Page 1

THERMATIC II CONTROL PANEL

Usage,

electrical connection

and start up instructions

Part No. 470902000

Page 2

2

CONTENTS

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1

.2 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. STARTUP OR RESTART AFTER A PROLONGED STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. CHOOSING THE OPERATING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Automatic operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Summer operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Manual operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. HEATING AND DOMESTIC HOT WATER SET TEMPERATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. SETTING THE TIME AND DAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7. PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

7.1 Factory programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.2 Program customization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. MESSAGES - ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. ISOMETRIC VIEWS AND SPARE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10. INSTALLER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11. WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12. INSTALLING USER-SYSTEM INTERFACE IN LIVING AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

13. INSTALLING USER-SYSTEM INTERFACE IN BOILER CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . .21

Page 3

3

The boiler must be connected by a qualified

p

rofessional. Strict compliance with these

usage, electrical connection and start up

instructions is a precondition for the correct

operation of the boiler.

1. GENERAL

1.1 Presentation

The E control panel with an Thermatic regulator

(user-system interface) to be fixed to the wall or

integrated into the boiler control panel can be used

for:

- automatic operation of heating when the ambient

temperature has been reached

- control of heating as a function of the outside temperature.

- regulation and programing of domestic hot water production (if it is present) with or without priority

- providing a frost free room temperature if the home is

empty. The duration of this period may be programed

up to 99 days.

The basic delivery of the T control panel comprises

- 1 T control panel

- 1 Thermatic regulator (user-system interface) with

support to be installed in the chosen room or to be included in the control panel.

- 1 boiler sensor measuring the water temperature in

the boiler

- 1 external sensor

Options

The following option can be ordered:

- domestic hot water sensor (package FM 45).

1.3 Technical characteristics

The T control panel can be used to program and regulate the room temperature as a function of the outside

temperature by controlling the burner. The boiler

thermostat must be set to a sufficiently high temperature for automatic regulation to operate correctly

The safety thermostat with auto reset (adjusted to

110°C/230°F) maintains operating safety.

In the case of domestic hot water (d.h.w.) production,

domestic hot water is regulated by the regulator acting

on the load pump giving priority to heating of domestic

hot water.

When a request is made for heating domestic hot

water, the domestic hot water priority stops the burner

and the d.h.w. load pump and stops the heating pump.

Under summer conditions, the boiler is not kept hot

between two domestic hot water loads. The domestic

hot water temperature is measured by the d.h.w.

sensor.

The regulator includes the possibility of a "antilegionellosis" protection.

1.2 Operating principle

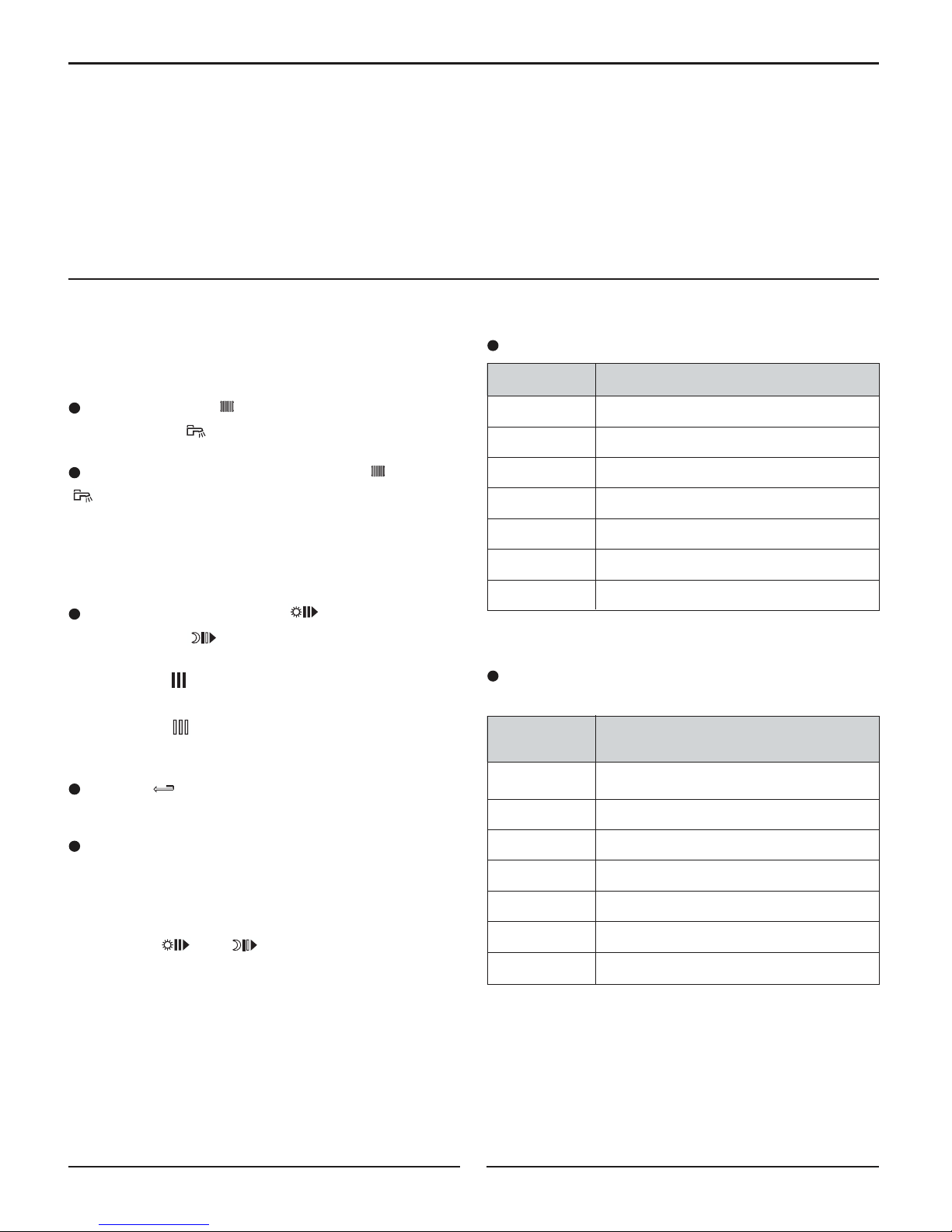

Temperature Resistance

in °C / °F in Ohm

- 20°C / -4°F 2 392 Ω

- 16°C / 3°F 2 088 Ω

- 12°C / 10°F 1 811 Ω

- 8°C / 18°F 1 562 Ω

4°C / 25°F 1 342 Ω

0°C / 32°F 1 149 Ω

Temperature Resistance

in °C / °F in Ohm

4°C / 39°F 984 Ω

8°C / 46°F 842 Ω

12°C / 54°F 720 Ω

16°C / 61°F 616 Ω

20°C / 68°F 528 Ω

24°C / 75°F 454 Ω

- Electrical power supply: 120V - 60 Hz

- Clock operating capacity: 2 years minimum

- Resistance of the external sensor in Ω (option)

- Value of water sensors in Ω

Temperature Resistance

in °C / °F in Ohm

0°C / 32°F 32 014 Ω

10°C / 50°F 19 691 Ω

20°C / 68°F 12 474 Ω

25°C / 77°F 10 000 Ω

30°C / 86°F 8 080 Ω

40°C / 104°F 5 372 Ω

Temperature Resistance

in °C / °F in Ohm

50°C / 122°F 3 661 Ω

60°C / 140°F 2 535 Ω

70°C / 158°F 1 794 Ω

80°C /176°F 1 290 Ω

90°C / 194°F 941 Ω

- EC-10, EC-20 and EC-100.

Page 4

4

2.

DESCRIPTION

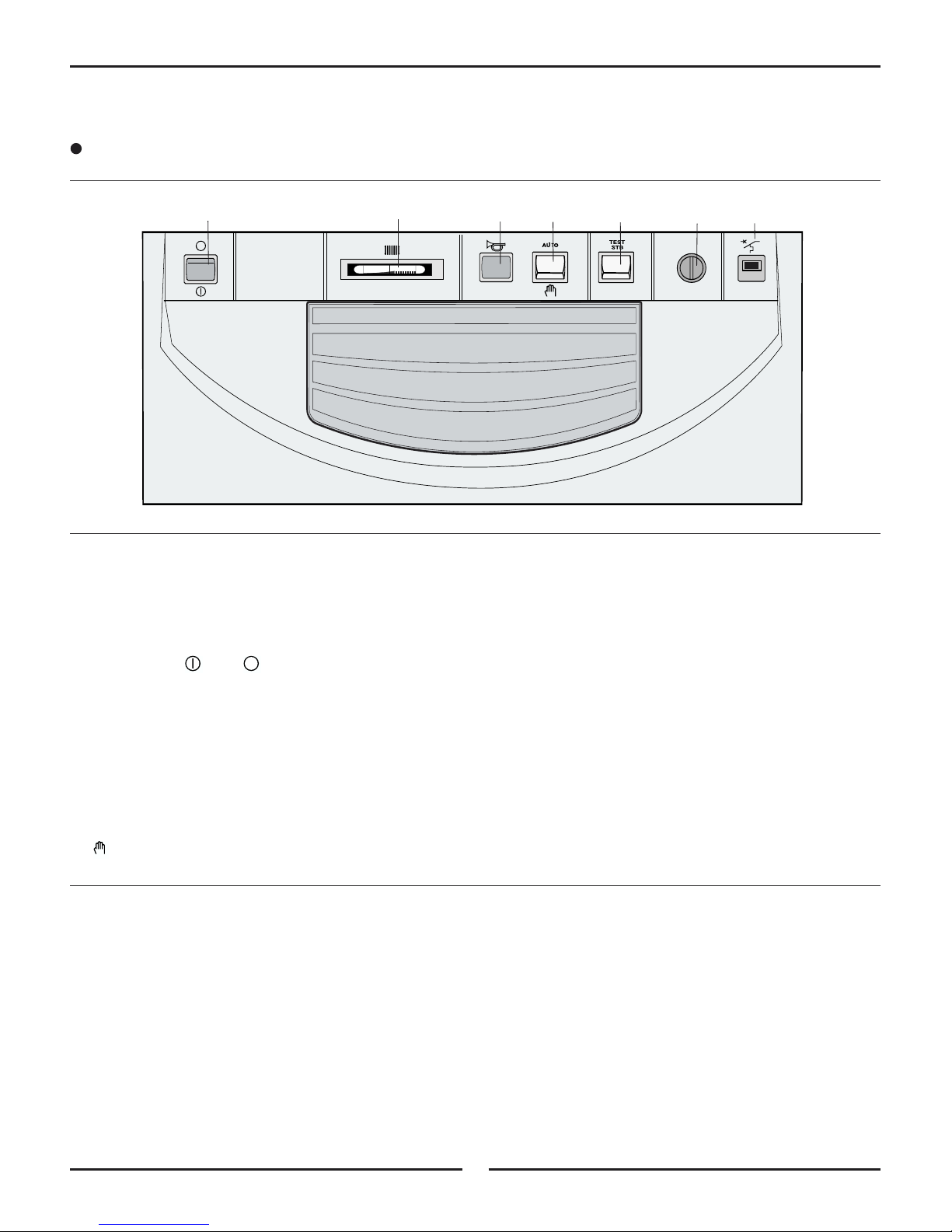

Control panel

0

I

6A

20°C40

8578N007

A. Timed circuit breaker (6 A)

B. Safety HIGH LIMIT with auto reset

(Set to 110°C / 230°F)

C. Power/Main /Off switch.

Note:we recommend leaving the boiler on during the

summer, particularly so that the heating pump cleaning function can remain in operation. It is preferable

to use "summer" mode for the period during which the

heating is to be cut off.

D.

2-position switch

AUTO : automatic operation

(manual) : forced operation

E.

"Test-STB" push button

When pushed and held in, safety

HIGH LIMIT

tests

and cutoff of the heating pump.

F. A larm light

This light is disabled.

H. Boiler temperature gauge

C

F

D

EBA

H

Page 5

5

3. STARTUP OR RESTART AFTER A PROLONGED STOP

0

I

6A

20°C40

8

578N007

STANDARD

MODE

PROG

PROG

+

-

1

234567

024

6810

1

2

141618 20 22

24

8575N078

Initial starting up shall be performed by the installer.

Before turning the boiler on, make sure that the install

ation is filled with water. Startup in the chronological

order described below:

C

D

B

6

1

5

7

The set temperature of the heating circuit and the

domestic hot water average storage temperature (if

there is an indirect d.h.w. tank) can be adjusted at

any time using key 1 (see chapter 4).

Select the operating mode using keys 5, 6 and 7

(see chapter 2).

Customize the heating program and the d.h.w. program

as you wish if you have domestic hot water production

(see chapter 6).

Check that the switch D is in the AUTO position.

Put the On/Off switch C into the On position.

Note

For production of domestic hot water (d.h.w. sensor

connected), an automatic bleed sequence is carried

out of the indirect d.h.w. exchanger for one minute by inter-

mittent operation of the domestic hot water pump and

the heating circulator pump, before changing to auto-

matic operation mode.

This bleed sequence is only activated if the indirect d.h.w.

tank temperature is greater than 25°C / 77°F.

Page 6

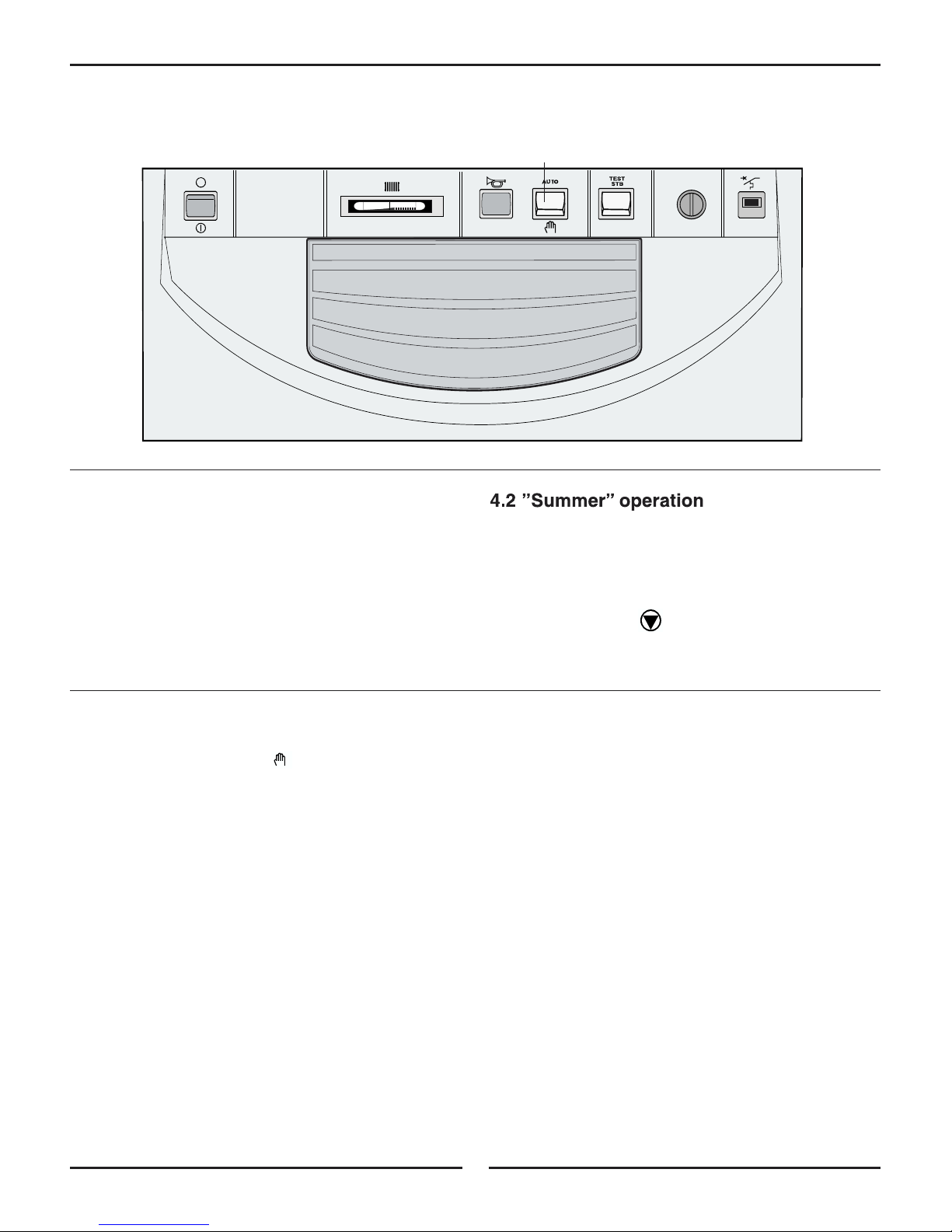

4. CHOOSING THE OPERATING MODE

D

Put the switch D in the AUTO position.

This position enables automatic regulation and

operation by the Thermatic regulator.

4.1 Automatic operation

0

I

6

A

2

0

°

C

4

0

8578N007

4.3 Manual operation

Put switch D to its position .

This position may be selected to make the boiler setting, for example, or if there is a problem with the electronic regulation:

- the burner is put into forced operation

- the boiler will operate according to the set temperature

at the regulator.

- the heating pump and the domestic hot water load

pump (if there is an indirect d.h.w. tank) are started the display is off.

Heating is automatically cut off during the summer

when the outside temperature is higher than the ”comfort” temperature setting for 2 hours.

The display remains identical, but the circulator pump is

permanently off.The symbol is no longer displayed.

Heating is started again when the outside temperature drops below the ”comfort” temperature for 2 hours.

6

Page 7

7

STANDARD

MODE

PROG

PROG

+

-

1234567

024

68101214

1

6

18 20 22

2

4

8575N078

4

2

6

1

5

7

3

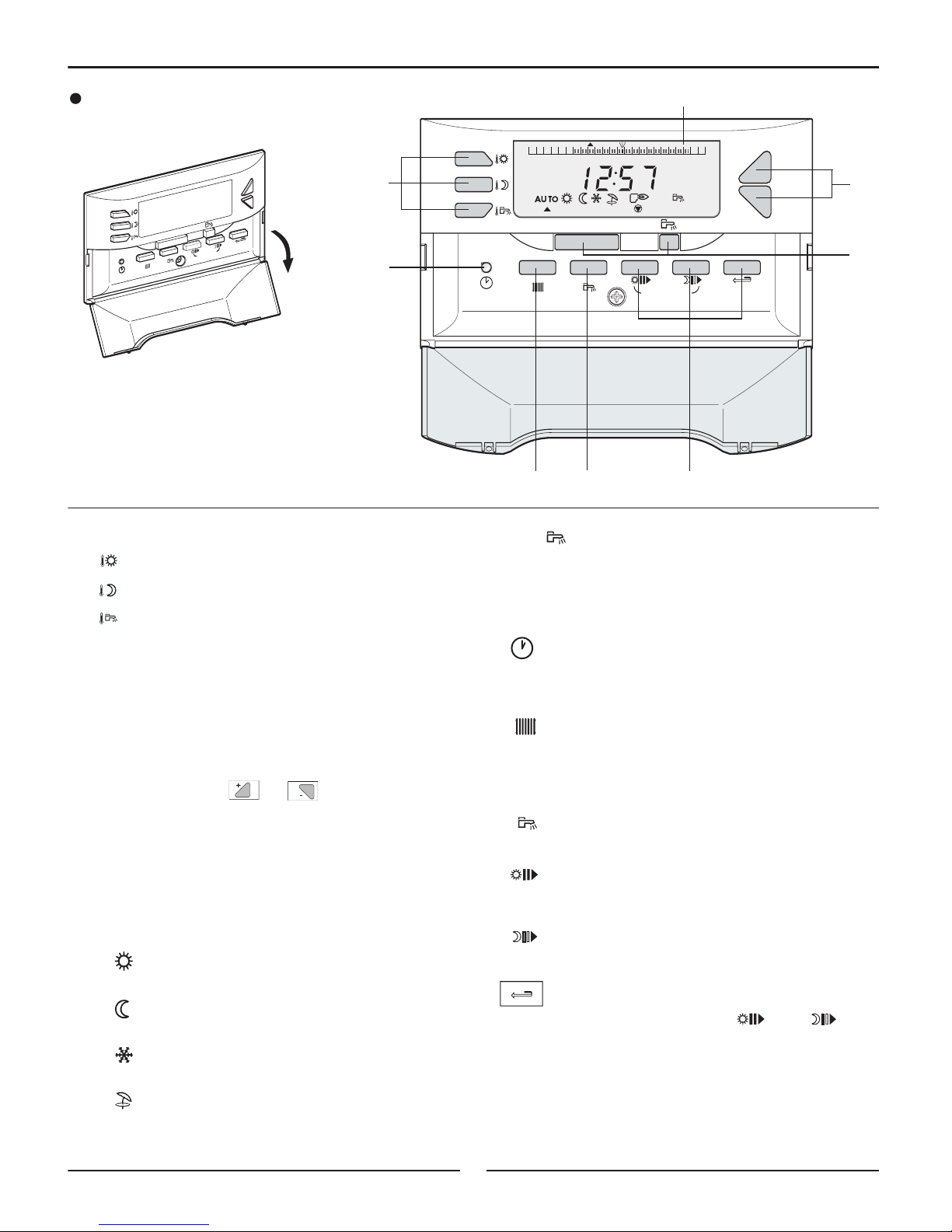

Thermatic regulator (user-system interface)

Flap open

1. Temperature adjustment keys (green keys)

"comfort" temperature

"low" temperature

"domestic hot water" temperature (if an

indirect d.h.w. tank is connected)

Note

When one of these keys is pressed:

- the active time program corresponding to the circuit is displayed in the graphic bar

- the measured temperature is displayed at the right

of the display.

2. Adjustment keys or (blue keys)

3. Operating mode selection keys (grey keys)

MODE key

To s elect one of the following operating modes:

AUTO : operation according to the time pro-

gram

:forced operation at comfort tempera-

ture until midnight

:forced operation at reduced tempe-

rature until midnight

: frost free operation during the pro-

grammed time

:stop manual heating, production of

domestic hot water only (if an indirectd.h.w. tank is connected)

Key

To fo rce heating of the domestic hot water tank outside the d.h.w. time program (if an indirect d.h.w. tank

is connected).

4. Time and day adjustment key

5. Key to adjust the heating program

PROG

6. Key to adjust the indirect domestic hot water tank

program

PROG

7. Programing keys

write (in 1/2 hour periods) the “comfort”

period or the indirect d.h.w. tank heating allowed

period (dark area)

write (in 1/2 hour periods) the “low”

period or the indirect d.h.w. tank heating not

allowed period (light area)

return to the program graphic bar

Simultaneously press the and keys

(STANDARD) for 5 seconds to reinitialize

programs to factory settings: heating and

d.h.w. from 6 a.m. to 10 p.m.

8. Program display graphic bar (12 a.m. to 12 p.m.)

"Comfort" periods are displayed in black bars at

programmed "comfort" times in the graphic bar.

S

T

A

N

D

A

R

D

MO

D

E

P

R

O

G

P

R

O

G

+

-

1

2

3

4

5

6

7

8575N077

8

Page 8

8

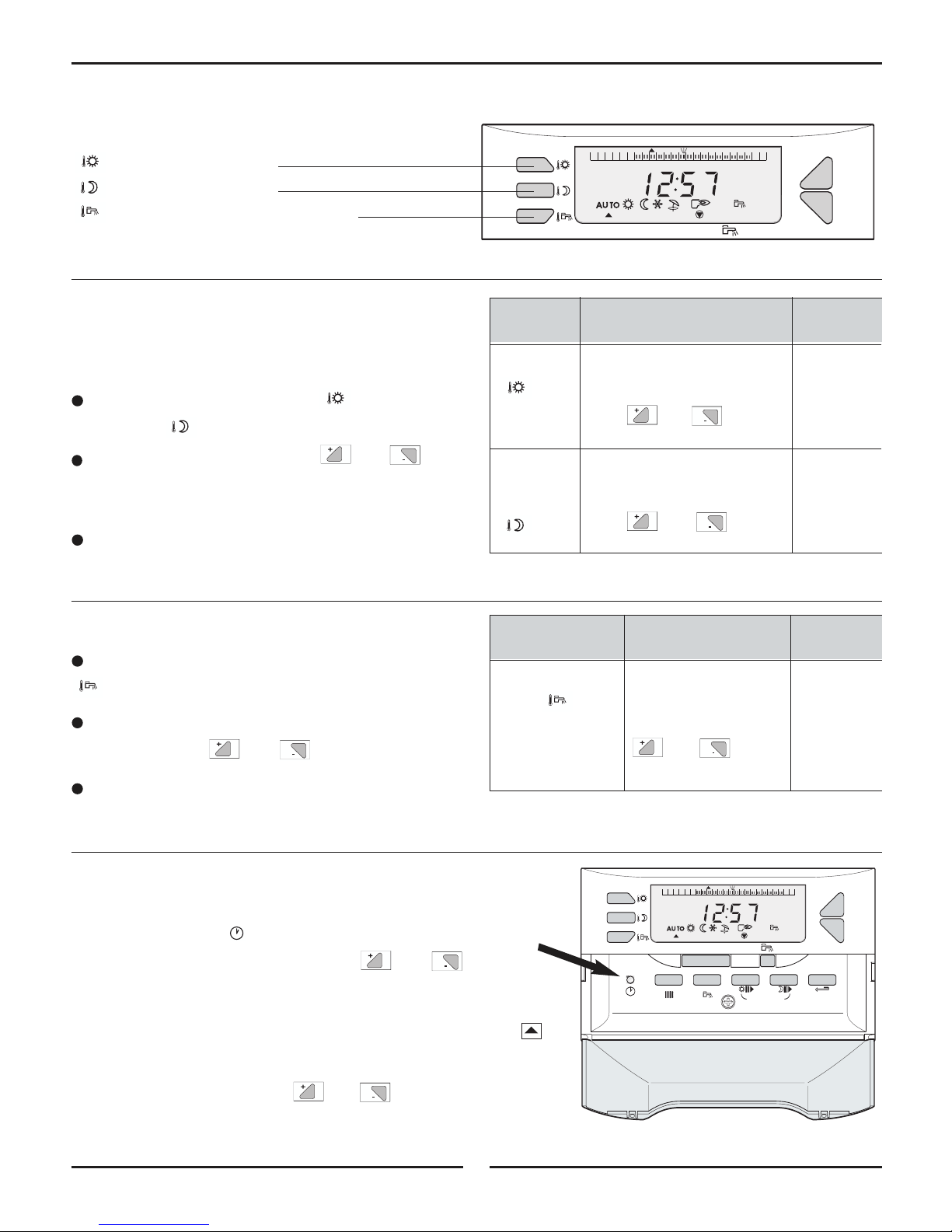

MODE

+

-

1234567

024

6810

1

2

14

1

6

18 20 22

2

4

5. HEATING AND DOMESTIC HOT WATER SET TEMPERATURES

8

575N079

Heating set temperature

Temperatures for "comfort" periods (dark area in the

graphic bar) and for "reduced" periods (light area in the

graphic bar) can be adjusted as follows:

Select the comfort temperature or the reduced

temperature .

Adjust the temperature using the and keys.

Note: the graphic bar displays the heating program for

the current day for the displayed circuit.

End of setting: after the setting is completed, the

normal display reappears after 2 minutes or when the

MODE key is pressed.

Indirect d.h.w. tank set temperature

Select the domestic hot water temperature using the

key.

Adjust the average domestic hot water storage tem-

perature using the and

keys.

End of setting: after the setting is completed, the

normal display reappears after 2 minutes or when the

MODE key is pressed.

Tem pe-

Setting range

Factory

gnitteserutar

Domestic hot

10°C to 80°C / 50°F to 175°F

water Adjustment in steps of

55°C / 130°F

(average 1°C / 5°F using

storage

and

temperature)

Tem pe-

Setting range

Factory

gnitteserutar

Comfort 5 to 30°C / 41°F to 86°F

Setting in steps of 0.5°C / 1°F 20°C / 68°F

using and

Reduced 5 to 30°C / 41°F to 86°F

temperature

Setting in steps of 0.5°C / 1°F 16°C / 60°F

using and

6. SETTING THE TIME AND DAY

STANDARD

MODE

PROG

PROG

+

-

1234567

024

6

810121

4

16

1

8 20 22

24

-Open the flap.

-Press the clock key using the tip of a ball point pen and then

adjust the time and the day using the and keys.

Press once to make a minute by minute setting.

Press again for hour by hour setting.

Press a third time for day by day setting by putting the arrow

in the graphic bar from 1 to 7 (1 = Monday)

Note:

A prolonged press on the or key increases the

scrolling speed.

A fine setting can be made by making short presses.

8575N078

Note: if there is no domestic hot water sensor, pressing this key has no effect.

:

”comfort” temperature

:”reduced” temperature

: "domestic hot water" temperature

Page 9

9

Days

D.H.W. heating

allowed

Monday

Tu esday

Wednesday

Thursday

Friday

Saturday

Sunday

7. PROGRAMING

7.1 Factory programing

Heating program

M

onday to Sunday: 6 a.m. to 10 p.m. : Comfort period

Indirect domestic hot water tank program

Monday to Sunday: 5 a.m. to 10 p.m. : Loading allowed

7.2 Program customization

Enter customized programs in the adjacent tables,

then save them as follows:

Press the PROG key to select the heating pro-

gram or PROG to select the d.h.w. program.

Select the day by pressing the PROG or PROG

keys several times.

Note:the program chosen for every weekday is automatically copied to other days but it can be modified

individually day by day.

Write dark areas using the key and write light

areas using the key (1/2 hour by 1/2 hour).

- Dark areas are applicable to "comfort" heating

or tank heating allowed periods.

- Light areas are applicable to "reduced" or

Indirect d.h.w. tank heating not allowed periods.

Use the key to come back in the event of any

error.

End of programming: Press the MODE key. Otherwise,

the program will be validated automatically after 2

minutes.

Note

Pressing the and keys simultaneously (STANDARD) for 5 seconds reinitializes the programs to the factory settings indicated in § 6.1 above.

Customized programs

HEATING PROGRAM

INDIRECT DOMESTIC HOT WATER TANK

PROGRAM DHW

Day

"Comfort" period

Monday

Tu esday

Wednesday

Thursday

Friday

Saturday

Sunday

Page 10

10

In the event of any malfunction, the following messages may appear on the display:

YDEMERESUACELBABORPTLUAFEGASSEM

AALL 5

5

5

5

55

00

Boiler sensor The corresponding Switch off the electrical power supply to the boiler using the

AALL 11

External sensor sensor On/Off switch to erase this message, and inform your fitter.

AALL 22

D

.h.w. sensor circuit is broken

However, you can operate the part of the installation concerned

AALL AA

R

oom sensor or is short circuited in ”Manual” mode. See comments below.

8. MESSAGES - ALARMS

AALL 00

and

AALL 11

The entire installation automatically changes to

”Manual” mode

- The heating circulator pump runs permanently and the

valve is no longer regulated electrically. It may be control-

ed manually if necessary.

AALL 22

The domestic hot water is no longer heated automatically. You can continue to produce domestic hot water

by changing to manual conditions using the ”AUTO/

” switch - see chapter 3. The d.h.w. heating temperature is equal to the boiler temperature.

AALL AA

Automatic operation in configuration without room

sensor.

Note:

If a fault occurs in a sensor, the installation continues to

operate with the following limitations and displays:

5

5

Page 11

Note : when ordering spare parts, do not forget to provide the code number given in the list opposite the part reference.

11

9. ISOMETRIC VIEWS AND SPARE PARTS LIST

Page 12

DHW SENSOR OPTION ( PACKAGE FM 45)

THERMATIC control panel

990

992

995

994

993

991

85757740A

EXTERNAL SENSOR

85757741

951

950

952

12

Page 13

13

T control panel

CONTROL PANEL

1 8578-7001

Complete Thermatic control panel

2 8578-8506 Complete Thermatic card cover

3 9786-4039 Thermatic front panel

4 9532-5027 Green On/Off two-pole switch

5 8500-0035 Two-pole switch

6 9532-5028 Moment inverter two pole switch

7 8500-0032 110°C safety thermostat

8 8500-0002 30-90 °C setting thermostat

9 9752-5181 Setting button

10 9534-0288 Circuit breaker 4A TS710/4A

11 9536-5147 Flat thermometer

12 9521-6220 Red light

13 8806-7511 Thermatic module CDC 2 (user-system interface)

14 9655-0352 WSBH-2 harness fastening

15 8575-8019 Board supports

16 8578-4905 D.H.W. harness

17 8578-4906 Burner cable

18 8806-5565 Thermatic relay board

19 8575-4905 3-pin connector power supply

20 8575-4922 4-pin connector power supply VA+CS

21 8575-4924 Pump 3-pin connector A/VS

22 8575-4918 2-pin connector boiler sensor

23 8575-4911 EPT2-pin connector room sensor

24 8575-4928 EPT connector RT

25 8575-5520 Control panel screw bag

26 9655-0357 8-pin flat cable L = 300

27 8575-4918 KVT 60 sensor - length 1 m

EXTERNAL SENSOR

950 8575-7741 External sensor (Package FM46)

951 9536-2450 External sensor AF60

952 8575-4906 2-pin external sensor connector

DHW SENSOR OPTION (PACKAGE FM 45)

990 8575-7740 D.h.w. sensor (Package FM 45)

991 8575-4935 Installed d.h.w. sensor

992 8575-4909 D.h.w. sensor 2-pin connector

993 9536-2448 KVT 60 sensor L = 5M

994 8575-4925 2-pin external connector d.h.w. sensor

995 9536-5613 Contact spring for thimble tube

Mark. Code No. DESCRIPTION Mark. Code No. DESCRIPTION

10/09/03

Page 14

14

ASSEMBLY,ELECTRICAL CONNECTIONS & INSTALLER SETTINGS

T control panel

This page is reserved for use by the installer

•

Assembling the control panel

Refer to the assembly sheet provided with the

boiler instructions.

•

Installing the boiler sensor

Refer to the assembly sheet provided with the

boiler instructions.

1/

2

H

H

(2.5 m min.)

1/

2

Z

Z

1/

2

H

(2.5 m min.)

H

8800N001

Installation :

The outside sensor is fixed to the outside wall using the

supplied accessories: (wood screws + inserts).

8800N002A

8800N003

Positions to be avoided:

•

Installing the outside sensor

The outside sensor is installed on the outside wall adjacent to the heated area. It must be easily accessible.

H

:inhabited height to be checked by the sensor

:recommended position on a corner

:possible position (if difficulties are encountered)

Z

:inhabited area to be checked by the sensor

The sensor must be placed on the outside wall so that

it is directly influenced by weather variations, but is not

directly influenced by solar radiation.

10. INSTALLER SECTION

Page 15

15

Electrical connections shall be carried out

by a qualified professional only.

The electrical wiring has been carefully

checked in the factory and the internal

connections of the control panel must not

be modified in any event.

Electrical connections shall be made respecting the

information given on the electrical diagrams delivered

with the equipment and the directives given in the

instructions.

The electrical connection must comply with applicable

standards and regulations in force.

ELECTRICAL CONNECTIONS

All connections are made on the 4x4 junction box

provided for this purpose on the top of the boiler.

The connecting cables may be brought inside the boiler through the cut-outs provided in the boiler back

panel, which may be used along with purchased cable

channels.

Fasten the sensor cables to the rear plate of the control

panel by means of a cable clamp (cable clamp supplied

in a separate pack) after mounting them on the plate.

IMPORTANT: The maximum current that can be

switched per output is 450 W inrush current less than 16 A.

Sensor cables must be separated from

cables in 120V circuits.

- In the boiler: use cable clamp on the boiler for

this purpose.

- Outside the boiler: use a minimum distance of

4 in. (10 cm) between them.

EC-10 / EC-100

•Installing options

Refer to the instructions delivered with the option.

Sensor

connection

side

120V connection side

Page 16

16

Basic connections

3 x 1,5 mm

2

mini.

3 x 0,75 mm

2

mini.

3 x 0,75 mm

2

mini.

L

A

N

R

E

T

X

E

S EXT

o o

15 14

O

B

D.H

.W.

AN

ODE

SY

STE

M

R

E

L

I

S CH

17 16

o o

M

O

D

O

H

C

I

T

S

E

WT

R

E

T

A

S ECS

19 18

o o

O

R

M

O

A

T

I

U

C

R

I

C

S AMB

A

o

21 20

o

ALI

12345CS67LN8910111213

o

232

2

O

H

P

E

L

E

T

Y

A

L

E

R

E

N

o

o o

15 1417 16

o o

19 18

o oo

21 20

o

3567LN8910111213

o

232

2

o

o o

15 1417 16

o o

19 18

o oo

21 20

o

567LN8910111213

o

232

2

o

o o

15 1417 16

o o

19 18

o oo

21 20

o

S

ENSOR

z

H

0

6

V

0

2

1

Y

L

P

P

U

S

N

I

A

M

O

C

Y

T

E

F

A

S

T

C

A

T

N

67

LN

M

U

P

G

N

I

T

A

E

H

P

8910

O

L

M

U

P

D

A

P

111213

D

N

I

M

R

A

L

A

O

T

A

C

I

R

o

232

2

o

8578N008

S

EXT

2 1

C Alim

L

S

CH

2 1

S

ECS

2 12 1

S

AMB A

2 1

2 1

2 x 0,75 mm

2

mini.

1

20V - 60Hz

LN

VA

(

A)

LN

LN

Sensor cables must be separated from

cables in 120V circuits (see page 15).

independent

d.h.w.

hot water

Boiler

sensor

Circulator

120V power

supply

Load pump

(indirect d.h.w. tank)

d.h.w.

sensor

External

sensor

(CIRCULATOR)

(INDIRECT D.H.W. TANK)

T

A

T

A

11. WIRING DIAGRAMS

Page 17

Page 18

Wiring Diagram

Beckett, Heatwise and some Carlin Burners

18

Page 19

Wiring Diagram

s

Riello and some Carlin Burner

19

Page 20

20

12. INSTALLING THE THERMATIC REGULATOR (USER-SYSTEM INTERFACE) IN THE LIVING AREA

S

TA

NDAR

D

MOD

E

PRO

G

PROG

+

-

1

2

3

4

5

6

7

1

2

4

3

5

Close off

the cable

inlet

opening

2. Attachment of the wall support and the electrical connection

200

1500

8800N036

8575N083

Pull down the terminal box cover.

Loosen the central screw by a few turns, if screw

on version, snap out if snap-in version.

Remove the control part.

Attach the wall support using the two screws

and inserts provided for this purpose.

Connect either a 2-wire telephone cable or an

electrical cable with a cross-section of up to 2 x

1.5 mm

2

on the 2-pin connector. The wires can be

reversed.

Reassemble the control part, performing the same

operations as for disassembly in the reverse order.

5

4

3

2

1

The remote control will be installed adjacent to an

internal partition, about 4 1/2 feet above the floor in a

judiciously chosen "control" room.

Locations in the room that are not recommended

Enclosed, exposed to solar radiation, heated by a flue

duct, exposed to cold or hot air currents in ventilation

ducts, close to an open fireplace, a heat source (television), behind a wall or a curtain.

1. Choose the position

- Measure the ambient temperature in the room in

which the regulator is stored, using a thermometer.

- Press the and keys simultaneously for

5 seconds.

- Use or to adjust the correction to make

the display match the thermometer measurements.

3. Room sensor calibration

STANDARD

MODE

PROG

PROG

+

-

1234567

8578N010

024

6810

12

141618 20 22

24

Page 21

21

S

T

A

NDA

RD

MOD

E

PRO

G

PRO

G

+

-

1

2

3

4

5

6

7

0

I

6

5

4

3

7

9

20°C40

8575N084C

2

1

4 4

7

6

55

3

• Electrical connection

Insert a flat screwdriver into the slot provided for this

purpose to release the top attachment tab.

Tilt the cover and remove it.

Insert the flat connection cable in the middle of

the back part.

Attach the back part of the Thermatic regulator to

the two notches.

4

3

2

1

Carefully clip the connector onto the P.C.B.

The tabs on the base are different

widths so that an inverted connection

is impossible.

Screw the back part of the regulator to the control

panel.

Fix the front part of the regulator to the back part,

by tightening screw, if screw-on version, or snap-in

if snap-in version.

7

6

5

13. INSTALLING THE THERMATIC REGULATOR (USER-SYSTEM INTERFACE) IN THE BOILER CONTROL PANEL

If you do not want to install the Thermatic regulator in

a living room, you can install it in the boiler control

panel by proceeding as follows.

In this case, you must install and

connect the external sensor to the

control panel (see above section :

Installing the outside sensor).

Page 22

22

"INSTALLER" SETTINGS

Settings

The various adjustable settings are given in the order

in which they appear in the "Installer settings table"

below.

The settings are displayed by pressing the clock

and

PROG

Heating Program keys under the flap for

5 seconds.

When you have finished, the data are stored after 2

minutes or when you press the MODE key.

STANDARD

MODE

PROG

PROG

+

-

1

234567

024

6

810

1

2

1

4

1

6

1

8 20 22

2

4

8575N078

T

he settings given below are applicable to

various functions and the installation configuration. They can only be modified by qualified professional.

N

ote:

The various parameters and settings are memorized

even after a power failure.

STANDARD

MODE

PROG

PROG

+

-

1

234567

024

6

810

12

1

4

1

6

1

8 20 22

2

4

8578N011

Access the installer level by simultaneous

pressing for 5 seconds

Page 23

23

Installer settings control panel

for 5 seconds

PROG

PROG

PROG

PROG

PROG

PROG

PROG

PROG

PROG

PROG

PROG

PROG

PROG

Press Parameter

number Item Factory setting Setting range

1

.

Boiler temperature measurement / /

3

.

4ot05.1tneidargtiucricrelioB

5

..

Maximum temperature of the heating 75°C / 170°F 40 to 90°C

F°002ot001tiucric

/

7

..

dekcolb=0

1

1

ytivitpada-fleS

desaeler=1eludomlortnoccitaTherm ehthtiwylno(

installed in the heated volume)

8

..

Influence of the ambient sensor 0 to 10

(only with thermatic control module installed

3 0 to 10

in the heated volume)

9

..

=

Pump runs continuously.

0

1 =

Pump cycles with thermostat.

10

11

12

13

14

15

16

..

Frost free ambient set temperature

(only with room sensor influence 6° C / 43°F 5 to 20° C / 40 to 70°F

not equal to 0)

..

Frost free external set temperature -3°C/-38°F Can turn “OFF” by setting

..

ytiroirp-non=01retawtohcitsemodotytiroirP

ytiroirp=1). tankw.h.dh indirecttiwylno(

..

Protection against legionellosis 0 0 = deactivated

(only with indirect d.h.w. tank)

1 = activated

..

Timeout for stopping heating & d.h.w.pumps 4 min. 0 to 10 min.

..

CTRL number of the CDC memory

..

CTRL number of the CPU memory

Pump Logic (only with Thermatic control

module installed in the boiler control panel)

If Control Panel, does not respond as it should, then you may need to perform a Total Reset. To perform a Total

Reset Procedure, push simultaneously the following 3 buttons (until the LCD displays Reset):

, MODE and .

to -8°C/-16°F

Page 24

24

Parameter 3

HEATING CIRCUIT GRADIENT

- the gradient of the boiler circuit is set to 1.5 in the

factory

Further information about various parameters

Parameter 5

MAXIMUM HEATING CIRCUIT TEMPERATURE

The supply temperature for the heating circuit can be

limited.

Note

If the maximum temperature is modified, also modify

the boiler thermostat stop that limits the maximum boiler temperature at 75°C / 167°F if necessary.

This is done by removing the thermostat button by pulling it and moving the stop inside the hole with pliers

to make it correspond to the required limiting temperature.

Important

If the installation is used without an external sensor,

we recommend that the maximum temperature of the

heating circuit should be set to a value less than or

equal to 75°C / 167°F for a conventional installation.

Parameter 1

BOILER TEMPERATURE

To d isplay the boiler water outlet temperature.

Parameter 7

SELF AD APTIVITY

-Free (setting 1): automatic adjustment of the heating

curve is allowed.

- Blocked (setting 0): the heating curve is fixed. It can

only be modified manually.

Parameter 8

ROOM SENSOR INFLUENCE

To e nable adjustment of the influence of the room sens

or on the boiler water temperature.

0 :the room sensor is ignored

(for example remote control badly positioned)

1 : taken into account slightly

3 : taken into account medium amount (recom-

mended)

10 :operation as room thermostat

Parameter 9

PUMP LOGIC

To s elect one of the following functions for operation if

the room sensor is ignored.

- (Setting 1): Pump cycles with thermostat. Control is

set at factory at (setting 1).

- (Setting 0): Pump runs continuously. Use this setting

ONLY in special cases.

Note

This parameter is not displayed if there is a room sensor in the circuit.

Parameter 10

ROOM FROST FREE TEMPERATURE

To adjust the minimum room temperature in frost free

mode. This temperature is only checked if the parameter 8 ”ROOM SENSOR INFLUENCE” is not equal to 0.

If parameter 8 ”ROOM SENSOR INFLUENCE” is

equal to 0, this parameter is not displayed and the set

temperature is fixed at 6°C / 43°F (not adjustable).

External temperature

”

Boiler” heating curve

Water outlet

temperature

M

aximum boiler

temperature

factory setting:

75° C / 167°F

M

inimum boiler temperature in comfort condit

ion: 30° C / 86°F

(factory setting)

+

68 +50

+32

+

14 -4

6

8

86

104

1

22

1

40

1

58

176

1

94

2

03

3

,04,0

°F

2

,0

1,5

1

,0

0

,7

0,5

2,25

8578N012

°

F

Page 25

25

Parameter 13

ANTILEGIONELLOSIS

The indirect d.h.w. tank is overheated at 70°C /158°F

every Saturday from 4h to 5h. The "antilegionellosis"

function acts to prevent the development of legionella

in the indirect d.h.w. tank, these bacteria are responsible

for legionellosis.

Note

When you want to activate the antilegionellosis function,

you should:

- increase the boiler thermostat setting to 80°C / 176°F.

- provide a mixing device preventing water from being

distributed at a temperature greater than 60°C / 140°F

in the domestic hot water distribution network.

Parameter 14

PUMPS TIMEOUT (DHW & HEATING PUMP)

-a timeout to switch off the heating circulator pump

prevents overheating of the boiler when changing from

winter conditions to summer conditions, since this could

a

ccidentally trip the safety thermostat.

-

the timeout when switching the d.h.w. heating pump

off prevents excessively hot water from entering the

heating circuit after the indirect d.h.w tank heating has

been stopped. It also prevents overheating in the boiler,

which could accidentally trip the safety thermostat.

Parameter 15

CDC MEMORY RELEASE CHECK

To d isplay the memory number used on a communicating remote control.

Parameter 16

CPU MEMORY RELEASE CHECK

To d isplay the number of the memory used on the E

control panel regulation card.

Parameter 11

EXTERNAL FROST FREE

Factory set at 3˚C/38˚F. Can be turned “OFF” by

setting parameter 11 to -8˚C/16˚F.

Parameter 12

DOMESTIC HOT WATER PRIORITY

To make the following selections when a indirect

d.h.w. tank is connected:

- DHW PRIORITY (setting 1): absolute priority to

heating of domestic hot water:the heating circulator

pump is switched off,

- DHW NOT PRIORITY (setting 0): the heating is not

cut off when the indirect d.h.w. tank is being heated

Important

The temperature in the radiators can reach the maximum programmed value for the boiler while the d.h.w.

tank is being heated.

Page 26

26

A HEATING PUMP

LOAD PUMP

B BURNER

CS SAFETY CONTACT

DJ6A CIRCUIT BREAKER

J PRINTED CIRCUIT BOARD

PLUG

L PHASE

N NEUTRAL

RL BR1 BURNER 1st STAGE

CONTROL RELAY

RL ECS LOAD PUMP CONTROL

RELAY

RL PA HEATING PUMP

CONTROL RELAY

S AMB. A ROOM SENSOR

S CH BOILER SENSOR

S EXT EXTERNAL SENSOR

S ECS

DOMESTIC HOT WATER

SENSOR

TELEPHONE RELAY

T

TRANSFORMER

TCH

BOILER THERMOSTATTSSAFETY THERMOSTAT

VA ALARM INDICATOR

X GROUND

ZG MAIN SWITCH

ZM MANUAL SWITCH

ZT TEST SWITCH

(8578-4904A) 8578N013

SKELETON

DIAGRAMS

Page 27

©Slant/Fin Corp. 2007. Printed in the U.S.A. 1107. Publication No. TCP-40

SLANT/FIN CORPORATION., Greenvale, N.Y. 11548 • www.slantfin.com

(516) 484-5921

(516) 484-2600 • F

Phone:

In Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario • www.slantfin.can

ax:

Loading...

Loading...