Slant/Fin VHG-100-CH, VHG-180-CH, VHG-80-CH, VHG-90-CO, VHG-150-CO Installation And Service Manual

...Page 1

Heating Contractor

Boiler Model Number

Address

Boiler Serial Number

Phone Number

Installation Date

INSTALLATION AND SERVICE MANUAL

- Do not store or use gasoline or

California Proposition 65 Warning: This product contains ch emicals known to the State

of California to cause cancer, birth defects, or other reproductive harm.

adjacent

for reference.

This manual must be

left with owner and

must be hung on or

to the boiler

RESIDENTIAL BOILER MODELS

VGH-80-CH / VGH-100-CH / VGH-120-CH /

VGH-150-CH / VGH-180-CH

VGH-90-CO / VGH-150-CO / VGH-200-CO

HIGH EFFICIENCY CONDENSING GAS BOILER

QUICK CONTENTS

FULL TABLE OF CONTENTS ................................ 3

1.0 SAFETY GUIDELINES .......................................... 8

2.0 INTRODUCTION. ................................................ 13

3.0 TECHNICAL DATA ........................................................ 16

4.0 BOILER DIMENSIONS .......................................... 26

5.0 ACCESSORIES AND UNPACKING ....................... 28

6.0 INSTALLATION LOCATION ................................... 29

7.0 CONNECTIONS ..................................................... 32

8.0 CIRCULATOR CHARACTERISTICS ...................... 47

9.0 FLUE GAS AND AIR SUPPLY SYSTEM ................ 52

10.0 ELECTRICAL INSTALLATION ............................... 76

11.0 USING THE DISPLAY ................................................ 88

12.0 TEMPERATURE PROTECTION......................... 113

13.0 ERROR INFORMATION ...................................... 113

14.0 CASCADING SYSTEM SETUP .......................... 119

15.0 SYSTEM TEST ................................................. 125

16.0 COMMISSIONING THE BOILER ........................ 126

17.0 ADJUSTING AND SETTING THE BOILER ......... 129

18.0 INSPECTION, MAINTENANCE AND SERVICE .. 136

29.0 USER INSTRUCTIONS ..................................... 148

20.0 INSTALLATION EXAMPLES .............................. 148

21.0 SPARE PARTS VGH -xx-CH ........................................ 152

22.0 SPARE PARTS VGH -xx-CO ........................................ 157

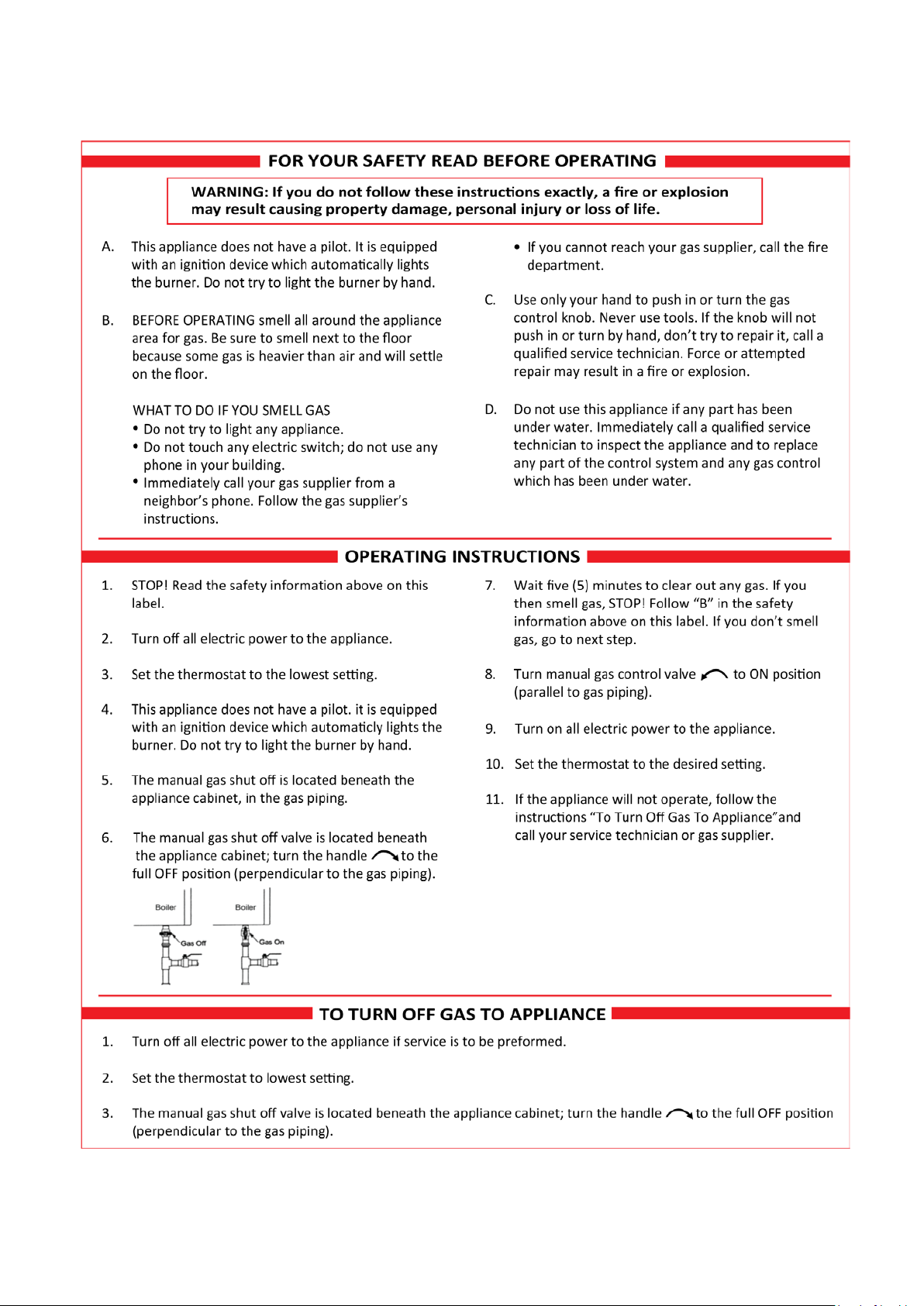

WARNING: If the information in

this manual is not followed

exactly, a fire or explosion may

result causing property damage,

personal injury or loss of life.

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

- WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use

any phone in your building.

•

Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

•

If you cannot reach your gas supplier, call the

fire department.

- Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Page 2

Page 3

TABLE OF CONTENTS

1 SAFETY GUIDELINES ................................................................................................................................ 8

2 INTRODUCTION ........................................................................................................................................ 13

TERMS AND ABBREVIATIONS ............................................................................................................. 13

CODES, STANDARDS AND REGULATIONS ............................................................................................ 14

MAINTENANCE AND INSPECTION ........................................................................................................ 14

FOR INSTALLATIONS IN THE COMMONWEALTH OF MASSACHUSETTS .................................................... 15

3 TECHNICAL DATA VGH RESIDENTIAL BOILERS ................................................................................. 16

Functional introduction ....................................................................................................... 16

LOCATION OF VERSION NUMBERS ...................................................................................................... 17

TECHNICAL SPECIFICATIONS DATASHE ETS ......................................................................................... 18

Technical specificat ions V G H-80-CH / VGH-90-CO / VGH-100-CH ................................. 18

Technical specifications VGH-120-CH / VGH-150-CO / VGH-150-CH ............................. 20

Technical specifications VGH-180-CH / VGH-200-CO ...................................................... 22

HIGH ALTITUDE OPERATION ............................................................................................................... 24

DHW SPECIFICATIONS VGH-CO SERIES ........................................................................................... 24

HEAT EXCHANGER INFORMATION....................................................................................................... 24

SPECIFICATIONS INPUT, OUTPUT, EFFICIENCY (AHRI) ........................................................................ 25

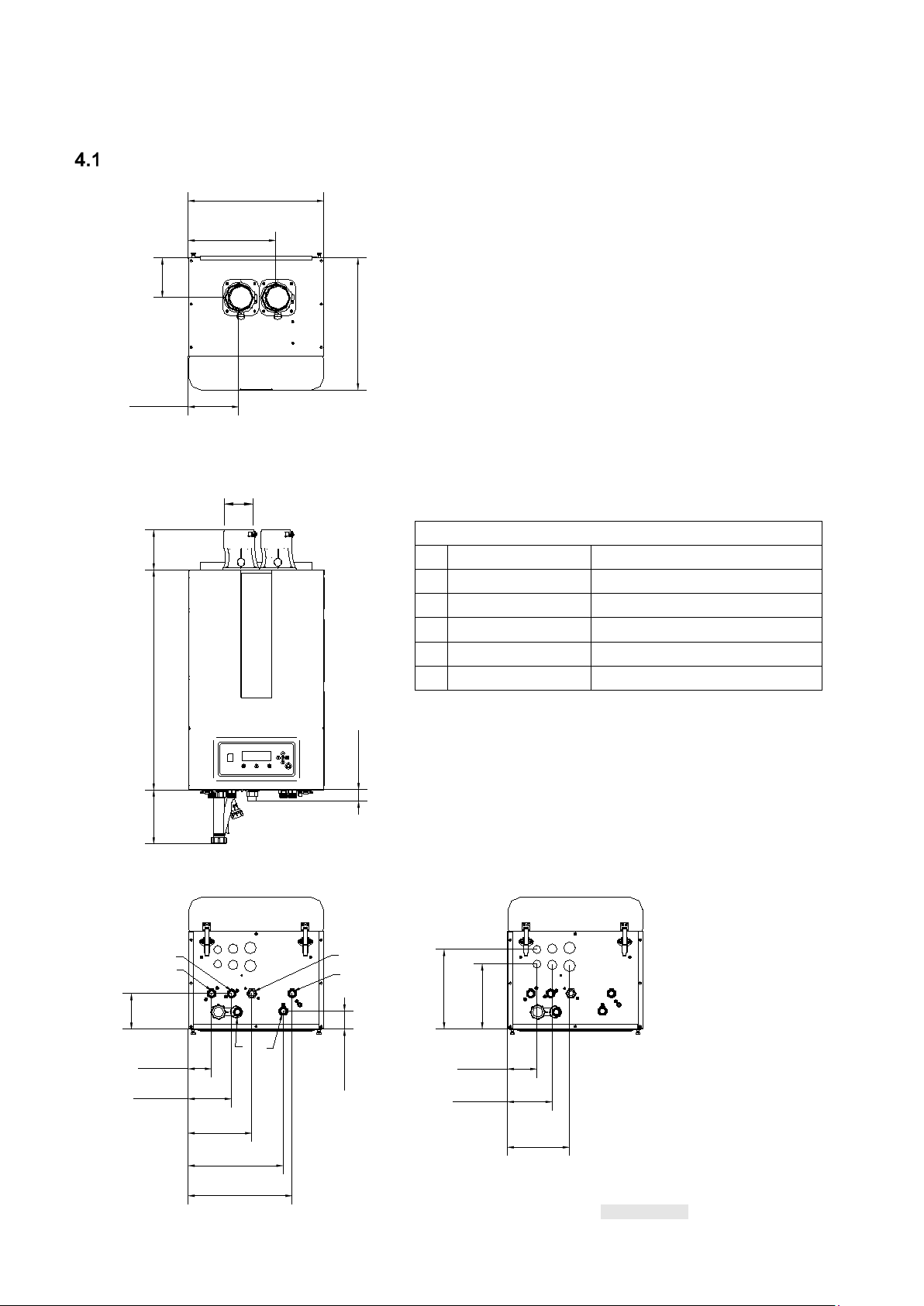

4 BOILER DIMENSIONS .............................................................................................................................. 26

VGH-80-CH / VGH-100-CH / VGH-120-CH / VGH-150-CH / VGH-180-CH ................................... 26

VGH-90-CO / VGH-150-CO / VGH-200-CO ................................................................................... 27

5 ACCESSORIES AND UNPACKING.......................................................................................................... 28

OPTIONAL ACCESSORIES .................................................................................................................. 28

SUPPLIED WITH THE BOILER .............................................................................................................. 28

6 INSTALLATION LOCATION OF THE VGH .............................................................................................. 29

GENERAL ......................................................................................................................................... 29

BOILER INSTALLATION LOCATION REQUIREMENTS .............................................................................. 29

INSTALLATION CLEARANCES ............................................................................................................. 30

MOUNTING THE BOILER ..................................................................................................................... 31

7 CONNECTIONS ......................................................................................................................................... 32

BOILER CONNECTIONS VGH-CH TYPES ............................................................................................ 32

BOILER CONNECTIONS VGH-CO TYPES ............................................................................................ 32

GAS PIPE CONNE CTION ..................................................................................................................... 33

Gas line connection ........................................................................................................... 33

CONDENSATE DRAIN CONNECTION .................................................................................................... 35

FLOW AND RETURN CONNECTIONS .................................................................................................... 35

EXPANSION VESSEL .......................................................................................................................... 36

PRESSURE RELIEF VALVE.................................................................................................................. 36

PRIMARY/SECONDARY PIPING .......................................................................................................... 36

CIRCULATOR FUNCTIONALITY ............................................................................................................ 37

FROST PROTECTION ......................................................................................................................... 38

INSTALLING A STRAINER AND/OR DIRT SEPARATOR ............................................................................. 38

SCALDING DANGER PROTECTION ....................................................................................................... 39

SUPPLY AND RETURN CONNECTIONS AND PRESSURE RELIEF VALVE. ................................................... 39

TEMPERATURE LIMITING DEVICE (DHW) ............................................................................................ 39

DRAIN VALVES (DHW) ...................................................................................................................... 39

SHUTOFF VALVES (DHW) ................................................................................................................. 39

CENTRAL HEATING WATER QUALITY .................................................................................................. 40

DOMESTIC WATER QUALITY ............................................................................................................. 41

USE OF GLYCOL ............................................................................................................................... 41

CHEMICAL WATER TREATMENT .......................................................................................................... 41

PLASTIC PIPING IN THE HEATING SYSTEM.......................................................................................... 42

UNDERFLOOR HEATING..................................................................................................................... 42

FLUSH THE SYSTEM WI TH FRESH WATER ............................................................................................ 43

AUTOMATIC AIR PURGING.................................................................................................................. 43

MANUAL DE-AIRING THE HEAT EXCHANGER ........................................................................................ 44

AUTOMATIC FEED VALVE .................................................................................................................. 44

WATER PRESSURE ........................................................................................................................... 44

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 3

Page 4

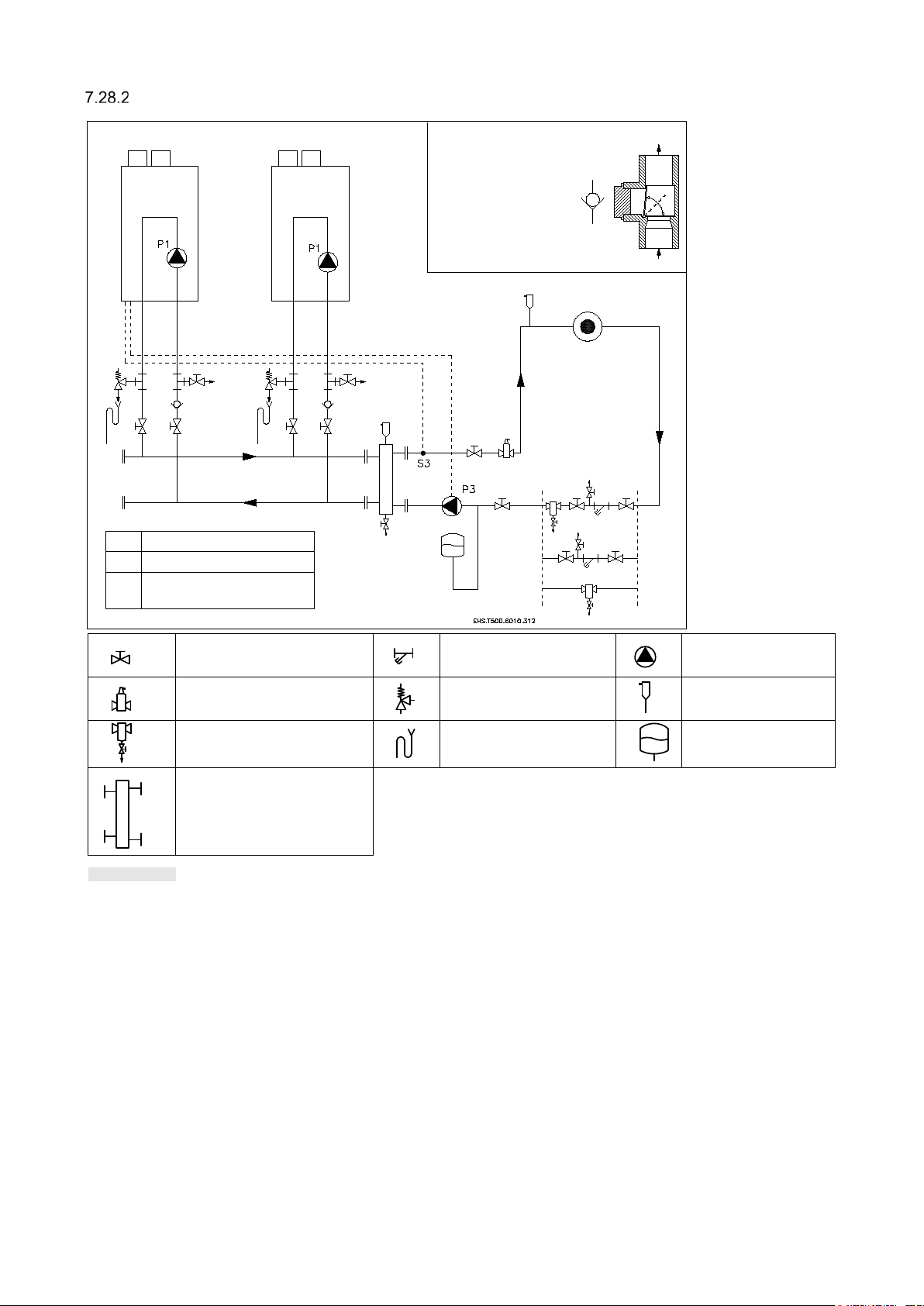

INSTALLATION EXAMPLES .................................................................................................................. 45

Examples of a normal single boiler heating circuit with low loss header (preferable) ....... 45

Example of a multiple boiler heating circuit with low loss header ...................................... 46

8 CIRCULATOR CHARACTERISTICS ........................................................................................................ 47

PRESSURE DROP AND FLOW GRAPHS ................................................................................................ 47

Boiler resistance graph VGH-80-CH / VGH-90-CO ........................................................... 47

Boiler resistance graph VGH-100-CH ................................................................................ 47

Boiler resistance graph VGH-120-CH / VGH-150-CO ....................................................... 48

Boiler resistance VGH-150-CH .......................................................................................... 48

Boiler resistance graph VGH-180-CH / VGH-200-CO ....................................................... 49

Graph showing the Available Circulation pump head ........................................................ 49

MINIMUM REQUIRED CIRCULATOR HEAD. ............................................................................................ 50

MODULATING CIRCULATOR FOR CH DEMAND ...................................................................................... 50

MODULATING CIRCULATOR MODES .................................................................................................... 50

CIRCULATORS: MAXIMUM ELECTRICAL POWER ................................................................................... 51

Circulator power cord positioning ...................................................................................... 51

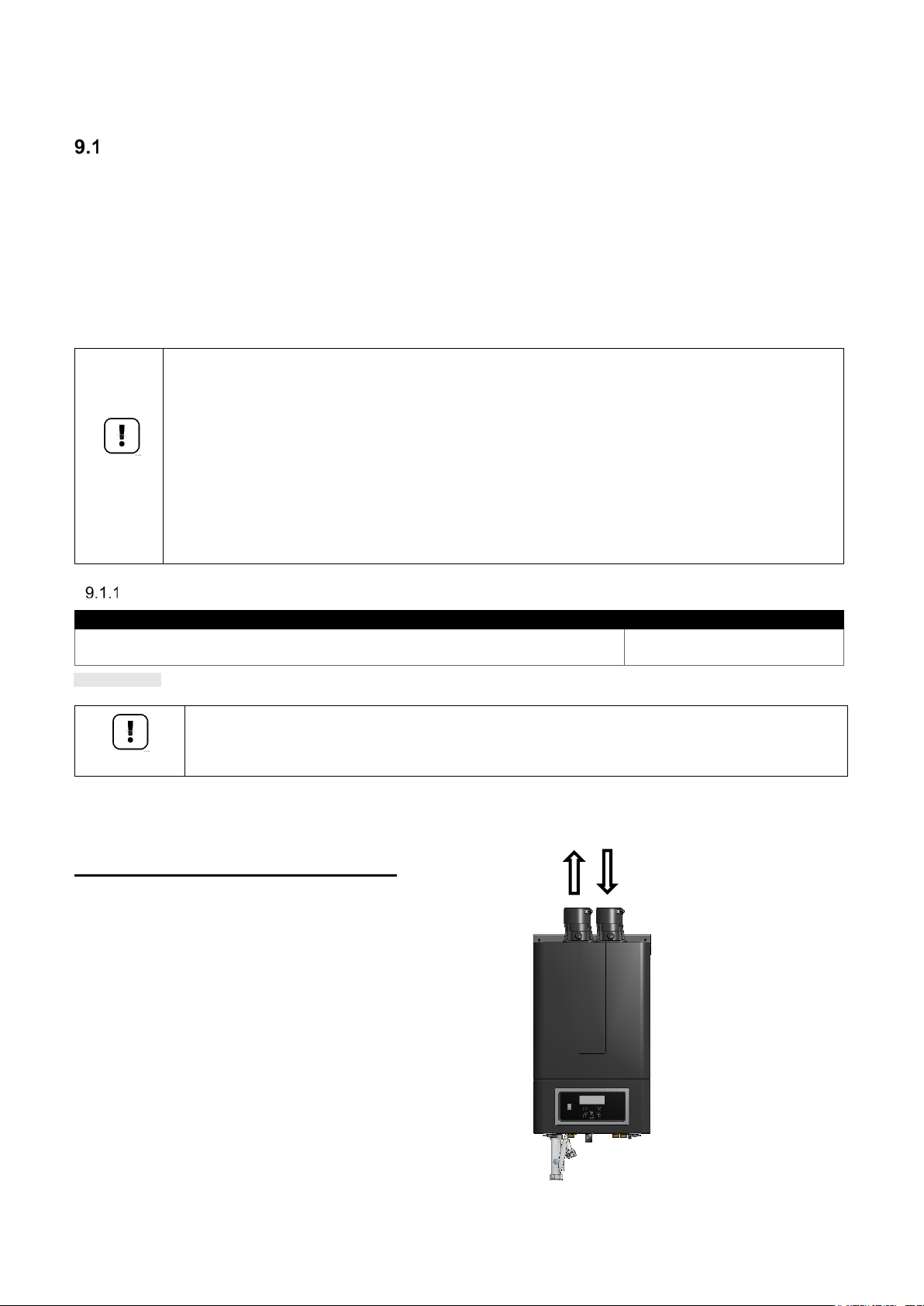

9 FLUE GAS AND AIR SUPPLY SYSTEM .................................................................................................. 52

GENERAL VENTING ........................................................................................................................... 52

Vent sizing ......................................................................................................................... 52

Vent and air inlet resistance table ...................................................................................... 53

VENT AND AIR INTAKE PIPE MATERIAL ................................................................................................ 53

Approved manufacturers.................................................................................................... 54

PVC / CPVC ................................................................................................................................... 54

Instructions for working with cementing PVC/ CPVC pipe connections ............................ 55

POLYPROPYLENE ............................................................................................................................. 55

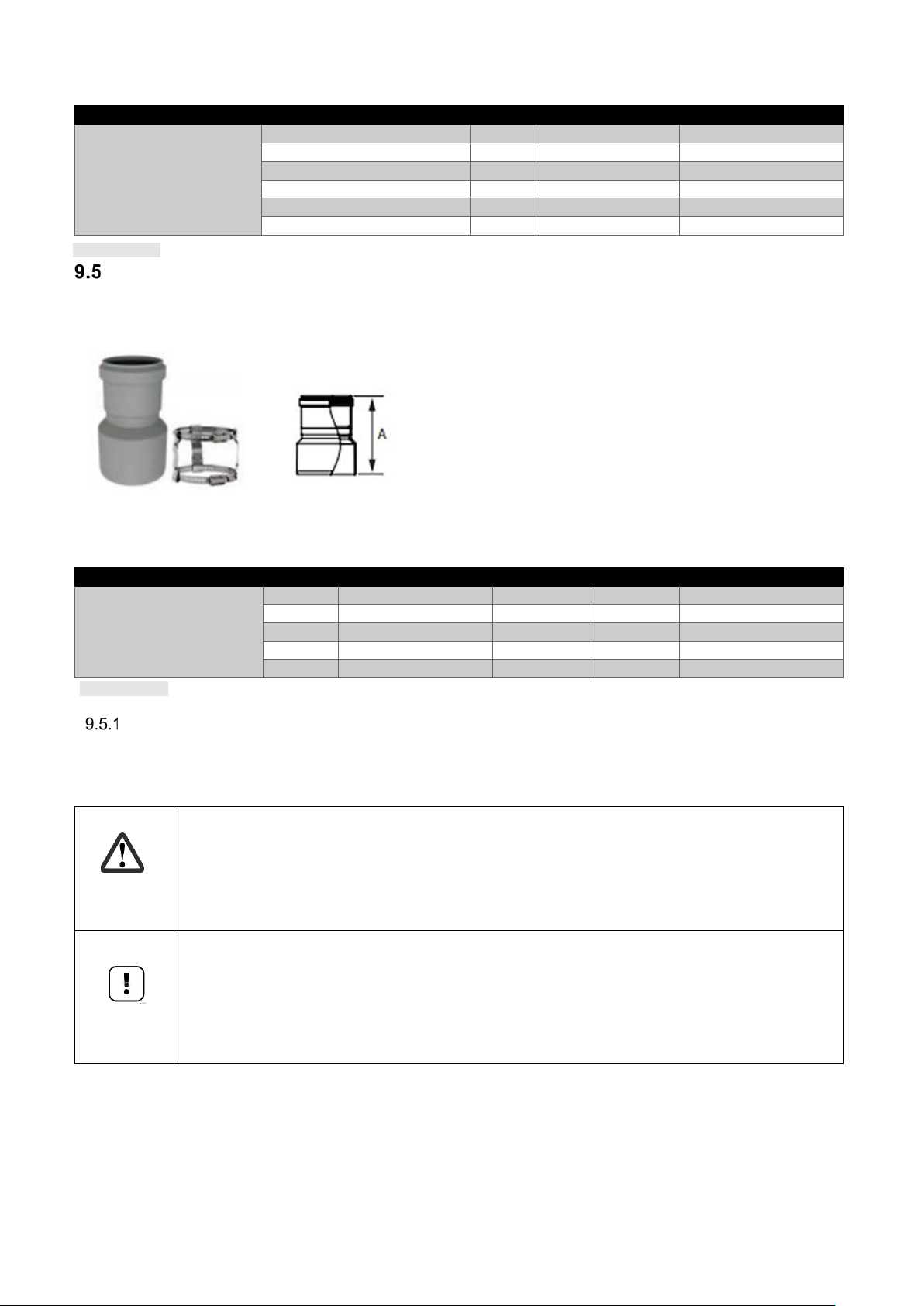

REDUCER ........................................................................................................................................ 56

Flexible polypropylene ....................................................................................................... 56

STAINLESS STEEL VENT .................................................................................................................... 57

SEALED COMBUSTION AIR SUPPLY .................................................................................................... 57

Combustion air quality ....................................................................................................... 57

Air supply through humid areas ......................................................................................... 57

Air intake/vent connections ................................................................................................ 58

Air inlet pipe materials ........................................................................................................ 58

ROOM AIR ........................................................................................................................................ 59

Air contamination ............................................................................................................... 61

PROPER VENT INSTALLATION AND TYPE OF GAS VENT OR VENT CONNECTOR ........................................ 63

INSTALL VENT AND COMBUSTION AIR PIPING ....................................................................................... 63

REQUIREMENTS FOR INSTALLATION IN CANADA .................................................................................. 64

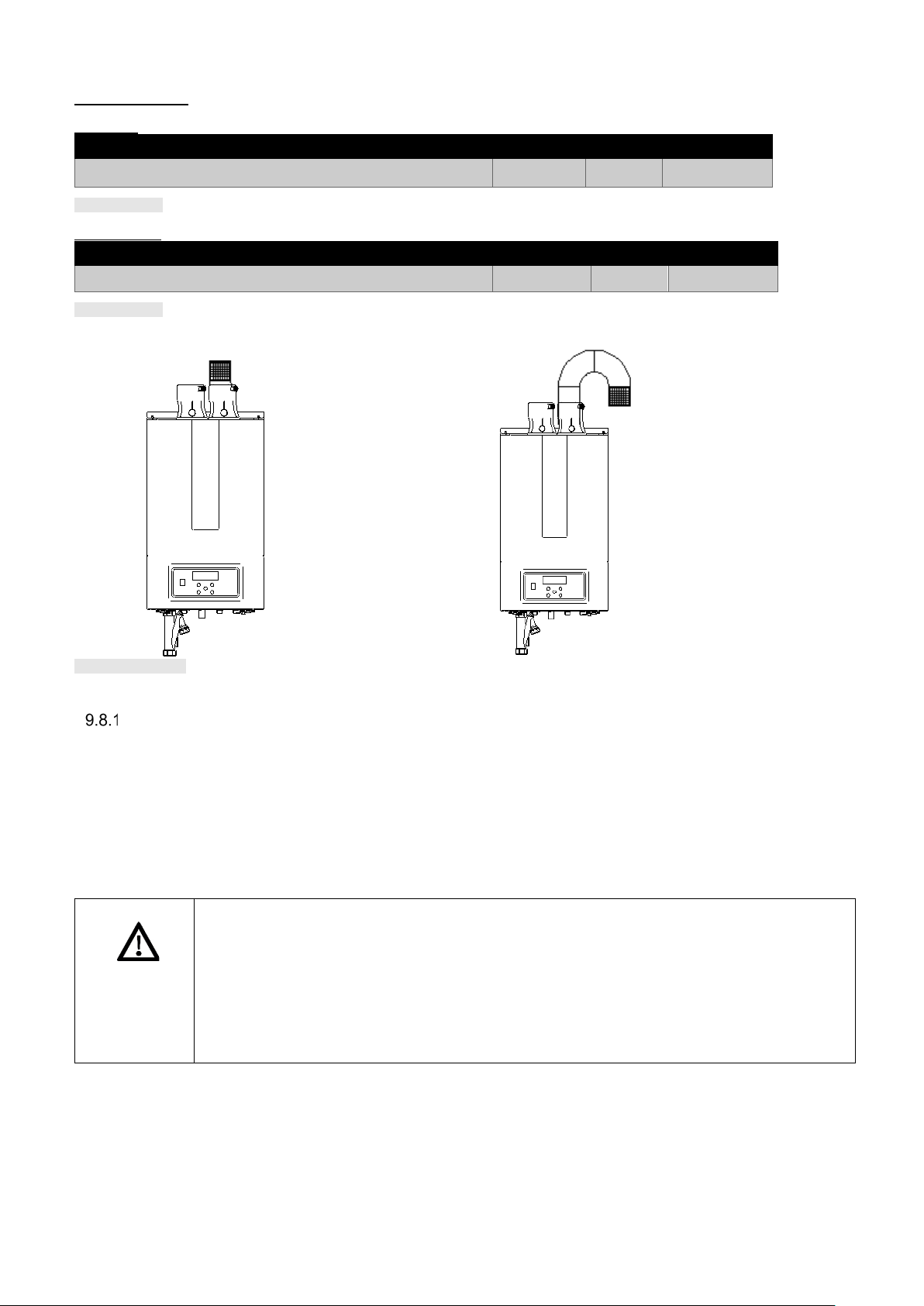

DIRECT VENTING OPTIONS ................................................................................................................ 64

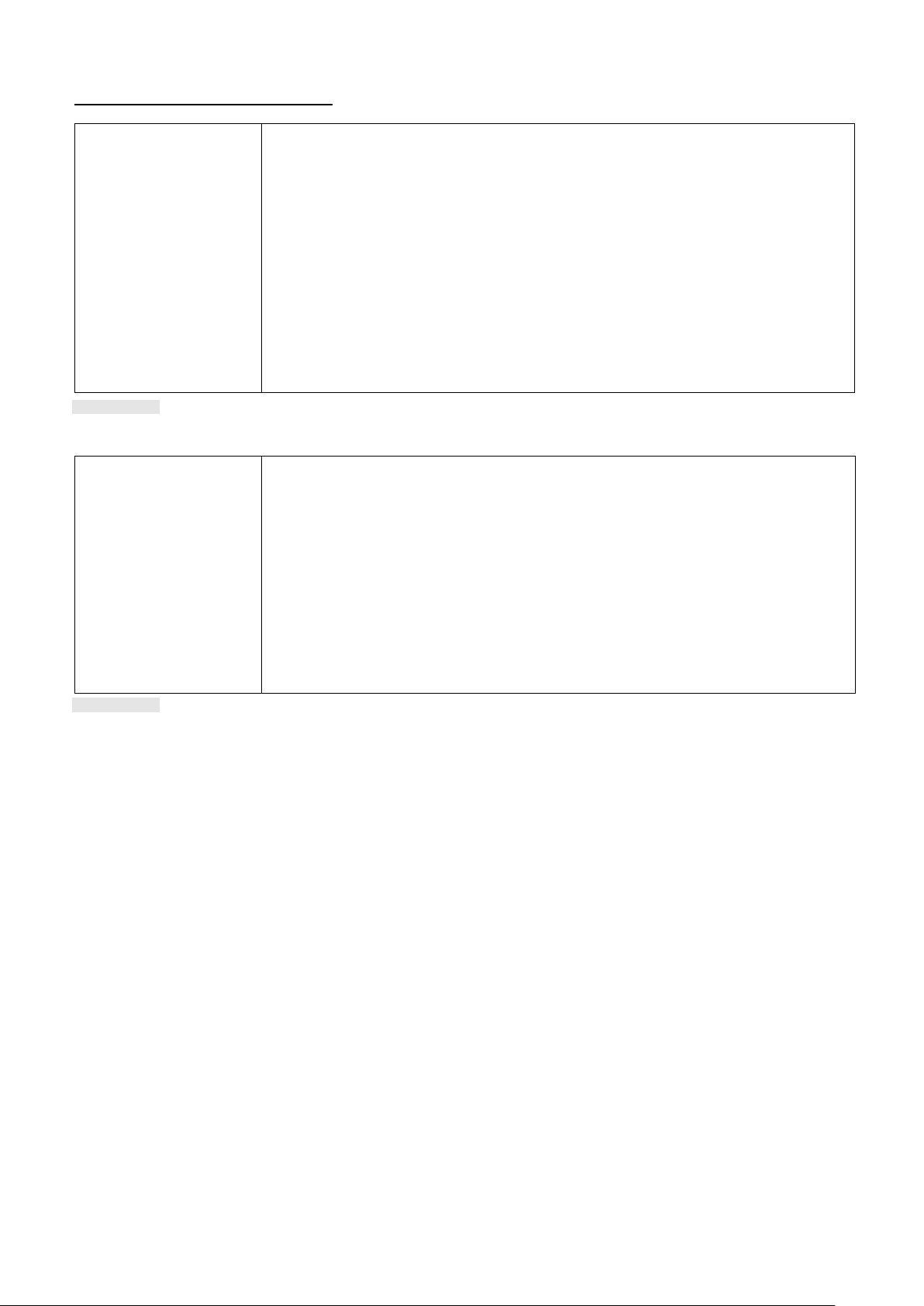

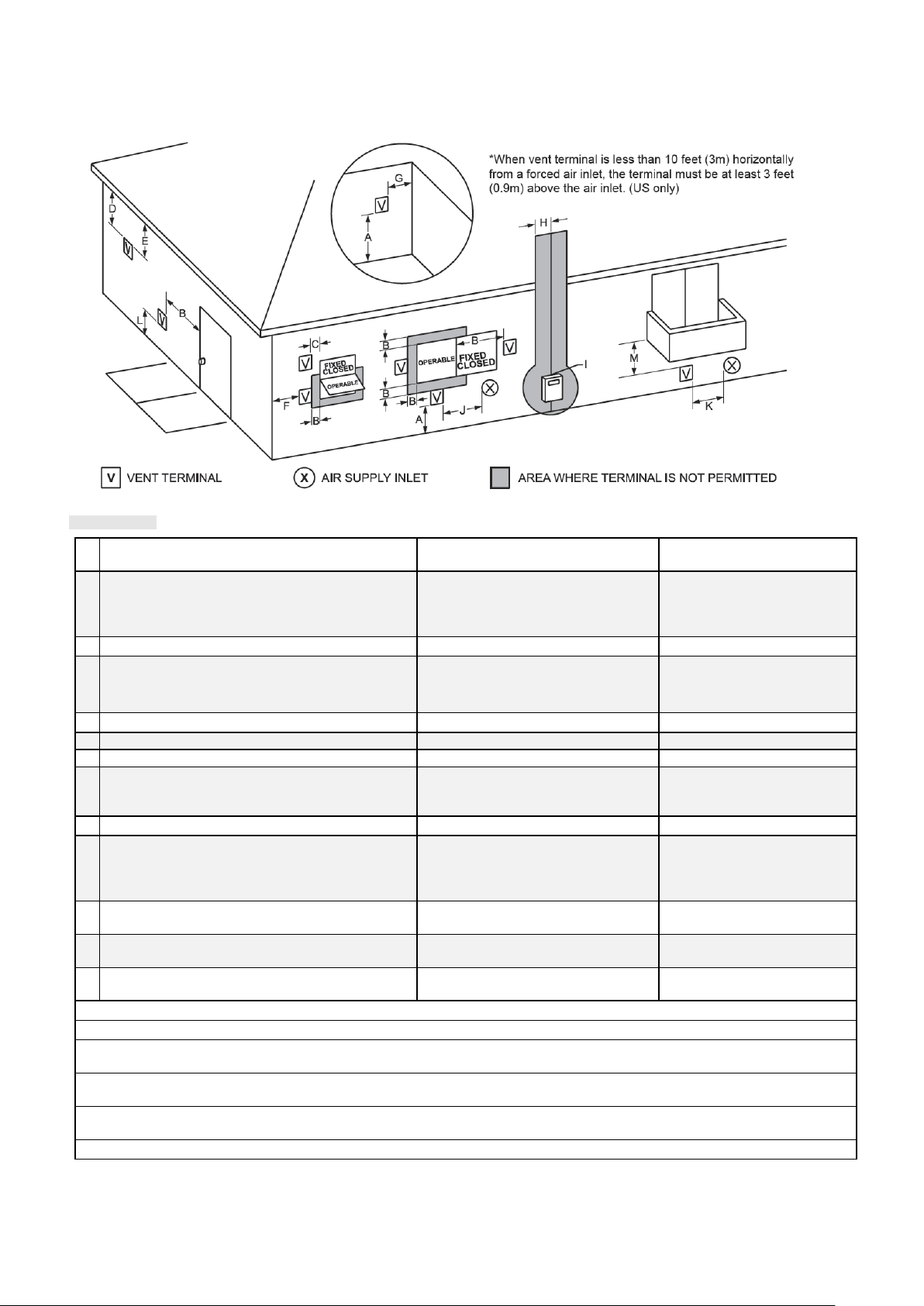

WALL (HORIZONTAL) DIRECT VENTING ............................................................................................... 67

Vent/air termination - wall .................................................................................................. 67

Determine Location ............................................................................................................ 67

ROOF (VERTICAL) DIRECT VENTING ................................................................................................... 72

Vent/air termination – vertical ............................................................................................ 72

Determine location ............................................................................................................. 72

COMMON VENTING ........................................................................................................................... 75

EXISTING COMMON VENTING GUIDELINES ......................................................................................... 75

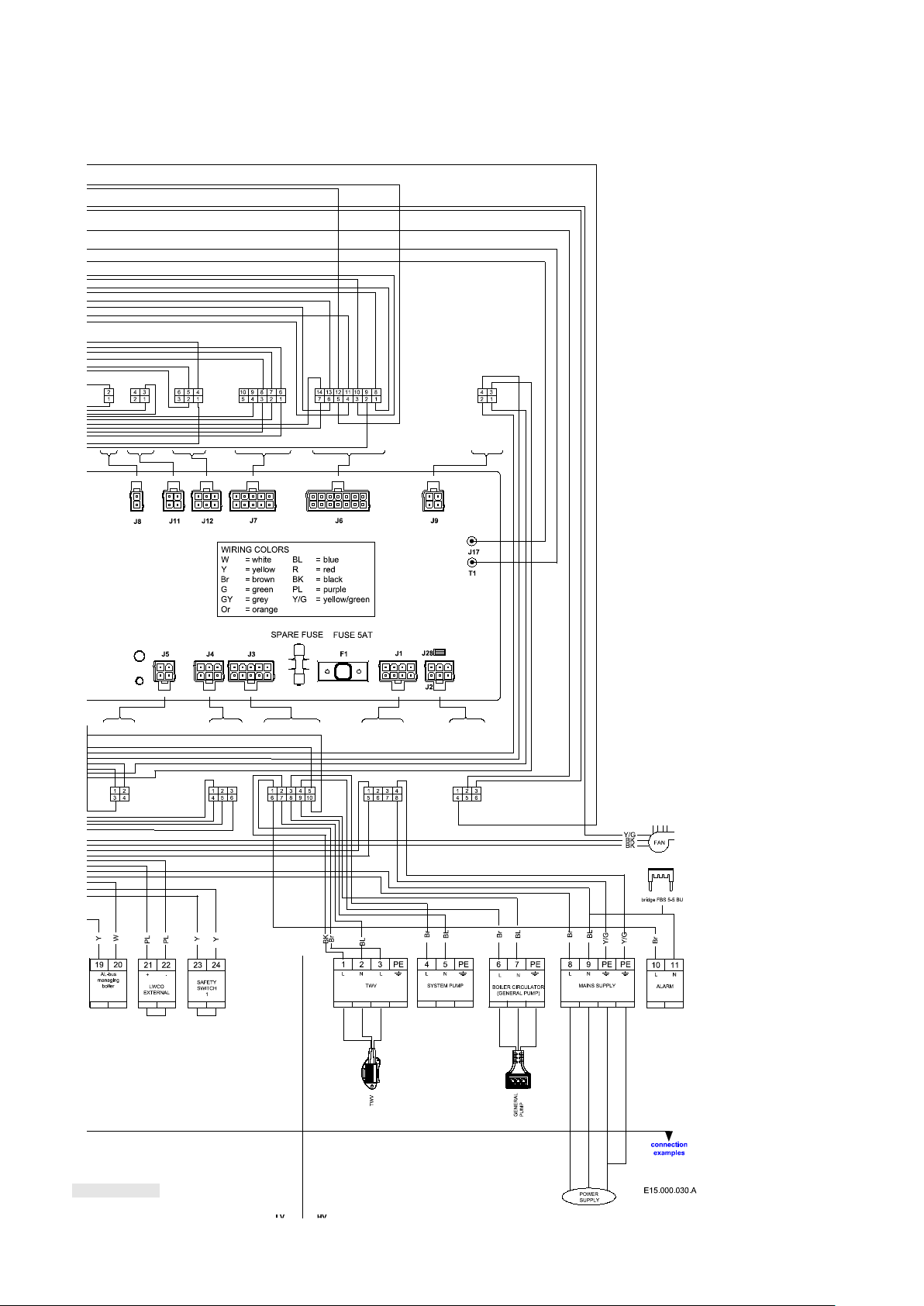

10 ELECTRICAL INSTALLATION ................................................................................................................. 76

GENERAL ......................................................................................................................................... 76

CONNECTION MAINS SUPPLY ............................................................................................................. 76

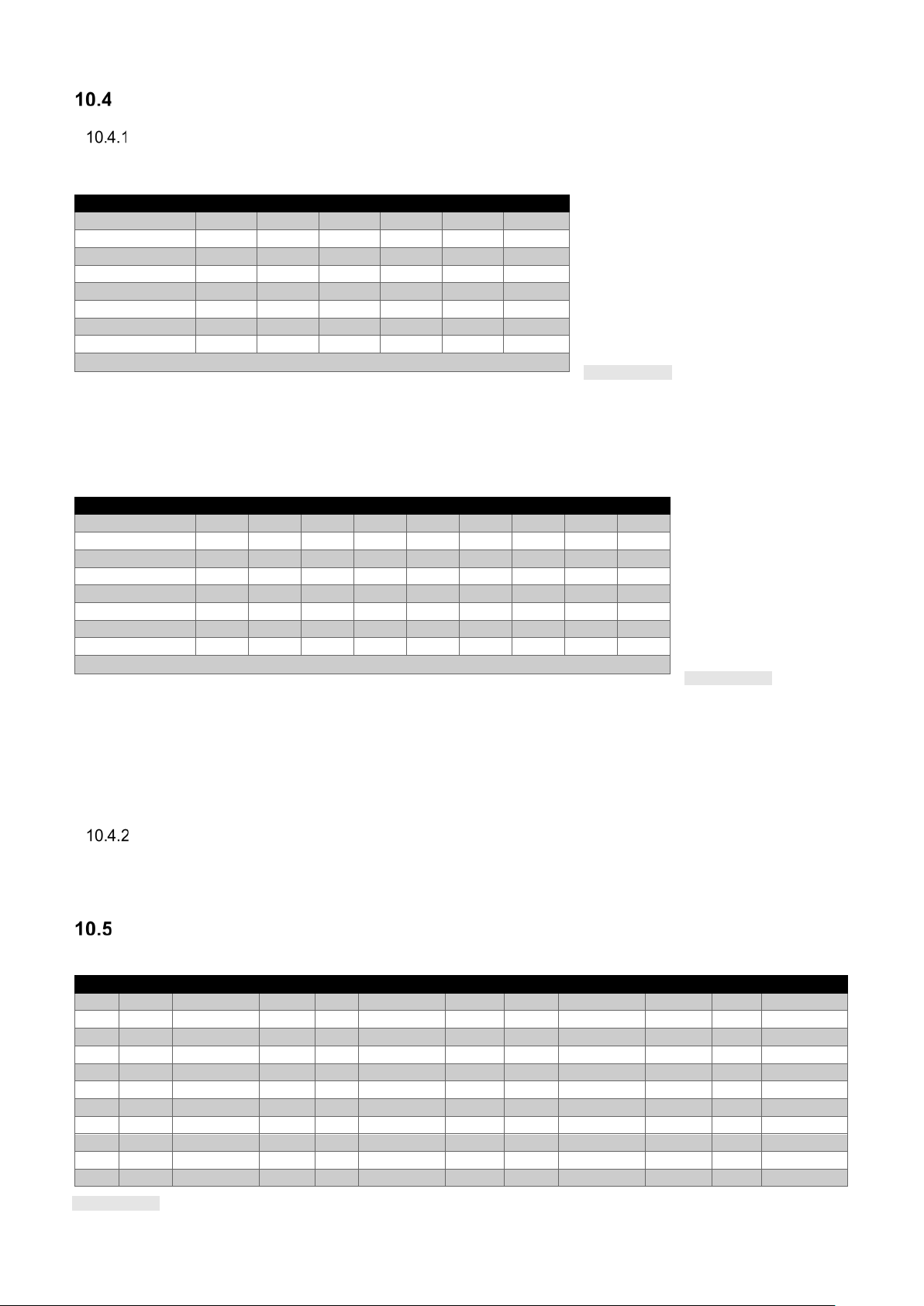

ELECTRICAL CONNECTIONS VGH-CH/CO BOILERS............................................................................ 76

Explanation of the low voltage connections VGH-CH boilers ............................................ 77

Explanation of the high voltage connections VGH-CH boiler s .......................................... 78

Explanation of the low voltage connections VGH-CO boil ers ............................................ 79

Explanation of the high voltage connections VGH-CO boi lers .......................................... 80

Ladder/Logic Diagram VGH-CH/CO BOILERS ................................................................. 81

Electrical schematic VGH-CH boilers ................................................................................ 82

Electrical schematic VGH-CO boilers ................................................................................ 84

SENSOR AVAILABILITY....................................................................................................................... 86

Sensor availability VGH-CH boilers ................................................................................... 86

Sensor availability VGH-CO boilers ................................................................................... 86

NTC SENSOR CURVE ........................................................................................................................ 86

4 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 5

PROGRAMMABLE IN- AND OUTPUTS ................................................................................................... 87

11 USING THE DISPLAY ............................................................................................................................... 88

DISPLAY AND BUTTONS ..................................................................................................................... 88

Display icons ...................................................................................................................... 89

SCREENS AND SETTINGS .................................................................................................................. 89

De-aeration Sequence ....................................................................................................... 89

CONTROL PANEL MENU STRUCTURE .................................................................................................. 90

Set Actual setpoint/DHW setpoint directly via the Status overview ................................... 91

Entering the menu .............................................................................................................. 91

Protected menu items ........................................................................................................ 92

Language settings .............................................................................................................. 92

BOILER HISTORY .............................................................................................................................. 93

ERROR LOGGING .............................................................................................................................. 93

SERVICE REMINDER .......................................................................................................................... 94

Service overdue logging .................................................................................................... 94

Reset the service reminder ................................................................................................ 94

GENERAL ......................................................................................................................................... 95

Circulator start exercise every 24 hours ............................................................................ 95

Frost protection .................................................................................................................. 95

Flue temperature protection ............................................................................................... 95

Appliance selection ............................................................................................................ 96

IGNITION CYCLE ............................................................................................................................... 96

Flame detection ................................................................................................................. 96

Flame recovery .................................................................................................................. 97

CONTROL FUNCTIONS CENTRAL HEATING .......................................................................................... 97

Room thermostat only; CH mode 0 (Default setting) ......................................................... 97

CH with an outdoor temperature reset and thermostat; CH mode 1 ................................. 98

CH with constant circulation system outdoor reset; CH mode 2 ..................................... 100

CH with constant circulation and permanent heat demand; CH mode 3 ......................... 101

Central Heating with analog input control of setpoint; CH mode 4 .................................. 101

CH with analog input control of power output; CH mode 5 .............................................. 102

CONTROL FUNCTIONS DOMESTIC HOT WATER ................................................................................ 103

No Domestic Hot Water; DHW mode 0 ........................................................................... 103

High pressure drop indirect tank DHW mode 1 and 2 (VGH-CH boilers only) ................ 103

DHW Storage with sensor; DHW mode 1 ........................................................................ 103

DHW Storage with thermostat; DHW mode 2.................................................................. 104

Instantaneous water heating with plate heat exchanger; DHW mode 5 .......................... 105

Anti-legionella protection.................................................................................................. 105

MENU STRUCTURE DISPLAY ............................................................................................................ 106

12 TEMPERATURE PRO TECTION ............................................................................................................. 113

13 ERROR INFORMATION .......................................................................................................................... 113

BOILER HISTORY ............................................................................................................................ 113

LOCKOUT CODES............................................................................................................................ 114

BLOCKING CODES .......................................................................................................................... 116

WARNINGS .................................................................................................................................... 118

14 CASCADING ............................................................................................................................................ 119

SYSTEM SETUP .............................................................................................................................. 119

BOILER CASCADE COMMUNICATION S ETUP ....................................................................................... 119

Setting the boiler address ................................................................................................ 120

E2prom address selection through e2prom setting ......................................................... 121

Cascade – Heating only (CH) Managing boiler ............................................................... 121

Cascade – Domestic Hot Water Settings ........................................................................ 121

Cascade – DHW priority .................................................................................................. 122

Cascade – Start/stop sequence ....................................................................................... 122

Cascade – Power balance mode ..................................................................................... 122

CASCADE – BOILER ROTATION ........................................................................................................ 122

Next depending to start selection .................................................................................... 123

CASCADE ERROR HANDLING .......................................................................................................... 123

Cascade Frost protection ................................................................................................. 123

Emergency mode ............................................................................................................. 124

Managing boiler error ....................................................................................................... 124

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 5

Page 6

SYSTEM TEST......................................................................................................................................... 125

15

16 COMMISSIONING THE BOILER............................................................................................................. 126

FIRST: FLUSHING THE BOILER WITH WATER ...................................................................................... 126

SECOND: FILLING & VENTING THE BOILER AND THE SYSTEM .............................................................. 126

THIRD: CHECK THE WATER FLOW ..................................................................................................... 126

MOUNTING THE CONDENSATE TRAP ................................................................................................ 127

CHECKING GAS PRE SSU RE.............................................................................................................. 127

FIRING FOR THE FIRST TIME ............................................................................................................ 128

17 ADJUSTING AND SETTING THE BOILER ............................................................................................ 129

INTRODUCTION ............................................................................................................................... 129

Combustion table ............................................................................................................. 129

Setting screws gas valve: drawings ................................................................................. 130

CO

/ O2 ADJUSTMENT PROCEDURES.............................................................................................. 131

2

VENTURI ADJUSTEMENT .................................................................................................................. 131

CONVERSION FROM NATURAL GAS TO PROPANE ............................................................................... 132

START UP CHECKLIST .................................................................................................................... 134

18 INSPECTION, MAINTENANCE AND SERVICE ..................................................................................... 136

GENERAL ....................................................................................................................................... 136

SAFETY INSTRUCTIONS CRYSTALLINE SILICA ................................................................................... 136

INSPECTION, MAINTENANCE AND SERVICE TASKS ............................................................................. 138

REPLACING HEATEXCHANGER PARTS. ............................................................................................. 142

Replacement of the burner door gasket .......................................................................... 142

Fiber braid replacement ................................................................................................... 142

Replacement of the burner door insulation. ..................................................................... 143

Replacement of the Rear wall insulation disk .................................................................. 145

Replacement Ignition / ionization electrode ..................................................................... 145

CLEANING THE BRAZED PLATE HEAT EXCHANGER ........................................................................... 146

MAINTENANCE CHECKLIST .............................................................................................................. 147

19 USER INSTRUCTIONS ........................................................................................................................... 148

20 INSTALLATION EXAMPLES .................................................................................................................. 148

21 SPARE PARTS VGH-xx-CH ................................................................................................................... 152

SPARE PART LIST VGH-XX-CH ....................................................................................................... 154

22 SPARE PARTS VGH-CO ........................................................................................................................ 157

SPARE PART LIST VGH-XX-CO ....................................................................................................... 159

6 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 7

IMPORTANT

THE FOLLOWING WARNINGS AND STATEMENTS BEFORE READING

indicates the presence of an imminently hazardous situation that will cause

death, serious personal injury or substantial property damage.

indicates the presence of a hazardous situation which can cause death,

serious personal injury or substantial property damage.

indicates a hazardous situation which will or can

cause minor or moderate personal injury or property damage.

hazards due to electric shock.

indicates speci al instruc tions on i nstallatio n, oper ation or mai ntenance t hat ar e

important but not related to personal injury or property damage.

is void. Failure to properly install this unit may result in property damage, serious injury to

occupants, or possibly death.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

WARNING

READ ALL OF

THE INSTALLATION INSTRUCTIONS

Danger Sign:

Warning Sign:

Caution Sign plus Safety Alert Symbol:

Caution Sign plus a lightning bolt indicates the risk of electric shock and the potential of

Notice Sign:

This Boiler must be installed by a licensed a n d t r ained H e at ing T echnician or the Warranty

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 7

Page 8

1 SAFETY GUIDELINES

8 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 9

CONSIGNES DE SÉCURITÉ.

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 9

Page 10

n the event of a blocked vent the boiler w ill

operation.

only be reset by

• Should overheating occur or the gas supply fail to shut off, do not turn off or disconnect the

Read this manual entirely before setting domestic hot water setpoint(s).

• WARNING: There are no u s er s erv ic eable par ts o n th i s boi ler. Warr anty does n ot c over

recommended personal protective equipment. Installation and service must be

appliance.

WARNING: Improper installation, adjustment,

humans)

AVERTISSEMENT: Une installation, un réglage, une

pouvant l'être).

CAUTION

DANGER

NOTICE

WARNING

Avertissement

WARNING

This boiler is equi pped with a pressure s witch. I

lockout. No attempt by the user/owner should be made to put the boiler back into

A qualified service technician must be notified of the issue. The boiler should

a qualified service technician after they have diagnosed and corrected the issued that caused

the safety lockout of the boiler.

electrical supply to the circ ulator. Instead, shut of f the gas s upply at a locat ion external t o

the appliance.

• Do not use this boiler if any part has been under water. Immediately call a qualified service

technician to inspect the boiler and to r eplac e any part of the c ontrol sy stem and any gas

control which has been under water.

• Scalding

Water temperatures over 125 ºF (5 2 ºC) c an c ause sev ere burns i nstant ly, or dea th fro m

scalds. Children, the disabled and the elderly are at the highest risk of being scalded.

Feel water before bathing or showering.

We highly recommend the ins tal lat ion of a c ar b on m on ox ide (CO ) de tec tor i n the boi ler r oo m

for all installations.

defects caused by at t emp ts to s erv ice t h is bo il er by s o meon e other than a qualif ie d ga s

service technician. These attempts could cause property damage, personal injury or loss

of life.

• WARNING: Crystalline Sil ica - Certain components in the combustion chamber may

contain this potential carcinogen. Improper installation, adjustment, alteration, service or

maintenance can cause property damage, serious injury (exposure to hazardous

materials) or death. Refer to Section 18.2

for information on handling instructi ons and

performed by a qualified installer, service agency or the gas supplier (who must read and

follow the supplied instructions be fore install ing, servic ing, or removin g this boiler. This

boiler contains materials that have been identified as carcinogenic, or possibly

carcinogenic, to humans).

• WARNING: There are no u s er ser v iceable par ts o n t h i s boi ler. Warranty does not c ov er

defects caused by at t emp ts to s erv ice t h is bo il er by s o meon e other than a qualif ie d ga s

service technician. These attempts could cause property damage, personal injury or loss

of life.

• a water heater that will be used t o supply p otable water s hall not be co nnected to a ny

heating system or component(s) previously used with a non-potable water heating

alteration, service or maintenance can cause

property damage, personal injury (exposure to

hazardous materials) * or loss of life.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier (who must read and follow the

supplied instructions before installing,

servicing, or removing this boiler. This boiler

contains materials that have been identified as

carcinogenic, or possibly carcinogenic, to

10 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

modification, une réparation ou un entretien non

conforme aux normes peut entraîner des dommages

matériels, des blessures (exposition à des matières

dangereuses) ou la mort. L'installation et l'entretien

doivent être effectués par un installateur ou un service

d'entretien qualifié ou le fournisseur de gaz (qui doivent

avoir lu les instructions fournies avant de faire

l'installation, l'entretien ou l'enlèvement de la chaudière

et les respecter. Cette chaudière contient des matériaux

qui ont été identifiés comme étant cancérogènes ou

Page 11

Avertissement

L'installation et l'entretien doivent être assurés par un installateur ou un service

AVERTISSEMENT. Assurez-vous de bien suivre les instructions données dans

AVERTISSEMEN T. Assure z-vous de b ien suivre les ins tructions d onnées d ans cette notice p our rédu ire au

minimum le risque d'incendie ou d'explosion ou pour éviter tout dommage matériel, toute blessure ou la mort.

(pour installateurs francophones)

cette notice pour réduire au minimum le risque d'incendie ou d'explosion ou pour

éviter tout dommage matériel, toute blessure ou la mort.

— Ne pas entreposer ni utiliser d'essence ou ni d'autres vapeurs ou liquides

inflammables à proximité de cet appareil ou de tout autre appareil.

— QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ :

•Ne pas tenter d’allumer d’appareils.

•Ne touchez à aucu n interrupteur. N e pas vous servir de s téléphones dans le bât iment

où vous vous trouvez.

•Appelez immédiatement votre fournisseur de gaz depuis un voisin. Suivez les

instructions du fournisseur.

•Si vous ne pouvez rejoindre le fournisseur de gaz, appelez le service des incendies.

d'entretien qualifié ou par le fournisseur de gaz.

INTRODUCTION

Ce manuel est écrit pour l’utilisateur.

Slant/Fin n'est pas responsable de tout dommage causé par ne pas suivre correctement de ces instructions. Pour

service et réparation, utiliser seulement pièces de rechange de Slant/Fin. Tout documentation produit par le

fabricant est sous réserve de la loi sur le droit d'auteur. Ce manuel est sujet à changement sans préavis.

Explications:

VGH = Chaudière à condensation

DHW = Eau Chaude Sanitaire (ECS)

CH = Chauffage central (pour objectif chauffage et/ ou eau chaude indirect)

BCU = commande (burner control unit)

PB = écran (Pixel Button)

CONSIGNES DE SÉCURITÉ

POUR VOTRE SÉCURITÉ LISEZ AVANT DE METTRE EN MARCHE

« A. Cet appareil ne comporte pas de veilleuse. Il est muni d'un dispositif d'allumage qui allume automatique-ment

le brûleur. Ne tentez pas d'allumer le brûleur manuellement.»

« B. AVANT DE FAI RE FO NCTIONNER , reniflez tout autour d e l'appar eil pour déceler une odeur de g az. Reniflez près du plancher, car certains gaz sont plus lourds que l'air et peuvent s'accumuler au niveau du sol. »

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ :

•Ne pas tenter d'allumer d'appareil.

•Ne touchez à aucun interrupteur; ne pas vous servir des téléphones se trouvant dans le bâtiment.

•Appelez immédiatement votre fournisseur de gaz depuis un voisin. Suivez les instructions du fournisseur.

•Si vous ne pouvez rejoindre le fournisseur, appelez le service des incendies.

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 11

Page 12

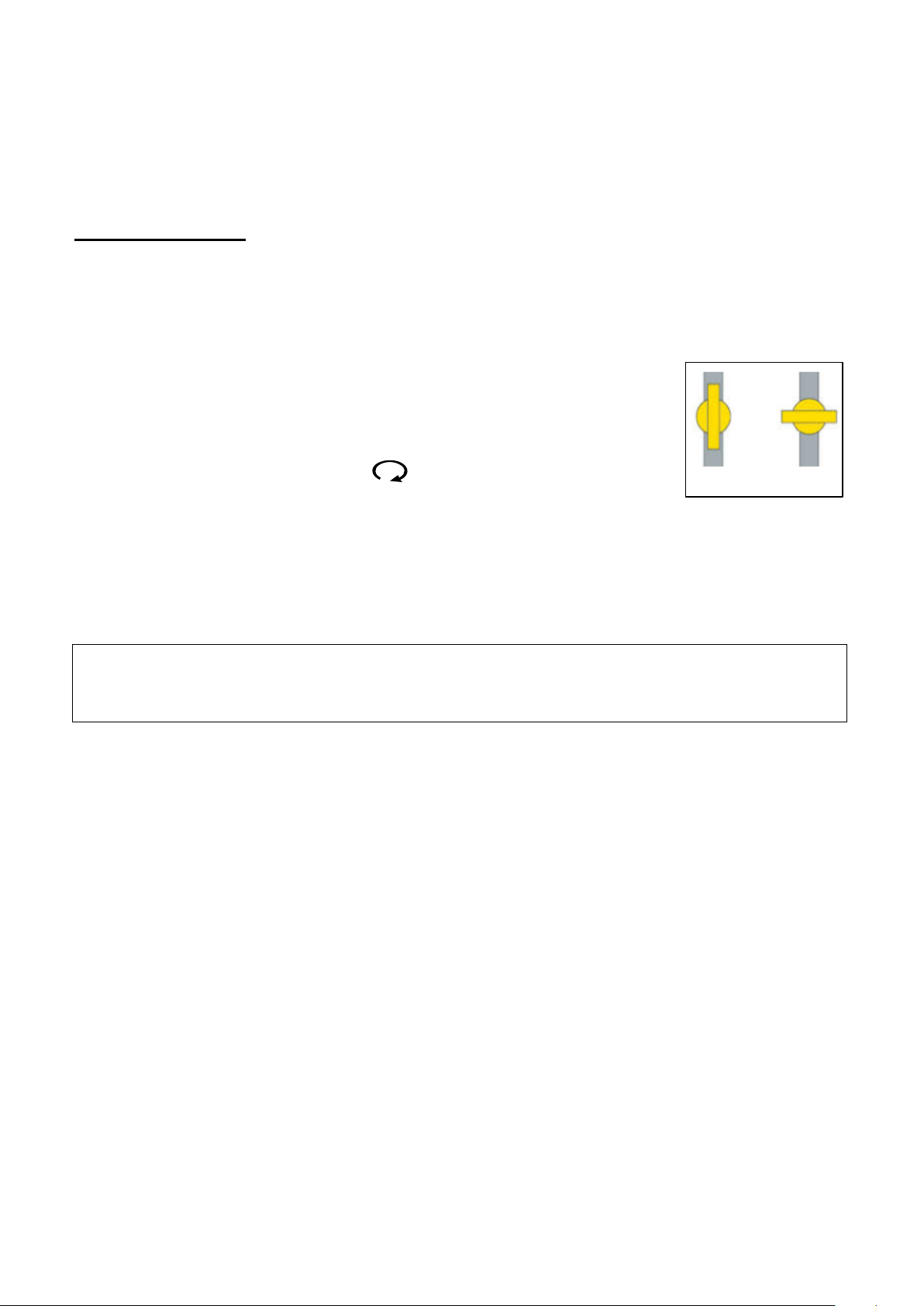

« C. Ne poussez o u to urne z la man ette d' a dm iss ion d u gaz qu'à l a m ain ; ne j a m ais ut il iser d' out il. S i la manette

OUVRIR FERMER

reste coincée, ne pas tenter de la réparer ; appelez u n technicien qualifié. Le fait de for cer la ma nette ou de la

réparer peut déclencher une explosion ou un incendie. »

« D. N'utilisez pas cet appareil s'il a été plongé dans l'eau, même partiellement. Faites inspecter l'appareil par un

technicien qualifié et remplacez toute partie du système de contrôle et toute commande qui ont été plongés dans

l'eau. »

Avertissement

Une installation, un r églage, une modificat ion, une réparation ou u n entretien non con-for me aux normes peut

entraîner des dommages matériels, des blessures (exposition à des matières dange-reuses) ou la mort.

L'installation et l'entretien doivent être effectués par un installateur ou un service d'entretien qualifié ou le

fournisseur de gaz (qui doivent avoir lu les instructions fournies avant de faire l'installation, l'en-tretien ou

l'enlèvement de la chaudière et les respecter. Cette chaudière contient des matériaux qui ont été iden-tifiés

comme étant cancérogènes ou pouvant l'être).

Comment couper l'admission de gaz de L’appareil:

1. Réglez le thermostat à la température la plus basse.

2. Coupez l'alimentation électrique de l'appareil s'il faut procéder à l'entretien

3. Le robinet d'arrêt de gaz est situé dessous la chaudière dans la conduite de gaz.

4. Tourner le robinet sens horaire à "OFF" (fermé) pour arrêter l’alimentation

en gaz. Ne pas forcer.

En cas de surchauffe ou s i l'admission de g az ne peut être coupée, ne pas c ouper ni débranc her l'aliment ation

électrique de la pompe. Fermer plutôt le robinet d'admission de gaz à l'extérieur de l'appareil.

Entretien et inspection

« Inspecter de faço n v isue ll e le s y s tème d'év ac ua tio n pour d ét erm in er l a gros s eu r et l'inclinaison hor iz ont ale qui

conviennent et s'assurer que le système est exempt d'obstruction, d'étranglement, de fuite, de corrosion et autres

défaillances qui pourraient présenter des risques. »

L'entretien et l'inspection de la chaud ière doivent être effectués aux occasions suivantes :

• Lorsqu'un certain nombre de codes d'erreur et/ou de verrouillage semblables apparaissent.

• Au moins tous les 12 mois, l'entretien doit être fait pour assurer un fonctionnement sûr et effic ace.

Les dommages causés par le manque d'entretien ne seront pas couverts par la garantie

Retrait d'une chaudière existante.

« Au moment du retrait d'une chaudière existante, les mesures suivantes doivent être prises pour chaque appareil

toujours raccordé au système d'évacuation commun et qui fonctionne alors que d'autres appareils toujours

raccordés au système d'évacuation ne fonctionnent pas :»

« Sceller toutes les ouvertures non utilisées du système d'évacuation. »

« Inspecter de façon visuelle le système d'évacuation pour déterminer la grosseur et l'inclinaison horizontale qui

conviennent et s'assurer que le système est exempt d'obstruction, d'étranglement, de fuite, de corrosion et autres

défaillances qui pourraient pr és enter des risqu es .

« Dans la mesure du poss ible, fermer toutes les port es et les fenêtres du bâtiment et tou tes les portes entre

l'espace où les apparei ls toujours raccordés au système d' évacuation sont installés et les autr es espaces du

bâtiment. Mettre en marc he les séc heuses, tous les appare ils non rac cordés au système d'év acuation c ommun

et tous les ventilateurs d'extraction comme les hottes de cuisinière et les ventilateurs des salles de bain. S'assurer

que ces ventilateurs fonct ionnent à la vitess e maximale. Ne pas fa ire fonctionner les ventilateurs d'été . Fermer

les registres des cheminées. » « Mettre l'appareil inspecté en marche. Suivre les instructions d'allumage. Régler

le thermostat de façon que l'appareil fonctionne de façon continue. »

« Une fois qu'il a été déterminé, selon la méthode indiquée ci-dessus, que chaque appareil raccordé au système

d'évacuation est m is à l'air libre de façon adé quate. Remettre les portes et les fenêtres, les ventilateurs, les

registres de cheminées et les appareils au gaz à leur position originale.

« Tout mauvais fonctionnement du système d'évacuation commun devrait être corrigé de façon que l'installation

soit conforme au N ational Fuel Gas Code, ANSI Z 223.1/NFPA 54 et (où) aux c odes d'installation CAN/CSAB149.1. Si la grosseur d'u ne s ection du s yst ème d'éva cuatio n doit être modifi ée, l e sys tème devrait être mo difi é

pour respecter les valeurs minimales des tableaux pertinents de l'appendice F du National Fuel Gas Code, ANSI

Z223.1/ NFPA 54 et (où) les codes d'installation CAN/CSA-B149.1. »

12 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 13

2 INTRODUCTION

1. Combi-boiler (CH & DHW)

2. Carbon mo noxid e

This manual is the installation and service manual for the high-efficiency heating systems from the VGH-CH

(Central Heating boi lers) series and VGH-CO (Combi boilers) series. This manual is spec ifically written for the

installer.

The distributor and manufacturer ar e not ac countable for any damag e c aused by installers not correctly following

these instructions.

For service and repair purposes use only original Slant/Fin spare parts.

All documentation produced by the manufacturer is subject to copyright law.

This manual is subject to change without notice.

Terms and abbreviations

In this manual the following terms and abbreviations are used:

A (Amp) Ampère

AFUE Annual Fuel Utilization Efficiency

AHRI Air-conditioning, Heating and Refrigeration Institute

ANSI American National Standards Institute

ASME American Society of Mechanical Engineers

ASSE American Society of Sanitary Engineering

bar Unit of pressure (1 bar = 14.5 PSI)

BCU Burner Control Unit

BTU British Thermal Unit

°C Degree Celsius

CaCO3 Calcium carbonate

CH Central Heating.

CO

CO2 Carbon dioxide

Combi A boiler providing a combination of central heating and domestic hot water

CVPC Chlorinated Polyvinyl Chloride, a thermoplastic

DHW Domestic Hot Water

°F Degree Fahrenheit

Hz Hertz

LB Digit-based Liquid Crystal Display Board

LCD Liquid Crystal Display

LPG Liquefied Petroleum Gas

MBH 1000 BTUs per hour

mg Milligram

NFPA National Fire Protection Association

NOx Mono-nitrogen oxides

NPT National Pipe Thread, American standard for threaded pipes and fittings

NTC Negative Temperature Coe fficie nt, a quality of sensors and resistors

O

2

PB Graphical Display Board

Oxygen

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 13

Page 14

PCB Printed Circuit Board

• ASME Boiler and Pressure Vessel Code

Section “Heating boilers”

• ASME Boiler and Pressure Vessel Code

Section “Recommended Rules for the Care and Operation of

Heating Boilers”

• ANSI Z223.1 / NFPA 54

National Fuel Gas Code

• ANSI / NFPA 70

National Electrical Code

• ANSI / NFPA 211

Chimneys, Fireplaces, Vents and Solid Fuel Burning

Appliances

PEX Cross-linked polyethylene

pH Acidity degree

PID Proportional Integral Derivative, a control concept used in automation

ppm Particles per million

psi Pounds per square inch, a unit of pressure

Pump Circulator

PVC Polyvinyl Chloride, a thermoplastic

PWM Pulse Width Modulation

RCF Refractory Ceramic Fibers

RT Room Thermostat

TDS Total Diss olv e d Solids, a characteristic used in water quality

UL Underwriters Laboratories, American testing and certification institute

VAC Volt Alternating Current

VDC Volt Direct Current

W Watt, a unit of power

W.C. Water column

Codes, standards and regulations

Installation, maintenance and repairs must be performed in strict accordance with the state and local requirements

and regulations.

In the absence of local requirements, the following standards and regulations apply:

Where required by the authority having jurisdiction, the installation must conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers, ANSI, ASME CSD-1.

Maintenance and inspection

For a good, safe and long-lasting operation of the boi ler and to maintain warranty it is m andatory to carry out

inspection, maintenance and service on the boiler at least once a year.

Maintenance and inspection of the boiler must be carried out in the following situations:

• When a number of similar error codes and/or lockouts appear.

• At least once every 12 months to ensure safe and efficient operation.

Damage caused by lack of maintenance will not be covered under warranty.

Visually inspect the venting system for pro per size and horizonta l pitch and determine ther e is no blockage or

restriction, leakage, corrosion or other deficiencies which could cause an unsafe condition.

More details on maintenance, inspections and repairs are cover ed in chapter 18.

14 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 15

For installations in the Commonwealth of Massachusetts

The following local requirements apply in addition to all other applicable NFPA requirements:

For direct-vent boilers, mec hanical-vent heat ing appliances or domestic hot water equi pment, where the bott om

of the vent termina l and the intake is installed below four feet above grade, th e following requ irements mus t be

met:

1) If not present o n each floor level wher e there are be drooms, a car bon monox ide det ector an d alarm must

be placed in a living area outside the bedrooms. The carbon monoxide detector and alarm must comply with

NFPA 720 (2005 Edition).

2) A carbon monoxide detector and alarm must be located in the room that houses the boiler and/or

equipment and must:

a) be powered by the same electrical circuit as the boiler and/or equipment so that only one service switch

services both the boiler and the carbon monoxide detector;

b) have battery back-up power;

c) meet ANSI/UL 2034 Standards and comply with NFPA 720 (2005 Edition); and

d) have been approved and listed by a Nationally Recognized Testing Lab as recognized under 527 CMR.

3) A product-approve d vent terminal must be us ed, and if applicable, a pro duct approved air intak e must be

used. Installation must be performed in strict compliance with the manufacturer’s instructions. A copy of the

installation instructions must remain with the boiler and/or equipment at the completion of the installation.

4) A metal or plastic identification plate must be mounted at the exterior of the building, four feet directly above

the location of ve nt ter mina l. The plate must be of suffic ient size to be eas ily read from a dis tance of eigh t

feet away and read “Gas Vent Directly Below”.

For direct-vent boilers mechanical-vent heating boilers or domestic hot water equipment, where the bottom of the

vent terminal and the intake is installed higher than four feet above grade, the following requirements must be met:

1) If not present o n each floor level wher e there are be drooms, a car bon monox ide det ector an d alarm must

be placed in a living area outside the bedrooms. The carbon monoxide detector and alarm must comply with

NFPA 720 (2005 Edition).

2) A carbon monoxide detector must:

a) be located in the room where the boiler and/or equipment is located;

b) be either hard-wired or battery powered or both; and:

c) comply with NFPA 720 (2005 Edition).

3) A product-approve d vent te rminal mus t be used, a nd if applicab le, a produc t- approved air intak e must be

used. Installation must be in strict compliance with the manufacturer’s instructions. A copy of the installation

instructions must remain with the boiler and/or equipment at the completion of the installation.

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 15

Page 16

3 TECHNI CAL DATA VGH RESIDENTIAL BOILERS

On/Off thermostat or modulating thermostat

Low Water Cut Off

System circulator

Alarm outputs

On/Off thermostat or modulating thermostat

Low Water Cut Off

System circulator

Alarm outputs

FUNCTIONAL INTRODUCTION

The VGH b oilers are cent ral heatin g/combi boilers w ith a maximu m high effici ency. Such a performance c an be

reached by, amongst o ther things, using a sp ecial heat exchanger m ade of stainless stee l. This allows the flue

gases to cool down below the condensation point, thus releasing extra heat. This has an immediate positive impact

on the efficiency.

The VGH boiler is factory set for Natural gas.

Fuel used must have Sulphur rates with a maximum a nnual peak over a s hort pe riod of tim e of 150 mg/m

3

ppm) and an annual average of 30 mg/m

. (22 ppm average).

Boiler control includes:

Cascade control for up to sixteen boilers

Remote operation and heat demand indication from each boiler

Weather compensation control – Outdoor reset.

Indirect tank control (On heat only boiler models)

Connections for VGH-CH boilers:

3

(110

0-10 VDC remote flow temperature (set point) control

0-10 VDC remote boiler input control

Outdoor temperature sensor

External indirect tank circulator or diverter valve

PWM control for external boiler circulator.

Connections for VGH-CO boilers:

0-10 VDC remote flow temperature (set point) control

0-10 VDC remote boiler input control

Outdoor temperature sensor

PWM control for external boiler circulator.

External flow switch or external safety device.

Modbus

External system sensor

DHW indirect sensor or aquastat.

External Ignition coil

External flow switch or external safety device.

Modbus

External system sensor

External Ignition coil

16 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 17

Information

Software Versions

Error Log

Figure 3.1

Software Versions

Display [63EF 83BC]

Figure 3.2

Figure 3.3

Location of version numbers

Burner Controller Hardware Version

– To be found on the second line of the white sticker on the side of the burner controller.

e.g. 957MN15_3Rh4b

Burner Controller Software Versions

• Press the menu button

• Go to Information

• Go to Software Versions.

Boiler Status

Boiler History

i

Boiler [5C79 14A9]

Device Group 900MN

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 17

Page 18

Technical specifications datasheets

IV

p nom inch W.C. (mbar)

p min inch W.C. (mbar)

p max inch W.C. (mbar)

Natural gas

7.0 (17.4)

3.5 (8.7)

10.5 (26.2)

Propane

11.0 (27.4)

8.0 (19.9)

13.0 (32.4)

Table 3. 1

TECHNICAL SPECIFICATIONS VGH-80-CH / VGH-90-CO / VGH-100-CH

GENERAL

Boiler category Type boiler VGH-80-CH VGH-90-CO VGH-100-CH

Dimensions (h x w x d) inch (mm) 28.2" x 17.4" x 16.9" (717mm x 442mm x 429mm)

Water content

gallon

(liter)

0.37 (1.4) 0.37 (1.4) 0.4 (1.75)

Weight (empty) lbs (kg) 74 (34) 77 (35) 77 (35)

Supply/return connection

CH

Supply/return connection

DHW

inch NPT ¾” NPT ¾” NPT ¾”

inch

NPT ¾” NPT ½” NPT ¾”

Gas connection inch NPT ¾” NPT ¾” NPT ¾”

Flue connection inch (mm) 3” (80mm) 3” (80mm) 3” (80mm)

GAS CONSUMPTION Values min-max:

Natural gas

Propane

1

Gas supply

Nat. gas

ft3/h

m3/h

ft3/h

3

/h

m

Inch W.C./

(mbar)

7.43 – 74.3

0.21 – 2.11

3.20 – 32.0

0.09 – 0.91

8.36 – 83.6

0.24 – 2.37

3.60 – 36.0

0.10 – 1.02

7.0 (17.4)

9.29 – 92.9

0.26 – 2.63

4.0 – 40.0

0.11 – 1.13

pressure

nominal 2

Propane

Inch W.C./

(mbar)

11.0 (27.4)

NOTES

1

Using propane, maximum fan speed needs to be reduced

2 Min. and max. gas supply pressures are listed in the table below.

18 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 19

Type boiler VGH-80-CH VGH-90-CO VGH-100-CH

Low Fire %

9.4 – 8.9

High Fire %

9.1 – 8.4

Low Fire %

9.8

High Fire %

10.1

Low Fire %

4.1 – 5.0

High Fire %

4.6 – 6.0

Low Fire %

6.0

High Fire %

5.5

Flue gas temperature at

70 °F (20 °C)

INSTALLATION

∆T = 20 F

26.3 (8.0)

26.3 (8.0)

35.6 (10.9)

T = 35 F

8.8 (2.7)

8.8 (2.7)

12.7 (3.9)

Pressure boiler min-max.

psi (bar)

11.6 – 43.5 (0.8 – 3.0)

Max. supply temperature

°F (°C)

194 (90)

flow rate at ∆T = 77 °F

gal/min (l/min)

-

2.3 (8.7)

-

Pressure DHW min-max

psi (bar)

-

14.5 - 116 (1.0 -8.0)

-

ELECTRIC

Minimum power consumption

W

140

140

140

Maximum power consumption

W

180

190

180

Power supply

V/Hz

120 / 60

Protection class

-

IPX4D5

Table 3. 2

Figure 3.6

IPX4D Air inlet.

Two 90° Bends with a bird screen

Boiler is IP20

applying a bird

Natural gas

CO2 flue gas

3

Propane

Natural gas

O2 flue gas

3

Propane

combustion air temperature =

Available pressure for the flue

and inlet system 4

Resistance

boiler

∆

°F (°C) 86 – 153 (30 – 67)

Inch W.C.

(Pa)

ft.head (m.W.C.)

ft.head (m.W.C.)

250 320 230

DHW PERFORMANCE

Thermal Efficiency 6 % 95.0

Standby power consumption W 6 6 6

NOTES

3

CO2 or O2 of the unit measured/set without the boiler front panel in place

4

Maximum allowed combined resistance of flue gas and air supply piping at high fire

5

For gas appliance type B23(P) (Room Air) only class IPX4D with special air inlet, otherwise the

protection class is IP20 (see also picture below)

6

Efficiency of DHW performance measured according to ANSI Z21.10.3-2015 • CSA 4.3-2015

screen only

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 19

Page 20

TECHNICAL SPECIFICATIONS VGH-120-CH / VGH-150-CO / VGH-150-CH

IV

Type boiler

VGH-120-CH

VGH-150-CO

VGH-150-CH

p nom inch W.C. (mbar)

p min inch W.C. (mbar)

p max inch W.C. (mbar)

Natural gas

7.0 (17.4)

3.5 (8.7)

10.5 (26.2)

Propane

11.0 (27.4)

8.0 (19.9)

13.0 (32.4)

Table 3. 3

GENERAL

Boiler category -

Dimensions (h x w x d) Inch (mm) 28.2" x 17.4" x 16.9" (717mm x 442mm x 429mm)

Water content

Gallon

(liter)

0.55 (2.1) 0.55 (2.1) 0.83 (3.15)

Weight (empty) Lbs (kg) 83 (38) 86 (39) 97 (44)

Supply/return connection

CH

Supply/return connection

DHW

inch NPT ¾” NPT ¾” NPT ¾”

inch

NPT ¾” NPT ½” NPT ¾”

Gas connection inch NPT ¾” NPT ¾” NPT ¾”

Flue connection Inch (mm) 3” (80mm) 3” (80mm) 3” (80mm)

GAS CONSUMPTION Values min-max:

Natural gas

Propane

1

Gas supply

Nat. gas

ft3/h

m3/h

ft3/h

3

/h

m

Inch W.C./

(mbar)

11.1 – 111.5

0.32 – 3.16

4.8 – 48.0

0.14 – 1.36

13.9 – 139.4

0.40 – 3.95

6.0 – 60.0

0.17 – 1.7

7.0 (17.4)

13.9 – 139.4

0.40 – 3.95

6.0 – 60.0

0.17 – 1.7

pressure

nominal 2

Propane

Inch W.C./

(mbar)

11.0 (27.4)

NOTES

1

Using propane, maximum fan speed needs to be reduced

2 Min. and max. gas supply pressures are listed in the table below.

20 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 21

Type boiler VGH-120-CH VGH-150-CO VGH-150-CH

Flue gas temperature at

70 °F (20 °C)

T = 35 F

Efficiency of DHW performance measured according to ANSI Z21.10.3-2015 • CSA 4.3-2015

Table 3. 4

Natural gas

Low Fire % 9.4 – 8.9

CO2 flue gas

3

High Fire % 9.1 – 8.4

Low Fire % 9.8

Propane

High Fire % 10.1

Low Fire % 4.1 – 5.0

Natural gas

O2 flue gas

3

High Fire % 4.6 – 6.0

Low Fire % 6.0

Propane

High Fire % 5.5

combustion air temperature =

Available pressure for the flue

and inlet system 4

°F (°C) 86 – 153 (30 – 67)

Inch W.C.

(Pa)

260 400 340

INSTALLATION

Resistance

boiler

∆T = 20 F

∆

ft.head (m.W.C.)

ft.head (m.W.C.)

25.2 (7.7) 25.2 (7.7) 47.6 (14.5)

9.7 (3.9) 9.7 (3.9) 15.8 (4.8)

Pressure boiler min-max. psi (bar) 11.6 – 43.5 (0.8 – 3.0)

Max. supply temperature °F (°C) 194 (90)

DHW PERFORMANCE

flow rate at ∆T = 77 °F

gal/min (l/min) - 3.4 (12.9) Pressure DHW min-max psi (bar) - 14.5 - 116 (1.0 -8.0) Thermal Efficiency 6 % 93.7

ELECTRIC

Minimum power consumption W 140 140 140

Maximum power consumption W 190 220 200

Standby power consumption W 6 6 6

Power supply V/Hz 120 / 60

Protection class - IPX4D5

NOTES

3

CO2 or O2 of the unit measured/set without the boiler front panel in place.

4

Maximum allowed combined resistance of flue gas and air supply piping at high fire

5

For gas appliance type B23(P) (Room Air) only class IPX4D with special air inlet, otherwise the

protection class is IP20 (see also picture at page 19)

6

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 21

Page 22

TECHNICAL SPECIFICATIONS VGH-180-CH / VGH-200-CO

IV

Type boiler

VGH-180-CH

VGH-200-CO

p nom inch W.C. (mbar)

p min inch W.C. (mbar)

p max inch W.C. (mbar)

Propane

11.0 (27.4)

8.0 (19.9)

13.0 (32.4)

Table 3. 5

GENERAL

Boiler category -

Dimensions (h x w x d) Inch (mm) 28.2" x 17.4" x 16.9" (717mm x 442mm x 429mm)

Water content

Gallon

(liter)

0.83 (3.15) 0.83 (3.15)

Weight (empty) Lbs (kg) 98 (44) 101 (46)

Supply/return connection

CH

Supply/return connection

DHW

inch NPT ¾” NPT ¾”

inch

NPT ¾” NPT ½”

Gas connection inch NPT ¾” NPT ¾”

Flue connection Inch (mm) 3” (80mm) 3” (80mm)

GAS CONSUMPTION Values min-max:

Natural gas

Propane

1

Gas supply

Nat. gas

ft3/h

m3/h

ft3/h

3

/h

m

Inch W.C./

(mbar)

16.7 – 167.4

0.47 – 4.74

7.2 – 72.1

0.2 – 2.04

18.6 – 186.0

0.52 – 5.26

8.0 – 80.0

0.23 – 22.7

7.0 (17.4)

pressure

nominal 2

Propane

Inch W.C./

(mbar)

11.0 (27.4)

NOTES

1

Using propane, maximum fan speed needs to be reduced.

2 Min. and max. gas supply pressures are listed in the table below.

Natural gas 7.0 (17.4) 3.5 (8.7) 10.5 (26.2)

22 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 23

Type boiler

VGH-180-CH

VGH-200-CO

CO2 flue gas

Low Fire %

9.4 – 8.9

High Fire %

9.1 – 8.4

Low Fire %

9.8

High Fire %

10.1

Low Fire %

4.1 – 5.0

High Fire %

4.6 – 6.0

Low Fire %

6.0

High Fire %

5.5

Inch W.C.

(Pa)

INSTALLATION

T = 20 F

68.4 (20.8)

68.4 (20.8)

T = 35 F

22.6 (6.9)

22.6 (6.9)

Pressure boiler min-max.

psi (bar)

11.6 – 43.5 (0.8 – 3.0)

Max. supply temperature

°F (°C)

194 (90)

DHW PERFORMANCE

flow rate at ∆T = 77 °F

gal/min (l/min)

-

4.6 (17.4)

Pressure DHW min-max

psi (bar)

-

14.5 - 116 (1.0 -8.0)

Thermal Efficiency 6

%

95.4

ELECTRIC

Minimum power consumption

W

150

150

Maximum power consumption

W

260

290

Standby power consumption

W 6 6

Power supply

V/Hz

120 / 60

Protection class - IPX4D5

NOTES

Efficiency of DHW performance measured according to ANSI Z21.10.3-2015 • CSA 4.3-2015

Table 3. 6

O2 flue gas

3

3

Natural gas

Propane

Natural gas

Propane

Flue gas temperature at combustion air

temperature = 70 °F (20 °C)

Available pressure for the flue and inlet system 4

Resistance

boiler

3

CO2 or O2 of the unit measured/set without the boiler front panel in place

4

Maximum allowed combined resistance of flue gas and air supply piping at high fire

5

For gas appliance type B23( P) (Room Air) only class IPX4D with special air inlet, otherwise the

∆

∆

°F (°C) 86 – 153 (30 – 67)

400 490

ft.head (m.W.C.)

ft.head (m.W.C.)

protection class is IP20 (see also picture at page 19)

6

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 23

Page 24

NOTICE

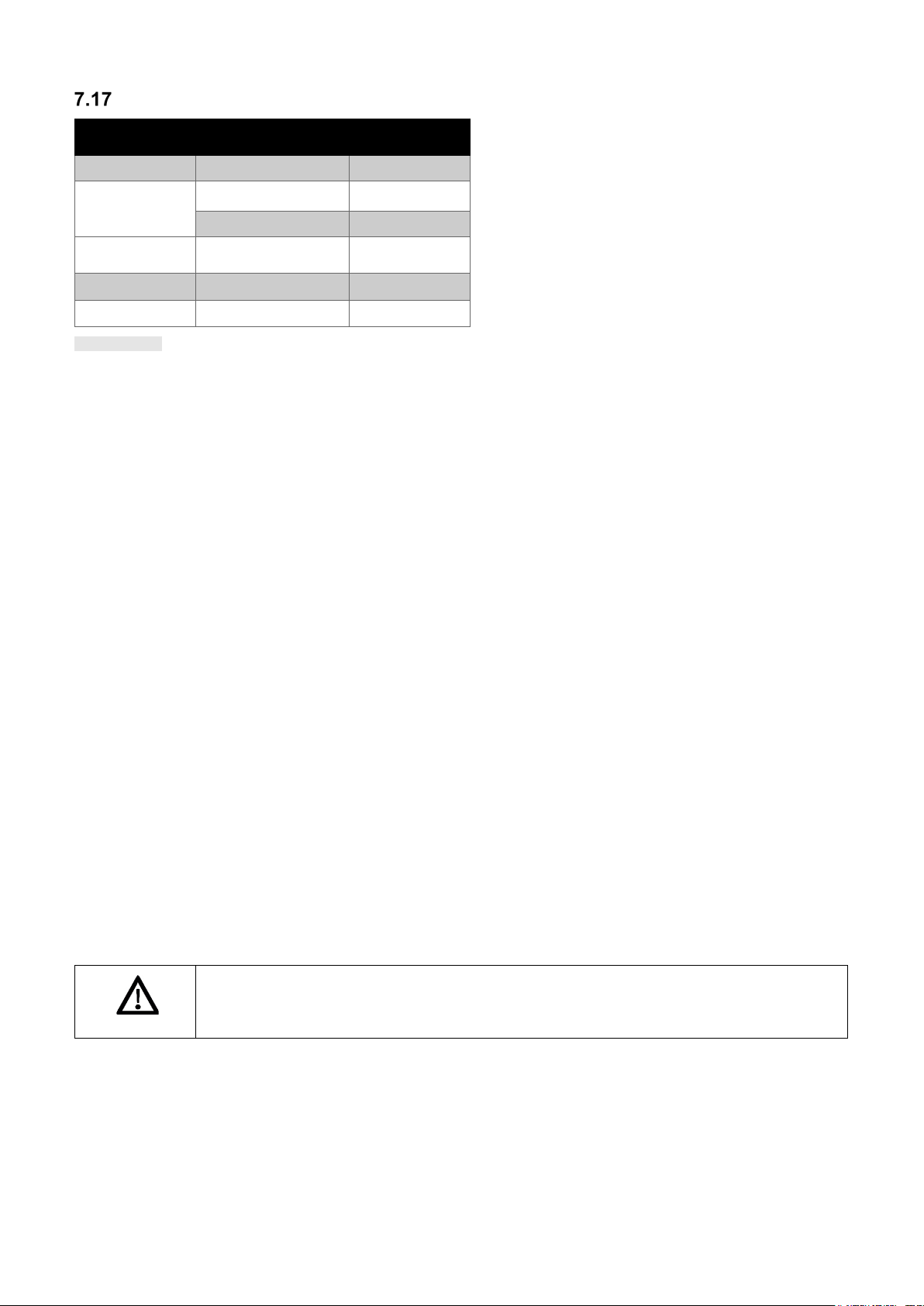

High altitude operation

High Altitude Operation

Elevations

2000 ft (610 m)

3000 ft (914 m)

4000 ft (1219 m)

4500 ft (1372 m)

Above 4500 ft (1372 m)

In USA

No de-rate

De-rate by 4 %

De-rate by 8 %

De-rate by 10 %

De-rate 4% per 1000 ft.

In Canada

No de-rate

De-rate by 10%

De-rate by 10 %

De-rate by 10 %

De-rate 4% per 1000 ft.

Model number

Min

Max

Combustion – At elevations above 2000 ft (610 m), the combustion of the appliance must be checked with

kits are neede d, sinc e the 1: 1 Gas /A ir ra tio o f th e gas v alv e and th e ven tu ri w ill re spo n d

instructions may result in property damage, serious injury, or death.

Table 3. 7

Table 3. 8

Boiler model

number

pressure

temperature*

capacity

surface

VGH-80-CH /

VGH-90-CO

461953

T4804.4CL

50 Psi

210 °F

91 MBH

7.99 SQTF

VGH -100-CH

461955

T4804.4CL

50 Psi

210 °F

136 MBH

9.99 SQFT

VGH -120-CH

/ VGH-150-CO

461959

T4806.4CL

50 Psi

210 °F

182 MBH

11.99

SQFT

VGH-150-CH /

VGH-200-CO

461963

T4807.4CL

50 Psi

210 °F

227 MBH

17.98

Table 3. 9

The boiler is designed to operate at its maximum listed capacity in installations at elevations less than or equal to 2000 ft

(610 m) above Sea Level. Since the density of air decreases as elevation increases, maximum specified capacity will be

de-rated for elevations above 2000 ft (610 m) in accordance with the table underneath.

In USA and Canada, de-rate by 4% extra for every 1000 ft. above 4500 ft.

a calibrated (altitude corrected) combustion analyzer to ensure safe and reliable operation. No orifices o r

high-altitude

automatically to reduced air pressure.

It is the Installers responsibility to check the combustion of the appliance. Failure to follow these

How to calculate De-rating at intermediate elevations for US:

Elevation between:

2000 and 3000 ft : (New value – 2000) x 0.004 Example: Elevation is 2600 ft. De-rating is (2600-2000)x0.004 = 2.4 %

3000 till 4000 ft : ((New value – 3000) x 0.004)+4 Example: Elevation is 3700 ft. De-rating is ((3700-3000)x0.004)+4 = 6.8 %

4000 till 4500 ft : ((New value – 4000) x 0.004)+8 Example: Elevation is 4200 ft. De-rating is ((4200-4000)x0.004)+8 = 8.8 %

Above 4500 ft : ((New value – 4500) x 0.004)+10 Example: Elevation is 4800 ft. De-rating is ((4800-4500)x0.004)+10 = 11.2 %

How to calculate De-rating at intermediate elevations for Canada:

Elevation between:

2000 till 4500 ft : All values de-rate by 10% Example: Elevation is 3600 ft. De-rating = 10 %

Above 4500 ft : ((New value – 4500) x 0.004)+10 Example: Elevation is 7600 ft. De-rating is ((7600-4500)x0.004)+10 = 22.4 %

DHW specifications VGH-CO series

VGH-CO series DHW specifications

DHW Input, MBH

VGH-90-CO 9 90

VGH-150-CO 15 150

VGH-200-CO 20 200

Heat exchanger inform ati on

The heat exchanger in this boiler is manufactured and certified by Sermeta.

This table gives an overview of the ASME-H specifications as certified:

CRN

Max

allowable

water

Max

allowable

water

Min relieve

valve

Heat exch.

VGH-180-CH /

* the maximum supply temperature of the boiler is 194F

24 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

SQFT

Page 25

Specifications input, output, efficiency (AHRI)

Min

Max

The ratings and efficiencies are based on standard test procedures and calculation methods as prescribed by the

Table 3. 10

Model

number

CH Input, MBH

1

Output

MBH

1

AHRI

AFUE

Net Ratings Water, MBH

VGH-80-CH 8 80 74 64 95.2

VGH-90-CO 9 80

74 64 95.2

VGH-100-CH 10 100 93 81 95.2

VGH-120-CH 12 120 111 97 95.2

VGH-150-CO 15 120 111 97 95.2

VGH-150-CH 15 150 140 122 95.2

VGH-180-CH 18 180 168 146 95.2

VGH-200-CO 20 180 168 146 95.2

1

Listed Input and Output ratings are at minimum vent lengths at Sea Level. Numbers will be lower with longer

venting and/or altitudes greater than 2000 feet [610 m].

• Ratings have been confirmed by the Hydronics Section of AHRI.

•

United States Department of Energy.

%

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 25

Page 26

4 BOILER DIMENSIONS

A

Supply CH

B

Indirect DHW

C

Gas

D

Indirect DHW

E

Return CH

F

Condensate

Figure 4.1

165 mm

[6.5 in]

285 mm

[11.22 in]

129 mm

[5.07 in]

130 mm

[5.12 in]

176 mm

[6.93 in]

DN80 mm (2x)

[3 in]

116 mm

[4.57 in]

59 mm

[2.33 in]

76 mm

[2.99 in]

141 mm

[5.55 in]

310 mm

[12.2 in]

339 mm

[13.35 in]

F

717 mm

[28.23 in]

259 mm

[10.2 in]

212 mm

[8.33 in]

96 mm

[3.78 in]

146 mm

[5.75 in]

202 mm

[7.96 in]

D

E

C

A

B

37 mm

[1.48 in]

207 mm

[8.17 in]

430 mm

[16.93 in]

442 mm

[17.4 in]

VGH-80-CH / VGH-100-CH / VGH-120-CH / VGH-150-CH / VGH-180-CH

Connections VGH-CH boilers

NPT ¾ “

NPT ¾ “

NPT ¾ “

NPT ¾ “

NPT ¾ “

Flexible hose Ø 1.06” (26.9 mm)

26 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 27

A

Supply CH

B

Supply tap water

C

Gas

D

Return tap water

E

Return CH

Figure 4.2

212 mm

[8.33 in]

259 mm

[10.2 in]

96 mm

[3.78 in]

146 mm

[5.75 in]

202 mm

[7.96 in]

E

D

C

A

B

116 mm

[4.57 in]

76 mm

[2.99 in]

141 mm

[5.55 in]

F

207 mm

[8.17 in]

274 mm

[10.79 in]

339 mm

[13.35 in]

176 mm

[6.93 in]

38 mm

[1.48 in]

717 mm

[28.23 in]

130 mm

[5.12 in]

DN80mm (2x)

[3 in]

442 mm

[17.4 in]

430 mm

[16.93 in]

129 mm

[5.07 in]

165 mm

[6.5 in]

285 mm

[11.22 in]

VGH-90-CO / VGH-150-CO / VGH-200-CO

Connections VGH-CO boilers

NPT ¾ “

NPT ½ “

NPT ¾ “

NPT ½ “

NPT ¾ “

F Condensate Flexible hose Ø 1.06” (26.9 mm)

E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO 27

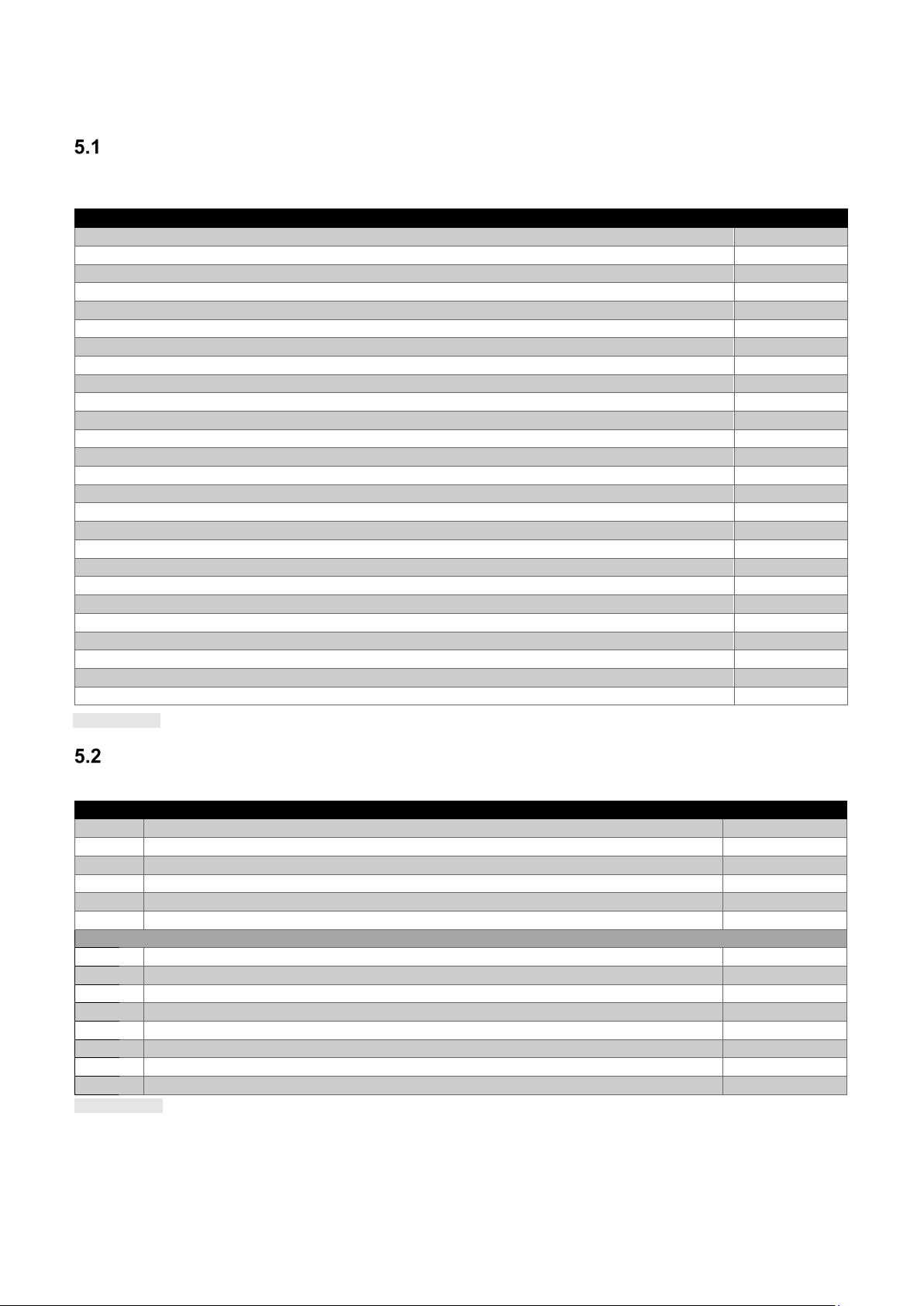

Page 28

5 ACCESSORIES AND UNPACKING

Item

Part number

Safety Flow Switch kit

81 7106 000

IP module

81 7111 000

Software + interface cable for programming the boiler with a computer/laptop

81 7135 000

External Ignition transformer with special burner controller; VGH-80-CH to VGH-120-CH

81 7276 000

External Ignition transformer with special burner controller; VGH-150-CH and VGH-180-CH

81 7277 000

External Ignition transformer with special burner controller; VGH-90-CO

81 7278 000

External Ignition transformer with special burner controller; VGH-150-CO

81 7279 000

External Ignition transformer with special burner controller; VGH-200-CO

81 7280 000

Special air inlet for IPX4D protection on B23(P) (Room Air) boilers

81 7281 000

Propane conversion kit VGH-80-CH and VGH-90-CO

81 7271 000

Propane conversion kit VGH-100-CH

81 7272 000

Propane conversion kit VGH-120-CH and VGH-150-CO

81 7273 000

Propane conversion kit VGH-150-CH

81 7275 000

Propane conversion kit VGH-180-CH

81 7274 000

Propane conversion kit VGH-200-CO

81 7304 000

VGH Residential Plumbing Kit Heating Only Boiler (VGH-xx-CH)

81 7154 000

VGH Residential Plumbing Kit Combi Boiler (VGH-xx-CO).

81 7155 000

Tank sensor for an Indirect Hot Water tank

81 7110 000

External flow temperature sensor for behind the low header 10kOhm@77°F

81 7109 000

MagFilter Pro XL

81 7284 000

Mag Flush Pro

81 7132 000

Heating System Cleaner

81 7133 000

Heating System Protector

81 7134 000

VGH Residential Yearly Maintenance Service Kit

81 7285 000

French I&O Manual Residential Boiler

81 7282 000

French User Manual residential Boiler

81 7283 000

Qty Description

Part number

1

Startup and commissioning check list

---

1

Wall bracket with locking plate and bolts

81 7264 000

3

Spare nuts for the burner plate (in a bag attached to the front of the gas valve)

See spare part list

1

Spare fuse for the boiler control (at the burner controller)

See spare part list

1

Bottom part of the condensate drain assembly

81 7263 000

1

Pressure/temperature residential VGH control kit

81 7288 000

This kit consists of

1 ASME pressure 30 psi relief valve (packed into an additional box)

65 0550 000

1 Outdoor (air) temperature sensor: 10kOhm@25°C -B3977

81 7108 000

1 Temperature and pressure gauge

91 0373 061

1 ¾ Gas shut off ball valve

83 3803 000

1 Boiler Drain

40 0201 000

1 Warranty card

41 1189 000

1 VGH Residential Installation and Service manual

81 7286 000

1 VGH Residential User Manual

81 7287 000

Table 5. 1

Table 5. 2

Optional Accessories

Depending on the selected boiler type, the selected controlling behavior for the central heating system and/or the

optional use of an indirect tank, the following items are available as accessories. Contact your supplier for ordering.

Supplied with the boiler

The VGH boiler will be supplied with the following documents and accessories:

After delivery, always check the boiler package to see if it is complete and without any defects. Report any defects

or missing parts immediately to your supplier.

28 E93.1901EN032 Installation and Service Manual SlantFin VGH-CH / CO

Page 29

CAUTION

6 INSTALLATION LOCATION OF THE VGH

The installation of the gas appliance must conform to the requirements of this manual and your

CSD-1

The wall used for mou nting t he b oiler must be ab le to hol d the weight of th e boile r, pipin g and

a (optional cascade) stand.

NOTICE

General

The boiler must be posit ioned and installed by a qua lified installer or the gas company in acc ordance with all

applicable standards , local codes and regulat ions (see also paragrap h 2.2). Commissioning of t he b oi ler must be