Page 1

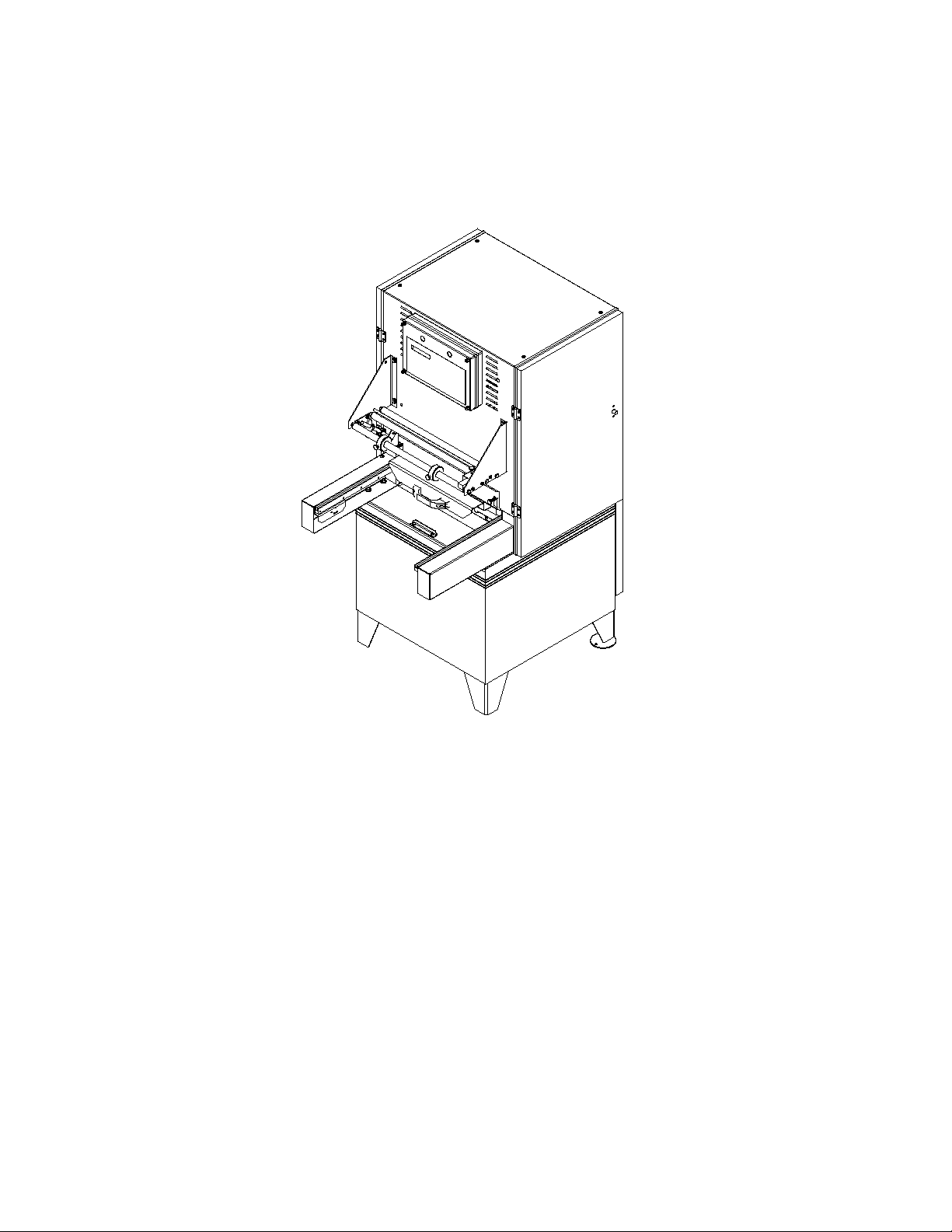

TS-30

TRAY SEALER

OWNER’S MANUAL

MACHINE NUMBER:…………………

SIPROMAC

240 BOUL. INDUSTRIEL

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA J0C 1K0

(819) 395-5151

Page 2

VACUUM TRAY SEALER

MODEL TS-30

TABLE OF CONTENT

Section 1- Setting up the machine

1.1. Floor print

1.2. Leveling

1.3. Vacuum pump setup

1.4. Connections

1.4.1. Electric connections

1.4.2. Pneumatic connections

Section 2- Operation

2.1. Operating procedures

2.1.1. General description

2.1.2. Sealing station

2.1.2.1. Chamber

2.1.2.2. Film rewinder

Page 3

2.2. Tooling insertion

2.2.1. Chamber setup

2.2.1.1. Die plate installation

2.2.1.2. Upper tooling insertion

2.2.2. Setup

2.3. Film insertion

2.4. Digital control setting

2.4.1. Basic

2.4.2. Function menu

2.4.2.1. F1- Create a program

2.4.2.2. F2- Delete a program

2.4.2.3. F3- Rewind Option

2.4.2.4. F4- Rewind input

2.4.3. Programs menu

2.4.3.1. Name

2.4.3.2. Vacuum

2.4.3.3. Vacuum plus

2.4.3.4. Gas plus

2.4.3.5. Seal time

2.4.3.6. Plate temp C

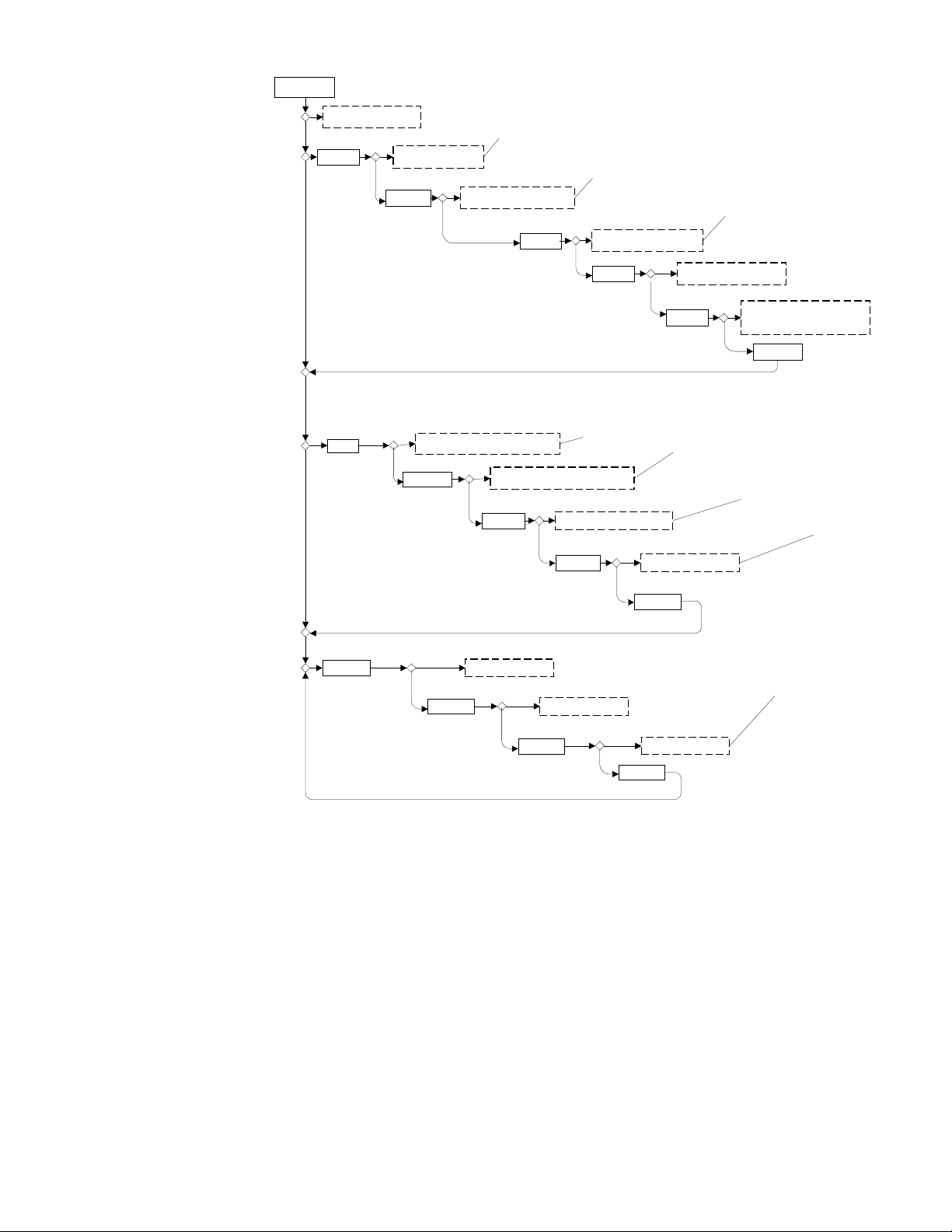

2.4.4. Operation sequence

2.4.4.1. Vacuum cycle

2.4.4.2. Gas cycle

2.4.4.3. Seal cycle

2.4.5. System monitor

Page 4

Section 3- Trouble shooting

3.1. Failure during a packaging cycle

3.1.1. "VACUUM ERROR" message is displayed on LCD

3.1.2. "GAS FLUSH ERROR" message is displayed on LCD

3.1.3. "CHAMBER ATM ERROR" message is displayed on LCD

3.1.4. "COVER DOWN ERROR" message is displayed on LCD

3.1.5. "`HIGH LIMIT TEMP" message is displayed on LCD

3.2. Insufficient vacuum in chamber

3.3. Faulty seal

3.3.1. Insufficient sealing

3.3.2. No seal

3.3.3. Seal does not stick

3.3.4. Fault in the valve

3.4. Control board failure

Section 4- Maintenace

4.1. Regular maintenance

4.2. Heating element replacement

4.3. Blade replacem ent

Section 5- Mechanical drawing

Section 6- Electrical drawing

6.1. Electrical panel assembly

6.2. Terminal control wiring

6.3. Electrical box power connecting details

6.4. PC board wiring

6.5. Power schematic diagram

6.6. Control shematic diagram

Page 5

6.7. Cover wiring

6.8. Tooling wiring and connecting

Section 7- Pneumatic drawing

Section 8- Tooling insertion check list

Section 9- TS-30 technical data

Page 6

1-1

1. Setting Up the machine

1.1. Floor print

The TS-30 must be positioning to assure proper accessibility for maintenance and

operation. Before choosing the site for the machine, please consider that you will

also need room for packaged and non-package products apart from the space

needed for the machine itself.

1.2. Leveling

To assure the proper operating of the TS-30, use a level and adjust its feet. Don’t

forget to lock the foot in position using the locknut after the leveling is

completed. If the TS-30 is equipped with optional wheel, just push the wheel

lock.

1.3. Vacuum pump setup

Before starting to work, check the oil level through the view glass on the pump,

to see if there is a sufficient quantity of oil in the pump. Never use oil other than

recommended by the manufacturer. Never exceed maximum quantity of oil

indicated, when adding or changing oil.

Page 7

1-2

1.4. Connections

1.4.1. Electric connections

Electrical connection must be set according to the Id plate of the TS-30

and the electrical schematic drawing found in section 6.1. Electrical

connections must be made by qualified personnel. This person must make

sure that the electrical entries correspond to the proper voltage and

amperage of the machine. An important step in connecting the machine is

to make sure that the pump turns in its correct rotation. Warning : The

pump should not rotate more than 3 to 4 seconds in the wrong

rotation or it may cause serious damage. The proper rotation is

indicated by an arrow on the pump motor.

1.4.2. Pneumatic connections

Used ½’’NPT inner diameter pneumatic pipe. See section 9 for pneumatic

specification of the TS-30. See section 7 for localization of pneumatics

parts.

Page 8

2-1

2. Operation

2.1. Operating Procedures

2.1.1. General description

The TS-30, Sipromac vacuum tray sealer has been designed to package a

wide variety of fresh, frozen or processed product that will be sold in a

clean, safe, appe al in g "ca se re ady" container. S ip r om ac tray seali n g M. A.P

(modified-atmosphere-packaging) machines will provide a controlled

oxygen level ensuring freshness for a longer period of time.

The simplified operation sequence is: first the operat or sets the tray on the

bottom chamber. Next, the operator push the drawer under the cover (the

upper chamber) and the optional film rewinder is automatically activated.

When the drawer re achs the correct position, the chamber is push against

the cover and the vacuum is made inside the chamber, followed by

injection of the neutral gas. Then the tray is pushed against an electric

element equipped with a knife to cut off and seal the film. Afterwards, the

chamber will open. The operator pulls back the drawer and take out the

tray and the excess film if the TS-30 is not equipped with a film rewinder.

2.1.2. Sealing Station

2.1.2.1. Chamber

2.1.2.2. Film rewinder

The chamber is divided in 2 parts: the upper chamber and the lower

chamber. A lid gasket allows for a vacuum in the chamber when

both parts come together. It is the lower chamber part that joins the

upper one by the mouvement of the cylinder. Then comes the

vacuum phase in the chamber and the addition of a substitute gas

until atmospheric pressure is reached.

All the tooling is located inside the chamber: the die plate is

located in the lower section and the knifes and heating elements

used to seal the film are in the upper section. The upper cylinder

pressures the h eating element in a way to seal the film on the tray.

A number of spring loaded film support keep the film tight by

maintaining a light pressure during the complete cycle.

A brake-motor leads the rewinder to provide the movement of the

film. The distance of film will move is controlled either by photocell indexer that can read the printed part of the film or by a

mecanical wheel made to each specifications of the trays. The

tightening cones prevent film rippling. Adjustement screws control

the pressure on top of the film for better film tension.

Page 9

2-2

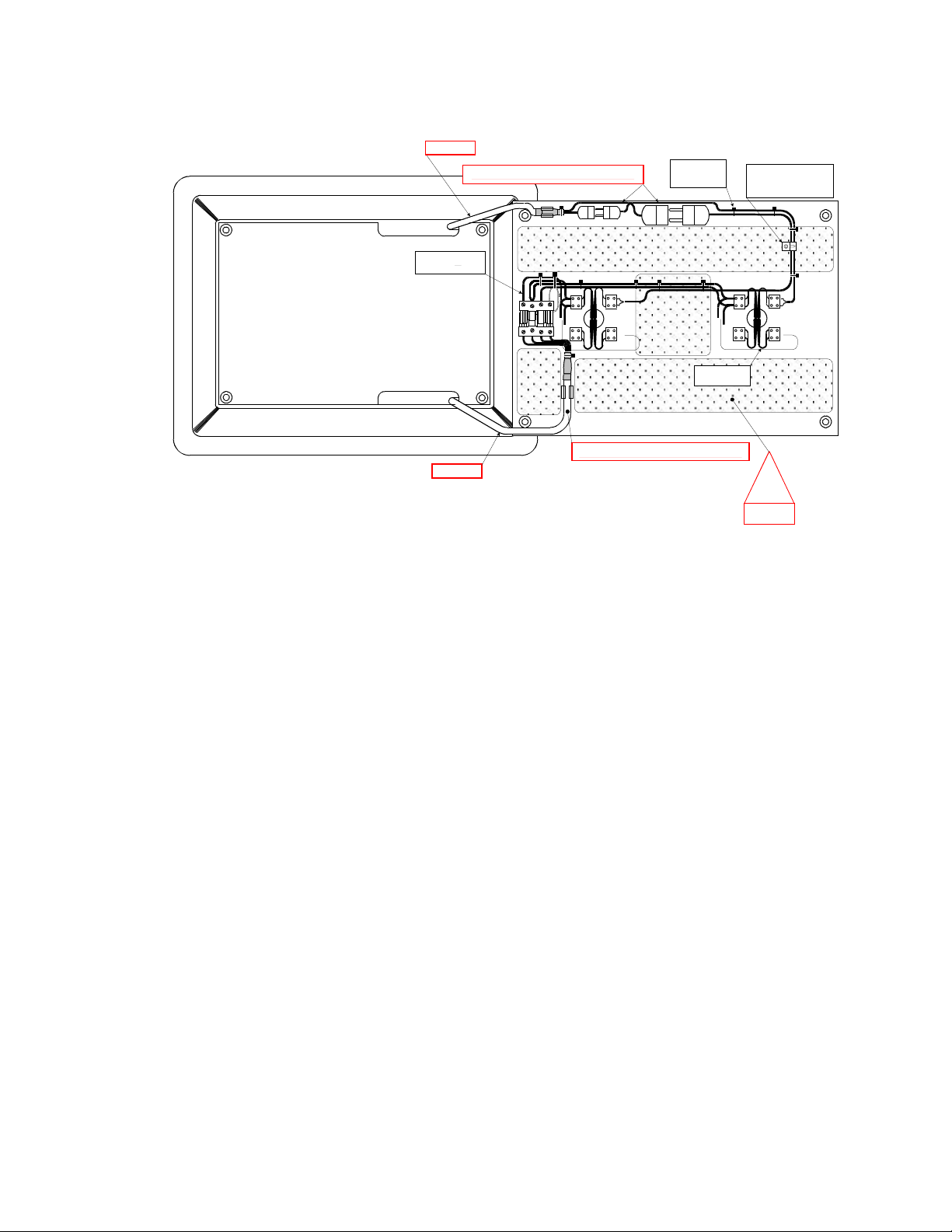

cover

+

-

+

-

Always respect initial wire way

+

-

red

wht

+

-

red

wht

gnd

tooling

red

wht

red

wht

82

82

82

79

79

79

80

80

80

80

80

80

cable ties black

( Tie wrap )

4''

# 057-0305

wire hi temp TEW / 2

AWG

16

# 030-0530

copper tubing

# 105-601

or 105-600

(according movement piece)

Always respect initial wire way

W 003

!

area parts in

movement

loop obligatory

for go & comes

movement

Z5

82 ( Z6)

80 ( Com)

79 ( Z5)

gnd

Z6

Z6

Z5

W 5 & 6

2.2. Tooling insertion

Here is the procedure to change a tooling or remove it for maintenance: (See

Section 8)-Tooling Insertion Check List to make sure all the steps are respected.

2.2.1. Chamber setup

Each tooling contains 2 sub-assemblies:

-the die plate witch is located in the lower chamber,

-the upper tooling witch is located in the upper chamber.

2.2.1.1. Die Plate installation

Take out all the hex socket head bolts (4) using "allen key ¼"

provided with tooling. Remove the die plate from the chamber.

Inverse these steps to put the tooling back. Die plates are d esigned

to avoid installation on the wrong side.

Page 10

2-3

2.2.1.2. Upper tooling insertion

2.2.2. Setup

2.3. Film insertion

The film must follow the path as shown in section 5. Using the m anual feeding

button make the rewinder turn until film 's lock faces up the tube. Make the film

pass over the roll and fix the lock on it. To fix the lock properly make the

rewinder turn one rotation using manual feeding button. The tightening cones

must be located in a way to stretch the film. Locate those on the edge of the film

cutout. Two wheels allow the centering of the roll with the chamber. An

ajustable roller and two handles keep the film tight and smooth on the roll even

when it is almost empty. Look carefull y at section 5 and follow the instructions

regarding the circuit of the film to have the glue on the film toward the tray.

Also, the film must be inside the eye indexer. To remove the used spool roll from

the rewinder, use the special flat tool and pull gently on the lock, then, turn it t o

loosen the film and take the spool out.

Unscrew the nuts (4) of the upper tooling with Allen key 3/16.

Rotate the tooling to the right like opening a door.

Disconnect the 3 connectors.

Inverse the previous steps to put upper tooling back. Make sure all

wires are in their respective connector.The upper tooling has the

same design particularities as the die plate to insure the installation

in the proper position. Put the film back

(See section 2.3)

If there's a ch ange i n the tray model, you may change the encoder wheel if

it is necessary, in cases where die plate had been changed.

Page 11

2-4

2.4. Digital control setting

2.4.1. Basic

Model TS-30 programming is made by the keyboard of the MC

programmable controller. There are 2 modes available on the MC-40:

Program Mode & Function Mode. The MC-40 can store up to 20 programs

with different parameters corresponding to various conditions of use. The

program Mode allows changing in t he current program and also changing

the parameters related to that program. The function Mode set the

parameters of the TS-30 and is valid for all the programs

Use "Power" key to power ON/OFF the vacuum tray sealer. When the unit

is on, the identification of the last executed program is displayed on the

LCD screen.

Use the "ESC" key to change from the program menu to the function menu

and from the fonction menu to the program menu.

In function menu, use "S ELECT" key to select a function and "ENTER"

key to accede and modify the selection.

In program menu, use "S ELECT" key to select a pro gram and "ENTER"

key to accede and modify the selection.

In programs submenu, use "ENTER" key to pass over the parameters and

go to the followin g one; the parameters blink t o point out the acquisition

mode. A return to program menu is performed aut omatically following the

last parameter acquisition.

In program submenu, use "ESC" key to get back to the program menu.

Strike any k ey to clear the error message which may be displayed on the

LCD screen.

There is a emergency stop button on your MC-40 keyboard used for

emergency power cut off.

Password on request ( contact your dealer )

2.4.2. Function menu

Page 12

2-5

2.4.2.1. F1- Create a program

SELECT Pxx+1 NO NAME

Pxx+2 NO NAMESELECT

SELECT Pxx+... NO NA ME

SELECT

*you may select the

program that you

had created only.

To select a program creat ed

ESC

F1 CREATE A PROGRAM

SELECT

F2 DELETE A PROGRAM

F3 REWIND OPT IO N

SELECT

ESC

Press enter to create

a program

1

-acces this function with enter

2

-

choose the program with select

3

-confirm delete with enter

choose with select

.

rewind enable

.

rewind desable

To create a program and rewind option

F4 REWIND INPUT

SELECT

choose with select

.

encoder

.

photocell

To modify a program created

ON/OFF

VACUUM:xx.x %

Pxx NO NAME

VACUUM PLUS:xx S

SEAL TIME: xx S

ENTER

Enter a value

Enter a value

The program name flash,

you may create a name

for Pxx.

Displayed if gas flush is

enable, see diagnostic

menu. Enter a value.

ENTER

ENTER

ENTER

ENTER

ENTER

GAZ PLUS: x.x S

When executing the "create a program" function, the program

submenu is acceded, starting with the identification. The initial

identification "Pxx NO NAME" is given to the program and all

parameters are established to zero; the program number is allocated

automatically.

For a selected program, set the identification, using the numeric

keyboard characte rs chart; pressing numeric key until the character

you wish is selected (4 times for the numeric value). Use

"ENTER" key to validate the character and to validate the

characters strin g at the end (the new char acters string is blinki ng).

In a middle of an acquisition, use "ESC" key to come backwards

and erase one or several characters.

Page 13

2-6

Example:

key ENTER to validate the characters string

EXAMPLE 1 (9 characters)

keys 2, 2, ENTER -> E

keys 8, 8, 8, ENTER -> X

keys 1, ENTER -> A

keys 5, ENTER -> M

keys 6, ENTER -> P

keys 4, 4, 4, ENTER -> L

keys 2, 2, ENTER -> E

keys 9, 9, 9, ENTER -> space

keys 1, 1, 1, 1, ENTER -> 1

After you entered the program's name, you may enter different

parameters speci fic to the program. You will find the meaning of

the parameters in section 2.4.3.

2.4.2.2. F2- Delete a program

When executing the "delete a program" function, the programs

menu is acceded and the number of the first program in memory

blink to point out the deletion mode. Use "SELECT" key to select a

program and "ENTER" key to accede and confirm deletion of the

selection. Use "ES C" key to unconfirm a deletion and to leave the

function. When leaving the function, the number of the actual

program on the LCD screen will cease to blink.

2.4.2.3. F3 -Rewind Option

This is an option on your Tray Sealer , it has to be enabled if you

have the automatic rewinder.

Page 14

2-7

2.4.2.4. F4- Rewind input

Example:

It's possible to change the input which controls the film's

rewinding. The two possibilities are: ENCODER or PHOTOCELL

choosen by “SELECT” key and “ENTER” key.

When you s elect ENCODER, the film's unwinding will stop when

the flat of the wheel faces the sensor.

If PHOTOCELL is elected you should see a black mark on the film

(±10mm2). This mark tells you where the film's unwinding stops.

2.4.3. Program menu

You can switch from Function Mode to Program Mode by using the E SC

key. You press SELECT key to see all the different programs. It is also

possible to modify the parameters of a program in MODE PROGRAM by

picking up the program you wish with “ENTER” key. Here are the

different parameters regarding each program.

2.4.3.1. Name

Set the program identification by using the numeric keyboard chart,

until the desired caracter is reach then press enter for the next

selection until the complete name is displayed.

2.4.3.2. Vacuum (0 - 99.5%)

Percentage of vacuum to reach i n t he cham ber con sidering "99.5%"

of vacuum almost total. To save cycle time, always use the

minimum vacuum necessary to obtain the correct oxygen level in

the tray.

For a selected program set the vacuum level, starting with the

values; the decimal point is automatically inserted following the

second digit entry and the validation is automatically performed

keys 9, 0, 0 or 9, 0, ENTER or 9, 0, 1 or

keys 9, 0, 2 or 9, 0, 3 or 9, 0, 4 -> 90.0 %

keys 9, 7, 5 or 9, 7, 6 or 9, 7, 7

keys 9, 7, 8 or 9, 7, 9 -> 97.5 %

keys 0, 0, 0 or 0,ENTER -> 0.0 %

Page 15

2-8

following the third digit entry (The new vacuum level blink). The

Example:

keys 1, 5

15 secs

vacuum level is truncated to the nearest lower half value. In the

middle of an acquisition, use "ENTER" key to validate the vacuum

level and "ESC" key to come backward and start over with a new

acquisition (the old vacuum level blink). Set the vacuum level to

zero to bypass the pressure transducer and proceed only using the

vacuum plus time.

2.4.3.3. Vacuum plus (0 – 99 secs)

This value means the time that vacuum will be maintained in the

chamber when we reach the instructions programmed in Vacuum.

During this delay the pump is still vacuuming.

For a selected program set the vacuum plus time, in seconds; the

validation is automatically performed following the second digit

entry (the new vacuum plus time blink). In a middle of an

acquisition, use "ENTER" key to validate the vacuum plus time

and "ESC" key to come backward and start over with a new

acquisition (the old vacuum plus time blink).

keys 0, 1 or 1, ENTER

-> 1 sec

->

2.4.3.4. Gas plus (0.0-5.0 sec)

Value of time for positive pressure of the neutral gas in the

chamber before sealing. It’s an extra pressure regarding to

atmospheric pressure.

If the film appears to bulge out on the top of the sealed tray you

must reduce the value of the Gas Plus. If the opp osite happens and

the film bulges in, increase the value of the Gas Plus.

2.4.3.5. Seal time (0 – 99 secs)

Running time value for the trays to be in contact with the h eating

element. Depend on film and tray material.

For a selected program set the sealing time, starting with the

seconds. Use "ENTER" key to validate the sealing time and "ESC"

key to come backward and start over with a new acquisition (the

old sealing time blink).

Page 16

2-9

Example:

keys 0, 1 or 1, ENTER -> 1 sec

2.4.3.6. Plate temperature (0 – 160 °C)

Heating element temperature. Depend on film and tray material.

N.B: the machine shuts off by itself if the temperature goes higher

than 175 °C.

2.4.4. Operation sequence

Here is a description of a complete sequence to illustrate the function of

each parameter.

2.4.4.1. Vacuum cycle

As soon as the switch indicates the chamber is below the cover,

the cylinder is operated and at the same time the vacuum valve

opens if there is any value other than 0% programmed in

VACUUM. The screen will let you know th e state of the vacuum

evolution. When we get the programmed value in VACUUM, the

cycle goes automatically to VACUUM PLUS cycle which

maintains the valve opened for the delay programmed. The vacuum

valve shuts automatically at the end of the cycle. The gas c ycle c an

now start.

2.4.4.2. Gas cycle

Gas valve opens automatically to reach an over pressure of gas in

the chamber corresponding to the time of GAS PLUS. Gas valve

then shuts and a d elay of 1 second allows time for stabilization in

the chamber before the sealing.

2.4.4.3. Seal cycle

Valve for the bellows is operating during the delay programmed in

SEAL TIME. Sealing is now completed. There is a .5 second delay

before going back at the atmospheric pressure. The atmosphere

control valve operates fo r a minimum of 1 sec and if the vacuum is

below 1% the chamber lock i s released and then the lower chamber

will go down.

Page 17

2-10

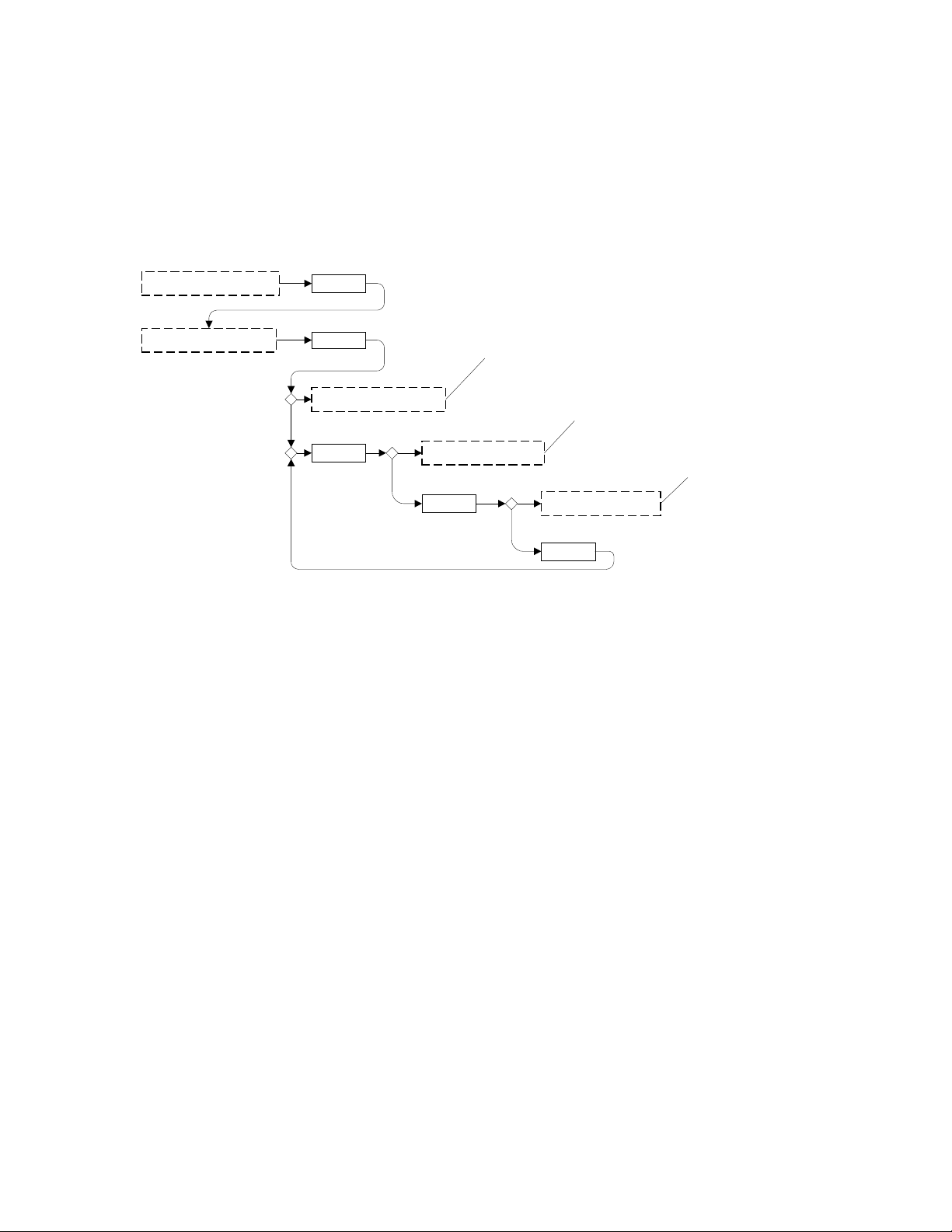

2.4.5. System monitor

DIAGNOSTIC MENU

SELECT

SYSTEM MONITOR

ENTER

SOFTWARE: XX.XX

WORK HRS: 00000

CYCLE: 0000000

SELECT

SELECT

SELECT

Shows the total number of

hours done by the machine.

Shows the total number

of cycles done by the

machine

Shows the MC-40

software version.

To access the system monitor, power up the vacuum packaging machine

while keeping the "ESC" key pushed. Use "SELECT" key to select the

system monitor function and "ENTER" key to access and visualize the

monitored parameters. Use "SELECT" key to change over from the software

revision, the amount of working hours done and the amount of complete

cycles performed since first initialization.

A password can be added. For this, please contact your supplier.

Page 18

3-1

3. Trouble shooting

3.1. Failure during a packaging cycle

3.1.1. "VACUUM ERROR" message is displayed on LCD

No pressure variation is picked up by the PCB transducer during the

vacuum sequence within a preset period of time.

-> Check vacuum lines for potential leaks or kinks.

3.1.2. "GAS FLUSH ERROR" message is displayed on LCD

No pressure variation is picked up by the PCB transducer during the gas

sequence within a preset period of time.

-> Check gas flush and vacuum lines for potential leaks or kinks.

3.1.3. "CHAMBER ATM ERROR" message is displayed on LCD

No pressure variation is picked up by the PCB transducer during the

atmosphere sequence within a preset period of time.

-> Check vacuum lines for potential leaks or kicks.

3.1.4. "COVER DOWN ERROR"

The cover switch is defective or needs adjustment , it will happen during

the vacuum cycle if that switch lost the signal .

3.1.5. "HI LIMIT TEMP"

The machine will shut-off by itself if the temperature goes higher than

175°C

In case of failure in triac element or MC-40 board.

Page 19

3-2

3.2. Insufficient vacuum in chamber

To find the leakage quickly, check for leaks with a precision vacuum meter,

going back step by step from the chamber to the pump.

Warning: Verify connections of measuring equipment before verifying machine.

Most frequent points of leakage: lid gasket, damaged vacuum hose or loose hose

clamps.

3.3. Faulty seal

3.3.1. Insufficient seal

-> Sealing pressure too low, bellows leaking or pressure bar jammed.

-> Silicone rubber uneven.

3.3.2. No seal

-> Faulty contact in sealing circuit or bad heating element.

-> Contactor does not work.

3.3.3. Seal does not stick

-> Seal area extremely contaminated by fat or meat juice.

-> Sealing temperature is too low.

Warning: Do not incr ease sealing ti me more than really necessa ry; higher

temperature will reduce working life of Teflon and silicone rubber.

Page 20

3-3

3.3.4. Fault in the valve

Vacuum or air valve does not open.

-> Check whether there is voltage on the magnetic valves during their

period of operation. If there is no voltage a wire is broken or the PC board

is damaged.

Vacuum valve does not close.

Lid does not open at the end of the cycle; air enters, but th ere is still 20 40% vacuum in chamber.

3.4. Control board failure

The board software allows access to a "Diagnostics Menu". Only qualified

service technicians are authorized to access this menu by entering a security

password.

By access either the "D1 input test" feature or the "D2 output test" feature, a

trained technician will be able to quickly know the origin of the problem: pump,

sealing system, pneumatic problem, security switch problem, etc..

Keep in mind that in most cases trouble is due to a leakage, loose electrical

connection or evident damage to the main component: vacuum pump, valves,

electrical contactors, thermal overload, fuses holder or transformer.

For assistance do not hesitate to contact your local service technicians.

Page 21

4-1

4. Maintenance

4.1. Regular maintenance

Routine controls to be made at regular intervals:

Check lid sealing for damage and hardened spots.

Check evacuation hose for damage (contraction of diameter or abrasions).

Check vacuum connections for tightness.

Check oil in pump (oil level in view glass; add if necessary. If the pump oil

changed color, replace it.)

Check vacuum in chamber with precision vacuumeter.

Check the dryer filter if crystal is not blue change the part.

Page 22

4-2

4.2. Heating element replacement

-> Take apart the upper tooling (see section 2.2.1.)

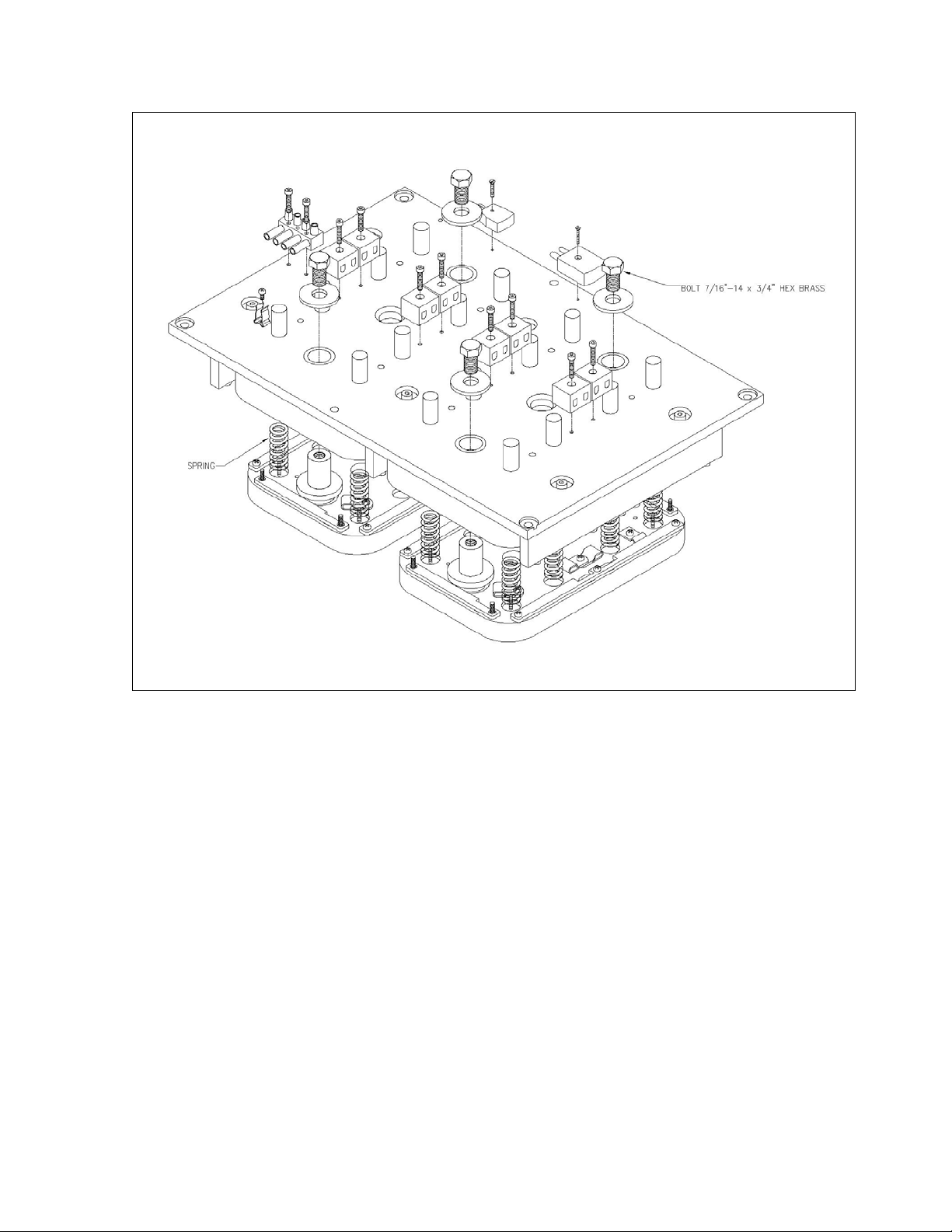

-> Locate where the springs are located. (See Picture 4.1) . Each tooling has it’s

particular configuration, drawing in this manual are only there for example.

Unscrew the bolts (7/16"-14 or ¼”-20) that hold the defective heating plate.

-> Locate the defect heating element with a multimeter (resistivity = 0) than unplug

the heating element.

-> Remove the defect element and replace it by a new one, use special ceramic putty

and high temp red silicon to set the element on the heating plate as was used by

Sipromac.

Some tooling does not require ceramic putty.

-> Reassemble the heating plate.

Page 23

4-3

4.3. Blade replacem ent

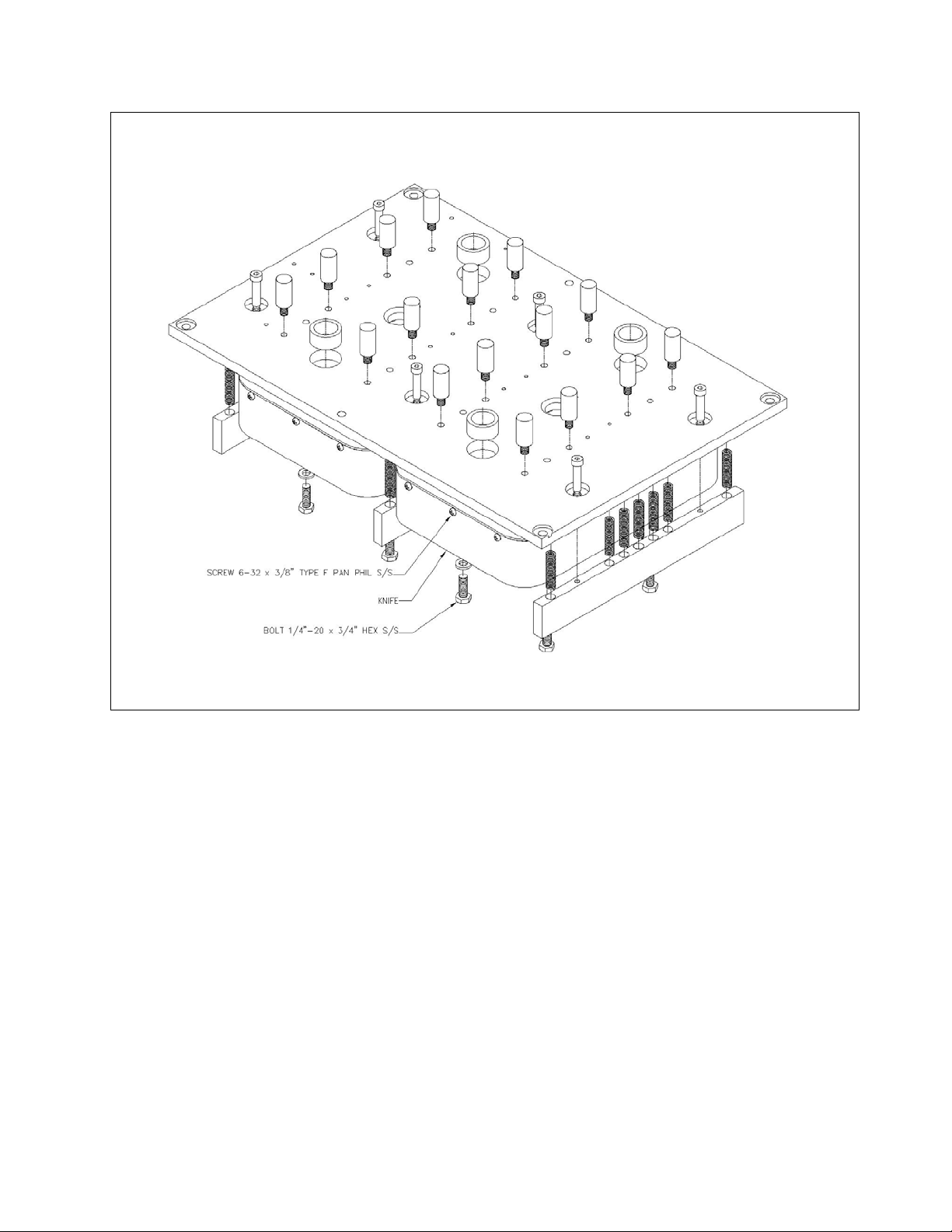

-> Take apart the heating plate (see section 4.2).

-> Unscrew bolts (1/4"-20 x 3/4") that hold the lower tool plate and take it apart. (see

Picture 4.2)

-> Unscrew screws (6-32 x 3/8") that hold the knife and change the knife.

-> Reassemble the lower tool plate.

4.1 - Heating element replacement

Page 24

4-4

Picture 4.2 - Blade replacement

Page 25

8-1

8. Tooling insertion check list

- Upper tooling insertion

- Film insertion and adjustment

- Mechanical indexer change

- Load appropriate program

Page 26

9-1

9. TS-30 Technical data

9.1. Power consuption

Electric spec.: 208-220V / 3 ph / 60Hz

Vacuum pump BUSCH 40 m3/h, 208-220V / 3 ph / 60Hz

BUSCH 63 m3/h, 208-220V / 3 ph / 60Hz

Power consumption:

Electricity (208-220V / 3 ph / 60Hz) to be confirmed

:

TS-30 without Vacuum pump : approx. 4.6 kW

With vacuum pump BUSH 40 m3/h: approx. 6.1 kW

With vacuum pump BUSH 63 m3/h: approx. 6.8 kW

Disconnect switch require and not supply

Pressurized air:

1/4`` FNPT

Consumption: 1.5 CFM @ 100 PSI

Gaz:

1/2`` FNPT

Minimum recommended supply flow capacity: 45 SCFM

Page 27

9-2

Page 28

19

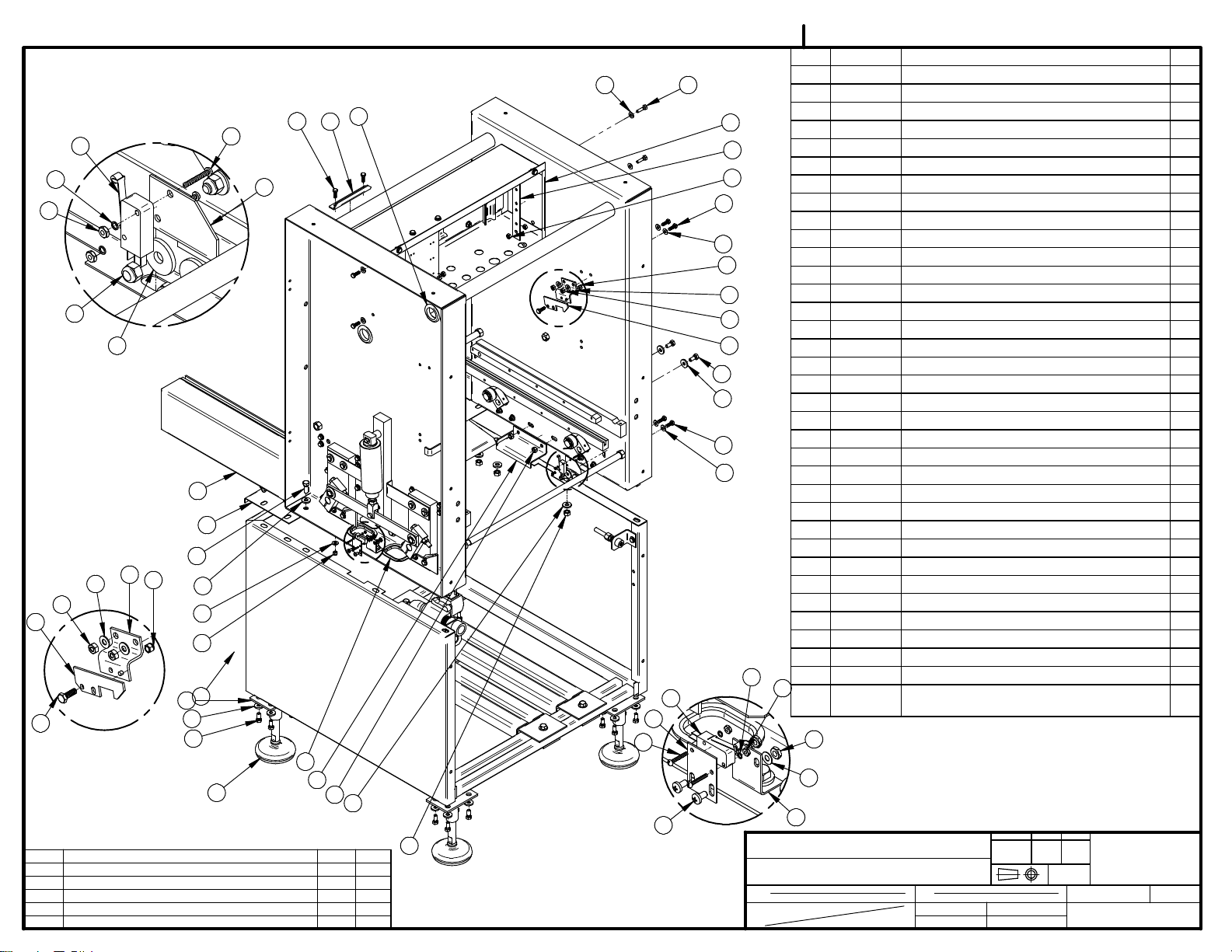

MECHANICAL DRAWING

Page 29

Page 30

20

22

23

7

12

13

4

DETAIL C

J

H

G

F

E

LET.

DETAIL A

21

19

5

2

9

11

6

7

8

6

7

1

34

32

31

35

ADJUSTABLE FOOT ADDED

026-0692 ETAIT 003-0129

003-0129 ÉTAIT 026-0691

179-0022 ÉTAIT 179-0014 #17

REDESSINÉ

MODIFICATION

005B0646

ITEM PART # DESCRIPTION QT.

6

4

16

3

15

14

29

18

12

4

6

C

7

11

12

13

31

32

4

6

A

B

22

20

25

21

17

30

33

13-08-13

09-06-16

09-05-25

08-12-24

06-07-05

DATE

8

SBU

D.A

J.G.

J.G.

J.G.

INT.

10

.

DETAIL B

28

MACHINE

PART

ITEM

MAT.

1 004B1031 STRUCTURE ASSEMBLY 1

2 001-2131 STRUCTURE TOP 1

3 001-2181 FRONT CHAMBER STOPPER 1

4 051-0190 BOLT 1/4-20 x 3/4" HEX S/S 9

5 004A0501 CHAMBER LIFTING PRE-ASS'Y 1

6 051-0740 WASHER 1/4" FLAT S/S 14

7 051-0581 NUT 1/4"-20 NYLON LOCK S/S 5

8 051-0783 WASHER 3/8" FLAT THICK S/S 20

9 051-0360 BOLT 3/8"-16nc. X 1" S/S 10

10 051-0620 NUT 3/8"-16 NC S/S 10

11 004A0539 COVER LOCK ASSEMBLY 1

12 051-0580 NUT 1/4"-20 S/S 8

13 001A3203 COVER LOCK 1

14 005-0633 ELECTRICAL BOX ASSEMBLY 1

15 051-0210 BOLT ¼"-20nc. X 1" S/S 2

16 036-0260 GROMMET 1-5/16"IDx2"OD RUBBER 5

17 179-0022 PLASTIC EDGE TRIM 3/16'' OFF-WHITE 3

18 001A2170 SWITCH SUPPORT 1

19 051-0757 WASHER 1/4" FLAT THICK S/S 2

20 026-0692 COVER GUARD SWITCH 3

21 051-0086 SCREW 4-40 X 3/4" RND SLOT S/S 6

22 051-0715 WASHER #4 LOCK SS 6

23 051-0540 NUT #4-40 HEX S/S 6

24 001A3820 CHAMBER PINNED SWITCH SUPPORT 2

25 001A3819 CHAMBER PINNED SWITCH FIXATION 2

26 051-0730 WASHER #10 FLAT S/S 4

27 051-0571 NUT #10-24 S/S 4

28 051-0143 SCREW 10-24 x 3/8" PAN PHIL S/S 4

29 004A1711 CONTROLLER SUPPORT PRE-ASSY 1

30 004A0516 CAHMBER STOPPER PRE-ASS'Y 2

31 051-0300 BOLT 5/16"-18 x 3/4" S/S 20

32 051-0762 WASHER 5/16" THICK FLAT S/S 20

33 051-0600 NUT 5/16" -18 S/S 4

34 004A4078 FOOT BASE 4

23

35 003A0397 SWIVEL LEVELING MOUNT SS 3/4"-10 X

6-1/2" RE-WORKED

27

26

24

DEPT. TOL.

METRIC

TS-30

MACHINE ASSEMBLY REAR VIEW

CNC

DWG BY

APP. BY

J.G.

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

06-07-05

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005B0646

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

SIPROMAC

QTY.

4

1

Page 31

004B1031

ITEM PART # DESCRIPTION QT.

1 004A0497 STRUCTURE PRE-ASS'Y 1

2 004A1029 PUMP SUPPORT ASSEMBLY 2

3 051-0780 WASHER 3/8" FLAT S/S 4

4 051-0385 BOLT 3/8"-16nc. X 1 3/4" S/S 4

5 005-0088 PUMP SUPP. FIX. PLATE ASS'Y 4

6 004A0571 AIR INLET ASS'Y 1

7 051-0740 WASHER 1/4" FLAT S/S 6

8 051-0180 BOLT. HEX. 1/4"-20 NC. x 1/2" S/S 3

9 051-0580 NUT 1/4"-20 S/S 3

1

10 004B0572 GAS INLET ASS'Y 1

11 005A1324 WATER INLET / OUTLET ASS'Y 1

12 007A0147 RA-40 PUMP INSTALLATION 1

1

A

9

6

7

7

8

DETAIL A

11 SEE NOTEVOIR NOTE

4

3

2

5

10

NOTE:

-POUR OPTION "WATER COOLED" SEULEMENT.

-ONLY FOR WATER COOLED OPTION.

REDESSINÉ S.E. & AJOUTER OPT. WATER COOLED

B

LET.

MODIFICATION

11-12-15

DATE

J.G.

INT.

MACHINE

PART

ITEM

MAT.

TS-30

STRUCTURE ASSEMBLY

CNC

DWG BY

APP. BY

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-12-15

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004B1031

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

33

VOIR SK209 POUR CONNECTION.

SEE SK209 FOR CONNECTION.

22

47

48

46

38

50 SEE NOTEVOIR NOTE

21

20

16

49 SEE NOTEVOIR NOTE

VOIR005A0828 POUR CONNECTION (POMPE).

SEE 005A0828 FOR CONNECTION (PUMP).

REDESSINÉ S.E. / AJOUTER OPT. WATER COOLED

J

LET.

MODIFICATION

32

25

26

005B0649

ITEM PART # DESCRIPTION QT.

42 051-0374 BOLT 3/8"-16nc. X 1¼" CAP SKT S/S 2

43 101-0660 STREET ELBOW 90 X 1/4`` NPT BRASS 1

44 114-2020 FILTER / DRYER ¼"mnpt. X 1/4"t.p. COMP. 1

45 101-0036 STRAIGHT ¼"mnpt. X 3/8"t.p. COMP. 1

46 003A0163 ABS BOX DRILLED 1

47 036-0420 PRESSE-ÉTOUPE CD21 1

30

31

29

37

36

48 051-0097 SCREW 6-32 x 3/8" TYPE F PAN PHIL S/S 4

49 101-0170 ELBOW 90° 1/4MNPTx1/4"HOSE 2

50 101-0035 STRAIGHT 1/4"mnpt. X 1/4"t.p. COMP. 2

27

28

24

23

VOIR SK210 POUR CONNECTION.

SEE SK210 FOR CONNECTION.

VOIR005A0828 POUR CONNECTION (POMPE).

SEE 005A0828 FOR CONNECTION (PUMP).

19

17

43

34

1

12

8

6

44

15

13

4

11

9 10

14

45

35

2

40

39

11-12-12

DATE

J.G.

INT.

18

41

42

NOTE:

-OPTION REFROIDIT À L'EAU SEULEMENT.

SI PAS D'OPTION REMPLACER ITEM 50 PAR ITEM 35.

-WATER COOLED OPTION ONLY.

IF NO OPTION REPLACE ITEM 50 BY ITEM 35.

3

MACHINE

PART

ITEM

MAT.

ITEM PART # DESCRIPTION QT.

1 004A0491 COVER PRE-ASSEMBLY 1

2 101-0670 ELBOW STREET 90º 1/2" NPT. BR. 3

3 100-0340 NIPPLE1/2"NPT. X 6" SS 1

4 102-0885 FEMALE COUPLER 3/4" X 1/2"NPTF HOSE

YELLOW

5 102-0885 MALE ADAPTER 3/4" X 1/2" FNPT YELLOW 1

6 101-0218 STRAIGHT ½"mnpt. X ½" HOSE BARB 2

7 104-0104 HOSE 1/2"ID x 3/4"OD PVC BRAIDED 1

8 105-0030 SCREW CLAMPS 3/8" - 7/8" SS/ZC 2

9 101-0390 NIPPLE ½"npt. X 3" BRASS 1

10 101-0620 ELBOW 90° 1/2" FNPT BRASS 1

11 102-0890 MALE ADPATER 3/4" X 1/2" MNPT YELLOW 1

12 104-0105 HOSE 1/2"ID VACUUM POLYWIRE 1

13 004-0762 BUSHING PUSHER PRE-ASS'Y 2

14 051-0162 SCREW 10-24nc. X 5/8" SKT S/S 8

15 077-0200 SPRING C1937-207-3500S COMP. 2

16 002-0684 COVER PLATE PUSHER 1

17 051-0380 BOLT 3/8"-16 x 1-1/2" S/S 8

18 002B1129 COVER PLATE PUSHER ROD 2

19 114-4100 BELLOWS Y1-1B8-562 3/4"npt. 1

20 076-0043 O RING 3/8"Ø id X 5/8"Ø od X 1/8" 4

21 002A1403 BELLOWS STUD 4

22 004A0573 BELLOWS SUPPORT PRE-ASSY 1

7

23 051-0372 BOLT 3/8"-16 x 1-1/4" S/S 4

24 051-0350 BOLT 3/8"-16 NC x 3/4" S/S 2

8

25 101-0938 RED. BUSH, 3/4"mnpt. X 3/8"fnpt. BRASS 1

26 101-0358 HEX. NIPPLE 3/8"NPT BRASS 1

6

27 114-1040 QUIK EXAUST 3/8"npt. 1

28 114-2008 SILENCIEUX 3/8" NPT 1

5

29 101-0910 RED BUSHING 3/8MNPTx1/4FNPT BR 1

30 101-0310 CLOSE NIPPLE 1/4" NPT BRASS 1

4

31 106-0071 VALVE 3WAY 24V 1/4"NPT(G186) 1

32 101-0058 ELBOW 90° ¼"mnpt. X 3/8"T.P. COMP. 1

33 104-0060 TUBE 3/8"OD x 1/4"ID POLYETHYL. 2

34 101-0920 RED BUSHING 1/2MNPTx1/4FNPT BR 2

2

35 101-1030 HEX. PLUG 1/4" NPT BR 1

36 101-0930 RED. BUSHING ½"mnpt. X 3/8"fnpt. BRASS 1

37 036-0327 WIRE CONNECTOR 3/8"npt. 4 HOLES 1

38 036-0326 WIRE CONNECTOR ½"npt. 4 HOLES 1

39 002-0604 COVER PIVOT PIN 2

40 008-0511 COVER SEAL 1

41 004-0660 COVER PLATE ASS'Y 1

DEPT. TOL.

METRIC

TS-30

COVER ASSEMBLY

CNC

DWG BY

APP. BY

J.G.

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

11-12-12

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005B0649

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(I)

QTY.

2

1

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

004-0762

ITEM PART # DESCRIPTION QT.

1 002-0670 BUSHING PUSHER 1

2

1

2 076-1320 SEAL CUP 1 1/8" X 3/4" X 3/16" 3

3 076-0140 O-RING 1¼" X 1 3/8" X 1/16" 1

4 081-0104 GREASE FITTING 90° x ¼"-28nf. S/S 1

D

C

B

LET.

ADDED TS-70-3S

INVERSER #3 LE PLUS BAS ML

REDESSINER S.E.

MODIFICATION

4

11-02-15

11-02-15

02-04-08

DATE

D.A.

D.A.

D.G.

INT.

3

MACHINE

TS-30, TS-70 & TS-70-3S

PART

BUSHING PUSHER PRE-ASS'Y

ITEM

MAT.

CNC

DWG BY

APP. BY

DENIS

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

02-04-08

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004-0762

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

2

Page 48

Page 49

LAISSER DÉPASSER LE "SET SCREW" DE 13mm DE LA COVER PLATE

3

2

004-0660

ITEM PART # DESCRIPTION QT.

1 0020658 COVER PLATE 1

2 0510217 SET SCREW ¼"20nc. X 1" S/S 4

3 0020587 TOOL PLATE SPACER 4

REDESSINÉ S.E. & VUE 002-0658 & NOTE

C

LET.

MODIFICATION

02-05-15

DATE

J.G.

INT.

MACHINE

PART

ITEM

MAT.

TS-70 & TS-30

COVER PLATE ASS'Y

CNC

DWG BY

APP. BY

DENIS

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

02-05-15

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004-0660

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 50

Page 51

Page 52

1

VOIR NOTE

SEE NOTE

VOIR NOTE

SEE NOTE

NOTE:

-ENLEVER ITEMS 13 @ 19 DE GAUCHE POUR OPTION "NO REWINDER".

-REMOVE LEFT ITEMS 13 @ 19 FOR OPTION NO REWINDER.

5

19

3

2

004A0537

ITEM PART # DESCRIPTION QT.

1 001A2139 FILM SUPPORT 2

2 051-0780 WASHER 3/8" FLAT S/S 8

3 051-0350 BOLT 3/8"-16 NC x 3/4" S/S 4

4 051-0620 NUT 3/8"-16 NC S/S 10

5 002A1159 FILM SUPPORT REINF. 1

6 051-0190 BOLT 1/4-20 x 3/4" HEX S/S 2

7 008-0501 FILM SUPPORT ROLLER 3

8 002-0569 FILM POSITIONER 2

9 051-0220 SCREW ¼"-20nc x 1" SKT. CAP S/S 2

10 057-0004 THMB SCREW KNOB 1/4" 2

11 075-2000 NYLON BEARING 7/8" W/ S/S BALLS 6

12 003-0092 ROLLER AXLE 6

13 004-0498 FILM SUPPORT BREAK HOLDER PRE-ASS'Y 2

14 051-0185 SCREW 1/4-20x 1/2"PAN PHIL S/S 4

15 051-0580 NUT 1/4"-20 S/S 4

16 002A0605 FILM SUPPORT BREAK 2

17 077-0095 SPRING C 0360-059-1250 S/S 2

18 051-0581 NUT 1/4"-20 NYLON LOCK S/S 2

19 004A3824 BREAK ADJ. SCREW 2

10

CHANGER QTÉE ITEM 13 @ 19 SELON OPTION

F

MODIF. #A-0446 077-0095 ÉTAIT 077-0080

E

D

LET.

REDESSINÉ

MODIFICATION

6

2

4

14

MACHINE

12

PART

TS-30

FILM SUPPORT ASSEMBLY

ITEM

MAT.

CNC

DWG BY

APP. BY

J.G.

J.G.

J.G.

INT.

16

17

15

11

2

3

4

13

18

7

89

11-12-14

09-08-24

07-05-07

DATE

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

07-05-07

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A0537

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

28

19

18

005-0629

36

5

36

5

13

14

37

9

11

10

DETAIL A

11

12

ITEM PART # DESCRIPTION QT.

23 004-0709 REWINDER HOUSING PRE-ASS'Y 1

24 051-0740 WASHER 1/4" FLAT S/S 12

25 051-0255 BOLT 1/4-20 x 1-3/4" HEX SS 4

26 051-0580 NUT 1/4"-20 S/S 8

27 002-0671 FILM ROLLER 1

28 004-0669 FILM HOLDER PRE-ASS'Y 1

29 001A2577 FILM HOLDER RETAINER 1

30 051-0097 SCREW 6-32 x 3/8" TYPE F PAN PHIL S/S 2

31 008-0582 GEARBOX / SHAFT KEY 1

32 004A1226 REWINDER GEARBOX ASSEMBLY 1

33 051-0189 BOLT 1/4-20 x 5/8" HEX S/S 4

34 051-0757 WASHER 1/4" FLAT THICK S/S 1

35 051-0210 BOLT ¼"-20nc. X 1" S/S 1

36 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 4

37 008-0522 TENSION ROD 1

38 001A2223 GEARBOX ARM 1

39 001A2760 GUIDE ROLLER EXTENSION 2

40 051-0360 BOLT 3/8"-16nc. X 1" S/S 2

27

30

29

25

23

24

21

26

33

2424

ITEM PART # DESCRIPTION QT.

1 004A0670 ROLLER SUPPORT PRE-ASS'Y 1

2 002-0673 REWINDER HINGE 1

3 002-0677 HINGE SHAFT 1

4 056-0331 EXT. RETAINING RING 1/2" S/S 2

5 051-0780 WASHER 3/8" FLAT S/S 16

6 051-0400 BOLT 3/8"-16 NC X 2 1/4" S/S 2

7 051-0620 NUT 3/8"-16 NC S/S 12

8 008A0526 REAR FILM GUIDE ROLLER 1

9 075-2000 NYLON BEARING 7/8" W/ S/S BALLS 2

10 051-0621 HALF-NUT 3/8"-16 SS 2

11 051-0783 WASHER 3/8" FLAT THICK S/S 10

12 003-0092 ROLLER AXLE 2

13 002-0858 REWINDER CONE 2

14 051-0178 SCREW 1/4"-20 x 5/16" SKT SET S/S 2

15 001-2222 ADJUSTABLE LOCK PLATE 1

16 051-0350 BOLT 3/8"-16 NC x 3/4" S/S 6

17 002-0672 ADJUSTABLE LOCK 1

18 051-0196 BOLT 1/4"-20 x 3/4" CAP HEX SKT.S/S 1

19 057-0004 THMB SCREW KNOB 1/4" 1

20 001-2228 ROLLER PLATE SUPPORT 1

38

21 002-0676 ROLLER PLATE 1

22 051-0410 BOLT 3/8"-nc. X 2.75" S/S 4

31

26

7 VOIR NOTE

39 VOIR NOTE

17

7

11

15

11

16

NOTE:

-INSTALLER ITEM #39 AU BESOIN

SELON TOOLING ET LE SENSE

AVANT/ ARRIÈRE AU BESOIN.

#13 002-0858 PLUS GROS EN DIAMÈTRE

J

H

LET.

REDESSINÉ

MODIFICATION

40

7

5

2

6

35

09-01-14

07-05-07

DATE

J.G.

J.G.

INT.

34

20

MACHINE

A

3

1

4

8

37

13

5

16 VOIR NOTE

39 VOIR NOTE36

12

11

PART

ITEM

MAT.

22

5

TS-30

REWINDER ASSEMBLY

32

-OPTION REWINDER-

DEPT. TOL.

METRIC

USINAGE

± 0.1

TOLERIE

±

0.5

±

0.

07-05-07

5

CNC

DWG BY

APP. BY

J.G.

SOUDAGE

DATE

DATE

INCH

± 0.004"

SIPROMAC

±

0.020"

±

0.020"

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

N.T.S.

DEPT.

M-I

NO.

005-0629

QTY.

1

Page 60

010-0041

ITEM PART # DESCRIPTION QT.

1 001-2254 AIR SWITCH SUPPORT 1

2 051-0540 NUT #4-40 HEX S/S 1

3 051-0713 WASHER #4 FLAT S/S 1

4 051-0086 SCREW 4-40 X 3/4" RND SLOT S/S 1

5 004-0830 FILM GUIDE PRE-ASSEMBLY 1

6 077-0100 SPRING C 0390-047-1000 S COMP. 1

7 051-0261 SCREW ¼"-20nc X 2" CAP HEX SKT S/S 1

8 057-0004 THMB SCREW KNOB 1/4" 1

5

6

7

8

2

3

1 UTILISER LES BOULONS EXISTANTS POUR INSTALLER / USE EXISTING BOLTS TO INSTALL.

REDESSINÉ S.E. 026-0691 ÉTAIT 026-0690

A

LET.

MODIFICATION

4

0260691

LIQUID TIGHT LIMIT SWITCH

11-12-12

J.G.

DATE

INT.

-REWINDER OPTION -

MACHINE

TS-30

PART

REWINDER SWITCH INST.

ITEM

MAT.

CNC

DWG BY

APP. BY

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

11-12-15

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

010-0041

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

I

QTY.

1

Page 61

Page 62

Page 63

Page 64

1251030 (BUSCH PUMP KB40)

6

5

1060030 (VALVE 2 WAY 24V 3/4"NPT (G95) 60Hz)

IN

005A0828

ITEM PART # DESCRIPTION QT.

1 103-0557 RED BUSHING 1 1/4"NPT X 3/4"NPT ZC 1

2 103-0237 CLOSE NIPPLE 3/4" NPT 3

3 103-0467 T 3/4" NPT ZINC 2

4 103-0527 RED.BUSH.3/4"NPTx1/4"NPT ZINC 1

5 101-0170 ELBOW 90° 1/4MNPTx1/4"HOSE 1

6 059-0015 RUBBER TIP 15/64"SHAFT 1

7 103-0537 RED. BUSH. 3/4"mnpt. X ½"fnpt. ZINC 2

8 103-0232 CLOSE-NIPPLE 1/2" ZINC 2

9 103-0462 T 1/2" NPT ZINC 1

10 103-0077 ELBOW STREET 1/2" NPT ZC 1

11 101-0218 STRAIGHT ½"mnpt. X ½" HOSE BARB 2

12 105-0030 SCREW CLAMPS 3/8" - 7/8" SS/ZC 2

VOIR 005B0649 POUR CONNECTION (CLOCHE)

SEE 005B0649 FOR CONNECTION (COVER)

LET.

1

VOIR 005B0643 POUR CONNECTION (CUVE)

SEE 005B0643 FOR CONNECTION (CHAMBER)

MODIFICATION

2

DATE

3

2

4

7

8

9

1060020 (VALVE 2 WAY 24V 1/2"NPT (G94) 60Hz)

12

11

10

NOTE:

- "BUSH " PUMP B-40 220V/ 1Ph/ 60Hz =125-0034

- "BUSH " PUMP KB-40 240V-460V/ 3Ph / 60Hz =125-1030

-OPTION PAS VALVE DE SECURITE -

INT.

MACHINE

PART

TS-30

PUMP INSTALLATION KB-40

ITEM

MAT.

CNC

DWG BY

APP. BY

Y.C.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

03-04-07

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A0828

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 65

004A4177

ITEM PART # DESCRIPTION QT.

1 004A3828 VALVE SUPPORT 1

2 100-0065 STREET ELBOW 1/4" NPT SS 1

3 100-0225 CLOSE NIPPLE 1/4" NPT SS 1

4 102-0390 MALE CONN. ¼"mnpt. X ¼"T. QUICK 2

5 106-0010 VALVE 2WAY 24V 1/4"NPT(G22) 60Hz 1

4

1

7

2

3

6 107-0022 BALL VALVE 1/4'' NPT SS 1

7 114-0144 PRESSURE REGUL.0-25PSI 1/4'' NPT

W/GAUGE

5

1

LET. MODIFICATION

DATE

INT.

-WATER COOLED OPTION -

6

MACHINE

TS-30

PART

WATER VALVE ASSY

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-02-06

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A4177

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 66

20

ELECTRICAL DRAWING

Page 67

FULL FILENAME H:\DESSIN\DEPTDESS\PRODUCTS\510-SIPROSEAL\TS-30\ELECTRIQUE-P NE UMATIQUE\006-2730 TS-30 POWER 1 PAGE.VSD

L2 L3

Gnd

L1

006-2730

Tested at: V / 3 Ph / 60 Hz

PAGE

1 de 1

AMPERAGE

name

plate

mesured

F 1

F 2

Gnd

Body

volt.

circuit

VACUUM PUMP

3

M /h

Model:

Sn :

40 or 63

W17

REWINDER (OPTION)

MOTOR

Model:

Sn :

GEARBOX :

Model :

Sn :

Ratio :

3 Ph / 60 Hz

month

year

06 05 19

PP XXPP

day

drawconcept

app

TOOLING

TOTAL :

block

006-2730

Kw :

SIPROMAC

St-Germain de Grantham

QUEBEC ,CANADA

PAGE

AA

1 de 1

C1 O/L1

C2

red

wht

blk

wht

red

blk

C6

F3

F3

C5

C5

F4

F4

control

circuit

C6

W001

M1

MOTOR REWINDER JUNCTION BOX

manual

scrolling

PBX

impulse

W002

W005

red

blk

wht

category

system

usual

fonctions

options

W003

L1

L2

JB1

CPF1

TRAY SEALERS

Z6

GND

COM

N

Z5

model

POWER

red

gre

brake system

D1

M2

solid state

motor terminals

coupling

TOOLING PLATE #:

TS 30

+

-

wht

blk

Page 68

FULL FILENAME H:\PRODUITS\510-SIPROSEAL\TS-30\ELECTRIQUE-PNEUMATIQUE\006-2737 TS-30 COMMAND 4 PAGE.VSD

MC40

Prog. version :

in out

TS-32e or f

006-2737

PAGE

1 de 4

10

JP4

8

7

9

10

JP3/1

gre / blk

org / blk

red / blk

wht / blk

blk

C1

C3

C11

C12

A1

34

25

25

13

F8

4A

24 Volts

F9

2A

6

9 Volts

233 (blu)

233 ( blu)

TR1

24

From page 1 de 1

9

50 / 60Hz

115VA

E. STOP

4

JP4

9

blu / red

yel

ES1

wht

wht

C10

A3

W8

JP4

34

35 (yel)

223 (blu)

Photocell

(OPTION)

S1

blk

wht

A9

229

A4

-

+

25

R2

OUT AUTOMATON

COMMON INTERN

PC BOARD

W 7

category

system

usual

fonctions

options

TRAY SEALER

model

TS 30

POWER SUPPLY CONTROL CIRCUIT

W16

red

volt.

circuit

A2

ALL

month

year

day

05 09 29

drawconcept

app

PP DLPP

223

block

006-2737

SIPROMAC

St-Germain de Grantham

QUEBEC ,CANADA

PAGE

1 de 4

Page 69

FULL FILENAME H:\PRODUITS\510-SIPROSEAL\TS-30\ELECTRIQUE-PNEUMATIQUE\006-2737 TS-30 COMMAND 4 PAGE.VSD

MC40

in out

24 VAC

W 7

W 8

PS1

AC

006-2737

PAGE

2 de 4

24 VAC

-24 VDC

24 VAC

Before E.STOP

POWER

SUPPLY

2

red

34

3

blk

15 VDC

251

251

RES1

252

249 ohms

250

252

250

254

255

RTD

TT1

TEMP.

SENSOR

Z6

JP6

251

B

RTD

TT2

OL1

96 95

35

TEMP.

SENSOR

Z5

VACUUM

PUMP

HEATING

PLATE

Z6

JP5

red

3

blk

2

Relay

13

8

JP3/2

7

or / red

wht / red

D10

D2

251

RES2

253

249 ohms

TO CPF2

TOOLING

# : ___

95

203

253

L1

N

L2

CPM2

male

W004

256

257

C1

C1

C6

JP3/2

PC

BOARD

11

common intern

5

JP3/2

automaton

blu / wht

D1

202

C5

HEATING

PLATE

Z5

C1

blk

13 14

W20

W 7 cont'd

W 8 cont'd

category

system

usual

fonctions

options

TRAY SEALER

HEATER CONTROL

model

TS 30

volt.

circuit

2 w

V8

year

11 03 23

PP DLPP

wht

ALL

month

drawconcept

day

app

SIPROMAC

block

St-Germain de Grantham

QUEBEC ,CANADA

006-2737

Option

Water

Cool

PAGE

2 de 4

Page 70

FULL FILENAME H:\PRODUITS\510-SIPROSEAL\TS-30\ELECTRIQUE-PNEUMATIQUE\006-2737 TS-30 COMMAND 4 PAGE.VSD

006-2737

PAGE

3 de 4

MC40

version :

TS-32 e

in out

3

JP4

2

JP4

6

JP4

34

5

JP4

PC BOARD

or f

brn

B1

encoder switch

LM1

blk

wht

red

A5

223

-24 VDC

SCROLLING

AUTOMATIC

CONTROL

W20

(OPTION)

rew. motor

pur

A10

224

C2

223

21 22

manual scrolling

(Rewinder option)

impulse

W17

org

B4

red

gre

PBX

TG

motor rewinder

A11

226

W 7 cont'd

W 8 cont'd

COMMON INTERN OUT AUTOMATON

13

14

C2

227

A12

wht

blk

junction box

solid state

brake system

A6

223

25

REWINDER

CONTROL

(OPTION)

rew. start switch

A7

223

blu

B2

W19

blk

LM2

wht

red

fault rewinder

7

8

1

JP3/2

2

JP3/2

blu / blk

blk / wht

MCR

R4

9

R3

240 241 242

5

1

category

system

usual

fonctions

options

D3

D12

222

209

photocellfault rew rewinder

R2

2

109

53

TRAY SEALER

REWINDER CONTROL

C2

54

model

TS 30

209

volt.

circuit

R3

rew.motor

C2

ALL

month

year

05 09 27

PP DLPP

day

drawconcept

app

SIPROMAC

block

St-Germain de Grantham

QUEBEC ,CANADA

006-2737

PAGE

3 de 4

Page 71

FULL FILENAME H:\PRODUITS\510-SIPROSEAL\TS-30\ELECTRIQUE-PNEUMATIQUE\006-2737 TS-30 COMMAND 4 PAGE.VSD

MC40

in out

version :

1

JP4

TS-32 e

or f

gry

B3

W8

W7 cont'd

6

6

blu

D5

JP3/1

chamber position switch

blk

W15

LM3

wht

red

006-2737

A8

C5

223

35 (yel)

PAGE

4 de 4

CHAMBER

POSITION

3

3

red

JP3/1

12

6

blk / red

JP3/2

1

1

blk

JP3/1

2

2

wht

JP3/1

9

3

red / wht

JP3/2

4

4

gre

JP3/1

5

5

org

JP3/1

PC

BOARD

On the LM3 , LM10 & LM11 limit switches, you must change the location

Note:

of the arm of the switch so the roller is outside of the switch. The axe of

the arm shall be on the farthest point, on the opposite side of the tabs.

D6

D11

D7

D8

D9

D4

LM10 LM11

blk

category

system

functions

options

TRAY SEALER

usual

blk

V2

4 w

W13

whtblk wht

W5

W6

blk

V7

2 w

W 11

model

PUMP & E.V. CONTROL

wht

W 10

wht

blk

C2

TS 30

W 12

2 w

V5

blk

W 9

W18

blk

blk

wht

2 w

3 w

3 w

volt.

circuit

V3

V6

V1

C6

C7

wht

C8

C9

wht

wht

C4

ALL

month

year

11 03 23

drawconcept

PP DLPP

day

app

SIPROMAC

block

St-Germain de Grantham

QUEBEC ,CANADA

006-2737

CAM

25

CYLINDER

VACUUM

VALVE

STANDARD

GAS CHAMBER

BELLOW

FILM CUT

ATMOSPHERE

PAGE

4 de 4

Page 72

# PART PART MACHINE

MACHINE

REF. QTY

SIPRO DESCRIPTION APPLICATION VOLTAGE

034-0755 FUSE HOLDER 30A 1 PÔLE PUMP 208V/3PH/60HZ TS-30 F1 3

034-0530 FUSE 20A/250V TD PUMP 208V/3PH/60HZ TS-30 F1 3

025-0025

MOTOR CONTACTOR 3HP IN 208V/3PH

PUMP 208V/3PH/60HZ TS-30 C1 1

025-0170

THERMAL OVERLOAD 7 TO 10A

PUMP 208V/3PH/60HZ TS-30 O/L1 1

030-0140 CAB TIRE PUMP 208V/3PH/60HZ TS-30 W001 2M.

125-0030

BUSCH RA-0040 208V/3/60 3HP CSA 8.4A

PUMP 208V/3PH/60HZ TS-30 M1 1

125-0040 BUSCH RA0063 230-460V/3PH/60HZ PUMP 208V/3PH/60HZ TS-30 M1 1

034-0755 FUSE HOLDER 30A 1 PÔLE REWINDER 208V/3PH/60HZ TS-30 F2 3

034-0500 FUSE 15A/250V TD REWINDER 208V/3PH/60HZ TS-30 F2 3

025-0010 MOTOR CONTACTOR REWINDER 208V/3PH/60HZ TS-30 C2 1

030-0250 CAB TIRE REWINDER 208V/3PH/60HZ TS-30 W002 2M.

037-1232

GEAR/MT: VF 30 30:1 230/460 3PH 60HZ BRAKE

REWINDER 208V/3PH/60HZ TS-30 M2 1

026-0690 LIQUID TIGHT LIMIT SWITCH

ALL TS-30 LM2 1

026-1010 TOGGLE SWITCH ETANCHE REWINDER JOG ALL TS-30 PBX 1

025-0600 4PDT RELAY 24VAC (55.34-24VAC) REW.FAULT ALL TS-30 R3 1

025-0610 4PDT RELAY SOCKET 24VAC REW.FAULT ALL TS-30 R3 1

025-0611 RELAY SOCKET RETAINING CLIP(FINDER) REW.FAULT ALL TS-30 R3 1

034-0755 FUSE HOLDER 30A 1 PÔLE HEATING 208V/3PH/60HZ TS-30 F3 2

034-0540 FUSE 20A/600V FA HEATING 208V/3PH/60HZ TS-30 F3 2

025-0010 MOTOR CONTACTOR HEATING 208V/3PH/60HZ TS-30 C5+C6 2

030-0140 CAB TIRE HEATING 208V/3PH/60HZ TS-30 W003 2M.

003A0163 ABS BOX DRILLED HEATING ALL TS-30 JB1 1

033-1000 POWER SUPPLY 24V 1 AMP. TEMP. READING ALL TS-30 PS1 1

031-0009 TEMPERATURE TRANSMITER TEMP. READING ALL TS-30 TT1+TT2 2

033-0309 RESISTOR 249 OHMS,1/4 W,1%,METAL FILM TEMP. READING ALL TS-30 RES1+RES2 2

031-0008 RTD MINIATURE SENSOR TEMP. READING ALL TS-30 2

034-0740 FUSE HOLDER M4/8SF TRANSFO ALL TS-30 F4-F8-F9 4

034-0205 FUSE 1A/250V TD TRANSFO 208V/3PH/60HZ TS-30 F4 2

029-0010 TRANSFO 115VA 575-400-230-208-190/24-9 TRANSFO 208V/3PH/60HZ TS-30 TR1 1

034-0240 FUSE 4A/250V TD 24VAC ALL TS-30 F8 1

034-0210 FUSE 2A/250V TD 9VAC ALL TS-30 F9 1

033-0015 MEMBRANE MC-40 SIPROMAC CONTROL ALL TS-30 1

033-0042 MICROPROCESSOR MC-40 TS-30 CONTROL ALL TS-30 1

026-0485 EMERGENCY STOP LEGEND E-STOP ALL TS-30 1

026-0150 EMERGENCY BUTTON,(PUSH-PULL) E-STOP ALL TS-30 1

026-0025 1 N.C CONTACT WITH BASE E-STOP ALL TS-30 1

026-0030 1 N.C. CONTACT BLOCK E-STOP ALL TS-30 1

026-0260 BLANKING PLUG ALL TS-30 1

026-0690 LIQUID TIGHT LIMIT SWITCH REW. START ALL TS-30 LM2 1

026-0692 LIQUID TIGHT LIMIT SWITCH BELLOW SECURITY ALL TS-30 LM10+LM11 2

026-0692 LIQUID TIGHT LIMIT SWITCH CHAMB. POS.+ENCODER ALL TS-30 LM2+LM3 2

Page 73

# PART PART MACHINE

MACHINE

REF. QTY

SIPRO DESCRIPTION APPLICATION VOLTAGE

027-0705 MALE COMPACT PLUG CONN.18/4 TOOLING ALL TS-30 CPM1+CPM2 2

027-0706 FEMALE COMPACT PLUG CONN.18/4 TOOLING ALL TS-30 CPF1+CPF2 2

114-0820 VALVE 4WAY 24VAC 1/8 NPT CAM ALL TS-30 V2 1

114-0850 DIN CONNECTOR CAM ALL TS-30 V2 1

106-0020 VALVE 2WAY 24V 1/2 NPT 60Hz VACUUM ALL TS-30 V3 1

106-0030 VALVE 2WAY 24V 3/4 NPT 60Hz GAS ALL TS-30 V5 1

106-0071 VALVE 3 WAY 24V 1/4 NPT (G186) BELLOW ALL TS-30 V6 1

106-0020 VALVE 2WAY 24V 1/2 NPT 60Hz ATMOSPHERE ALL TS-30 V7 1

106-0410 SCREW TERMINAL ADAPTER(ASCO) ALL ASCO VALVE ALL TS-30 V6 1

106-0420 JUNCTION BOX PLASTIC ALL ASCO VALVE ALL TS-30 B6 1

036-3020 SEALED DIN CONNECTOR (3M CABLE) ALL SMC VALVE ALL TS-30 V3, V5, V7 3

028-0140 BARETTE/BORNIER 12VIS 300V/20A. CONTROL ALL TS-30 A-B-C-D 4

Page 74

TS-30

OPERCULEUSE

Manuel du Propriétaire

MACHINE NUMBER:…………………

SIPROMAC

240 BOUL. INDUSTRIEL

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA J0C 1K0

(819) 395-5151

Page 75

OPERCULEUSE

MODÈLE TS-30

TABLE DES MATIÈRES

Section 1- Installation

1.1. Environnement

1.2. Nivelage

1.3. Installation de la Pompe à vide

1.4. Branchements

1.4.1. Branchements électrique

1.4.2. Branchement pneumatique

Section 2- Fonctionnement

2.1. Principe de fonctionnement

2.1.1. Description générale

2.1.2. Station de scellage

2.1.2.1. Chambre

2.1.2.2. Rembobineur de film

Page 76

2.2. Installation de l’outillage

2.2.1. Préparation de la chambre

2.2.1.1. Installation de la plaque matrice

2.2.1.2. Installation de l’outillage supérieur

2.2.2. Préparation

2.3. Installation du film

2.4. Paramétrage du contrôle

2.4.1. Essentiel

2.4.2. Menu Fonction

2.4.2.1. F1- Créer un programme

2.4.2.2. F2- Effacer un programme

2.4.2.3. F3- Option Rembobineur

2.4.2.4. F4- Saisie de Rembobinage

2.4.3. Menu Programme

2.4.3.1. Name

2.4.3.2. Vacuum

2.4.3.3. Vacuum plus

2.4.3.4. Gas plus

2.4.3.5. Seal time

2.4.3.6. Plate temp C

2.4.4. Séquence d’opération

2.4.4.1. Vacuum cycle

2.4.4.2. Gas cycle

2.4.4.3. Seal cycle

2.4.5. System monitor

Page 77

Section 3- Diagnostique des pannes

3.1. Défaillance pendant le cycle d’emballage

3.1.1. "VACUUM ERROR" message affiché sur l’écran

3.1.2. "GAS FLUSH ERROR" message affiché sur l’écran

3.1.3. "CHAMBER ATM ERROR" message affiché sur l’écran

3.1.4. "COVER DOWN ERROR" message affiché sur l’écran

3.1.5. "`HIGH LIMIT TEMP" message affiché sur l’écran

3.2. Vide insuffisant dans la chambre

3.3. Scellage défectueux

3.3.1. Scellage insuffisant

3.3.2. Manque de scellage

3.3.3. Scellage se décolle

3.3.4. Valve défectueuse

3.4. Panneau de contrôle défectueux

Section 4- Entretien

4.1. Entretien régulier

4.2. Changement des éléments chauffant

4.3. Changement des lames

Section 5- Dessins mécanique

Section 6- Dessins électrique

6.1. Assemblage du panneau de contrôle

6.2. Branchement des terminaux de contrôle

6.3. Détail du branchement de la boite électrique

6.4. Branchement de la carte de contrôle

6.5. Schéma de puissance

6.6. Schéma de contrôle

Page 78

6.7. Branchement du couvercle

6.8. Branchement de l’outillage

Section 7- Dessins pneumatique

Section 8- Liste de contrôle d’installation de l’outillage

Section 9- Données techniques TS-30

Page 79

1-1

Section 1- Installation

1.1. Environnement

La machine doit être positionnée pour assurer une accessibilité appropriée pour

l’entretien et l’opération. Choisir un endroit qui procure assez d’espace pour les

produits emballés et non-emballés.

1.2. Nivelage

Pour assurer un bon fonctionnement de la machine, le niveau doit être fait à

l’aide des pieds. Ne pas oublier de verrouiller les pieds avec la contre écrou une

fois le niveau fait. Si la machine est équipée de roulettes, activer les freins

lorsque celle-ci est en place.

1.3. Installation de la pompe à vide

Vérifier le niveau d’huile par le hublot sur la pompe. Au besoin, ajouter

seulement l’huile recommandée par le fabricant. Ne jamais dépasser le niveau

maximum d’huile.

1.4. Branchements

1.4.1. Branchements électrique

Page 80

1-2

Les branchements électriques doivent être fait conformément à la plaque

signalétique de la machine et au schéma électrique de la section 6.1 par du

personnel qualifié. S’assurer que l’entrée électrique corresponde au

voltage et ampérage requis pour la machine. S’assurer que la pompe

tourne dans le sens indiqué sur le bâti. Attention: la pompe ne doit pas

être activé plus de 3 à 4 secondes dans le sens contraire indiqué sur le

bâti ou la pompe risque d’être endommagée.

1.4.2. Branchement pneumatique

Utiliser un boyau ou tuyau d’un diamètre intérieur de ½’’minimum pour

l’alimentation d’air. Voir la section 9 pour les spécifications de la

machine. Voir la section 7 pour la localisation des composantes

pneumatique.

Page 81

2-1

2. Fonctionnement

2.1. Principe de fonctionnement

2.1.1. Principe de fonctionnement

La machine Operculeuse TS-30 de Sipromac a été conçue pour

l’emballage d’aliments frais, congelés ou preparés dans un contenant

propre, sécuritaire et attrayant. L’operculeuse MAP (emballage

atmosphere controllé) fourni un niveau controllé d’oxygène qui assure une

fraicheur pour une période prolongée.

La séquence de fonctionnement simple commence par le positionnement

de barquettes dans la chambre. L’opérateur referme ensuite le tiroir ce qui

active automatiquement le rembobineur qui positionne le film. Lorsque le

tiroir atteint sa position de fonctionnement, la chambre est soulevée contre

le couvercle, le vide est fait suivie par l’injection de gas neutre. Les

barquettes et le film sont alors poussés contre l’élément de scellage et la

lame qui coupe l’excédent de film. L’opérateur ouvre le tiroir et enlève les

barquettes et l’exédent de film (si la machine n’est pas équipée d’un

rembobineur).

2.1.2. Station de scellage

2.1.2.1. Chambre

La chamber est divisée en deux parties; la supérieur et l’inférieur.

Un joint d’étanchéité permet un vide dans la chamber lorsque les

deux parties sont réunies. La chambre inférieur est soulevée pour

joindre la chambre supérieur losque le cylindre est activé. Le vide

est fait dans la chambre puis un gaz de substitue est ajouté pour

combler le vide.

L’outillage est situé dans la chambre; la plaque matrice dans la

section inférieure, les lames et les éléments de scellage dans la

section supérieure. Les cylindres permettent la pression nécessaire

pour le scellage du film sur la barquette. Un certain nombre de

supports à resort maintiennent le film serré pendant la durée du

cycle.

2.1.2.2. Rembobineur de film

Un Moteur-frein actionne le rembobineur ce qui permet le

movement du film. Le mouvement du film est controlé par une

cellule photo-électrique qui peut lire l’impression sur le film ou par

une roue de la dimension appropriée à chaque barquette. Le cone

de serrage prévient le vaguement du film. Une vis d’ajustement

contrôle la pression pour une meuilleure tension dans le film.

Page 82

2-2

cover

+

-

+

-

Always respect initial wire way

+

-

red

wht

+

-

red

wht

gnd

tooling

red

wht

red

wht

82

82

82

79

79

79

80

80

80

80

80

80

cable ties black

( Tie wrap )

4''

# 057-0305

wire hi temp TEW / 2

AWG 16

# 030-0530

copper tubing

# 105-601

or 105-600

(according movement piece)

Always respect initial wire way

W 003

!

area parts in

movement

loop obligatory

for go & comes

movement

Z5

82 ( Z6)

80 ( Com)

79 ( Z5)

gnd

Z6

Z6

Z5

W 5 & 6

2.2. Installation de l’outillage

Procédure pour le changement d’outillage ou l’enlèvement pour

l’entretien:( Voir Section 8)- Liste de contrôle d’installation de l’outillage

pour s’assurer que toutes les étapes sont respectées.

2.2.1. Préparation de la chambre

Chaque outillage contient 2 sous-assemblages:

-la plaque matrice, localisé dans la chambre inférieure,

-l’outillage supérieur, localisé dans la chambre supérieure.

2.2.1.1. Installation de la plaque matrice

Retiré tout les boulons (4) à six pan creux à l’aide d’une clé

hexagonal ¼" inclus avec l’outillage. Retiré la plaque matrice de la

chambre.

Inversé ces étapes pour installer l’outillage. La plaque matrice est

conçue pour empêcher l’installation dans le mauvais sens.

Page 83

2-3

2.2.1.2. Installation de l’outillage supérieur

2.2.2. Préparation

Lors du changement d’outillage, assurez-vous que la roue d’encodeur du

rembobineur est de la bonne dimension.

2.3. Installation du film

Le film doit être installé suivant le trajet tel qu’indiqué dans la section 5.

Assurez-vous que la barre de rétention du film soit en position haute; au besoin

utilisez le bouton ‘’Manual Feed’’ pour le positionnement. Passé le film sur le

rouleau, descendre la barre de retention et activé le bouton ‘’Manual Feed’’ pour

une rotation. Les cones de rétention doivent êtres positionné pour permettrent

l’étirement du film et sur la bordure de la découpe. Deux roulettes permettent le

centrage des rouleaux avec la chambre. Une roulette ajustable et deux poignées

garde une tension constante sur le film meme lorsque celui-ci est Presque vide.

Lire attentivement la section 5 et suivre les instructions sur le sens de la colle. Le

changement de bobine sur le rembobineur ce fait è l’aide de l’outil plat spécial et

en tirant avec précaution sur la barrure, tourné pour enlever la tension sur le film

et enlever la bobine.

Retiré tout les boulons (4) à six pan creux à l’aide d’une clé

hexagonal 3/16".

Faire une rotation de l’outillage vers la droite.

Déconnecté les trois connecteurs.

Inversé ces étapes pour installer l’outillage. Assurez-vous que les

connecteurs soit à leurs places respectives. L’outillage supérieur est

conçu pour empêcher l’installation dans le mauvais sens. Installé le

film. (Voir section 2.3)

Page 84

2-4

2.4. Paramétrage du contrôle

2.4.1. Essentiel

Le paramétrage de la machine est fait à l’aide du clavier de l’automate

programmable MC. Il y a deux modes disponibles sur le MC-40:

paramétrage (Program Mode) et fonctionnement (Function Mode).

L’automate à une capacitée de 20 programmes différents. Le mode

paramétrage permet des changements dans le programme actuel, le mode

fonctionnement permet des changements qui s’appliquent au

fonctionnement de la machine ainsi qu’a toutes les programmes. La touche

“Power" pour allumer et éteindre la machine. Lorsque la machine est

allumée, le nom du dernier programme exécuté apparait à l’écran

Appuyé sur la touche "ESC" pour changer de menu.

Dans le menu ‘’function menu’’, appuyé sur la touche "SELECT" pour

sélectionner une function et appuyé sur la touche "ENTER" pour accéder et

modifier la sélection.

Dans le menu ’’program menu’’, appuyé sur la touche "SELECT" pour

sélectionner un programme et appuyé sur la touche "ENTER" pour accéder

et modifier la sélection.

Dans le sous-menu ’’program’’, appuyé sur la touche "ENTER" pour

passer au paramètre suivant; le clignotement des données à l’écran signifie

le mode d’aquisition de donnée. Le retour au menu principal est

automatique suivant la dernière aquisition de donnée.

Dans le sous-menu ’’program’’, appuyé sur la touche "ESC" pour revenir

au menu principal.

Le bouton d’Arrêt d’urgence sur le panneau avant arrête le cycle en cours.

Pour redémarrer, tirer le bouton d’arrêt d’urgence et appuyé sur n’importe

quel bouton pour enlever le message d’erreur.

Contacté votre distributeur pour connaitre le ‘’ Password’’.

Page 85

2-5

2.4.2. Function menu

SELECT Pxx+1 NO NAME

Pxx+2 NO NAMESELECT

SELECT Pxx+... NO NAME

SELECT

*you may select the

program that you

had created only.

To select a program created

ESC

F1 CREATE A PROGRAM

SELECT

F2 DELETE A PROGRAM

F3 REWIND OPTION

SELECT

ESC

Press enter to create

a program

1-acces this function with enter

2-choose the program with select

3-confirm delete with enter

choose with select

.rewind enable

.rewind desable

To create a program and rewind option

F4 REWIND INPUT

SELECT

choose with select

.encoder

.photocell

To modify a program created

ON/OFF

VACUUM:xx.x %

Pxx NO NAME

VACUUM PLUS:xx S

SEAL TIME: xx S

ENTER

Enter a value

Enter a value

The program name flash,

you may create a name

for Pxx.

Displayed if gas flush is

enable, see diagnostic

menu. Enter a value.

ENTER

ENTER

ENTER

ENTER

ENTER

GAZ PLUS: x.x S

2.4.2.1. F1- Create a program

Lors de la création d’un programme "create a program", le sous-

menu d’identification est atteint. L’identification initial "Pxx NO

NAME" apparait et tout les paramètres sont à zéro. Le numéro du

programme est donné automatiquement.

Utilisé le clavier pour nommer un programme ou entrer des

valeurs. Appuyé sur la touche le nombre de fois nécessaire pour

atteindre le character desiré. Appuyé sur la touche "ENTER" pour

accepter chaque charactère et une fois de plus pour accepter

l’ensemble. Appuyé su la touche "ESC" pour revenir en arrière et

effacer un ou plusieurs charactères.

Page 86

2-6

Exemple:

EXEMPLE 1 (9 charactères)

2, 2, ENTER -> E

8, 8, 8, ENTER -> X

1, ENTER -> A

5, ENTER -> M

6, ENTER -> P

4, 4, 4, ENTER -> L

2, 2, ENTER -> E

9, 9, 9, ENTER -> space

1, 1, 1, 1, ENTER -> 1

Appuyez sur ‘’ ENTER’’ pour valider.

Après avoir nommer le programme, les paramètres spécifiques à ce

programme peuvent être inscrits. Voir la section 2.4.3 pour la liste

des paramètres.

2.4.2.2. F2- Delete a program

Lors de la fonction "delete a program", le menu ‘’programs

menu’’ est atteint et le nombre du premier programme clignote.

Appuyé sur la touche "SELECT" pour sélectionner le programme et

ensuite appuyé sur la touche "ENTER" pour confirmer la

supression. Appuyé sur la touche "ESC" pour quitter la fonction,

l’écran cessera de clignoter.

2.4.2.3. F3 -Rewind Option

Cette fonction doit être validée si votre machine est équipée du

rembobineur automatique.

Page 87

2-7

2.4.2.4. F4- Rewind input

Exemple:

9, 0, 0 ou 9, 0, ‘’ENTER’’ ou 9, 0, 1 ou

9, 0, 2 ou 9, 0, 3 ou 9, 0, 4 -> 90.0 %

9, 7, 5 ou 9, 7, 6 ou 9, 7, 7

9, 7, 8 ou 9, 7, 9 -> 97.5 %

0, 0, 0 ou 0,’’ENTER’’ -> 0.0 %

Il est possible de changer l’entrée qui contrôle le rembobineur de

film, soit encodeur ou cellule photo-électrique, en appuyant sur la

touche “SELECT” suivie de la touche “ENTER”.

Lorsque la l’option encodeur est sélectionné, le film déroule

jusqu’à ce que la longueur soit atteint.

Lorsque l’option cellule photo-électrique est sélectionné, le film

déroule automatique à l’aide de repère (±10mm2) sur le film.

2.4.3. Program menu

En appuyant sur la touche "ESC" vous changez de menu; de ‘’Function

Mode’’ à ‘’Program Mode’’. Appuyé sur la touche ‘’SELECT’’ vous

pouvez voir les différents programmes. Il est également possible de

modifier les paramètres d’un programme en appuyant sur la touche

“ENTER” lorsque le nom du programme apparait à l’écran. Voici la liste

des paramètres d’un programme.

2.4.3.1. Name

L’identification du programme ce fait en utilisant le clavier

numérique (voir la section 2.4.2.1).

2.4.3.2. Vacuum (0 - 99.5%)

Représente le pourcentage de vide à atteindre dans la chamber

sous-vide, 99.5% est considéré un vide quasi-total. Pour atteindre

le meilleur rendement, utilisé le minimum de vide nécessaire pour

obtenir le résultat souhaité.

Pour inscrire le pourcentage de vide, utilisé le clavier numérique.

Le point décimal est automatique ajouté après les deux premier

chiffres. La validation est automatique lorsque toutes les caractères

sont inscrit (l’affichage se met à clignoter).

Le niveau de vide est arrondi à la demi-valeur. Lors de

l’acquisition de donnée, appuyé sur la touche "ENTER" pour la

Page 88

2-8

validation et appuyé sur la touche "ESC" pour revenir en arrière.

Exemple:

keys 0, 1 or 1, ‘’ENTER’’ -> 1 sec

keys 1, 5 -> 15 secs

Exemple:

keys 0, 1 or 1, ‘’ENTER’’ -> 1 sec

En inscrivant une valeur nulle, il est possible de contourner

l’utilisation du capteur de pression et utiliser seulement le temps

‘’vacuum plus’’.

2.4.3.3. Vacuum plus (0 – 99 secs)

Cet valeur indique le temps que la pompe continuera à faire le vide

une fois que la valeur de vide (Vacuum) sera atteint.

Pour inscrire le nombre de seconde de vide plus (Vacuum plus),

utilisé le clavier numérique. La validation est automatique lorsque

toutes les caractères sont inscrit (l’affichage se met à clignoter).