Page 1

THERMOFORMING MACHINES

Models

TM-150 / TM-250 / TM-540

Heavy-duty

The heavy-duty stainless

steel single-piece frame

carries a lifetime guarantee.

User-friendly

The machine’s intuitive

interface combined with an

ergonomic design allows

for easy loading and simple

operation.

Easy maintenance

The system’s components

are corrosion-proof

and their design allows

for simple and easy

maintenance in order to

meet the strictest hygiene

standards.

Why should you use a thermoforming machine?

• Thermoformed packages are cost ecient and can be customized

according to products;

• Thermoforming packaging is a high-performance process ideally suited

for continuous production;

• To protect against external contamination and increase the shelf life of

food products;

• Thermoformed packages are hermetic and resistant to

freezing temperatures.

SIPROVAC

TM

SIPROSHRINK TMSIPROSEAL

TM

SIPROTHERMO TMSIPROINJEC

TM

SIPROMIX

TM

SIPROSMOKE

TM

SIPROFREEZE

TM

Page 2

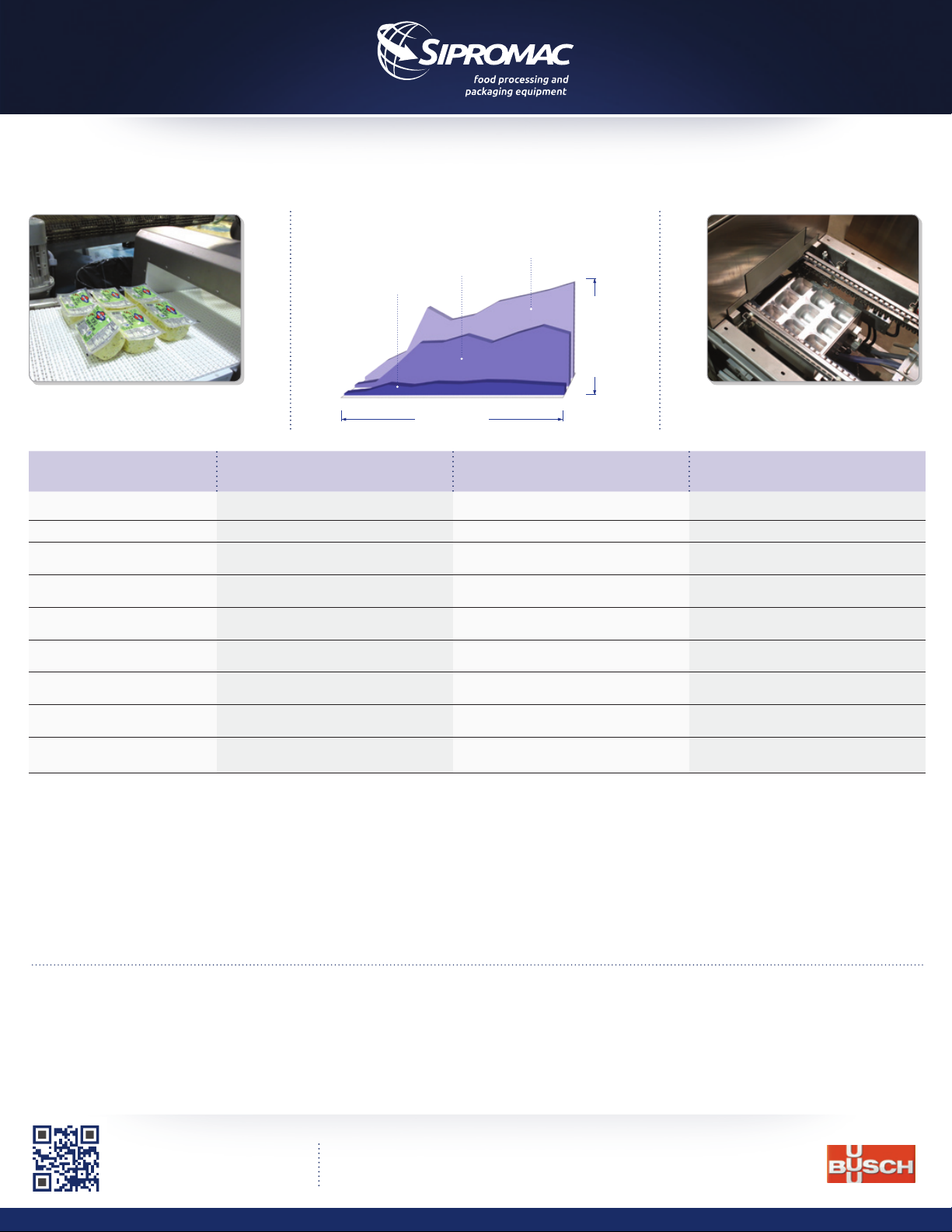

Conveyor Forming equipment

Annual maintenance cost

With the unmatched quality of its heavy-duty design

and structural rigidity that help prevent premature

wear and tear, Sipromac thermoforming machines offer the lowest annual maintenance cost in the industry.

Competitor B

Competitor A

Sipromac

Years of use

10090807060504030201

Annual cost ($)

THERMOFORMING

MACHINES

WIDTH OF FILM

FILM ADVANCE

DEPTH OF FORMING

POWER SUPPLY

PUMP CAPACITY (STD)

MAXIMUM ROLL

OUTSIDE DIAMETER

ROLL INSIDE DIAMETER

PRODUCTION CAPACITY

MICROPROCESSSOR

Remote mechanical commands

Basic Features:

• Welded, stainless steel frame

• Stainless steel loading area

• 5/8” conveyor chain

• Schneider PLC control unit

•

Touch control panel, with user-friendly interface

• Schneider servo motor drive for accurate

speed control

TM-150 TS-250 TS-540

320 mm / 420 mm 420 mm / 520 mm Up to 641 mm

340 mm 500 mm 700 mm

120 mm (std.) 150 mm (opt.) 120 mm (std.) 150 mm (opt.) 120 mm (std.) 150 mm (opt.)

220-208 V / 3 pH / 60 Hz 220-208 V / 3 pH / 60 Hz 220-208 V / 3 pH / 60 Hz

100 m3 5.0 HP

14” (350 mm)

3” (76 mm)

14 cycles per min. (Max)

with 6” touchscreen

• Electric cabinet (IP65)

• Pneumatic component cabinet

•

Protection guard with electronic interlock system

• 2 independent tool lifting stations

• Trim re-winder

• Water cooled tooling

• Quick compressed air forming capacity

• Remote diagnostic

255 m3 10.0 HP

14”

(350 mm) 14” (350 mm)

3” (76 mm)

14 cycles per min. (Max)

Remote mechanical commands

with 10” touchscreen

Booster

3” (76 mm)

14 cycles per min. (Max)

Remote mechanical commands

with 10” touchscreen

• Easy changeover of sealing plate

• Dedicated top and bottom vacuum valves

• Rotating knives (1 set)

• Active lm unwinding system with

dancer rool

• User manual and set of spare parts

Optional Features:

(Available on selected models)

• Unloading conveyor system

• Coding system

• Printing system

• Thermal transfer coder

Check out our other products

by visiting our website:

www.sipromac.com

• Photo cell for pre-printed lm

• Waste collector

• Automatic chain lubrication

• Choices of tooling head tracks or forming

• Labeling system

• Gas injection system (MAP)

• Multiple supply voltage available

• ETL, CSA, UL certication

tooling drawer

All features are subject to change without notice.

Phone: 819 395-5151 | Toll Free: 1 855 395-5252 Canada/U.S.

Email: sipromac@sipromac.com

240, boulevard Industriel, Saint-Germain-de-Grantham QC, Canada J0C 1K0

Loading...

Loading...