the service for which they are intended in a thoroughly reliable and efficient manner when properly installed and serviced,

for a period of three years (1 year for special finishes) from date of purchase. During this period, Sloan Valve Company will, at its option, repair or replace

any part or parts which prove to be thus defective if returned to Sloan Valve Company, at customer’s cost, and this shall be the sole remedy available under

this warranty. No claims will be allowed for labor, transportation or other incidental costs. This warranty extends only to persons or organizations who purchase

Sloan Valve Company’s products directly from Sloan Valve Company for purpose of resale. This warranty does not cover the life of the batteries (battery powered

models).

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY

RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE WHATSOEVER.

EW-62000

EW-62050

Double Station

Sensor Activated

Solid Surface Lavatory System

EW-63000

EW-63050

Triple Station

Sensor Activated

Solid Surface Lavatory System

EW-62000-XX-X-MSD Model Shown

EW-63000-XX-X-MSD Model Shown

2

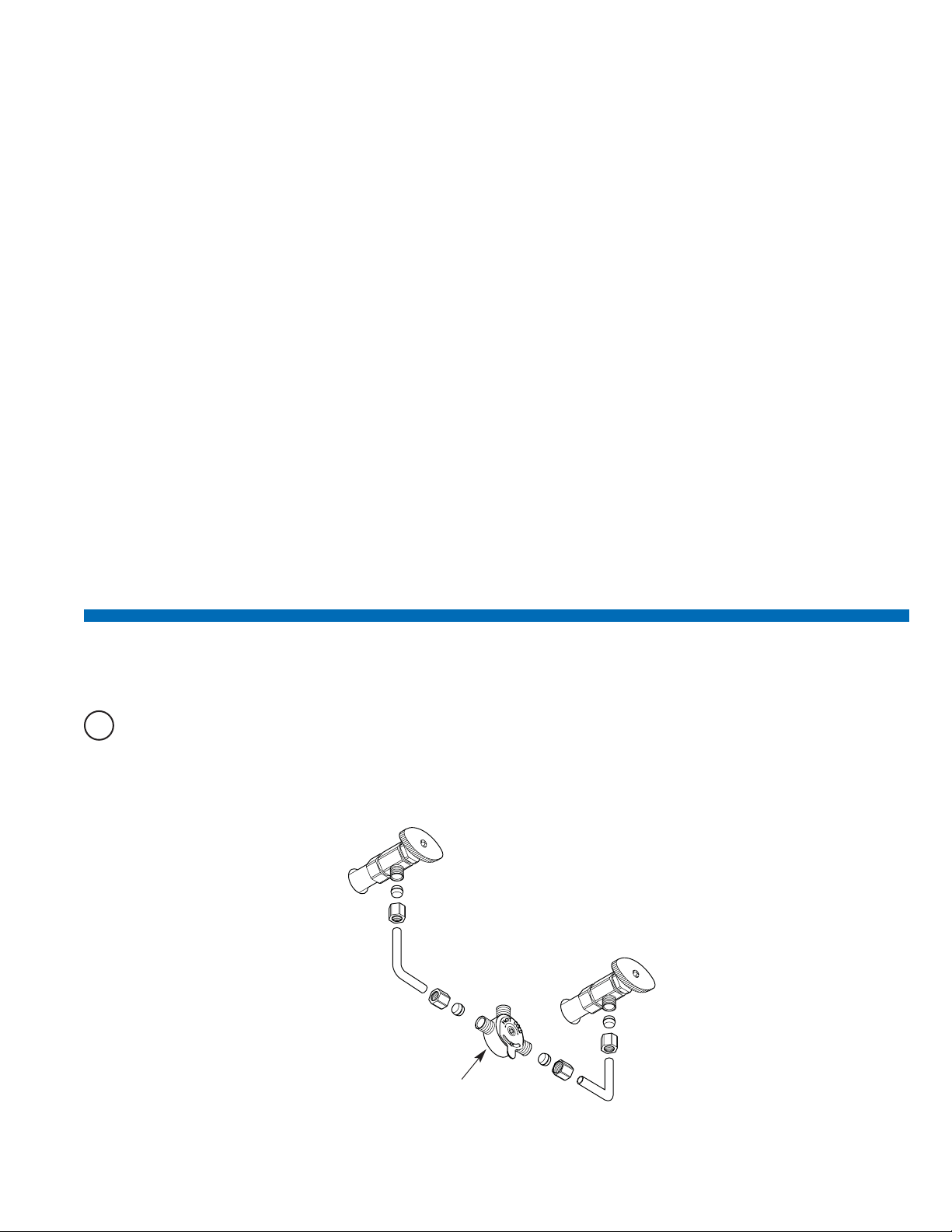

LAVATORY SYSTEM ROUGH-IN

MODEL EW-62000

MODEL EW-62050

Double Station Lavatory System

Flow Rate: 0.5 gpm/1.9 Lpm Max. Spray

Lavatory System Weight (Packaged):

Approximately 82 Lbs/37 Kg

MODEL EW-63000

MODEL EW-63050

Triple Station Lavatory System

Flow Rate: 0.5 gpm/1.9 Lpm Max. Spray

Lavatory System Weight (Packaged):

Approximately 124 Lbs/56 Kg

VARIABLE MOUNTING HEIGHT CHART (2 AND 3 STATION)

DIMENSION T.A.S. † T.A.S. † A.D.A.

DESCRIPTION AGES 4-10 AGES 11-15 STANDARD

A ROUGH-IN, DRAIN 20” (508 mm) 22” (559 mm) 24” (610 mm)

B ROUGH-IN, SUPPLY 23” (584 mm) 25” (635 mm) 27” (686 mm)

C RECOMMENDED RIM HEIGHT 29-3/4” (756 mm) 31-3/4” (806 mm) 33-3/4” (857 mm)

D FLOOR CLEARANCE, 2 STATION 11-1/8” (283 mm) 13-1/8” (333 mm) 15-1/8” (384 mm)

D FLOOR CLEARANCE, 3 STATION 12-1/16” (306 mm) 14-1/16” (357 mm) 16-1/16” (408 mm)

E BRACKETS, HEIGHT ‡ 25-3/4” (654 mm) 27-3/4” (705 mm) 29-3/4” (756 mm)

F BRACKETS, TOP HOLE ‡ 25” (635 mm) 27” (686 mm) 29” (737 mm)

† When no mirror is required above the basin.

‡ Refer to Step 2.

21”

(533 mm)

1-1/2”

(38 mm)

DRAIN (2)

110 VOLT,

60 Hz ,

15 AMP, GFCI

PROTECTED

ELECTRICAL

OUTLET

(BY OTHERS)

A

(SEE

CHART)

OPTIONAL LIQUID SOAP DISPENSER FILL

11-1/4”

(286 mm)

PLASTIC

CABINET

14-3/4”

(375 mm)

CENTERLINE

(286 mm)

50”

(1270 mm)

8-1/4”

(210 mm)

(152 mm)

C/L OF

DRAIN

11-1/4”

6 ”

14-3/4”

(375 mm)

C/L OF

DRAIN

FACE

OF

WALL

HOT/COLD

SUPPLY LINES

B

(SEE CHART)

1/2”

FINISHED

FLOOR

6-5/16”

(160 mm)

C

(SEE

CHART)

11-1/8”

(283 mm)

PLASTIC

CABINET

24-7/8”

(632 mm)

D

(SEE

CHART)

OPTIONAL LIQUID SOAP DISPENSER FILL

21”

(533 mm)

1-1/2” (38 mm)

DRAIN (2)

110 VOLT, 60 Hz,

A

(SEE

CHART)

15 AMP, GFCI

PROTECTED

ELECTRICAL

OUTLET

(BY OTHERS)

11-1/4”

(286 mm)

14-3/4”

(375 mm)

CENTERLINE

(286 mm)

76”

(1930 mm)

11-1/4”

PLASTIC

CABINET

21-1/4”

(540 mm)

14-3/4”

(375 mm)

6”

(152 mm)

FACE

OF

WALL

6-5/16”

(160 mm)

1/2”

HOT/COLD

SUPPLY LINES

C

(SEE

CHART)

B

(SEE CHART)

FINISHED

FLOOR

11-1/8”

(283 mm)

PLASTIC

CABINET

24”

(610 mm)

D

(SEE

CHART)

3

PRIOR TO INSTALLATION

Prior to installing the Sloan EW-60000 Series Lavatory System, install

the items listed below. Also, refer to the appropriate rough-in diagram on

Page 2 and brackets diagram on Page 4.

• Install electrical receptacle(s) for plug-in transformer(s) — 120 VAC,

2 amp service for each SFP-36 (6 VDC, 2300 mA) plug-in transformer

used (EW-62000/EW-63000 only).

• Hot and cold water supply lines or tempered water supply line (If there

is no tempered water supply, install mechanical mixing valve between

hot and cold water supply)

• Drain lines

Important:

• ADEQUATE STRUCTURAL SUPPORT IN OR BEHIND THE WALL IS

REQUIRED. REFER TO THE APPROPRIATE ROUGH-IN DIAGRAM ON

PAGE 2 FOR DRY WEIGHT OF SINK. STRUCTURAL SUPPORT

MUST HAVE A MINIMUM PULLOUT RATING OF 1000 POUNDS

(450 Kg) FOR EACH FASTENER.

• INSTALL ALL ELECTRICAL WIRING IN ACCORDANCE WITH

NATIONAL/LOCAL CODES AND REGULATIONS.

• INSTALL ALL PLUMBING IN ACCORDANCE WITH APPLICABLE CODES

AND REGULATIONS.

• USE APPROPRIATE PRECAUTIONS WHILE CONNECTING

TRANSFORMER TO 120 VAC POWER SOURCE.

• DO NOT PLUG TRANSFORMER INTO POWER SOURCE (RECEPTACLE)

UNTIL ALL WIRING IS COMPLETED.

• BEFORE CONNECTING FLEX HOSES TO SUPPLY STOPS, FLUSH ALL

WATER LINES UNTIL WATER IS CLEAR.

TOOLS REQUIRED FOR INSTALLATION

• Electric drill for drilling anchor holes.

• Standard sockets and open-end wrench set for installing anchoring

fasteners and connecting water lines.

• Pipe wrench for installing drain lines.

• Phillips and straight blade screwdrivers.

• Tubing Cutter

• Level

• Carpenter’s square

• Caulk gun

SINK LOCATION

Determine the appropriate wall location for the Lavatory System.

Consider that hot and cold water supply lines, drain lines, and an

electrical source (receptacle) will be required. Compare the physical

dimensions of the Lavatory System to the space available for the

installation. If wall is not load-bearing, a carrier may be required behind

the wall. Refer to the appropriate Rough-in diagram on Page 2 for

Lavatory System dimensions.

Prior to Lavatory System installation, electric wiring, water supply and

drain must be installed.

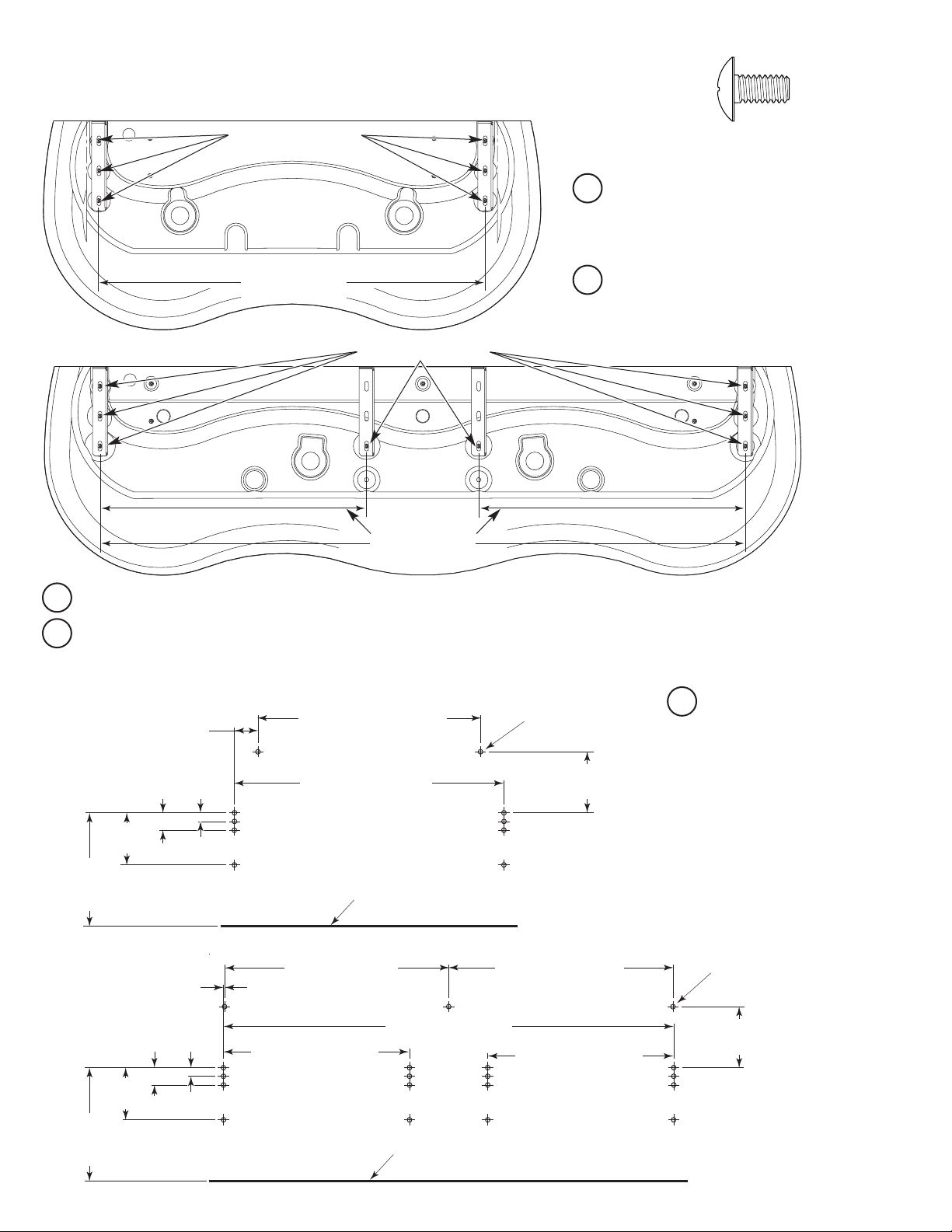

1

Install Mechanical Mixing Valve

A

If there is no tempered water supply, install Mechanical Mixing Valve between hot and cold water supply.

MIX-60-A

MECHANICAL MIXING VALVE

4

2

Mount Brackets and Basin to Wall

1/4”-20 x 1/2” Truss Head Screw

(Actual Size)

D

Mount Basin and Brackets to wall using fasteners with washers that hold over 1000 lbf (pounds-force) withdrawal load each.

Note: If desired, detach Brackets from Basin and mount Brackets to wall first. Then mount Basin to Brackets using 1/4”-20 x 1/2” Truss Head Screws.

Grid Strainer may be installed prior to attaching Basin to Brackets. Refer to Step 3.

E

Level Brackets in all

directions before tightening

fasteners securely. If desired,

apply caulk between Basin

and Wall.

Note: If installation is on soft wall

place 1/16” thick stainless or

galvanized steel sheets between the

Wall and the Brackets. These sheets

must be larger in area than the

mounting surfaces of the Brackets,

and must have thru-holes that align

with the Bracket’s mounting holes.

A

Attach Brackets to Basin using 1/4”-20 x 1/2”

Truss Head Screws. Double Station uses six

(6) Fasteners. Triple Station uses eight (8)

Fasteners.

B

Measure distance between brackets. Make

sure the carrier (when needed) can

accommodate the proper location for the

brackets.

C

Determine the appropriate location for the holes to secure the brackets to the wall. Use the following dimensions as a reference.

DOUBLE STATION

DOUBLE STATION

TRIPLE STATION

TRIPLE STATION

1/4”-20 x 1/2”

TRUSS HEAD SCREWS (6)

1/4”-20 x 1/2”

TRUSS HEAD SCREWS (8)

DISTANCE BETWEEN

BRACKETS

DISTANCE BETWEEN

BRACKETS

3-3/8” (86 mm)

APPROXIMATE LOCATION

2-1/2”

(64 mm)

7-1/2”

(191 mm)

“F”

SEE TABLE ON

PAGE 2

1-1/4”

(32 mm)

32” (813 mm)

APPROXIMATE LOCATION

DISTANCE BETWEEN

BRACKETS - STEP 2B

FINISHED FLOOR

HEAD SECURING

LOCATIONS (2)

8-3/4” (222 mm)

APPROXIMATE LOCATION

1/8” (3 mm)

APPROXIMATE LOCATION

2-1/2”

(64 mm)

7-1/2”

(191 mm)

“F”

SEE TABLE ON

PAGE 2

1-1/4”

(32 mm)

32” (813 mm)

APPROXIMATE LOCATION

DISTANCE BETWEEN

BRACKETS - STEP 2B

DISTANCE BETWEEN

BRACKETS - STEP 2B

FINISHED FLOOR

32-1/4” (819 mm)

APPROXIMATE LOCATION

DISTANCE BETWEEN

BRACKETS - STEP 2B

HEAD SECURING

LOCATIONS (3)

8-3/4” (222 mm)

APPROXIMATE LOCATION

Loading...

Loading...