Slant/Fin Oil Hot Water User Manual

®

HOT WATER/OIL

APPLICATION GUIDE

WET-BASED CAST-IRON MODULAR BOILERS

Guidelines for the design, purchase and installation of Slant/Fin Caravan oil-fired and dual fuel hot water modular boiler systems.

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Ratings and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ecommended piping and water flow . . . . . . . . . . . . . . . . .3-6

R

Optional factory supply and return headers . . . . . . . . . . . . . .7

Boiler room design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Boiler room air supply requirements . . . . . . . . . . . . . . . . . . . .8

Typical layouts for oil-fired systems . . . . . . . . . . . . . . . . . . . . .9

Venting a oil-fired system . . . . . . . . . . . . . . . . . . . . . . . . .10,11

Fuel oil storage facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Fuel oil delivery systems for single fuel burners . . . . . . .12-14

CODES AND STANDARDS

Oil-fired Caravan installations must comply to local codes or, in the

absence of local codes, to the ANSI/NFPA 31, Installation of Oil

Burning Equipment, latest edition.

In addition, where required by the authority having jurisdiction, the

installation must conform to American Society of Mechanical

Engineers Safety Codes for controls and safety devices for

automatically fired boilers, No. CSD-1. The installation must also

conform to the additional requirements of Slant/Fin Instruction Book

publication no. L-40 latest edition.

All electrical wiring is to be done in accordance with the National

Electrical Code ANSI/NFPA No. 70-latest edition and all local

electrical codes. The unit must be electrically grounded if an external

power source is used.

In Canada, the installation must be in accordance with standards

CGA B149.1 and B149.2, installation codes for oil burning

appliances and equipment and/or local codes. All electrical

connections are to be made in accordance with Standard C.S.A.

C22.1 Canadian Electrical Code Part 1 and/or local codes.

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

Field wiring at modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

C-3 system wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

S

SC-3 ladder wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SC-9 space heating wiring . . . . . . . . . . . . . . . . . . . . . . . . . .20

C-9 space heating ladder wiring . . . . . . . . . . . . . . . . . . . . .21

S

SC-9 space and domestic hot water wiring . . . . . . . . . . . . .22

SC-9 space and domestic hot water ladder wiring . . . . . . . .23

Caravan warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Request for Caravan rating plate . . . . . . . . . . . . . . . . . . .25-28

INTRODUCTION OF FRESH WATER

Introduction of excessive amounts of fresh water into a system can

cause scaling and leave deposits in the boiler and the surrounding

pipes. This will lead to inefficient boiler operation and breakdown.

Fresh water will enter the system as a result of hidden leaks such

as may occur in underground piping. Relief valves should be piped

to a location that shows visible signs of relief.

Process applications that use fresh water, require the use of heat

exchangers. Any process application that results in introduction of

fresh water into a boiler can cause scaling with deposits forming in

the boiler and surrounding piping. This will damage the boiler.

Introduction of fresh water from leaks will cause similar damage.

Use of fresh water will void warranty.

In some areas it may be necessary to use a feed water treatment to

control the corrosive makeup of the feed water. Check with the local

authority, to determine if the feed water will need a conditioning

treatment before being supplied to the boiler.

LOCAL CODE APPROVALS

New York City:

New York City Bar No. 51-58

Pennsylvania:

174-BT-S

Publication No. CG-10-HWO

Printed in the U.S.A. 1212

www.slantfin.com

INTRODUCTION

This Caravan application manual is intended to simplify the selection

and application of Slant/Fin modular systems for a variety of space

heating and domestic hot water requirements. Where any additional

information is required, contract your local wholesaler, Slant/Fin

C. Faster, easier installation - modules are completely factory

assembled, including individual jackets to save on-site labor.

Optional easy to install supply and return headers with flexible

quick connect fittings are available for hot water systems.

sales representative, or the Slant/Fin factory.

D. Safety - each module contains an individual high limit control

A. Design flexibility - Caravan modular boiler systems are

vailable in virtually any size capacity simply by adding modules.

a

B. Boiler room design, size and flexibility - since Caravan

modules have the burner and controls mounted to the front, they

and a flame safeguard control. ASME relief valve is provided

eparately for mounting directly on boiler.

s

E. Fast domestic hot water recovery - Caravan offers an external

heat exchanger of the positive circulating type.

can be installed with minimum clearances as per codes, thus

saving a significant amount of floor space.

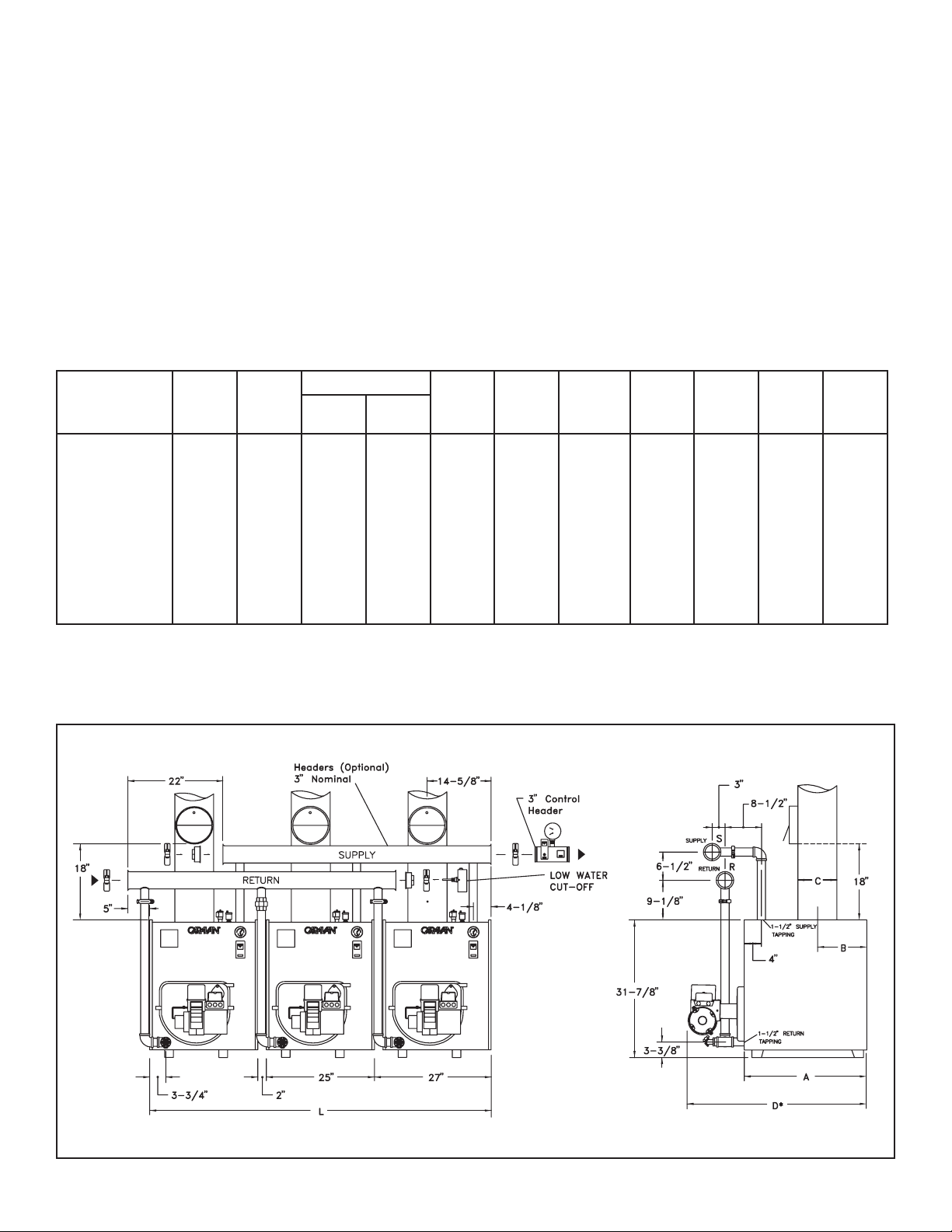

Table 1: Oil Caravan ratings hot water models - LDWO Series (100 psi maximum working pressure)

odel No.

M

LDWO-600-2-5

LDWO-750-2-6

LDWO-850-2-7

LDWO-900-3-5

LDWO-1100-3-6

LDWO-1300-3-7

LDWO-1700-4-7

LDWO-2100-5-7

LDWO-2500-6-7

LDWO-2900-7-7

LDWO-3400-8-7

* Light oil, 140,000 Btuh per gallon.

† Net ratings are based on a piping and pick-up allowance of 1.15. Slant/Fin should

be consulted before selecting a boiler for installation having unusual piping and

pick-up requirements.

No. of

eating

H

odules

M

2

2

2

3

3

3

4

5

6

7

8

Firing

ate

R

#2 Oil

GPH*

4.30

5.20

6.00

6.40

7.80

9.00

12.00

15.00

18.00

21.00

24.00

Ratings (MBH)

nput

I

602

728

840

896

1092

1260

1680

2100

2520

2940

3360

Gross

Output

500

596

711

750

903

1066

1421

1777

2132

2487

2843

‡ EDR

W

Sq. Ft.)

(

2900

3487

4120

4347

5233

6180

8240

10300

12360

14420

16480

ater

AHRI

et

N

Ratings

(MBH)†

435

523

618

652

785

927

1236

1545

1854

2163

2472

‡ Based on 150 Btuh per square foot E.D.R. at 170°F average water temperature.

§ Modules in excess of 8 are piped in parallel to first eight.

For larger sizes, use multiples of the above.

oiler

B

Horsepower

14.9

17.8

21.2

22.4

26.9

31.8

42.4

53.0

63.7

74.3

84.9

Water

ontent

C

gal.)

(

31.0

35.6

45.2

46.5

53.4

67.8

90.4

113.0

135.6

158.2

180.8

hip

S

Wt.

1570

1790

2000

2355

2685

3000

4000

5000

6000

7000

8000

Recommen

ed

d

Header

Size§

2"

2"

3"

3"

3"

3"

3"

3"

3"

4"

4"

Thermal

ff

E

%

82.7

82.7

84.6

82.7

82.7

84.6

84.6

84.6

84.6

84.6

84.6

2

odel No.

M

DWO-600-2-5 21

L

A B

5

⁄8 87⁄3

LDWO-750-2-6 25 9

29

C

2

8

34

†

D

3

⁄8 4

*

L

'4"

⁄32 8 373⁄4 4'4"

LDWO-850-2-7 283⁄8 1119⁄32 9 411⁄8 4'4"

LDWO-900-3-5 215⁄8 87⁄32 8 343⁄8 6'7"

LDWO-1100-3-6 25 9

29

⁄32 8 373⁄4 6'7"

LDWO-1300-3-7 283⁄8 1119⁄32 9 411⁄8 6'7"

LDWO-1700-4-7 283⁄8 1119⁄32 9 411⁄8 8'10"

LDWO-2100-5-7 28

LDWO-2500-6-7 28

LDWO-2900-7-7 283⁄8 1119⁄32 9 411⁄8 15'7"

LDWO-3400-8-7 28

Note: Standard boiler unit prefix is LDWO.

3

⁄8 1119⁄32 9 411⁄8 11'1"

3

⁄8 1119⁄32 9 411⁄8 13'4"

3

⁄8 1119⁄32 9 411⁄8 17'10"

Figure 1. Oil Caravan dimensions and typical piping/hot water models

* 27" spacing between modules.

Design Data

Max. ASME Working Pressure: 100 psi

Power Requirements: 120 V/60 HZ,

Amp (s) per module:

For Carlin burners 6.0

RECOMMENDED PIPING AND WATER FLOW

Good system design addresses flow rates through boilers. It is

possible to have too little flow and too much flow. Most boiler

system designs are based on a 20˚F to 30˚F temperature rise in

the boiler when it is firing at full input.

When the flow rate is too high through a module the water flow

tends to short circuit from the return tapping to the supply tapping

of a module. When flow rate is too high the boiler efficiency may

drop and there is excess electrical consumption by the circulator.

Recommended water flows and resultant pressure drops through

Caravan modules are as follows. Flow rate is for 20 rise in water

temperature and pressure drop is determined at recommended

flow rate and includes 1-1/2” pipe that connects module to

Slant/Fin header.

7-section modules are used in LDWO-850, LDWO-1300,

Module

Flow Rate/

Module GPM

7-section 34 0.30

6-section 30 0.30

5-section 25 0.30

LDWO-1700, LDWO-2100, LDWO-2500, LDWO-2900 and LDWO-3400.

6-section modules are used in LWO-750 and LWO-1100.

5-section modules are used in LWO-600 and LWO-900.

Operating Pressures

System static pressure should be at least 15 PSI cold in modules.

When circulators are operating the pressure in the modules

should be at least 15 PSI when the water is cold.

Optional Piping Method - Primary/Secondary

When applying oil-fired Caravan boilers to a low temperature

water system care should be taken to maintain 130˚F return water

temperature inside the Caravan boiler. One way to accomplish this

is to design the boiler using primary/secondary piping.

Slant/Fin recommends a minimum of 15˚F system water

temperature rise across modules that are firing. If the desired

temperature rise is lower than a primary/secondary arrangement

should be used, either for the whole modular boiler or using a

Pressure

Drop/Module PSI

multiple boiler system as described below. The 15˚F minimum

temperature rise can be maintained in the modules without

affecting the system water.

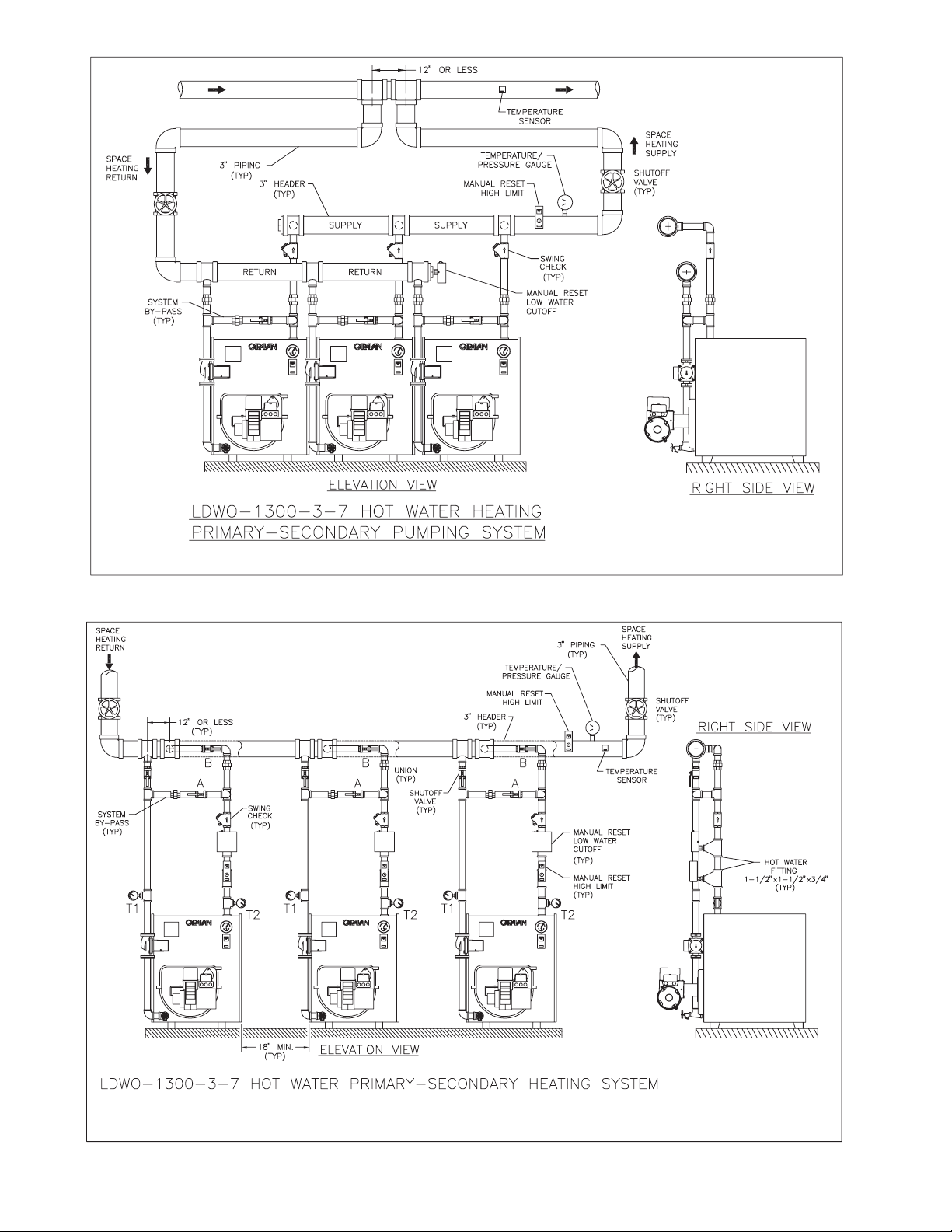

1. Primary/secondary piping may be applied to a Caravan

modular boiler system as demonstrated on Figure 4. In this

type of application the modular boiler is contained within the

primary loop. However, this is still a modular boiler, if it has

no valves between the modules.

2. Primary/secondary piping may also be used on each individual

“module”, please see figure 5. In this arrangement the Caravan

is no longer a “modular” boiler, it is now a “multiple” boiler

system. In a multiple boiler system each module is actually a

standalone boiler and each boiler should be equipped with a

manual reset hi limit and low water cutoff. Certain local codes

also require a minimum distance between each boiler.

Please remember to always follow code requirements applicable

to the building that the boilers are being installed in.

Most Caravan systems are applied as a modular boiler, not as a

multiple boiler. A modular boiler system is efficient, easy to maintain and very dependable. When a multiple boiler is used there are

additional circulators, manual reset hi limits and low water cut-offs

to install and maintain.

Some people believe a multiple boiler system is more efficient

because water flows through only those units that are firing. They

may think water flowing through modules not firing leads to energy

loss in those modules. However, we must remember a boiler heat

exchanger is designed to absorb heat from high temperature combustion and transfer it to low temperature water (certainly below

250˚F water). Boilers do not make good “convectors” and very little

heat is passed through the venting of a module not firing. Oil-fired

modules experience very low airflow through the heat exchanger

when not firing.

In most applications we recommend a step or stage controller,

that modulates system water temperature, be used on a Caravan

system. These controls ensure the number of modules firing

equals the actual demand for heat. Slant/Fin’s step controllers are

the SC-3 and SC-9 model controls. Please see the Control section

of this manual for more information on these controls.

3

Figure 2. Typical space heat piping – For primary circulation only.

Figure 3. Typical space heat and domestic piping – For primary circulation only.

4

Figure 4. Primary/Secondary piping of modular boiler.

Figure 5. Primary/Secondary piping of multiple boiler.

5

ECOMMENDED SYSTEM PIPING AND WATER FLOW

R

Minimum flow rate formula:

Minimum flow rate through modules =

Gross output (MBH)

20,000

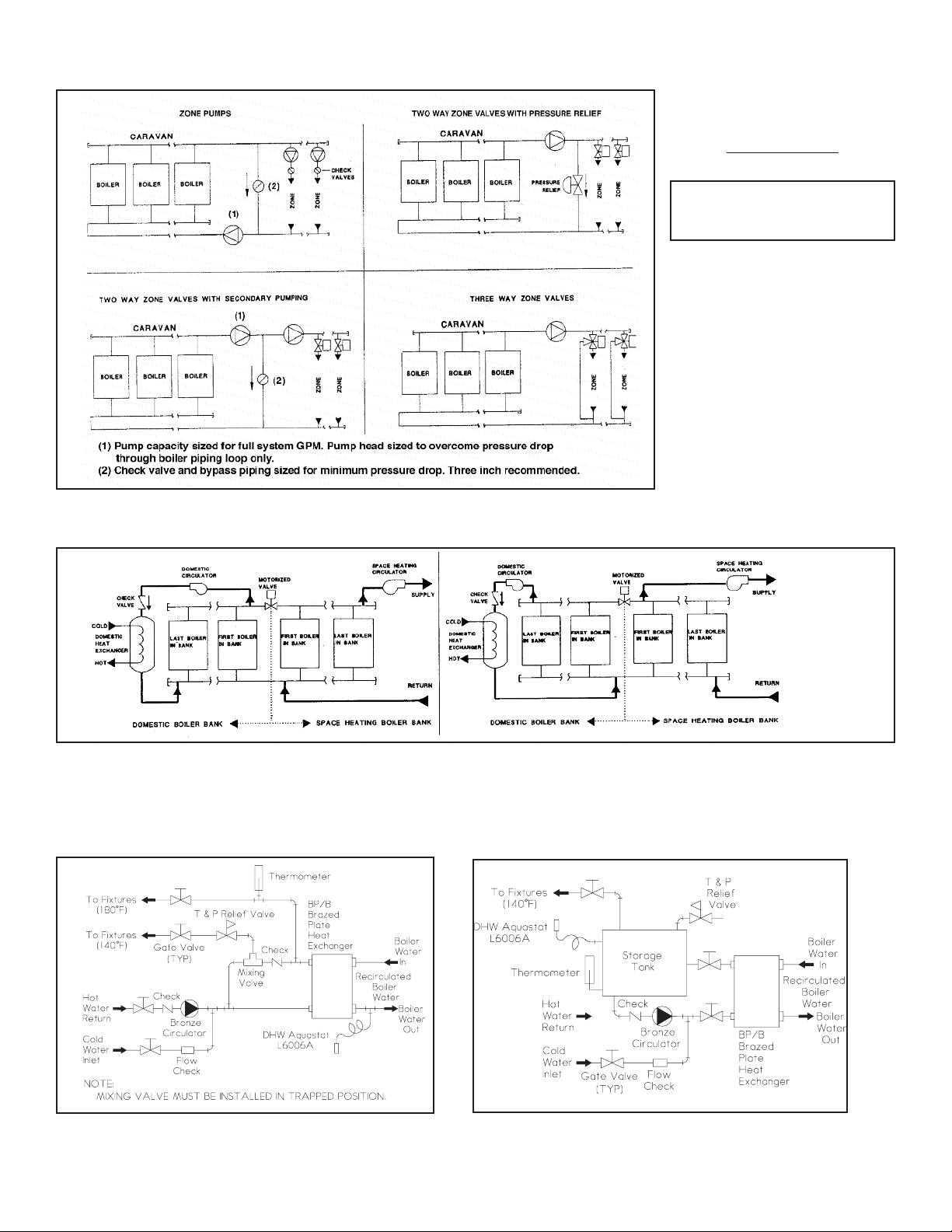

Figure 6. Recommended boiler piping for variable volume zone circulation

Note: A water flow proving device

is recommended on all

Caravan systems.

Figure 7. Supply and return piping locations for space heat with domestic hot water

SUGGESTED DOMESTIC HOT WATER PIPING

Figure 8: Instantaneous tankless coil—

two temperature with recirculation

Figure 9: Storage tank from tankless coil with recircula-

tion locations for space heat with domestic

hot water

6

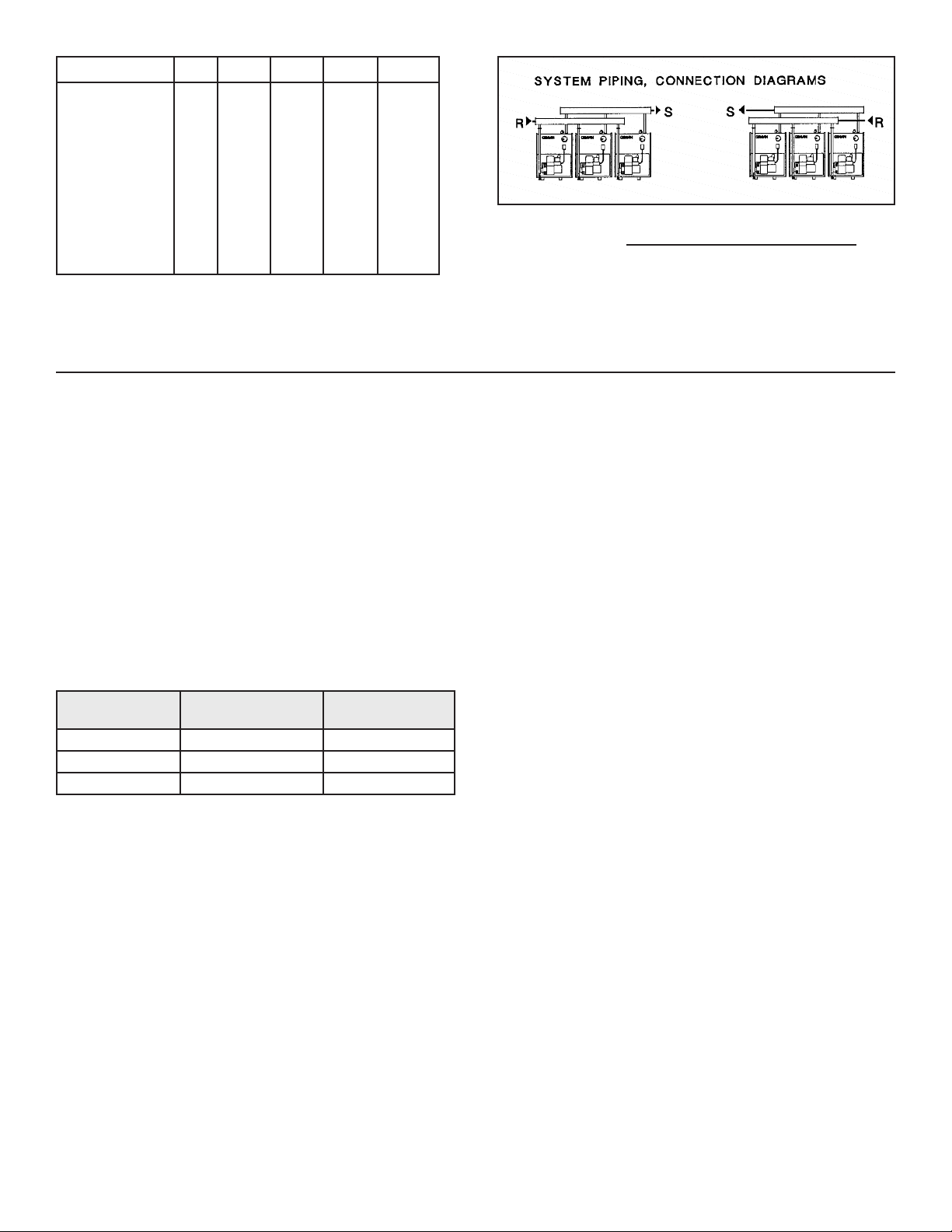

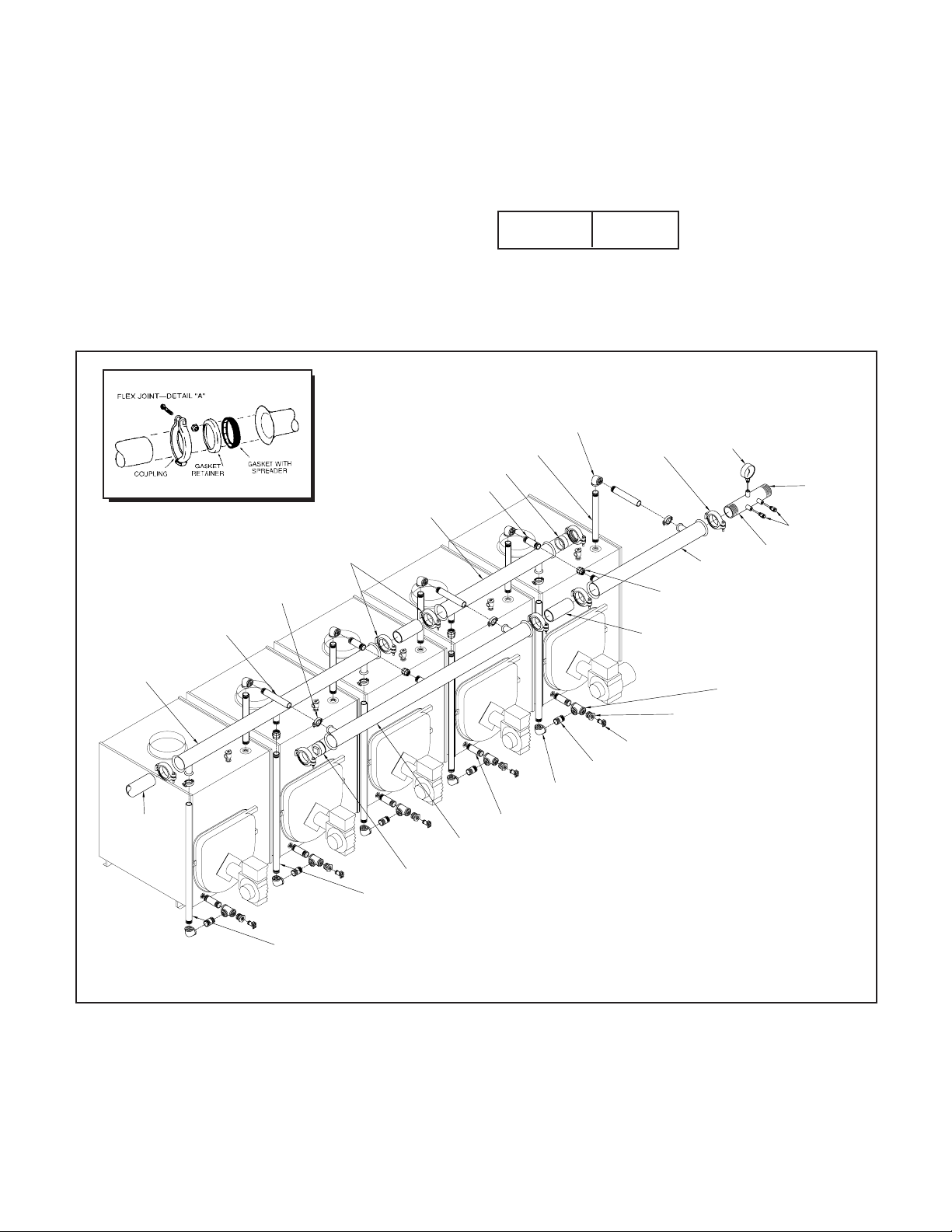

EQUIPMENT INCLUDED

3

'' RETURN HEADER

WITH 1

1

/2'' STUBS

(3 MODULE)

* 3'' BUILDING

PIPING

(

BY OTHERS)

1

1

/2'' X 34'' SQUARE NIPPLE

1

1

/2'' X 30'' NIPPLE

CAST END CAP

WITH

3

/4'' TAPP ING.

SUPPLY OR RETURN.

FOR USE WITH LWCO.

3

'' SUPPLY HEADER

WITH 1

1

/2'' STUBS

(3 MODULE)

1

1

/2'' X 4'' NIPPLE

3'' PIPE X 20''

(BY OTHERS)

1

1

/2'

' UNION

1

1

/2'' X 11/2'' X 11/2'' TE E

1

1

/2'

' X

3

/4'

' BUSHING

3

/4'' DRAIN VALVE

1

1

/2'' X CLOSE NIPPLE

1

1

/2'' ELBOW

3'' SUPPLY HEADER

W

ITH 1

1

/2'

' STUBS

(

2 MODULE)

*3

'' BUILDIING PIPE

CONNECTION

1

/2'

' PRESSURE

TEMPERATURE

GAUGE

1

/2'' WEL LS

3'' FLEX JOINT

(SEE DETAIL "A")

1

1

/2'' ELBOW

1

1

/2'' X 15'' NIPPLE

C

AST END CAP

3

'' RETURN HEADER

WITH 1

1

/2'' STUBS

(2 MODULE)

3'' FLEX JOINTS

(

SEE DETAIL "A")

1

1

/2'' X 8'' SQUARE NIPPLE

1

1

/2'' FLEX JOINT

(

SEE DETAIL "A")

1

1

/2'

' X 4'' NIPPLE

CONTROL HEADER

3'' x

1

/2'' x 1/2'' x 1/2''

LDWO SERIES –– Hot Water Models

• Pre-assembled heat exchangers with built-in air separators

• Insulated baked enamel jacket.

• Flue collector.

• Draft regulator.

• Flame retention oil burner with nozzle and CAD cell.

• Primary burner control.

• Temperature limit.

• Flue brush.

• Module temperature and pressure gauge.

• System pressure and temperature gauge.

(unmounted-1 per system).

• Pressure relief valve (unmounted-1 per module).

• Control header (unmounted-1 per system, up to 8 modules).

OPTIONAL EQUIPMENT

• Headers.

• Control System.

Pressure/Temp Rating for flex joint fittings

150 psi 275˚ F

*Building piping must be rigidly secured so it cannot

move where connected to headers.

NOTE:

Shown reverse return (Preferred). For direct return,

header assembly piping connections may be made at

the same end of the boiler bank, not as shown.

Some governing agencies do not allow compression

type couplings. Consult your local code requirements.

Figure 10. Oil Caravan—optional header assembly for all models LDWO and LWDF hot water Caravan systems.

7

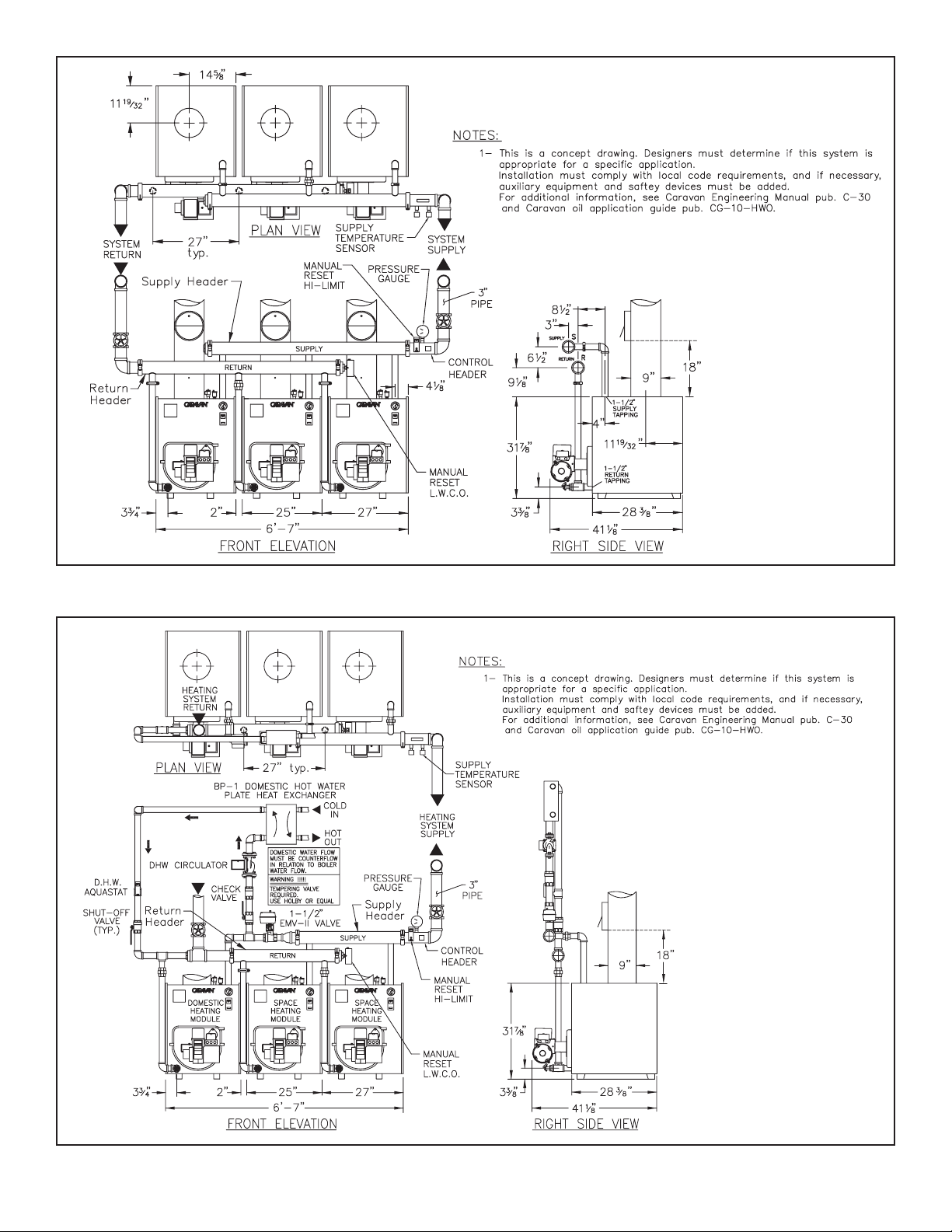

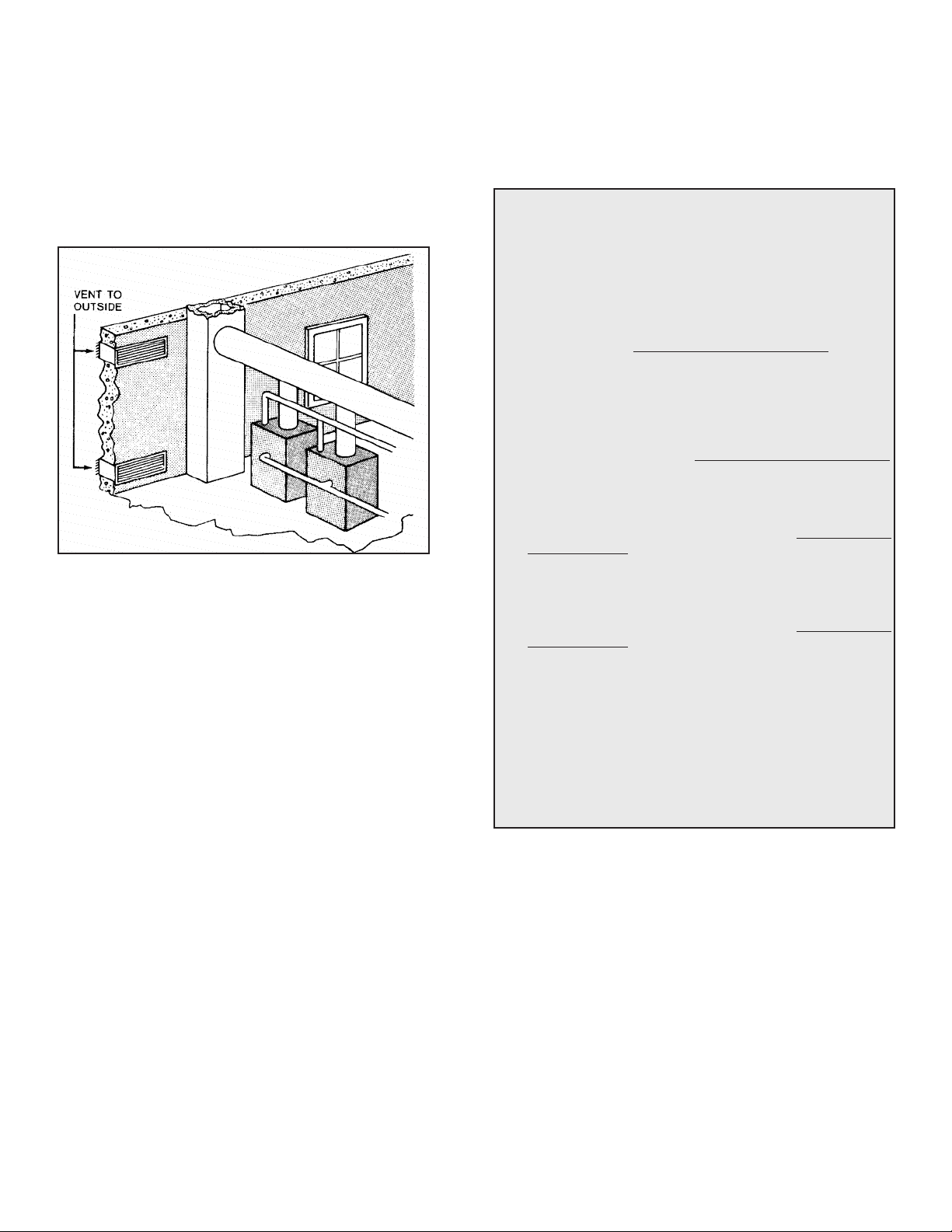

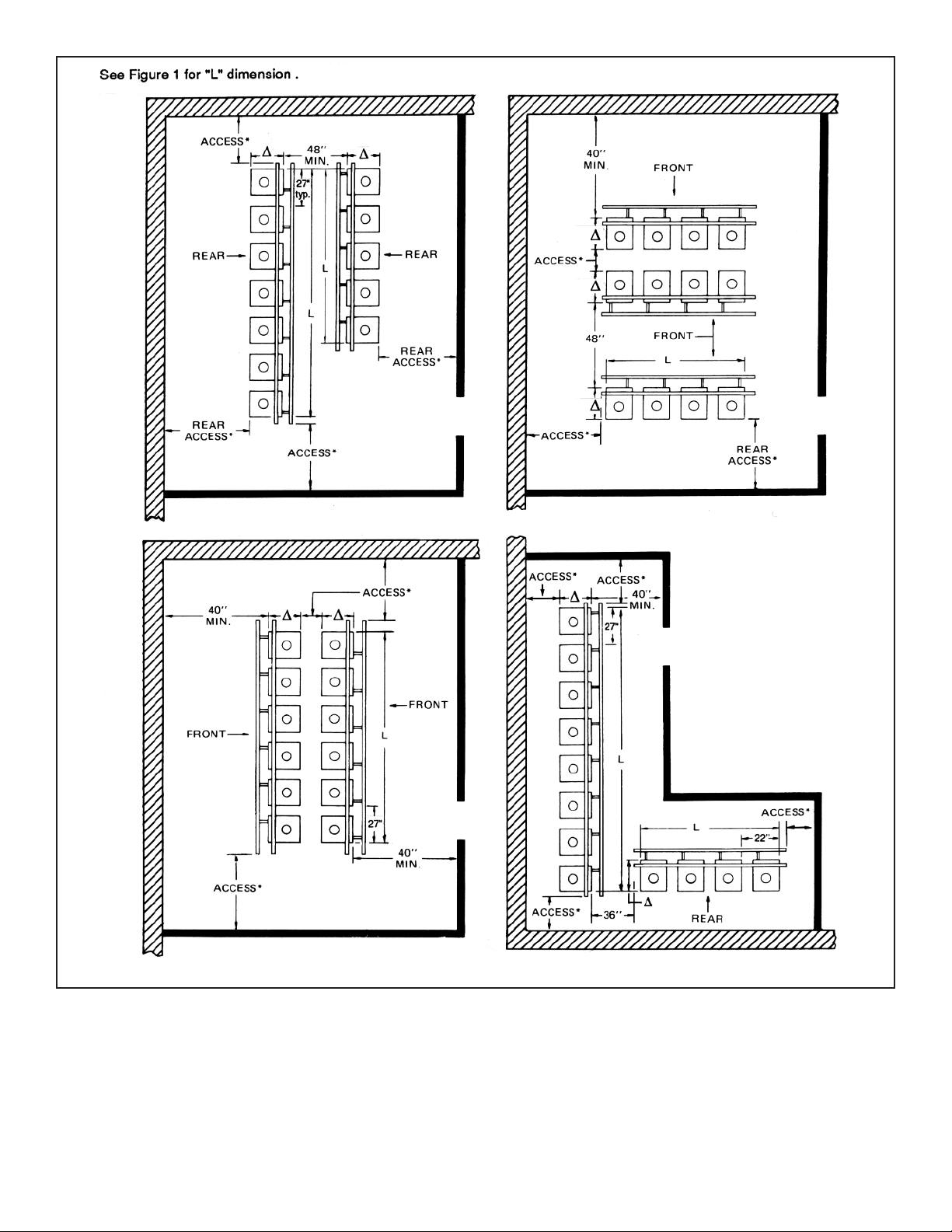

BOILER ROOM DESIGN

Caravan modular boiler systems allow better utilization of floor

space and permit future expansion with minimum cost. Caravan

modules are hand truckable, fit through doorways and often may

be installed around an existing inoperative boiler. They can be

grouped in heating module batteries of single, multiple or angular

rows. Oil-fired boiler systems consisting of 9 or more modules

should be piped in parallel in two or more batteries. Illustrated

below are typical boiler room layouts and dimensional data on the

ize requirements of oil-fired hot water boilers.

s

Figure 11. Correct location of combustion-air supply ducts

BOILER ROOM AIR SUPPLY

To ensure safe, efficient operation, the modular boiler system must

be supplied with sufficient air to support complete combustion,

replacing air entering draft dampers or draft hoods and ventilating

the boiler room or areas. For additional information, not listed

below, see ANSI,Z223.1, section 5.3.3.

INSTALLATION IN ENCLOSED BOILER ROOM REQUIRES

WO UNOBSTRUCTED OPENINGS FOR PASSAGE OF

T

AIR INTO THE BOILER ROOM:

1. Air drawn horizontally from outdoors DIRECTLY

through an outside wall; one louvered opening near

the floor (below burner air inlet) and one louvered

opening near the ceiling (above the highest draft

regulator), each opening with a minimum FREE air

passage area of 1 square inch per 4000 BTUH

system input.

2. Air drawn horizontally from outdoors through

HORIZONTAL DUCTS; one opening near the floor (below

burner inlet) and one opening near the ceiling (above the

highest draft regulator), each opening with a minimum

FREE air passage area of 1 square inch per 2000 BTUH

of total system input.

3. Air drawn VERTICALLY from outdoors; one opening

at the floor and one opening at the ceiling, each opening

with a minimum FREE air passage area of 1 square inch

per 4000 BTUH of total system input.

4. Air drawn from inside the building; one opening near

the floor (below burner inlet) and one opening near the

ceiling (above the highest draft regulator), each opening

with a minimum FREE air passage area of 1 square inch

per 1000 BTUH of total system input.

of total

IF BOILERS ARE INSTALLED ADJACENT TO OTHER FUEL

BURNING EQUIPMENT, THE AREA OF FREE OPENINGS

MUST BE APPROPRIATELY INCREASED TO ACCOMMODATE

THE ADDITIONAL LOAD.

UNLESS PROPERLY CONTROLLED, AVOID THE USE OF

FORCED VENTILATION, SINCE IT CAN CREATE AN

UNDESIRABLE PRESSURE DIFFERENTIAL BETWEEN

BOILER ROOM AND AIR SOURCE.

8

Figure 12. Typical layouts for oil-fired systems

* Caravan can be installed as close as 1" from the wall, local codes

permitting. However, 24" is recommended for service inspection

access.

∆ See Figure 1 dimensions A and D.

9

Loading...

Loading...