Page 1

1

VACCUM MACHINE

650A

OWNER’S MANUAL

MANUEL DE L’UTILISATEUR

Page 2

2

Page 3

3

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This symbol points out important s afety inst ructi ons w hich, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions

in this manual before attempting to operate your machine.

Failure to comply with these instructions may result in personal injury.

General Operation

• Read, understand, and follow all instructions in the manual and on the machine before

starting. Keep this manual in a safe place for further and regular reference and for ordering

replacement parts.

• Only allow responsible individuals familiar with the instructions to operate the machine. Be

sure to know controls and how to stop the machine quickly.

• Never put your hands near moving parts.

• Only allow qualified individuals for the maintenance of your machine.

• Remove all obstacles, which may interfere with the machine functions.

• Clear the work area such as electrical wires, buckets, knives etc.

• Be sure that everyone else is clear of your work area before operating the machine.

• Do not sit nor stand on the machine.

• Always turn off the machine after your work is done. Never leave a running machine

unattended.

• Always disconnect and wait till the machine has cooled before attempting any maintenance.

• Do not wear loose fitting clothes or jewelry as they may get caught in moving parts of the

machine.

• Always wear security shoes, to prevent injury caused by moving the machine or objects falling

from the machine.

• Never exceed the time limit to seal, which is recommended by the manufacturer. This is to

avoid any damage that may be caused to the sealing bars and to eliminate the risk of fire in

the machine. Thus avoiding corporal burns.

• Never touch the sealing bars after they have been used, this will avoid corporal burns. Wait a

few minutes to let the machine cool down before touching.

• Always make sure that the sealing bars are well installed in their "Guide Blocks" before

starting a cycle.

• Never incline the machine more than 30 degrees, it may tip over and hurt someone seriously.

• Work only in daylight or good artificial light.

Do not operate the machine while under the influence of alcohol or dr ugs!

Page 4

4

Service

• Use proper containers when draining the oil. Do not use food or beverage containers that may

mislead someone into drinking from them. Properly dispose of the containers, or store in a

safe place immediately following the draining of the oil.

• Prior to disposal, determine the proper method to dispose of waste from your local office of

Environmental Protection Agency. Recycling centers are established to properly dispose of

materials in an environmentally safe fashion.

Do not pour oil or other fluids into the ground, down a drain or into a body of

water

.

Warning-Your responsibility:

This machine should only be operated by personal who c an read, understand and respect

warnings and instruc tions regarding this machine in the owners manual. Save these

instructions for future reference.

Page 5

5

VACUUM PACKAGING MACHINE

I OPERATION INSTRUCTIONS

II MECHANICAL

A- Front view general assembly drawing

B- Rear view general assembly drawing

C- Cover adjustment procedure

D- Central shaft assembly drawing

E- Seal bar assembly drawings

(twin seal)

F- Seal bar assembly drawings

(electrical bag cut option)

G- Seal bar assembly drawings

(top and bottom sealing option)

H- Gas injection kit installation drawing

(gas injection option)

III ELECTRICAL

A- Electrical drawings

IV PNEUMATIC

A- Pneumatic drawing

MODEL 650A

(MC-40 SIPROMAC)

GENERAL TABLE OF CONTENTS

Page 6

6

VACUUM PACKAGING MACHINES

OPERATION INSTRUCTIONS

TABLE OF CONTENTS

1. Setting up the machine

2. Electrical connection

3. Operation

3.1 Working principles

3.2 Special packaging

3.2.1 Gas flushing

3.2.2 Top and bottom sealing (bi-active)

3.2.2 3.2.3 Electrical bag cut

3.3 Setting of digital controls

3.4 Daily cleaning

4. Trouble shooting

4.1 Failure during a packaging cycle

4.2 Insufficient vacuum

4.2.1 Leakage in the bag

4.2.2 No leakage in the bag

4.2.3 Insufficient vacuum in the chamber

4.3 Faulty seal

4.3.1 Insufficient seal

4.3.2 No seal

4.3.3 Permanent sealing current

4.3.4 Seal does not stick

4.4 Fault in the valves

4.5 Control board failure

5. Regular maintenance

2010-08-30

Page 7

7

VACUUM PACKAGING MACHINES

1. SETTING UP THE MACHINE:

Before choosing the site for the machine, pl ease consider that you w ill als o need room

for packaged and non-packaged products apar t from the space needed for th e mach ine

itself.

Keep in mind that the machine must not be set up upon uneven ground. Especially wi th

mobile models, the weight of the pump might then cause w arping of t he machine. Then

the lid will not fit correctly.

Before starting to work, check the oil view glass on the pump, if there is a sufficient

quantity of oil in the pump. Never use oil other than recommanded by the producer.

Never exceed maximum quantity of oil indicated, when adding or changing oil. Verify

weekly.

Normal ambient temperature for the vacuum pump is between 10 to 70oC.For

temperature below 10oC; it is recommended to use synthetic oil. Please consult

factory and pump manufacturer manual for more information or when ambient

temperature are outside normal limits

2. ELECTRICAL CONNECTION:

Electrical connections must be made by qualified personnel. This person must make

sure that the electrical entries corresponds to the proper voltage and amperage of the

machine. GROUNDING INSTRUCTIONS: This appliance must be connected to a

grounded, metal, permanent wir ing system; or an equipment-grounding conductor must

be run with the circui t conductors and connected to the equipment-grounding terminal or

lead on the appliance. A quali fied electrici an should be c onsulted i f there is any doubt

as to whether an outlet box is properly grounded.

All vacuum machines are supplied with an electrical schematic drawing.

An important step in connecting the machine is to make sure that the pump turns in

its correct rotation.

The pump should not rotate more than 3 to 4 sec onds in the wrong rotation or it

may cause serious damage. The proper r ota ti on i s indicated by an arrow on the

pump motor.

3. OPERATION:

3.1 Working principles:

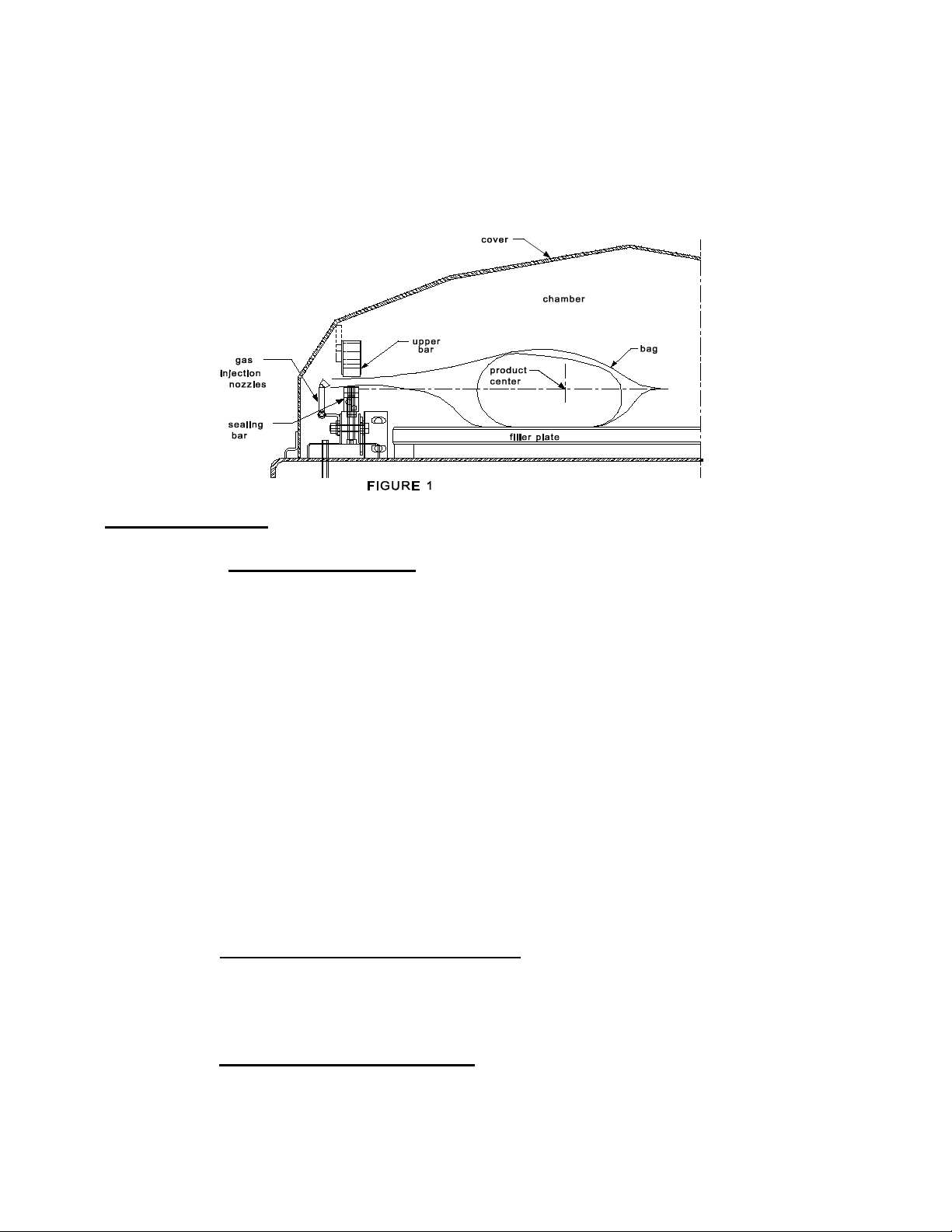

A vacuum packaging cycle is made of 3 stages. First the vacuum is made, the air is

completly taken out of the chamber and from bag contai ning the product. (See figure 1 ).

Then it is possible to inject neutral gas from the nozzles, if the product is delicate.

Finally, a mechanism pushes the sealing bar to the rubber support to seal the bag.

SIPROMAC INC.

Page 8

8

To obtain nice packages, the products and the bags have to be of proportional sizes. The

bag's opening should never exceed 50 cm(2") past the seal bars. The product should be

centered in height in relation to the seal bar by adjusting the spacers provided.

To obtain a good seal, make sure that no residue of fat is left between the bag's inner

sides where sealing is done.

3.2 Special packaging:

3.2.1 Gas flushing (option):

There is an atmospheric pressure of 1 kg/ sq. cm (14 lbs/sq. inch) upon products when

fully evacuated. Products which can be damaged by high pressure must be packaged

with a partial vacuum, or the pressure must be counterbalance by inflating the bag with

gas (nitrogen or carbon dioxide) before sealing after evacuation.

For gas flushing, the bags are placed on the sealing bars, the open end placed over

the gas nozzles mounted alongside the sealing bar. After evacuation, the vacuum

valve closes and the gas valve opens. Gas time (sec.) can be set in the program

menu.

The necessary gas tank and pressure valve mounted on tank is not supplied, The

pressure of the gas regulator should be set at approximately 1/3 kg/sq. cm

( 5 lbs/sq.inch.). Each machine has an adaptor for gas connection when gas flush

option is ordered.

3.2.2 Top and bottom sealing (optional):

When sealing aluminium laminate bags (especially bags for e.g. coffee) it is imperative

to have an upper and a lower sealing bar.

3.2.2 Electrical bag cut (optional):

This option is used to obtain a package that the excess bagtail is cut off close to the

seal (cannot be used with top and bottom sealing).

Page 9

9

3.3 Vacuum packaging operation:

3.3 Vacuum packaging operation:

Note: Refer to the menus structure on page 14 and the keyboard detail on page 15.

3.3.1 Basics:

Use key "POWER" to power ON / OFF the vacuum packaging machine. When the unit

is energized, the identification of the last executed program is displayed on LCD screen.

Use the "ESC" key to change over from the programs menu to the functions menu and

from the functions menu to the programs menu.

In functions menu, use key "SELECT" to select a function and key "ENTER" to accede

and executed the selection.

In programs menu, use key "SELECT" to select a program and key "ENTER" to accede

and modify the selection.

In programs submenu, use key "ENTER" to pass over the parameters and point to the

following one; the parameters are blinking to point out the acquisition mode. A return to

programs menu is performed automatically following the last parameter acquisition.

In program submenu, use key "ESC" to get back to the programs menu.Strike any key

to clear the error messages which may be displayed on LCD screen.

3.3.2 Functions:

3.3.2.1 Create a program:

When executing the "create a program" function, the program submenu is

acceded, starting with the identification. The initial identification "Pxx NO NAME"

is given to the program and all parameters are established to zero; the program

number is allocated automatically.

3.3.2.2 Delete a program:

When executing the "delete a program" function, the programs menu is acceded

and the number of the first program in memory is blinking to point out the

deletion mode. Use key "SELECT" to select a program and key "ENTER" to

accede and confirm deletion of the selection. Use key "ESC" to unconfirm a

deletion and to leave the function. When leaving the function, the number of the

actual program on LCD screen cease to blink.

3.3.2.3 Select operating mode:

When executing the "select operating mode" function, which is available only for

the automatic units, the actual selection is blinking to point out the acquisition

mode. Use key "SELECT" to get through the operating modes, which are

automatic, semi-automatic and manual; the validation of the selected operating

mode is performed automatically. Use key "ESC" or "ENTER" to leave the

function and get back to the program menu.

Page 10

10

3.3.3 Programs menu:

3.3.3.1 Program identification:

For a selected program, set the identification, using the numeric keyboard

characters chart; press numeric key untill the desired character is selected

(4 times for the numeric value). Use key "ENTER" to validate the character and

to validate the characters string at the end(the new characters string is blinking).

In a middle of an acquisition, use key "ESC" to come backward and erase one or

several characters.

Example: EXAMPLE 1 keys 2, 2, ENTER E

(9 characters) keys 8, 8, 8, ENTER X

keys 1, ENTER A

keys 5, ENTER M

keys 6, ENTER P

keys 4, 4, 4, ENTER L

keys 2, 2, ENTER E

keys 9, 9, 9, ENTER space

keys 1, 1, 1, 1, ENTER 1

key ENTER to validate the characters string

3.3.3.2 Vacuum level setting:

For a selected program set the vacuum level, starting with the values; the

decimal point is automatically inserted following the second digit entry and the

validation is automatically performed following the third digit entry (the new

vacuum level is blinking). The vacuum level is rounded off to the nearest half

value. In the middle of an acquisition, use key "ENTER" to validate the vacuum

level and key "ESC" to come backward and start over with a new acquisition

(the old vacuum level is blinking). Set vacuum level to zero to bypass the

pressure transducer and proceed only using the vacuum plus time.

Examples: 90.0% keys 9, 0, 0 or 9, 0, ENTER or

keys 9, 0, 1 or 9, 0, 2 or 9, 0, 3 or 9, 0, 4

97.5% keys 9, 7, 5 or

keys 9, 7, 6 or 9, 0, 7 or 9, 0, 8 or 9, 0, 9

0.0% keys 0, 0, 0 or 0, ENTER

3.3.3.3 Vacuum plus time setting:

For a selected program set the vacuum plus time, in seconds; the validation is

automatically performed following the second digit entry (the new vacuum plus

time is blinking). In a middle of an acquisition, use key "ENTER" to validate the

vacuum plus time and key "ESC" to come backward and start over with a new

acquisition (the old vacuum plus time is blinking).

Examples: 1s keys 0, 1 or 1, ENTER

Page 11

11

15s keys 1, 5

Page 12

12

3.3.3.4 Gas flush level setting:

For a selected program set the gas flush level following the same procedure as

for the vacuum level; the maximum gas flush level setting is 10% below the

vacuum setting.

3.3.3.5 Sealing time setting:

For a selected program set the sealing time, starting with the seconds; the

decimal point is automatically inserted following the first digit entry and the

validation is automatically performed following the third digit entry (the new

sealing time is blinking). The sealing time is truncated to the nearest half

hundredth. In a middle of an acquisition, use key "ENTER" to validate the sealing

time and key "ESC" to come backward and start over with a new acquisition

(the old sealing time is blinking).

Examples: 4.50s keys 4, 5, 0 or 4, 5, ENTER or

3.3.4 Vacuum cycle execution:

For the manual units and the automatic units set on manual, close the cover to initiate a

vacuum cycle. For the automatic units set on semi-automatic or on automatic, use push

button "STOP / START" to initiate or interrupt a vacuum cycle. A selected program can

be initiated only in the programs menu, when no modifications are in progress, and the

access to the other programs and functions is denied. During cycle execution the

operation status is sequencally displayed on LCD screen, except for the parameters

established to zero, which are not displayed:

- chamber vacuum level during vacuum sequence,

- vacuum plus time status during vacuum plus sequence,

- chamber vacuum level during gas flush sequence,

- sealing time status during sealing sequence,

- chamber vacuum level during atmosphere sequence.7

During cycle execution, use key "1" to abort the vacuum sequence and execute the

following sequence, which is gas flush or sealing, and key "ENTER" to accede and

modify the program; the parameters become valid only for the following vacuum cycles.

3.3.5 System monitor:

To accede the diagnostics menu, power up the vacuum packaging machine while

keeping pushed in the "ESC"key. Use key "SELECT" to select the system monitor

function and key "ENTER" to accede and visualize the monitored parameters. Use key

"SELECT" to change over from the software revision, the amount of working hours

done and the amount of complete cycles performed since first initialization.

keys 4, 5, 1 or 4, 5, 2 or 4, 5, 3 or 4, 5, 4

2.35s keys 2, 3, 5 or

keys 2, 3, 6 or 2, 3, 7 or 2, 3, 8 or 2, 3, 9

0.00s keys 0, 0, 0 or 0, ENTER

Page 13

13

-MENUS STRUCTURE-

• Functions menu:

"F1 CREATE A PRGM"

"F2 DELETE A PRGM"

"F3 SELECT OPMODE" (automatic units only)

• Programs menu:

"Pxx NAME"

Program submenu:

"VACU UM: xx.x%" (10.0% - 99.5%)

"VACUUM PLUS: xxs"(0s - 99s)

"GAS FLUSH: xx.x%" (0.0% - 10% below the vacuum level) (units with gas option)

"SEAL TIME: x.xxs" (0.00s - maximum unit allocated setting)

"Pxx NAME" (12 characters)

• Diagnostics menu (keys "ESC" & "POWER" for access):

"DIAGNOSTICS MENU" (access code required)

"D1 INPUTS TEST"

"D2 OUTPUTS TEST"

"D3 MODEL SELECT"

"D4 GAS OPTION"

"D5 SEALING TIME"

"D6 COOLING TIME"

"D7 OFFSET CALIB.”

"D8 VACUUM SENSOR”

"D9 SIPROMAC PUB”

"D10 LOADING TIME" (automatic units only)

"D11 UNLOADNG TIME" (automatic units only)

"SYSTEM MONITOR" (no access code required)

"SOFTWARE: R x.xx"

"WORK HRS: xxxxx"

"CYCLES: xxxxxxx"

Page 14

14

-KEYBOARD DETAILS-

MC-40 CONTROLS

Page 15

15

WARNING: All electrical work describe d i n thi s brochure should be done by

a QUALIFIED and AUTHORIZED technician

.

3.4 Daily cleaning:

For hygenic cleanliness, it is imperative to clean chamber and spacers daily. Also clean

the lid rubber to assure tight seat of the lid.

Cleaning instructions for gas injection nozzl es: Periodically on a regular basis the gas

injection nozzles must be removed with the connection tube and soaked in a food grade

soap and water solution, then dried and re-installed.

4. TROUBLE SHOOTING:

4.1 Failure during packaging cycle:

4.1.1 "VACUUM ERROR" message is displayed on LCD:

No pressure variation is picked up by the PCB transducer during the vacuum sequence

within a preset period of time.

- Check vacuum lines for potential leaks or kinks.

4.1.2 "GAS FLUSH ERROR" message is displayed on LCD:

No pressure variation is picked up by the PCB transducer duringthe gas flush sequence

within a preset period of time.

- Check gas flush and vacuum lines for potential leaks or kinks.

4.1.3 "ATMOSPHERE ERROR" message is displayed on LCD:

No pressure variation is picked up by the PCB transducer during the atmosphere

sequence within a preset period of time.

- Check vacuum lines for potential leaks or kinks.

4.1.4 "COVER DOWN ERROR" message is displayed on LCD(manual units):

The input signal of the down position switch has been lost during cycle execution.

- Check limit switch adjustment.

Page 16

16

4.2 I nsufficient vacuum:

4.2.1 Leakage in the bag:

Most frequently, insufficient vacuum in bags is due to leakage in bag and not due to any

fault of the machine.

Pin-hole leak for which there is no obvious explanation is due to faulty bag material.

Pin-hole leak caused by sharp edge of the product (bone, etc.).Use bone-guard or

thicker film.

Tear in bag by careless handling (sharp edge on filling table, damage made by retailer

or customer).

Leakage in lateral or bottom seal, complain to supplier of bags or film.

4.2.2 No leakage in the bag:

Bag is too large, therefore the surplus of air remains visible (there is surplus of air in

0.4% of the bag volume in each bag). Use bags of suitable size.

Vacuum level is too low:

Pressure bar is jammed and closes opening of bag during evacuation.

4.2.3 Insufficient vacuum in chamber:

If troubles described under 4.2.1 and 4.2.2 do not apply, there is something wrong with

the evacuation.To find the leakage quickly, check for leaks with a precision vacuumeter,

going back step by step from the chamber to the pump.

At the chamber (measuring point at base of valve) at maximum time of evacuation. If

more than 6 torr, proceed directly to the pump, if more than 3 torr:have pump service by

pump supplier.If pressure at pump is good, reconnect hoses to pump and measure

again.

Verify at vacuum hose connections and valve connections.

When proceeding this way, starting from pump, loss of pressure per step must not

exceed 0.5 to 1 torr.

Caution:Verify connections of measuring equipment before verifing machine.

Most frequent points of leakage: lid gasket, damaged vacuum hose or loose hose

clamps.

Page 17

17

4.3 Faulty seal:

4.3.1 Insufficient seal:

Damaged teflon or silicone rubber.

Sealing pressure too low, bellows leaking or pressure bar jammed.

Leakers in seal: heating wire mechanically damaged (knicked) or silicone rubber

uneven.

4.3.2 No seal:

Sealing wire burnt.

Faulty contact in sealing circuit.

Sealing transformer burnt through.

Contactor does not work.

4.3.3 Permanent sealing current:

Contactor is jammed check sealing transformer for damage through overload.

4.3.4 Seal does not stick:

Insufficient layer of polyethylene (inferior quality of bags).

Seal area extremely contaminated by fat or meat juice. Use filling aid.

Sealing temperature is too low (when using very thick films).

Caution: Do not increase sealing time more than really necessary; higher temperature

4.4 Fault in the valve:

Vacuum or air valve does not open.

Check whether there is voltage on the magnetic valves during their period of operation. If

there is no voltage a wire is broken or the PC board is damaged.

Lid does not open at the end of the cycle; air enters, but there is still 20 - 40% vacuum in

chamber. Vacuum valve does not close.

will reduce working life of teflon and silicone rubber.

Page 18

18

4.5 MC4 0 Control board failure

NOTE:Refer to menu structure on page 13.

This board software is allowing access to a "Diagnostics Menu". Only qualified service

technicians are authorized to access this menu by entering a security password.

By acceding either the "D1 input test" feature or the "D2 output test" feature,a trained

technician will be able to quickly know the origin of the problem: pump, sealing system,

pneumatic problem, security switches problem, etc...

Keep in mind that in most cases trouble is due to a leakage, loose electrical connection or

evident dammage to the main components: vacuum pump, valves, electrical contactors,

thermal overload, fuses holder or transformer.

For assistance do not hesitate to contact your local service technicians.

5. Regular maintenance:

Routine controls to be made at regular intervals:

Check teflon for wear.

Check silicone rubber for burnt spots and smooth even position.

Check pressure bar for jamming.

Check lid sealing for damage and hardened spots.

Check switch-point of micro switch, adjust if necessary.

Check evacuation hose for damage (contraction of diameter, or abrasions).

Check vacuum connections for tightness.

Check oil in pump (oil level in view glass; add if necessary. Regular change of oil - necessity

indicated by change of color).

Check vacuum in chamber with precision vacuumeter.

Check function of cycle with various settings of timers.

Page 19

19

MODEL 650A

COVER ADJUSTMENT PROCEDURE

Reference Drawing:# 005-0325

# 004-0122

PROBLEM: MACHINE TABLE AND COVER SEEMS TO BE STRAIGHT, LID GASKET IS GOOD

BUT COVER DOES NOT SIT PROPERLY ON BOTH SIDES OF TABLE.

1. Floor should be flat (within 1/8" approx.).

2.1 Mark position of original adjustment of guide arm length and its lower shaft position (See

drawing # 005-0416; items: #39 & #16).

2.2 Loosen the two bolts on the guide arm (See drawing # 005-0325; items #39).

2.3 Now move the cover each side and check how cover sits on the table. Distance between table

and lid gasket should be under 1/16" approx. If so, go to step 3.0 for guide arm

adjustment. Otherwise go to step 2.4 for central arm adjustment.

2.4 Put chamber in upright position and check with a square angle to see if arms are parallel. If

not, loosen bolt at the end of one arm and adjust until square (See drawing # 005-0416;

items #33, #14 & #44).

2.5 When closing cover (guide arm still loose), if cover is not sitting properly on either the front or

rear of the table, you have to change the height of a central pillow block (See drawing #

004-0122; item #3) until cover is sealing properly each side (less than 1/16").

3. Adjustment of guide arm: two things have to be adjusted, the length and the lower axis position.

Each of these should be adjusted separately. Fix the lower axis in a central position, then adjust

guide arm length by marking its position. When chamber is at the left and at the right, tighten at

the center of your marks. Adjustment can be done a couple of times until everything is ok.

Page 20

20

MECHANICAL DRAWING

Page 21

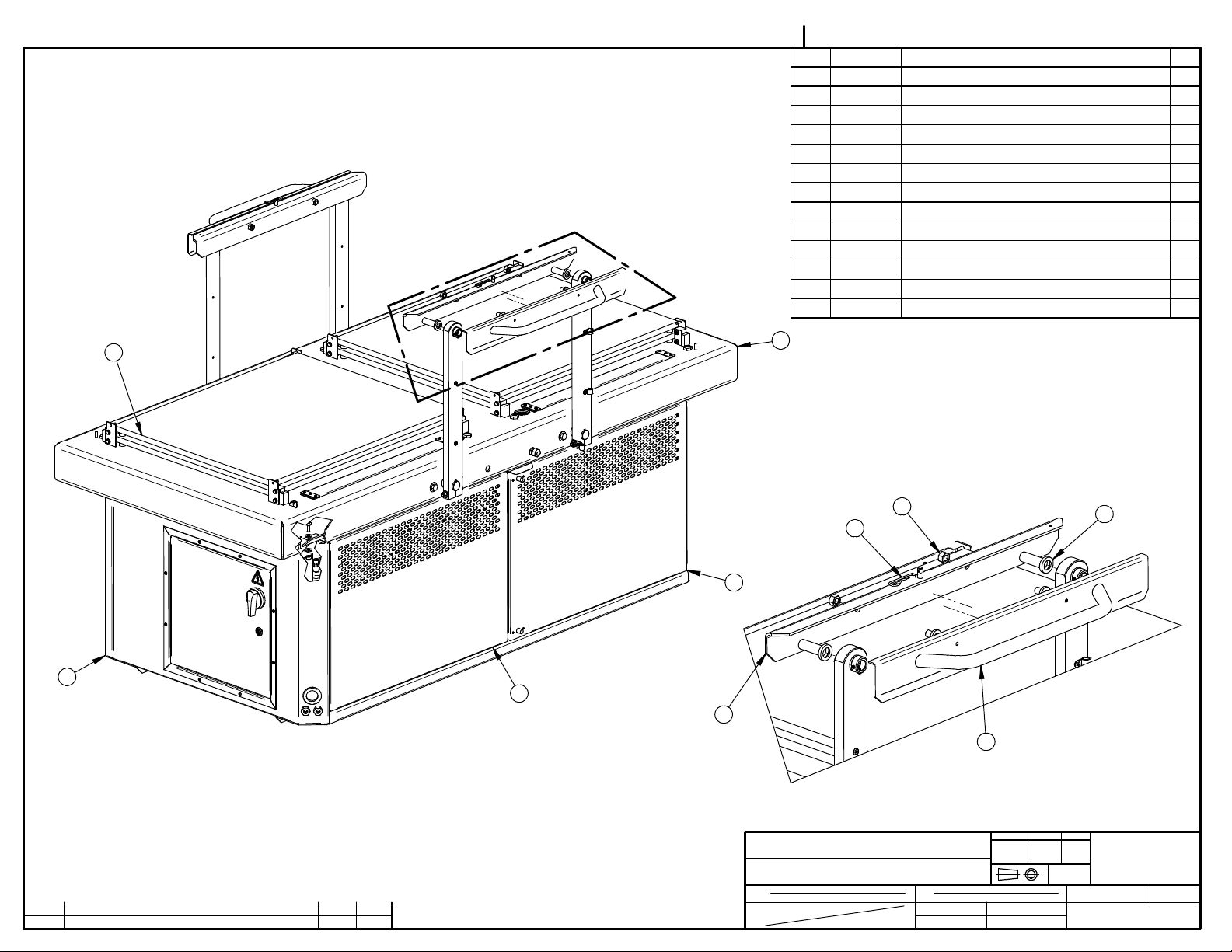

A

005C0352

ITEM PART # DESCRIPTION QT.

1 004A0213 COVER HANDLE ASS'Y 2

2 004A4239 LEFT REAR ACCESS DOOR PRE-ASSY 1

3 005-0349 FILLER PLATE ASSEMBLY 4

4 005-0359 ARM SUPPORT ASSEMBLY 2

5 005A1518 TABLE ASSEMBLY W/ARM 1

6 005A1519 RIGHT REAR ACCESS DOOR ASSY 1

7 005C0465 STRUCTURE ASSEMBLY 1

8 008-0368 ARM SUPPORT SPACER 4

9 051-0360 BOLT 3/8"-16nc. X 1" S/S 6

10 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 6

11 051-0630 NUT 1/2"-13 S/S 4

12 051-0783 WASHER 3/8" FLAT THICK S/S 12

13 056-0125 HITCH PIN CLIPS 3mm X 60mm S/S 2

3

5

11

DETAIL A

8

13

6

7

2

4

1

LET. MODIFICATION

DATE

INT.

MACHINE

PART

ITEM

MAT.

650A

BASE MACHINE ASSY

CNC

3D DWG BY

2D DWG BY

SBU

AG

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-07-14

DATE

14-08-04

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005C0352

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 22

005A1524

ITEM PART # DESCRIPTION QT.

1 001B6779 VALVE SUPPORT BRACKET 1

2 051-0144 SCREW #10-24 N.C 1/2"PAN PHIL. S/S 4

3 051-0572 NUT #10-24 NYLON LOCK S/S 4

4 100-0225 CLOSE NIPPLE 1/4" NPT SS 1

5 100-0463 TEE 1/4" NPT S/S 1

6 102-0361 Y BRANCH 1/4'' MNPT X 3/8'' T. QUICK 2

7 102-0410 MALE CONN.1/4"MNPTx3/8"T.QUICK 1

8 106-00701 VALVE 3WAY 24V 1/4''NPT 1

5

3

1

2

LET. MODIFICATION

8

DATE

INT.

6

4

7

MACHINE

PART

ITEM

MAT.

650A

BELLOWS VALVE ASSY

CNC

3D DWG BY

2D DWG BY

SBU

XX

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-07-17

DATE

YY-MM-DD

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1524

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 23

005A1519

ITEM PART # DESCRIPTION QT.

1 004A4238 RIGHT REAR ACCESS DOOR PRE-ASSY 1

2 056-2600 SPRING PAWL LATCHE SS KNOB 2

3 051-0071 SCREW 4-40 x 1/4" RND SLOT S/S 4

4 051-0541 NUT # 4-40 NYLON LOCK SS 4

A

2

4

1

3

LET. MODIFICATION

DATE

INT.

MACHINE

650A

PART

RIGHT REAR ACCESS DOOR ASSY

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DETAIL A

DEPT. TOL.

METRIC

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

13-09-16

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1519

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 24

005C0465

3

12

7

11

DETAIL B

DETAIL A

9

10

8

6

4

2

ITEM PART # DESCRIPTION QT.

1 004A4090 ACCESS DOOR ASSEMBLY 1

2 004A4098 ELECTRIC BOX ASS'Y 1

3 004A4138 VACUUM SENSOR FILTER 1

4 004C0138 STRUCTURE PRE-ASSY 1

5 036-0265 GROMMET 1-1/2'' ID X 2-3/8'' OD RUBBER 1

6 036-0409 PRESSE-ETOUPE CD13 3

7 051-01385 SCREW 10-24 x 1/2"FLAT-UND. PHIL S/S 8

8 051-0144 SCREW #10-24 N.C 1/2"PAN PHIL. S/S 8

9 051-0180 BOLT. HEX. 1/4"-20 NC. x 1/2" S/S 2

10 051-0740 WASHER 1/4" FLAT S/S 2

11 056-3010-1 HINGE CONCEALED SS304 - BASE 4

12 056-3010-3 HINGE CONCEALED SS304 - PIN 4

13 102-0551 BULKHEAD 1/4"NPT X 3/8 TUBE QUICK 2

SILICONE ON EACH SIDE

AND ON TOP

SILICONE SUR CÔTÉ ET

DESSUS

5

13

LET. MODIFICATION

DATE

INT.

B

MACHINE

PART

ITEM

MAT.

A

650A

STRUCTURE ASSEMBLY

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-07-16

DATE

1

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005C0465

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(M)-I

QTY.

1

Page 25

004A4138

ITEM PART # DESCRIPTION QT.

1 004A4139 VACUUM SENSOR FILTER SUPPORT 1

2 114-2020 FILTER / DRYER ¼"mnpt. X 1/4"t.p. COMP. 1

3 102-0410 MALE CONN.1/4"MNPTx3/8"T.QUICK 2

3

2

LET. MODIFICATION

DATE

INT.

3

1

MACHINE

PART

ITEM

MAT.

VACUUM

VACUUM SENSOR FILTER

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-11-19

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A4138

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 26

ITEM PART # DESCRIPTION QT.

11 051-0580 NUT 1/4"-20 S/S 4

12 051-0210 BOLT ¼"-20nc. X 1" S/S 4

13 051-0581 NUT 1/4"-20 NYLON LOCK S/S 4

14 051-0139 SCREW 10-24 x 1/2" FLAT PHIL S/S 4

15 028-0105 GROUND BARRIER (6 HOLES) 1

16 051-0128 SCREW 10-24 x 3/8'' TRUSS PHIL S/S 4

1

3

2

14

004A4098

ITEM PART # DESCRIPTION QT.

1 004A4099 E-BOX PRE-ASSY 1

2 056-3010-1 HINGE CONCEALED SS304 - BASE 2

3 056-3010-3 HINGE CONCEALED SS304 - PIN 2

4 004A4102 E-BOX FALSE BOTTOM 1

5 036-0430 PRESSE-ÉTOUPE CD29 1

6 036-0409 PRESSE-ETOUPE CD13 3

7 004A4100 E-BOX DOOR ASSEMBLY 1

8 036-0420 PRESSE-ÉTOUPE CD21 2

9 036-0440 PRESSE-ÉTOUPE CD36 1

10 051-0600 NUT 5/16" -18 S/S 4

16

PUMP

4

5

16

8

SEAL BAR

10

11

12

A

TOP BOTTOM OPTION

VALVES

MC-40

6

DETAIL A

9

NOTE:

15

- 026-3161 - DISCONNECT SWITCH SHAFT: COUPER À

134 MM DE LONG.

LET. MODIFICATION

7

DATE

INT.

13

MACHINE

PART

ITEM

MAT.

VACUUM

ELECTRIC BOX ASS'Y

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-09-23

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A4098

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 27

004A4100

ITEM PART # DESCRIPTION QT.

1 004A4101 E-BOX DOOR PRE-ASSY 1

2 056-2612 CAM LOCK QUARTER TURN SS304 1

3 179-0026 D-SHAPED RUBBER SEAL 1683mm LONG 1

4 026-3160 HANDLE RED/YELLOW NEMA 4X,

COMPACT, PADLOCKABLE

4

5 127-0100 STICKER ELEC.HAZARD ISO 2-1/2''

TRIANGLE

5 CENTER WITH HANDLE

16.4

1

1

LET. MODIFICATION

434

2

418

3

1

DATE

INT.

MACHINE

PART

ITEM

MAT.

VACUUM

E-BOX DOOR ASSEMBLY

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-09-17

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A4100

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 28

004A4090

ITEM PART # DESCRIPTION QT.

1 004A4089 ACCESS PANEL PRE-ASSY 1

2 056-2600 SPRING PAWL LATCHE SS KNOB 1

3 051-0071 SCREW 4-40 x 1/4" RND SLOT S/S 2

4 051-0541 NUT # 4-40 NYLON LOCK SS 2

2

3

4

1

LET. MODIFICATION

DATE

INT.

MACHINE

PART

ITEM

MAT.

VACUUM

ACCESS DOOR ASSEMBLY

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-09-11

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A4090

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 29

005A1518

ITEM PART # DESCRIPTION QT.

12

16

2

16

14

DETAIL A

5

A

6

1 001-1876 LOWER WIRE SUPPORT 1

2 002-0326 LEFT SEAL BAR GUIDE BLOCK 4

3 002-0327 RIGHT SEAL BAR GUIDE BLOCK 4

4 002-0390 COVER ARM COLLAR 4

5 004B0383 COVER ARM ASSY 4

6 004C0137 TABLE ASSEMBLY 1

7 005-0651 BELLOWS ASSEMBLY 4

8 036-0409 PRESSE-ETOUPE CD13 1

9 051-0178 SCREW 1/4"-20 x 5/16" SKT SET S/S 8

10 051-0185 SCREW 1/4-20x 1/2"PAN PHIL S/S 1

11 051-0212 SCREW 1/4"-20 x 1" PAN PHILL S/S 8

12 051-0250 BOLT ¼"-20nc. X 1½" S/S 16

13 051-0422 BOLT 3/8"-16nc. X 3¼" S/S 4

14 051-0581 NUT 1/4"-20 NYLON LOCK S/S 17

15 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 4

16 051-0740 WASHER 1/4" FLAT S/S 32

17 051-0783 WASHER 3/8" FLAT THICK S/S 8

18 056-01675 KEY 1/4" SQ. x 1 1/4" ROUNDED END S/S 4

19 105-0450 METAL CABLE CLAMPS #6 SS 3

B

7

15

17

18

13

17

LET. MODIFICATION

C

DETAIL C

DATE

INT.

D

3

10

14

1

19

DETAIL D

MACHINE

PART

ITEM

MAT.

650A

TABLE ASSEMBLY W/ARM

CNC

3D DWG BY

2D DWG BY

4

9

DETAIL B

DEPT. TOL.

METRIC

USINAGE

± 0.1

TOLERIE

±

SOUDAGE

±

DATE

DATE

14-07-10

14-07-31

SBU

AG

INCH

± 0.004"

0.5

±

0.020"

0.

5

±

0.020"

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

N.T.S.

DEPT.

NO.

005A1518

SIPROMAC

M

QTY.

1

Page 30

ITEM PART # DESCRIPTION QT.

20 051-0760 WASHER 5/16" FLAT S/S 16

21 051-0790 WASHER 1/2" FLAT S/S 16

22 075-1655 2 BOLT FLANGED BEARING 1-1/4"

4

PLASTIC

004C0137

ITEM PART # DESCRIPTION QT.

15 051-0441 BOLT 1/2"-13 x 1 1/2" SS 8

16 051-0560 NUT #8-32 NYLON LOCK S/S 6

17 051-0600 NUT 5/16" -18 S/S 16

18 051-0630 NUT 1/2"-13 S/S 8

19 051-0720 WASHER #8 FLAT S/S 6

ITEM PART # DESCRIPTION QT.

1 002A3941 SPRING ADJ. PIVOT 8

2 002A4002 SPRING ADJ. PIVOT SPACER 16

3 002B0331 CENTRAL SHAFT 2

4 004A3937 SHACKLE ASS'Y 8

5 004A3968 SPRING INSERT ASSEMBLY 8

6 005A1437 MICRO SWITCH COLLAR ASSY 3

7 005A1517 SPRING BLOCK PRE-ASSY 4

8 005C0355 TABLE WELDED ASSEMBLY 1

9 008A1953 SPRING 8

10 026-0750 ROLLER PLUNGER SWITCH SPDT 3

11 036-0400 WIRE CONNECT. 3/8'' NPT

8

CD09/O-RING/NUT

12 036-0400 WIRE CONNECTOR 3/8'' NPT NUT 8

13 051-0142 SCREW 8-32 x1-1/2"RND PHIL S/S 6

14 051-0300 BOLT 5/16"-18 x 3/4" S/S 16

PROCÉDURE D'AJUSTEMENT DES

RESSORTS / SPRING ADJUSTMENT

PROCEDURE:

- LES RESSORTS DOIVENT ÊTRE INSTALLÉ

LORSQUE LA TABLE EST INSTALLÉ SUR LE BATI.

- INSTALLER LES RESSORTS DE FAÇON LÂCHE ET

SERRER LES ÉCROUS À LA MAIN.

- TENDRE DE FAÇON ÉGALE LES RESSORTS. LA

LONGEUR ÉTIRÉ MOINS LA LONGEUR INITIAL DOIT

ÊTRE ÉGALE POUR CHAQUE RESSORT.

- NE PAS FAIRE PLUS DE 10 TOURS PAR RESSORT À

LA FOIS

------------

- SPRING MUST BE INSTALLED ONCE THE TABLE IS

ASSEMBLED ON THE STRUCTURE

- INSTALL THEM LOOSELLY BY THIGHTENING THE

NUT BY HAND

- TENSION SPRING EQUALLY. THE STRECHTED

LENGTH MINUS THE INITIAL LENGTH MUST BE THE

SAME ON EACH SPRING.

- DO NOT STRETCH THE SPRING BY MORE THAN

10 NUT TURN AT A TIME PER SPRING.

LET. MODIFICATION

DATE

INT.

MACHINE

PART

ITEM

MAT.

650A

TABLE ASSEMBLY

CNC

3D DWG BY

2D DWG BY

SBU

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-07-09

DATE

14-10-08

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004C0137

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 31

004C0137

11

B

22

21

18

15

2

20

14

5

9

117

17

DETAIL B

DETAIL A

9

4

7

3

6

A

8

59.4

AJUSTEMENT DE L'ARBRE / SHAFT ADJUSTMENT

- UTILISER LES CALES POUR POSITIONNER L'ARBRE

- CENTRER L'ARBRE HORIZONTALEMENT DANS LE TROU DE LA TABLE

------------

- USE BLOC TO SPACE THE SHAFT ACCORDINGLY

- CENTER SHAFT HORIZONTALLY IN THE TABLE HOLE

59.4

C

MACHINE

PART

ITEM

MAT.

650A

TABLE ASSEMBLY

CNC

3D DWG BY

2D DWG BY

SBU

DETAIL C

DEPT. TOL.

METRIC

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

14-07-09

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004C0137

10

19

16

13

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 32

004A3968

ITEM PART # DESCRIPTION QT.

1 002A3989 SPRING ADJUSTMENT ROD 1

2 051-0600 NUT 5/16" -18 S/S 2

3 002B3940 SPRING INSERT 1

2

3

2

1

B

A

AJOUT 420A ET 650A

AJOUTER 620A

LET. MODIFICATION

14-08-04

13-01-23

DATE

SBU

J.G.

INT.

MACHINE

VACUUM

PART

SPRING INSERT ASSEMBLY

ITEM

MAT.

CNC

DWG BY

APP. BY

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-01-15

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A3968

650A

620A

600A

420A

MACHINE

QTY

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(M)

QTY.

LISTE

8

4

4

2

Page 33

004A3937

ITEM PART # DESCRIPTION QT.

1 004A3935 SHACKLE PRE-ASS'Y 1

2 001A6269 SHACKLE PLATE 1

3 056-0118 COTTER PIN 3/32" x 1" S/S 1

2

1

B

A

AJOUT 420A ET 650A

AJOUTER 620A

LET. MODIFICATION

14-08-04

13-01-23

DATE

SBU

J.G.

INT.

MACHINE

PART

ITEM

MAT.

3

VACUUMS

SHACKLE ASS'Y

CNC

DWG BY

APP. BY

J.G.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

12-11-06

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004A3937

650A

620A

600A

420A

MACHINE

QTY

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(M)

QTY.

LISTE

8

4

4

2

Page 34

Page 35

Page 36

005F0548

ITEM PART # DESCRIPTION QT.

1 001-0269 SEAL BAR GUIDE 2

9

5

1

6

8

3

2

2 001B1900 INTERIOR BELLOWS COVER 1

3 001B1901 EXTERIOR BELLOWS COVER 1

4 002B4161 SEAL BAR SUPPORT (ECO) 1

5 004D0255 SEAL BAR PRE-ASS'Y 1

6 051-0230 HEX BOLT 1/4-20 x 1 1/4" SS 10

7 051-0251 CAP. HEX. SKT BOLT 1/4"-20 NC. x 1 1/2" 5

8 051-0581 NUT 1/4"-20 NYLON LOCK S/S 10

9 051-0740 WASHER 1/4" FLAT S/S 4

-ITEM #2 ÉGAL AVEC L'ITEM #4 & #5.

-ITEM #2 FLUSH WITH ITEM #4 & #5.

LET.

MODIFICATION

-END VIEW-

DATE

INT.

4

7

-BAG CUT OPTION-

MACHINE

650A, 680A & 700A

PART

SEAL BAR ASS'Y W/SUPPORT

ITEM

MAT.

CNC

DWG BY

APP. BY

S.L.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-02-12

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005F0548

700A

680A

650A

MACHINE

QTY

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I-(M)

QTY.

LISTE

4

4

4

Page 37

004D0255

ITEM PART # DESCRIPTION QT.

1 002A4171 SEAL BAR 1

2 002A4172 BANDING BUCKLE 4

3 005A1443 ELEMENT BINDER RIGHT 2

4 005A1444 ELEMENT BINDER LEFT 2

5 027-0400 CONNECTOR ADAPTOR 6

6 039-02115 ROUND CUT-OFF ELEMENT 0.9MM 1

7 039-0222 TAPERED BAND 3MM X 0.3MM 1

7

6

8 051-0146 SCREW 10-24 X 1" PAN PHIL S/S 1

9 051-0146 SCREW 10-24 X 1" PAN PHIL S/S 1

10 051-01752 SET SCREW 10-32 SS 3/16" 2

11 051-01752 SET SCREW 10-32 SS 3/16" 2

12 051-0550 NUT #8-32 SS 8

13 077-0014 SPRING C0240-040-1250 SS COMP. 4

14 171-0180 TAPE CLEAR SUPER BOND 3/4" 854.5mm (0.026) 2

15 176-0200 TEFLON TAPE, 5MIL 1

16 176-0203 TEFLON TAPE UNCOATED 5MIL (0.78) 1

16OVER THE ELEMENT INSTALLÉ SUR L'ÉLÉMENT

LET.

13

8

DETAIL A

MODIFICATION

15UNDER THE ELEMENT INSTALLÉ SOUS L'ÉLÉMENT

3 ALLOW TO MOVE FREELYPERMETTRE DE BOUGER LIBREMENT

1

12

14

5

QTY.

LISTE

4

4

4

QTY

DATE

INT.

A

10

2

-BAG CUT (ECO) -

MACHINE

650A , 680A & 700A

PART

ITEM

MAT.

SEAL BAR PRE-ASS'Y

CNC

DWG BY

APP. BY

S.L.

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-02-12

DATE

METRIC

± 0.1

±

0.5

±

0.

INCH

± 0.004"

±

5

±

N.T.S.

0.020"

0.020"

DEPT.

NO.

700A

680A

650A

MACHINE

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(M)-I

004D0255

Page 38

005D0549

ITEM PART # DESCRIPTION QT.

1 004B0256 SEAL BAR PRE-ASS'Y 1

1

8

6

7

4

5

8

9

2 002A0357 SEAL BAR SUPPORT 1

3 051-0251 CAP. HEX. SKT BOLT 1/4"-20 NC. x 1 1/2" 5

4 001A1900 INTERIOR BELLOWS COVER 1

5 001A1901 EXTERIOR BELLOWS COVER 1

6 001-0269 SEAL BAR GUIDE 2

7 051-0230 HEX BOLT 1/4-20 x 1 1/4" SS 10

8 051-0740 WASHER 1/4" FLAT S/S 8

9 051-0581 NUT 1/4"-20 NYLON LOCK S/S 10

ITEM #2 ÉGAL AVEC L'ITEM #4 & #5.

ITEM #2 FLUSH WITH ITEM #4 & #5.

I

LET.

004B0256 WAS 004A0256

MODIFICATION

-END VIEW-

13-08-12

DATE

SBU

INT.

2

3

-TOP & BOTTOM SEALING OPTION-

MACHINE

650A, 680A & 700A

PART

SEAL BAR ASS'Y W/SUPPORT

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-08-12

DATE

METRIC

± 0.1

±

0.5

±

0.

700A

680A

650A

MACHINE

INCH

± 0.004"

SIPROMAC

±

0.020"

5

±

0.020"

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

N.T.S.

DEPT.

M-I-(M)

NO.

005D0549

QTY.

4

4

4

QTY

LIST

Page 39

004B0256

ITEM PART # DESCRIPTION QT.

1 002A4129 SEAL BAR 1

2 001-2666 ELEMENT BINDER 2

3 051-0146 SCREW 10-24 X 1" PAN PHIL S/S 8

4 051-0572 NUT #10-24 NYLON LOCK S/S 8

5 051-0100 SCREW 8-32 X 3/8" PAN PHIL S/S 2

6 051-0550 NUT #8-32 SS 4

7 027-0400 CONNECTOR ADAPTOR 2

8 179-0003 SILICONE 2mm x 15mm (0.9) 1

9 176-0220 TEFLON TAPE, PRESS SENSITIVE 2" (0.104) 1

3

14

10 039-0220 BI-ACTIVE SEALING ELEMENT (0.09) 1

11 056-1400 1/4"SET SCREW BANDING BUCKLE S/S 2

12 176-0203 TEFLON TAPE, 5MIL UNCOATED ZONE

854.5mm (0.085)

13 077-0095 SPRING C 0360-059-1250 S/S 2

14 001-0266 TEFLON HOLD DOWN PLATE 2

12

1

14

4

13

6

7

6

4

AJOUT PINCE TEFLON, CHANGE TEFLON

G

LET.

MODIFICATION

2PERMETTRE DE BOUGER LIBREMENT ALLOW TO MOVE FREELY

DETAIL B

5

11 INSTALL AGAINST NOTCH OF ITEM #2INSTALLER CONTRE L'ENCOCHE DE L'ITEM #2

13-08-12

SBU

DATE

INT.

BEND AFTER SEAL BAND

INSTALLATION

PLIER APRÈS L'INSTALLATION

10

DE LA BANDE DE SCELLAGE

9

B

8

1

VOIR DÉTAIL A

3

11

TOP & BOTTOM

SEALING OPTION

MACHINE

580A, 650A, 680A & 700A

PART

ITEM

MAT.

SEAL BAR PRE-ASS'Y

CNC

DWG BY

APP. BY

DÉTAIL A

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

13-08-12

SBU

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004B0256

700A

680A

650A

580A

MACHINE

QTY

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-(M)-I

QTY.

LISTE

4

4

4

2

Page 40

005C0437

ITEM PART # DESCRIPTION QT.

1 002B0378 UPPER SEAL BAR SUPPORT 1

2 002C0396 UPPER SEAL BAR 1

3 051-0232 SCREW 1/4-20x 1-1/4"SKT CAP SS 8

4 001-2666 ELEMENT BINDER 2

5 051-0146 SCREW 10-24 X 1" PAN PHIL S/S 9

6 051-0572 NUT #10-24 NYLON LOCK S/S 9

CE COTÉ DE LA BARRE DOIT ÊTRE ÉGAL

AU SUPPORT

THIS SIDE OF SEAL BAR TO FIT FLUSH

WITH SUPPORT

1

6

15

3

7 051-0104 SCREW 8-32 x 3/8" RND PHIL S/S 2

8 051-0550 NUT #8-32 SS 4

9 027-0400 CONNECTOR ADAPTOR 2

10 179-0003 SILICONE 2mm x 15mm ADHESIVE 828mm

(0.83)

11 176-0220 TEFLON TAPE 0.010", PRESS SENSITIVE 2"

828mm (2.72)

12 039-0220 BI-ACTIVE SEALING ELEMENT (6mm) 871mm

(0.087)

13 056-1400 1/4"SET SCREW BANDING BUCKLE S/S 2

14 077-0095 SPRING C 0360-059-1250 S/S 2

15 001B1571 UPPER TEFLON HOLDER 2

16 176-0203 TEFLON TAPE UNCOATED 0.005", 828mm

(2.72)

6

10

11

8

8

9

2

12

16

1

1

1

1

A

AJOUT PINCE TEFLON, CHANGE TEFLON

K

LET.

MODIFICATION

13-08-12

DATE

SBU

INT.

15

5

DETAIL A

13

13 INSTALL AGAINST NOTCH OF ITEM #4INSTALLER CONTRE L'ENCOCHE DE L'ITEM #4

4PERMETTRE DE BOUGER LIBREMENT ALLOW TO MOVE FREELY

-TOP & BOTTOM SEALING OPTION-

MACHINE

580A, 650A, 680A & 700A

PART

UPPER SEAL BAR ASS'Y W/SUPPORT

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

DATE

METRIC

± 0.1

±

0.5

±

0.

13-08-12

7

5

N.T.S.

5

INCH

± 0.004"

SIPROMAC

±

0.020"

±

0.020"

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

DEPT.

M-(M)-I

NO.

005C0437

QTY.

2

Page 41

Page 42

005A1535

ITEM PART # DESCRIPTION QT.

1 001B6563 PUMP SUPPORT 2

2 004A4240 BELLOWS ELBOW CONNECTOR ASSY 1

3 051-0360 BOLT 3/8"-16nc. X 1" S/S 8

2

7

9

11

8

10

4 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 8

5 051-0783 WASHER 3/8" FLAT THICK S/S 20

6 051-09931 BOLT M10 X 20MM HEX SS 4

7 100-1250 STRAIGHT 2"MNPT X 2" HOSE BARB SS 1

8 104-0151 HOSE 2"ID VACUUM TIGERFLEX 560MM 1

9 105-0258 EAR CLAMP 2" S/S 2

10 125-0070 BUSCH RA-0165 230-460V/3PH/60HZ 1

11 125-0075 BUSCH RA-0165 575V/3PH/60HZ 1

1

INSTALLER TROU DE CE CÔTÉ

DU RÉSERVOIR D'HUILE

INSTALL THIS HOLE ON THE OIL

RESERVOIR SIDE

LET. MODIFICATION

DATE

4

INT.

5

3

6 USE BLUE LOCTITE

165M³ BUSCH PUMP

MACHINE

PART

ITEM

MAT.

650A

PUMP "BUSCH" 165M³

CNC

3D DWG BY

2D DWG BY

SBU

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-10-08

DATE

14-10-08

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1535

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M-I

QTY.

1

Page 43

005A1522

ITEM PART # DESCRIPTION QT.

1 004-0183 VAC./ATM. VALVE SUPP. PRE-ASS'Y 1

2 051-0360 BOLT 3/8"-16nc. X 1" S/S 2

3 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 2

4 051-0780 WASHER 3/8" FLAT S/S 4

5 100-0095 STREET ELBOW 90° X 2'' NPT SS 2

6 100-0250 CLOSE NIPPLE 2" NPT SS 3

7 100-0250 CLOSE NIPPLE 1-1/2"NPT S/S 1

8 100-0487 TEE 2"npt. S/S 2

9 100-0558 RED. BUSHING 2"mnpt. X 1"fnpt S/S 1

10 100-0561 RED.BUSH. 2"NPTx1-1/2"NPT SS 1

11 100-1250 STRAIGHT 2"MNPT X 2" HOSE BARB SS 3

14

12

15

13

12 104-0151 HOSE 2"ID VACUUM 572MM 1

13 104-0151 HOSE 2"ID VACUUM 610MM 1

14 105-0120 SCREW CLAMPS 1-13/16'' TO 2-3/4'' ALL S/S 1

15 105-0258 EAR CLAMP 2" S/S 3

16 106-0051 VALVE 2WAY 24V 1-1/2"NPT60Hz 1

17 106-0060 VALVE 2WAY 24V 2'' NPT(B80) 60HZ 1

2

4

3

DETAIL A

LET. MODIFICATION

OUT

11

5

17

OUT

IN

9

IN

8

6

16

A

7

10

1

-OPTION - 165M³, 255M³ & 305M³ PUMP

MACHINE

PART

VACUUM/ATMOSPHERE VALVE ASSY

ITEM

MAT.

DATE

INT.

VACUUM

7

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-09-18

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1522

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 44

OUT

16

005A1521

ITEM PART # DESCRIPTION QT.

1 004-0183 VAC./ATM. VALVE SUPP. PRE-ASS'Y 1

2 051-0360 BOLT 3/8"-16nc. X 1" S/S 2

3 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 2

4 051-0780 WASHER 3/8" FLAT S/S 4

5 100-0095 STREET ELBOW 90° X 2'' NPT SS 2

6 100-0250 CLOSE NIPPLE 2" NPT SS 2

7 100-0250 CLOSE NIPPLE 1-1/2"NPT S/S 1

8 100-0487 TEE 2"npt. S/S 1

12

11

5

9 100-0558 RED. BUSHING 2"mnpt. X 1"fnpt S/S 1

10 100-0561 RED.BUSH. 2"NPTx1-1/2"NPT SS 1

11 100-1250 STRAIGHT 2"MNPT X 2" HOSE BARB SS 2

12 104-0151 HOSE 2"ID VACUUM 572MM 1

13

13 105-0120 SCREW CLAMPS 1-13/16'' TO 2-3/4'' ALL S/S 1

14 105-0258 EAR CLAMP 2" S/S 1

15 106-0051 VALVE 2WAY 24V 1-1/2"NPT60Hz 1

16 106-0060 VALVE 2WAY 24V 2'' NPT(B80) 60HZ 1

LET. MODIFICATION

15

DATE

OUT

2

4

IN

14

3

DETAIL A

9

-OPTION - 165M³, 255M³ & 305M³ PUMP

MACHINE

VACUUM

PART

VACUUM/ATMOSPHERE VALVE ASSY

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

13-09-18

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

005A1521

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

INT.

7

10

8

IN

1

6

A

Page 45

ITEM PART # DESCRIPTION QT.

8 104-0151 HOSE 2"ID VACUUM TIGERFLEX 560MM 1

9 105-0258 EAR CLAMP 2" S/S 2

10 125-0080 BUSCH RA-0255 230-460V/3PH/60HZ 1

11 125-0085 BUSCH RA-0255 575V/3PH/60HZ 1

12 125-0087 BUSCH RA-0305 230-460V/3PH/60HZ 1

13 125-0088 BUSCH RA-0305 575V/3PH/60HZ 1

005A1520

ITEM PART # DESCRIPTION QT.

1 001B6563 PUMP SUPPORT 2

2 004A4240 BELLOWS ELBOW CONNECTOR ASSY 1

3 051-0360 BOLT 3/8"-16nc. X 1" S/S 8

4 051-0622 NUT 3/8"-16nc. NYLON LOCK S/S 8

5 051-0783 WASHER 3/8" FLAT THICK S/S 20

6 051-09931 BOLT M10 X 20MM HEX SS 4

7 100-1250 STRAIGHT 2"MNPT X 2" HOSE BARB SS 1

10 11

12 13

2

7

9

8

SMALL HOLES MUST

BE ON OIL RESERVOIR SIDE

A

LET. MODIFICATION

001B6563 WAS 001A6563

1

3

5

5

4

14-05-28

DATE

6USE BLUE LOCTITE

SBU

INT.

-OPTION - 255M³ & 305M³ PUMP

MACHINE

650A

PART

PUMP "BUSCH" 255 & 305 M³

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-07-16

DATE

METRIC

± 0.1

±

0.5

±

0.

5

N.T.S.

INCH

± 0.004"

SIPROMAC

±

0.020"

±

0.020"

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

DEPT.

M-I

NO.

005A1520

QTY.

1

Page 46

004B4113

ITEM PART # DESCRIPTION QT.

1 106-0010 VALVE 2WAY N.C. 24VAC 1/4'' NPT(SMC) 1

2 102-0330 ELBOW 1/4" NPT X 3/8" HOSE QUICK 1

3 100-0065 STREET ELBOW 1/4" NPT SS 1

4 102-0361 Y BRANCH 1/4'' MNPT X 3/8'' T. QUICK 1

1

A

VALVE UPDATE

LET. MODIFICATION

2

3

4

QTY.

LISTE

2

1

QTY

14-05-27

DATE

SBU

INT.

-OPTION - GAS

MACHINE

VACUUM

PART

GAS VALVE ASSEMBLY (OPTION)

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-05-27

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004B4113

DOUBLE CHAMBER

SINGLE CHAMBER

MACHINE

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

Page 47

AIR PRESSURE

004B4105

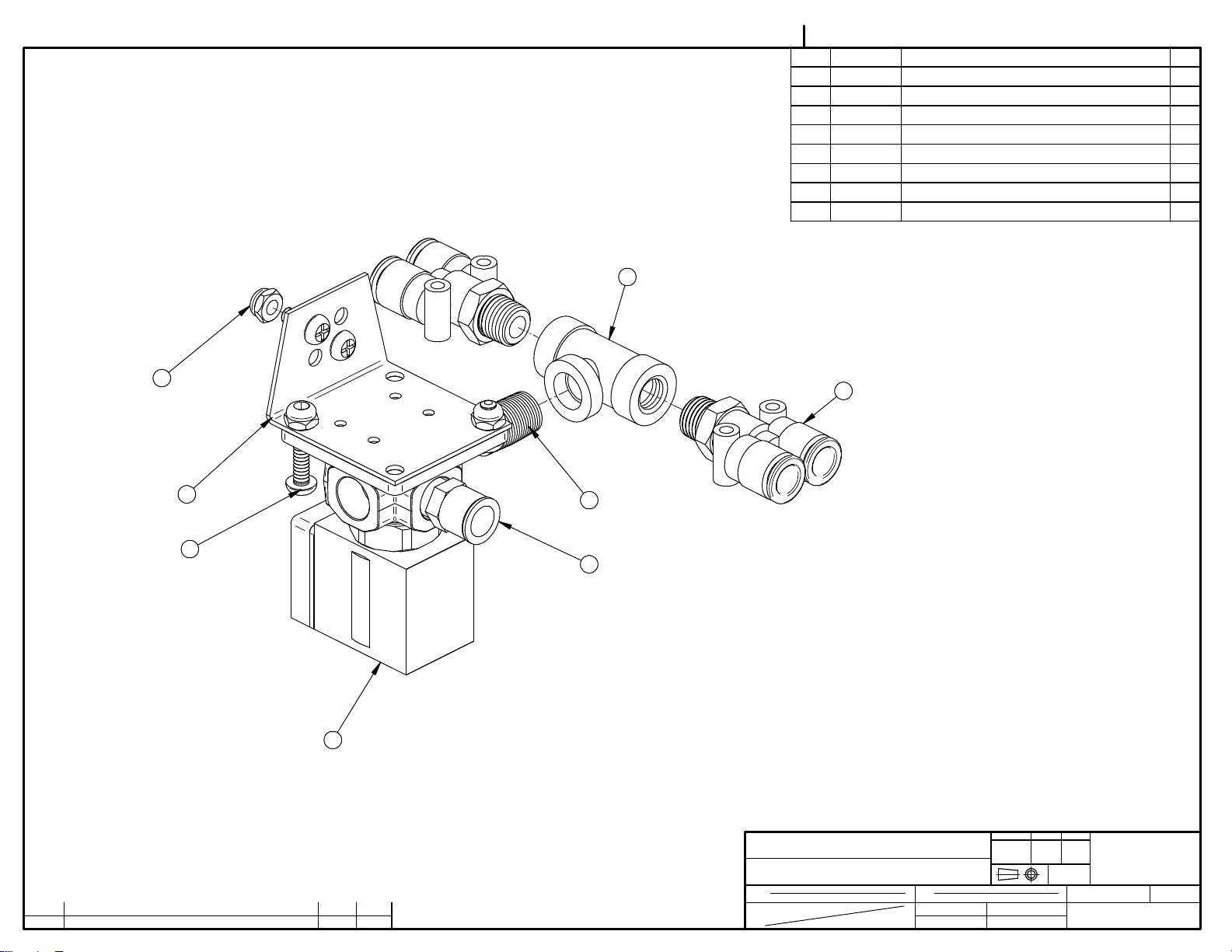

ITEM PART # DESCRIPTION QT.

1 001B6779 VALVE SUPPORT BRACKET 1

6

8

2 051-0144 SCREW #10-24 N.C 1/2"PAN PHIL. S/S 4

3 051-0572 NUT #10-24 NYLON LOCK S/S 4

4 100-0225 CLOSE NIPPLE 1/4" NPT SS 1

5 100-0463 TEE 1/4" NPT S/S 1

6 102-0330 ELBOW 1/4" NPT X 3/8" HOSE QUICK 3

7 102-0361 Y BRANCH 1/4'' MNPT X 3/8'' T. QUICK 1

8 106-00701 VALVE 3WAY 24V 1/4''NPT 1

TO OTHER VALVE

6

7

TO BELLOWS

FROM PUMP

5

4

6

1

2

3

A

UPDATE VALVE

LET. MODIFICATION

14-05-27

DATE

SBU

INT.

-OPTION - AIR REGULATOR

MACHINE

VACUUM

PART

BELLOWS VALVE ASSY (OPT AIR REG)

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-05-27

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004B4105

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 48

40°

004B4103

ITEM PART # DESCRIPTION QT.

1 004A4140 AIR REGULATOR SUPPORT 1

7 100-0065 STREET ELBOW 1/4" NPT SS 2

3 100-0225 CLOSE NIPPLE 1/4" NPT SS 1

2 100-0463 TEE 1/4" NPT S/S 1

6 102-0330 ELBOW 1/4" NPT X 3/8" HOSE QUICK 3

9 102-0361 Y BRANCH 1/4'' MNPT X 3/8'' T. QUICK 1

8 106-00701 VALVE 3WAY 24V 1/4''NPT 1

4 114-0147 PRESSURE REGUL. 0-60 PSI 1/4" NPT 1

5 114-0245 PRESSURE GAUGE 60 PSI 1/8" NPT 1

AIR PRESSURE

INLET

6

5

VACUUM FROM

OTHER VALVE

4

3

6

AIR PRESSURE

TO OTHER VALVE

2

1

9

TO BELLOWS

7

6

A

VALVE UPDATED

LET. MODIFICATION

14-05-27

DATE

SBU

INT.

8

-OPTION - AIR REGULATOR

MACHINE

600A & 620A

PART

AIR REGULATOR VALVE ASSY

ITEM

MAT.

CNC

DWG BY

APP. BY

SBU

DEPT. TOL.

USINAGE

TOLERIE

SOUDAGE

DATE

14-05-27

DATE

METRIC

INCH

± 0.1

± 0.004"

±

0.5

±

0.020"

±

0.

5

±

0.020"

N.T.S.

DEPT.

NO.

004B4103

SIPROMAC

ST-GERMAIN DE GRANTHAM

QUEBEC CANADA

M

QTY.

1

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Loading...

Loading...