Page 1

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento

y seguridad

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: Appel gratuit : Número de teléfono gratuito:

1-877-SKIL999 (1-877-754-5999) http://www.skil.com

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 11 Ver página 20

6215

6220

6245

6250

6355

6360

SM 2610968981 2/03 2/10/03 3:14 PM Page 1

Page 2

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified

electrician to install a polarized outlet. Do

not change the plug in any way. Double

Insulation eliminates the need for the

three wire grounded power cord and

grounded power supply system. Before

plugging in the tool, be certain the outlet

voltage supplied is within the voltage marked

on the nameplate. Do not use “AC only”

rated tools with a DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased

risk of electric shock if your body is

grounded. If operating the power tool in

damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to

supply the power to your tool. Electrician’s

rubber gloves and footwear will further

enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the

cord to carry the tools or pull the plug

from an outlet. Keep cord away from

heat, oil, sharp edges or moving parts.

Replace damaged cords immediately.

Damaged cords increase the risk of electric

shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor

use and reduce the risk of electric shock.

Refer to “Recommended sizes of Extension

Cords” in the Accessory section of this

manual.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

Keep handles dry, clean and free from oil

and grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in. Carrying tools

with your finger on the switch or plugging in

tools that have the switch “ON” invites

accidents.

Remove adjusting keys or wrenches

before turning the tool “ON”. A wrench or

a key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing

and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal

injury.

SAVE THESE INSTRUCTIONS

-2-

!

WARNING

Power Tool Safety Rules

SM 2610968981 2/03 2/10/03 3:14 PM Page 2

Page 3

-3-

Safety Rules for Drills

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tools may contact hidden wiring

or its own cord. Contact with a “live” wire

will make exposed metal parts of the tool

“live” and shock the operator. Do not drill,

fasten or break into existing walls or other

blind areas where electrical wiring may exist.

If this situation is unavoidable, disconnect all

fuses or circuit breakers feeding this

worksite.

Always use auxiliary handle for maximum

control over torque reaction or kick-back.

High torque 3/8" and larger chuck capacity

drills are equipped with auxiliary handles.

Always wear safety goggles or eye

protection when using this tool. Use a

dust mask or respirator for applications

which generate dust.

Secure the material being drilled. Never

hold it in your hand or across legs.

Unstable support can cause the drill bit to

bind causing loss of control and injury.

Never leave the trigger locked "ON".

Before plugging the tool in, check that the

trigger lock is "OFF". Accidental start-ups

could cause injury.

Position the cord clear of rotating bit. Do

not wrap the cord around your arm or

wrist. If you lose control and have the cord

wrapped around your arm or wrist it may

entrap you and cause injury.

Position yourself to avoid being caught

between the tool or side handle and walls

or posts. Should the bit become bound or

jammed in the work, the reaction torque of

the tool could crush your hand or leg.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do

the job better and safer at the rate for which

it is designed.Do not use tool if switch

does not turn it “ON” or “OFF”. Any tool

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools, with sharp cutting edges are less likely

to bind and are easier to control. Any

alteration or modification is a misuse and

may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop

a periodic maintenance schedule for your

tool.

Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be

suitable for one tool, may become

hazardous when used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury. Certain cleaning

agents such as gasoline, carbon

tetrachloride, ammonia, etc. may damage

plastic parts.

SM 2610968981 2/03 2/10/03 3:14 PM Page 3

Page 4

If the bit becomes bound in the

workpiece, release the trigger

immediately, reverse the direction of

rotation and slowly squeeze the trigger to

back out the bit. Be ready for a strong

reaction torque. The drill body will tend to

twist in the opposite direction as the drill bit

is rotating.

Do not grasp the tool or place your hands

too close to the spinning chuck or drill bit.

Your hand may be lacerated.

Do not use the switch "Lock-ON" feature

in situations where drill bit binding is

likely. (For example: just before the bit is

ready to break through the material,

anytime when using a "Hole Saw", auger

bits........ etc.) When the bit binds, the drill's

body will twist or kick-back in opposite

direction and the release of the trigger

"Lock-ON" may be difficult.

Be aware of the location and setting of

the switch "Lock-ON" button. If the switch

is locked "ON" during the use, be ready for

emergency situations to switch it "OFF", by

first pulling the trigger then immediately

releasing it without pressing the "Lock-ON"

button.

When installing a drill bit, insert the shank

of the bit well within the jaws of the

chuck. If the bit is not inserted deep

enough, the grip of the jaws over the bit is

reduced and the loss of control is increased.

Do not use dull or damaged bits and

accessories. Dull or damaged bits have a

greater tendency to bind in the workpiece.

When removing the bit from the tool avoid

contact with skin and use proper

protective gloves when grasping the bit

or accessory. Accessories may be hot after

prolonged use.

Check to see that keys and adjusting

wrenches are removed from the drill

before switching the tool "ON". Keys or

wrenches can fly away at high velocity

striking you or a bystander.

Do not run the drill while carrying it at

your side. A spinning drill bit could become

entangled with clothing and injury may

result.

This tool may be used with sanding and

polishing disks, grinding wheels, wire

wheel and wire cup brushes. These

accessories must be rated for at least the

speed recommended on the tool warning

label. Wheels and other accessories

running over rated speed can fly apart and

cause injury.

Avoid bouncing and snagging the wheels,

discs or brushes especially when working

corners, sharp edges, etc. This can cause

loss of control and kickback.

Some dust created by

power sanding, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

-4-

!

WARNING

SM 2610968981 2/03 2/10/03 3:14 PM Page 4

Page 5

-5-

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Symbols

0

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

This symbol

designates

that

this tool

complies

to NOM

Mexican

Standards.

This symbol designates

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

SM 2610968981 2/03 2/10/03 3:14 PM Page 5

Page 6

-6-

Functional Description and Specifications

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

MAXIMUM CAPACITIES

Model Chuck Size Screw Mild Hard Soft Wire Cup WireWheel Sanding/

No. and type Sizes Metal Wood Wood Brushes brushes Polishing

6215 3/8” Keyed #8 x 1-1/2” 3/8” 3/4” 1” 1-1/2” 3” NR

6220 3/8” Keyless #8 x 1-1/2” 3/8” 3/4” 1” 1-1/2” 3” NR

6245 3/8” Keyed #8 x 2 -1/2” 3/8” 1” 1-1/2” 1-1/2” 4” 5”

6250 3/8” Keyless #8 x 2 -1/2” 3/8” 1” 1-1/2” 1-1/2” 4” 5”

6355 1/2” Keyed #8 x 3” 1/2” 1” 1-1/2” 2-3/4” 4” 5”

6360 1/2” Keyless #8 x 3” 1/2” 1” 1-1/2” 2-3/4” 4” 5”

NR = Not recommended

ATTENTION: 3/8 inch drills are not recommended for running lag bolts

NOTE: For tool specifications refer to the nameplate on your tool.

CHUCK

DRILL

LEVEL

AIR

VENTS

FORWARD/

REVERSING

& TRIGGER

LOCK

TRIGGER

“LOCK-ON”

BUTTON

CHUCK

KEY &

STORAGE

AREA

CHUCK

AIR

VENTS

TRIGGER

CHUCK

KEY &

STORAGE

AREA

DRILL

LEVEL

* AUXILIARY

HANDLE

PRESET

SPEED

ADJUSTING

DIAL

FORWARD/

REVERSING

& TRIGGER

LOCK

PRESET

SPEED

ADJUSTING

DIAL

FRONT

HOUSING

COLLAR

* NOT AVAILABLE ON

ALL MODELS

MOTOR

HOUSING

MOTOR

HOUSING

FIG. 1

“LOCK-ON”

BUTTON

Drills

FIG. 2

SM 2610968981 2/03 2/10/03 3:14 PM Page 6

Page 7

-7-

Operating Instructions

* TRIGGER CONTROLLED VARIABLE SPEED

Your tool is equipped with a variable speed

trigger switch. The tool speed can be

controlled from minimum to maximum

nameplate rated RPM by the pressure you

apply to the trigger. Apply more pressure to

increase the speed and release pressure to

decrease speed (Fig. 1).

* TRIGGER "ON-OFF" SWITCH

TO TURN THE TOOL "ON" squeeze the

trigger switch. TO TURN THE TOOL "OFF",

release the trigger switch, which is spring

loaded and will return to the "OFF" position

automatically.

"LOCK-ON" BUTTON

The "Lock-ON" button, located in the handle

of your tool allows for continuous operation at

maximum RPM without holding the trigger.

TO LOCK TRIGGER "ON": squeeze trigger,

depress button and release trigger.

TO UNLOCK THE TRIGGER: squeeze trigger

and release it without depressing the "LockON" button.

If the “Lock-ON” button is

continuously being depressed,

the trigger can not be released.

FORWARD/REVERSING LEVER &

TRIGGER LOCK

Your tool is equipped with a forward/reversing

lever and trigger lock located above the trigger

(Fig. 1). This lever was designed for changing

rotation of the chuck, and for locking the

trigger in an“OFF” position to help prevent

accidental starts. For forward rotation, (with

the chuck pointed away from you) move lever

to the far left. For reverse rotation move the

lever to the far right. To activate trigger lock

move lever to the center off position.

Do not change direction of

rotation until the tool comes to

a complete stop. Shifting during rotation of the

chuck can cause damage to the tool.

PRESET SPEED ADJUSTING DIAL

This feature enables you to preset the trigger

at desired speeds by rotating the dial on the

trigger to a higher or lower setting. Regardless

of the pressure applied on the trigger, the tool

will not operate any faster than maximum

speed setting selected. The following be used

as a general guide for various drilling

applications (Fig. 3).

!

WARNING

INSERTING BIT

For small bits, open jaws enough to insert the

bit up to the flutes. For large bits, insert the bit

as far as it will go. Center the bit as you close

the jaws by hand. This positions the bit

properly, giving maximum contact between

the chuck jaws and the bit shank.

* KEYED MODELS

To tighten chuck, insert key into each of the

three key holes in succession and tighten

firmly. The chuck can be released by using

one hole only (Fig. 4).

* KEYLESS MODELS

To tighten, hold the chuck collar firmly with

one hand and securely tighten the chuck

sleeve with the other hand (Fig. 5).

To prevent friction burns, or

possible hand injury, do not

loosen or tighten the chuck by using the

power of the drill.

!

WARNING

Decrease Speed

Increase Speed

Low range Mid range High range

screwdriving drilling metal drilling wood

FIG. 4

FIG. 5

Counter

Clockwise

Clockwise

CHUCK

SLEEVE

CHUCK

COLLAR

!

CAUTION

FIG. 3

SM 2610968981 2/03 2/10/03 3:14 PM Page 7

Page 8

FASTENING WITH SCREWS

The procedure shown in (Fig. 6) will enable

you to fasten materials together with your

hammer drill in the drill mode without

stripping, splitting or separating the material.

First, clamp the pieces together and drill the

first hole 2/3 the diameter of the screw. If the

material is soft, drill only 2/3 the proper

length. If it is hard, drill the entire length.

Second, unclamp the pieces and drill the

second hole the same diameter as the screw

shank in the first or top piece of wood.

Third, if flat head screw is used, countersink

the hole to make the screw flush with the

surface. Then, simply apply even pressure

when driving the screw. The screw shank

clearance hole in the first piece allows the

screw head to pull the pieces tightly

together.

The adjustable screw drill accessory will do

all of these operations quickly and easily.

Screw drills are available for screw sizes No.

6, 8, 10 and 12.

-8-

* AUXILIARY HANDLE

The auxiliary handle will provide additional

control, support and guidance for the tool. The

handle is adjustable to any position around the

360° handle collar mount. To mount, slide

handle completely over the handle collar

mount and rotate handle clockwise to tighten

(Fig. 2).

CHUCK KEY & STORAGE AREA

Keyed models are equipped with a chuck key

that is conveniently located on the cord

protector where it is always handy and unlikely

to get lost or misplaced.

DRILL LEVEL

Your tool is equipped with drill level located on

top of the housing that will allow you to

accurately enter the workpiece in a horizontal

position.

USING THE LEVEL: Place drill bit where hole is

to be drilled, position drill so the bubble in the

level is centered between the lines, then start

drilling the hole, once the bit has entered the

workpiece check from time to time to be sure

the bit is maintaining the horizontal position.

You will extend the life of your bits and do

neater work if you always put the bit in

contact with the work before pulling the

trigger. During the operation, hold the tool

firmly and exert light, steady pressure. Too

much pressure at low speed will stall the

tool. Too little pressure will keep the bit from

cutting and cause excess friction by sliding

over the surface. This can be damaging to

both tool and bit.

DRILLING WITH VARIABLE SPEED

The trigger controlled variable speed feature

will eliminate the need for center punches in

hard materials. The variable speed trigger

allows you to slowly increase RPM. By using

a slow starting speed, you are able to keep

the bit from “wandering”. You can increase

the speed as the bit “bites” into the work by

squeezing the trigger.

DRIVING WITH VARIABLE SPEED

Variable speed drills will double as a power

screwdriver by using a screwdriver bit in the

drill mode. The technique is to start slowly,

increasing the speed as the screw runs

down. Set the screw snugly by slowing to a

stop. Prior to driving screws, pilot and

clearance holes should be drilled.

2. Drill same diameter

as screw shank

3. Countersink

same diameter

as screw head

1. Drill 2/3 diameter

and 2/3 of screw

length for soft

materials, full

length for hard

materials

Screw

Apply a slight

even pressure

when driving

screws

Adjustable

Screw

Drill

FASTENING

WITH SCREWS

FIG. 6

Operating Tips

SM 2610968981 2/03 2/10/03 3:14 PM Page 8

Page 9

DRILL BITS

Always inspect drill bits for excessive wear.

Use only bits that are sharp and in good

condition.

TWIST BITS: Available with straight and

reduced shanks for wood and light duty metal

drilling. High speed bits cut faster and last

longer on hard materials.

CARBIDE TIPPED BITS: Used for drilling

stone, concrete, plaster, cement and other

unusually hard nonmetals. Use continuous

heavy feed pressure when employing carbide

tip bits.

DRILLING WOOD

Be certain workpiece is clamped or anchored

firmly. Always apply pressure in a straight line

with the drill bit. Maintain enough pressure to

keep the drill “biting”.

When drilling holes in wood, twist bits can be

used. Twist bits may overheat unless pulled

out frequently to clear chips from flutes.

Use a “back-up” block of wood for work that is

likely to splinter, such as thin materials.

You will drill a cleaner hole if you ease up on

the pressure just before the bit breaks through

the wood. Then complete the hole from the

back side.

DRILLING METAL

There are two rules for drilling hard materials.

First, the harder the material, the greater the

pressure you need to apply to the tool.

Second, the harder the material, the slower the

speed. Here are a couple of tips for drilling in

metal. Lubricate the tip of the bit occasionally

with cutting oil except when drilling soft metals

such as aluminum, copper or cast iron. If the

hole to be drilled is fairly large, drill a smaller

hole first, then enlarge to the required size, it’s

often faster in the long run. Maintain enough

pressure to assure that the bit does not just

spin in the hole. This will dull the bit and greatly

shorten its life.

DRILLING MASONRY

Soft materials such as brick are relatively easy

to drill. Concrete however, will require much

more pressure to keep the bit from spinning.

Be sure to use carbide tip bits for all masonry

work.

Before using an accessory,

be certain that its maximum

safe operating speed is not exceeded by the

nameplate speed of the tool. Do not exceed

the recommended wheel diameter.

SANDING AND POLISHING

You will find the “Lock-ON” button feature a

convenience for the continuous operation

required for rough sanding. Fine sanding and

polishing require “touch”. Select the most

efficient speed.

When using polishing bonnets, alway be sure

the excess string that secures the bonnet is

tucked well within the bonnet during operation.

WIRE BRUSHES

Work with brushes requires high speeds. Use

of the “Lock-ON” button feature will provide a

much easier operation.

BRUSHING PRESSURE

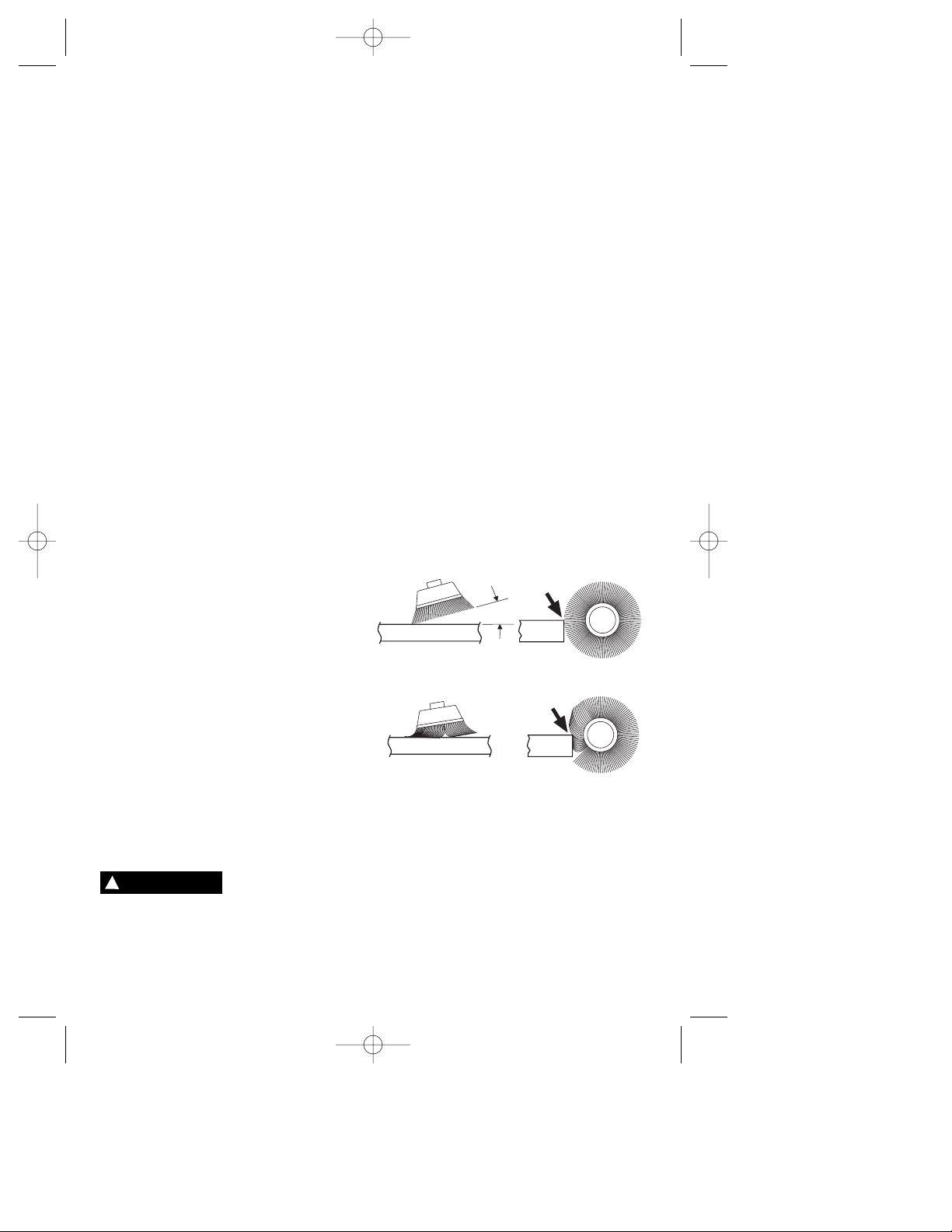

1. Remember, the tips of a wire brush do the

work. Operate the brush with the lightest

pressure so only the tips of the wire come in

contact with the work.

2. If heavier pressures are used, the wires

will be overstressed, resulting in a wiping

action; and if this is continued, the life of the

brush will be shortened due to wire fatigue.

3. Apply the brush to the work in such a way

that as much of the brush face as possible is

in full contact with the work. Applying the

side or edge of the brush to the work will

result in wire breakage and shortened brush

life.

RUNNING NUTS AND BOLTS

Variable speed control must be used with

caution for driving nuts and bolts with socket

set attachments. The technique is to start

slowly, increasing speed as the nut or bolt runs

down. Set the nut or bolt snugly by slowing the

drill to a stop. If this procedure is not followed,

the tool will have a tendency to torque or twist

in your hands when the nut or bolt seats.

-9-

!

WARNING

15°

CORRECT: Wire tips doing the work.

INCORRECT: Excessive pressure can cause wire breakage.

SM 2610968981 2/03 2/10/03 3:14 PM Page 9

Page 10

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of

internal wires and components which

could cause serious hazard. We

recommend that all tool service be

performed by a Skil Factory Service Center

or Authorized Skil Service Station.

TOOL LUBRICATION

Your Skil tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool

have been engineered for many hours of

dependable service. To maintain peak

efficiency of the motor, we recommend

every two to six months the brushes be

examined. Only genuine Skil replacement

brushes specially designed for your tool

should be used.

BEARINGS

After about 300-400 hours of operation, or

at every second brush change, the bearings

should be replaced at Skil Factory Service

Center or Authorized Skil Service Station.

Bearings which become noisy (due to heavy

load or very abrasive material cutting)

should be replaced at once to avoid

overheating or motor failure.

Cleaning

To avoid accidents always

disconnect the tool from

the power supply before cleaning or

performing any maintenance. The tool

may be cleaned most effectively with

compressed dry air. Always wear safety

goggles when cleaning tools with

compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed

objects through openings.

Certain cleaning agents

and solvents damage

plastic parts. Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning

solvents, ammonia and household

detergents that contain ammonia.

-10-

!

WARNING

!

WARNING

Maintenance

Accessories

!

CAUTION

If an extension cord is

necessary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

tool must be used. This will prevent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3wire extension cords that have 3-prong

plugs and receptacles.

NOTE: The smaller the gauge number, the heavier

the cord.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

!

WARNING

SM 2610968981 2/03 2/10/03 3:14 PM Page 10

Page 11

-11-

Vous devez lire et comprendre toutes les instructions. Lenon-respect, même

partiel, des instructions ci-après entraîne un risque de choc életrique, d'incendie

et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

Règles de Sécurité Générales

AVERTISSEMENT

!

Aire de travail

Veillez à ce que l'aire de travail soit propre et bien

éclairée. Le désordre et le manque de lumière

favorisent les accidents.

N'utilisez pas d'outils électriques dans une

atmosphère explosive, par exemple enprésence de

liquides, de gaz ou de poussières inflammables. Les

outils électriques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillezavec un outil

électrique. Ils pourraient vous distraire et vous faire

faire une fausse manoeuvre.

Sécurité électrique

Les outils à double isolation sont équipés d'une fiche

polarisée (une des lames est pluslarge que l'autre),

qui ne peut se brancher que d'une seule façon dans

une prise polarisée. Si la fiche n'entre pas

parfaitement dans la prise, inversez sa position ; si

elle n'entre toujours pasbien, demandez à un

électricien qualifié d'installer une prise de courant

polarisée. Ne modifiez pas la fiche de l'outil. La

double isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre ainsi que

d'une prise de courant mise à la terre.Avant de brancher

l'outil, assurez-vous que la tension de la prise

correspond, à celle indiquée sur la plaque signalétique.

N'utilisez pas d'outils prévus pour courant alternatif

seulement avec une source de courant continu.

Évitez tout contact corporel avec des surfaces mises à

la terre (tuyauterie, radiateurs, cuisinières,

réfrigérateurs, etc.). Le risque de choc électrique est

plus grand si votre corps est encontact avec la terre.Si

l'utilisation de l'outil électrique dans un endroit humide

est inévitable, un disjoncteur de fuite à la terre doit être

utilisé pour alimenter votre outil. Des chaussures et des

gants en caoutchouc d'électricien contribueront à

accroître davantage votre sécurité personnelle.

N'exposez pas les outils électriques à la pluie ou à

l'eau. La présence d'eau dans un outil électrique

augmente le risque de choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil

par son cordon et ne débranchez pas la fiche en tirant

sur le cordon. N'exposez pas le cordon à la chaleur, à

des huiles, à des arêtes vives ou à des pièces en

mouvement. Remplacez immédiatement un cordon

endommagé. Un cordon endommagé augmente le

risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur,

employez un prolongateur pour l'extérieur marqué «

W-A » ou « W ». Ces cordons sont faits pour être

utilisés à l'extérieur et réduisent le risque de choc

électrique. Reportez-vous aux « Dimensions

recommandées des cordons de rallonge » dans la

section Accessoires de ce manuel.

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et

faites preuve de jugement. N'utilisez pas un outil

électrique si vous êtes fatigué ou sous l'influence de

drogues, d'alcool ou de médicaments. Un instant

d'inattention suffit pour entraîner des blessures graves.

Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les cheveux

longs. N'approchez jamais les cheveux, les

vêtements ou les gants des pièces en mouvement.

Des vêtements flottants, des bijoux ou des cheveux

longs risquent d'être happés par des pièces en

mouvement. Gardez les poignées sèches, propres et

exemptes d'huile et de graisse.

Méfiez-vous d'un démarrage accidentel. Avant de

brancher l'outil, assurez-vous que son interrupteur est

sur ARRÈT. Le fait de transporter un outil avec le doigt

sur la détente ou de brancher un outil dont l'interrupteur

est en position MARCHE peut mener tout droit à un

accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil. Une clé laissée dans une pièce

tournante de l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon

appui et restez en équilibre entout temps. Un bonne

stabilité vous permet de mieux réagir à une situation

inattendue.

Utilisez des accessoires de sécurité. Portez toujours

des lunettes ou une visière. Selon les conditions,

portez aussi un masque antipoussière, des bottes de

sécurité antidérapantes, un casque protecteur et/ou un

appareil antibruit.

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au

moyen de brides ou de toute autre façon adéquate. Le

fait de tenir la pièce avec la main ou contre votre corps

offre une stabilité insuffisante et peut amener un

dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la

tâche. L'outil correct fonctionne mieux et de façon plus

SM 2610968981 2/03 2/10/03 3:14 PM Page 11

Page 12

Tenez l'outil par les surfaces isolées de préhension

en exécutant une opération au cours de laquelle

l'outil de coupe peut venir en contact avec les fils

cachés ou son propre cordon. Le contact avec un fil

sous tension rendra les pièces métalliques exposées

de l'outil sous tension et causera des chocs à

l'opérateur. Ne percez, fixez et ne rentrez pas dans

des murs existants ou autres endroits aveugles

pouvant abriter des fils électriques. Si cette situation

est inévitable, débranchez tous les fusibles ou les

disjoncteurs alimentant ce site.

Utilisez toujours la poignée auxiliaire pour un

contrôle maximal sur la réaction de couple ou le

rebond. Les perceuses de 3/8 po à haut couple et les

perceuses avec mandrin à plus grande capacité sont

équipées de poignées auxiliaires.

Portez toujours des lunettes à coques latérales ou

des lunettes de protection en utilisant cet outil.

Utilisez un respirateur ou un masque anti-poussières

pour les applications produisant de la poussière.

Assujettissez l'ouvrage à percer. Ne le tenez jamais

dans votre main ou par-dessus vos jambes. Un

support instable peut faire gripper le foret,

provoquant ainsi une perte de contrôle et des

blessures.

Ne tenez jamais la gâchette bloquée en position de

marche. Avant de brancher l'outil, assurez-vous

que le blocage de la gâchette est inhibé. Les mises

en marche accidentelles peuvent causer des

blessures.

Placez le cordon à l'écart du foret en rotation.

N'enroulez pas le cordon autour de votre bras ou de

votre poignet. Si vous perdez contrôle et que le

cordon s'enroule autour de votre bras ou de votre

poignet, il peut vous emprisonner et vous blesser.

Placez-vous de manière à éviter d'être pris entre

l'outil ou la poignée latérale et les murs ou les

montants. Si le foret se coince ou grippe dans

l'ouvrage, le couple de réaction de l'outil pourrait

écraser votre main ou votre pied.

Si le foret grippe dans l'ouvrage, relâchez la

gâchette immédiatement, inversez le sens de

rotation et appuyez lentement sur la gâchette pour

faire ressortir le foret. Soyez prêt à un fort couple de

réaction. Le corps de la perceuse aura tendance à

tordre en sens opposé à mesure que le foret tourne.

Ne saisissez pas l'outil et ne placez vos mains trop

près du foret ou du mandrin en rotation. Votre main

pourrait être lacérée.

-12-

sécuritaire. Respectez aussi la vitesse de travail qui lui

est propre.

N'utilisez pas un outil si son interrupteur est bloqué.

Un outil que vous ne pouvez pas commander par son

interrupteur est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un

réglage, de changer d'accessoire oude ranger l'outil.

De telles mesures préventives de sécurité réduisent le

risque de démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et

d'autres personnes inexpérimentées. Les outils sont

dangereux dans les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils de

coupe doivent être toujours bien affûtés et propres.

Des outils bien entretenus, dont les arêtes sont bien

tranchantes, sont moins susceptibles de coincer et plus

faciles à diriger.Toute altération ou modification

constitue un usage erroné et peut causer un danger.

Soyez attentif à tout désalignement ou coincement

des pièces en mouvement, à tout bris ou à toute autre

condition préjudiciable au bon fonctionnement de

l'outil. Si vous constatez qu'un outil est endommagé,

faites-le réparer avant de vous en servir. De

nombreux accidents sont causés par des outils en

mauvais état. Élaborez un calendrier d'entretien

périodique de votre outil.

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil. Certains

accessoires peuvent convenir à un outil, mais être

dangereux avec un autre.

Réparation

La réparation des outils électriques doit être confiée à

un réparateur qualifié. L'entretien ou la réparation d'un

outil électrique par un amateur peut avoir des

conséquences graves. Ainsi, des fils internes peuvent

être mal placés ou pincés, des ressorts de rappel de

protecteur peuvent être montés erronément.

Pour la réparation d'un outil, n'employez que des

pièces de rechange d'origine. Suivez les directives

données à la section « Réparation » de ce manuel.

L'emploi de pièces non autorisées ou le non-respect

des instructions d'entretien peut créer un risque de

choc électrique ou de blessures. Certains agents

nettoyants tels qu'essence, tétrachlorure de carbone,

ammoniac, etc., peuvent abîmer les pièces en plastique.

Consignes de sécurité pour les perceuses

SM 2610968981 2/03 2/10/03 3:14 PM Page 12

Page 13

-13-

N'utilisez pas le dispositif de blocage en position de

marche de l'interrupteur dans des situations où le

foret est susceptible de gripper. (Par exemple :

immédiatement avant que le foret ne soit prêt à

rentrer à travers le matériau, chaque fois que vous

utilisez une « scie à perforation », des mèches

hélicoïdales, etc.) Lorsque le foret grippe, le corps

de la perceuse tord ou rebondit en sens opposé, et il

peut être difficile de relâcher le dispositif de blocage

en position de marche de la gâchette.

Soyez au courant de l'emplacement et de la

position du bouton de blocage en marche de la

gâchette. Si l'interrupteur est bloqué en marche

durant l'usage, soyez prêt, dans des cas d'urgence, à

le mettre à l'arrêt en appuyant d'abord sur la gâchette,

puis en la relâchant immédiatement sans appuyer sur

le bouton de blocage en marche.

En installant un foret, insérez la tige du foret bien à

l'intérieur des mâchoires du mandrin. Si le foret

n'est pas inséré assez profondément, la prise des

mâchoires sur le foret est réduite et la perte de

contrôle est accrue.

N'utilisez pas de forets et d'accessoires émoussés

ou endommagés. Les forets émoussés ou

endommagés ont tendance à gripper dans l'ouvrage.

En retirant le foret de l'outil, évitez tout contact

avec la peau et utilisez des gants protecteurs

appropriés en saisissant le foret ou l'accessoire.

Les accessoires peuvent être chauds après une

utilisation prolongée.

Assurez-vous que les clés de serrage et de réglage

sont retirées de la perceuse avant de mettre l'outil

en marche. Les clés de serrage ou de réglage

peuvent être projetées à grande vitesse et frapper une

personne présente ou vous-même.

Ne faites pas fonctionner la perceuse en la portant

à votre côté. Un foret en rotation pourrait

s'emmêlever à vos vêtements, ce qui pourrait causer

des blessures.

Cet outil peut être utilisé avec les disques de

ponçage et de polissage, les meules, les brosses à

coupe métallique et à meule métallique. Ces

accessoires doivent être au moins prévus pour la

vitesse recommandée sur l’étiquette

d’avertissement de l’outil. Les meules et les autres

accessoires fonctionnant à une vitesse supérieure à la

vitesse nominale peuvent voler en éclats et causer des

blessures.

Évitez de faire rebondir et de heurter les meules,

les disques ou les brossses, surtout lorsque vous

travaillez sur des angles, des arêtes vives, etc. Ceci

peut causer une perte de contrôle et un rebond.

Les travaux à la machine

tel que ponçage, sciage,

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

AVERTISSEMENT

!

SM 2610968981 2/03 2/10/03 3:14 PM Page 13

Page 14

-14-

Symboles

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

etc.

n

0

Vitesse à vide Vitesse de rotation, à vide

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

une vitesse plus grande.

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Ni-Cad RBRCmc Désigne le programme de recyclage des piles

Ni-Cad.

0

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne de

normalisation.

Ce symbole signifie que

cet outil est approuvé

conformément aux normes

canadiennes par Underwriters

Laboratories.

Ce symbole

signifie que

cet outil se

conforme aux

normes

mexicaines

NOM.

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories et qu’il a été

homologué selon les normes

canadiennes par Underwriters

Laboratories.

SM 2610968981 2/03 2/10/03 3:14 PM Page 14

Page 15

-15-

Description fonctionnelle et spécifications

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

REMARQUE : Pour spécifications de l'outil, reportez-vous à la plaque signalétique de votre outil.

AVERTISSEMENT

!

CAPACITÉS MAXIMALES

Dimension Brosses en Brosses de

No. de et type Tailles Métal Bois Bois coupe meule Ponçage/

modèle de mandrin de vis doux dur tendre métallique métallique polissage

6215 3/8 po à clé No. 8 x 1-1/2 po 3/8 po 3/4 po 1 po 1-1/2 po 3 po NR

6220 3/8 po sans clé No. 8 x 1-1/2 po 3/8 po 3/4 po 1 po 1-1/2 po 3 po NR

6245 3/8 po à clé No. 8 x 2 -1/2 po 3/8 po 1 po 1-1/2 po 1-1/2 po 4 po 5 po

6250 3/8 po sans clé No. 8 x 2 -1/2 po 3/8 po 1 po 1-1/2 po 1-1/2 po 4 po 5 po

6355 1/2 po à clé No. 8 x 3 po 1/2 po 1 po 1-1/2 po 2-3/4 po 4 po 5 po

6360 1/2 po sans clé No. 8 x 3 po 1/2 po 1 po 1-1/2 po 2-3/4 po 4 po 5 po

NR = Non recommandé

ATTENTION : Les perceuses de 3/8 po ne sont pas recommandées pour utilisation avec des tire-fond.

* NON DISPONIBLE SUR TOUS

LES MODÉLES

MANDRIN

NIVEAU DE PERÇAGE

ÉVENTS

LEVIER DE MARCHE

AVANT/ARRIÈRE

ET VERROUILLAGE DE

GÂCHETTE

GÂCHETTE

BOUTON DE

BLOCAGE

EN

MARCHE

CLÉ DE

MANDRIN

ET AIRE DE

RANGEMENT

MANDRIN

ÉVENTS

GÂCHETTE

CLÉ DE

MANDRIN

ET AIRE DE

RANGEMENT

NIVEAU DE

PERÇAGE

* POIGNÉE

AUXILIAIR

E

CADRAN

D'AJUSTEMENT DE

VITESSE

PRÉRÉGLÉE

LEVIER DE MARCHE

AVANT/ARRIÈRE

ET VERROUILLAGE

DE GÂCHETTE

CADRAN

D'AJUSTEMENT DE

VITESSE

PRÉRÉGLÉE

COLLIER DU

BOÎTIER AVANT

BOÎTIER

DU MOTEUR

BOÎTIER

DU MOTEUR

FIG. 1

BOUTON DE

BLOCAGE

EN

MARCHE

Perceuses

FIG. 2

SM 2610968981 2/03 2/10/03 3:14 PM Page 15

Page 16

* VITESSE VARIABLE COMMANDÉE PAR GÂCHETTE

Votre perceuse est équipée d’une gâchette à vitesse

variable. La vitesse de la perceuse peut être réglée de

zéro au régime maximum spécifié sur la plaque

signalétique. La vitesse s’ajuste par la pression que vous

exercez sur la gâchette. Exercez plus de pression pour

augmenter la vitesse, et relâchez la pression pour

diminuer la vitesse (fig. 1).

* GÂCHETTE DE COMMANDE MARCHE/ARRÊT

Pour mettre l’outil en marche, appuyez sur la gâchette.

Pour mettre l’outil à l’arrêt, relâchez la gâchette qui est à

ressort et reviendra automatiquement à la position

d’arrêt.

BOUTON DE BLOCAGE EN MARCHE

La perceuse est également pourvue d’un bouton de

blocage en marche situé du côté gauche de la poignée

de la gâchette qui permet le fonctionnement au régime

maximum — sans devoir tenir la gâchette (fig. 1).

POUR BLOQUER L’INTERRUPTEUR EN MARCHE :

appuyez sur la gâchette, appuyez sur le bouton et

relâchez la gâchettePOUR DEBLOQUER L’INTERRUPTEUR

: appuyez sur la gâchette et relâchez-la sans appuyer sur le

bouton de blocage en marche.

Si l’utilisateur appuie

continuellement sur le

bouton de blocage en marche, la gâchette ne peut pas

être relâchée.

LEVIER DE MARCHE AVANT/ARRIÈRE

ET VERROUILLAGE DE GÂCHETTE

Votre outil est équipé d’un levier de marche

avant/arrière et d’un verrouillage de gâchette se

trouvant au-dessus de la gâchette (fig. 1). Ce levier a été

conçu de manière à changer la rotation du mandrin et à

verrouiller la gâchette en position d’arrêt pour aider à

prévenir les démarrages accidentels. Pour la rotation

avant (le mandrin étant dirigé en sens opposé à vous),

déplacez le levier à l’extrême gauche. Pour la rotation

inverse, déplacez le levier à l’extrême droite. Pour actionner le verrouillage de gâchette, déplacez le levier à la

position centrale (arrêt).

Ne changez pas le sens de

rotation avant que l'outil ne

se soit complètement immobilisé. Un changement

durant la rotation du mandrin pourrait endommager

l'outil.

CADRAN D'AJUSTEMENT DE VITESSE PRÉRÉGLÉE

Cette fonction vous permet de prérégler la gâchette aux

vitesses désirées en tournant le cadran de la gâchette à

un réglage plus élevé ou plus bas. Quelle que soit la

pression exercée sur la gâchette, l'outil ne fonctionnera

pas à une vitesse supérieure au réglage maximal de

vitesse sélectionné. Vous trouverez ci-après un guide

général pour différentes applications de perçage (fig. 3).

-16-

Consignes de fonctionnement

INSERTION DU FORET

Pour les petits forets, ouvrez les mâchoires

suffisamment de manière à insérer le foret jusqu’aux

cannelures. Pour les gros forets, insérez le foret aussi

loin que possible. Centrez le foret à mesure que vous

refermez manuellement les mâchoires. Ceci positionne

le foret de manière appropriée, assurant ainsi un contact

maximal entre les mâchoires du mandrin et la tige du

foret.

* MODÈLES À CLÉ

Pour serrer le mandrin, insérez la clé dans chacun des

trois trous de clé successivement et serrez fermement.

Le mandrin peut être relâché en utilisant un trou

seulement (fig. 4).

* MODÈLES SANS CLÉ

Pour serrer, tenez le collier du mandrin fermement d’une

main, et serrez solidement le manchon du mandrin de

l’autre main (fig. 5).

Pour prévenir les brûlures

par friction ou les blessures

éventuelles à la main, ne serrez pas ou ne desserrez pas

le mandrin en utilisant la puissance de la perceuse.

AVERTISSEMENT

!

AVERTISSEMENT

!

Réduire la vitesse

Augmenter la vitesse

Plage basse Plage moyenne Plage élevée

Vissage Perçage de métaux Perçage du bois

FIG. 4

FIG. 5

Sens

anti-horaire

Sens

horaire

DOUILLE DE

MANDRIN

COLLIER DE

MANDRIN

AVERTISSEMENT

!

FIG. 3

SM 2610968981 2/03 2/10/03 3:14 PM Page 16

Page 17

-17-

*POIGNÉE AUXILIAIRE

La poignée auxiliaire permettra de mieux contrôler, supporter et guider l’outil. La poignée est réglable à toute

position autour du support de collier de poignée de

360°. Pour monter, faites glisser la poignée entièrement

par-dessus le support de collier de poignée, et tournez la

poignée en sens horaire pour serrer (fig. 2).

CLÉ DE MANDRIN ET AIRE DE RANGEMENT

Les modèles à clé sont équipés d'une clé de mandrin qui

est située commodément sur le protecteur de cordon où

elle est toujours à la portée de la main et peu susceptible

d'être perdue ou égarée.

NIVEAU DE PERÇAGE

Votre outil est équipé d'un niveau de perçage situé sur le

dessus du boîtier qui vous permettra de pénétrer

exactement l'ouvrage en position horizontale.

UTILISATION DU NIVEAU : Placez le foret là où le trou

doit être percé, positionnez la perceuse de manière à ce

que la bulle du niveau soit centrée entre les lignes, puis

commencez à percer le trou. Lorsque le foret a pénétré

l'ouvrage, vérifiez de temps à autre pour vous assurer

que le foret maintient la position horizontale.

FIXATION À L’AIDE DE VIS

La procédure illustrée à la (fig. 6) vous permettra de fixer

des matériaux ensemble à l’aide de votre drille en mode

de perçage sans dénuder, fendre ni séparer le matériau.

Fixez d’abord les pièces ensemble à l’aide d’une bride, et

percez le premier trou aux 2/3 du diamètre de la vis. Si le

matériau est tendre, percez uniquement les 2/3 de la

longueur voulue. Si le matériau est dur, percez toute la

longueur.

Détachez ensuite les pièces et percez le deuxième trou

du même diamètre que la tige de la vis dans la première

pièce ou la pièce supérieure de bois.

En troisième lieu, si une vis à tête plate est employée,

fraisez le trou pour mettre la vis de niveau avec la

surface. Puis, exercez tout simplement une pression

uniforme en enfonçant la vis. Le trou de dégagement de

la tige de la vis dans la première pièce permet à la tête de

la vis de tirer les pièces fermement ensemble.

L’accessoire réglable de drille exécutera rapidement et

facilement toutes ces opérations. Des drilles sont

offertes pour vis de tailles 6, 8, 10 et 12.

Consignes de fonctionnement

2. Percez le même

diamètre que la tige

de la vis.

3. Fraisez le même

diamètre que la

tête de la vis.

1. Percez les 2/3 du

diamètre et les 2/3 de la

longueur de la vis pour

les matériaux tendres, la

longueur complète pour

les matériaux durs.

Vis

Exercez une légère

pression uniforme

en enfonçant les vis.

Drille

réglable

FIXATION À

L’AIDE DE VIS

FIG. 6

Vous prolongerez la durée de vos forets et accomplirez

un travail plus net si vous mettez toujours le foret en

contact avec le matériau avant d’appuyer sur la gâchette.

Durant le fonctionnement, tenez l’outil fermement et

exercez une pression légère et constante. Une trop

grande pression à basse vitesse bloquera l’outil. Une

pression insuffisante empêchera le foret de couper et

causera une friction excessive en glissant par-dessus la

surface. L’outil et le foret peuvent ainsi être abîmés.

PERÇAGE À VITESSE VARIABLE

La fonction de vitesse variable commandée par gâchette

éliminera la nécessité de poinçonner un trou central dans

les matériaux durs. La gâchette à vitesse variable vous

permet d’augmenter lentement le régime. En utilisant

une vitesse lente au départ, vous pouvez empêcher le

foret d’« errer ». Vous pouvez augmenter la vitesse à

mesure que le foret « mord » dans le matériau en

appuyant sur la gâchette.

ENFONCEMENT À VITESSE VARIABLE

Les perceuses à vitesse variable peuvent également

servir de tournevis motorisé en utilisant un foret de

tournevis en mode de perçage. La technique consiste à

commencer lentement, puis à augmenter la vitesse à

mesure que la vis s’enfonce. Posez la vis de manière à

obtenir un ajustement doux en ralentissant jusqu’à

l’arrêt. Avant d’enfoncer des vis, il faut percer des trous

de positionnement et de dégagement.

SM 2610968981 2/03 2/10/03 3:14 PM Page 17

Page 18

FORETS

Inspectez toujours les forets pour y relever toute usure

excessive. N’utilisez que des forets affilés et en bon état.

FORETS À SIMPLE SPIRALE : Offerts avec tiges droites

et réduites pour le perçage du bois et le perçage non

exigeant des métaux. Les forets à grande vitesse

coupent plus rapidement et durent plus longtemps sur

les matériaux durs.

FORETS À POINTE EN CARBURE : S’utilisent pour

percer la pierre, le béton, le plâtre, le ciment et les autres

matériaux non métalliques exceptionnellement durs.

Exercez une forte pression continue d’alimentation

lorsque vous employez des forets à pointe en carbure.

PERÇAGE DU BOIS

Assurez-vous que le matériau est assujetti par brides de

fixation ou ancré fermement. Exercez toujours une

pression en ligne droite avec le foret. Maintenez

suffisamment de pression pour que le foret continue à «

mordre ».

Vous pouvez utiliser des forets à simple spirale pour

percer des trous dans le bois. Ces forets peuvent

surchauffer à moins que vous ne les retiriez

fréquemment pour enlever les copeaux sur les

cannelures.

Utilisez un bloc d’appui en bois pour les matériaux susceptibles de voler en éclats tels que les matériaux

minces.

Vous percerez un trou plus net si vous relâchez la

pression immédiatement avant que le foret ne traverse le

bois. Terminez ensuite le trou à l’arrière.

PERÇAGE DES MÉTAUX

Il existe deux règles pour percer les matériaux durs. En

premier lieu, plus le matériau est dur, plus il vous faut

exercer de pression sur l’outil. En deuxième lieu, plus le

matériau est dur, plus vous devez percer lentement.

Voici quelques conseils pour percer les métaux. Lubrifiez

la pointe du foret à l’occasion à l’aide d’huile de coupe,

sauf lorsque vous percez des métaux tendres tels que

l’aluminium, le cuivre ou la fonte de fer. Si le trou à

percer est assez grand, percez d’abord un plus petit trou,

puis agrandissez-le aux dimensions nécessaires. C’est

souvent plus rapide à long terme. Maintenez

suffisamment de pression pour faire en sorte que le foret

ne fasse pas seulement tourner dans le trou. Ceci

émoussera le foret et réduira considérablement sa vie

utile.

PERÇAGE DE LA MAÇONNERIE

Les matériaux tendres tels que la brique sont

relativement faciles à percer. Cependant, le béton

nécessitera une pression beaucoup plus grande pour

empêcher le foret de tourner. Veillez à utiliser des forets

à pointe en carbure pour tout le travail de maçonnerie.

Avant d'utiliser un

accessoire, assurez-vous

que sa vitesse maximale de fonctionnement sûr n'est

pas dépassée par la vitesse indiquée sur la plaque

signalétique de l'outil. Ne dépassez pas le diamètre

recommandé de la meule.

PONÇAGE ET POLISSAGE

Vous constaterez que le bouton de blocage en marche

est une fonction pratique pour le fonctionnement continu

que nécessite le ponçage brut. Le polissage et le

ponçage de finition nécessitent une « touche ».

Choisissez la vitesse la plus efficace.

En utilisant les bonnets de polissage, assurez-vous

toujours que l'excédent de corde qui fixe le bonnet est

bien rentré à l'intérieur du bonnet durant le

fonctionnement.

BROSSES MÉTALLIQUES

Le travail avec les brosses nécessite des grandes

vitesses. L’utilisation du bouton de blocage en marche

facilitera le travail.

PRESSION DE BROSSAGE

1. Souvenez-vous : ce sont les pointes d’une brosse

métallique qui font le travail. N’appliquez qu’une

pression très légère sur la brosse de sorte que seules

les pointes des poils viennent en contact avec la

pièce.

2. Si vous appliquez une pression trop importante, les

poils seront surchargés, résultant en un balayage de

la pièce. Si ceci se prolonge, la durée de vie de la

brosse s’en trouvera écourtée à cause de la fatigue

des poils.

3. Appliquez la brosse sur la pièce de manière à ce

que la plus grande partie possible de sa tranche soit

en contact total avec la pièce. Appliquer le côté ou le

bord de la brosse sur la pièce résulterait en une

cassure des poils et écourterait sa durée de vie.

POSE DES ÉCROUS ET DES BOULONS

La commande à vitesse variable doit être utilisée

soigneusement pour poser des écrous et des boulons

avec des accessoires de douille. La technique consiste à

commencer lentement, puis à augmenter la vitesse à

mesure que l’écrou ou le boulon s’enfonce. Posez l’écrou

ou le boulon de manière à obtenir un ajustement doux en

ralentissant la perceuse jusqu’à l’arrêt. Si cette technique

n’est pas suivie, l’outil aura tendance à tordre dans vos

mains lorsque l’écrou ou le boulon se calera.

-18-

AVERTISSEMENT

!

15°

CORRECT Les pointes des poils font le travail.

INCORRECT Pression excessive risquant de briser les poils.

SM 2610968981 2/03 2/10/03 3:14 PM Page 18

Page 19

Entretien

L’entretien préventif

effectué par des employés

non autorisés peut entraîner un positionnement

erroné des composants et des fils internes, et ainsi

causer des dangers sévères. Il est recommandé que

l’entretien et la réparation de nos outils soient confiés

à un centre de service-usine Skil ou à un centre de

service après-vente Skil agréé.

GRAISSAGE DE L’OUTIL

Votre outil Skil a été convenablement graissé et est

prêt à utiliser. Il est recommandé que les outils à

engrenages soient regraissés avec une graisse

spéciale à l’occasion de tout remplacement de balais.

BALAIS DE CHARBON

Les balais et le collecteur de votre outil ont été conçus

pour donner plusieurs heures de fonctionnement sans

aléas. Pour maintenir le moteur en forme, nous

recommandons d’examiner les balais tous les deux à

six mois. Vous ne devriez utiliser que les balais de

rechange d’origine Skil qui conviennent spécialement

à votre outil.

ROULEMENTS

Après environ 300 à 400 heures d’utilisation, ou à

tous les deux remplacements des balais, il faudrait

confier le remplacement des roulements à un centre

de service-usine Skil ou à un centre de service aprèsvente Skil agréé. Les roulements qui sont devenus

bruyants (à cause de sciage de matériaux très abrasifs

ou de durs efforts) devraient être remplacés à l’instant

pour éviter la surchauffe et la défaillance du moteur.

Nettoyage

Pour éviter le risque

d’accidents, débranchez

toujours l’outil de la prise de courant avant de

procéder au nettoyage ou à l’entretien. Vous pouvez

très bien le nettoyer à l’air comprimé. Dans ce cas,

portez toujours des lunettes de sécurité.

Gardez les prises d’air et les interrupteurs propres et

libres de débris. N’essayez pas de les nettoyer en

introduisant des objets pointus dans leurs ouvertures.

Certains produits de

nettoyage et dissolvants

dont la gazoline, le tétrachlorure de carbone, les

nettoyeurs chlorés, l’ammoniaque et les détergents

ménagers contenant de l’ammoniaque peuvent

abîmer les pièces en plastique.

-19-

Maintenance

Accessoires

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

Si un cordon de rallonge

s'avère nécessaire, vous

devez utiliser un cordon avec conducteurs de

dimension adéquate pouvant porter le courant

nécessaire à votre outil. Ceci préviendra une chute

excessive de tension, une perte de courant ou une

surchauffe. Les outils mis à la terre doivent utiliser des

cordons de rallonge trifilaires pourvus de fiches à trois

broches ainsi que des prises à trois broches.

REMARQUE : Plus le calibre est petit, plus le fil est gros.

DIMENSIONS DE RALLONGES RECOMMANDÉES

OUTILS 120 VOLTS COURANT ALTERNATIF

AVERTISSEMENT

!

Intensité

nominale

de l’outil

Longueur en pieds

Longueur en mètres

3-6

6-8

8-10

10-12

12-16

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — — — — — —

25 50 100 150 15 30 60 120

Calibre A.W.G.

Calibre en mm

2

SM 2610968981 2/03 2/10/03 3:14 PM Page 19

Page 20

-20-

Lea y entienda todas las instrucciones. El incumplimiento de todas las instrucciones

indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones

personales graves.

CONSERVE ESTAS INSTRUCCIONES

Normas de seguridad para herramientas mecánicas

ADVERTENCIA

!

Area de trabajo

Mantenga el área de trabajo limpia y bien iluminada.

Las mesas desordenadas y las áreas oscuras invitan a

que se produzcan accidentes.

No utilice herramientas mecánicas en atmósferas

explosivas, tales como las existentes en presencia de

líquidos, gases o polvos inflamables. Las

herramientas mecánicas generan chispas y éstas

pueden dar lugar a la ignición del polvo o los vapores.

Mantenga a las personas que se encuentren

presentes, a los niños y a los visitantes alejados al

utilizar una herramienta mecánica. Las distracciones

pueden hacer que usted pierda el control.

Seguridad eléctrica

Las herramientas con aislamiento doble están

equipadas con un enchufe polarizado (un terminal es

más ancho que el otro). Este enchufe entrará en un

tomacorriente polarizado solamente de una manera.

Si el enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin entrar,

póngase en contacto con un electricista competente

para instalar un tomacorriente polarizado. No haga

ningún tipo de cambio en el enchufe. El aislamiento

doble elimina la necesidad del sistema de cordón de

energía de tres hilos conectado a tierra y la fuente de

energía conectada a tierra. Antes de enchufar la

herramienta, asegúrese de que la tensión del

tomacorriente suministrada se encuentre dentro del

margen de la tensión especificada en la placa del

fabricante. No utilice herramientas con capacidad

nominal "AC solamente" ("AC only") con una fuente de

energía DC.

Evite el contacto del cuerpo con las superficies

conectadas a tierra tales como tuberías, radiadores,

estufas de cocina y refrigeradores. Hay mayor riesgo

de que se produzcan sacudidas eléctricas si su cuerpo

está conectado a tierra. Si la utilización de la

herramienta mecánica en lugares húmedos es

inevitable, se debe usar un interruptor de circuito para

fallos a tierra para suministrar la energía a la

herramienta. Los guantes de goma para electricista y el

calzado antideslizante aumentarán más la seguridad

personal.

No exponga las herramientas mecánicas a la lluvia ni

a situaciones húmedas. La entrada de agua en una

herramienta mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar

las herramientas ni para sacar el enchufe de un

tomacorriente. Mantenga el cordón alejado del calor,

el aceite, los bordes afilados o las piezas móviles.

Cambie los cordones dañados inmediatamente. Los

cordones dañados aumentan el riesgo de que se

produzcan sacudidas eléctricas.

Al utilizar una herramienta mecánica a la intemperie,

utilice un cordón de extensión para intemperie

marcado "W-A" o "W". Estos cordones tienen

capacidad nominal para uso a la intemperie y reducen el

riesgo de que se produzcan sacudidas eléctricas.

Consulte "Tamaños recomendados de los cordones de

extensión" en la sección Accesorios de este manual.

Seguridad personal

Manténgase alerta, fíjese en lo que está haciendo y

use el sentido común cuando utilice una herramienta

mecánica. No use la herramienta cuando esté

cansado o se encuentre bajo la influencia de drogas,

alcohol o medicamentos. Un momento de distracción

al utilizar herramientas mecánicas puede dar lugar a

lesiones personales graves.

Vístase adecuadamente. No se ponga ropa holgada ni

joyas. Sujétese el pelo. Mantenga el pelo, la ropa y

los guantes alejados de las piezas móviles. La ropa

holgada, las joyas o el pelo largo pueden quedar

atrapados en las piezas móviles. Mantenga los mangos

secos, limpios y libres de aceite y grasa.

Evite el arranque accidental. Asegúrese de que el

interruptor esté en la posición "OFF" (apagado) antes

de enchufar la herramienta. El llevar las herramientas

con el dedo en el interruptor o el enchufar herramientas

que tengan el interruptor en la posición "ON"

(encendido) invita a que se produzcan accidentes.

Quite las llaves de ajuste o de tuerca antes de

encender la herramienta. Una llave de ajuste o de

tuerca que se deje puesta en una pieza giratoria de la

herramienta puede ocasionar lesiones personales.

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio adecuados en todo

momento. El apoyo de los pies y el equilibrio

adecuados permiten un mejor control de la herramienta

en situaciones inesperadas.

Utilice equipo de seguridad. Use siempre protección

de los ojos. Se debe utilizar una máscara antipolvo,

zapatos de seguridad antideslizantes, casco o

protección de los oídos según lo requieran las

condiciones.

SM 2610968981 2/03 2/10/03 3:14 PM Page 20

Page 21

-21-

Utilización y cuidado de las herramientas

Utilice abrazaderas u otro modo práctico de fijar y

soportar la pieza de trabajo a una plataforma estable.

La sujeción de la pieza de trabajo con la mano o contra

el cuerpo resulta inestable y puede ocasionar pérdida de

control.

No fuerce la herramienta. Use la herramienta

correcta para la aplicación que desea. La herramienta

correcta hará el trabajo mejor y con más seguridad a la

capacidad nominal para la que está diseñada.

No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no se pueda

controlar con el interruptor es peligrosa y debe ser

reparada.

Desconecte el enchufe de la fuente de energía antes

de hacer cualquier ajuste, cambiar accesorios o

guardar la herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de arrancar la herramienta

accidentalmente.

Guarde las herramientas que no esté usando fuera

del alcance de los niños y otras personas no

capacitadas. Las herramientas son peligrosas en las

manos de los usuarios no capacitados.

Mantenga las herramientas con cuidado. Conserve

las herramientas de corte afiladas y limpias. Las

herramientas mantenidas adecuadamente, con bordes

de corte afilados, tienen menos probabilidades de

atascarse y son más fáciles de controlar. Toda

alteración o modificación constituye un uso incorrecto y

puede tener como resultado una situación peligrosa.

Compruebe la desalineación o el atasco de las piezas

móviles, la ruptura de piezas y cualquier otra

situación que pueda afectar el funcionamiento de las

herramientas. Si la herramienta está dañada, haga

que realicen un servicio de ajustes y reparaciones a

la herramienta antes de usarla. Muchos accidentes

son causados por herramientas mantenidas

deficientemente. Establezca un programa de

mantenimiento periódico para la herramienta.

Utilice únicamente accesorios que estén

recomendados por el fabricante de su modelo. Los

accesorios que pueden ser adecuados para una

herramienta pueden volverse peligrosos cuando se

utilizan en otra herramienta.

Servicio

El servicio de ajustes y reparaciones de una

herramienta debe ser realizado únicamente por

personal de reparaciones competente. El servicio o

mantenimiento realizado por personal no competente

podría ocasionar un peligro de que se produzcan

lesiones. Por ejemplo: Los cables internos pueden

colocarse mal o pellizcarse, los resortes de retorno de

los protectores de seguridad pueden montarse

inadecuadamente.

Al realizar servicio de ajustes y reparaciones de una

herramienta, utilice únicamente piezas de repuesto

idénticas. Siga las instrucciones que aparecen en la

sección Mantenimiento de este manual. El uso de

piezas no autorizadas o el incumplimiento de las

instrucciones de Mantenimiento puede ocasionar un

peligro de que se produzcan sacudidas eléctricas o

lesiones. Ciertos agentes de limpieza, tales como

gasolina, tetracloruro de carbono, amoníaco, etc.,

pueden dañar las piezas de plástico.

Normas de seguridad para taladros

Sujete la herramienta por las superficies de agarre

aisladas cuando realice una operación en la que la

herramienta de corte pueda entrar en contacto con

cables ocultos o con su propio cordón. El contacto

con un cable que tenga corriente hará que ésta pase a

las partes metálicas descubiertas de la herramienta y

que el operador reciba sacudidas eléctricas. No

taladre, rompa, ni haga trabajo de sujeción en

paredes existentes ni en otras áreas ciegas donde

pueda haber cables eléctricos. Si esta situación es

inevitable, desconecte todos los fusibles o

cortacircuitos que alimentan este sitio de trabajo.

Use siempre el mango auxiliar para tener un

control máximo sobre la reacción de par motor o

retroceso. Los taladros de par motor alto y

capacidad de mandril de 3/8" y mayor están

equipados con mangos auxiliars.

Use siempre gafas de seguridad o protección de los

ojos cuando utilice esta herramienta. Use una

máscara antipolvo o un respirador para

aplicaciones que generan polvo.

Fije el material que se está taladrando. Nunca lo

tenga en las manos ni sobre las piernas. Un

soporte inestable puede hacer que la broca

taladradora se atasque, causando pérdida de control y

lesiones.

Nunca deje el gatillo fijo en la posición "ON"

(encendido). Antes de enchufar la herramienta,

compruebe que el cierre del gatillo esté en la

posición "OFF" (apagado). Un arranque accidental

podría causar lesiones.

Posicione el cordón de modo que esté alejado de la

broca que gira. No enrolle el cordón alrededor del

SM 2610968981 2/03 2/10/03 3:14 PM Page 21

Page 22

brazo o de la muñeca. Si pierde el control y tiene el

cordón enrollado en el brazo o en la muñeca, el

cordón puede atraparle y causarle lesiones.

Sitúese de modo que evite ser atrapado entre la

herramienta o el mango lateral y las paredes o los

postes. Si la broca se atasca o se engancha en la

pieza de trabajo, el par motor de reacción de la

herramienta podría aplastarle la mano o la pierna.

Si la broca se atasca en la pieza de trabajo, suelte

el gatillo inmediatamente, invierta el sentido de

giro y apriete lentamente el gatillo para sacar la

broca. Esté preparado para un fuerte par motor de