Sloan ETF-800 Installation Manual

Code No. 0816702

Rev. 0b (11/08)

INSTALLATION INSTRUCTIONS FOR

ELECTRONIC SENSOR ACTIVATED HAND WASHING FAUCET

LIMITED WARRANTY

Sloan Valve Company warrants its Optima ETF-800 Electronic Hand

Washing Faucet to be made of first class materials, free from defects of

material or workmanship under normal use and to perform the service for

which it is intended in a thoroughly reliable and efficient manner when

properly installed and serviced, for a period of three years (1 year for

special finishes) from date of purchase. During this period, Sloan Valve

Company will, at its option, repair or replace any part or parts which prove

to be thus defective if returned to Sloan Valve Company, at customer’s

cost, and this shall be the sole remedy available under this warranty. No

claims will be allowed for labor, transportation or other incidental costs.

This warranty extends only to persons or organizations who purchase

Sloan Valve Company’s products directly from Sloan Valve Company for

purpose of resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN

VALVE COMPANY RESPONSIBLE FOR ANY CONSEQUENTIAL

DAMAGES OF ANY MEASURE WHATSOEVER.

ETF-800

Wall Mounted, Sensor Activated

Electronic Hand Washing Faucet for

tempered or hot/cold water operation.

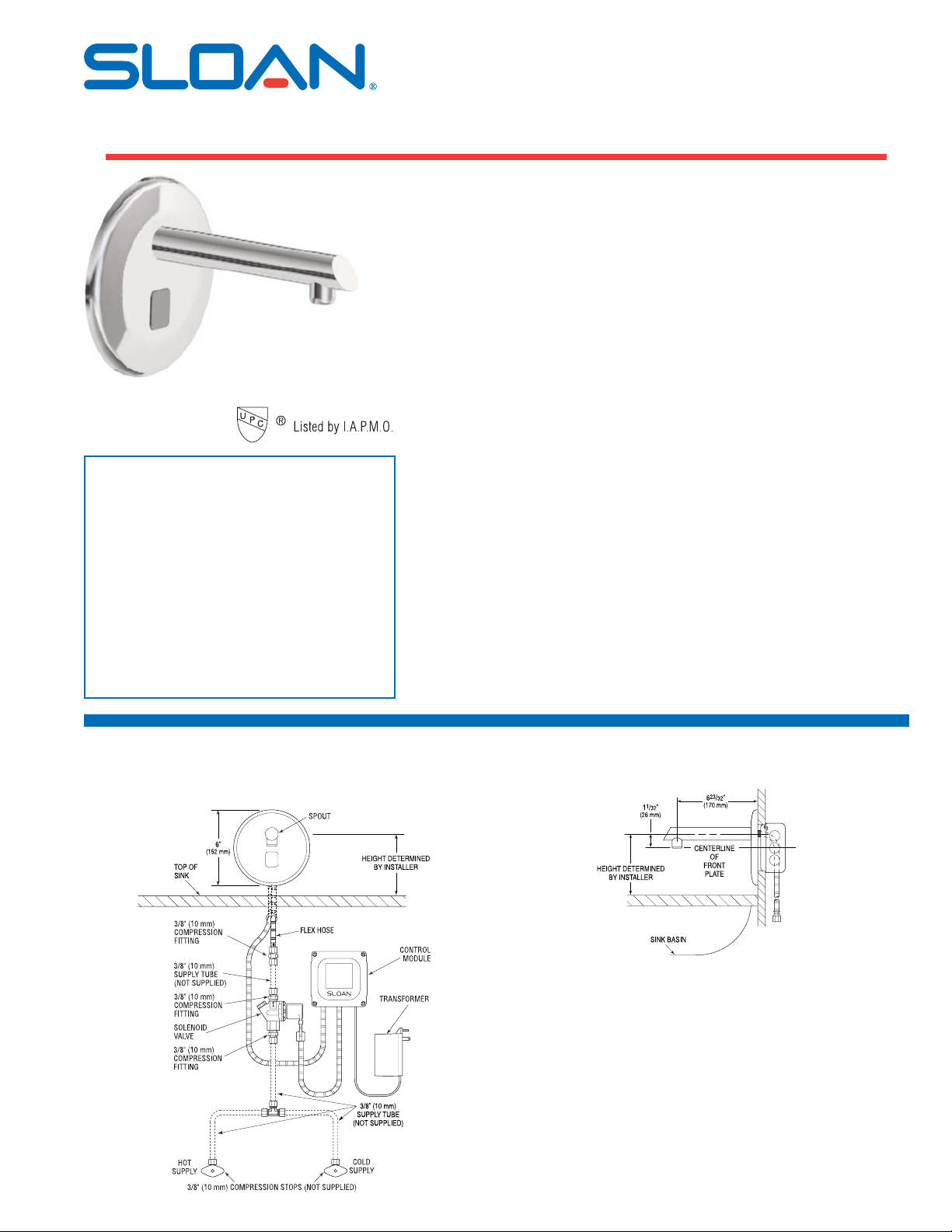

FAUCET ROUGH-IN

Rough-in Dimensions (side view)

ETF-800 Faucet with Bak-Chek®Te e

for Hot and Cold Water Supply

PRIOR TO INSTALLATION

Prior to installing the Sloan ETF-800 Faucet, install the items listed below. Also, refer to the Rough-In.

• When Using Plug-In Transformer — Install electrical receptacle for plug-in transformer (120 VAC, 2 amp

service for each ETF-233 (24 VAC, 35 VA) plug-in transformer used).

• When Using Box Mount Transformer — Install electrical wiring to transformer location (120 VAC, 2 amp

service for each EL-248-40 (24 VAC, 40 VA) transformer used).

• Lavatory/sink

• Drain line

• Hot and cold water supply lines or tempered water supply line

Multiple Faucets

Multiple faucets can be powered by a single transformer, provided that the transformer has been properly

sized. Allow a minimum of 15 VA of current rating for each solenoid valve used. Refer to “Step 7 — Install

Transformer” for further information.

Important:

• INSTALL ALL ELECTRICAL WIRING IN ACCORDANCE WITH NATIONAL/LOCAL CODES AND REGULATIONS.

• INSTALL ALL PLUMBING IN ACCORDANCE WITH APPLICABLE CODES AND REGULATIONS.

• A 24 VAC STEP-DOWN TRANSFORMER MUST BE USED.

• USE APPROPRIATE PRECAUTIONS WHILE CONNECTING TRANSFORMER TO 120 VAC POWER SOURCE.

• DO NOT PLUG TRANSFORMER INTO POWER SOURCE (RECEPTACLE) UNTIL ALL WIRING IS COMPLETED.

ALLOWING 24 VAC TRANSFORMER WIRES TO TOUCH OR SHORT WHILE POWER IS BEING SUPPLIED

WILL CAUSE PERMANENT DAMAGE TO THE TRANSFORMER AND CIRCUIT CONTROL MODULE.

• KEEP THREAD SEALANT OUT OF YOUR WATERWAY TO PREVENT COMPONENT PART DAMAGE! DO NOT

USE ANY SEALANT ON COMPRESSION FITTINGS. FOR THREADED PIPE FITTINGS, DO NOT APPLY

SEALANT TO THE FIRST TWO “STARTER” THREADS.

• FLUSH ALL WATER LINES UNTIL WATER IS CLEAR BEFORE CONNECTING SOLENOID TO SUPPLY STOPS.

• Saw for cutting mounting hole in wall

• Electric drill and standard drill bits

• Straight blade and phillips blade screwdrivers

• Standard open end wrenches

• Basin wrench

• 1/8” hex wrench

• Pipe wrench for installing drain lines

• Pliers

• Wire stripper/crimping tool

TOOLS REQUIRED FOR INSTALLATION

Bak-Chek

®

Tee Usage

When connecting the Sloan ETF-800 Faucet to

both hot and cold water supplies, a Bak-Chek

®

Tee is provided and required as illustrated in

Figure 6. Water temperature can be controlled by

adjusting the supply stops.

When connecting the faucet to a single line water

supply or a pre-tempered water supply, a BakChek

®

Tee is not required.

Compliant to:

ASME A112.18.1

and CSA B125.1

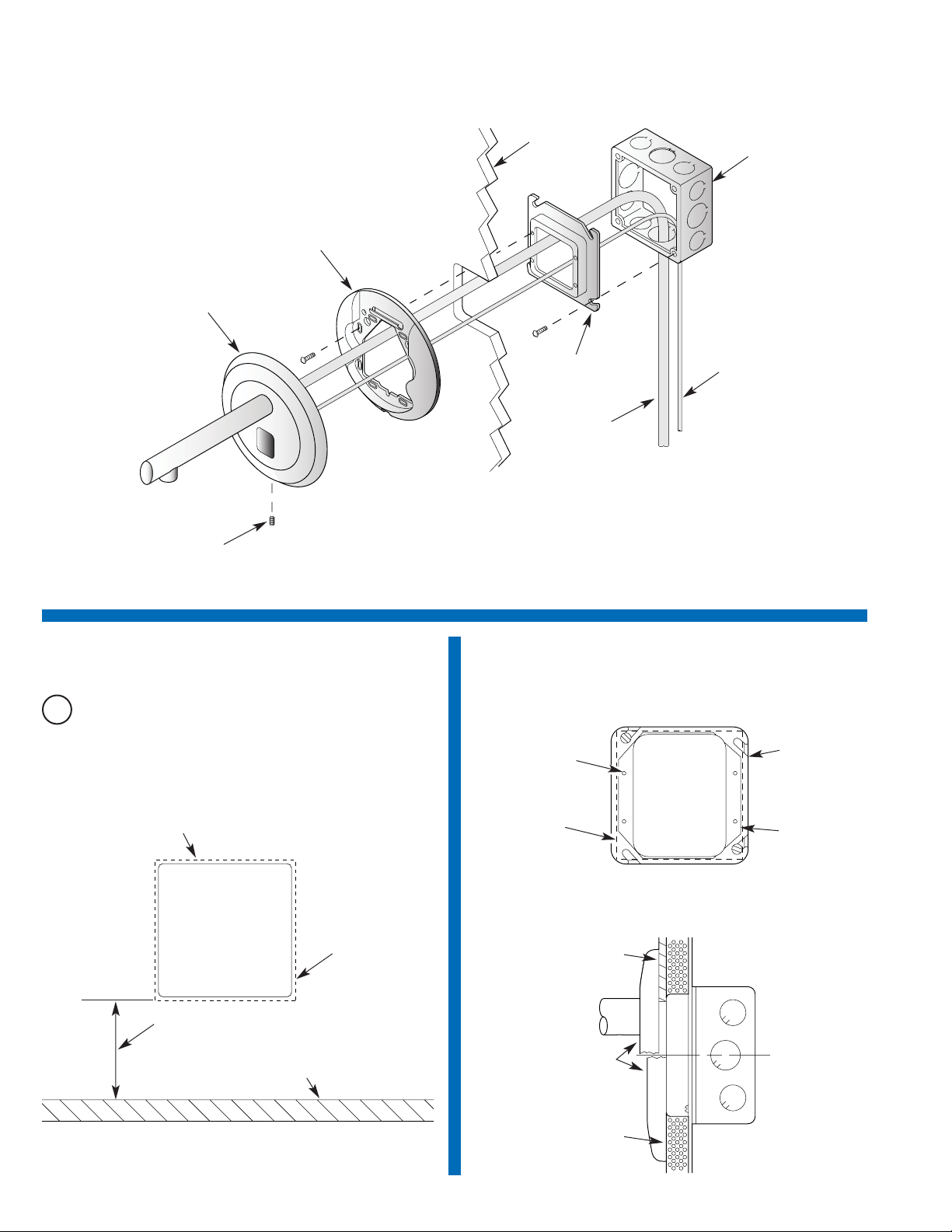

2

FINISHED

TILE WALL

FINISHED

PLASTER

WALL

FAUCET

WALL

PLATE

INSTALL PLASTER

RING SO THAT

SCREW HOLES ARE

ON THE LEFT AND

RIGHT SIDE OF BOX

FINISHED WALL

OPENING

ELECTRICAL BOX

PLASTER RING

Exploded Assembly View

FAUCET/WALL

PLATE ASSEMBLY

SET SCREW

MOUNTING PLATE

WALL

PLASTER RING

SENSOR CABLE

FLEX HOSE

ELECTRICAL BOX

(4” X 4”)

1

Determine Mounting Location and

Cut Mounting Hole

A

Measure and mark mounting hole location on wall.

OUTLINE OF

ELECTRICAL BOX

TOP OF SINK

Electrical Box Installation Diagram

FRONT VIEW

SIDE VIEW

HEIGHT DETERMINED

BY CUSTOMER

INSTALLATION

CUTOUT FOR STANDARD

4” x 4” ELECTRICAL BOX

(SUPPLIED BY OTHERS)

3

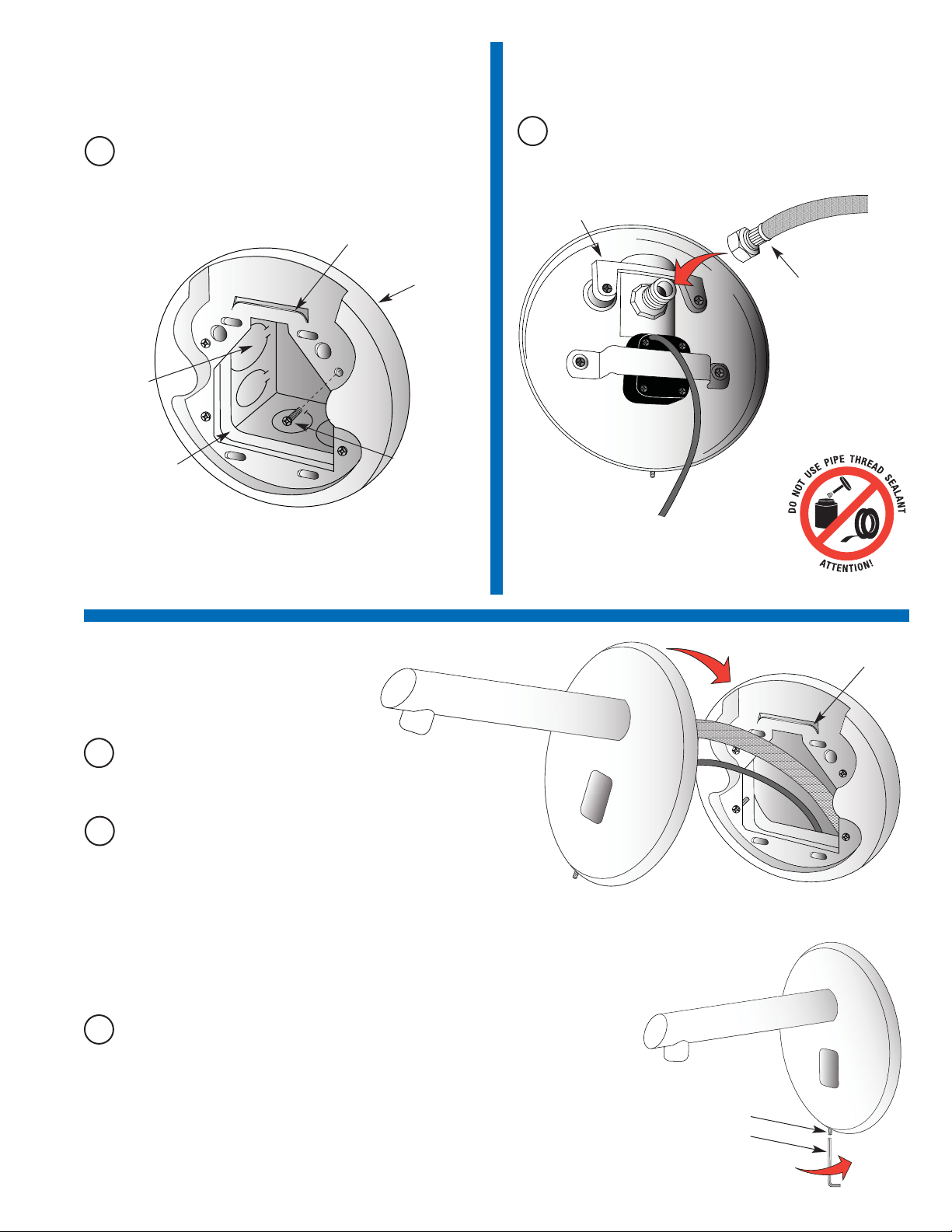

4

Install Faucet

A

Feed Sensor Cable and Flex Hose through Mounting

Plate, Plaster Ring and Electrical Box.

B

Install Faucet onto Mounting Plate Lip at a slight upward

angle and lower Faucet until Wall plate rests against the

wall. The Faucet’s mounting bracket should be secure

within the mounting lip.

3

Connect Flex Hose to Faucet

A

Connect Flex Hose to Faucet. Tighten fitting securely.

2

Install Electrical Box and Mounting

Plate to Wall

A

Position and hold Electrical Box with Plaster Ring behind

wall. Fasten Mounting Plate to Plaster Ring using four (4)

screws. Tighten screws securely.

C

Tighten Set Screw at bottom of Wall Plate using Hex Wrench.

ELECTRICAL BOX

PLASTER RING

MOUNTING

SCREWS (4)

MOUNTING

PLATE

MOUNTING

PLATE LIP

SET SCREW

MOUNTING

PLATE LIP

HEX WRENCH

MOUNTING BRACKET

FLEX HOSE

Note: Refer to Exploded Assembly View on Page 2..

Note: Refer to Exploded Assembly View on Page 2..

ELECTRICAL

BOX

Loading...

Loading...