Page 1

Page 2

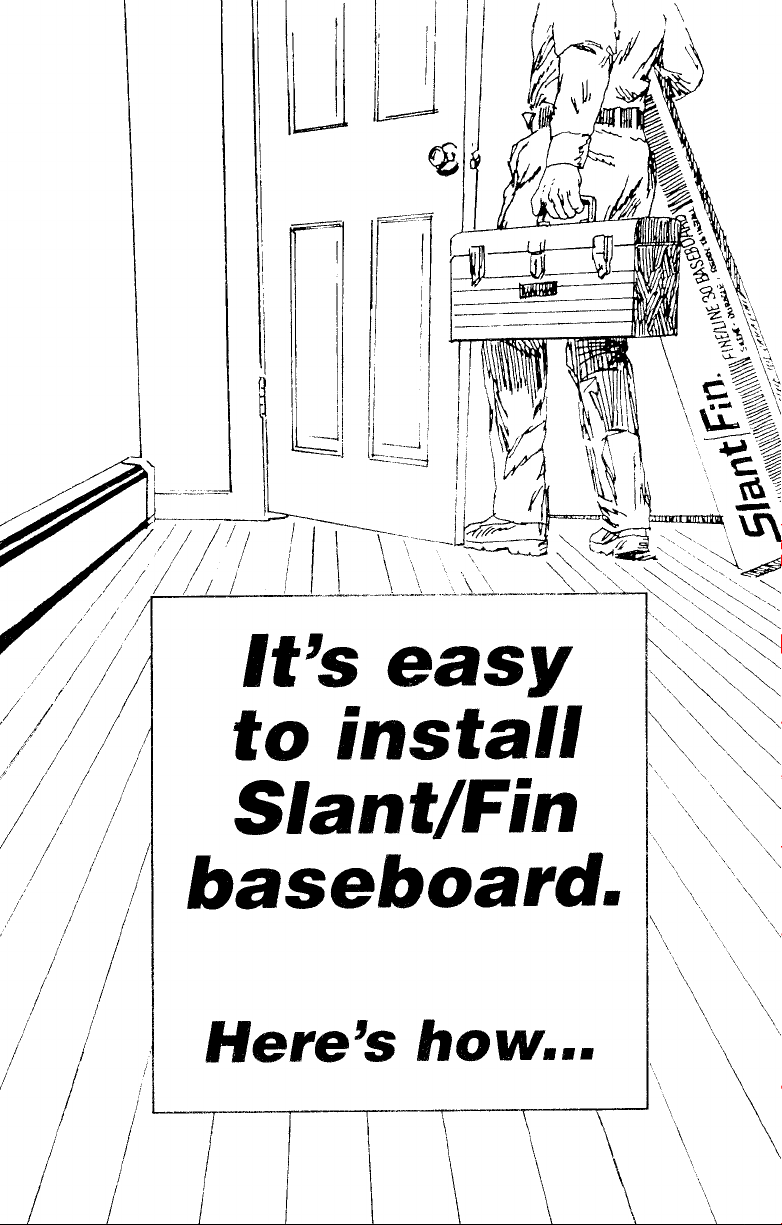

highlights of quick, easy Slant/Fin installation

1. Drill holes for risers and

connecting piping.

3. Join the elements to risers and each other and rest on brackets.

2. Nail baseboard to wall. For faster installation,

use “T-Shot” Nailing Tool, or, use power

screw gun.

4. Drop piping under doorways.

Page 3

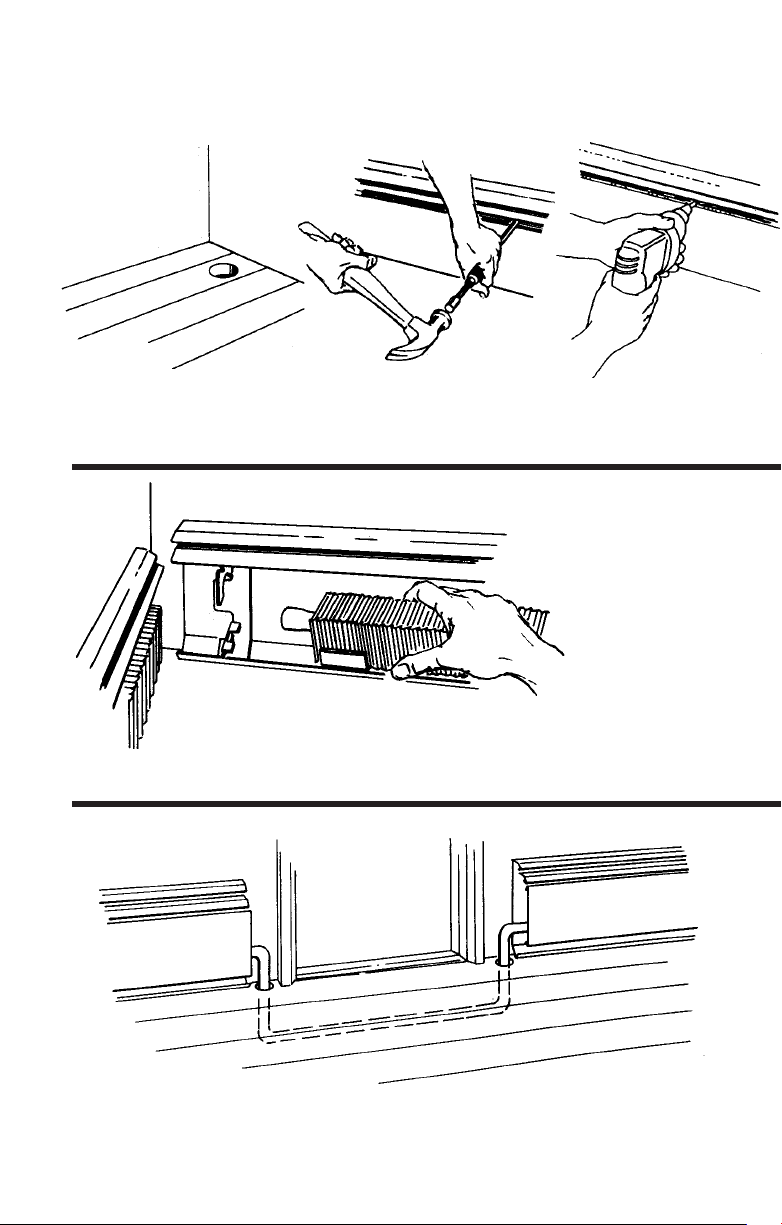

Slant/Fin installation

5. Snap front panel back in place.

7. Snap on inside corners and outside corners.

6. Join baseboard lengths

with splice plates.

8. Install wall trims at partitions.

9. Slide on end caps f

or finishing touch.

Page 4

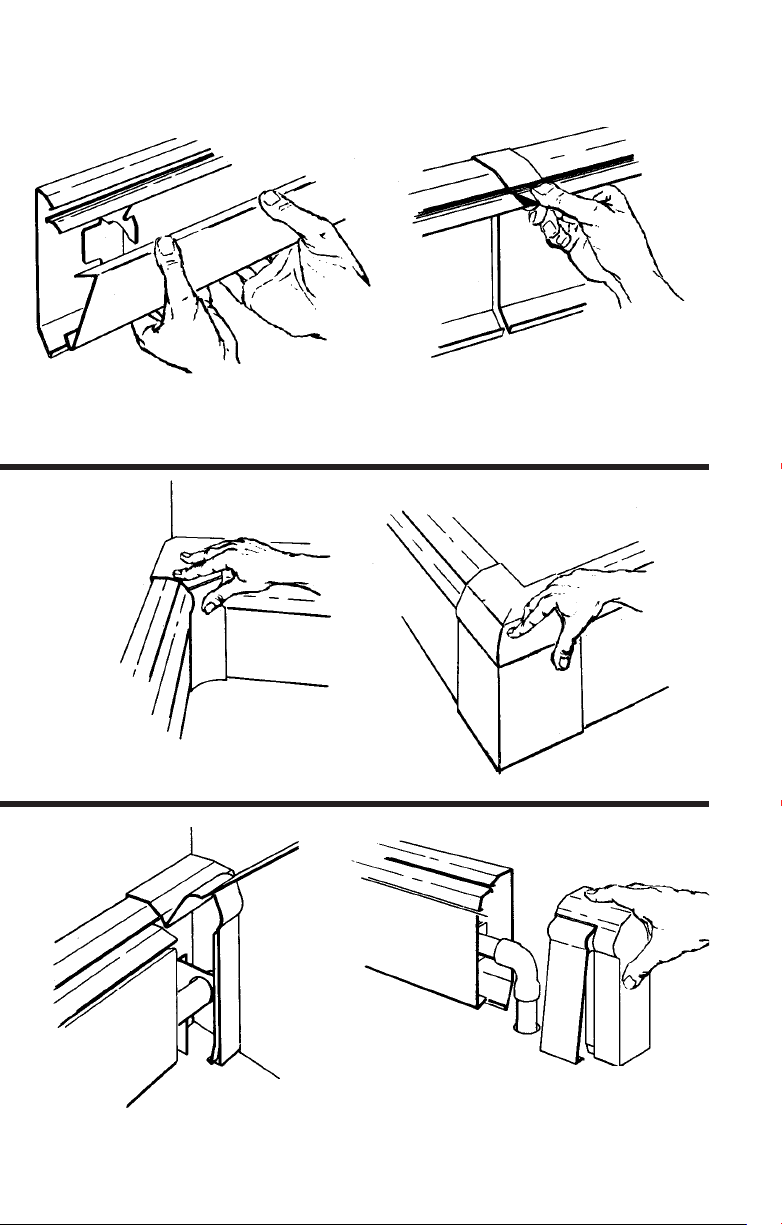

®

easiest kind of heating

to install

(and the most beautiful)

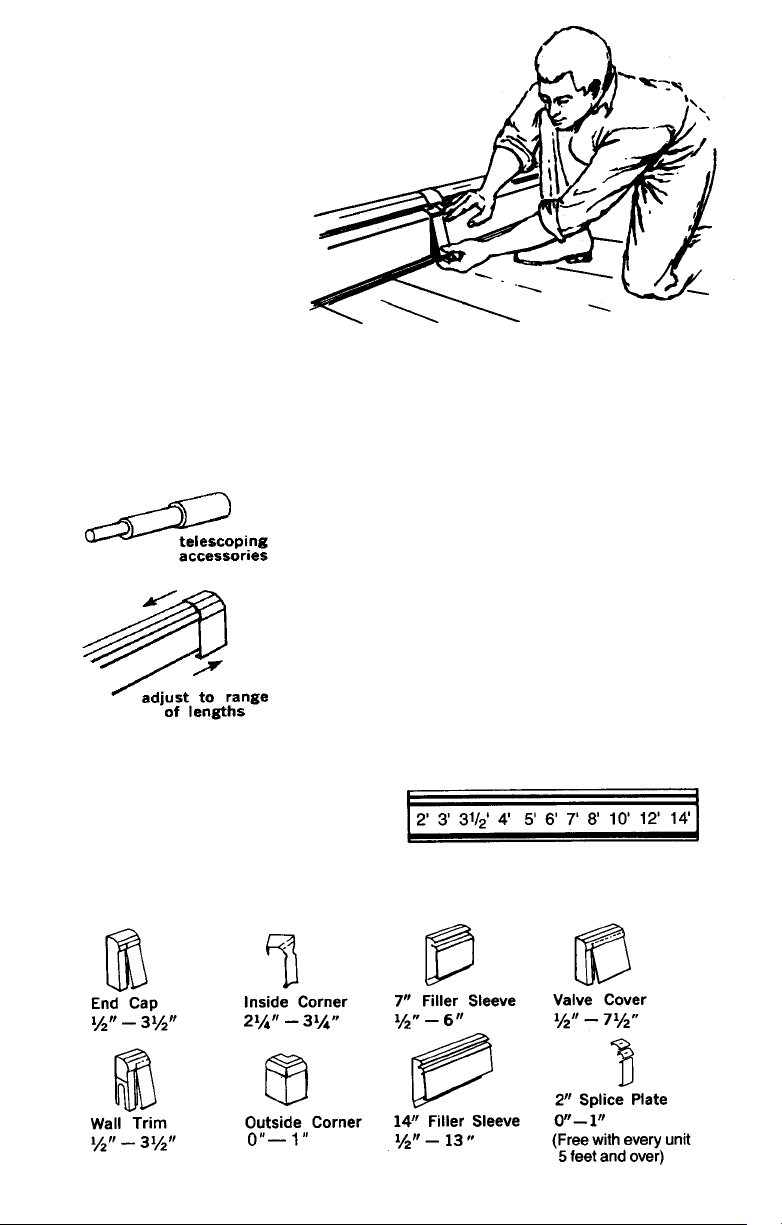

You’ll find that pre-assembled Slant/Fin baseboard

is surprisingly easy to handle. With Slant/Fin precut lengths and telescoping accessories you can

leave your hacksaw at home. All parts snap together securely at the touch of your fingers, and they

stay together. You end up with a neat, wall-to-wall

installation of beautiful and efficient baseboard

heating, without a shortened temper or bleeding

hands. And you’re in and out in half the time you’d

need with most other baseboards.

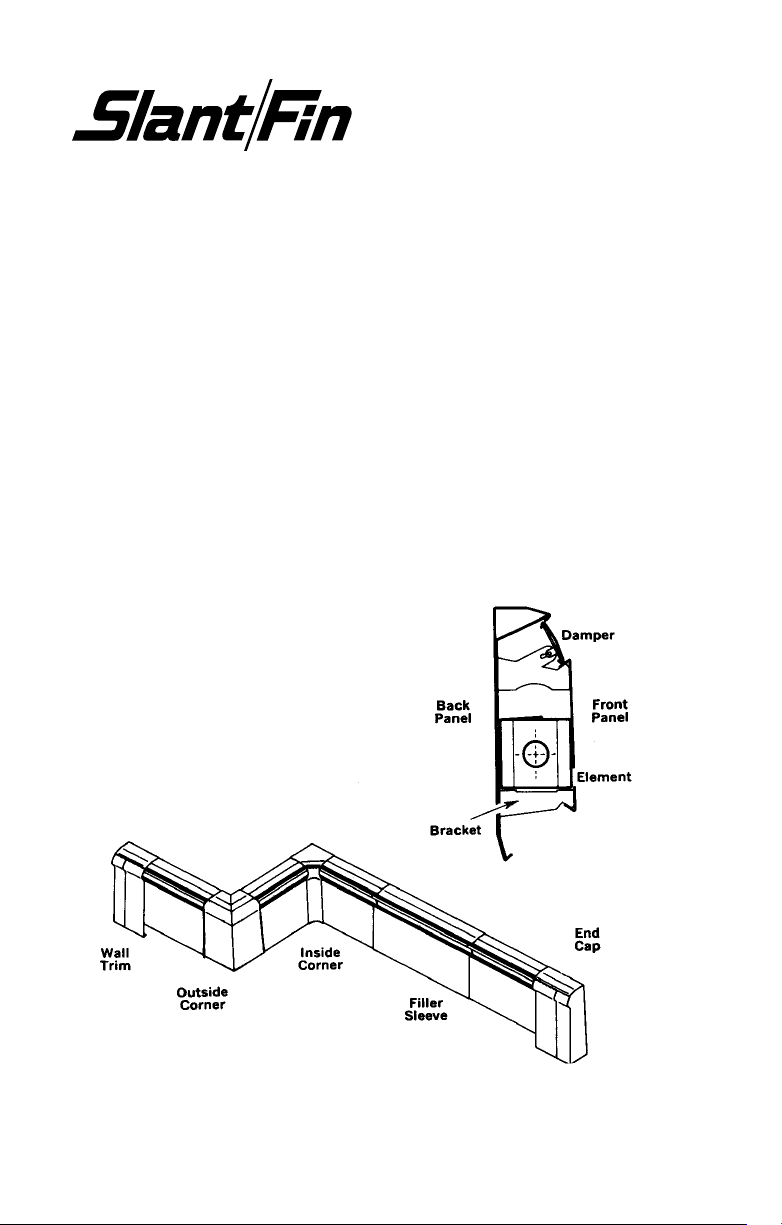

what the parts are called...

Baseboard and all accessor

recessed installation.

ies serve both flush or

Page 5

variety of stock lengths and

adjustable accessories assure

neat fit without cutting...

Slant/Fin baseboard units come in a wide variety of

standard lengths.The Slant/Fin accessories simply

snap over and behind the baseboard units permitting

them to slide left or right. The amount of overlap can

be adjusted from only 1/2” to almost the full width of

the accessory.This way you can virtually “stretch” or

compress standard lengths of baseboard and accessories to fit any length of wall without cutting them.

Slant/Fin installs faster than any other baseboard in

he world.

LENGTH NEEDED: (Simply determine which combination satisfies requirements).

These stock lengths are available in

both the complete baseboard package and enclosure only (the unit

without heating element, sometimes

referred to as dummy cover).

S/F accessories adjust telescopically to these lengths:

Page 6

plan your piping...

Here are examples of three basic piping systems, shown with and without options

for zoning.

1. SERIES LOOP

Series loop--single zone

(The simplest, most economical

system to install.) The Slant/Fin

baseboard damper provides individual room control. A single circuit runs from the boiler to the first

run of baseboard, continues from

there to the next room and so on.

The last baseboard unit in the

series is connected to the return

at the boiler. It keeps pipe, fittings,

controls and labor costs to a minimum. Use separate loop for each

zone.

Series loop--multiple zones

Each zone is a “Series loop” with

any number of Slant/Fin baseboard units and controlled by its

own room thermostat.

zone valve arrangement,

In the

each zone has an electrically

operated zone valve and there is

a single pump for the whole

system.

zone pump arrangement,

In the

each zone is provided with a

pump, a flow control valve and a

relay.

ies loop--m

Ser

individual pumps

ulti-z

one with

Page 7

2. SPLIT LOOP Provides more even

heat distribution and the option of

separate zone control. The house is

“divided” into two (or more) sections, each with its own circuit.

Each circuit draws water of the

same temperature from a central

trunk line. Balancing valves should

be installed in each circuit at return

end just before entering circulator.

3. ONE PIPE WITH DIVERTER TEES

Permits individual room shut-off or

thermostatic control. Each baseboard unit is connected to the main

by a supply and return branch connection (usually with a shut-off

valve at the diverter tee). This offers

a sophisticated system of room

temperature control, particularly in

conjunction with Slant/Fin’s fully

modulating damper.

air elimination...

Provision must be made for venting air from system, to prevent

noise or blockage of circulation by air pockets. Either install a

manual air vent at every drop, or install an automatic air eliminator

device at the boiler and a vent at highest point of the system for

extra safety. A vent at every drop is an advantage in case the system is later drained and refilled without purging.

Page 8

figure out

what material

to order...

First take wall to wall measurements

of all rooms from the plan or by actual field measurement. Next, calculate

the heat loss for each room, using

the IBR or equivalent method. Then

translate the output required into the

list of materials needed for each

room and wall.

NOTE: Often a shorter-than-wall length of radiation is called for. For instance, only

8 feet of radiation may be required on a 12 foot wall. You can drop the pipe through

the floor after 8’ (Method A) or continue the run to the far wall for an attractive wallto-wall look, using enclosure only with plain tubing inside (Method B). Although this

uses more material, it’s often the simplest way to do the job. At the far wall you can

drop the pipe through the floor or run it through the wall to the next room. Straight

through eliminates potential air problems. (See page 15 for tips on installing enclosure only.)

Solid line indicates baseboard.

Broken line indicates piping below

floor, or in “enclosure only”.

Method A: pipe drops through the

floor at end of “complete assembly”

baseboard.

Method B: bare

pipe runs to far wall

inside “enclosure

only”.

e out a schedule of the material you need, room by room, so when you get it

Mak

you can sort it out easily for quick installation. Then place your order.

Page 9

begin by drilling

riser holes...

The riser connects sub-floor supply tubing to

the baseboard. The diameter of the riser hole

and the location of the hole with respect to

the walls will vary depending on the type of

baseboard you’re using. Here is a handy

chart to follow:

1

”

⁄4

1

”

⁄4

1

”

⁄4

1

”

⁄4

1

”

⁄4

1

”

⁄2

3

”

⁄4

Back Wall

to Center

(floor holes)

3

”

1

⁄8

21

⁄64

21

1

⁄64

3

”

1

⁄8

3

”

1

⁄4

9

”

1

⁄16

9

”

1

⁄16

3

”

1

⁄4

Diameter

Model

BL-50/75

15-50

15-75

30-75

81A

83A2

84A3 1” 1

85A/86AX 1

* Hole is 1/2” larger than pipe to allow for expansion. Install riser

snug to inside edge of hole to allow maximum room for riser to

move to outside edge of hole when pipe expands.

1

⁄2

Pipe

”

1

3

3

3

3

or

1

3

”

⁄2

”

⁄4

”

⁄4

”

⁄4

”

⁄4

”

⁄4

Hole*

”

⁄4

1

1” 1

1

1

1

1

1

Floor to

Center

(partition holes)

2

”

”

3”

3”

3

3

3

3

3

5

”

⁄16

3

”

⁄16

7

”

⁄8

1

”

⁄2

1

”

⁄2

7

”

⁄8

distribute the cartons along the

walls...

To make installation easy, lay out the cartons

of material and accessories along the wall in

the order in which they will be installed. Preplanning should specify which combination of

baseboard and accessories fits best.

9

Page 10

nail it up...

The pre-assembled baseboard goes right from carton to wall with Slant/Fin’s

“T-Shot” Nailing Tool (or power screw gun).You can load the Nailing Tool with

any nail up to

slip the Nailing Tool between the damper and front panel. Hit the drive rod

with the hammer and that’s it. Add another row of nails below the front panel.

If you’re working without a “T-Shot” or screw gun, snap off the front panel by

lifting it upward so the bottom bracket bends slightly upward, then pull toward

you with thumb.

1. for plaster walls...

Locate the studs in the wall and mark location above baseboard, or

on floor. It’s best to nail the baseboard at top and bottom to each stud.

2. for concrete or cinder block walls...

Use masonry nails, or install a furring strip and nail into it.

3. for a particularly solid installation...

Slide the bracket to the stud position and drive nail through the bracket

holes and the back panel.

before you drive your nails...

Make sure you leave enough room at the ends of the baseboard or other

points where accessories will have to be installed later.

NOTE: To avoid scratching or cutting yourself, always handle baseboard with care.

5

⁄16” round head. Just place the baseboard against the wall, and

solder the elements...

1. Clean and solder the adjoining element ends together using a non-corrosive

flux, and connect elements to risers.

2. Immediately upon completion, flush system thoroughly. Left unflushed, flux

can cause pitting in copper tubing of unfilled systems.

Fill system as soon as possib

3.

4. Make sure cradles are centered over brackets to allow for smooth expansion

without scraping noises.

le but prevent from freezing.

Page 11

Provide for

expansion with

HYDRO/TITE

expansion couplings

on long straight runs.

All piping expands when heated. In shorter runs, the movement of the risers

in their holes will take care of expansion. But on longer runs, it’s wise to

install an expansion compensator to prevent strains at the joints and buckling

of the elements. Install a Hydro/Tite at the center of a long run.

FLOW DIRECTION must be as shown, to

keep sludge from clogging the seals inside

the Hydro/Tite.

PULL OPEN until red line just shows under

the knurled collar. Install in this extended

position.

DON’T LOOSEN or tighten the knurled

collar. Proper adjustment (set at factory)

is hand-tight only.

KEEP HEAT AWAY from the knurled collar

and the coupling body, to avoid damage.

Use soft solder only

.

Page 12

replace front cover...

BASELINE 2000, FINE/LINE 30 & MULTI/PAK 80

Place lower edge underneath lower bracket.

Lift slightly and press upper edge forward

with thumb till panel snaps into place.

FINE/LINE 15

Place top edge of front panel on bracket

with panel in “up” position, swing down.

Important: to lock the panel to the bracket, pull cover outward away from bracket,

while swinging down. Push bottom of

panel to engage lower bracket.

snap on the accessories...

WALL TRIMS, END CAPS, CORNERS

For a neat finish at partitions, use the wall

trim (adjustable up to 3

recommended at each drop; either wall

trim or end caps (both hinged) provide

easy access to vent. These accessories

eliminate the wasteful need for cutting

large baseboard units to fit small gaps,

and save you time and effort. Attractive

inside and outside corners assure a

custom look.

FILLER SLEEVE, SPLICE PLATES

The Filler Sleeve has 4 parts: back

piece, damper sleever, top sleeve, front

sleeve. The Splice Plate is exactly the

same, but without a back piece.

12

1

”

⁄2

). Air vents are

Page 13

FILLER SLEEVES (cont’d)

1. When mounting the baseboard to the wall,

be sure the filler sleeve will overlap each

baseboard unit by at least

2. Slip in the back piece so that the bent

edge rests in the bottom channel of the

baseboard. Nail the back piece to the wall

to hold it in place.

3. Move both dampers to half-open position.

Hold the damper sleeve with the crimped

edge away from you. Hook it’s front edge

over the front edges of the dampers. Snap

the back edge of the sleeve into place by

pinching -- with thumb pressure on the

baseboard top panel and finger pressure

up under the back edge of the damper.

3A. (For Multi/Pak 80)

Move both dampers to

half open position.

Hook the damper

sleeve’s top edge over

the top edge of the

dampers. Press down

on the sleeve and

snap the bottom edge

into place.

1

⁄2”.

4. Hook the sharp angle of the top sleeve

over the front edge of the baseboard’s top

panel. Press down on the back edge until

the sleeve snaps into place.

5. Replace baseboard front covers. Hook the

front sleeve’s top edge over the front covers and snap the bottom edge into place.

Page 14

fine points, for a perfect job

RISER-RINGS slip

around tubing where it

passes through

flooring. They provide

neat, clean, sanitary

seal and absorb

expansion squeaks

and vibration noises.

May be installed after

connections are made.

FAST/FLEX CONNECTORS can be hand-formed

to fit varied piping problems. Use them to fit around

obstructions, compensate for misalignment, soak

up vibration and expansion at turns, eliminate

many solder joints. Cannot be used as an

expansion compensator.

for problem areas...

PEX-TO-BASEBOARD

CONNECTOR

PEX tubing is used to

and from the boiler,

Slant/Fin Terra Therma

PEX adapters connect

tubing to copper baseboard heating element.

When

HYDRONIC FLOOR BOX HEATER

recesses neatly into the floor for

upted heating comf

uninterr

doors and floor length windows. Ask for

publication HFB-10

t at patio

or

THE KICKER multi-purpose fan

convection heater fits in kickspace

under kitchen cabinets or bathroom

vanities. Ask for publication TK-10

Page 15

fine points using enclosure only...

Use Slant/Fin hanger to

support the bare tubing at

the same height as adjoining heating elements. Insert the short hook of the

hanger as shown. Install

from the left side, so that

the large hook (which

holds the tubing) faces the

rear panel.

when a normal loop

can’t be run...

In some installations, it’s not possible to drop the return line below the floor. In

this case, run the return tubing within the baseboard enclosure. Support with

wire hanger which you can shorten to hold the tubing in the space between the

heating element and bracket arm. For Base/Line 2000, a special cutout in the

bracket arm accommodates return tubing. Use a Slant/Fin return bend to connect the heating element with the return line above it. This fitting has a conven-

1

”

⁄8

ient

IPS threaded opening to receive an air vent.

replacing old

standing radiators...

A handy illustrated guide from Slant/Fin helps

you figure how many feet of baseboard it takes to

equal the heat output of most styles of standing

cast-iron r

adiators

or publication RC-40.

Ask f

.

Note: If the baseboard is

installed below the boiler

level, as in many slab

jobs, the return bend may

be installed with the vent

opening pointed downward, and plugged. This

permits easy drainage if

needed.

15

Page 16

...wasn’t that easy?

®

©Slant/Fin Corp. 1994. Printed in USA 103. Publication No. BB-40

Amer

baseboard con

ale, N.Y. 11548 • Phone: (516) 484-2600

v

Green

SLANT/FIN CORPORA

TION,

ica’

www.slantfin.com

. 1 brand of

s No

ection heating

v

Loading...

Loading...