Page 1

FOR GAS-FIRED, OIL FIRED AND DUAL FUEL HOT WATER HEATING PLANTS

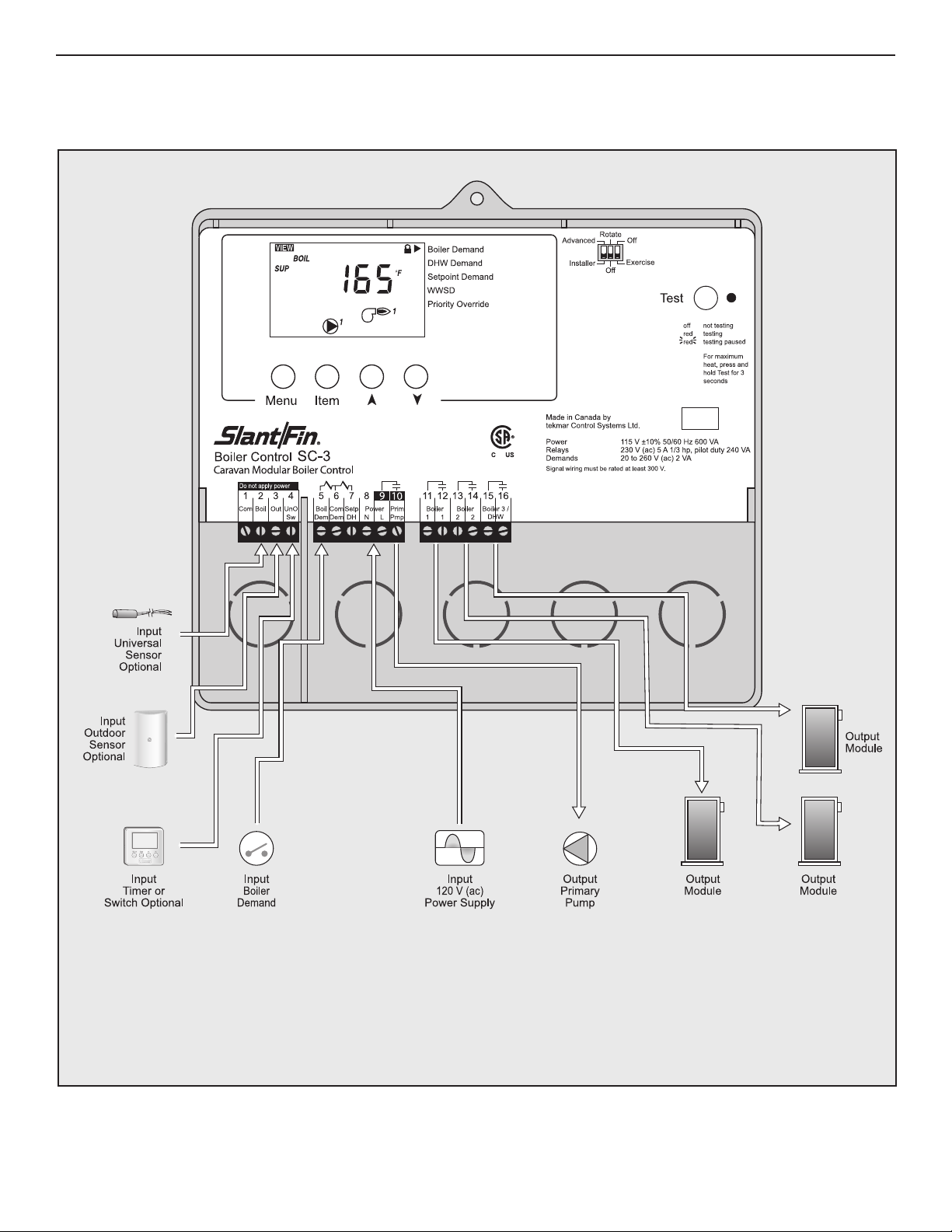

SC-3 Controller

MODULAR BOILER CONTROLLER SERIES

INSTALLATION AND OPERATING INSTRUCTIONS

SC-3 Applications

• Space Heat Systems With Outdoor Reset

• Constant Temperature Setpoint Control

CONTENTS

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

a) Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

b) Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

c) View of Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

d) System Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Select System Type . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

A. Space Heating Only with Outdoor Reset . . . . . . .12

a) Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . .12

b) Functions and Defaults . . . . . . . . . . . . . . . . . . . .13

c) Adjusting the Settings . . . . . . . . . . . . . . . . . . . . .13

B. Space Heating Only w/Setpoint Control . . . . . . . .17

a) Dip Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . .17

b) Functions and Defaults . . . . . . . . . . . . . . . . . . . . . .18

c) Adjusting the Settings . . . . . . . . . . . . . . . . . . . . . . .20

Viewing the Performance . . . . . . . . . . . . . . . . . . . . . . . . .22

Useful Hints and Reloading Factory Defaults . . . . . . . .23

Testing the Contol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Factory Default Listings . . . . . . . . . . . . . . . . . . . . . . . . . .28

If your system is different than the above, call the Slant/Fin

technical services group at 800-873-4346 to

determine the proper control.

The SC-3 is a microprocessor control which will sequence up to

three heating stages based on outdoor air temperature and supply

water temperature. Designed to handle a Caravan gas-fired,

oil-fired or *dual fuel-fired hot water heating plant for space

heating or “Setpoint” operation. A large easy to read display

provides current system temperatures and operating status.

ADDITIONAL FUNCTIONS INCLUDE:

Pump exercising. Pump purging. Boiler demand for space heating

loads. Set point demands for set point loads. Test sequence to

ensure proper component operation. CSA C US certified. Setback

input for energy savings.

SPACE HEATING OPERATION: When the outdoor air temperature drops below a preset value, the heating system is energized.

The SC-3 Controller determines the number of stages required to

meet the space heating needs and fires them. During operation,

the Controller scans system temperatures, adding or deleting

stages as necessary to satisfy heating load.

Controller Packing List

1- SC-3 Modular Controller P/N 435081

1- Outdoor sensor with enclosure P/N 339070

1- Universal sensor P/N 339071

SETPOINT OPERATION:

The SC-3 adds and deletes stages to minimize the difference

between the desired Setpoint temperature and the actual

measured Supply Water Temperature.

Dual-Fuel

* Not available in Canada

Printed in U.S.A. 605 PUBLICATION SC-3-40

Part No. 435083000

Page 2

3 SC-3 Controller

INSTALLATION

CAUTION

Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury. It is your

responsibility to ensure that this control is safely installed according to all applicable codes and standards. This electronic control is not

intended for uses as a primary limit control. Other controls that are intended and certified as safety limit must be placed into the control

circuit. Do not open the control. Refer to qualified personnel for servicing. Opening voids warranty and could result in damage to the

equipment and possibly even personal injury.

CONTROL PANEL MOUNTING

The control panel is to be mounted in an indoor area where the ambient temperature range will be 30 to 120˚F (0 to 50˚C) and less that

95% RH. Power Supply is to be 115 V (ac) +/- 10% 50/60 Hz 600 VA.

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian InterferenceCausing Equipment Regulations. However, if this control does cause harmful interference to radio or television reception, which is determined by turning the control on and off, the user is encouraged to try and correct the interference by re-orienting or relocating the receiving

antenna, relocating the receiver with respect to the control, and/or connecting the control to a different circuit from that to which the receiver

is connected.

WARNING: The nonmetallic enclosure does not provide grounding between conduit connections. Use grounding type bushings and jumper

wires as needed.

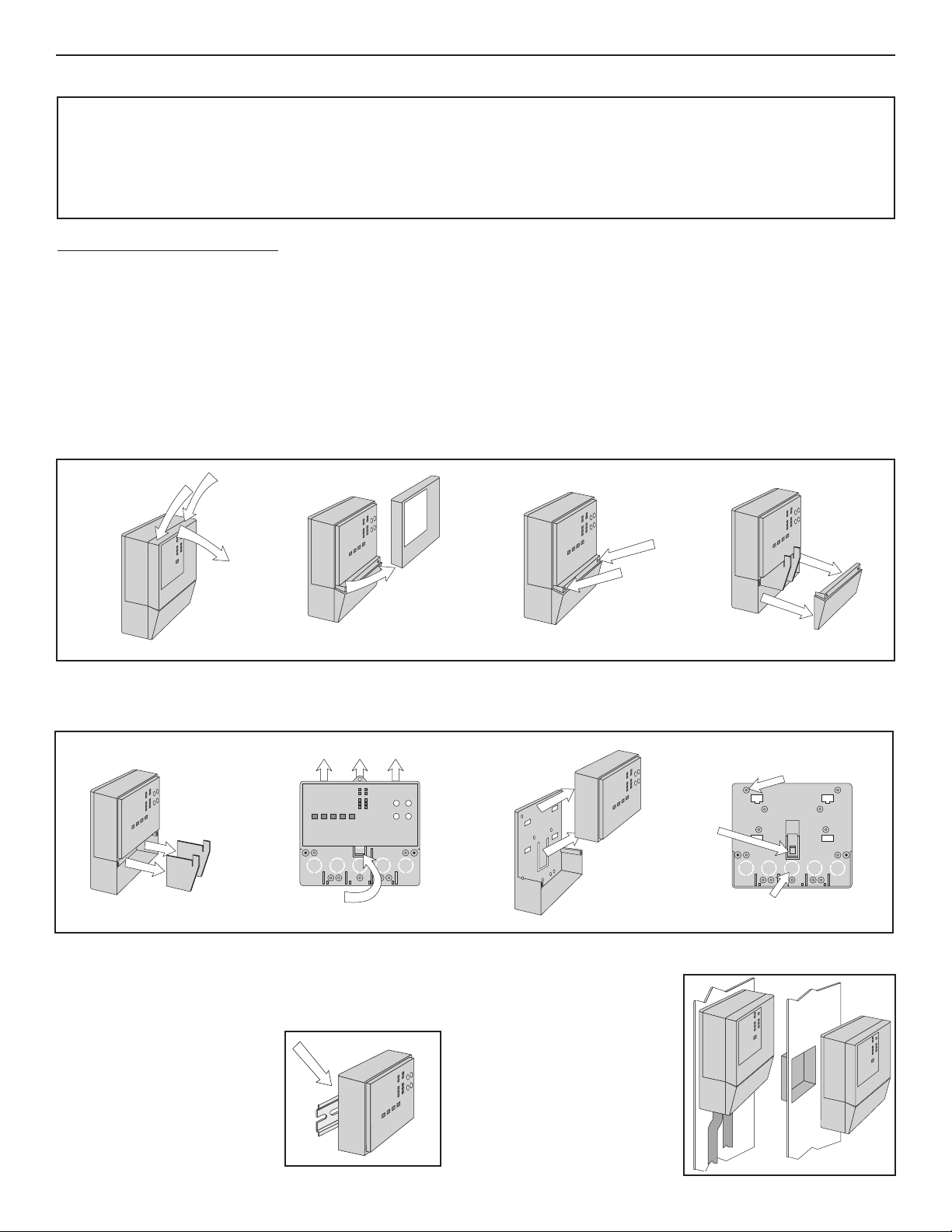

Press down at the fingertip

grips on top of the front cover

and pull out and down.

Remove the safety dividers

from the wiring chamber by

pulling them straight out of their

grooves.

The control can be mounted on

a standard DIN rail. First

remove the control from its

base and then, using the hooks

and spring clip on the back of

the control, mount it onto the

DIN rail. This will be a popular

option for those who prefer to

mount the control inside a larger electrical panel.

Lift the front cover up and away

from the control.

Press the control release clip

on the base inside the wiring

chamber and slide the control

upwards.

Loosen the screws at the front

of the wiring cover.

The control lifts up and away from

the base.

The wiring can enter the bottom or

the back of the enclosure. Knockouts provided in the base allow the

wiring to be run in conduit up to the

enclosure. The base also has holes

that line up with the mounting holes

of most common electrical boxes.

The wiring cover pulls straight

out from the wiring chamber.

The base is ready for mounting.

Page 3

SC-3 Controller 4

INSTALLING THE SENSORS

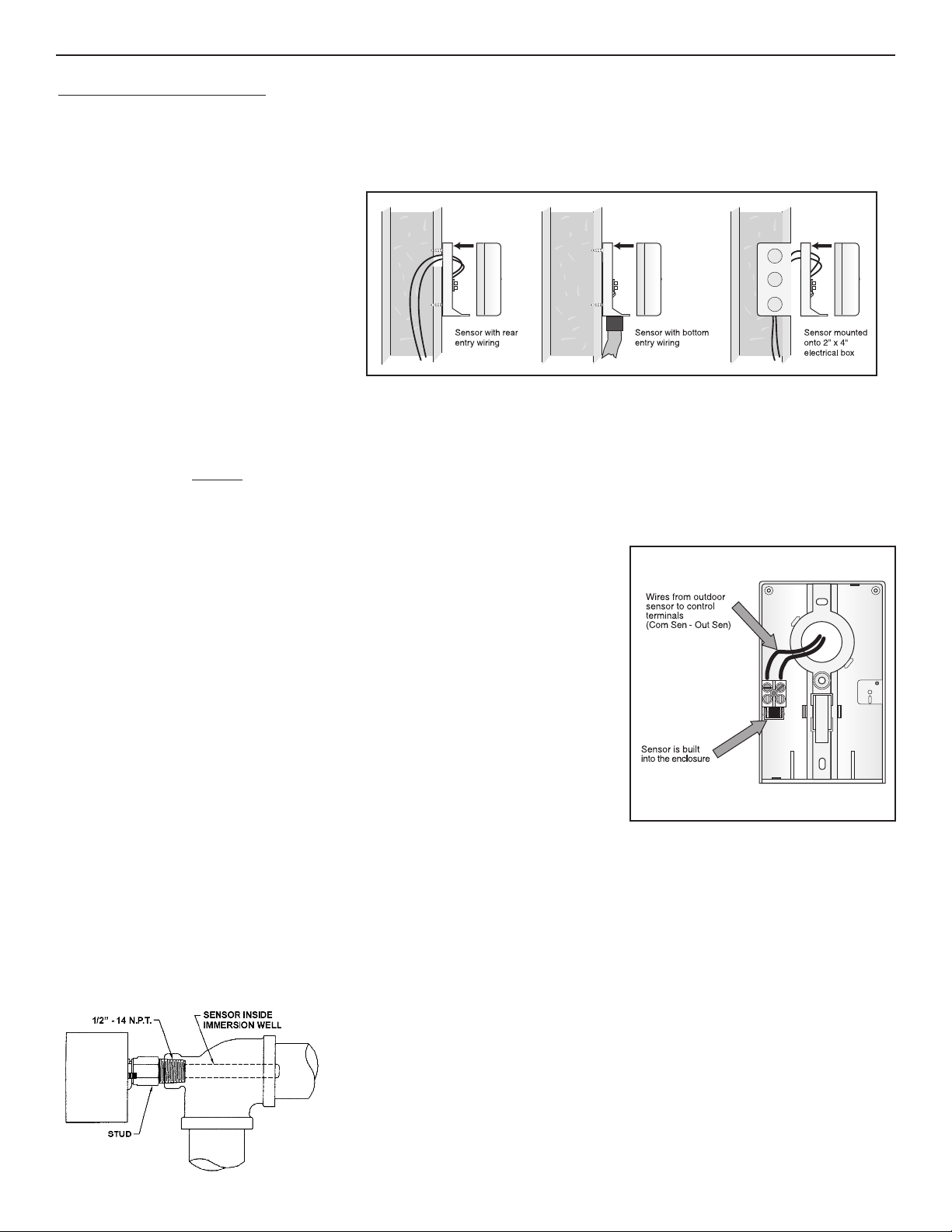

OUTDOOR SENSOR SF P/N 339070

MOUNTING THE SENSOR

Note: The temperature sensor (thermistor) is built into the enclosure.

• Remove the screw and pull the front cover

ff the sensor enclosure.

o

• The enclosure can either be mounted directly

onto a wall or a 2” x 4” electrical box.

When it is wall mounted, the wiring

should enter through the back or bottom

of the enclosure. Do not mount the enclosure

with the conduit knockout facing upwards

as rain could enter the enclosure and

damage the sensor.

• In order to prevent heat transmitted through the wall from affecting the sensor reading, it may be necessary to install and insulating

barrier behind the enclosure.

• The sensor should be mounted on a northern wall of the building. It should not be exposed to heat sources such as ventilation or

window openings. Caution

temperatures that are not high enough to meet the demand.

: If sunlight strikes the sensor enclosure or the surface area surrounding it, the system will provide water

• It should be installed at an elevation above the ground that will prevent accidental damage or tampering.

WIRING AND TESTING THE SENSOR

• Connect 18 AWG or similar wire to the two terminals provided in the enclosure and

run the wires from the sensor to the control. Do not run the wires close to and parallel to

telephone or power cables. If the sensor wires are located in an area with strong sources

of electromagnetic interference (EMI), shielded cable or twisted pair should be used or the

wires can be run in a grounded metal conduit. If using shielded cable, the shield wire

should be connected to the Com Sen terminal on the control and not to earth ground.

• Follow the sensor testing instruction that follows and connect the wires to the control.

• Replace the front cover of the sensor enclosure.

UNIVERSAL SENSORS

MOUNTING THE SENSOR SF P/N 339071

Note: These sensors are designed to mount in an immersion well or on a pipe.

For example - If a Sensor is mounted onto a 1” type L copper pipe, there is approximately an 8 second delay between a sudden change in

water temperature and the time the sensor measures the change. This delay increases considerably when steel pipe is used.

It is strongly recommended that an immersion well be used, especially when steel pipe of greater than 1-1/4” is used and also

when large diameter pipes are used and fluid stratification is probable.

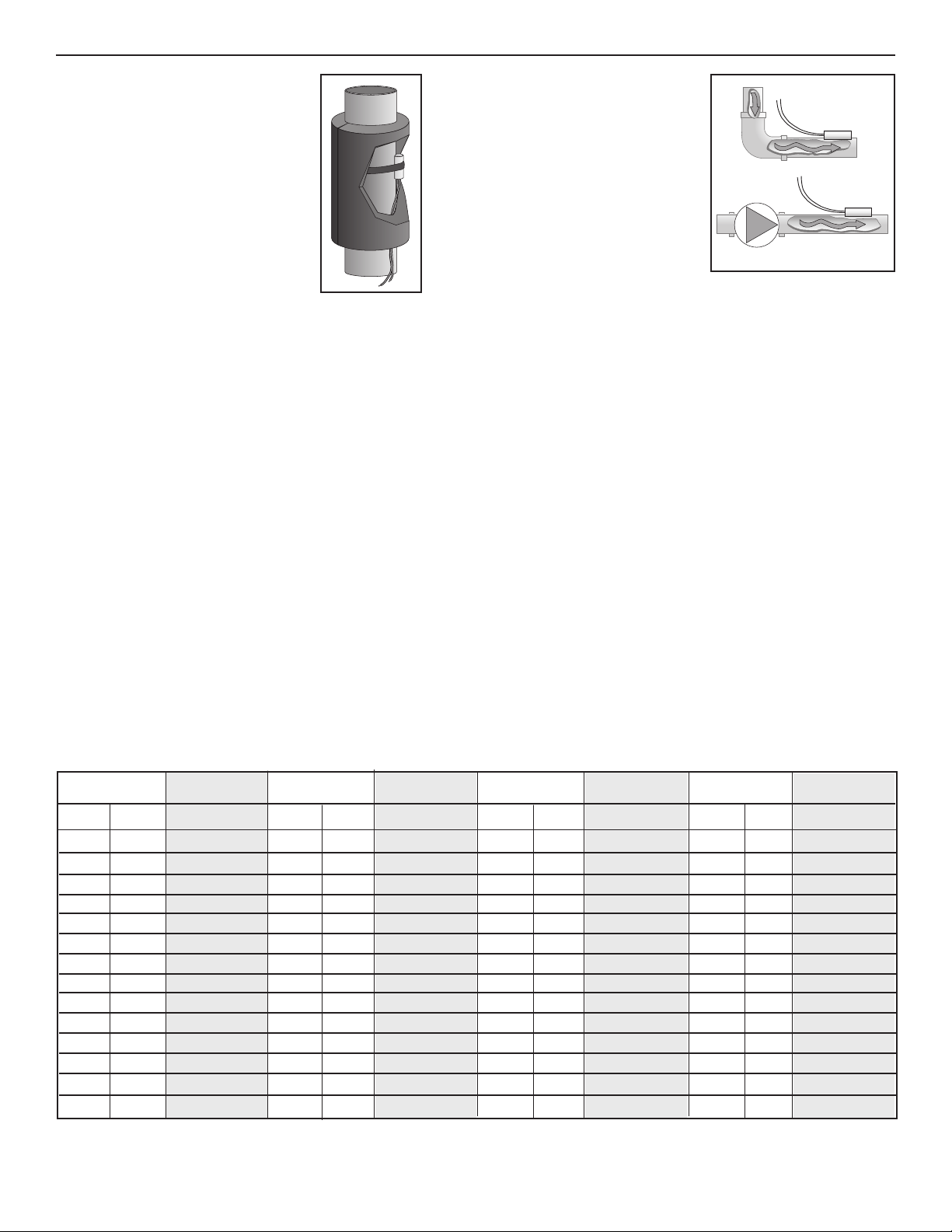

Sensor Mounted In Immersion Well

SF P/N 410569

Page 4

5 SC-3 Controller

The Universal Sensor can be

strapped directly to the pipe using

the cable tie provided. Insulation

should be placed around the sensor

to reduce the effect of air currents on

the sensor measurement. The flat

ortion of the sensor should be mounted

p

against the pipe.

The Universal Sensor should be placed

downstream of a pump or after an elbow

or similar fitting. This is especially important if large diameter pipes are used as

the thermal stratification within the pipe

can result in erroneous sensor readings.

Proper sensor location requires that the

luid is thoroughly mixed within the pipe

f

before it reaches the sensor.

WIRING AND TESTING THE SENSOR

WARNING: Do not run sensor wires close to and parallel to telephone or power cables. If the sensor wires are located in an area with

strong sources of electromagnetic interference, shielded cable or twisted pair should be used or the wires can be run in a grounded metal

conduit. If using shielded cable, the shield wire should be connected to the Com Sen terminal on the control and not to earth ground.

• It is necessary to connect 18 AWG wire to the two sensor wires. Wire nuts can be used to hold the wires together.

• Follow the sensor testing instructions that follow and then connect the wires to the control.

SENSOR TESTING INSTRUCTIONS

A good quality test meter capable of measuring up to 5,000 kΩ (1 kΩ = 1000 Ω) is required to measure the sensor resistance. In addition

to this, the actual temperature must be measured with either a good quality digital thermometer, or if a thermometer is not available,

a second sensor can be placed alongside the one to be tested and the readings compared.

First measure the temperature using the thermometer and then measure the resistance of the sensor at the control. The wires from the

sensor must not be connected to the control while the test is performed. Using the chart below, estimate the temperature measured by

the sensor. The sensor and thermometer readings should be close. If the test meter reads a very high resistance, there may be a broken

wire, a poor wiring connection or a defective sensor. If the resistance is very low, the wiring may be shorted, there may be moisture in

the sensor or the sensor may be defective. To test for a defective sensor, measure the resistance directly at the sensor location.

Do not apply voltage to a sensor at any time as damage to the sensor may result.

Temperature Resistance Temperature Resistance Temperature Resistance Temperature Resistance

˚F ˚C ˚F ˚C ˚F ˚C ˚F ˚C

-50 -46 490,813 20 -7 46,218 90 32 7,334 160 71 1,689

-45 -43 405,710 25 -4 39,913 95 35 6,532 165 74 1,538

-40 -40 336,606 30 -1 34,558 100 38 5,828 170 77 1,403

-35 -37 280,279 35 2 29,996 105 41 5,210 175 79 1,281

-30 -34 234,196 40 4 26,099 110 43 4,665 180 82 1,172

-25 -32 196,358 45 7 22,763 115 46 4,184 185 85 1,073

-20 -29 165,180 50 10 19,900 120 49 3,760 190 88 983

-15 -26 139,402 55 13 17,436 125 52 3,383 195 91 903

-10 -23 118,018 60 16 15,311 130 54 3,050 200 93 829

-5 -21 100,221 65 18 13,474 135 57 2,754 205 96 763

0 -18 85,362 70 21 11,883 140 60 2,490 210 99 703

5 -15 72,918 75 24 10,501 145 63 2,255 215 102 648

10 -12 62,465 80 27 9,299 150 66 2,045 220 104 598

15 -9 53,658 85 29 8,250 155 68 1,857 225 107 553

Page 5

SC-3 Controller 6

Page 6

7 SC-3 Controller

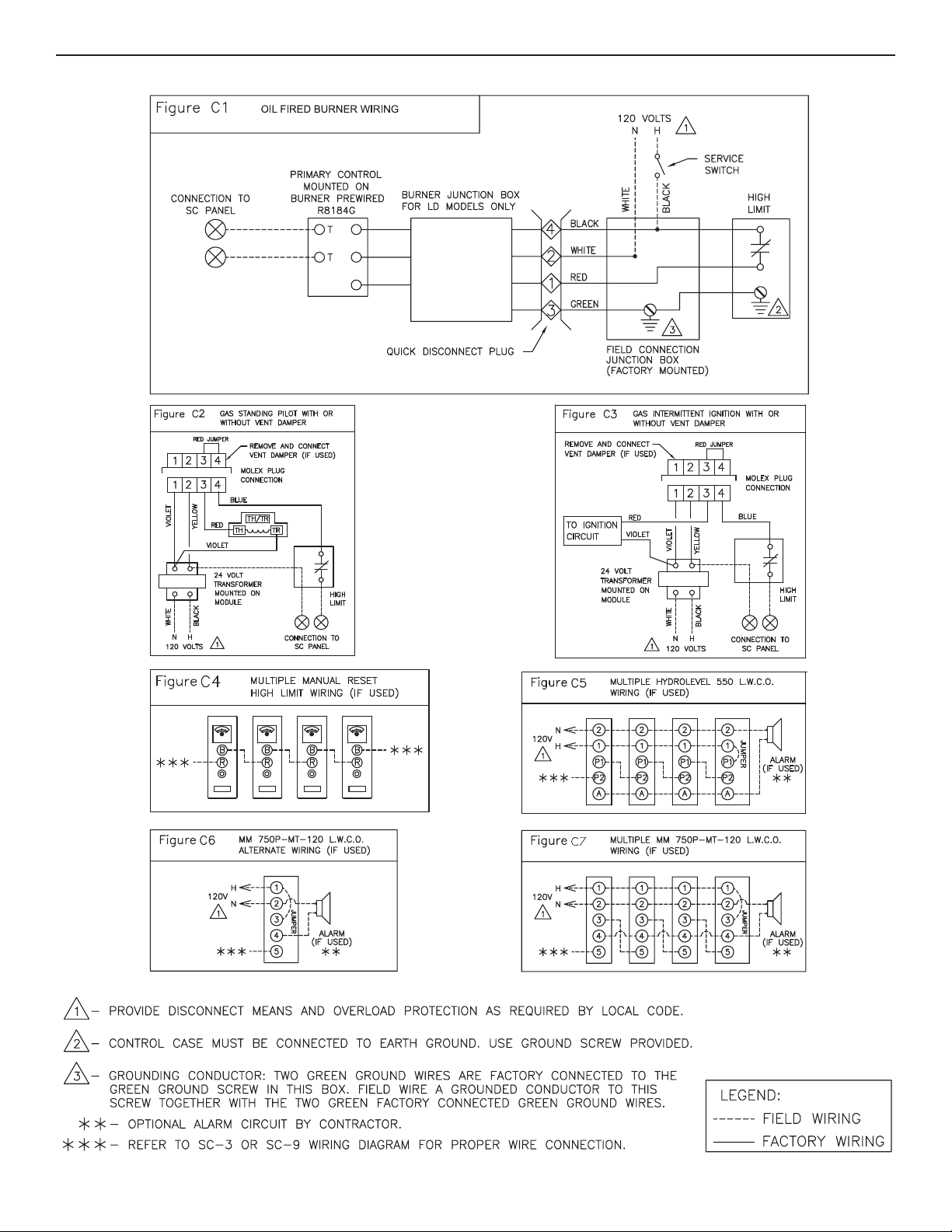

WIRING THE SYSTEM

Use one of the following wiring diagrams to wire your system, along with the appropriate diagram on page 9.

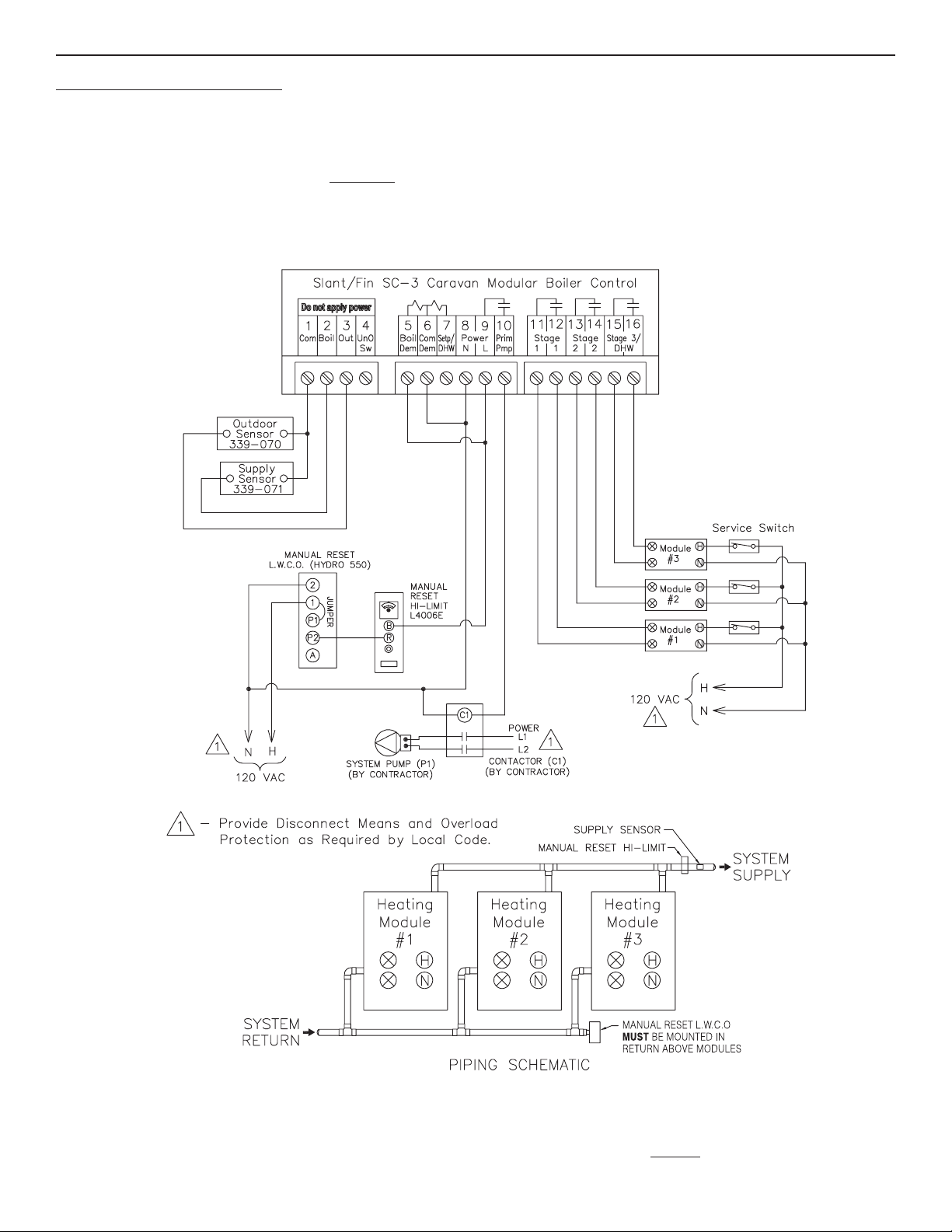

1. Gas fired - Space Heating only

. Oil fired - Space Heating only

3

If using MM 750P-MT120 L.W.C.O. use Figure C6

on page 9 to wire the control

1. Gas fired - Space Heating only

NOTE: For boiler termination wiring at modules, see page 9

Page 7

SC-3 Controller 8

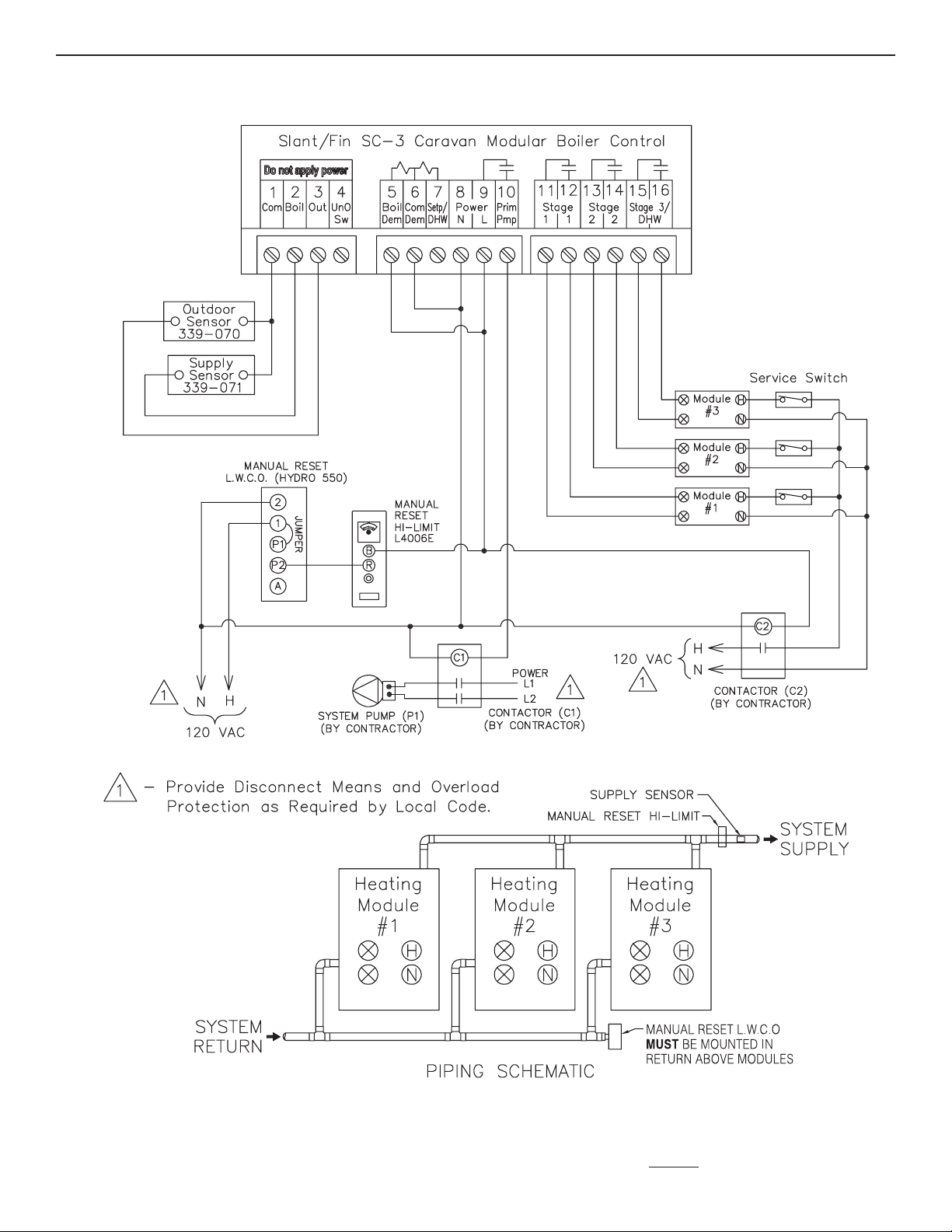

2. Oil fired - Space Heating only

NOTE: For boiler termination wiring at modules, see page 9

Page 8

9 SC-3 Controller

Page 9

SC-3 Controller 10

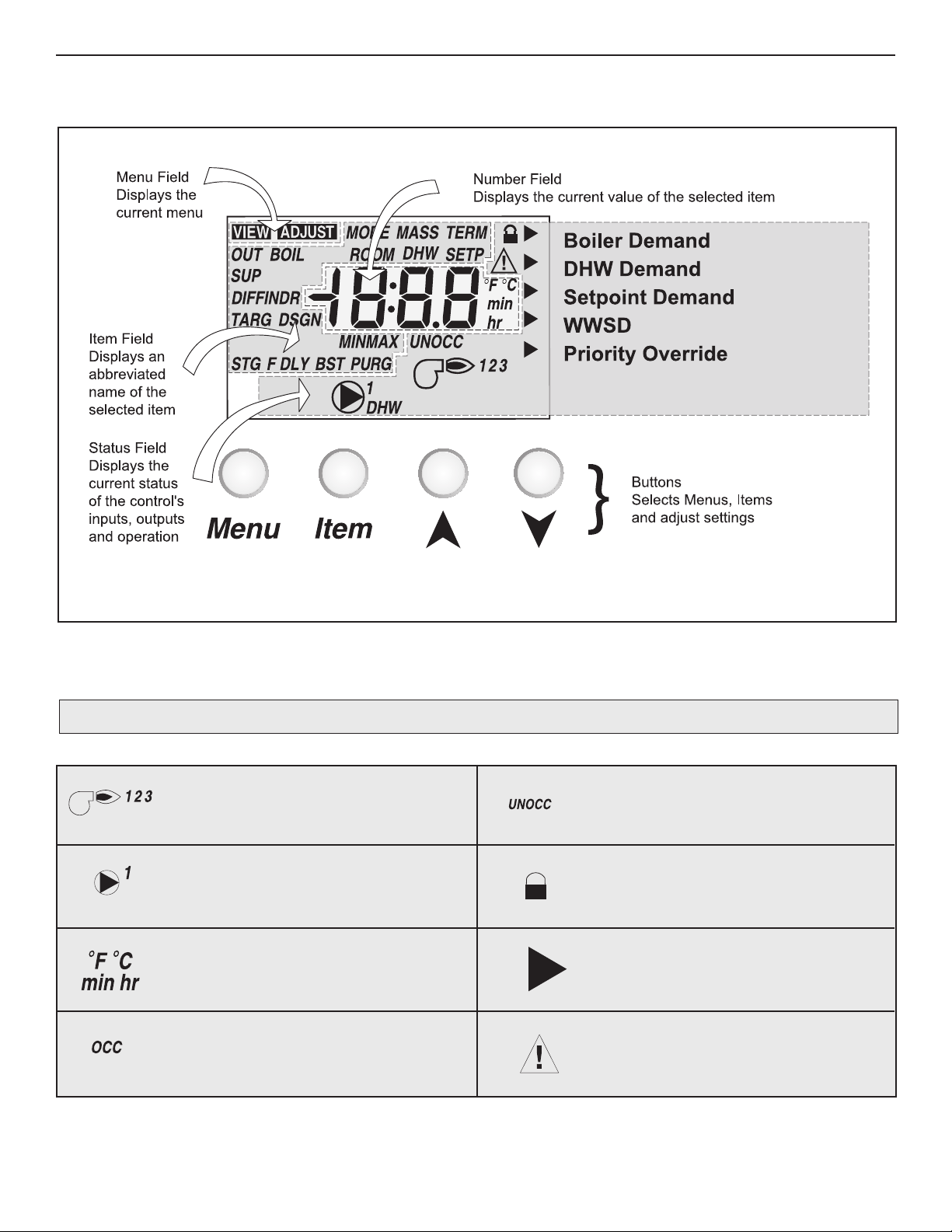

DISPLAY:

Symbol Description

Stage

Displays which stage relays are turned on.

Pump

Displays when the primary pump relay is turned

on.

˚F, ˚C, min, hr

Units of measurement.

Occupied Schedule

Displays when the control is in Occupied Mode.

UnOccupied Schedule

Displays when the control is in UnOccupied

Mode.

Installer Access Level

Displays when the Installer/Advanced Dip

switch is set to Installer

Pointer

Displays the control operation as indicated by

the text.

Warning/Alarm

Displays when an error exists or the alarm relay

is turned on.

Page 10

11 SC-3 Controller

User Interface

The control uses a Liquid Crystal Display (LCD) as the method of supplying information. You use the LCD in order to setup and monitor the

operation of your system. The control has four push buttons (Menu, Item, s,t) for selecting and adjusting settings. As you program your con-

trol, record your settings in the ADJUST menu table which is found in the second half of this brochure.

enu

M

All of the items displayed by the control are organized into two menus.

These menus are listed on the top left hand side of the display (Menu

Field). To select a menu, use the Menu button. By pressing and releasing

the Menu button, the display switches between the two menus. Once a menu

is selected, there will be a group of items that can be viewed within the menu.

Item

The abbreviated name of the selected item will be displayed in the item field

of the display. To view the next available item, press and release the Item

button. Once you have reached the last available item in a menu, pressing and

releasing the Item button will return the display to the first item in the selected

menu.

Adjust

To make an adjustment to a setting in the control, begin by selecting the

ADJUST menu using the Menu button. Then select the desired item using the

Item button. Finally, use the s, and / or t button to make the adjustment.

Additional information can be gained by observing the Status field of the LCD. The status field will indicate which of the control’s

outputs are currently active. Most symbols in the status field are only visible when the VIEW menu is selected.

SELECT SYSTEM TYPE:

A. Space Heating ONLY with Outdoor Reset (Most systems) . . . . . . . . . . . . . . . . . . . . . . Page 12

B. Space Heating ONLY with Setpoint Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

To set up the control, go to the appropriate page for your system.

If your system is different than the above, call the Slant/Fin technical services

group at 800-873-4346 to determine which control can accommodate it.

Page 11

SC-3 Controller 12

A. SPACE HEATING ONLY WITH OUTDOOR RESET

CONTROL SET UP

DIP SWITCH SETTINGS:

General

The DIP switch settings on the control are very important and

should be set to the appropriate settings prior to making any

adjustments to the control through the User Interface. The DIP

switch settings change the items that are available to be viewed

and / or adjusted in the User Interface.

If a DIP switch is changed while the control is powered up, the

control responds to the change in setting by returning the display

to the VIEW menu.

Page 12

13 SC-3 Controller

SPACE HEATING ONLY WITH OUTDOOR RESET

Advanced / Installer

The Adv / Installer DIP switch selects the access level of the control. In the

Installer access level, a limited number of items may be viewed and / or

adjusted. In the Advanced access level, all items may be viewed and / or

adjusted.

Set to Advanced

Rotate / Off

The Rotate / Off DIP switch selects whether or not the control is to provide

qual Run Time Rotation of the boiler stages. If the switch is set to Rotate,

E

the stages will be rotated accordingly. If the switch is set to Off, the firing

sequence is fixed starting with the module 1 to module 3.

We recommend that it be set to Rotate for most systems

Off / Exercise

The Off / Exercise DIP switch selects whether or not the control is to exercise the primary pump and boiler pumps. If the DIP switch is set to Exercise,

the pumps are operated for 10 seconds after every three days of inactivity.

We recommend that it be set to Exercise for most systems.

THE CONTROL MUST BE ADJUSTED FOR YOUR APPLICATION.

IF ANY OF THE DEFAULT SETTINGS DO NOT SUIT YOUR APPLICATION, GO TO THE ADJUSTING SECTION

THAT FOLLOWS EACH FUNCTION AND WRITE IN THE DESIRED SETTING IN THE SQUARE BOX

PROVIDED FOR THAT FUNCTION. THEN PERFORM THE ADJUSTMENT AS LISTED.

THESE INSTRUCTIONS ARE WRITTEN WHERE EACH FUNCTION IS ADJUSTED IN A “STAND ALONE” MANNER MEANING YOU ARE PROGRAMMING

THAT ONE FUNCTION ONLY

LETTERS FOR EACH STEP AND PROGRAM THE CONTROL PROGRESSIVELY THROUGH EACH FUNCTION.

ITALIC

IT IS BEST IF YOU TAKE A FEW MINUTES TO GO THROUGH THE ENTIRE LIST OF FUNCTIONS AND

ENTER ANY NEW SETTINGS THAT ARE APPROPRIATE FOR YOUR INSTALLATION

GO TO THE CONTROL AND ADJUST ONLY THOSE FUNCTIONS THAT HAVE A NEW SETTING LISTED.

Display Description

Room Occupied - The desired room air temperature during the occupied period.

Press the

Item button until ROOM appears above the temperature readout and OCC is flashing

below it. Use the up and down arrow buttons to change to the desired reading.

Range Available: 35˚ to 100˚F (2˚ to 38˚C)

. IF YOU WANT TO PROGRESSIVELY GO THROUGH EACH STEP, JUST SKIP THE INSTRUCTIONS WRITTEN IN

. WHEN FINISHED,

Menu button until ADJUST is visible on the top line of the display. Press the

Default

Setting

70˚F

New

Setting

(21˚C)

Room Unoccupied - The desired room air temperature during the unoccupied period.

Press the

Item button until ROOM appears above the temperature readout and UNOCC is flashing

below it. Use the up and down arrow buttons to change to the desired reading.

Range Available: 35˚ to 100˚F (2˚ to 38˚C)

Menu button until ADJUST is visible on the top line of the display. Press the

65˚F

(18.5˚C)

Page 13

SC-3 Controller 14

OUT

DSGN

SPACE HEATING ONLY WITH OUTDOOR RESET

Display Description

Boost - The amount of morning boost.

Press the

Item button until OFF appears with BST below and to the left of OFF.

Keep setting on OFF. This is only used when a setback timer is used.

Contact Slant/Fin if you have any questions.

oiler 1- Selects whether or not module 1 is operational - Au (auto) or OFF

B

DO NOT CHANGE

Press the

Item button until BOIL to the left of, and above Au and 1 is below it. Use the up and down

arrow buttons to change to the desired setting. However for the setting of Au should be

retained, do not change to OFF.

Boiler 2 - Selects whether or not module 2 is operational - Au (auto) or OFF

DO NOT CHANGE

Press the

Item button until BOIL to the left of, and above Au and 2 is below it. Use the up and down

arrow buttons to change to the desired setting. However, the setting of Au should be

retained, do not change to OFF.

Boiler 3 - Selects whether or not module 3 is operational - Au (auto) or OFF

If you do not have 3 boiler modules

Press the

Item button until BOIL to the left of, and above Au and 3 is below it. Use the up and down

arrow buttons to change to OFF.

Menu button until ADJUST is visible on the top line of the display. Press the

Menu button until ADJUST is visible on the top line of the display. Press

Menu button until ADJUST is visible on the top line of display. Press the

Menu button until ADJUST is visible on the top line of the display. Press the

efault

D

Setting

OFF

Au

Au

Au

ew

N

Setting

Outdoor design - The design outdoor temperature used in the heat loss calculations for

the heating system.

Press the

Item button until OUT and DSGN appear. Use the up and down arrow buttons to change

to the desired setting.

Range Available: -60˚ to 45˚F (-51˚ to 7˚C)

Boiler Indoor - The design indoor air temperature used in the heat loss calculation for the

heating system.

Press the

button until BOIL and INDR appear. Use the up and down arrow buttons to change to the

desired setting.

Boiler Design - The design supply water temperature used in the design of the system.

Press the

Item button until BOIL and DSGN appears. Use the up and down arrow buttons to change

to the desired temperature.

Range Available: 70˚ to 220˚F (21˚ to 104˚C)

Boiler Minimum - The minimum allowed boiler target temperature for Slant/Fin cast iron

boilers we recommend 130˚F minimum.

Press the

Item button until BOIL and MIN appears. Use the up and down arrow buttons to change to

the DESIRED SETPOINT temperature -140˚F or more.

Range Available: OFF, 80˚ - 180˚F (OFF, 27˚ - 82˚C)

Menu button until ADJUST is visible on the top line of the display. Press the

Menu button until ADJUST is visible on the top line of the display. Press ITEM

Menu button until ADJUST is visible on the top line of the display. Press the

Menu button until ADJUST is visible on the top line of the display. Press the

10˚F

(-12˚C)

70˚F

(21˚C)

180˚F

(82˚C)

140˚F

(60˚C)

Page 14

15 SC-3 Controller

SPACE HEATING ONLY WITH OUTDOOR RESET

Display Description

Boiler Maximum - The maximum allowed boiler target temperature. Set at least 10˚F

above Boiler Design

Press the

Item button until BOIL and MAX appears. Use the up and down arrow buttons to change

o the desired temperature.

t

Range Available: 120˚ to 225˚F or OFF (49˚ to 107˚C or OFF)

Fire Delay 1 - The time delay the control can expect between the time that the relay

ontact closes to fire the first stage of the boiler and the burner actually fires.

c

Press the Menu button until ADJUST is visible on the top line of display. Press the

Item button until F DLY appears. Use the up and down arrow buttons to change to

the desired time delay.

Range Available: 0:00 to 3:00 minutes (1 sec increment)

Boiler Mass - This inputs the thermal mass characteristics of the boiler modules.

Press the

Item button until BOIL is below ADJUST and MASS is to the right of ADJUST. Default is

2 with 1 being low mass and 3 being high mass. For Slant/Fin boilers we recommend you

retain the default setting of 2.

Stage Delay - The minimum time delay between the operation of stages. Under Au

(Auto) setting the control determines the best stage delay based on operation of the

system.

Press the

Item button until STG DLY appears. Use the up and down arrow buttons to change to the

desired setting.

Range Available: Au (Auto), 0:30 to 19:55 min (5 sec increment)

Menu button until ADJUST is visible on the top line of display. Press the

Menu button until ADJUST is visible on the top line of display. Press the

Menu button until ADJUST is visible on the top line of the display. Press the

setting.

Default

etting

S

200˚F

(93.5˚C)

0:10

min

2

Au

New

etting

S

Boiler Differential - The temperature differential that the control is to use when it is

operating the boiler(s). Under Au (Auto) the control determines the best differential as

the load changes. This reduces potential short cycling during light load conditions.

Press the

Item button until BOIL and DIFF appears. Use the up and down arrow buttons to change

to the desired setting.

Range Available: Au (Auto), 2˚ to 42˚F (Au, 1˚ to 23˚C)

Menu button until ADJUST is visible on the top line of the display. Press the

Au

The following step will happen only when module step 3 is set to OFF

DHW Mode - Selects the DHW MODE of operation. This item is only available when

Boiler 3 is set to OFF.

Press the

ITEM button until MODE and DHW appear. Keep setting on OFF.

Range Available: OFF

Menu button until ADJUST is visible on the top line of the display. Press the

1 (parallel, no priority)

2 (parallel, priority)

3 (pri-sec, no priority)

4 (pri sec, priority)

Default = OFF

OFF OFF

If you change setting of DHW MODE to 1, 2, 3, or 4 you will go to (XCHG) a different step than the next step.

If this happens go back to DHW MODE and change setting to OFF.

Setpoint Mode - Selects the Setpoint Mode of operation. This item is only available

when DHW MODE is set to OFF.

Press the

ITEM button until MODE and SETP appear. Keep setting on 1.

Range Available: 1 (parallel, no priority)

MENU button until ADJUST is visible on the top line of the display. Press the

1

2 (parallel, priority)

3 (Primary pump)

Default = 1

Page 15

SC-3 Controller 16

SPACE HEATING ONLY WITH OUTDOOR RESET

Display Description

Setpoint Occupied - The minimum supply temperature when a setpoint demand is

resent during the Occupied period. This item is only available when DHW MODE is set

p

to OFF.

Press the

Item button until SETP appears above the temperature and OCC appears below the

emperature. Keep default setting of 180˚F.

t

Range Available: OFF, 60 to 220˚F (OFF, 16 to 104˚C)

Setpoint UnOccupied - Selects whether or not a setpoint demand will be responded to

during the UnOccupied period. This item is only available when DHW MODE is set

to OFF.

Press the

Item button until SETP and UNOCC appear. Keep default setting of OFF.

Range Available: OFF, On

WWSD Occupied - The system’s warm weather shut down temperature during the

occupied period.

Press the

Item button until OCC appears and arrow points to WWSD. Use the up and down arrow

buttons to change to the desired temperature.

Range Available: 35˚ to 100˚F (2˚ to 28˚C or OFF)

Menu button until ADJUST is visible on the top line of display. Press the

Default = 180˚F (82˚C)

Menu button until ADJUST is visible on the top line of display. Press the

Default = OFF

Menu button until ADJUST is visible on the top line of display. Press the

efault

D

Setting

180˚F

(82˚C)

OFF

70˚F

(21˚C)

ew

N

Setting

WWSD UnOccupied - The system’s warm weather shut down temperature during the

UnOccupied period.

Press the

Item button until UNOCC appears and arrow points to WWSD. Use the up and down

arrow buttons to change to the desired temperature. This is available with optional timer

terminals 1 (com) and 4 (UnO Sw) are made.

Range Available: 35˚ to 100˚F, OFF (2˚ to 38˚C, OFF)

Primary Pump Purge - The maximum length of time that the primary pump will continue

to operate after the boiler demand has been removed.

Press the

Item button until PURG and MIN appear. Use the up and down arrow buttons to adjust to

the desired setting.

Range Available: OFF, 0:10 to 19:55 min (5 sec increment)

Units - The units of measure that all of the temperatures are to be displayed by the

control.

Press the

ITEM button until ˚F or ˚C appears. Use the up and down arrow buttons to change to

the desired setting -˚F or ˚C

Menu button until ADJUST is visible on the top line of the display. Press the

Menu button until ADJUST is visible on the top line of the display. Press the

Menu button until ADJUST is visible on the top line of the display. Press the

60˚F

(15.5˚C)

0:20

min

˚F

NOTE: When you press ITEM button again you will go to the beginning of the sequence

Page 16

17 SC-3 Controller

B. SPACE HEATING ONLY WITH SETPOINT CONTROL

CONTROL SET UP

DIP SWITCH SETTINGS:

General

The DIP switch settings on the control are very important and

should be set to the appropriate settings prior to making any

adjustments to the control through the User Interface. The DIP

switch settings change the items that are available to be viewed

and / or adjusted in the User Interface.

If a DIP switch is changed while the control is powered up, the

control responds to the change in setting by returning the display

to the VIEW menu.

SPACE HEATING ONLY WITH SETPOINT CONTROL

Page 17

SC-3 Controller 18

Advanced / Installer

The Adv / Installer DIP switch selects the access level of the control. In the

Installer access level, a limited number of items may be viewed and / or

adjusted. In the Advanced access level, all items may be viewed and / or

adjusted.

SPACE HEATING ONLY WITH SETPOINT CONTROL

Set to Advanced

Rotate / Off

The Rotate / Off DIP switch selects whether or not the control is to provide

Equal Run Time Rotation of the boiler stages. If the switch is set to Rotate,

the stages will be rotated accordingly. If the switch is set to Off, the firing

sequence is fixed starting with the module 1 to module 3.

We recommend that it be set to Rotate for most

systems.

Off/Exercise

The Off / Exercise DIP switch selects whether or not the control is to exercise

the primary pump and boiler pumps. If the DIP switch is set to Exercise, the

pumps are operated for 10 seconds after every three days of inactivity.

We recommend that it be set to Exercise for most

systems.

THE CONTROL MUST BE ADJUSTED FOR YOUR APPLICATION.

IF ANY OF THE DEFAULT SETTINGS DO NOT SUIT YOUR APPLICATION,

GO TO THE ADJUSTING SECTION THAT FOLLOWS EACH FUNCTION

AND WRITE IN THE DESIRED SETTING IN THE SQUARE BOX PROVIDED

FOR THAT FUNCTION. THEN PERFORM THE ADJUSTMENT AS LISTED.

IT IS BEST IF YOU TAKE A FEW MINUTES TO GO THROUGH THE ENTIRE LIST OF FUNCTIONS AND

ENTER ANY NEW SETTINGS THAT ARE APPROPRIATE FOR YOUR INSTALLATION

GO TO THE CONTROL AND ADJUST ONLY THOSE FUNCTIONS THAT HAVE A NEW SETTING LISTED.

. WHEN FINISHED,

Page 18

19 SC-3 Controller

SPACE HEATING ONLY WITH SETPOINT CONTROL

Setpoint operation is only available when DHW MODE is set to OFF. Since DHW MODE

is only available if BOILER 3 is set to OFF, DHW will default to OFF if BOILER 3 is set to

AU.

SETPOINT

The control can operate to satisfy the requirements of a setpoint load in addition to a space heating load. A setpoint load overrides the

urrent outdoor reset temperature and WWSD setting in order to provide heat to the setpoint load.

c

SETPOINT DEMAND

A setpoint demand is required in order for the control to provide heat to the setpoint load.

The control registers a setpoint demand when a voltage between 24 and 230 V (ac) is

applied across the Setp / DHW and Com Dem terminals (7 and 6). Once voltage is applied,

the Setpoint Demand pointer turns on in the LCD. The control operates the boiler(s) to

maintain at least the SETPOINT setting.

BOILER TARGET DURING SETPOINT

The boiler target temperature during a setpoint demand is increased to at least the SETPOINT

setting. This temperature is maintained as long as the control has a setpoint demand.

SETPOINT MODE

A setpoint demand is required in order for the control to provide heat to the setpoint load. The control registers a setpoint demand when a

voltage between 24 and 230 V (ac) is applied across the Setp / DHW and Com Dem terminals (7 and 6). Once voltage is applied, the

Setpoint Demand pointer turns on in the LCD. The control operates the boiler(s) to maintain at least the SETPOINT setting.

Setpoint MODE 1 - Setpoint in Parallel

Whenever a setpoint demand is present, the boiler(s) is operated to maintain the setpoint target. The primary pump (Prim Pmp) does not

turn on, but may operate based on a Boiler Demand.

It is assumed that the Setpoint pump will provide adequate flow through the heat exchanger and the boiler.

Setpoint MODE 2 - Setpoint in Parallel with Priority

Whenever a setpoint demand is present, the boiler(s) is operated to

maintain the setpoint target and the primary pump (Prim Pmp) contact

is opened.

It is assumed that the Setpoint pump will provide adequate flow

through the heat exchanger and the boiler.

Setpoint MODE 3 - Primary Pump during Setpoint

Whenever a setpoint demand is present, the primary pump (Prim Pmp) is turned on and the boiler(s) is operated to maintain the setpoint

target. Setpoint MODE 3 is the most common application to Slant/Fin setpoint operation. MODE 3 is used in this manual.

SETPOINT PRIORITY OVERRIDE

The setpoint has a Priority Override while in SETP MODE 2. In order to prevent the building from cooling off too much or the possibility of

a potential freeze up during setpoint priority, the control limits the amount of time for setpoint priority. The length of Setpoint priority is

determined by the PRIORITY OVERRIDE setting. Once the allowed time for priority has elapsed, the control overrides the setpoint

priority and operates setpoint and heating simultaneously by turning on the primary pump (Prim Pmp).

CONDITIONAL SETPOINT PRIORITY

If the boiler(s) supply temperature is maintained at or above the required temperature during setpoint generation, this indicates that the

boiler(s) has enough capacity for setpoint and possibly heating as well. As long as the boiler target temperature is maintained and the

heating and setpoint targets are similar, setpoint and heating occur at the same time.

Page 19

SC-3 Controller 20

SPACE HEATING ONLY WITH SETPOINT CONTROL

STEP ONE:

Go to page 12.

A. SPACE HEATING ONLY WITH OUTDOOR RESET

If BOILER 3 is set to Au program all steps up to and including BOILER DIFFERENTIAL. If

BOILER 3 is set to OFF program all steps up to and including DHW MODE. If BOILER 3 is set to

Au the DHW MODE will not be present. Since DHW MODE is only available if BOILER 3 is set to

OFF, DHW will default to OFF if BOILER 3 is set to AU.

STEP TWO:

Continue programming as listed on the following pages

Display Description

Setpoint Mode - Selects the Setpoint Mode of operation. This item is only available

when DHW MODE is set to OFF.

Press the

Item button until MODE and SETP appear. Use the up and down arrow buttons to

change to the desired setting.

Range Available: 1 (parallel, no priority)

Setpoint Occupied - The minimum supply temperature when a setpoint demand is

present during the Occupied period. This item is only available when DHW MODE is

set to OFF.

Press the

Item button until SETP appears above the temperature and OCC appears below the

temperature. Use the up and down arrow buttons to change to the desired setpoint

temperature.

Range Available: OFF, 60 to 220˚F (OFF, 16 to 104˚C)

Setpoint UnOccupied - Selects whether or not a setpoint demand will be responded

to during the UnOccupied period. This item is only available when DHW MODE is set

to OFF.

Press the

Item button until SETP and UNOCC appear. Use the up and down arrow buttons to

change to the desired setting.

Range Available: OFF, On

Menu button until ADJUST is visible on the top line of display. Press the

2 (parallel, priority)

3 (primary pump)

Default = 1

Menu button until ADJUST is visible on the top line of display. Press the

Default = 180˚F (82˚C)

Menu button until ADJUST is visible on the top line of display. Press the

Default = OFF

Default

Setting

1 3

180˚F

(82˚C)

OFF

New

Setting

Priority Override - Sets the maximum amount of time the control provides DHW or

Setpoint priority before resuming space heating. This item is only available when

SETPOINT MODE is set to 2, or when DHW MODE is set to 2 or 4.

Press the

Use the up and down arrow buttons to change to the desired setting.

Range Available: 0:20 to 4:00 hr, OFF (10 minute increments)

Menu button until ADJUST is visible on the top line of display.

Default = OFF

OFF

Page 20

21 SC-3 Controller

SPACE HEATING ONLY WITH SETPOINT CONTROL

Display Description

WWSD Occupied - The systems warm weather shut down temperature during the

Occupied period. A setpoint demand overrides this setting.

Press the

Item button until OCC appears and arrow points to WWSD. Use the up and down arrow

buttons to change to the desired temperature.

Range Available: 35˚ to 100˚F (2˚ to 38˚C or OFF)

W

UnOccupied period.

Press the

Item button until UNOCC appears and arrow points to WWSD. Use the up and down

arrow buttons to change to the desired temperature. This is available with optional timer.

Terminals 1 (com) and 4 (UnO Sw) are made.

Range Available: 35˚ to 100˚F (2˚ to 38˚C or OFF)

Primary Pump Purge - The maximum length of time that the primary pump will

continue to operate after the boiler demand has been removed.

Press the

Item button until PURG and MIN appear. Use the up and down arrow buttons to adjust

to

the desired setting.

Range Available: OFF, 0:10 to 19:55 min (5 sec increment)

Menu button until ADJUST is visible on the top line of display. Press the

WSD UnOccupied- The systems warm weather shut down temperature during the

Menu button until ADJUST is visible on the top line of display. Press the

Menu button until ADJUST is visible on the top line of display. Press the

Default

Setting

70˚F

(21˚C)

60˚F

(15.5˚C)

0:20

min

New

Setting

Units - The units of measure that all of the temperatures are to be displayed by the

control.

Press the

Item button until ˚F or ˚C appears. Use the up and down arrow buttons to change to

the desired setting -˚F or ˚C.

Menu button until ADJUST is visible on the top line of the display. Press the

˚F

NOTE: When you press ITEM button again you will go to the beginning of the sequence

Page 21

SC-3 Controller 22

VIEW THE PERFORMANCE

FUNCTION DESCRIPTION STEPS

OUTDOOR

BOILER SUPPLY

BOILER TARGET

BOILER 1 HOUR

BOILER 2 HOURS

Current outdoor air temperature

as measured by the outdoor

ensor.

s

Current boiler supply water

temperature as measured by the

boiler supply sensor.

Boiler target temperature is the

temperature the control is trying

to maintain at the boiler supply

sensor.

The total running time of

module 1 since this item was

last cleared.

The total running time of

module 2 since this item was

last cleared.

Press the Menu button until VIEW is visible on the top line of the display.

Press the Item button until OUT appears. Read the numeric display.

Press the Menu button until VIEW is visible on the top line of the display.

Press the Item button until BOIL SUP appears. Read the numeric display.

Move the Adv/ Installer DIP switch to the Adv position temporarily.

Press the Menu button until VIEW is visible on the top line of the display.

Press the Item button until BOIL TARG appears. Read the numeric display.

Move the Adv/ Installer DIP switch back to the Installer position.

Move the Adv/Installer DIP switch to the Adv position temporarily.

Press the Menu button until VIEW is visible. Press the Item button until

BOIL appears on the second line of the display, and 1 in the lower right

section. Read the numeric display in hours. To clear this item back to 0,

press the Up and Down buttons simultaneously while viewing this item.

Move the Adv/Installer DIP switch back to the Installer position.

Move the Adv/Installer DIP switch to the Adv position temporarily.

Press the Menu button until VIEW is visible. Press the Item button until

BOIL appears on the second line of the display, and 2 in the lower right

section. Read the numeric display in hours. To clear this item back to 0,

press the Up and Down buttons simultaneously while viewing this item.

Move the Adv/Installer DIP switch back to the Installer position.

BOILER 3 HOURS

The total running time of

module 3 since this item was

last cleared.

Move the Adv/Installer DIP switch to the Adv position temporarily.

Press the Menu button until VIEW is visible. Press the Item button until

BOIL appears on the second line of the display, and 3 in the lower right

section. Read the numeric display in hours. To clear this item back to 0,

press the Up and Down buttons simultaneously while viewing this item.

Move the Adv/Installer DIP switch back to the Installer position.

Follow the above procedure for all remaining boiler stages

Page 22

23 SC-3 Controller

USEFUL HINTS

Hint #1

Reloading Factory Defaults

To reload the factory defaults, power down the control for 10 seconds. Power up the control while simultaneously holding the Menu and

t buttons. The control will now display the E01 error message. To clear this error message, follow the procedure in the Error Message

section below.

he control was reloaded to factory default settings. However, the control will stop operation until all of the items in

T

the ADJUST menu of the control have been checked by the user or installer. After checking all items press MENU.

NOTE: The Installer / Adv DIP Switch must be set to Adv in order to clear the error.

Hint #2

Room Occupied Setting

Changing the Room Occupied setting will change the heating curve. If you want more heat you should increase this setting above 70˚F

(21˚C). If you want less heat you can decrease the setting below 70˚F (21˚C).

Page 23

SC-3 Controller 24

TESTING THE CONTROL

The control has a built-in test routine that is used to test the main

control functions. The control continually monitors the sensors and

displays an error message whenever a fault is found. See the following

ages for a list of the control’s error messages and possible causes.

p

When the Test button is pressed, the test light is turned on. The

individual outputs and relays are tested in the following test sequence.

Test Sequence

Each step in the test sequence lasts 10 seconds.

During the test routine, if a demand from the system is present, the test sequence may be paused by pressing the Test button. If the Test

button is not pressed again for 5 minutes while the test sequence is paused, the control exits the entire test routine. If the test sequence is

paused, the Test button can be pressed again to advance to the next step. This can also be used to rapidly advance through the test

sequence. To reach the desired step, repeatedly press and release the Test button until the appropriate device and segment in the display

turn on.

STEP 1: The primary pump is turned on and remains on for the entire test routine.

STEP 2: If Boiler 1 is set to Auto, the Boiler 1 contact is closed and waits for the FIRE DELAY

setting for 10 seconds.

STEP 3: If Boiler 2 is set to Auto, the Boiler 2 contact is closed and waits for the FIRE DELAY

setting or 10 seconds.

STEP 4: If Boiler 3 is set to Auto, the Boiler 3 / DHW contact is closed and waits for the

FIRE DELAY setting or 10 seconds.

STEP 5: All boiler contacts are opened.

STEP 6: If DHW MODE is set to 1 or 2, the primary pump shuts off and the Boiler 3 / DHW

contact is closed.

If DHW MODE is set to 3 or 4, the primary pump remains on and the Boiler 3 / DHW

contact is closed.

STEP 7: All contacts are opened and the control exits the test sequence.

Page 24

25 SC-3 Controller

Error Messages

The control was unable to read a piece of information stored in its memory. Because of this, the

control was required to reload the factory settings into all of the items in the ADJUST menu. The

control will stop operation until all of the items in the ADJUST menu of the control have been

checked by the user or installer.

ote: The Installer / Adv DIP Switch must be set to Adv in order to clear the error.

N

The control is no longer able to read the outdoor sensor due to a short circuit. In this case the

control assumes an outdoor temperature of 32˚F (0˚C) and continues operation. Locate and repair

the problem. To clear the error message from the control after the sensor has been repaired, press

either the Menu or Item button.

This error message only occurs if the External Input/Stand Alone DIP switch is set to Stand Alone.

The control is no longer able to read the outdoor sensor due to an open circuit. In this case the

control assumes an outdoor temperature of 32˚F (0˚C) and continues operation. Locate and repair

the problem. To clear the error message from the control after the sensor has been repaired, press

either the Menu or Item button.

This error message only occurs if the External Input/Stand Alone DIP switch is set to Stand Alone.

The control is no longer able to read the boiler supply sensor due to a short circuit. The control will

not operate the boiler(s) until the sensor is repaired. Locate and repair the problem. To clear the

error message from the control after the sensor has been repaired, press either the Menu or Item

button.

The control is no longer able to read the boiler supply sensor due to an open circuit. The control

will not operate the boiler(s) until the sensor is repaired. Locate and repair the problem. To clear

the error message from the control after the sensor has been repaired, press either the Menu or

Item button.

The control is no longer able to read the boiler return sensor due to a short circuit. The control will

continue to operate normally. Locate and repair the problem. To clear the error message from the

control after the sensor has been repaired, press either the Menu or Item button.

The control is no longer able to read the boiler return sensor due to an open circuit. The control

will continue to operate normally. Locate and repair the problem. To clear the error message from

the control after the sensor has been repaired, press either the Menu or Item button.

If the boiler return sensor was deliberately removed from the control, remove power from the control and repower the control to clear the error message.

Page 25

SC-3 Controller 26

Boiler Control SC-3 - Three Stage Boiler & Setpoint

Control –– Microprocessor PID control; This is not a safety (limit) control.

ackaged weight –– 3 lb. (1400g), Enclosure A, blue modified PPO plastic

P

Dimensions –– 6-5/8” H x 7-9/16” W x 2-13/16” D (170 x 193 x 72 mm)

Approvals –– CSA C US, meets ICES & FCC regulations for EMI/RFI.

Ambient conditions –– Indoor use only, 30 to 120˚F (0 to 50˚C), <95% RH non-condensing.

Power Supply –– 115 V (ac) ± 10% 50/60 Hz 600 VA

Relays –– 230 V (ac) ± 5 A 1/3 hp pilot duty 240 VA

Demands –– 20 to 260 V (ac) 2 VA

Sensors included –– NTC thermistor, 10 k ‰ @ 77˚F (25˚C ± 0.2˚C) §=3892

Outdoor Sensor 339070 and Universal Sensor 339071.

The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise.

Conversely, this Class B digital apparatus complies with Part 15 of the FCC Rules and meets all requirements of the Canadian

Interference-Causing Equipment Regulations. However, if this control does cause harmful interference to radio or television reception,

which is determined by turning the control off and on, the user is encouraged to try to correct the interference by re-orientating or relocating the receiving antenna, relocating the receiver with respect to this control, and/or connecting the control to a different circuit from

that to which the receiver is connected.

Caution: The nonmetallic enclosure does not provide grounding between conduit connections. Use grounding type

bushings and jumper wires.

Page 26

27 SC-3 Controller

NOTES

Page 27

LISTING OF ALL FACTORY DEFAULT SETTINGS

FUNCTION

ROOM OCC

ROOM UN OCC

BST

MODE

BOIL 1

BOIL 2

BOIL 3

OUT DSGN

BOIL INDR

BOILER DESIGN

DEFAULT

SETTING

70˚F (21˚C)

65˚F (18˚C)

OFF

1

Au

Au

Au

10˚F (12˚C)

70˚F (21˚C)

180˚F (82˚C)

FUNCTION

BOIL MIN

BOIL MAX

F DLY 1

DLY

BOIL MASS

STG DLY

BOIL DIFF

DHW MODE

SETP OCC

SETP UNOCC

OCC WWSD

UN OCC WWSD

DEFAULT

SETTING

140˚F (60˚C)

210˚F (98˚C)

0:10 Min

1:00 Min

2

Au

Au

OFF

180˚ (82˚C)

OFF

70˚ (21˚C)

60˚

PURGE

˚F or ˚C

DHW EXCHANGE

OCCUPIED

DHW EXCHANGE

UNOCCUPIED

DHW BOILERS

SETPOINT MODE

0:20 Min

˚F

180˚F (82˚C)

OFF

2

1

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...