Page 1

A major answer to the changing heating-fuel situation

HOT WATER MODELS IN 9 SIZES

8 kw (27,301 Btuh) to 40 kw (136,506 Btuh)

Before purchasing this appliance,

read important energy cost and

efficiency information available

from your contractor.

Page 2

Monitron Compact, easy to install for new or “standby” installations

TM

Monitron combines the availability and dependability of electricity with the

comfort and performance of conventional hydronic heating using baseboard,

radiant or cast-iron radiators.

Monitron as a replacement unit: Works with virtually any existing

hot water hydronic radiation system. Although rated in kilowatts, it is

also clearly identified by BTU output.

Monitron as a standby unit: Particularly suitable for commercial

and industrial facilities, or office buildings which can’t risk down-time

with their existing heating equipment. If oil or gas is temporarily unavailable, the owner easily switches the heating system to the electric boiler.

Monitron as a primary heating unit offers:

• The convenience of electricity and the comfort of hydronics.

• The elimination of a chimney.

• Competitive pricing with electric baseboard systems.

• Simple zoning by zone valves.

Monitron by Slant/Fin is the electronic-age boiler designed to save

energy for new or existing heating systems.

TO ZONE VALVE

TRANSFORMER

WHEN USED

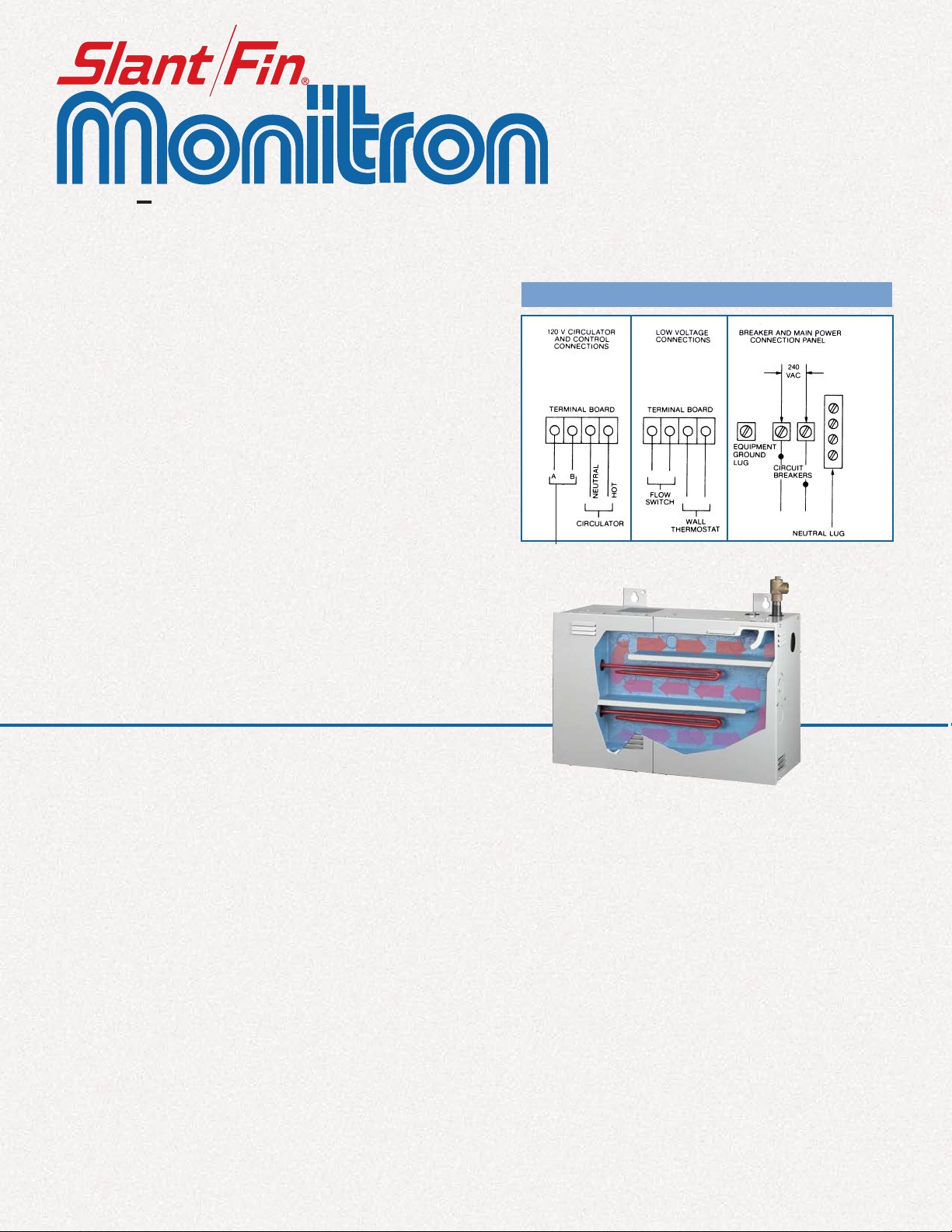

TYPICAL WIRING DIAGRAM

Monitron installed as primary boiler.

America’s Best - Built Electric Boiler

• One piece cast-iron heat exchanger.

• Built in air eliminator.

• Internal baffles improve heat transfer.

Energy-saver

electric sequential control package

With manual mild-weather energy-saver switches *

NORMAL OPERATIONS

When the thermostat calls for heat, the circulator turns on and the

first electric heater bank is energized. At preset 30-second intervals,

the other heater banks automatically energize. The circulator continues operating until the room thermostat is satisfied. A flow switch

supplied by Slant/Fin or others is required. It prevents the elements

from being energized unless the circulator is operating. This avoids

element burnout.

* All models except EH-8 and EH-10

OPTIONAL MILD-WEATHER OPERATION

Mild-weather energy savings are made possible through the use of

circuit breakers on the breaker panel.This permits the owner to

manually switch off one or more of the elements.Then, when just a

moderate amount of heat is needed, all the elements are not energized, cycling is reduced, and overheating is diminished.This energy-saving feature is standard on Monitron models EH-12-S through

EH-40-S.

Standard equipment

• Dual limit aquastat

• Altitude pressure and temperature gauge

• Safety relief valve (unmounted)

• Circulator relay and heater contactors

• Circuit breaker (one or two heaters per breaker)

• Low voltage thermostat with adjustable heat anticipator

(packed separately)

• Drain cock,

• Built-in air separator

3

⁄4 " (packed separately)

• Cast-iron ASME approved heat exchanger

• Terminal blocks for circulator, thermostat, flow switch and

• Sequencer

• Complete jacketing

• U.L. listed, ASME authorized

• Flow switch. Not included with, but necessary on all models

• Circuit breaker for circulator and control circuit.

*

for zone valve transformer

Page 3

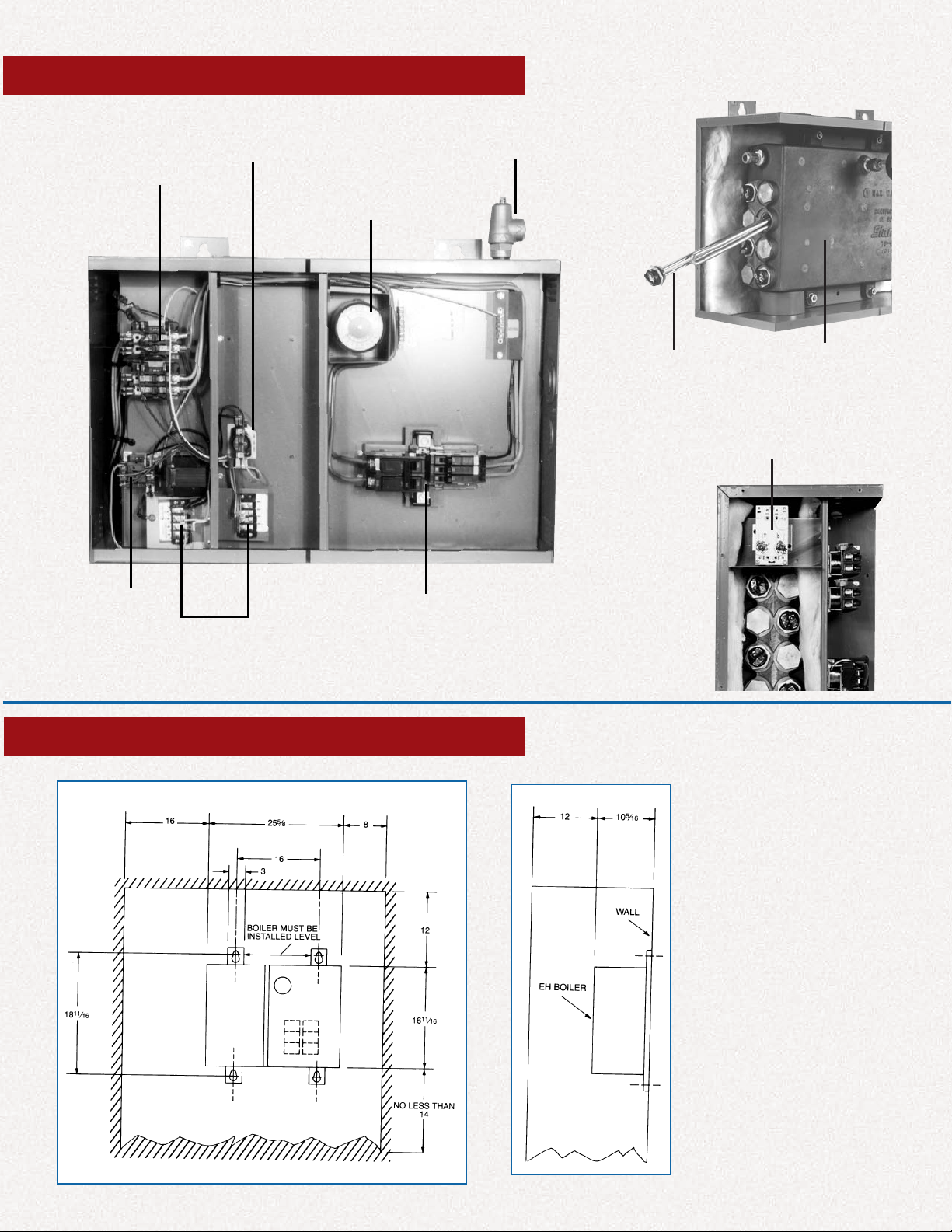

FEATURES

CONTACTORS

FOR HEATER

ELEMENTS

SEQUENCER

30 PSI PRESSURE

RELIEF VALVE

ALTITUDE

PRESSURE

AND TEMPERATURE

GAUGE

CIRCULATOR

RELAY

TERMINAL

BLOCKS

DIMENSIONS

CIRCUIT BREAKERS

HEATER

ELEMENTS

DUAL LIMIT AQUASTAT

CAST IRON

ASME HEAT

EXCHANGER

NOTES:

1. May be totally enclosed.

2. All clearance dimensions are

minimum.

3. All dimensions are in inches.

Page 4

RATINGS AND SPECIFICATIONS

SINGLE

SINGLE

PHASE

Boiler

Model No.

EH8S 8 27000 14-12 12 6-2/0 14-4 6-4 33 ––– ––– ––– ––– ––– –––

EH10S 10 34000 14-12 12 6-2/0 14-4 6-4 42 ––– ––– ––– ––– ––– –––

EH12S 12 41000 14-12 12 6-2/0 14-4 6-4 50 9.012 31000 6-2/0 14-4 6-4 25.1

EH16S 16 55000 14-12 12 6-2/0 14-4 6-4 67 12.016 41000 6-2/0 14-4 6-4 ‡38.1

EH20S 20 68000 14-12 12 6-2/0 14-4 6-4 83 15.020 51000 6-2/0 14-4 6-4 ‡48

EH24S 24 82000 14-12 12 6/2/0 14-4 6-4 100 18.024 62000 6-2/0 14-4 6-4 ‡60

EH28S 28 96000 14-12 12 2-250 MCM 14-4 6-4 117 21.028 72000 6-2/0 14-4 6-4 ‡60

EH32S 32 109000 14-12 12 2-250 MCM 14-4 6-4 133 24.032 82000 6-2/0 14-4 6-4 ‡73

EH40S 40 137000 14-12 12 2-250 MCM 6-2/0 ––– 167 30.040 103000 6-2/0 14-4 6-4 ‡95.4

* Multiply by 0.751 for values at 208 volts AC.

** Multiply by 0.867 for values at 208 volts AC.

† For total current add, to the value shown in the table, the current draw for

‡ Leg with the highest value of line current of an unbalanced 3 phase load.

* KW at

240 VAC

circulator and/or zone valve transformer (12 Amp. max.),

PHASE

D.O.E

Capacity

*(Btu/hr) at

240 VAC

Neutral Lug

Size (AWG)

Solid

Cu ¶ AL

Stranded

Cu ¶ AL

SINGLE PHASE –– THREE WIRE

Main Lug

Size (AWG)

CU ¶ AL

Grounding

Lug Size

(AWG)

Cu

¶ AL

THREE PHASE –– FOUR WIRE 208 VAC WYE §

† ** Heater

Amps at

240 VAC

¶ Aluminum conductors may be used, lug size, conduit size, ampacity and all

applicable codes permitting. However, aluminum conductors may not be

used for model EH-40 single phase.

§ 3 phase 240V special model also available.

Consult factory for information.

KW at

208 VAC

D.O.E

Capacity

(Btuh) at

208 VAC

Main Lug

Size (AWG)

CU ¶ AL

Grounding

Lug Size

(AWG)

¶ AL

Cu

† Heater

Amps at

208 VAC

Specify Model as follows: Model Number. Single or three Phase.

“135S” for single phase, 120V/240V, 120V/208V WYE. 3 wire (see

note (1) below) with control circuit breaker.

Example: EH-20-135S=20KW boiler for 120V/240V.

120V/208V Single Phase 3 wire.

“345S” for three phase, 120V/208V WYE. 4 wire (see note (1)

below) with control circuit breaker.

Note No. 1: Voltage of any line to ground cannot exceed

125 VAC.

ELECTRICAL

• Single branch circuit for 3 wire 120/208 V WYE, 120/240 Volt a.c.

single phase, 60 Hz or for 4 wire 120/208V WYE three

phase, 60Hz a.c. See note (1) above.

• Circulator relay 12 AMP Max, 120V a.c.

• Heating elements: Low-density replaceable. Copper sheathed

• Relays: Heavy-duty contactors, 48 AMP U.L. rating

TYPICAL PIPING DIAGRAM

FOR USE WITH TWO-WAY ZONE VALVES

and silver brazed base.

NOTES:

1. Optional blocking gate valve and hose end valve

used (with drain valve) for fast fill and purge of

system.

IMPORTANT Close bypass line valve

(if used) during purging.

2. Circulator should not be installed at lowest point

of piping.

3. There should be no elbows, tees, or change of

pipe size for at least 5 diameters of pipe size

(see table below) upstream and downstream of

flow switch.

Boiler Model

EH-40 FS8W 1 1⁄4 IN. 8 1⁄2 IN.

EH-8 Thru EH-32 FS4-3T3-1 1 IN. 6 1⁄2 IN.

Flow Switch

McDonnell

& Miller No.

Minimum Length of

Straight Pipe Upstream

Pipe

Size

and Down-Stream

of Flow Switch

© Slant/Fin Corp. 2003. Printed in U.S.A. 1203. Publication EH-10

SLANT/FIN CORPORATION., Greenvale, N.Y. 11548 • www.slantfin.com

Phone: (516) 484-2600 • Fax: (516) 484-5921

In Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario • www.slantfin.ca

Loading...

Loading...