Sit TRASCO GRMP Series, TRASCO GRMALU Series, TRASCO GRB Series, TRASCO GRS Series, TRASCO GRF Series Operating And Maintenance Manual

TRASCO® Couplings

OPERATING AND MAINTENANCE MANUAL

SIT S.p.A. Viale A. Volta, 2 - 20090 Cusago (MI) - Italy

Tel. +39.02891441 Fax +39.0289144291 - info@sitspa.com www.sitspa.com

INDEX

Pag.

1

1.1

1.2

1.3

1.4

1.5

2

2.1

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.6

2.1.7

2.2

2.2.1

2.3

3

4

4.1

4.2

4.2.1

4.2.2

4.3

44

4.4.1

4.4.2

4.4.3

5

5.1

5.2

5.3

5.3.1

5.3.2

5.4

5.4.1

5.4.2

5.5

5.6

5.7

5.8

5.8.1

5.8.2

5.9

GENERAL INFORMATION 4

PURPOSE OF THE DOCUMENT 4

PROPER USE 4

WARNING SYMBOLS FOR SAFETY 4

GENERAL ADVICE IN CASE OF DANGER 5

REFERENCE LAWS AND STANDARDS 5

CHARACTERISTICS OF TRASCO® COUPLINGS 5

HUBS 6

GRMP SERIES HUBS 6

GRMALU SERIES HUBS 8

GRB SERIES HUBS 8

GRS SERIES HUBS 10

GRF SERIES HUBS 11

HUBS MACHINING 13

POSITION AND SIZE OF THE SETSCREW 14

ELASTIC SPIDER 15

ELASTIC SPIDER PERFORMANCE 16

COUPLING MISALIGNMENTS 17

STORAGE 17

ASSEMBLING 18

GRMP COUPLING ASSEMBLY 18

GRB COUPLING ASSEMBLING 20

TAPER BUSH MOUNTING 20

TAPER BUSH DISASSEMBLING 21

GRS COUPLING ASSEMBLING 21

GRF COUPLING ASSEMBLING 22

FLANGE-FLANGE VERSION 22

SHAFT-FLANGE VERSION 23

SHAFT-SHAFT VERSION 24

ATEX ANNEX 25

ATEX ZONE CLASSIFICATION 25

ATEX EQUIPMENT CLASSIFICATION 26

APPROPRIATE USE OF TRASCO® COUPLINGS IN ATEX ZONES 26

GAS TEMPERATURE CLASSES FOR GROUP II EQUIPMENT 26

TEMPERATURE CLASSES FOR GROUP I EQUIPMENT 26

MARKING 27

COMPLETE MARKING 27

COMPACT MARKING 27

HUB MACHINING IN ATEX ENVIRONMENT 28

ELASTIC SPIDER CHECK 28

INTERNAL MANUFACTURING CHECK 29

STARTING 29

PROTECTION DEVICES FOR COUPLINGS IN HAZARDOUS ATMOSPHERES 30

ELECTRICAL CONTINUITY 30

DECLARATION OF CONFORMITY 31

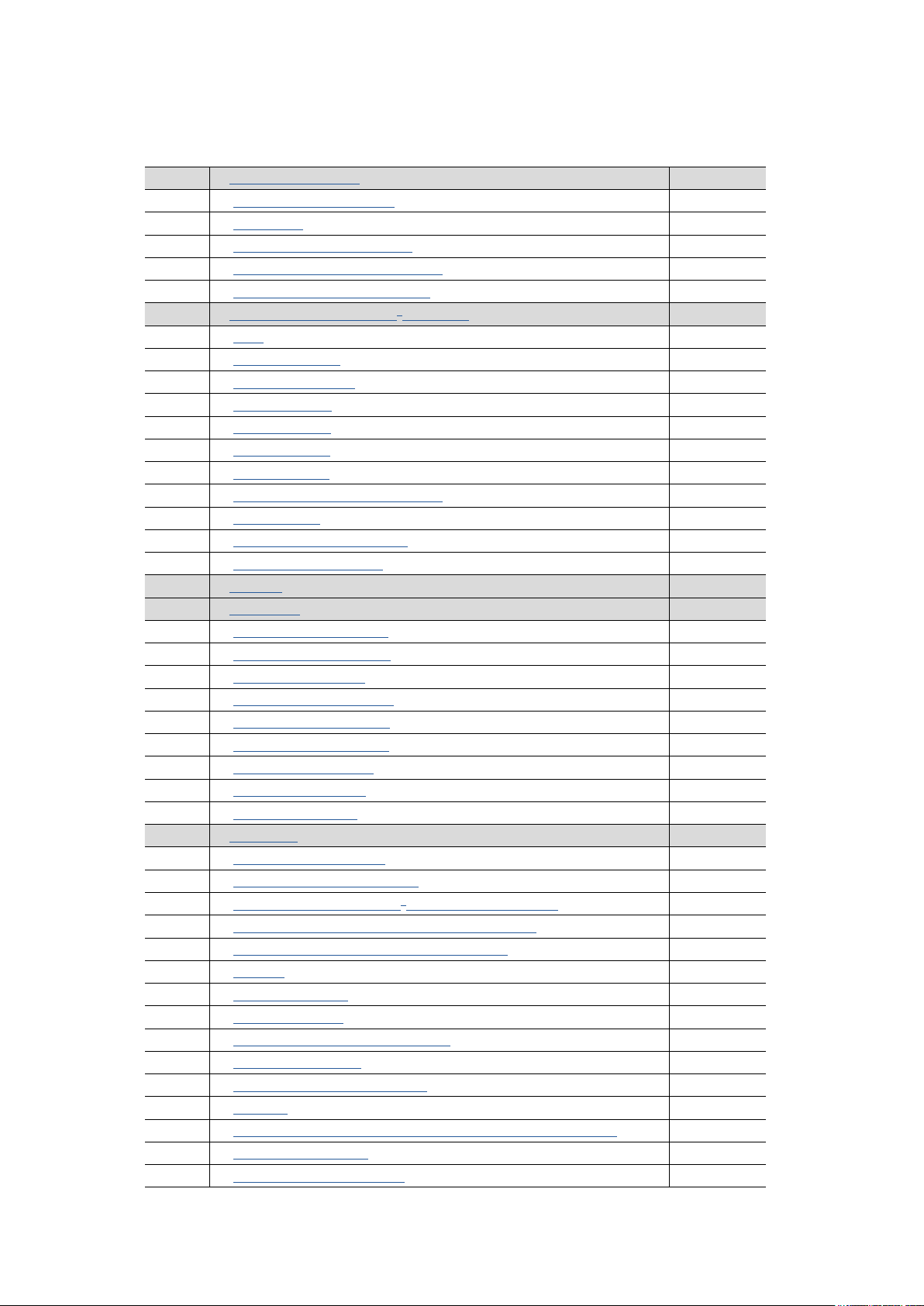

INDEX OF TABLES

Pag.

TABLE 2.1

TABLE 2.2

TABLE 2.3

TABLE 2.4

TABLE 2.5

TABLE 2.6

TABLE 2.7

TABLE 2.8

TABLE 2.9

TABLE 2.10

TABLE 2.11

TABLE 4.1

TABLE 4.2

TABLE 4.3

TABLE 5.1

TABLE 5.2

TABLE 5.3

TABLE 5.4

TRASCO®: HUBS MATERIALS 6

DIMENSIONS TRASCO® GRMP 7

TRASCO® GRMP LENGTHS 7

DIMENSIONS TRASCO® GRMALU 8

DIMENSIONS TRASCO® GRB 9

DIMENSIONS TRASCO® GRS 10

DIMENSIONS TRASCO® GRF 11

DIMENSIONS TRASCO® GRF 12

TRASCO®: POSIZIONE GRANO DI FISSAGGIO 14

ELASTIC SPIDER PERFORMANCE 16

TRASCO®: MISALIGNMENTS 17

QUOTE M 19

GRANI BUSSOLE CONICHE 20

GRF SCREWS 22

ATEX ZONE CLASSIFICATION 25

ATEX GROUPS AND CATEGORIES CLASSIFICATION 26

GAS TEMPERATURE CLASSES 26

QUOTE Z FOR CHECKING SPIDER WEAR 28

INDEX OF FIGURES

Pag.

FIGURE 2-1

FIGURE 2-2

FIGURE 2-3

FIGURE 2-4

FIGURE 2-5

FIGURE 2-6

FIGURE 2-7

FIGURE 2-8

FIGURE 2-9

FIGURE 4-1

FIGURE 4-2

FIGURE 4-3

FIGURE 4-4

FIGURE 4-5

FIGURE 4-6

FIGURE 4-7

TRASCO® GRMP HUBS 6

TRASCO® SERIES GRB 8

TRASCO® SERIES GRS 10

TRASCO® GRF HUBS 11

TRASCO® GRF C HUBS 12

PROCESSING TOLERANCE 13

SETSCREW POSITION 14

ELASTIC SPIDER 15

TRASCO®: MISALIGNMENTS 17

GRMP COUPLING 18

GRMP: MOUNTING 19

TYPES OF GRB 20

GRS INTERMEDIATE ELEMENT 21

FLANGE-FLANGE VERSION (CF/CFN) 22

SHAFT-FLANGE VERSION (CF/CFN) 23

SHAFT-SHAFT VERSION (CF/CFN) 24

www.sitspa.com TRASCO® - Operating and Maintenance Manual

1 General information

We recommend that you carefully read all the mounting instructions before installing the coupling, paying particular attention to the safety

instructions.

TRASCO® coupling is suitable for use in potentially explosive atmospheres. When using the coupling in hazardous areas, strictly observe

the special information and instructions regarding safety in the ATEX attachment.

The mounting instructions are part of the product; please keep them safe and close to the coupling.

They are available in electronic format on the website www.sitspa.com.

All the rights of this manual are reserved and are the property of SIT S.p.A.; therefore, its sale and reproduction without permission are

prohibited.

1.1 Purpose of the document

The purpose of this document is the description of the TRASCO

use in potentially explosive environments in accordance with ATEX Directive 2014/34/EU.

All the indications are provided, so that it is properly dimensioned, stored and assembled.

As regards the couplings that have to work in potentially explosive environments, all the indications and standards for identifying the

installation areas for which the coupling is certified to operate in safe conditions are provided.

®

couplings, both in the standard version and in the version suitable for

1.2 Proper use

Before handling a SIT coupling for moving, installing, or performing maintenance, it is advisable to carefully read the mounting instructions.

Any kind of changes aren’t authorized except those expressly provided for in the operating and maintenance manual.

SIT assumes no liability for damage resulting from tampered material and, therefore, no longer original.

SIT reserves the right to make changes to the product; as a consequence, this manual will be updated. The technical specifications listed

in the operating and maintenance manual exactly match the state of the art at the time of printing.

1.3 Warning symbols for safety

The warning symbols included in this manual alert the user to possible risks that may occur during handling, assembling and use of the

coupling.

It is necessary to pay particular attention to them.

STOP

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

DANGER

CAUTION

ATTENTION

PRECAUTION

Danger of injury to persons.

Possible damages to the machine.

Important guidelines to follow.

Hints about explosion protections.

4

www.sitspa.com TRASCO® - Operating and Maintenance Manual

1.4 General advice in case of danger

DANGER!

Every operation performed on the coupling, either with mounting

or maintenance, must be carried out with the machine not con-

STOP

nected to the power supply. Accidental contact with the rotating

parts can cause serious injury to the operator. It is recommended

to read these operating instructions to ensure safety.

• Affix proper warning signs around the machine

• Instruct the operator before giving permission to work on the coupling

• Operate on the coupling and on the transmission in safe conditions

• Make sure the machine power is disconnected before carrying out any operation

• Do not touch any moving part of the machine and wait until it stops completely

• Protect the coupling against accidental contact with protection devices

1.5 Reference laws and standards

This evaluation was carried out in accordance with the provisions of the relevant laws, directives, standards mentioned below:

DIN 740/2

ATEX DIRECTIVE 2014/34/EU

ATEX GUIDELINES 2014/34/EU

EN 1127-1:2011

EN 13463-1:2009

EN 13463-5:2011

Reference standard for flexible couplings

Equipment and protective systems intended for use in potentially explosive atmospheres

Guidelines to the application of Directive 2014/34/EU

Explosion prevention and protection against explosion. Basic concepts and methodology

Non-electrical equipment for potentially explosive atmospheres. Basic method and requirements

Non-electrical equipment for potentially explosive atmospheres. Constructional safety "c"

®

2 Characteristics of TRASCO

®

TRASCO

is very compact and allows a safe transmission of motion between the motor and the driven machine, absorbing shocks and torsional

vibrations. It also allows, through the elastic deformation of the elastic spider, to compensate for angular, radial and axial misalignments

due to small variations in length of the shafts. The hub teeth and spider profiles are designed so as to obtain a uniform pressure distribution.

The elastic element is subject only to compression stress and does not induce any axial or radial stresses, providing the TRASCO®

coupling with great load capacity and durability. The coupling can be assembled both horizontally and vertically, and it correctly tolerates

load variations and reversals.

couplings are a flexible and constant-velocity coupling that ensures maximum performance with same overall dimensions. It

couplings

The TRASCO® series is suitable for use in areas classified with the

presence of flammable gases, vapours and mists or combustible

dusts (Zone 1/21, category 2 GD).

It is designed and built in accordance with the ATEX Directive

2014/34/EU and in accordance with the following European stan

dards:

• EN 1127-1:2011

• EN 13463-1:2009

-

• EN 13463-5:2011

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

5

www.sitspa.com TRASCO® - Operating and Maintenance Manual

GRMP...A

AR

GRMP...B

2.1 Hubs

The TRASCO® coupling consists of two metal hubs that have cut-outs with circular sections which contain the teeth of the elastic spider.

The materials of standard hubs are laminated cast iron, spheroidal cast iron or aluminium, depending on the types and sizes.

For details see TABLE 2.1 - TRASCO®: hubs materials.

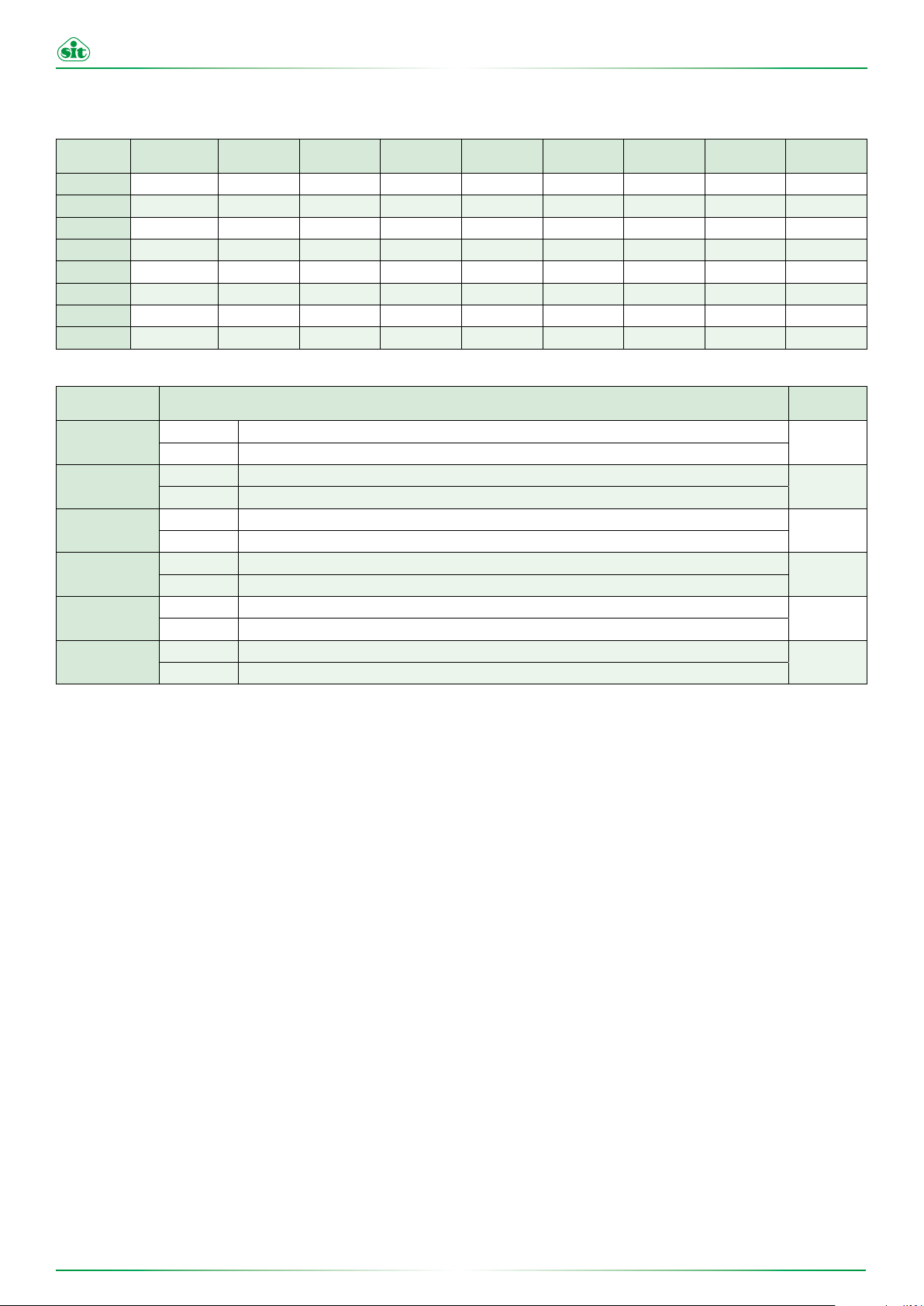

TABLE 2.1 - TRASCO®: hubs materials

SERIES SIZE STANDARD MATERIAL OPTIONAL MATERIALS

19/24 Steel sintered Steel / Stainless steel / Aluminium / spheroidal cast iron

GRMP

from 24/32 to 90/100 Grey cast iron Steel / Stainless steel / Aluminium / spheroidal cast iron

from 100/110 to 180/200 spheroidal cast iron Steel / Stainless steel / Aluminium / spheroidal cast iron

GRMALU

GRB

GRS

GRF

Table 2.1 - Note: For details contact the Technical Department.

All Aluminium diecast Steel / Stainless steel / Aluminium / spheroidal cast iron

All Grey cast iron Steel / Stainless steel / Aluminium / spheroidal cast iron

All Aluminium Steel / Stainless steel / Aluminium / spheroidal cast iron

All spheroidal cast iron Steel / Stainless steel / Aluminium / spheroidal cast iron

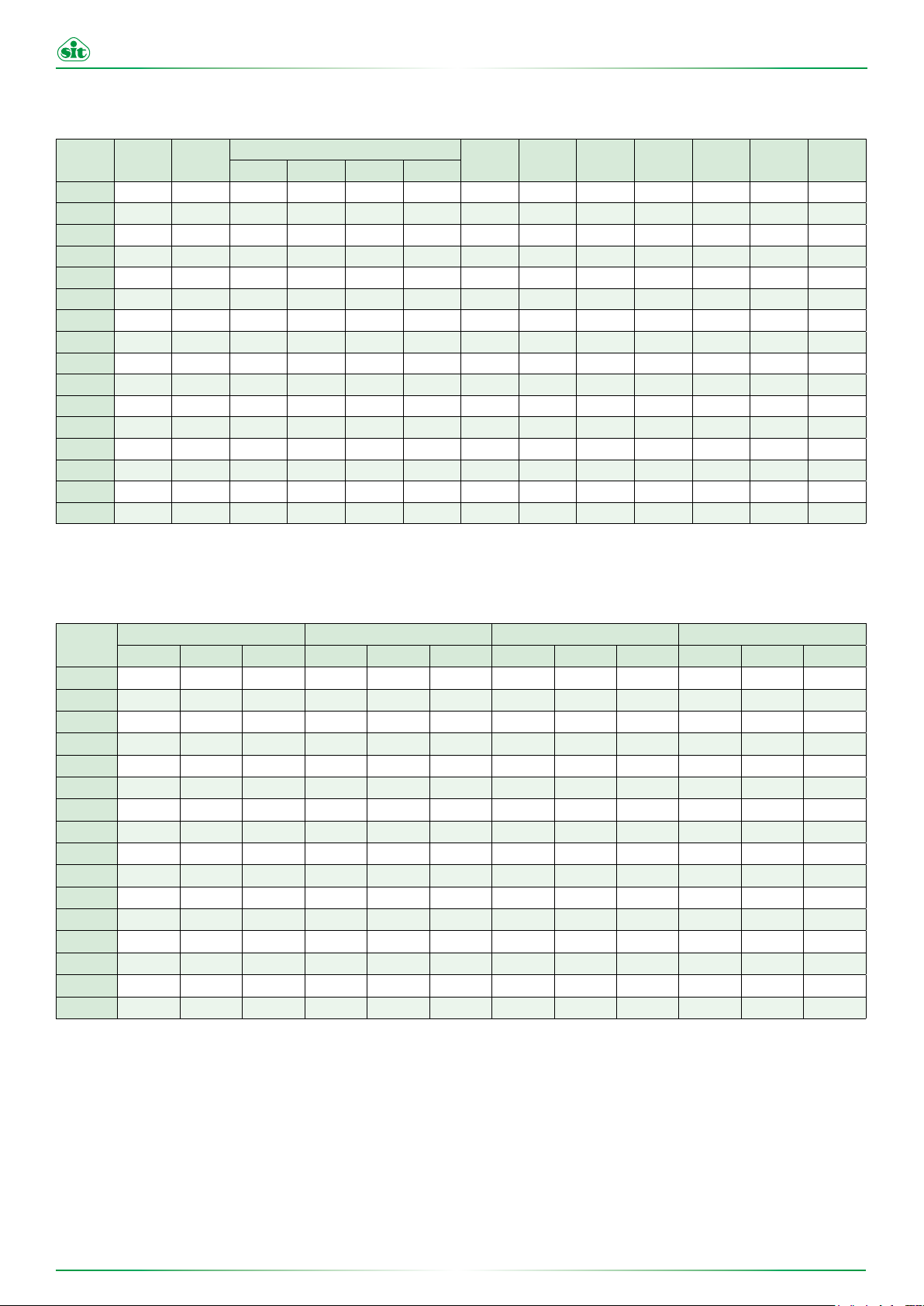

2.1.1 GRMP series hubs

The TRASCO® hubs series GRMP are made, depending on the size, in two versions: A (hollow) and B (full).

They are different for the exterior design and for the maximum bore that can be achieved.

Each of them has the respective AL and BL extended version (TABLE 2.2 - TRASCO® GRMP dimensions, TABLE 2.3 - TRASCO®

GRMP lengths).

Table 2.3 - TRASCO® GRMP lengths

A B AL BL

Figure 2-1 - GRMP TRASCO® Hubs

The milling of the seat of the flexible element of the GRMP guarantees a perfect coupling with the elastic spider in order to ensure a long

life in the correct operating conditions.

H

I

t

E

A

aF

gF

Hub Hub

Mozzo

“A”

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

M

N

P

G

L

H

SS

I

B

bF

Mozzo

gF

“B”

6

www.sitspa.com TRASCO® - Operating and Maintenance Manual

Table 2.2 - Dimension TRASCO® GRMP

SIZE Fa

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

140/160

160/185

180/200

- 24 - - - - 40 40 16 2 12 18

24 32 8 10 8 10 55 40 55 18 2 14 27

28 38 8 10 8 10 65 48 65 20 2,5 15 30

38 45 10 12 14 14 80 66 80 24 3 18 38

42 55 10 12 16 16 95 75 95 26 3 20 46

48 60 12 12 16 16 105 85 105 28 3,5 21 51

55 70 15 15 16 16 120 98 120 30 4 22 60

65 75 15 15 20 20 135 115 135 35 4,5 26 68

75 90 15 15 22 22 160 135 160 40 5 30 80

90 100 20 20 30 30 200 160 180 45 5,5 34 100

115 - 45 - - - 225 180 - 50 6 38 113

125 - 55 - - - 255 200 - 55 6,5 42 127

145 - 55 - - - 290 230 - 60 7 46 147

160 - 55 - - - 320 255 - 65 8 50 165

185 - 75 - - - 370 290 - 75 9 57 190

200 - 80 - - - 420 325 - 85 11 64 220

Fb

max

Table 2.2 - * dimensions in mm

®

Table 2.3 - TRASCO

GRMP lengths

Fg

max Fb AL BL

E A B M S N G

SIZE

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

140/160

160/185

180/200

Execution A Execution B Execution AL Execution BL

H L (A+A) I H L (B+B) I H L (AL+AL) I H L (BL+BL) I

25 66 - - - - - 50 - - 25 66

30 78 24 - 50 128 44 60 128 - 30 78

35 90 28 - 60 160 53 80 160 - 35 90

45 114 37 - 80 214 72 110 214 - 45 114

50 126 40 - 110 246 100 110 246 - 50 126

56 140 45 - 110 278 99 140 278 - 56 140

65 160 52 - 110 280 97 140 280 - 65 160

75 185 61 - 140 315 126 140 315 - 75 185

85 210 69 - 140 350 124 170 350 - 85 210

100 245 81 81 170 425 151 210 425 191 100 245

110 270 89 - - - - - - - 110 270

120 295 96 - - - - - - - 120 295

140 340 112 - - - - - - - 140 340

155 375 124 - - - - - - - 155 375

175 425 140 - - - - - - - 175 425

195 475 156 - - - - - - - 195 475

Table 2.3 - * dimensions in mm

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

7

www.sitspa.com TRASCO® - Operating and Maintenance Manual

Ø

d

Ø

d

L

Ø

B

Ø

B

Ø

E

I I

NS

H H

S

M

GRMP...A

AR

GRMP...B

2.1.2 GRMALU series hubs

The TRASCO® GRMALU series hubs are made of die-casting aluminium for A and B versions

(TABLE 2.4 - TRASCO® GRMALU dimensions).

E

Table 2.4 - Dimensions TRASCO® GRMALU

SIZE

19/24

24/32

28/38

38/45

42/55

48/60

Fa

maxFbmax

- 24 - - 40 40 40 66 25 16 2 12 - 18 10 M5

24 32 - - 55 40 55 78 30 18 2 14 24 27 10 M5

28 38 12 28 65 48 65 90 35 20 2.5 15 28 30 15 M6

38 45 22 38 80 66 77 114 45 24 3 18 37 38 15 M8

- 55 - 22 95 - 95 126 50 26 3 20 - 46 20 M8

- 60 - 30 105 - 105 140 56 28 3.5 21 - 51 20 M8

Table 2.4 - * dimensions in mm

Fg

A B

H

I

t

P

A

aF

gF

Hub Hub

Mozzo

“A”

E A B L H M S N I G t P

M

N

G

H

SS

I

B

bF

gF

Mozzo

“B”

L

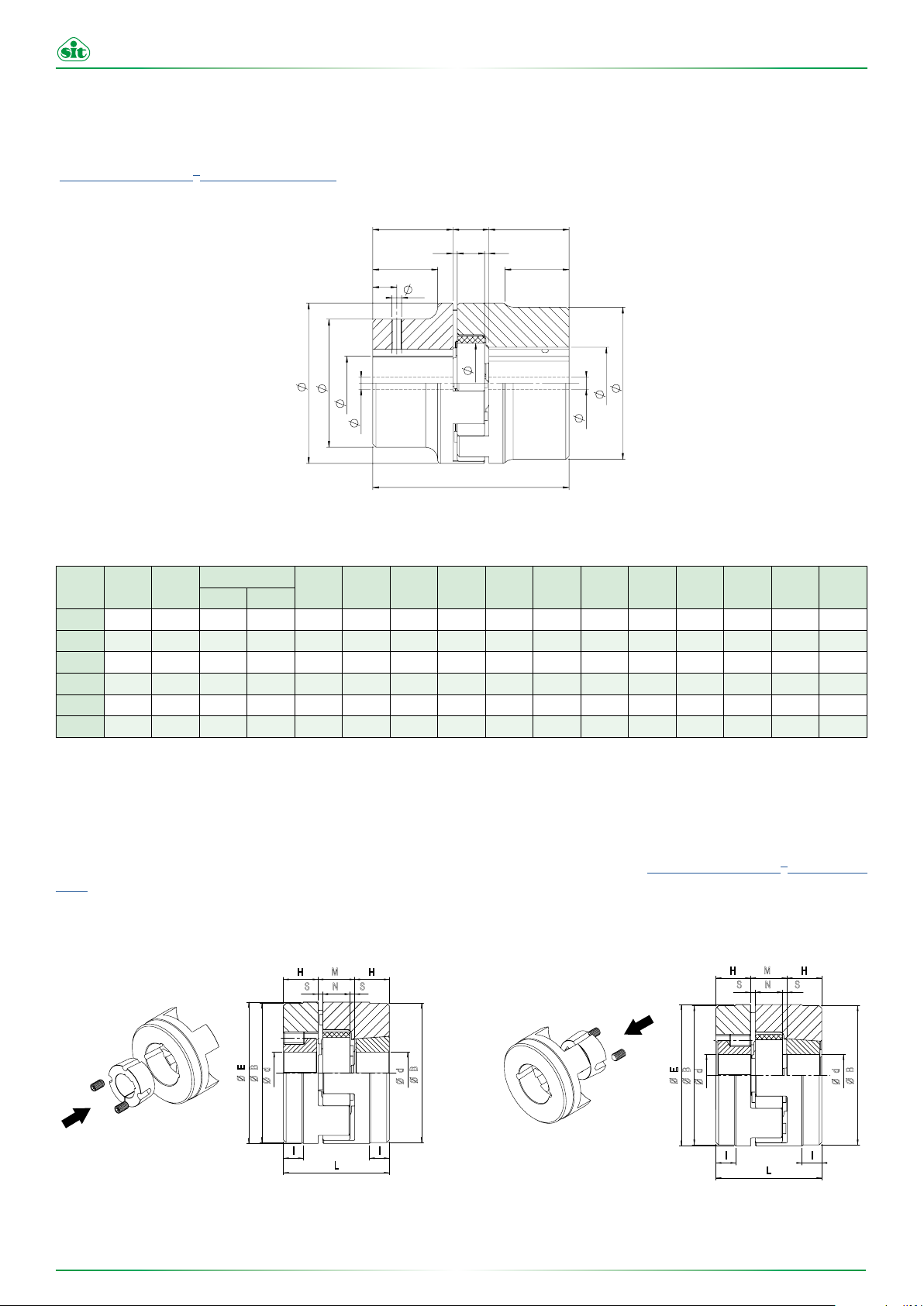

2.1.3 GRB series hubs

The TRASCO® GRB series couplings for taper bush combines high performance characteristics, typical of standard hub coupling, the

ease of use, assembly and disassembly, resulting from the coupling with a SER-SIT® taper bush. (TABLE 2.5 - TRASCO® GRB dimen-

sions).

They are produced in two versions:

• B1, with bush mounting from the outside of the hub

• B2, with bush mounting from the inside of the hub

B1 B2

H H

H HM

NS S

E

B

d

Ø

Ø

Ø

I I

L

B

d

Ø

Ø

E

B

d

Ø

Ø

Ø

M

NS

I I

L

Figure 2-2 - TRASCO® series GRB

S

B

d

Ø

Ø

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

8

www.sitspa.com TRASCO® - Operating and Maintenance Manual

Table 2.5 - DimensionsTRASCO® GRB

SIZE

28/38 1108 (2820) 65 65 66 23 20 2,5 15 -

38/45 1108 (2820) 80 78 70 23 24 3 18 15

42/55 1610 (4025) 95 94 78 26 26 3 20 16

48/60 1615 (4040) 105 104 106 39 28 3,5 21 28

55/70 2012 (5030) 120 118 96 33 30 4 22 20

65/75 2012 (5030) 135 133 101 33 35 4,5 26 19

75/90 2517 (6545) 160 158 130 45 40 5 30 36

90/100 3535 (9090) 200 180 223 89 45 5,5 34 70

SER-SIT SIZE

1108 (2820)

1610 (4025)

1615 (4040)

2012 (5030)

2517 (6545)

3535 (9090)

SER-SIT TAPER

BUSH

[mm] 11-12-14-15-16-17-18-19-20-22-24-25-26-27-28

[inch] 3/8-1/2-5/8-3/4-7/8-1-1 1/8

[mm] 12-14-15-16-18-19-20-22-24-25-26-28-30-32-35-38-40-42

[inch] 3/8-1/2-5/8-3/4-7/8-1-1 1/8-1 1/4-1 3/8-1 1/2-1 5/8

[mm] 12-14-15-16-18-19-20-22-24-25-26-28-30-32-35-38-40-42

[inch] 1/2-5/8-3/4-7/8-1-1 1/8-1 1/4-1 3/8-1 1/2-1 5/8-1 3/4

[mm] 14-15-16-18-19-20-22-24-25-26-28-30-32-35-38-40-42-45-48-50

[inch] 5/8-3/4-7/8-1-1 1/8-1 1/4-1 3/8-1 1/2-1 5/8-1 3/4-1 7/8-2

[mm] 18-19-20-22-24-25-28-30-32-35-38-40-42-45-48-50-55-60-65

[inch] 3/4-7/8-1-1 1/8-1 1/4-1 3/8-1 1/2-1 5/8-1 3/4-1 7/8-2-2 1/8-2 1/4-2 3/8-2 1/2

[mm] 25-35-38-40-42-45-48-50-55-60-65-70-75-80-85-90

[inch] 1 1/2-1 5/8-1 3/4-1 7/8-2-2 1/8-2 1/4-2 3/8-2 1/2-2 5/8-2 3/4-2 7/8-3-3 1/8-3 1/4-3 3/8-3 1/2

E B L H M S N I

BORE DIAMETER (H7)

Tolerance of the seat of the keyway JS9

Torque

[Nm]

1300

5000

150

490

490

800

Table 2.5

* dimensions in mm

** Transmittable friction torque without the keyway

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

9

www.sitspa.com TRASCO® - Operating and Maintenance Manual

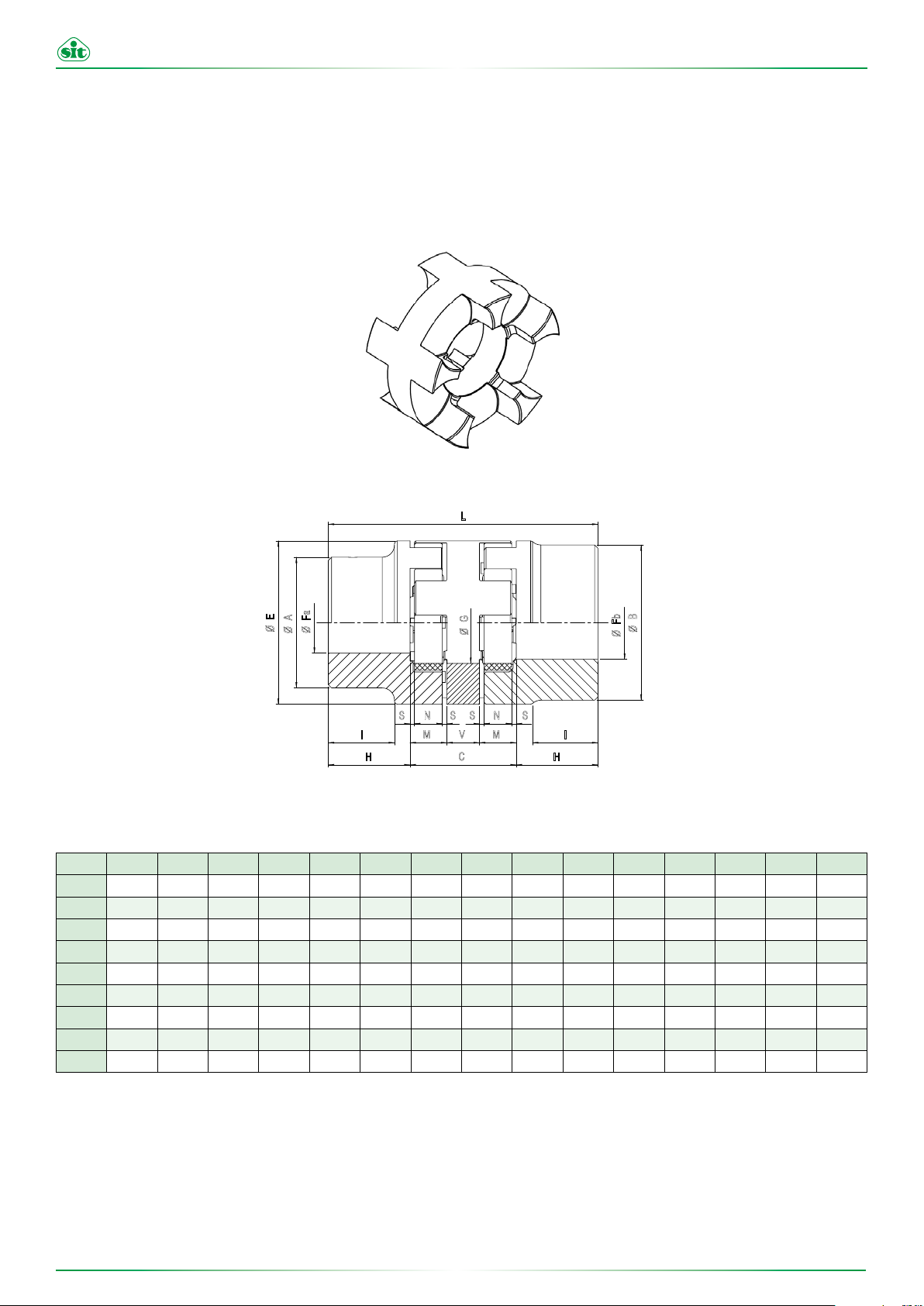

2.1.4 GRS series hubs

The GRS series hubs are intermediate elements that increase the ability of the coupling to compensate for axial, radial and angular

misalignments.

The presence of two elastic spiders allows a high damping effect of the vibrations, with consequent reduction of the transmission noise

and a reduced wear of the connected components, such as bearings.

Figure 2-3 - TRASCO® GRS series

L

E

Fa

A

Ø

Ø

Ø

S N N S

I I

H C H

Table 2.6 - DimensionsTRASCO

SIZE Fa Fb H V C M S N L E A B G ΔKr ΔKw

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

9-24 11-32 30 16 52 18 2 14 112 55 40 55 27 0,89 1°30’

9-28 11-38 35 18 58 20 2,5 15 128 65 48 65 30 1 1°30’

11-38 13-45 45 20 68 24 3 18 158 80 66 80 38 1,15 1°30’

11-42 13-55 50 22 74 26 3 20 174 95 75 95 46 1,26 1°30’

13-48 13-60 56 24 80 28 3,5 21 192 105 85 105 51 1,36 1°30’

16-55 16-70 65 28 88 30 4 22 218 120 98 120 60 1,52 1°30’

16-65 16-75 75 32 102 35 4,5 26 252 135 115 135 68 1,75 1°30’

16-75 16-90 85 36 116 40 5 30 286 160 135 160 80 2 1°30’

21-90 21-100 100 40 130 45 5,5 34 330 200 160 180 100 2,5 1°30’

®

GRS

G

Ø

S S

M V M

Fb

Ø

B

Ø

* dimensions in mm

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

10

www.sitspa.com TRASCO® - Operating and Maintenance Manual

BF

A

E

H

M

V

S

P

Lc

Ea

Bc

N

S

Fa

C

D Nr

G

S

Ea

E

V

Bc

P

C

N

S

M

V

La

D Nr

G

S

Ea

E

V

Fa

A

H

I

A

G

Lb

S

N

M

V

H

Bb

I

Fa

CF

2CF

BF

A

E

H

M

V

S

P

Lc

Ea

Bc

N

S

Fa

C

D Nr

G

S

Ea

E

V

Fa

A

H

I

A

G

Lb

S

N

M

V

H

Bb

I

Fa

CF

2CF

BF

S

Ea

E

V

Fa

A

H

I

A

G

Lb

S

N

M

V

H

Bb

I

Fa

CF

BF

S

Ea

E

V

Fa

A

H

I

A

G

Lb

S

N

M

V

H

Bb

I

Fa

CF

2.1.5 GRF series hubs

The GRF series is the flange version that fits all the hubs of the TRASCO® family.

There are three different possibilities of coupling:

• Flange-flange: through the fastening bores of the flange CF (CFN in the compact version)

• Shaft-flange: on the shaft side, it is possible to install any hub of the TRASCO® family

• Shaft-shaft: with this version, it is possible to replace the flexible element without moving the hubs on the shafts or motor and driven

machine.

CF

GRMP...A

CF

CF

MF

CFF

AR

CFF

MF

La

E

G

N

S

M

V

FLANGE - FLANGE SHAFT - FLANGE SHAFT - SHAFT

Table 2.7 - Dimensioni TRASCO

Fa

SIZE

19/24

24/32

28/32

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

minFamax

6 19 40 65 40/32 40 50 5 4,5 18 25 26 1,5 17 8 16 2 12 32 74 49

8 24 55 80 55/40 55 65 5 4,5 27 30 31 1,5 22 8 18 2 14 34 86 56

10 28 65 100 65/48 65 80 6 6,5 30 35 36 1,5 25 10 20 2,5 15 40 100 65

12 38 80 115 66 80 95 6 6,5 38 45 46 1,5 35 10 24 3 18 44 124 79

14 42 95 140 75 95 115 6 9 46 50 51 2 38 12 26 3 20 50 138 88

15 48 105 150 85 105 125 8 9 51 56 57 2 44 12 28 3,5 21 52 152 96

20 55 120 175 98 120 145 8 11 60 65 66 2 49 16 30 4 22 62 176 111

22 65 135 190 115 135 160 10 11 68 75 76 2 59 16 35 4,5 26 67 201 126

30 75 160 215 135 160 185 10 14 80 85 87 2,5 66 19 40 5 30 78 229 144

40 90 200 260 160 200 225 12 14 100 100 102 3 80 20 45 5,5 34 85 265 165

45 115 225 285 180 225 250 12 14 113 110 112 4 85 25 50 6 38 100 295 185

55 125 255 330 200 255 290 12 18 127 120 122 4 94 26 55 6,5 42 107 321 201

55 145 290 370 230 290 325 16 18 147 140 142 5 110 30 60 7 46 120 370 230

C

Ea

D Nr

Bc

P

S

V

®

GRF

E Ea A C D

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

E

A

Fa

Figure 2-4 - GRF TRASCO

Nr.

screws

Lc

D Nr

C

G

N

S

S

H

V

M

Ea

Bc

P

E

A

Fa

Lc

G

Bc

N

S

S

H

V

M

®

Hubs

P G H Bb Bc I V M S N La Lb Lc

11

C

P

D Nr

Ea

www.sitspa.com TRASCO® - Operating and Maintenance Manual

E

A

H

N

SS

M

V

Bc

E

Lc

Fa

D Nr

G

C

P

GRMP...A

BFN

AR

CFN

MFN

N

S

Bc

E

S

M

V V

La

D Nr

P

Fa

G

NE S S

M

V V

H

I

H

I

B

B

Bb

Lb

D Nr

G

C

P

Fa

Fa

ALBERO-FLANGIA

FLANGIA-FLANGIA

ALBERO-ALBERO

H

N

SS

M

V

Bc

E

Lc

D Nr

G

C

P

BFN

AR

CFN

MFN

NE S S

M

V V

H

I

H

I

B

B

Bb

Lb

D Nr

G

C

P

Fa

Fa

ALBERO-FLANGIA

ALBERO-ALBERO

NE S S

M

V V

H

I

H

I

B

Bb

Lb

D Nr

G

C

P

Fa

Fa

ALBERO-ALBERO

E

A

H

N

SS

M

V

Bc

E

Lc

Fa

D Nr

G

C

P

N

S S

M

V V

H

I

H

I

B

B

Bb

Lb

G

C

P

Fa

Fa

NE S S

M

V V

H

I

H

I

B

B

Bb

Lb

D Nr

G

C

P

Fa

Fa

GRMP...A

La

E

A

Fa

G

Bc

Fa

E

D Nr

P

M

S

N

V V

S

Lc

N

SS

H

M

C

G

Bc

V

E

D Nr

P

B

Fa

I

V V

H

FLANGE - FLANGE SHAFT - FLANGE SHAFT - SHAFT

Lb

NE S S

M

AR

CFN

G

Bb

I

H

BFN

MFN

B

C

Fa

D Nr

P

Table 2.8 - Dimensioni TRASCO

SIZE

19/24

24/32

28/32

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

Fa

minFamax

6 19 40 65 40/32 40 50 5 4,5 18 25 26 1,5 17 8 16 2 12 32 74 49

8 24 55 80 55/40 55 65 5 4,5 27 30 31 1,5 22 8 18 2 14 34 86 56

10 28 65 100 65/48 65 80 6 6,5 30 35 36 1,5 25 10 20 2,5 15 40 100 65

12 38 80 115 66 80 95 6 6,5 38 45 46 1,5 35 10 24 3 18 44 124 79

14 42 95 140 75 95 115 6 9 46 50 51 2 38 12 26 3 20 50 138 88

15 48 105 150 85 105 125 8 9 51 56 57 2 44 12 28 3,5 21 52 152 96

20 55 120 175 98 120 145 8 11 60 65 66 2 49 16 30 4 22 62 176 111

22 65 135 190 115 135 160 10 11 68 75 76 2 59 16 35 4,5 26 67 201 126

30 75 160 215 135 160 185 10 14 80 85 87 2,5 66 19 40 5 30 78 229 144

40 90 200 260 160 200 225 12 14 100 100 102 3 80 20 45 5,5 34 85 265 165

45 115 225 285 180 225 250 12 14 113 110 112 4 85 25 50 6 38 100 295 185

55 125 255 330 200 255 290 12 18 127 120 122 4 94 26 55 6,5 42 107 321 201

55 145 290 370 230 290 325 16 18 147 140 142 5 110 30 60 7 46 120 370 230

E Ea A C D

Figure 2-5 - GRF C Hubs

®

GRF

screws

P G H Bb Bc I V M S N La Lb Lc

Nr.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

12

www.sitspa.com TRASCO® - Operating and Maintenance Manual

2.1.6 Hubs machining

Any machining of the hubs must not compromise its functionality.

As for the maximum diameter of the bore that can be achieved, please refer to the table in the catalogue.

The bore machining must be carried out in accordance with the concentricity values with the outer diameter and the perpendicularity

values between the hole and the flat internal surface of the hub with a degree of tolerance IT8.

Figure 2-6 - Processing tolerance

It is important not to exceed, for all the materials of which the hub is composed, the maximum value of the hole provided

by SIT and reported in the technical catalogue; if this value is not respected the coupling may break, causing serious

dangers during the rotation.

DANGER!

The maximum bore allowed and indicated in the catalogue table must

not be exceeded. Higher values could cause breakage and danger

STOP

around the machine.

If the hub bore is machined by the customer, the concentricity and ra

dial oscillation values specified by SIT must be respected.

Carefully align the hubs when machining the finished bore.

CAUTION!

The customer is responsible for all the machining performed.

SIT assumes no liability arising from incorrect machining or for failure

to observe the instructions contained in this manual and in the technical

catalogue.

PRECAUTION!

Except for the machining of the hole, the seat of the keyway and the

threaded bore for the setscrew in accordance with the values shown in

the technical catalogue, any machining of couplings that must be used

in hazardous areas must obtain the express permission of SIT.

The customer must provide SIT with a technical drawing which shows

the machining to be carried out. It is the responsibility of SIT to evalua

te and approve it.

Any spare parts for these couplings must be standard hubs unbored or

with pilot bore marked with the ATEX marking.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

13

www.sitspa.com TRASCO® - Operating and Maintenance Manual

GRMP....A

2.1.7 Position and size of the setscrew

SIT supplies flathead setscrews class 45H according to DIN 913 for fastening the hub on the shaft.

For the position and size of the setscrews, refer to TABLE 2.9 - TRASCO®: setscrew position and to the drawing of FIGURE 2.7 - Set-

screw position.

t

P

Figure 2-7 - Setscrew position

Table 2.9 - TRASCO®: posizione grano di fissaggio

SIZE THREAD

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

140/160

160/185

180/200

DISTANCE

[mm]

M5 10 2

M5 10 2

M6 15 4,8

M8 15 10

M8 20 10

M8 20 10

M10 20 17

M10 20 17

M10 25 17

M12 30 40

M12 30 40

M16 35 80

M16 40 80

M20 45 140

M20 50 140

M20 50 140

THIGHTNING TORQUE

[Nm]

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

14

www.sitspa.com TRASCO® - Operating and Maintenance Manual

2.2 Elastic spider

The elastic spider is a toothed ring produced with special polyurethane compounds that allows for optimised coupling performance

according to the application.

The flexible element is particularly resistant to ageing, hydrolysis (therefore also suitable for tropical climates), fatigue, abrasion and is

self-damping.

Figure 2-8 - Elastic spider

The operating temperature ranges of the spider is from -50 °C to +150 °C.

The standard version, is available, as standard product, in three hardness to suit different applications:

• yellow ring 92 Sh A

• red ring 98 Sh A

• green ring 64 Sh D

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

15

www.sitspa.com TRASCO® - Operating and Maintenance Manual

2.2.1 Elastic spider performance

Table 2.10 - Elastic spider performance

SIZE COLOUR

Yellow 92 Sh A 10 20 2,7 14000

19/24

Green 64 Sh D 21 42 5,5 14000

Yellow 92 Sh A 35 70 9 10600

24/32

Green 64 Sh D 75 150 19,5 10600

Yellow 92 Sh A 95 190 25 8500

28/38

Green 64 Sh D 200 400 52 8500

Yellow 92 Sh A 190 380 49 7100

38/45

Green 64 Sh D 405 810 105 7100

Yellow 92 Sh A 265 530 69 6000

42/55

Green 64 Sh D 560 1120 145 6000

Yellow 92 Sh A 310 620 81 5600

48/60

Green 64 Sh D 655 1310 170 5600

Yellow 92 Sh A 410 820 107 4750

55/70

Green 64 Sh D 825 1650 215 4750

Yellow 92 Sh A 625 1250 163 4250

65/75

Green 64 Sh D 1175 2350 305 4250

Yellow 92 Sh A 1280 2560 333 3550

75/90

Green 64 Sh D 2410 4820 325 3550

Yellow 92 Sh A 2400 4800 624 2800

90/100

Green 64 Sh D 4500 9000 1170 2800

Yellow 92 Sh A 3300 6600 858 2500

100/110

Green 64 Sh D 6185 12370 1608 2500

Yellow 92 Sh A 4800 9600 1248 2240

110/125

Green 64 Sh D 9000 18000 2340 2240

Yellow 92 Sh A 6650 13300 1729 2000

125/145

Green 64 Sh D 12500 25000 3250 2000

140/160

160/185

180/200

HARDNESS

[Shore]

Red 98 Sh A 17 34 4,4 14000

Red 98 Sh A 60 120 16 10600

Red 98 Sh A 160 320 42 8500

Red 98 Sh A 325 650 85 7100

Red 98 Sh A 450 900 117 6000

Red 98 Sh A 525 1050 137 5600

Red 98 Sh A 680 1250 178 4750

Red 98 Sh A 950 1900 245 4250

Red 98 Sh A 1950 3900 500 3550

Red 98 Sh A 3600 7200 936 2800

Red 95 Sh A 4950 9900 1287 2500

Red 98 Sh A 7200 14400 1872 2240

Red 95 Sh A 10000 20000 2600 2000

Red 95 Sh A 12800 25600 3328 1800

Red 95 Sh A 19200 38400 4992 1500

Red 95 Sh A 28000 56000 7280 1400

RATED TORQUE

Tkn

[Nm]

MAXIMUM TORQUE

Tmax

[Nm]

VIBRATORY TORQUE

Tkw

[Nm]

MAXIMUM SPEED

[rpm]

Note: For GRB and GRCAL types it is necessary to check the transmissible torque capacity, respectively, as from the bush and clamp

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

16

www.sitspa.com TRASCO® - Operating and Maintenance Manual

2.3 Coupling misalignments

TABLE 2.11 shows the misalignment values based on the different coupling sizes that can accomodated.

Axial misalignment Axial misalignment Axial misalignment

®

Figure 2-9 - TRASCO

Table 2.11 - TRASCO®: misalignments

: misalignments

SIZE

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

140/160

160/185

180/200

Note: Values valid in room temperature conditions of 20 °C and for speeds up to 1500 rpm. For other conditions, contact our Technical Department.

Axial mis. ΔKa

[mm]

1,2 1°30’ 0,20

1,4 1°30’ 0,22

1,5 1°30’ 0,25

1,8 1°30’ 0,28

2,0 1°30’ 0,32

2,1 1°30’ 0,36

2,2 1°30’ 0,38

2,6 1°30’ 0,42

3,0 1°30’ 0,48

3,4 1°30’ 0,50

3,8 1°30’ 0,52

4,2 1°30’ 0,55

4,6 1°30’ 0,60

5,0 1°30’ 0,62

5,7 1°30’ 0,64

6,4 1°30’ 0,68

Angular mis. ΔKw

[°]

Radial mis. ΔKr

[mm]

In order to guarantee a long life of the coupling, it is necessary to pay close attention to the alignment.

PRECAUTION!

In case of use in potentially explosive areas of group II with II 2GD c

marking, only half of the above indicated misalignments is allowed. If

these values are not complied with, the coupling is considered as deli

-

berately damaged.

3 Storage

The couplings must be stored in covered and dry places.

It is important that the storage areas are protected against light sources, ultraviolet lamps, mercury vapour and high electrical voltage

sources.

The moisture percentage must be maintained below 65%.

In good storage conditions the characteristics of the spiders can remain unchanged for up to 6 years.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

17

www.sitspa.com TRASCO® - Operating and Maintenance Manual

4 Assembling

The TRASCO® coupling is supplied unassembled, therefore it is recommended to check the presence of all the components and check

that they match the application requirements.

The characteristic of the TRASCO® family of couplings gives the possibility of mounting any hub version provided that they belong to

the same size.

As regards the hubs, the size is printed on the marking located on the lateral surface.

The size of the spider is printed on a flat surface.

ATTENTION!

Install the hubs using only with the spider provided by SIT S.p.A. and of

the same size.

SIT S.p.A. assumes no liability for malfunctions and/or failures due to incorrect assembly or that does not comply with the instructions provided

in this manual.

4.1 GRMP coupling assembly

Components:

• 2 hubs

• 1 elastic spider

• 2 setscrews

ATTENTION!

Before assembling SIT recommends to check that the following parts

are matching: shafts diameters, hubs bores, keyways size and their seat

on the hubs.

If the dimensions of shaft and keyway is less than the diameter of the

GRMP...A

AR

GRMP...B

Figure 4-1 - GRMP coupling

spider hole, one or both shafts may protrude into the spider.

• Install the hubs on the driving and driven shafts (see FIGURE 4.2 - GRMP: mounting)

• Insert the spider into one of the two hubs

• Check the driving and driven hub to achieve the value M (see FIGURE 4.2 and TABLE 4.1)

• If the motor and driven machine are already firmly assembled, move axially the hubs on the shafts to adjust the M dimension

• Set the hubs using the setscrews, tightening according to TABLE 2.9 - TRASCO®: SETSCREW POSITION

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

18

www.sitspa.com TRASCO® - Operating and Maintenance Manual

Figure 4-2 - GRMP: mounting

Table 4.1 - Quote M

SIZE

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

140/160

160/185

180/200

QUOTE M

[mm]

16

18

20

24

26

28

30

35

40

45

50

55

60

65

75

85

PRECAUTIONS!

Be very careful in the dangerous areas.

DANGER!

STOP

Touching overheated hubs may causes burns. We recommend wearing

safety gloves.

CAUTION!

For the installation make sure that the distance M is maintained in order to ensure

that the spider can be moved axially. If this advice is disregarded, the device could

be damaged.

CAUTION!

If the dimensions of shaft and key is lower than the diameter of the spider hole,

one or both shafts may protrude into the spider.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

19

www.sitspa.com TRASCO® - Operating and Maintenance Manual

4.2 GRB coupling assembling

4.2.1 Taper bush mounting

Components:

• 2 hubs (B1 with bush mounting from the outside, B2 with bush mounting from the inside, FIGURE 4.3 - Types of GRB)

• 1 spider

• 2 bushes

• setscrews

B1 B2

Figure 4-3 - Types of GRB

The taper bush SER-SIT® is a clamping device with threaded holes.

Only half of the holes are in the bush, the other half are in the hub.

For correct assembling please follow these guidelines:

• Insert the bush into the hub matching the fastening holes

• Position the setscrews and tighten them partially

• Insert the whole shaft to the desired position (make sure that the M value reported in TABLE 4.1 - M Value is respected) and fully

tighten the setscrews according to the tightening torques specified in TABLE 4.2 - CONICAL CLAMPING BUSHES SETCREWS

• After a short period of operation, please check that the setscrews are not loose.

Table 4.2 - Conical clamping bushes setcrews

Taper bush size

®

SER-SIT

1108 22,3 38 2 1/4” 13 3 5,5

1610 25,4 57 2 3/8” 16 5 20

1615 38,1 57 2 3/8” 16 5 20

2012 31,8 70 2 7/16” 22 5 30

2517 44,5 85 2 1/2” 25 6 50

3535 88,9 127 3 1/2” 38 10 115

Dimensions Screws Tightening torque

L

[mm]

D

[mm]

N°

Withworth thread

[inch]

Length

[mm]

Wrench

[mm]

[Nm]

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

20

www.sitspa.com TRASCO® - Operating and Maintenance Manual

Ø

Fa

S S

M V M

Ø

Fb

Ø

G

L

Ø

A

S N N S

I I

H C

H

Ø

B

If used in hazardous areas, it is advisable to use Loctite to prevent the

setscrews loosening.

PRECAUTION!

It is not allowed to use the taper bush without keyway in high-risk areas,

but only for category 3 equipment.

4.2.2 Taper bush disassembling

To remove the taper bush from the hub, remove the setscrews.

Then, insert one of these into the threaded hole of the bush forcing its disassembling.

4.3 GRS coupling assembling

Components:

• 2 hubs

• 2 spiders

• 1 intermediate element

• 2 setscrews

GRMP...A

AR

GRS

AR

GRMP...B

GRS

Figure 4-4 - GRS intermediate element

Follow the instructions of the GRMP type making sure to check the value M (see TABLE 4.1 - M Value) for both spiders.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

21

www.sitspa.com TRASCO® - Operating and Maintenance Manual

BF

CF

GRMP...A

A

E

H

M

V

S

P

Lc

Ea

Bc

N

S

Fa

C

D Nr

G

S

Ea

E

V

Bc

P

C

N

S

M

V

La

D Nr

G

S

V

Fa

A

H

I

G

Lb

S

N

M

V

CF

2CF

E

A

H

N

SS

M

V

Bc

E

Lc

Fa

D Nr

G

C

P

GRMP...A

N

S

Bc

E

S

M

V V

La

D Nr

P

Fa

G

N

S S

M

V V

H

I

B

Lb

Fa

ALBERO-FLANGIA

FLANGIA-FLANGIA

ALBERO-ALBERO

4.4 GRF coupling assembling

4.4.1 Flange-flange version

Components:

• 1 spider

• 2 flanges (CF/CFN)

CF

CF

GRFCF+AR+GRFCF GRFCFN+AR+GRFCFN

• Place the CF/CFN flanges onto the motor and the driven machine tightening the screws partially

• Tighten the screws with a torque wrench at the correct tightening torque indicated in TABLE 4.3 - GRF screws

• Place the spider onto one of the 2 flanges

• Check the driving and driven hub to achieve the value M according to TABLE 4.1 - M Value

Table 4.3 - GRF screws

SIZE No. SCREWS

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

Figure 4-5 - Flange-flange version (CF/CFN)

10 36° M12 120 16

10 36° M16 295 19

12 30° M16 295 20

12 30° M16 295 25

12 30° M20 580 26

16 22°30’ M20 580 30

ANGULAR SPAN OF

BORES

5 72° M5 10 8

5 72° M5 10 8

6 60° M8 41 10

6 60° M8 41 10

6 60° M8 41 12

8 45° M10 83 12

8 45° M10 83 16

BORES

ANGULAR SPAN OF

TIGHTENING TORQUE

[Nm]

[mm]

FLANGE THICKNESS “V”

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

22

www.sitspa.com TRASCO® - Operating and Maintenance Manual

BF

A

E

H

M

V

S

P

Lc

Ea

Bc

N

S

Fa

C

D Nr

G

S

Ea

E

V

Fa

A

H

I

A

G

Lb

S

N

M

V

H

Bb

I

Fa

MF

CFF

AR

MF

CFF

CF

H

N

SS

M

V

Bc

E

Lc

Fa

D Nr

G

C

P

BFN

AR

CFN

MFN

N

E

S S

M

V V

H

I

H

I

B

B

Bb

Lb

D Nr

G

C

P

Fa

Fa

ALBERO-FLANGIA

ALBERO-ALBERO

4.4.2 Shaft-flange version

Components:

• 1 hub TRASCO

®

• 1 spider

• 1 flange (CF/CFN)

GRMP...A

GRMP...A

CF

TRASCO®+AR+GRFCF TRASCO®+AR+GRFCFN

• Install the hub on the shaft fastening with the setscrews according to TABLE 2.9 - TRASCO®: SETSCREWS POSITION

• Place the CF/CFN flanges on the motor and the driven machine tightening the screws partially

• Tighten the screws with a torque wrench at the tightening torque indicated in TABLE 4.3 - GRF Screws

• Place the spider on one of the 2 flanges

• Check the driving and driven hub to achieve the value M according to TABLE 4.1 - M Value

Figure 4-6 - Shaft-flange version (CF/CFN)

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

23

www.sitspa.com TRASCO® - Operating and Maintenance Manual

BF

GRMP...A

S

Ea

E

V

Fa

H

I

A

G

Lb

S

N

M

V

H

Bb

I

Fa

N

E

S S

M

V V

H

I

H

I

B

Bb

Lb

D Nr

G

C

P

Fa

ALBERO-ALBERO

4.4.3 Shaft-shaft version

Components:

• 1 spider

• 2 flanges (CF/CFN)

• 2 flanged hubs (MF/MFN)

• Cylindrical head screws

• 2 setscrews

AR

MF

CFF

AR

CFF

MF

CFN

MF+GRFCF+AR+GRFCF+MF MF+GRFCFN+AR+GRFCFN+MF

Figure 4-7 - Shaft-shaft version (CF/CFN)

• install the flanged hubs on the shafts, being careful that the shafts do not protrude

• check the driving and driven hub to achieve the value M+2V (for M see TABLE 4.1 - M Value, for V see TABLE 4.3 - GRF Screws)

• fasten the flanged hubs with the setscrews according to TABLE 2.9 - TRASCO®: SETSCREW POSITION

• join together the 2 flanges (CF/CFN) and the spider, then position the assembly between the flanged hubs

• tighten the parts by hand

• tighten the screws with a torque wrench as shown in the TABLE 4.3 - GRF Screws

BFN

MFN

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

24

www.sitspa.com TRASCO® - Operating and Maintenance Manual

5 ATEX Annex

This Annex is an integral part of the sale of the SIT TRASCO® coupling according to the ATEX Directive 2014/34/EU, contains the Declaration of Conformity, and, therefore, is delivered together with the coupling.

The User and Maintenance Manual, may be downloaded in electronic format on the website www.sitspa.com.

The analysis of the coupling machining process was carried out by SIT S.p.A.

CAUTION!

These instructions must be complied with in addition to the

warnings provided in the technical specifications.

5.1 ATEX zone classification

Below is the cross reference between hazardous zones, substances and categories according to the ATEX Directive 2014/34/EU.

Tabella 5.1 - ATEX zone classification

SUBSTANCE ZONE ZONE DESCRIPTION ATEX CATEGORY/MARKING

GASES, VAPOURS, MISTS

Zone 0

Zone 1

Zone2

Zone 20

A place in which an explosive atmosphere, consi-sting of a mixture with air of dangerous substan-ces in the form of a gas, vapour or mist,

is present continuously or for long periods or

frequently (>1000 hours/year).

A place in which an explosive atmosphere, consi-sting of a mixture of air of dangerous substances in the form of a gas, vapour or mist, is likely

to occur in normal operation occasionally (10

- 1000 hours/year).

A place in which an explosive atmosphere, consi-sting of a mixture of air of dangerous substances in the form of gas, vapour or mist, is not likely to

occur in normal operation but, if it does occur, will

persist for a short period only (<10 hours/year).

A place in which an explosive atmosphere, in

the form of a cloud of combustible dust in air

is pre-sent continuously or for long periods or

frequently (>1000 hours/year).

1G

2G or 1G

3G, 2G or 1G

1D

A place in which an explosive atmosphere, in

Zone 21

DUSTS

Zone 22

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

the form of a cloud of combustible dust in air, is

likely to occur in normal operation occasionally

(10 - 1000 hours/year).

A place in which an explosive atmosphere, in

the form of a cloud of combustible dust in air,

is not likely to occur in normal operation but, if it

occurs, will persist for a short period only (<10

hours/year).

25

2D or 1D

3D, 2D or 1D

www.sitspa.com TRASCO® - Operating and Maintenance Manual

5.2 ATEX equipment classification

Below is the classification of equipment and protection systems according to the ATEX Directive 2014/34/EU.

Tabella 5.2 - ATEX groups and categories classification

GROUP CATEGORY RISK LEVEL PROTECTION CHARACTERISTICS OPERATING CONDITIONS

M1 Very high

GROUP I

(mining industry)

M2 High

1 Very high

GROUP II

(industry, except

mining industry)

2 High

3 Normal Suitable for normal operation.

5.3 Appropriate use of TRASCO

Two independent means of protection

or sa-fety ensured even in the event of

two faults occurring independently of

each other.

Suitable for normal operation and for

severe operating conditions. Where

appropriate, also suitable for frequent

disturbances or defects which normally

need to be taken into account.

Two independent means of protection

or sa-fety ensured even in the event of

two faults occurring independently of

each other.

Suitable for normal operating conditions

and for frequent disturbances or devices in which faults normally need to be

taken into account.

®

couplings in ATEX zones

The equipment remains connected to the

power supply and in operation even in the

presence of explosive atmospheres.

The equipment is disconnected from the

power supply in the presence of explosive

atmospheres.

The equipment remains connected to the

power supply and in operation in zones 0,

1, 2 (G) and/or 20, 21, 22 (D).

The equipment remains connected to the

power supply and in operation in zones 1, 2

(G) and/or 21, 22 (D).

The equipment remains connected to the

power supply and in operation in zones 2

(G) and/or 22 (D).

The analysis carried out by SIT S.p.A. led to the conclusion that the couplings can be used in the presence of flammable gases, vapours, mists or combustible dusts according to the following scheme:

• Gases, vapours or mists in zones 1 and 2 (not suitable for zone 0)

• Dusts in zones 21 and 22 (not suitable for zone 20)

• Equipment in group II and categories 2 and 3 (not suitable for category 1)

• Explosion group IIC, including groups IIA and IIB

• Equipment in group I and categories M2 (not suitable for category M1)

5.3.1 Gas temperature classes for Group II equipment

Tabella 5.3 - Gas temperature classes

TEMPERATURE CLASS

T1, T2, T3 150

T4 135

T5 100

T6 85

MAXIMUM SURFACE TEMPERATURE

[°C]

AMBIENT OR OPERATING TEMPERATURE

[°C]

-30°C < Ta < 120°C

-30°C < Ta < 115°C

-30°C < Ta < 80°C

-30°C < Ta < 65°C

The table indicates the temperature above which the gases, belonging to the respective class, ignite.

The ambient or operating temperature of the couplings was determined by SIT according to the characteristics of the coupling and

taking into account a safety factor equal to 20 K.

Temperature classes for Group I equipment

Couplings mounted on Group I Category M2 equipment can operate in environments with the following temperature range:

-30°C < Ta < 90°C

The coupling is not suitable for Category M1 equipment.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

26

www.sitspa.com TRASCO® - Operating and Maintenance Manual

5.4 Marking

SIT TRASCO® couplings are marked as required by Directive ATEX 2014/34/EU for equipment operating in zones classified for the

presen-ce of a potential hazardous atmosphere.

The marking is indelible and positioned, at SIT’s discretion, in a suitable area of the hub surface.

5.4.1 Complete marking

II 2G c IIC T6/T5/T4/T3 -30°<Ta<65°/80°/115°/120°C

II 2D c T 120°C

I M2 c -30°<Ta<90°C

SYMBOL DESCRIPTION

I/II

2

G

D

c

IIC

T6

Ta

The line regarding gases shows the temperature classes and the related admissible ambient temperature range, given the coupling

cha-racteristics and a safety factor of 20 K.

With regards to that for dusts and for Group I, only the maximum temperature is indicated, since there are no subdivisions into classes.

Group (I mining industry, II surface machine)

Category 2 (zone 1 / zone 21)

Explosive atmosphere with gases, vapours or mists

Explosive atmosphere with dust

Constructional safety

Explosion group for gases

Temperature class corresponding to a maximum surface temperature

Ambient temperature range

5.4.2 Compact marking

Where the size of the coupling does not allow complete marking, the Directive allows a reduced version which refers to this manual for

its comprehension.

II 2GD c IIC T X / I M2 c X

The letter C at the end of the marking indicates the method of protection that the user must ensure around the coupling, i.e. a bell housing type protection according to the EN 13463-5 standard.

The letter X refers to this manual which includes a summary table of the temperature class and the resulting maximum permissible

ambient temperature that must be at least 20 K less, in accordance with the elastic spider’s ability to resist.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

27

www.sitspa.com TRASCO® - Operating and Maintenance Manual

Z

5.5 Hub machining in ATEX environment

The machining of the bore, the seat of the keyway and the threaded bore for the fixing screw must follow the instructions provided in

the UNI-ISO 2768 standard. Any other machining on couplings to be used in hazardous zones must obtain the express consent of SIT.

The customer must provide SIT with a technical drawing showing the machining to be carried out. It is the responsibility of SIT to evaluate

and approve it.

5.6 Elastic spider check

The elastic spider must undergo periodic checks for wear.

The first check must be made after 2000 hours of operation or after 3 months from the start of use.

The next check should be made after 4000 hours or 12 months, provided that the first inspection did not show excessive wear values that

led to replacement of the elastic spider.

The check is performed using a feeler gauge to assess the wear of each element of the spider.

If the measured value (Z value) is higher than that indicated in the Z VALUE FOR CHECKING SPIDER WEAR, it is recommended to replace

the spider with an equivalent one.

Table 5.4 - Z value for checking spider wear

SIZE

19/24

24/32

28/38

38/45

42/55

48/60

55/70

65/75

75/90

90/100

100/110

110/125

125/145

140/160

160/185

180/200

QUOTE Z

[mm]

3

3

3

3

4

4

5

5

6

8

9

9

10

12

14

14

CAUTION!

Replace the elastic spider with an equivalent one of the same size.

SIT S.p.A. does not accept any liability for incorrect replacements.

For information on correct assembly, please refer to the User and

Maintenance Manual which can be downloaded in electronic format

from the website www.sitspa.com.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

28

www.sitspa.com TRASCO® - Operating and Maintenance Manual

5.7 Internal manufacturing check

Before marking and placing on the market, TRASCO® transmission couplings have been subjected to the checks and inspections provided

for by the internal manufacturing system and by the company’s quality system.

SIT S.p.A. has in fact obtained Certification of the Quality Management System according to international UNI EN ISO 9001 standard.

5.8 Starting

CAUTION!

All operations must be performed by trained and qualified

per-sonnel; different or additional uses to those envisaged in

this User and Maintenance Manual are not permitted.

Before placing the coupling into service, check:

• The tightening torque of the hub screws.

• The correct alignment has been achieved.

• The correct distance between the hubs.

Working in hazardous zones, tightening of the screws must be made even more securely by using Loctite (medium strength). The

user must periodically check, depending on the type of use and the substances used:

• the state of wear and correct functioning of the coupling

• the presence of vibrations and/or noise: in this case, the user must identify the causes and contact the manufacturer

For use in zones classified for the presence of combustible dust, ensure regular cleaning in order to avoid the formation of dust layers;

for this purpose, use equipment suitable for the classification of the zone.

This operation must be performed with the elements tightly coupled and in the absence of electrical voltage.

Ensure routine maintenance, according to a frequency to be determined according to the operating conditions, environment and

temperatu-re. Nevertheless, residual risks can be present during normal operation of the coupling, if:

• it is not subjected to the normal maintenance plans provided from the user and maintenance manual

• it is not used as provided in the design specifications

Different or additional uses not included in the technical specification are not permitted and SIT shall not be liable for any damage

related to unauthorised uses.

All maintenance operations must be carried out as indicated in the user and maintenance manuals: no modifications are permitted

without the written consent of SIT.

Unauthorised replacements or those using non-original parts invalidate the safety of TRASCO® couplings; all spare parts must be

obtained from SIT.

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

29

www.sitspa.com TRASCO® - Operating and Maintenance Manual

5.8.1 Protection devices for couplings in hazardous atmospheres

Protection devices for couplings against unintended contact must be firmly attached.

Couplings for use in hazardous atmospheres must be protected by sturdy guards (if possible made of stainless steel) against falling

objects. They must be able to be easily opened and the aperture size must not exceed the following limits:

• lateral aperture: 8 mm

• upper aperture: 4 mm

The minimum distance between the mechanical guard and the rotating parts must be equal to 5 mm in all directions.

The guard must be electrically conductive within the range allowed by law and can only be removed after having isolated the machine

from the electrical supply.

Those in aluminium and NBR can be used between the pump and the electric motor only if the magnesium content is less than 7,5%.

5.8.2 Electrical continuity

TRASCO® couplings must be installed and maintained in accordance with the standards and rules of good practice for classified environ-ments against the risk of explosion due to gases, vapours and dusts.

CAUTION!

TRASCO® couplings must not be insulated from the earth;

en-sure that connection of the couplings with the earth is

always guaranteed over time.

The electrical continuity between the two metal parts of TRASCO

it is mounted (for example motor-pump).

The electrical resistance, measured between the various metallic parts of the coupling and the point of reference, must be verified at the

time of initial installation and, subsequently, during periodic checks.

®

couplings is ensured by the conductivity of the components on which

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

30

www.sitspa.com TRASCO® - Operating and Maintenance Manual

5.9 Declaration of conformity

DECLARATION OF CONFORMITY

SIT S.p.A.

We

Viale A. Volta 2

20090 Cusago (MI)

declare under our sole responsibility that the product:

TRASCO® Coupling

to which this declaration refers,

is in conformity with the following European Directive

Directive ATEX 2014/34/UE

Such conformity has been verified based on the requirements of the

following standards or standards documents:

EN 13463-1 :2009 EN 13463-5 :2011

The technical documentation is filed with

DNV GL AS

P.O.Box 300 Veristasveien 1

1322 HOVIK

Norway

SIT S.p.A.

Cusago, 24/05/2016

114.01 - Rev. 3 - 24 April 2019 Approved by SIT S.p.A.

31

Riccardo Scaglia

Managing Director

Loading...

Loading...