Page 1

INTREPID TRDV Series

DIRECT VENT OIL-FIRED WATER BOILER

VENTING INSTALLATION INSTRUCTIONS

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PAGE

Basic Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Application (Flex-L Vent Terminal)

Direct Vent Applications . . . . . . . . . . . . . . . . . . . . . .2 & 3

nstalling the joint assembly . . . . . . . . . . . . . . . . . . . . . . . .4

I

Outside Terminal

Installing the outside terminal . . . . . . . . . . . . . . . . . . . . .5

Connections to the outside terminal . . . . . . . . . . . . . . . .6

Connections to appliance . . . . . . . . . . . . . . . . . . . . . . . . . .7

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Vent system part numbers . . . . . . . . . . . . . . . . . . . . . . . . .8

Alternate Field Controls Vent Terminal . . . . . . . . . . . . . .8-14

Slant/Fin TR SERIES, models TRDV are approved for installation as a direct vent system. The following basic guidelines

should be observed according to the venting system in use.

In addition, it is strongly recommended that the applicable

precautions for Natural Draft Applications be used.

Installation Considerations

In addition to all the pertinent information regarding Natural

Draft Applications whenever a Mechanical Draft Application is

used it should be installed using the following instructions and

Figures 2 and 3 as reference.

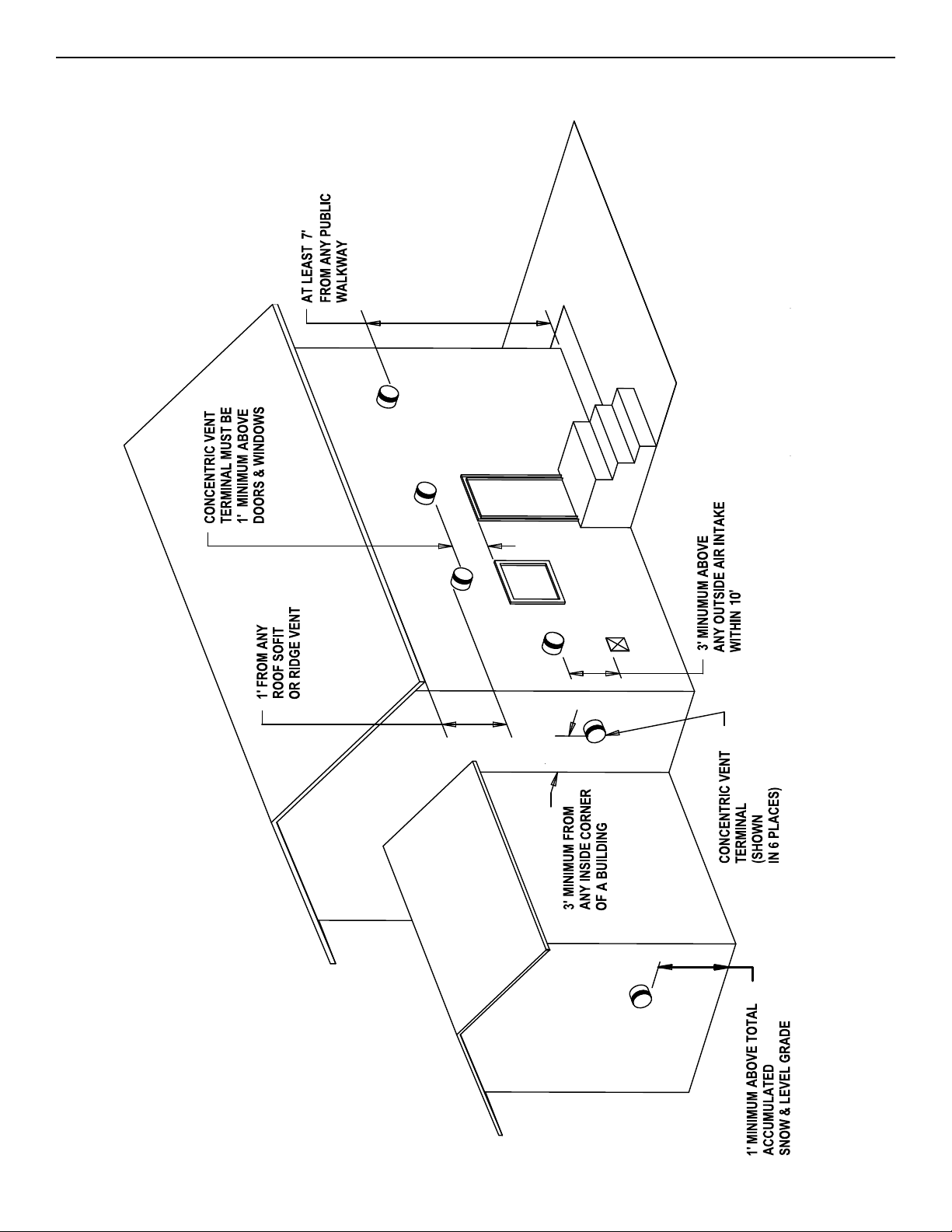

• The terminating vent hood, and the inlet air hood are on

the same wall surface. and are on the wall opposite from

the prevailing wind wall, if possible.

• All of the air for combustion to the burner is supplied

directly from the outside of the building or structure.

• Not less than 12 in. above the total accumulated

snow and level grade.

• Not less than 4 ft. horizontally or below any

window, and door or air inlet and also not less than

1 ft. above any of these openings.

• Not less than 3 ft. above a powered air inlet

device that is within 10 ft.

• Not less than 2 ft. from any other building.

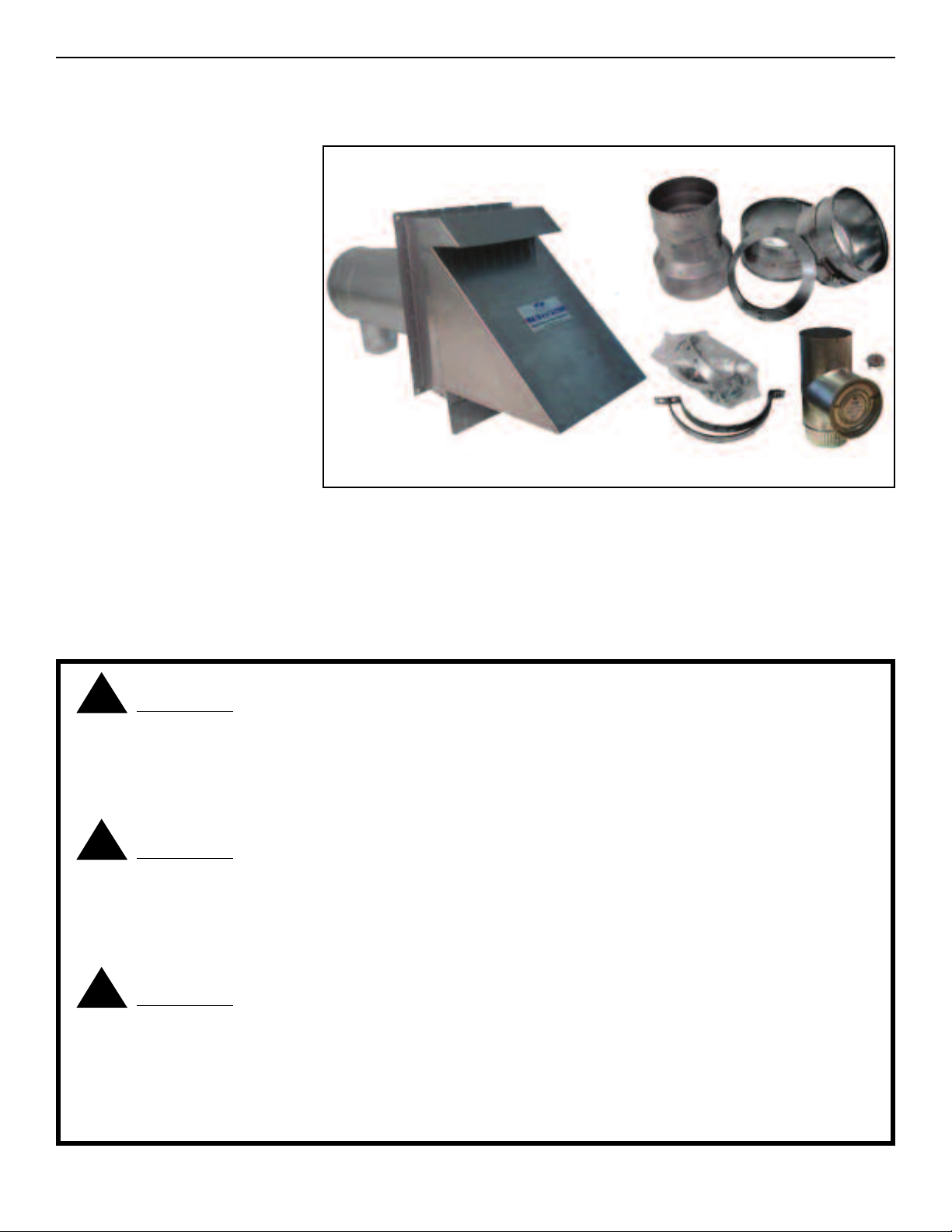

FIGURE 1: Slant/Fin model TRDV oil boiler with

vent kit

• At least 3 ft. from any inside corner of a building

• At least 1 ft. from any roof soffit or ridge vent.

• At least 7 ft. above any public walkway.

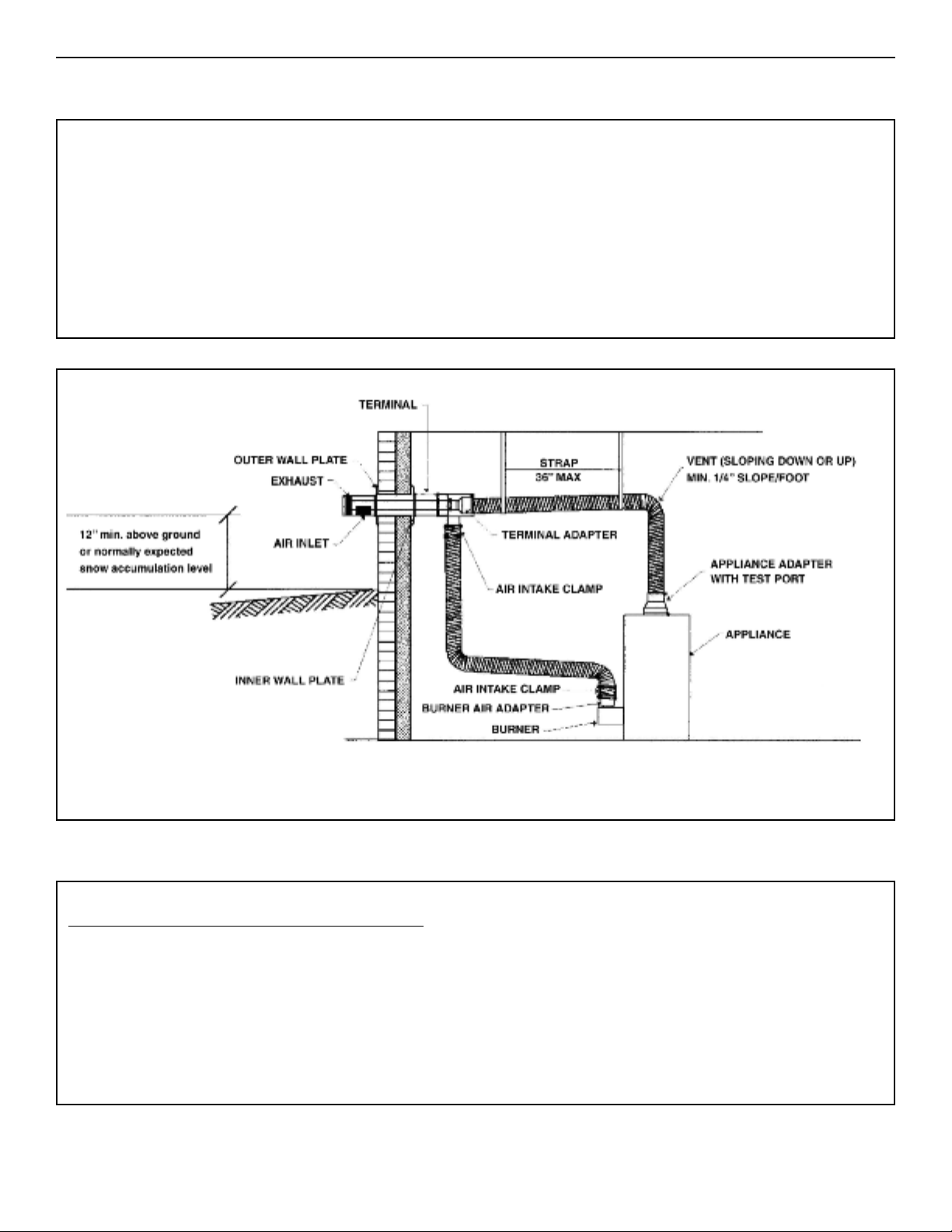

• All of the vent construction consists of suitable materials,

and terminates at an approved stainless steel hood.

• All of the vent piping must be sealed from air leaks.

• The vent pipe bend radius is 12 in.

• Brace metal strapping every 36 in. to support

vent pipe and prevent it from sagging.

• Follow the national codes for the installation of oil burning

equipment in USA-NFPA 31, in Canada CAN/CSA - B139

and local regulations.

PUBLICATION NO. TRDV40-V

Printed in U.S.A. 613

Part No. 43-2770

Page 2

2 TRDV SERIES

FLEX- VENT TERMINAL

FIGURE 2: Vent terminal installation locations

Page 3

TRDV SERIES 3

FLEX- L

Do not install vent terminals on prevailing wind wall side of structure.

Moisture and ice may form around terminal. Make sure the surface is in good

repair and protected from damage.

Slant/Fin models TRDV boilers can be installed on sealed or direct vented

systems. They must be ordered from the factory with an approved Direct Vent

System. Part numbers for the kits and accessories can be found on page 8 of

this manual.

NOTE: Vacuum Relief Valve (VRV) not shown. VRV must be located as shown

on page 8.

FIGURE 3: Typical installation

ADDITIONAL INSTALLATION CONSIDERATIONS (Figures 2 & 3)

1) Kit or system may vary based on specific needs of appliance.

2) Utilize the appliance adapter test port for combustion testing required by appliance manufacturers.

The vent terminal has a 0” clearance to combustibles

The insulator to vent pipe has 1” clearance to combustibles.

Page 4

4 TRDV SERIES

FLEX- L

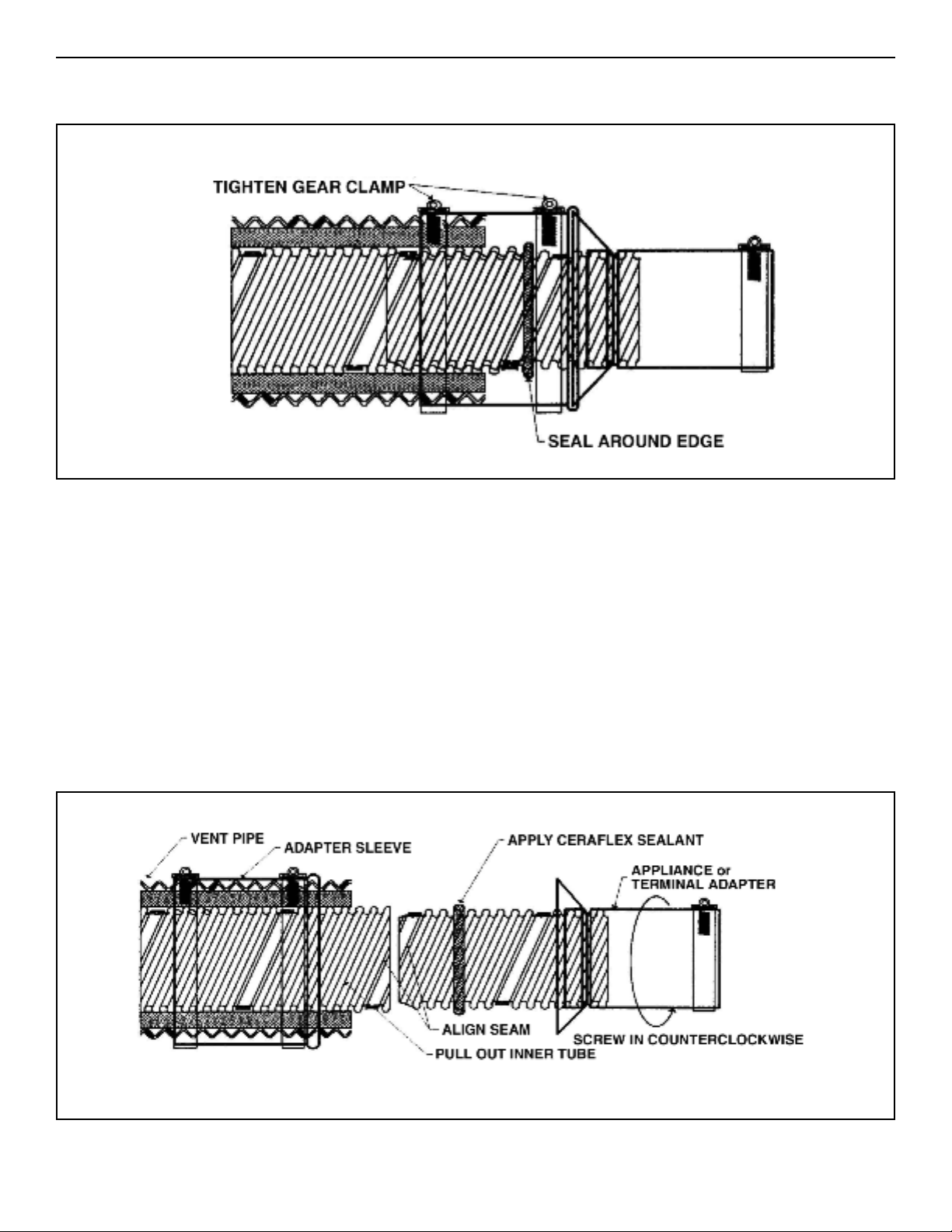

FIGURE 4: Joint assembly

INSTALLING THE JOINT ASSEMBLY

1. Loosen the gear clamps attached to the adapter sleeve and

slide the adapter sleeve over the vent pipe, Figure 4 and

Figure 5.

2. Pull the corrugated inner tube out of the vent pipe for easy

access and insert the adapter.

3. Apply sealant around the corrugated end of the adapter.

4. Align the flat seams at the end of both corrugated tubes and

insert the adapter into the vent tube. Screw the adapter into

the vent pipe with a counter-clockwise motion. The adapter

should be fully inserted into the inner vent tube until it’s tight.

The seams of both tubes must be aligned for ease of insertion.

If the adapter does not completely screw into the vent pipe,

unscrew it and try again as per Step #4.

5. Seal around the edge of vent pipe inner tube.

6. Slide the adapter sleeve back onto adapter and tighten the

gear clamps to complete the connection.

7. If the vent requires cutting to length, a fine tooth hacksaw can

be used. Remove any burrs and flare out the end of the inner

vent tube for easy installation of the adapter.

FIGURE 5: Joint assembly

Page 5

TRDV SERIES 5

FLEX- L

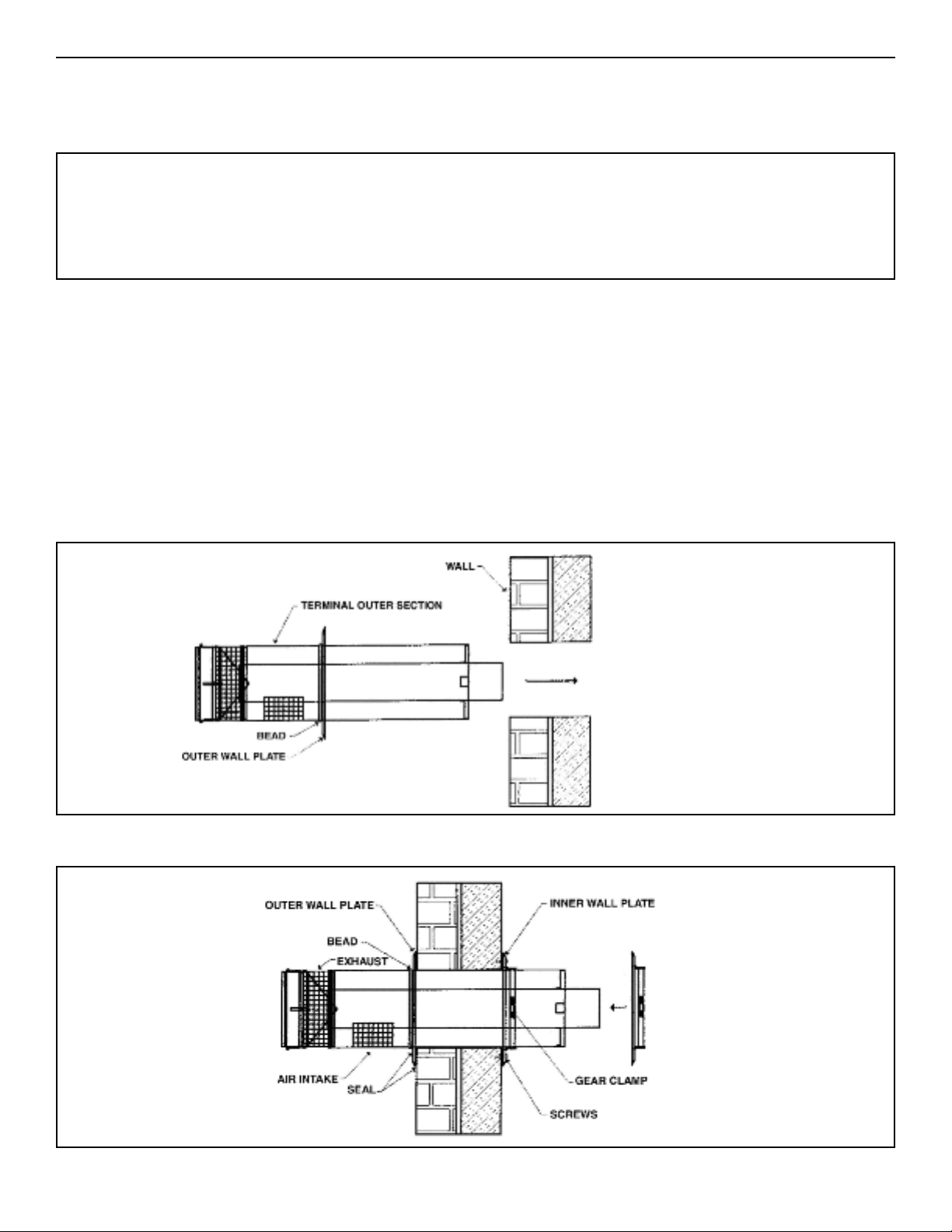

INSTALLING THE OUTSIDE TERMINAL

The maximum wall thickness be no more than 14 in. Contact Slant/Fin for recommendation in

case of a thicker wall.

The system is not designed for common venting. Use for a single appliance only.

Use Figure 6 and Figure 7 to complete the following steps.

1. Determine the terminal location.

2. Cut 8-1/4in. diameter hole through the wall (slightly

larger than the O-D. of the terminal)

3. Pull apart the inner and outer terminal sections.

4. Slide the outer wall plate over the outer section of the terminal

until it rests against the bead.

5. From the outside of the building, insert the outer section

through the hole until it resets against the wall.

6. From the inside of the building, slide the inner wall plate over

the outer and secure using the (4) screws.

7. Position the outer section so the seam on the flue collar is on

the top and the air intake on the bottom. Secure the outer

section by tightening the gear clamp around it. The gear clamp

is factory welded to the inner wall plate.

8. Seal with a weather proof sealant around the bead and edge of

the outer wall plate to prevent water from getting inside.

FIGURE 6: Vent terminal installation into wall

FIGURE 7: Vent terminal mounting

Page 6

6 TRDV SERIES

FLEX- L

CONNECTIONS TO THE OUTSIDE TERMINAL

Use Figure 8 and Figure 9 to complete the following steps.

1. Slide the inner section over the vent pipe.

2. Connect the inner adapter to the vent pipe as per joint

assembly.

3. Apply a bead of sealant around the terminal flue collar.

4. Slide the appliance adapter over the flue collar

. Tighten the gear clamp of the terminal adapter around the flue

5

collar.

6. Seal the seam in the adapter with sealant.

7. Slide the inner section over the outer section and secure by

tightening the gear clamp.

8. Air intake piping is field supplied and must be installed

according to local code requirements. Galvanized flue pipe or

Flex L air intake piping can be used. For optional Flex L air

intake piping, stretch the air intake flex to desired length and

slide over the air intake collar. Seal the connection with the aluminum tape and secure using air intake clamp. Beaded end of

Figure 7) the air intake clamp should go first over the air intake

(

collar.

9. All seams and gaps should be sealed. For the Flex L piping,

seal the gap between the vent pipe and the inner section with

silicone sealant.

FIGURE 8: Vent terminal to flue pipe connection

FIGURE 9: Connection to fresh air intake

Page 7

TRDV SERIES 7

FLEX- L

CONNECTIONS TO APPLIANCE

Using Figures 10 and 11 complete the following steps:

1. Connect the appliance adapter to the vent pipe as per joint

assembly.

2. Apply a bead of sealant around the appliance flue collar.

3. Slide the appliance adapter over the appliance flue collar.

4. Tighten the gear clamp of the appliance adapter around the

flue collar.

5. Seal the seam in the adapter with sealant.

6. Install burner air adapter.

7. Air intake piping is field supplied and must be installed according to local code requirements. Galvanized flue pipe or Flex L air

intake piping can be used. For optional Flex L air intake piping,

tretch the air intake flex to desired length and slide over the air

s

intake collar. Slide the end of the air intake piping over the burner

air adapter. Seal the connection with aluminum tape and secure

using air intake clamp. Beaded end of the air intake clamp

should go first over burner air adapter. See figures 12-13 on the

bottom of this page.

8. A vacuum relief valve must be installed on the air intake side of

the venting system. Locate the vacuum relief valve as close as

possible to burner inlet. Follow the vacuum relief (draft regulator)

manufacturer’s instructions for installation. See figures 14 and 15

for vacuum relief valve.

FIGURE 10: Connection to appliance FIGURE 11: Connection to appliance

Utilize the appliance adapter

test port for combustion testing.

FIGURE 12: Connection to burner

FIGURE 13: Connection to burner

Page 8

8 TRDV SERIES

FLEX-L VENT SYSTEM PART NUMBERS

FIGURE 14: Connection of vacuum relief valve

Item

S/F Part

umber

N

1 43-2771 Vent terminal (Flex L p/n CFT4) required

43-2785 Kit includes: 5 ft. length vent piping,

43-2786 Kit includes: 10 ft. length vent piping,

2

43-2787 Kit includes: 15 ft. length vent piping,

43-2788 Kit includes: 20 ft. length vent piping,

3

43-2779 Riello burner adapter-air intake (Flex L

43-2796 Vacuum relief valve 4” with tee

4

appliance adapter, terminal adapter

and 10 oz. tube silicone (Flex L p/n

CFK054-SF)

appliance adapter, terminal adapter

and 10 oz. tube silicone (Flex L p/n

CFK104-SF)

appliance adapter, terminal adapter

and 10 oz. tube silicone (Flex L p/n

CFK154-SF)

appliance adapter, terminal adapter

and 10 oz. tube silicone

(Flex L p/n CFK204-SF)

p/n CFBA34-RL)

(Field controls p/n 46257100)

Description

required

required

required

one

one

Optional vent system parts:

FIGURE 15: Vacuum relief valve

S/F Part Number

43-2793

43-2794

43-2795

Description

10 oz. tube silicone

3 oz. tube silicone

4” Air Intake Clamp

MAINTENANCE

For the appliance see the installation manual, TRDV-40, for the required maintenance. The vent system must be checked annually by a

qualified heating professional. Vent system must be sealed and the intake and exhaust opening clear of any obstructions.

FIELD CONTROLS VENT SYSTEM PART NUMBERS

Item S/F P/N Description Comment

1 47-0196 EC-16/ TRDV Direct Vent System of:

Field Controls FDVS-46 Direct Vent System &

Field Controls (P/N 46257100) Vacuum Relief Valve

2 43-2774 Field Controls 3-4" Riello Burner Adapter One

One

required

required

3 47-0197

47-0198

Field Controls FOVP-415 (15' of 4” Insultd. Vent Pipe)

Field Controls FOVP-410 (10' of 4” Insultd. Vent Pipe)

One

required

Page 9

TRDV SERIES 9

FIELD CONTROLS

FIELD CONTROLS VENT TERMINAL

Do not install vent terminals on prevailing wind wall side of structure.

Moisture and ice may form around terminal. Make sure the surface is in good

repair and protected from damage.

Slant/Fin model TRDV boilers can be installed on sealed or direct

vented systems. They must be ordered from the factory with an approved

Direct Vent System. Part numbers for the kits and accessories can be found

on page 8 of this manual.

Typical installation. Note: Vacuum relief valve (VRV) not shown. VRV must be located as shown on page 8.

Vent Terminal

Page 10

10 TRDV SERIES

FIELD CONTROLS

ITEMS INCLUDED IN KIT:

FDVS Direct Vent Termination

*VRV-4 Vacuum Relief Valve

Backing Plate

Installation Instruction

Sheet

**Bagged Hardware

**Cover Ring

**Cover Sleeve

**Appliance Adapter

**Adapter Clamp

*Not included in some models

**Included with FOVP (Flex Oil Vent Pipe)

for some models

The Field Direct Vent System (FDVS) is a non-powered positive pressure side wall vent termination system for use only with

specifically listed oil fired appliances. The system provides an outlet for exhaust gases and an intake for combustion air in a single concentric terminal. The FDVS termination is designed to direct the hot exhaust gases away from the structure using the static pressure generated by a special oil burner. All of the internal parts in contact with the flue gases are made from corrosion resistant 316L stainless

steel. The FDVS, with its built-in combustion air tee, allows connecting standard galvanized pipe from the FDVS termination to the air

intake of a special oil burner or by use of a Field Controls Airboot, depending on the model of the oil burner.

FIELD DIRECT VENT SYSTEM

Model: FDVS

!

WARNING:

This system MUST be installed by a qualified agency in accordance with the manufacturer’s installation instructions.

The definition of a qualified agency is: any individual, firm, corporation or company which either in person or through a representative is engaged in, and is responsible for, the installation and operation of oil appliances, who is experienced in such work,

familiar with all the precautions required, and has complied with all the requirements of the authority having jurisdiction.

!

WARNING:

· Read the installation instructions carefully and completely before proceeding with the installation.

· For continued safe operation, the appliance vent system combination is required to be inspected and maintained annually by

a qualified agency. Failure to properly maintain the appliance vent system combination can lead to Death, Personal Injury and

or Property Damage

!

WARNING:

1. Safety inspection of a venting system should be performed before and after installing a venting system on an existing or new

appliance. Procedures to follow are the latest version of those recommended by the National Fuel Gas Code, ANSI Z223.1,

UL-726, NFPA31, CSA B139, CSA B140.0.03 appliance manufacturer’s recommendations, or refer to the General Installation

Inspection section of this manual.

2. Plan the vent system layout before installation to avoid the possibility of accidental contact with concealed wiring or

plumbing inside walls.

Page 11

TRDV SERIES 11

(

a)

(

b)

(c)

(

e)

(g)

(c)

(c)

FIELD CONTROLS

Figure 16. End View

Model “L”

FDVS-4 7-1/4"

Diagram A

INSTALLATION OF FDVS DIRECT VENT SYSTEM

Installation of the Vent Termination

1. Remove vent system components from box and inspect for

damage. If the carton has been crushed or mutilated, check

components very carefully for damage. DO NOT install if

any damage is apparent.

2. Remove the combustion air tee assembly from the vent

termination. Set the tee aside for later use.

3. The location of the vent termination must be installed

according to all local codes that are applicable. In the USA

according to the latest version of the National Fire

Protection Association NFPA-31,National Fuel Gas Code

ANSI Z223.1. Where requirements for venting standards

differ the most stringent standard shall apply. In Canada

according to the latest version of CSA B140 and the

CSA B139 Installation Code. Refer to the following

requirements or See Diagram A for typical locations.

5. Seal the back side of the base plate around the outer pipe

of the vent termination with a bead of high temperature sili

cone sealant. (See Figure 17) Mount the vent termination

through the wall, keeping the outer pipe centered in the

hole. (See Figure 16) Fasten the vent termination to the out

side wall with appropriate fasteners. Seal the edges

of the vent termination base plate to the wall with a hightemperature silicone sealant.

6. Mount the backing plate over the outer pipe. Fasten the

backing plate to the inside wall with appropriate fasteners.

(See Figure 17) DO NOT BLOCK the intake or exhaust

openings, or the intake access panel on the vent

termination body. Wood or vinyl siding should be cut so that

the unit mounts directly on the wallboard to provide a stable

support. If the siding is greater than 1/2" thick use a spacer

plate or board behind the vent termination mounting plate.

(See Figure 17)

Table 1.

a. The exit termination of mechanical draft systems shall

not be less than 7' above grade when located adjacent

to public walkways.

b. A venting system shall terminate at least 3' above any

forced air inlet located within 10'.

c. The venting system of other than a direct vent appliance

shall terminate at least 4' below, 4' horizontally from, or

1' above any door, window or gravity air inlet into the

building.

d. The vent termination of a direct vent appliance with an

input of 50,000 BTU's per hour or less, shall be located

at least 9" from any opening through which vented

gases could enter the building. With input over 50,000

BTU's per hour, a 12" termination clearance shall be

required.

e. The vent termination point shall not be installed closer

than 3' from an inside corner of an L-shaped structure.

f. The vent termination should not be mounted directly

above, or within 3' horizontally from an oil tank vent or

gas meter.

Figure 17. Side View

g. The bottom of the vent terminal shall be located at least

12" above finished grade or expected snow line, which

ever is greater.

4. After determining the location of the venting system

termination (See Diagram A), cut a hole in the wall sized

according to “L” dimension in Table 1. (See Figure 16)

Page 12

12 TRDV SERIES

FIELD CONTROLS

INSTALLATION OF THE VENT TERMINATION

COMBUSTION AIR TEE

1. Assemble the combustion air tee assembly body to the vent

ermination outer pipe, and rotate to the desired position.

t

Attach the tee assembly body to the vent termination outer

pipe with at least 3 sheet metal screws evenly spaced apart

(not included).

. After completing

2

assembly of the

vent pipe to the

termination

nner pipe (Fig. 19),

i

apply the supplied

high temperature

sealant to the cover

pan around the

inner pipe, around

the joint between

the collar and the Tee assembly, and seal or

tape the joint from the FDVS Termination to the Tee assembly.

NOTE: The tee may be rotated into any position so that the collar

is in a convenient orientation.

CLEARANCE TO COMBUSTIBLES: FDVS Termination: 0",

FOVP Flexible Oil Vent Pipe: 1". These clearances are to maintained unless superceded by National and/or local codes

(see Step 3).

CONNECTING THE VENT PIPE FROM THE FDVS

TO THE APPLIANCE

1. The venting system should be installed and supported in

accordance with the latest version in the USA of the National

Fuel Gas Code ANSI Z223.1, UL-726, National Fire

Protection Association NFPA31, and in Canada CSA B140,

CSA B139 Installation Code or in accordance with any other

local codes or the authority having jurisdiction. Where

requirements for venting differ the most stringent standard

requirements shall apply. A vent pipe connector, designed for

positive pressure venting, shall be supported for the design

and weight of the material employed, to maintain clearances,

prevent physical damage and separation of joints. All joints

MUST be sealed, for positive vent pressure, to prevent flue

gas leakage into the structure.

2. Route the vent pipe from the appliance to the vent termination

using the minimum number of bends as possible. The last

horizontal section of the vent pipe should have a slight downward slope from the appliance to the vent termination. For

clearances to combustible materials and other installation

requirements, refer to the National Fuel Gas Code ANSI

Z223.1, UL-726, NFPA31, CSA B140, CSA B139 and/or any

applicable local codes.

3. The maximum length of vent pipe run for the EC-10DV boiler

series is 15 feet. The minimum diameter of the approved vent

pipe is 4" for the EC-10DV boiler series. Use a reducer or

increaser, if necessary, at the vent termination to connect the

vent pipe.

4. Support the Flexible Oil Vent Pipe (FOVP) at regular intervals

of maximum 36" spacing with appropriate strapping or hangers, per National and local code requirements. Do not install

screws into or otherwise penetrate any part of the vent pipe

under any circumstances.

Figure 18 - Top View

CONNECTING THE COMBUSTION AIR INTAKE PIPE FROM

THE FDVS TO THE APPLIANCE

1. Use 4" galvanized steel pipe or stainless steel pipe from the

DVS terminal combustion air tee collar to the appliance oil

F

burner combustion air inlet (or Air boot, if applicable.) Use a

reducer or increaser, if necessary at the burner combustion air

inlet to connect the combustion air intake pipe.

. The VRV should be installed close to the air inlet of the

2

burner, see fig. 14 on page 8.

GENERAL INSTALLATION INSPECTION

ecommended procedures for safety inspection of an appliance

R

should be in accordance with the latest version of the National

Fuel Gas Code ANSI Z 223.1, UL 726, and the National Fire

Protection Association NFPA 31 in the USA, CSA B140 and CSA

B139 Installation Code in Canada. The following procedure will

help evaluate the venting system. It is intended as a guide to aid

in determining that the venting system is properly installed and is

in a safe condition for continuous use. This procedure should be

recognized as a generalized procedure which cannot anticipate

all situations. Accordingly, in some cases, deviation from this procedure may be necessary to determine safe operation of the

equipment. If it is determined that a condition exists which could

result in unsafe operation, the appliance should be shut off and

the owner advised of the unsafe condition. Corrections must be

made before the appliance is put into continuous operation. The

following steps should be followed in making a safety inspection.

1. Visually inspect the venting system for proper size and deter

mine that there is no flue gas spillage, blockage, restriction,

leakage, corrosion, or other deficiency which could cause an

unsafe operation.

2. Place in operation the appliance being inspected. Follow the

lighting instructions and adjust thermostat so appliance will

operate continuously.

3. Determine that the burner is operating properly and that the

burner ignition operates satisfactorily by interrupting and

reestablishing the electrical power of the appliance in any

convenient manner. Test the burner safety device to determine

if it is operating properly by disconnecting the flame

safety circuit.

4. Test for spillage at the burner inlet air location around the VRV

after 5 minutes of operation. Use a draft gauge, flame of a

match or candle, or smoke from a cigarette, cigar or pipe.

Shut off appliance thermostat and check for spillage around

the VRV. If a flow reversal is noticed, house depressurization

is occurring and make up air is required.

MAINTENANCE

Inspect all vent connections annually for looseness, evidence of

corrosion, or flue gas leakage. Replace, seal, or tighten pipe

connections if necessary. As part of the yearly maintenance

schedule, remove the Intake Access Panel on the exterior of the

FDVS vent termination (See Figure 17) and remove any debris or

foreign material. Be sure to properly replace the panel.

Page 13

TRDV SERIES 13

FIELD CONTROLS

REFER TO PAGE 8 FOR VACUUM RELIEF VALVE CONNECTIONS AND VENT SYSTEM PART NUMBERS

APPLIANCE ADAPTER INSTALLATION:

1. Apply a bead of sealant to appliance collar approx. 1” from

end of collar (Figure 20).

2. Remove all oil and grease from the inside of the appliance

adapter, and apply a bead of sealant to inside of adapter ?”

from end (Figure 20).

3. With a twisting motion, assemble the appliance adapter onto t

he appliance collar.

4. Using a mallet and block of wood, drive the adapter onto the

appliance collar, using care to avoid damaging the appliance

collar or the adapter (Figure 21).

5. Assemble adapter clamp halves using the supplied 5/16” bolts

and square nuts, and install the appliance clamp onto the

adapter and tighten securely (Figure 20).

6. Install the supplied self-drilling, self-tapping anchoring screws

through the 4 holes in the appliance clamp into the appliance

collar (Figure 21). No pilot hole is required.

7. Apply sealant to the end of the adapter and anchoring screws.

(Figure 21).

8. After testing and burner adjustments have been made, apply

sealant to the supplied 3/8” sampling port plug screw and

install the screw in the sampling port (Figure 21).

9. Maintain the following clearances to combustibles. If the

appliance collar is within 18" of combustible material, wrap

minimum 1-1/2" ceramic insulation (installer-supplied) around

the exposed portion of the termination inner pipe and

appliance adapter (Figure 25).

Figure 19

Figure 20

Figure 21

Page 14

14 TRDV SERIES

FIELD CONTROLS

REFER TO PAGE 8 FOR VACUUM RELIEF VALVE CONNECTIONS AND VENT SYSTEM PART NUMBERS

JOINT ASSEMBLY: VENT PIPE TO TERMINATION

AND APPLIANCE ADAPTER

If necessary, the vent pipe may be cut to length with a hacksaw or

cut off saw.

CAUTION: Use safety glasses and other appropriate safety gear.

1. Pull outer vent pipe back 1”-2” from inner vent pipe end and

remove insulation (Figure 22).

2. Slide Cover Sleeve onto end of vent pipe a few inches back

from end of outer vent pipe (Figure 22).

3. Slide Cover Ring over stop bead on termination inner pipe or

appliance adapter (Figure 22).

4. Assemble inner pipe clamp halves using the supplied

and square nuts, and position inner pipe clamp

inner pipe (Figure 22).

5. Remove all oil and grease from end of termination inner pipe

or appliance adapter, and apply a bead of sealant to between

the stop bead and retainer bead (Figure 23).

6. Apply a thick bead of sealant to inside of inner vent pipe

from the end of pipe, working the sealant into the corrugations

(Figure 23).

7. Push the inner vent pipe onto the termination inner pipe or

appliance adapter all the way up to the stop bead.

8. Tighten the inner pipe clamp bolts until both clamp halves are

within 1/8" of each other at each end (Figure 24).

9. Slide the cover sleeve and cover ring together to engage the

ring in the groove of the sleeve, and tighten the cover sleeve

clamp (Figure 25).

10.To maintain 1" clearance to combustibles, wrap minimum

1-1/2" thick ceramic insulation (installer-supplied) around the

exposed portion of the termination inner pipe (Figure 25), and

secure with foil tape (installer supplied).

1

⁄4” bolts

1

⁄4” from end of

1

⁄2”

Figure 22

Figure 23

Figure 24

Figure 25

Page 15

TRDV SERIES 15

Notes:

Page 16

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...