Page 1

VACUUM TUMBLER

VT-500

OWNER’S MANUAL

Page 2

SAFETY INSTRUCTIONS

WARNING TO ALL PURCHASERS, OPERATORS AND OPERATION SUPERVISORS :

MAKE CERTAIN EVERY PERSON WHO IS TO OPERATE THIS MACHINE HAS READ THIS MANUAL

BEFORE BEING PERMITTED TO OPERATE THIS MACHINE.

HAVE ALL OPERATORS SIGN THE SIGNATURE PAGE FOUND AT THE END OF THIS MANUAL.

FAILURE TO READ AND ADHERE TO THE FOLLOWING IMPROTANT INSTRUCTIONS COULD RESULT IN BODILY INJURY.

READ THIS MANUAL COMPLETELY BEFORE OPERATING

ADDITIONAL MANUALS AS WELL AS REPLACEMENT SAFETY LEBELS ARE AVAILABLE.

1. DO NOT OPERATE THIS MACHINE UNTIL IT HAS BEEN INSPECTED AND MADE READY FOR OPERATION.

2. CREATE A SECURITY PERIMETER BEFORE USING THE TUMBLER, TO PREVENT ANY POTENTIAL CAUSE OF

ACCIDENT.

3. DO NOT TOUCH MOVING PARTS.

4. DO NOT OPERATE OR WORK AROUND THIS MACHINE WITH LOOSE FITTING CLOTHING. IT COULD

BECOME ENTANGLED IN THE MACHINE

5. NEVER TRY TO MANUALLY STOP OR TURN THE TUMBLER. USE THE CONTROL TO POSITION THE TUMBLER AS

DESIRED.

6. FAILURE TO PROPERLY GROUND THIS MACHINE COULD RESULT IN ELECTRICAL SHOCK. ONLY A

QUALIFIED ELECTRICIAN WHO IS FAMILIAR WITH THE APPORPRIATE ELECTRICAL CODES SHOULD PROVIDE

THE PROPER ELECTRICAL CONNECTION.

7. DO NOT ALTER OR MODIFY THIS TUMBLER IN ANY WAY FROM ITS ORIGINAL FORM. ALLOW ONLY

AUTHORIZED PERSONAL TO SERVICE YOUR MACHINE.

8. ALWAYS TRUN OFF THE MACHINE WHEN IT IS NOT IN USE.

9. UNPLUG THE MACHINE FORM THE POWER SOURCE BEFORE REMOVING ANY PANELS OR HOUSING FOR

MAINTENANCE OR MAKING ADJUSTMENTS TO THE MACHINE.

10. ALWAYS OPERATE ON A LEVEL SURFACE.

11. KEEP UNAUTHORIZED PERSONAL AWAY FROM MACHINE.

12. THESE TUMBLERS ARE DESIGNED TO HANDLE VACUUM AND NOT PRESSURE. NOTE: DO NOT PUT

ANYTHING IN THE DRUM WHICH WOULD GENERATE A PRESSURE SUCH AS CARBON DIOXIDE SNOW OR

PELLETS

13. INSTALL THE MACHINE IN A POSITION THAT PROVIDES ADEQUATE SPACE TO ALLOW SAFE CLEARANCE

OF ANY PERSONAL IN THE AREA.

Page 3

OPERATING & PROGRAMING INSTRUCTIONS

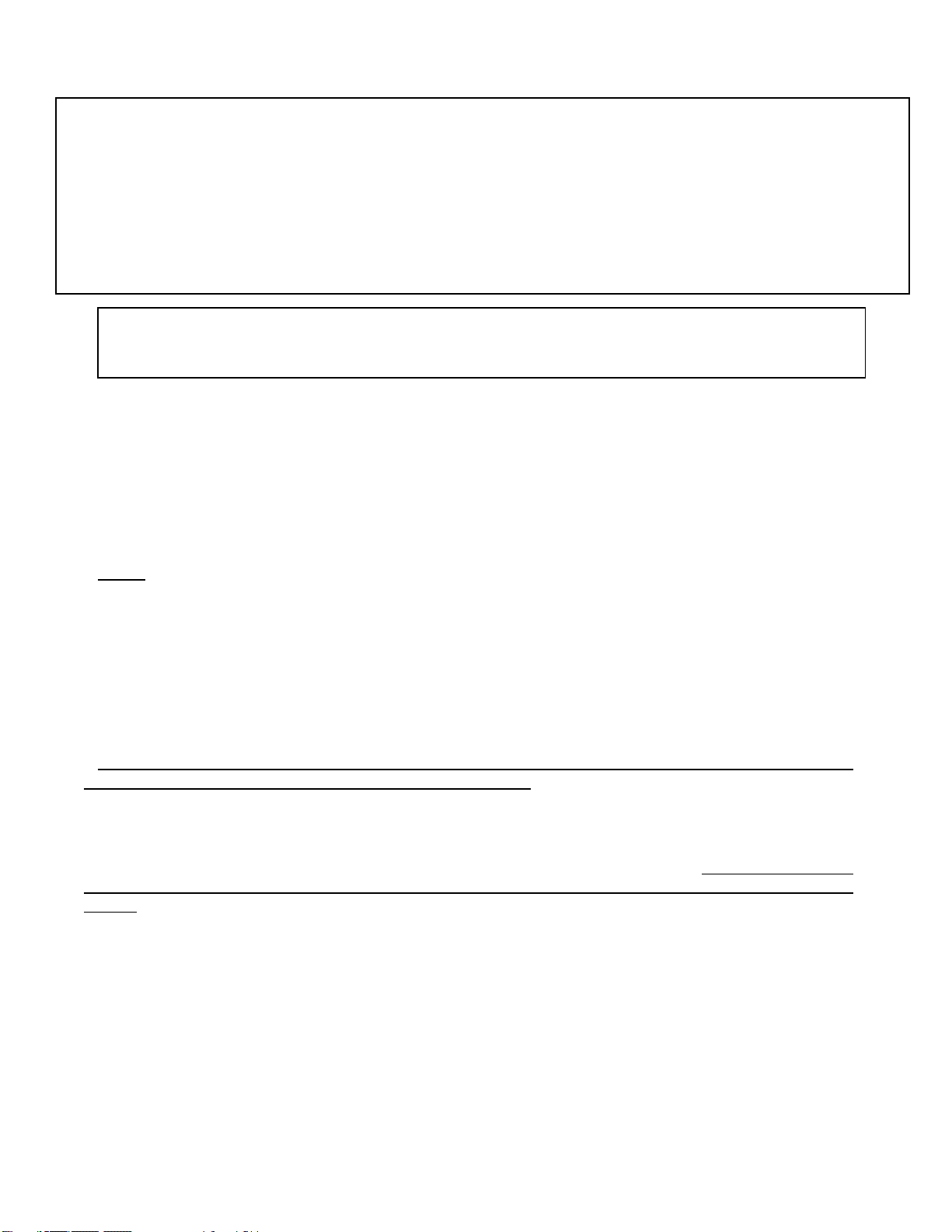

Power up:

Turn the O I selector to I position.

Manual operation:

With the O I selector to I position, you can manually start the pump and the rotation

without the PLC. Turn the pump selector to position I to start the pump, put back the

selector at position 0 to stop the pump. If the selector stays at position I the pump will

work continuously regardless of the program running.

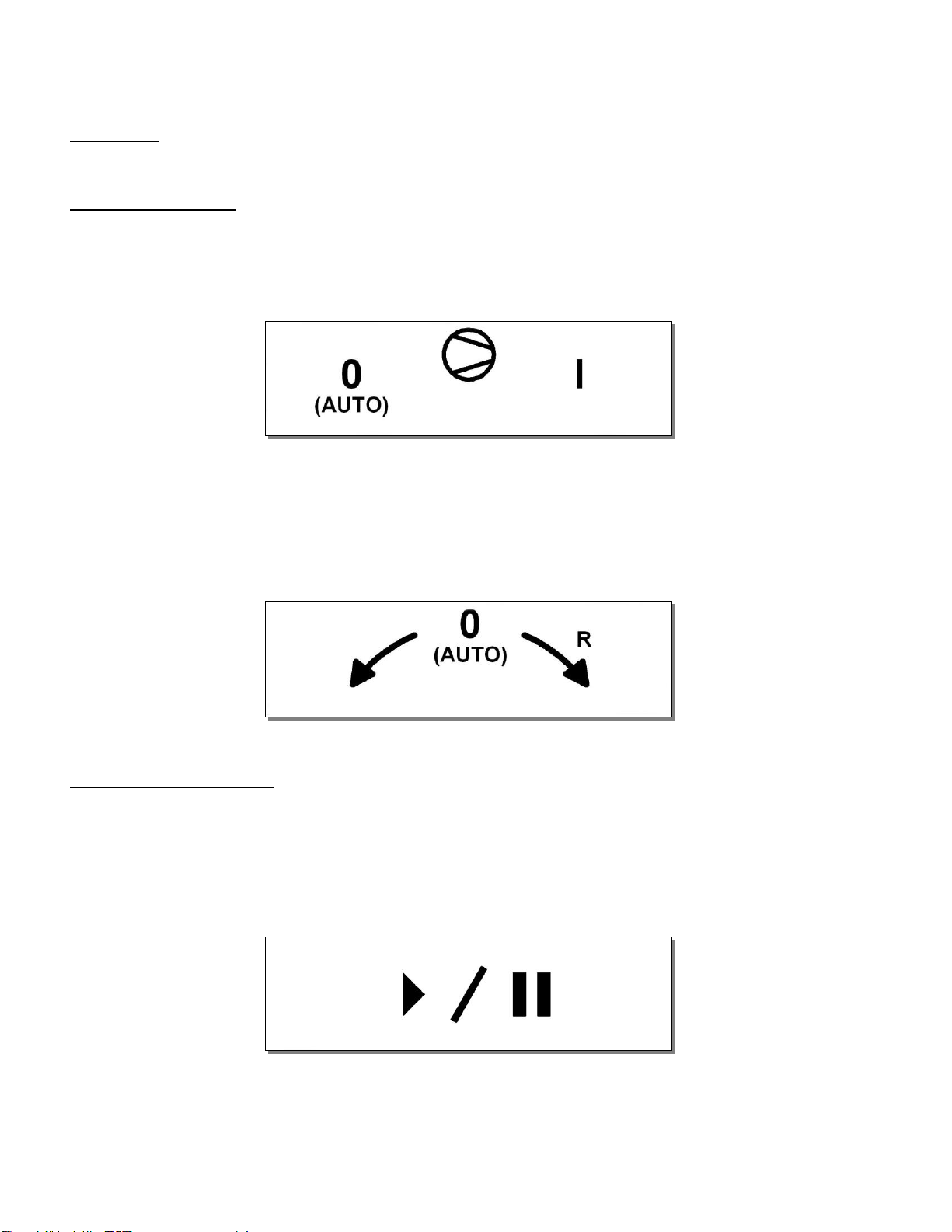

To jog the tumbler or to make the tumbler run at 4 rpm fixed speed without the use of

the PLC (backup mode), use the rotation selector. Rotation in the R direction is for

unloading (reverse rotation). Standard rotation when operating is counterclockwise.

Turn the rotation selector to position 0 to make the rotation work accordingly with the

program.

Working with program:

Press ON/OFF to power on the tumbler. When the tumbler is energized, the

identification of the last executed program is displayed on the LCD screen. If

EMERGENCY STOP appears on the screen release the E-STOP button. Use the

start/pause push button to start the program in memory, make sure the pump selector

and the rotation selector are at position 0 (auto) before starting the program.

To change the program in memory see Activating a program in the next section. You

can manually make the vacuum inside the tumbler by activating the pump on the

remote control, stop the pump when it’s done.

Page 4

PROGRAMMING OPERATION:

The ESC key switches you between the Function Menus and Program Menus. The

SELECT key scrolls you through either the Function submenus or the Program submenus

depending on which mode you are currently in. The ENTER key allows you to access

particular functions, programs and options. Below is a list of how each menu is

organized.

FUNCTION MENUS:

F1 CREATE A PRGM

F2 DELETE A PRGM

F3 UNLOCK A PRGM

PROGRAM MENUS:

PRGRM CYCLE NAME: For example, P01: (12 character limit)

PRGRM SEGMENT #1

SEGMT TIME: 0h00

MASSAGE ON: 0h00

MASSAGE OFF: 0h00

VACUUM PUMP : OFF

SP < ************ >

PRGRM SEGMENT #2

SEGMT TIME: 0h00

MASSAGE ON: 0h00

MASSAGE OFF: 0h00

VACUUM PUMP : OFF

SP < ************ >

PRGRM SEGMENT #3

SEGMT TIME: 0h00

MASSAGE ON: 0h00

MASSAGE OFF: 0h00

VACUUM PUMP : OFF

SP < ************ >

Page 5

CREATING A PROGRAM NAME:

1. If F1 CREATE A PRGM is not displayed on the LCD screen Press ESC. Once F1

CREATE A PRGM appears press ENTER.

2. PRGM CYCLE NAME will appear on the LCD screen. Press ENTER to create a new

program name.

3. Pxx NO NAME will flash. (The program number (Pxx) will be allocated

automatically). Begin typing the program name by using the numeric keyboard;

press a numeric key until the desired character appears. Once the correct letter is

displayed press ENTER and the cursor will move one space to the right. Upon

completion of typing program name press ENTER two times. The newly typed

program name will flash. Press ENTER to confirm. Your program name has been

completed.

4. To set program features enter the program menu by pressing ESC. The newly

created program name will appear on the LCD screen. Press ENTER if the displayed

program name is the one needing to be set or modified. Or press the SELECT key to

display other pre-set programs. Once the correct program name appears press

ENTER. See setting program options below for more information.

SETTING PROGRAM OPTIONS:

Within each program three segments are available to set the tumbler times and

speeds. A complete program duration may be up to 72 hours in length (24 hours per

segment). PRGRM SEGMENT #1 can be set fro X amount of time with the MASSAGE

OFF (no rotation will occur), this can be use to draw vacuum inside the tumbler prior to

tumble. Then PRGRM SEGMENT #2 can be set for X amount of time with the MASSAGE

ON (rotation will occur) at a set RPM (rotations per minute). Perhaps after this tumbling

cycle you will want to tumble for X more amount of time but at a different speed. In

PRGRM SEGMENT #3 type this final tumbling time MASSAGE ON and at what RPM.

Depending on your tumbling needs, one two or all three of the segments may be

programmed. In short, the different cycles may be used for a pause in tumbling or

tumbling at different speed.

1. PRGRM SEGMENT #1: will appear once a program name has been selected for

modification or programming. To make changes to this segment press ENTER.

2. SEGMT TIME: 0h00 will appear. Enter the length of tumbling segment #1. Hours

must be entered in two number increments (i.e. 01, 05, 12, etc. up to 24) followed

by the minutes. In total, you must enter 4 numbers to set the tumbling cycle time.

When completed the time will flash. Press ENTER to confirm and move the next

screen.

3. MASSAGE ON: 0h00 will appear. Type the length of time you want to tumble.

Type the same time as the SEGMT TIME if tumbling is desired during this. If no time

is entered the machine will not rotate. In this case PRGRM SEGMENT #1 will act as

a timer, delaying tumbling until the next segment is activated. Press ENTER to

confirm time and/or move to the next screen.

4. MASSAGE OFF: 0h00 will appear. This option is for producers who want to

temporarily stop tumbling in a tumbling cycle. No time need be entered if a

MASSAGE ON time has been entered. If no tumbling is desired in the segment,

type the same time as SEGMT TIME. Press ENTER to confirm time or move to next

screen.

Page 6

SETTING PROGRAM OPTIONS:

5. VACUUM PUMP OFF: will appear and OFF will flash. Press the SELECT key to scroll

from OFF to ON. Press ENTER to confirm.

6. SP < ************ >will appear. Press key #4 to reduce or key #5 to increase the

speed level. Press ENTER to confirm.

7. PRGRM SEGMENT #1 will re-appear. If this is only a one-segment tumbling program

press ESC to display program name and press ENTER to begin tumbling. If

additional segments need to be set, press the SELECT key to scroll to PRGRM

SEGMENT #2 and press ENTER to set options. Same procedure applies for setting

PRGRM SEGMENT #3. Following instructions from setting PRGRM SEGMENT #1.

MODIFYING PRE-SET PROGRAM OPITONS:

1. To modify a pre-set program press ESC if in function mode (i.e. F1, F2, or F3 ).

2. When a program name appears either press ENTER if that is the program to be

modified or press the SELECT key to scroll though pre-set programs. When the

desired program appears press ENTER.

3. PRGRM SEGMENT #1 will appear. To make changes in this segment press ENTER.

4. As you press ENTER, numbers for each submenu will flash. If you want to make a

change, enter the new time or speed and press ENTER. If no changes are needed

to a time or speed press ENTER to confirm and advance you to the next submenu

screen.

5. To move onto segments #2 and/or #3 press ENTER until PRGRM SEGMENT #1

appears and press the SELECT key to scroll to other segments. Press ENTER when

desired segment appears. Repeat steps as above.

ACTIVATING A PROGRAM:

1. Press ENTER if the program name you want to run appears to activate.

2. To select a different program than the one on the screen, press the SELECT key.

3. Press ENTER after the correct program name appears.

4. The selected program will run until all segment have been completed, or the

programmed is manually stopped.

Page 7

VACUUM PUMP DAILY MAINTENANCE:

Maintenance procedure is required after each utilization of the tumbler to evacuate

water condensation inside the pump.

1. At the end of each program, close the valve between the pump and the water

separator.

2. Start and run the pump for a minimum of 20 minutes.

***IMPORTANT NOTICE; failure to do this regular maintenance could damage the

pump and void the warranty supplied by Busch Vacuum Pumps & Systems.

STOPPING A PROGRAM:

1. To interrupt a program in progress rotate the M-START button to the right. Doing so

only stops the rotation of the tumbler. The machine will remember how much

time has elapsed.

2. Rotate the M-START button to the right again to continue, if so desired.

3. Press ESC to access the function menus if you would like to clear out the program

memory from a program manually stopped before completion.

4. Press the SELECT key to scroll to F3 UNLOCK A PRGM and then press ENTER. The

name of the current program will appear.

5. Press ENTER to reset the counters. At this point another program may be

accessed.

*A program is locked from the beginning of execution through completion to prevent

any unintentional modification to the status of the current program.

DELETING A PROGRAM:

1. To delete a pre-set program form the tumbler’s memory access the function

menus and scroll to F2 DELETE A PRGM and press ENTER.

2. The first program in memory will blink. Press ENTER to delete or the SELECT key to

move to the next program.

3. Once the program needing to be deleted appears press ENTER.

4. Press ESC to unconfirmed a deflection and/or to exit the delete function.

Page 8

PROGRAM SAMPLE

OBJECTIVE :

TUMBLE CHICKEN PARTS FOR 15 MIN. AT MAX. SPEED WITH VACUUM PUMP ON.

PRESS RESULTING DISPLAY

1. On/Off Display Lights

2. ESC until F1 Create a PRGM

3. Enter PRGM Cycle name

4. Enter P01 No name (Flashing)

5. Number keypad P01 chick parts

until desired letter appears

Enter after each selection

Enter Twice Program Cycle name

6. Select PRGM SEG #1

7. Enter SEGMT TIME:0h00 (Flashing)

8. 0015 SEGMT TIME:0h15

9. Enter MASSAGE ON: 0h00

10. 0015 MASSAGE ON: 0h15

11. ENTER MASSAGE OFF: 0h00

12. ENTER VACUUM PUMP: OFF

13. SELECT VACUUM PUMP: ON

14. ENTER SP<************>

15. ENTER PRGM SEGMENT #1

16. ESC P01 CHICK

PROGRAM IS NOW COMPLETE

No other segments are necessary unless you want to change speeds during the

program. You can insert a segment at the beginning to make the vacuum inside the

tumbler without rotation.

If you make a mistake when entering, press ESC key.

Press ENTER to review program selections.

Page 9

MC-40 CONTROLS

PROGRAM SAMPLE

JOG :

Jog is also available on the PLC control. Press key pad 2 to jog forward. Press key pad

1 for continuous reverse rotation. NOTE: Wait 5 seconds after tank stops before using

jog.

TO UNLOCK A PROGRAM if programming is not responding

Push ESC until F1 Create a PRGM appears

Push SELECT until F3 Unlock a PRGM appears

Push ENTER

KEY BOARD DETAIL

Page 10

CLEANING & SANITATION

The Vacuum Tumbler drum and machine must be cleaned and sanitized daily and

whenever one marinating product is switched to another.

1. After removing all excess marinating solution, add the necessary amount of water

and mild detergent to create a solution for pre washing.

Hot water is not recommended in the first step,

as it may cause the “myosin protein” left over

from the tumbling process to build up and

discolour the inside surface of the drum

2. Fasten the cover into position and rotate the drum at full speed for approximately

two (2) minutes.

3. Use the REV button to rotate in the reverse direction for two (2) minutes.

4. Drain the cleaning solution by removing the drain plug form the clean out port .

5. Wash the inside of the drum with hot soapy water and then rinse with hot water.

6. Always lock out the power source when cleaning the tumbler except when

rotation described in step 2 and 3.

Lid gasket should be washed and sanitized in warm soapy water. Remove the

gasket from lid and clean the lid too.

7. The outside surface of the machine should also be wiped down and cleaned.

8. During cleaning of the machine, do not direct water on the controls. Instead,

wipe with a damp cloth and dry with a clean dry towel.

9. After cleaning, the machine should be sanitized with a USDA FDA approved

sanitizing solution.

Page 11

MAINTENANCE

1. Lock out energy source from the machine before doing any maintenance.

2. Check the gear reducer for oil leak montly.

3. Remove the hood cover to check condition of parts.

Page 12

OPERATOR’S SIGNATURE PAGE

My signature below attests that I have completely read and understand this manual.

I Realize that this machine, if operated carelessly, can cause serious injury to myself

and others.

Name (print) Signature Date

Page 13

DA/047

DA/044

Page 14

005D1292

ITEM PART # DESCRIPTION QT.

1 005D1293 TUMBLER PRE-ASSEMBLY 1

2 051-0740 WASHER 1/4" FLAT S/S 11

3 051-0948 BOLT M6 x 12 SS 3

4 004-0431 ELECTRICAL BOX PRE-ASSEMBLY 1

12

1

17

18

16

15

14

5 051-0190 BOLT 1/4-20 x 3/4" HEX S/S 2

6 051-0581 NUT 1/4"-20 NYLON LOCK S/S 2

7 005-0587 E-BOX COVER PRE-ASS'Y 1

8 052-0402 BOLT. HEX. 1/4"-20 NC. x 1/2" BRASS 4

9 052-0420 SCREW 1/4"-20 N.C x 3/4" PAN SLOT BRASS 6

10 102-0750 PLASTIC DRUM PLUG 3/4"NPT 1

11 005B1296 COVER ASSEMBLY 1

12 005A1303 SWIVEL JOINT ASS'Y 1

13 005A1302 WHEEL COVER ASS'Y 2

14 001A5931 CYLINDER GUARD 1

15 051-0757 WASHER 1/4" FLAT THICK S/S 6

16 051-0189 BOLT 1/4-20 x 5/8" HEX S/S 6

17 007A0146 KB-20 PUMP HOOK-UP ASS'Y 1

18 005B1326 JOG ASSEMBLY 1

19 004A3956 REAR STRUCTURE PANEL ASSEMBLY 1

DETAIL A

13

15

5

2

B

A

LET.

19

9

NEW COVER DESIGN

REDESSINÉ

MODIFICATION

A

13-11-15

12-09-10

DATE

10

SBU

SBU

INT.

4

16

2

6

11

2

8

MACHINE

VT-500

PART

VACCUM TUMBLER ASSEMBLY

ITEM

MAT.

CNC

DWG BY

APP. BY

2

SBU

7

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-11-14

DATE

3

METRIC

INCH

± 0.1

±

±

0.5

0.

5

± 0.004"

±

±

N.T.S.

SIPROMAC

0.020"

0.020"

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

DEPT.

M-I

NO.

QTY.

1

005D1292

Page 15

DETAIL B

20

A

24

B

ITEM PART # DESCRIPTION QT.

23

25 002A3814 CYLINDER SPACER 1

26 004C2452 SWIVEL LEG PRE-ASS' Y 4

10

22

21

22

21

3

005D1293

ITEM PART # DESCRIPTION QT.

1 004C3620 FRAME PRE-ASS'Y 1

2 130-0064 POLYURETHANE WHEEL 5'' DIA. X 2''

3 051-0790 WASHER 1/2" FLAT S/S 4

4 003A0374 WHEEL AXIS 2

5 051-0631 NUT ½"-13nc. NYLON LOCK S/S 2

6 075-2500 PILLOW BLOCK 2 C/W EXCENT.COL 1

7 051-0800 WASHER 5/8" FLAT S/S 4

8 051-0458 BOLT 5/8"-11nc. X 2" S/S 2

9 051-0650 NUT 5/8"-11 SS 2

10 005B1295 CYLINDER ASSEMBLY 1

11 004A3629 GEARBOX ASSMBLY 1

12 051-0781 WASHER 3/8" LOCK S/S 1

13 051-0780 WASHER 3/8" FLAT S/S 1

14 051-0999 BOLT M10 x 65MM HEX S/S 1

15 051-1082 NUT M10 SS 2

16 008A1745 GEARBOX KEY 1

17 056-0437 RET.RING INT. 1-15/16'' STEEL 1

18 002A3779 GEARBOX WASHER 1

19 051-0421 BOLT 7/16"-14NC x 1-1/4" S/S 1

20 005B1300 STRUCTURE ASSEMBLY 1

21 051-0740 WASHER 1/4" FLAT S/S 16

22 051-0180 BOLT. HEX. 1/4"-20 NC. x 1/2" S/S 13

23 005A1301 SEPARATOR ASSEMBLY 1

24 051-0580 NUT 1/4"-20 S/S 3

4

THREAD

12

20

15

22

21

25

11

2

B

A

LET.

005B1295 WAS 005A1295

REDESSINÉ / AJOUT PATTE AJUSTABLE

MODIFICATION

13-11-15

12-09-10

DATE

SBU

SBU

INT.

1

7

9

NOTE:

-INSTALLER ITEM #20

AVANT D'INSTALLER ITEM #10

2

3

5

17

18

26

19

13

14

10

16

8

7

6

1

DETAIL A

MACHINE

VT-500

PART

TUMBLER PRE-ASSEMBLY

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-11-14

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005D1293

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 16

005B1296

ITEM PART # DESCRIPTION QT.

1 004B3618 COVER PRE-ASSEMBLY 1

2 008A1746 COVER GASKET 1

3 105-0436 SCREW COLLAR 1'' X 1-1/2'' X 5/8'' ALL SS 1

4 077-0601 CONICAL COMPRESSION SPRING 2.25"OD

X 1.125"OD X 3"L X 0.120"W (0.24" COMP.)

5 005A1416 LOCK BAR W/ HUB 1

1

B

NEW DESIGN

LET. MODIFICATION

3

2

1

13-11-14

DATE

SBU

INT.

4

5

MACHINE

PART

ITEM

MAT.

VT-500

COVER ASSEMBLY

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-11-14

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005B1296

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I-(M)

QTY.

1

Page 17

20

005B1300

ITEM PART # DESCRIPTION QT.

16 001A5922 UPPER E-BOX SUPPORT 1

17 036-0250 GROMMET 1 1/8ID x 1 7/8OD RUBBER 1

18 179-0014 RUBBER 1/4"x3/8"x1/16"U SHAPED (0.5512) 1

19 057-0089 1/4" x 5/8"O.D. EPDM RUB. SEAL. WASHER 4

20 057-0550 PLASTIC PLUG BUTTOM 3 1/2" HOLE 1

21 036-0400 WIRE CONNECTOR 3/8'' NPT NUT 1

1

11

B

3

14

ITEM PART # DESCRIPTION QT.

1 004A3621 STRUCTURE PRE-ASS'Y 1

2 051-0740 WASHER 1/4" FLAT S/S 12

3 005-0589 REAR P.C. BOARD SUPPORT ASSEMBLY 1

4 051-0189 BOLT 1/4-20 x 5/8" HEX S/S 4

5 051-0757 WASHER 1/4" FLAT THICK S/S 4

6 051-0287 BOLT 1/4-20 x 3-1/4" S/S 4

7 058-0140 PLASTIC SPACER 0.266" x 1/2" x 2 1/4" 4

8 051-0750 WASHER 1/4" LOCK S/S 4

9 051-0580 NUT 1/4"-20 S/S 4

10 036-0400 WIRE CONNECT. 3/8'' NPT CD09/O-RING/NUT 2

11 036-0409 PRESSE-ETOUPE CD13 2

12 005B1329 FRONT P.C. BOARD SUPPORT ASSEMBLY 1

13 051-0591 NUT 1/4"-20 ACORN S/S 4

14 036-0420 PRESSE-ÉTOUPE CD21 1

15 051-0581 NUT 1/4"-20 NYLON LOCK S/S 4

7

8

9

12

2

2

16

LET.

4

18

2

4

2

15

DETAIL A

C

B

A

005A1329 NOW 005B1329

AJOUTER 036-0409 SUR DEVANT

REDESSINÉ (005A1329 ÉTAIT 005-0588)

MODIFICATION

A

4

D

17

C

19

2

15

13

10

2

DETAIL D

12-09-10

SBU

12-07-17

J.G.

12-01-10

J.G.

DATE

INT.

5

DETAIL B

MACHINE

PART

STRUCTURE ASSEMBLY

ITEM

MAT.

11

VT-500

SEE DETAIL D

6

DETAIL C

15

2

10

DEPT. TOL.

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005B1300

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

CNC

DWG BY

APP. BY

J.G.

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

12-01-10

Page 18

005A1301

ITEM PART # DESCRIPTION QT.

1 004-0372 SEPARATOR SUPPORT PRE-ASS`Y 1

2 003-0106 SEPARATOR BODY 1

3 101-0870 T 3/4"NPT BR 1

4 101-0280 STRAIGHT 3/4" MNPT x 3/4" HOSE BARB 1

5 101-0945 RED. BUSH. 3/4"npt X ¼"npt. BR 1

6 114-0280 VAC GAUGE 0-30HG 1/4'' MNPT REAR

PORT(W/GLYC)

7 005A1163 FLOW STOPPER ASSEMBLY 1

2

8

8 100-0080 STREET ELBOW 3/4"npt. S/S 2

9 100-0235 CLOSE NIPPLE 3/4"npt, S/S 1

10 107-0061 BALL VALVE 3/4" NPT BRASS FOR STEAM 1

11 101-0660 ELBOW STREET 90° X 1/4'' NPT BRASS 1

1

9

12 100-0360 NIPPLE 3/4"npt. X 2" S/S 1

13 102-0904 FEMALE COUPLER 3/4'' X 3/4'' FNPT WHITE 1

14 102-0902 MALE ADAPTER 3/4'' X 3/4'' HOSE BARB

WHITE

3

4

8

10

1

1

5

B

A

LET.

REPLACE 101-0280 BY #13,14 & 15

CHANGER CERTAINE PIÈCE DE L'ASS'Y

MODIFICATION

7

12

13

14

11

6

12-03-08

11-12-15

DATE

CF

CF

INT.

MACHINE

PART

ITEM

MAT.

VT-500

SEPARATOR ASSEMBLY

CNC

DWG BY

APP. BY

J.G. (CF)

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-08-17

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1301

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 19

004A3629

ITEM PART # DESCRIPTION QT.

1 037-0944 MODULE WORM GEARBOX 1SI75 1

2 037-09215 MODULE TORQUE ARM 1SI75 1

2

1

3 037-0941 MODULE WORM GEARBOX 1SI40 1

4 037-0946 MODULE NEMA 56C MOTOR ADAPTER 1SI40 1

5 037-0936 MODULE DOUBLE WORM GEAR ADAPTER

SI40

1

LET.

MODIFICATION

5

3

4

037-0953

MOTOR 80S/4-56C, 3/4HP, 230-460V-60HZ

DATE

INT.

MACHINE

PART

ITEM

MAT.

VT-500

GEARBOX ASSMBLY

CNC

DWG BY

APP. BY

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-08-24

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A3629

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I-(M)

QTY.

1

Page 20

2 COUPER DROIT & COLLER ENSEMBLE

PERCER 6mmØ

2 TROUS

10 TYP.

10

005A1302

ITEM PART # DESCRIPTION QT.

1 004A3622 WHEEL COVER PRE-ASS'Y 1

2 179-0150 VINYL/BUNA-N FOAM RUBBER WITH

ADHESIVE 73.5mm (0.0057)

3 057-0110 10-24 X 3/8'' BINDING POST BLACK PLAST. 2

2

26.8 ±1

3

1

LET.

MODIFICATION

DATE

INT.

MACHINE

PART

ITEM

MAT.

VT-500

WHEEL COVER ASS'Y

CNC

DWG BY

APP. BY

J.G. (CF)

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-08-18

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1302

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

2

Page 21

007A0146

ITEM PART # DESCRIPTION QT.

1 100-0325 NIPPLE ½"npt. X 2" S/S 1

2

3

1

4

2 101-0670 ELBOW STREET 90º 1/2" NPT. BR. 1

3 108-0030 CHECK VALVE 1/2'' NPT STEAM 1

4 101-0220 STRAIGHT ½"MNPTx3/4" HOSE BARB BRASS 1

125-1020

BUSCH KB-0020 115V/1PH/60HZ

LET.

MODIFICATION

DATE

INT.

MACHINE

VT-500

PART

KB-20 PUMP HOOK-UP ASS'Y

ITEM

MAT.

CNC

DWG BY

APP. BY

CF

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-12-15

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

007A0146

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 22

005A1303

ITEM PART # DESCRIPTION QT.

1 002-0053 SWIVEL JOINT 1

2 076-0130 "O" RING 1"I.D. x 1 3/8"O.D. x 3/16" 3

3 100-0080 STREET ELBOW 3/4"npt. S/S 1

4 100-0370 NIPPLE 3/4"npt X 6" S/S 1

5 100-0130 COUPLING 3/4" NPT SS 1

6 101-0280 STRAIGHT 3/4" MNPT x 3/4" HOSE BARB 1

2

6

LET.

MODIFICATION

5

1

4

3

DATE

INT.

MACHINE

PART

ITEM

MAT.

VT-500

SWIVEL JOINT ASS'Y

CNC

DWG BY

APP. BY

J.G. (CF)

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-08-23

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1303

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 23

005B1326

ITEM PART # DESCRIPTION QT.

13 026-0010 1 N.O. CONTACT WITH BASE 3

14 026-0110 BLACK CAP PUSH BUTTON (WATER) 1

15 026-0030 1 N.C. CONTACT BLOCK 2

16 026-0050 3 POSITION SELECTOR 1

17 026-0040 2 POSITION SELECTOR 1

18 026-0150 EMERGENCY BUTTON (PULL-PUSH) 1

19 026-0025 1 N.C. CONTACT WITH BASE 1

7

8

6

12

13

ITEM PART # DESCRIPTION QT.

1 004A3834 JOG PRE-ASS'Y 1

2 003A0310 CONTROL BOX (JOG) 1

3 051-0740 WASHER 1/4" FLAT S/S 8

4 051-0580 NUT 1/4"-20 S/S 4

5 051-0190 BOLT 1/4-20 x 3/4" HEX S/S 4

6 051-0111 SCREW 8-32 x 3/4" RND PHIL S/S 4

7 051-0720 WASHER #8 FLAT S/S 4

8 051-0560 NUT #8-32 NYLON LOCK S/S 4

9 001B6121 PUMP SWITCH ID. 1

10 001B6122 PUMP SWITCH ID. 1

11 001B6123 M-START SWITCH ID. 1

12 026-0020 1 N.O. CONTACT BLOCK 2

A

LET.

2

16

17

14

18

CHANGEMENT BOUTON

MODIFICATION

12-09-10

DATE

SBU

INT.

1

5

3

UTILISER DU SILICONE #169-0210 POUR SCELLER.

USE SILICON #169-0210 TO SEAL.

4

9

15

19

10

11

MACHINE

PART

ITEM

MAT.

VT-500

JOG ASSEMBLY

CNC

DWG BY

APP. BY

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

12-01-10

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005B1326

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(I)

QTY.

1

Page 24

004A3956

ITEM PART # DESCRIPTION QT.

1 001A5906 STRUCTURE ACCES PANEL 1

2 001A6298 EXHAUST DUCT 1

3 051-01435 SCREW 10-24 x 1/2'' HEX S/S 9

4 051-0730 WASHER #10 FLAT S/S 9

5 051-0571 NUT #10-24 S/S 9

3

1

LET. MODIFICATION

DATE

INT.

MACHINE

VT-500

PART

REAR STRUCTURE PANEL ASSEMBLY

ITEM

MAT.

CNC

DWG BY

APP. BY

J.G.

2

5USES "LOCTITE" UTILISER DU "LOCTITE"

DEPT. TOL.

METRIC

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

12-12-06

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A3956

4

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 25

DA/044

Page 26

L1 N GND

F1

F2

C1

C2

L1

AMPERAGE

THEORIC MESURED

WM1

GNDGND

T1

N

T2

T3

FV1

A1

B1

A2

B2

C2C1

EF1

O/L2

GRE

BLK

WHT

RED

GRE

BLK

WHT

M

WM2

M

M1

DRUM ROTATION

MOTOR

M2

VACUUM PUMP

MOTOR

A

V

A

V

A

V

A

V

F101

NOTE:

RC FILTERS

MUST BE CONNECTED

ON EACH AC COIL.

(Not shown on diagram)

4

9v

24v

TR

category

MASSAGER VT-500

system

usual

fonctions

options

3

2

1

model

F105

F104

volt.

circuit

1PH/60HZ

POWER

year month

11 10 10

drawconcept

app

DL SP DL

006-2937

SIPROMAC

day

St-Germain de Grantham

QUEBEC ,CANADA

PAGE:1 OF 3

Page 27

MC-40

OUTPUT

1

PIN3

JP3/1

2

PIN4

JP3/1

W1

(20/12)

BLK

WHT

CYCLE ON

C2

2324

O/L2

95 96

C2

VACUUM MOTOR

CONTACTOR

3

PIN5

JP3/1

4

PIN6

JP3/1

5

PIN7

JP3/1

6

PIN8

JP3/1

7

PIN1

JP3/2

8

PIN2

JP3/2

7

PIN9

JP3/1

8

PIN10

JP3/1

9

PIN11

JP3/1

10

PIN12

JP3/1

RED

GRE

ORG

PIK

BEG

YEL

BRN

PUR

GRY

E-STOP

BLU

26

27

29

category

MASSAGER VT-500

system

MC-40 OUTPUT

usual

fonctions

options

model

R4

R3

C1

YEL (24 VAC COMMON)

volt.

circuit

COMMAND

(24VAC)

1 (24VAC)

ALL

year month

11 10 10

drawconcept

DL SP DL

R4

START RELAY

R3

REVERSE RELAY

(9VAC)

3 (9VAC)

C1

FREQUENCY VAR.

CONTACTOR

SIPROMAC

day

St-Germain de Grantham

QUEBEC ,CANADA

app

006-2937

PAGE:2 OF 3

Page 28

MC-40

INPUT

1

2

3

4

JP4

BLK

RED

GRE

START/STOP

E-STOP

FULL:

ATV12

MENU

SET:

PARAMETERS SET TO:

ACC

15

DEC

DRC:

I/0:

LSP

HSP

NCR

TUNE YES DONE

TFR

R1 RUN

0.0

(2RPM@15.1HZ)

100

(9RPM@71.9HZ)

2.7

100

FUN: RRS L2H

FLT: THT-ITH 4

6

MC-40

ANALOG

OUTPUT

1

2

3

4

JP7

W104

(22/4)

BLK

WHT

RED

GRE 7

R3

12 8

R4

9 5

FREQ.

VAR.

ATV31

+10V

AI1

COM

LI2

8

10

+24V

LI1

category

MASSAGER VT-500

system

MC-40 INPUT AND ANALOG OUTPUT

usual

fonctions

options

model

volt.

circuit

COMMAND

ALL

year month

11 10 10

drawconcept

app

DL SP DL

SIPROMAC

day

St-Germain de Grantham

006-2937

QUEBEC ,CANADA

PAGE:3 OF 3

Page 29

# PART PART MACHINE MACHINE REF. QTY

SIPRO DESCRIPTION APPLICATION VOLTAGE

028-0018 TERMINAL BLOCK M6/8 ALIMENTATION 120V/1PH/60HZ VT-500 L1-N 4

028-0105 GROUND BARRIER (6 HOLES) ALIMENTATION 120V/1PH/60HZ VT-500 GRD 1

028-0060 SEPARATOR M4/6 ALIMENTATION 120V/1PH/60HZ VT-500 L1-N-GRD 2

034-0755 FUSE HOLDER 30A 1 PÔLE 600V DRIVE MOTOR 120V/1PH/60HZ VT-500 F1 1

034-0560 FUSE 25A/600V FA DRIVE MOTOR 120V/1PH/60HZ VT-500 F1 1

025-0025 CONTACTOR 1 HP IN 120V 1PH-CSA DRIVE MOTOR 120V/1PH/60HZ VT-500 C1 1

041-0017

DRIVE MOTOR 120V/1PH/60HZ VT-500 FV1 1

041-1001 EMI FILTER 4AMP 3MH, 3PH. DRIVE MOTOR 120V/1PH/60HZ VT-500 EF1 1

030-0250 CAB TIRE MOTOR 120V/1PH/60HZ VT-500 WM1 2M.

037-0953

MOTOR 80S/4-56C, 3/4HP, 230V/60HZ 2.7A

MOTOR 120V/1PH/60HZ VT-500 M1 1

034-0755 FUSE HOLDER 30A 1 PÔLE 600V PUMP 120V/1PH/60HZ VT-500 F2 1

034-0530 FUSE 20A/250V TD PUMP 120V/1PH/60HZ VT-500 F2 1

025-0030 CONTACTOR 1 HP IN 120V 1PH-CSA PUMP 120V/1PH/60HZ VT-500 C2 1

025-0190

THERMAL OVERLOAD 12 TO 18A

PUMP 120V/1PH/60HZ VT-500 O/L2 1

030-0160 CAB TIRE PUMP 120V/1PH/60HZ VT-500 WM2 2M.

125-1020 BUSCH KB-0020 115V/1PH/60HZ PUMP 120V/1PH/60HZ VT-500 M2 1

034-0740

FUSE HOLDER M4/8SF-CSA

TRANSFO 120V/1PH/60HZ VT-500 F101 1

034-0205 FUSE 5X20MM 1A/250V TIME DELAY TRANSFO 120V/1PH/60HZ VT-500 F101 1

029-0008 TRANSFO 65VA/120/24-9 TRANSFO 120V/1PH/60HZ VT-500 TR 1

034-0740

FUSE HOLDER M4/8SF-CSA

24VAC+9VAC ALL VT-500 F104+105 2

034-0210 FUSE 5X20MM 2A/250V TIME DELAY 9VAC ALL VT-500 F105 1

034-0240 FUSE 5X20MM 4A/250V TIME DELAY 24VAC ALL VT-500 F104 1

036-0740 12 CONTACTS CONNECTOR OUTPUT MC-40 ALL VT-500 1

036-0860 MTA-100 RECEPTACLE ANALOG OUTPUT MC-40 ALL VT-500 1

036-0820 0.156 CENTERLINE CRIMP HOUSING INPUT MC-40 ALL VT-500 1

036-0850 0.156 CENTERLINE CRIMP TERMIN. INPUT MC-40 ALL VT-500 4

033-0036 MICROPROCESSOR MC-40 VT MASSAGERS MC-40 ALL VT-500 1

033-0015 MEMBRANE SIPROMAC MC-40 CONTROL ALL VT-500 1

026-0240 LIGHT HEAD BODY CYCLE ON LIGHT ALL VT-500 CYCLE ON 1

026-0300 LIGHT BULB 24V CYCLE ON LIGHT ALL VT-500 CYCLE ON 1

026-0220 YELLOW LIGHT HEAD CYCLE ON LIGHT ALL VT-500 CYCLE ON 1

026-0475 ``CYCLE ON``LEGEND CYCLE ON LIGHT ALL VT-500 CYCLE ON 1

026-0025 N.C. WITH BASE EMERGENCY STOP ALL VT-500 E-STOP 1

026-0030 N.C. WITHOUT BASE EMERGENCY STOP ALL VT-500 E-STOP 1

026-0150 E. STOP BUTTON PUSH PULL EMERGENCY STOP ALL VT-500 E-STOP 1

026-0485 ``E. STOP``LEGEND EMERGENCY STOP ALL VT-500 E-STOP 1

026-0010 1 N.O. CONTACT WITH BASE STOP/START ALL VT-500 START/STOP 1

026-0110 BLACK CAP PUSH BUTTON (WATER) STOP/START ALL VT-500 START/STOP 1

026-0435 STOP-START LEGEND STOP/START ALL VT-500 START/STOP 1

025-0600 4PDT RELAY 24VAC (55.34-24VAC) REV. FOW. ALL VT-500 R3+R4 2

025-0610 4PDT RELAY SOCKET 24VAC REV. FOW. ALL VT-500 R3+R4 2

Page 30

MASSAGEUR SOUS-VIDE

VT-500

MANUEL DE L’UTILISATEUR

Page 31

AVERTISSEMENT À TOUS LES ACHETEURS, OPÉRATEURS ET SURVEILLANTS

D'OPÉRATION :

SOYEZ CERTAIN QUE CHAQUE PERSONNE QUI DOIT ACTIONNER CETTE MACHINE A LU CE MANUEL.

S`ASSURER QUE TOUS LES OPÉRATEURS ONT SIGNÉS LA PAGE DE SIGNATURE À LA FIN DE CE MANUEL.

LISEZ ET SUIVEZ LES INSTRUCTIONS SUIVANTES SINON DES BLESSURES CORPORELLES POURRAIENT SURVENIR

LISEZ CE MANUEL COMPLÈTEMENT AVANT L'UTILISATION DE L`APPAREIL.

DES MANUELS ET DES AUTOCOLLANTS DE SÉCURITÉ DE REMPLACEMENT SONT DISPONIBLE SUR

DEMANDE.

INSTRUCTIONS DE SÉCURITÉ

1. N'ACTIONNEZ PAS CETTE MACHINE JUSQU'À CE QU'ELLE AIT ÉTÉ INSPECTÉE ET NE SOIT PRÊTE POUR LE

FONCTIONNEMENT.

2. CRÉEZ UN PÉRIMÈTRE DE SÉCURITÉ AVANT D'UTILISER LE BARATTE, POUR EMPÊCHER TOUTE CAUSE

POTENTIELLE D'ACCIDENT.

4. NE TOUCHEZ PAS LES PIÈCES MOBILES.

5. NE TRAVAILLEZ PAS AUTOUR DE CETTE MACHINE AVEC DES VETEMENTS AMPLE. IL POURRAIT S`EMPÊTRÉ

DANS LA MACHINE.

6. NE JAMAIS ESSAYEZ D'ARRÊTER OU DE TOURNER MANUELLEMENT LA BARATTE. UTILISEZ LE CONTRÔLE

POUR PLACER LE BARATTE COMME DÉSIRÉ.

7. NE PAS METTRE À LA TERRE CORRECTEMENT CETTE MACHINE PEUT AVOIR COMME CONSÉQUENCE LE

CHOC ÉLECTRIQUE. SEULEMENT UN ÉLECTRICIEN QUALIFIÉ QUI CONNAÎT LE CODE ÉLECTRIQUE DEVRAIT

FAIRE LE RACCORDEMENT ÉLECTRIQUE.

8. NE CHANGEZ PAS OU NE MODIFIEZ PAS CE BARATTE DE QUELQUE FAÇON DE SA FORME ORIGINALE. NE

PERMETTEZ SEULEMENT QU` AU PERSONNEL AUTORISÉ D'ENTRETENIR VOTRE MACHINE.

9. TOUJOURS METTRE À OFF LA MACHINE QUAND ELLE N` EST PAS UTILISÉ.

10. DÉBRANCHEZ LA SOURCE D'ÉNERGIE ÉLECTRIQUE DE LA MACHINE AVANT D'ENLEVER TOUS LES

PANNEAUX POUR L'ENTRETIEN OU FAIRE DES AJUSTEMENTS À LA MACHINE.

11. OPÉREZ TOUJOURS SUR UNE SURFACE DE NIVEAU.

12. GARDEZ LE PERSONNEL NON AUTORISÉ LOIN DE LA MACHINE.

13. CES BARATTES NE SONT CONÇUES QUE POUR SUPPORTER LE VIDE ET NON LA PRESSION NOTE : NE

METTEZ RIEN DANS LA SAUMURE QUI POURRAIT PRODUIRE UNE TELLE PRESSION COMME LES GRANULES

D'ANHYDRIDE CARBONIQUE PAR EXEMPLE.

14. INSTALLEZ LA MACHINE DANS UNE POSITION QUI FOURNIT SUFFISAMENT D`ESPACE POUR PERMETTRE LE

DÉGAGEMENT SÛR DU PERSONNEL DANS LE SECTEUR.

Page 32

FONCTION ET INSTRUCTIONS DE PROGRAMMATION

Démarrage :

Tournez le sélecteur 0 I en position I.

Opération manuelle :

Avec le sélecteur 0 I en position I, il est possible de démarrer la pompe et la rotation

sans le PLC. Tourner le sélecteur de pompe en position I pour démarrer la pompe,

remettre le sélecteur en position 0 pour faire l’arrêt de la pompe. Si le sélecteur reste

en position I, la pompe fonctionnera en continue sans tenir compte du programme en

cour.

Pour tourner la barrette par à coup (JOG) ou pour faire tourner la baratte à une

vitesse fixe de 4 tours par minute sans l’aide du PLC (mode manuel), utilisez le

sélecteur de rotation. La rotation dans le sens R sert à vider la baratte (rotation à la

renverse). Le sens de rotation conventionnel pour baratter est dans le sens contraire

d’aiguilles d’une montre. Positionnez le sélecteur à la position 0 pour que la rotation

s’effectue comme programmée.

Opération avec les programmes :

Tournez le sélecteur 0 I en position I. Appuyer "ON/OFF" pour mettre en marche le

baratte. Quand la baratte est activée, l'identification du dernier programme exécuté

est affichée sur l'écran à cristaux liquides. Si l'ARRÊT d'URGENCE apparaît sur l`écran

tirer sur le bouton d'E-STOP. Utilisez le bouton poussoir démarrer/pause pour démarrer

le programme en mémoire. Assurez vous que le sélecteur de pompe et de rotation

sont positionnés à la position 0 (auto) avant de démarrer le programme.

Pour changer le programme en mémoire voir la section Lancement d’un programme

ci-après. Vous pouvez manuellement faire le vide dans la baratte en activant la

pompe sur la manette. Arrêtez la pompe lorsque le vide est atteint

Page 33

PROGRAMMATION :

ESC permet de passer du menu fonction au menu programme et vis et versa. SELECT

permet de choisir un sous menu dans le mode choisit. ENTER permet d'accéder à des

fonctions, à des programmes et à des options particulières. Ci dessous une liste de la

façon dont chaque menu est organisée.

MENUS DE FONCTION :

F1 CREATE UN PRGM

F2 DELETE A PRGM

F3 UNLCK A PRGM

MENUS DE PROGRAMME :

NOM DE CYCLE DE PRGRM : Par exemple, P01 : (limite de 12 caractères)

SEGMENT #1 DE PRGRM

SEGMT TIME : 0h00

MASSAGE ON : 0h00

MASSAGE OFF : 0h00

POMPE DE VIDE : OFF

SP < ************ >

SEGMENT #2 DE PRGRM

SEGMT TIME : 0h00

MASSAGE ON : 0h00

MASSAGE OFF: 0h00

POMPE DE VIDE : OFF

SP < ************ >

SEGMENT #3 DE PRGRM

SEGMT TIME: 0h00

MASSAGE ON : 0h00

MASSAGE OFF : 0h00

POMPE DE VIDE : OFF

SP < ************ >

Page 34

CRÉER UN NOM DE PROGRAMME :

1. Si F1 CREATE A PRGM n'est pas affiché appuyer sur ESC. Une fois que F1 CREATE A

PRGM apparaît appuyé sur la touche ENTER.

2. PRGM CYCLE NAME apparaîtra sur l'écran d'affichage à cristaux liquides. Appuyer

sur ENTER pour créer un nouveau nom de programme.

3. Pxx NO NAME clignotera. (Le numéro de programme (Pxx) sera assigné

automatiquement). Commencez à taper le nom de programme en utilisant le

clavier numérique ; appuyez sur une touche numérique jusqu'à ce que le

caractère désiré apparaisse. Une fois que la lettre correcte est afficher appuyer sur

ENTER et le curseur se déplacera d'un espace vers la droite. Pour confirmer la fin

du nom appuyer sur ENTER deux fois. Le nouveau nom de programme clignotera.

Appuyer sur ENTER pour confirmer. Votre nom de programme à été enregistré.

4. Appuyer sur ESC pour afficher le nouveau programme ou appuyer ENTER pour

modifier le programme choisit. Appuyer sur SELECT pour choisir un autre

programme déjà fait. Une fois que le nom désirer est afficher appuyer sur ENTER.

Voyez les options de programme ci-dessous pour plus d'information.

RÉGLAGE DES OPTIONS DE PROGRAMME :

Dans chaque programme trois segments sont disponibles pour choisir des temps et

des vitesses de baratte. Une durée complète de programme peut allez jusqu'à 72

heures de durée (24 heures par segment). Le SEGMENT #1 du PRGRM peut être de X

heure avec le MASSAGE OFF (aucune rotation ne se produira), peut-etre utilisé pour

faire le vide dans la baratte avant de commencer la rotation. Alors le SEGMENT #2 de

PRGRM peut être programmé avec X temps de MASSAGE ON (la rotation se produira)

à une vitesse de X RPM (rotations par minute). Peut-être après ce cycle vous voudrez

augmenter le temps ou la vitesse. Dans ce cas le SEGMENT #3 de PRGRM permet de

modifier le MASSAGE ON et de choisir une nouvelle vitesse en RPM. Selon vos besoins,

un deux ou chacun des trois des segments peut être programmé. En bref, les

différents cycles peuvent être employés pour une pause dans le barattage ou pour

barater à une vitesse différente.

1. SEGMENT #1 DE PRGRM : apparaîtra une fois qu'un nom de programme a été choisi

pour la modification ou la programmation. Pour faire des changements à cette

section de segment appuyer sur ENTER.

2. SEGMT TIME : 0h00 apparaîtra. Enter la durer du segment #1. Les heures sont entré

avec deux nombres (c.-à-d. 01, 05, 12, etc. jusqu'à 24) suivi des minutes. Au total,

vous devez écrire 4 nombres pour ajuster la durée de cycle courant. Quand le

temps entrer clignotera, appuyer sur ENTER pour confirmer et se déplacer au

prochain écran.

3. MASSAGE ON : 0h00 apparaîtra. Entrer la durée que vous voulez barater. Entrer le

même temps que le SEGMT TIME si on veut barater pendant toute la durée du

segment. Si aucun temps n'est entré la machine ne tournera pas. Dans ce cas-ci

le SEGMENT #1 de PRGRM agira en tant que temporisateur, retardant le

barattage jusqu'à ce que le prochain segment soit activé. Appuyer sur ENTER

pour confirmer le temps et/ou se déplacer au prochain écran.

4. MASSAGE OFF : 0h00 apparaîtra. Cette option est pour les utilisateurs qui veulent

cesser temporairement de barater dans un cycle. Si aucun barattage n'est désiré

Page 35

dans le segment, Entrer le même temps que le SEGMT TIME. Appuyer sur ENTER

pour confirmer le temps ou se déplacer au prochain écran.

RÉGLAGE DES OPTIONS DE PROGRAMME :

5. VACUUM PUMP OFF : apparaîtra et OFF clignotera. Appuyer sur SELECT pour choisir

entre ON ou OFF. Appuyer sur ENTER pour confirmer.

6. SP < ************ >apparaîtra. Appuyer sur #4 pour réduire ou #5 pour augmenter

le niveau de vitesse. Appuyer sur ENTER pour confirmer.

7. SEGMENT #1 DE PRGRM réapparaîtra. Si un seul segment est programmé appuyée

sur ESC pour montrer le nom de programme et appuyer sur ENTER pour

commencer à barater. Si des segments additionnels doivent être entré, Appuyer

sur SELECT pour choisir le SEGMENT #2 et appuyer sur ENTER pour enter des

valeurs. Le même procédé s'applique pour programmer le SEGMENT #3 de

PRGRM. Les mêmes Instructions que pour le SEGMENT #1 de PRGRM s`applique.

MODIFICATION D`UN PROGRAMME EXISTANT :

1. Pour modifier un programme préréglée appuyer sur ESC si en mode de fonction (c.-

à-d. F1, F2, ou F3).

2. Quand un nom de programme apparaît appuyer sur ENTER, appuyer sur SELECT pour

choisir le programme qui est à modifier et accéder au données. Quand le

programme désiré apparaît appuyer sur ENTER.

3. SEGMENT #1 DE PRGRM apparaîtra. Pour faire des changements sur ce segment

appuyez sur ENTER.

4. Après avoir appuyé sur ENTER, les données de chaque sous-menu clignoteront. Si

vous voulez faire un changement, entrer le nouveau temps ou la vitesse et

confirmer avec ENTER. Si aucun changement de temps ou de vitesse n'est pas

nécessaire appuyer sur ENTER pour confirmer et avancer au prochain écran de

sous-menu.

5. Pour passer aux segments #2 et/ou #3 appuyer jusqu'à SEGMENT #1 DE PRGRM et

appuyer sur SELECT. Appuyer sur ENTER une fois que le segment désirée apparaît.

Répétez les étapes comme ci-dessus.

LANCEMENT D'UN PROGRAMME :

1. Appuyer ENTER si le nom de programme que vous voulez est affiché.

2. Pour choisir un programme différent que celui sur l'écran, appuyé sur SELECT.

3. Appuyer START/STOP après que le programme est celui désirée.

4. Le programme choisi fonctionnera jusqu'à ce que tout le segment ait été

accompli, ou que le programme soit manuellement arrêté.

Page 36

ENTRETIEN QUOTIDIEN DE POMPE DE VIDE :

Le procédé d'entretien est exigé après chaque utilisation de la baratte pour évacuer

la condensation de l'eau à l'intérieur de la pompe.

1. À la fin de chaque programme, fermée la valve entre la pompe et le séparateur

d'eau.

2. Mettez en marche la pompe, pour 20 minutes au minimum.

*** NOTIFICATION IMPORTANTE ; le manque de faire cet entretien régulier peut

endommager la pompe et annuler la garantie fournie par le manufacturier de pompes

et des systèmes de vide Busch.

ARRÊT D'UN PROGRAMME :

1. Pour interrompre un programme en marche, tournez le sélecteur M-START vers la

droite. Ceci arrête ainsi seulement la rotation de la baratte. La machine se

rappellera combien d'heure s'est écoulée.

2. Tournez à nouveau le sélecteur M-START vers la droite pour continuer, si désiré.

3. Appuyer ESC pour accéder aux menus de fonction pour désactivée un programme

arrêter de façon manuel.

4. Appuyer sur ESC jusqu`à ce que F3 UNLOCK A PRGM apparaisse et appuyer alors

sur ENTER. Le nom du programme en cours apparaîtra.

5. Appuyer ENTER pour remettre à zéro les compteurs. A partir de ce moment un autre

programme peut être accédé.

* Un programme est verrouillé du début de l'exécution jusqu`à la fin complet pour

empêcher n'importe quelle modification involontaire du statut du programme en

cours.

SUPPRIMER UN PROGRAMME :

1. Pour supprimer un programme préréglé dans la mémoire de la baratte accéder

au menus de fonction et choisir F2 DELETE A PRGM et appuyer sur ENTER.

2. Le premier programme dans la mémoire clignotera. Appuyer sur ENTER pour

supprimer ou SELECT pour se déplacer au prochain programme.

3. Une fois que le programme devant être supprimé apparaît appuyer sur ENTER.

4. Appuyer ESC pour annuler un et/ou pour sortir du menu delete a pgm.

Page 37

EXEMPLE DE PROGRAMME

OBJECTIF :

PIÈCES DE POULET A BARRATER PENDANT 15 MN. VITESSE MAXIMUM AVEC LA

POMPE DE VIDE ON.

APPUYER AFFICHAGE RÉSULTANT

1. "ON/OFF" Voyants d'affichage

2. ESC jusqu'à F1 create a PRGM

3. ENTER Nom de cycle de PRGM

4. ENTER P01 no name (clignotant)

5. Bloc de touches de nombre P01 chick parts

Jusqu' à ce que la lettre désirée apparaît

Enter après chaque choix

Enter deux fois Programmez le nom de cycle

6. Select PRGM SEG #1

7. ENTER SEGMT TEMPS : 0h00 (clignotant)

8. 0015 SEGMT TIME : 0h15

9. Enter MASSAGE ON : 0h00

10. 0015 MASSAGE ON : 0h15

11. ENTER MASSAGE OFF : 0h00

12. ENTER POMPE DE VIDE : OFF

13. SELECT POMPE DE VIDE : ON

14. ENTER SP<************>

15. ENTER PRGM SEGMENT #1

16. ESC P01 CHICK

LE PROGRAMME EST MAINTENANT COMPLET

Aucun autre segment n'est nécessaire à moins que vous vouliez changer de vitesses

pendant le programme. Il peut être utile d’insérer un segment en début de programme

pour effectuer le vide dans la baratte avant de commencer la rotation.

Si vous faites une erreur, appuyée sur la touche ESC pour annuler.

Appuyer sur ENTER pour passer en revue les choix de programme.

Page 38

EXEMPLE DE PROGRAMME

JOG :

JOG est aussi disponible sur le PLC. Appuyer sur 2 pour pulser la rotation. Appuyer sur 1

pour une rotation continue inversée. NOTE : Attendre 5 secondes après un arrêt

complet avant d'employer le jog.

POUR UNLOCKER UN PROGRAMME :

Appuyer sur ESC jusqu'à ce que F1 créent un PRGM apparaisse

Appuyer sur SELECT jusqu'à ce que F3 unlock a PRGM apparaisse

Appuyer sur ENTER

KEYBOARD DETAIL

Page 39

NETTOYAGE ET HYGIÈNE

Le tambour de la machine à barater doit être nettoyés et aseptisé quotidiennement

ou à toutes les fois qu'un produit est changé pour un autre.

1. Après avoir enlever toute la solution de saumure, ajoutez la quantité nécessaire

d'eau et de détergent doux pour créer une solution pour le prélavage.

De l'eau chaude n'est pas recommandée dans

la première étape, comme il peut causer la

« protéine de myosine » et son accumulation

peut décolorer la surface intérieure du tambour

2. Attachez le couvert en place et faite tournez le tambour à pleine vitesse

pendant approximativement deux (2) minutes.

3. Utilisez le sélecteur REV pour faire tourner la baratte en rotation inverse pendant

approximativement deux (2) minutes.

4. Vidangez la solution de nettoyage en enlevant le bouchon de vidange.

5. Lavez l'intérieur du tambour avec de l'eau savonneuse chaude et puis rincez

avec de l'eau chaude.

6. Coupez toujours la source d'énergie pour nettoyer la BARRATTE excepter pour

l`opération décris à l`étape 2 et 3.

La garniture de couvercle devrait être lavée et aseptisée dans l'eau savonneuse

chaude. Détacher la garniture du couvercle pour facilité le nettoyage et

nettoyer aussi le couvercle.

7. La surface extérieure de la machine devrait également être essuyé et nettoyé.

8. Pendant le nettoyage de la machine, ne dirigez pas l'eau sur les commandes.

Au lieu de cela, utiliser un chiffon humide et essuyer avec une serviette sèche

propre.

9. Après nettoyage, la machine devrait être aseptisée avec une solution

d`aseptisation approuvée par le FDA de l'USDA.

Page 40

ENTRETIEN

1. Couper la source d'énergie de la machine avant de faire n'importe quel

entretien.

2. Vérifiez si il y a présence de fuite d'huile du réducteur de vitesse sur une base

mensuelle.

3. Enlevez la couverture de capot sur l'état de contrôle des pièces.

Page 41

PAGE DE SIGNATURE D'OPÉRATEUR

Ma signature ci-dessous certifie que j'ai complètement lu et comprends ce manuel.

Je me rends compte que cette machine, utilisé négligemment, peut me causer des

dommages sérieux et au autres.

Nom (copies) Signature Date

DA/047

Page 42

NOTES

Loading...

Loading...