Page 1

®

LDZO SERIES—Oil-Fired/Steam

A Caravan modular boiler system consists of

two or more compact cast-iron boilers that offer

significant advantages in terms of installed

cost, efficiency and reliability. Caravan

systems are based on step-fir

modules to meet space heating demands.

LDZO systems are available in 602,000 to

multi-million Btuh gross input. For additional

information, see Caravan Engineering

Manual, pub. C-30.

Standard Equipment

One per module unless otherwise noted

Pre-assembled cast-iron heat exchanger

with insulated jacket

Flame retention oil burner, with nozzle;

cadmium sulfide flame detector

Primary burner control

System pressure gauge and siphon

(unmounted, one per system)

Module pressure gauge and siphon

(unmounted)

Module pressure relief valve (ASME)

(unmounted) 15 PSI.

Draft regulator (unmounted)

Flue brush

ing just enough

Modular Boiler Submittal Data

Module drain cock

(unmounted)

Water level sight glass

(unmounted)

ASME Required Options

67 Low water cut off (one per module)

PA404A Pressure control (one per module)

67M Lo

w water cut off (one per system)

L4079B Manual reset pressure control

(one per system)

Ratings

Oil Caravan ratings and dimensions/steam models — LDZO Series

Ratings f

Burner

Capacity

(GPH)*

Input

(MBH)

Gr

Output

MBH

Model No.

No. of

Heating

Modules

LDZO-600-2-5 2 4.3 602 500 85.90 375 1563 14.9 21.4 1426 3"

LDZO-750-2-6 2 5.2 728 596 85.80 447 1863 17.8 25.2 1630 3"

LDZO-850-2-7 2 6.0 840 684 85.50 513 2138 20.4 29.0 1838 3"

LDZO-900-3-5 3 6.4 896 750 85.90 563 2345 22.4 32.1 2139 3"

LDZO-1100-3-6 3 7.8 1092 894 85.80 671 2796 26.7 37.8 2445 5"

LDZO-1300-3-7 3 9.0 1260 1026 85.50 770 3208 30.6 43.5 2756 5"

LDZO-1700-4-7 4 12.0 1680 1368 85.50 1035 4313 40.9 58.0 3675 6"

LDZO-2100-5-7 5 15.0 2100 1710 85.50 1319 5496 51.1 72.5 4594 6"

* Light oil, 140,000 Btu. per gallon.

† Net ratings are based on piping and pick-up allowance of 1.33.

Slant/Fin should be consulted before selecting a boiler for

installation having unusual piping and/or pick-up requirements.

For higher elevations, input may need to be reduced

oss

or No. 2 Oil

I=B=R

Comb.

Efficiency

Boiler

Net

Output

MBH†

‡ Based on 240 Btuh per square foot E.D.R. at 215˚F average

steam temperature.

Modules in e

banks.

Sq.Ft

Steam‡

xcess of 5 are piped in parallel in two or more

Horse-

power

Water

Content

(gal)

Weight

with

W

ater

mended

Recom-

Header

Size

Page 2

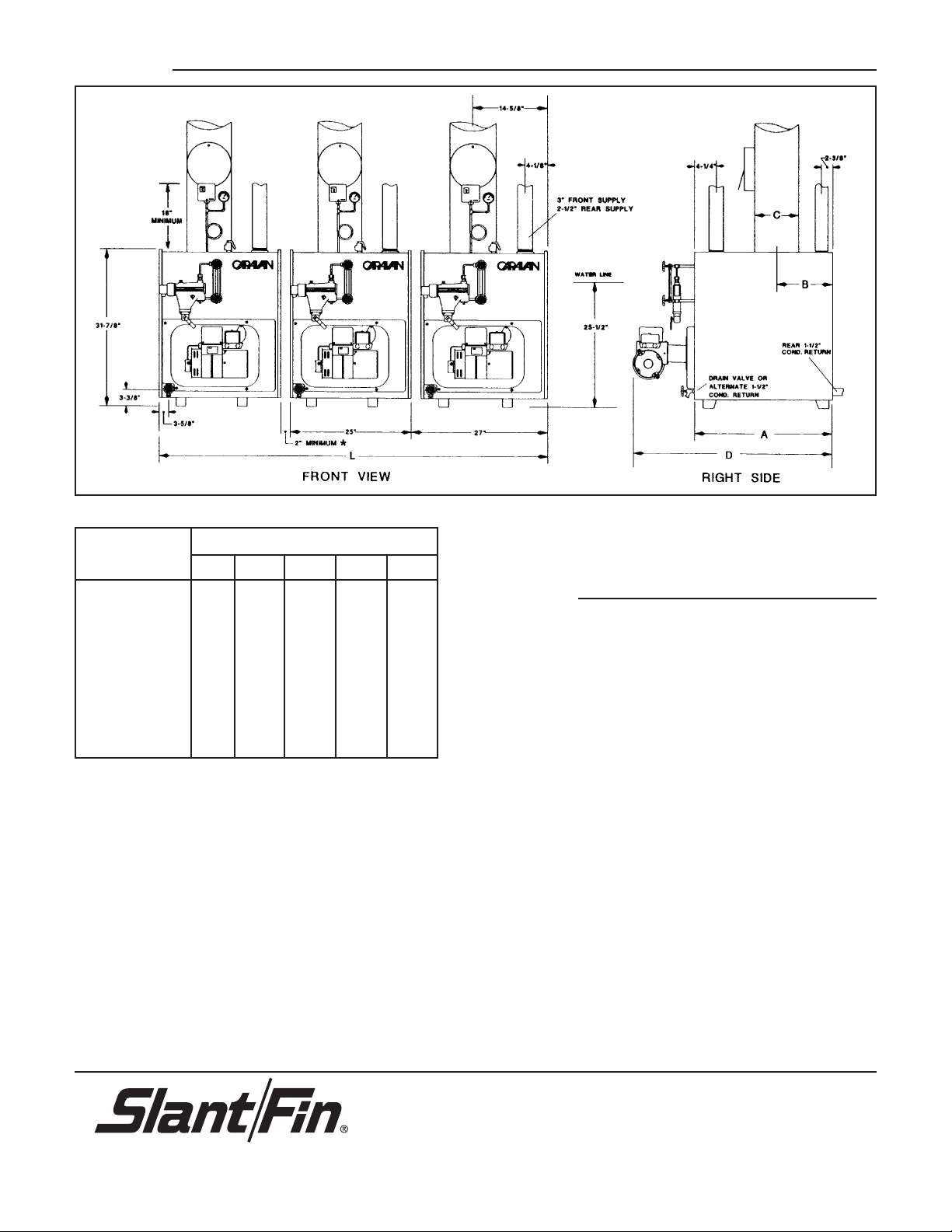

Dimensions

* CHECK LOCAL CODES TO VERIFY COMPLIANCE

Dimensions*

Model No.

ALBCD

LDZO-600-2-5 215⁄8 87⁄32 8343⁄8 4'4"

2

LDZO-750-2-6 25 9

LDZO-850-2-7 28

LDZO-900-3-5 21

LDZO-1100-3-6 25 9

LDZO-1300-3-7 28

LDZO-1700-4-7 28

LDZO-2100-5-7 28

* Inches

, except “L” which is feet/inches.

9

⁄32 8373⁄4 4'4"

3

⁄8 1119⁄32 9411⁄8 4'4"

5

⁄8 87⁄32 8 343⁄8 6'7"

29

⁄32 8373⁄4 6'7"

3

⁄8 1119⁄3

3

⁄8 1119⁄32 9411⁄8 8'10"

3

⁄8 1119⁄32 9411⁄8 11'1"

9 411⁄8 6'7"

2

Design Data

Max.

ASME Working Pressure: 15 psi

Power Requirements: 120 V/60 HZ,

6.0 amps per module

©Slant/Fin Corp. 1991. Printed in the U.S.A. 1003. Publication No. C-10-MOS

SLANT/FIN CORPORATION, Greenvale, N.Y. 11548 • Phone: (516) 484-2600

FAX: (516) 484-5921 • Canada: Slant/Fin LTD/LTEE, Mississauga, Ontario

www.slantfin.com

Loading...

Loading...