Page 1

Quantum XL-100

INSTRUCTION MANUAL

SINGER

Page 2

CONGRATULATIONS

...on the purchase of this new Singer* computer sewing machine. To

achieve the most enjoyment and satisfaction from this product, it

is recommended that the instruction manual be read through step by step

while seated in front of the machine. This will help

get to know all of its parts and capabilities.

INSTRUCTION BOOK SINGER* QUANTUM XL-ioo

The manufacturer reserves the right to change the appearance, design, or

accessories of this sewing machine as considered

necessary without any notification or obligation.

*A trademark of The Singer Company

Copyright 1994 Singer Sewing Company.

All rights reserved throughout the world.

“IMPORTANT SAFETY INSTRUCTIONS”

“When using an electrical appliance, basic safety precautions should always be followed, including the following:’

“Read all instructions before using this sewing machine.”

DANGER.

1. “An appliance should never be left unattended when plugged in. Always unplug this appliance from the electric outlet

immediately after using and before cleaning.”

2. “Always unplug before relamping. Replace bulb with same type rated 5 Watts.”

it

WARNING

“Do not allow to be used as a toy. Close attention is necessary when this appliance is used by or near children.”

1.

2.

“Use this appliance only for its intended use as described in this manual. Use only attachments recommended by the

manufacturer as contained in this manual.”

“Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged

3.

or dropped into water. Return the appliance to the nearest authorized dealer or service center for examination, repair,

electrical or mechanical adjustment.”

“Never operate the appliance with any air openings blocked. Keep ventilation openings of the sewing machine and foot

4.

controller free from the accumulation of lint, dust, and loose cloth.”

“Keep fingers away from all moving parts. Special care is required around the sewing machine needle.”

5.

“Always use the proper needle plate. The wrong plate can cause the needle to break.”

6.

7.

“Do not use bent needles.”

“Do not pull or push fabric while stitching. It may deflect the needle causing it to break.”

8.

“Switch the sewing machine off (“0") when making any adjustments in the needle area, such as threading needle, changing

9.

needle, threading bobbin, or changing presser foot, and the like.” >

“Always unplug sewing machine from the electrical outlet when removing covers,lubricating, or when making any other user

10.

servicing adjustments mentioned in the instruction manual.”

11.

“Never drop or insert any object into any opening.”

12.

“Do not use outdoors.”

“Do not operate where aerosol (spray) products are being used or where oxygen is being administered.”

13.

14.

“To disconnect, turn all controls to the off (“0") position, then remove plug from outlet.

“Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.”

15.

cc

SAVE THESE INSTRUCTIONS

This sewing machine is intended for household use only.”

_To reduce the risk of electric shock:”

_To reduce the risk of burns, fire, electric shock, or injury to persons:”

55

Page 3

CONTENTS

Important Safeguards...........................................................2

Various Types of Stitches

Principal Parts....................................................................4,5

Accessories...........................................................................5

Major Functions....................................................................6

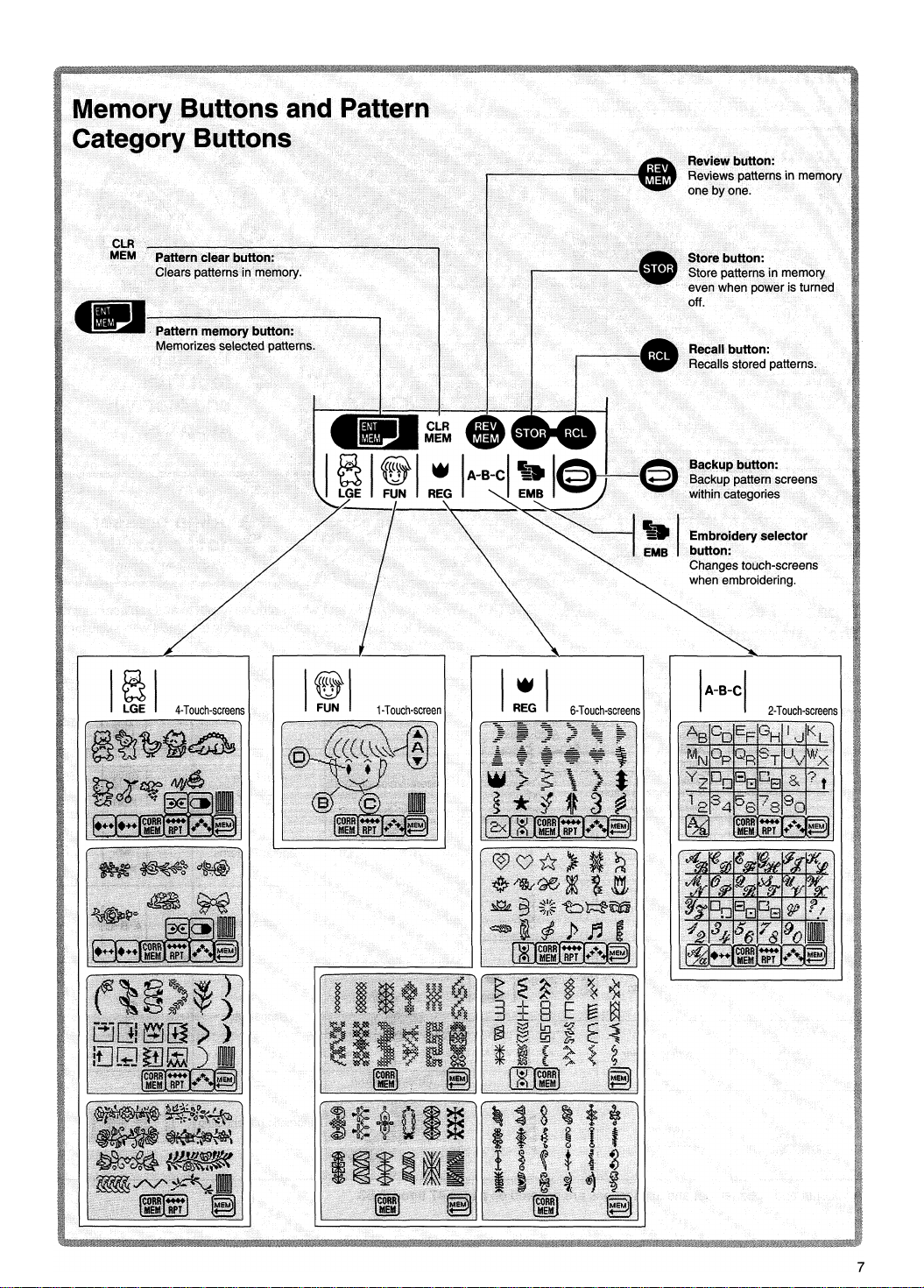

Memory Buttons and Pattern Category Buttons

Changing Presser Feet.........................................................8

Types of feet and their application

Connecting Machine.............................................................9

Winding Bobbin.............................................................10,11

Threading Machine........................................................12,13

Trial Sewing!..................................................................14,15

How to operate automatic thread cutter

How to select needle position

How to use the thread cutting groove

How to Select Utility Patterns

How to Adjust Stitch Length of Utility Patterns

Stitch length of each stitch pattern

How to Adjust Stitch Width of Utility Patterns

Automatic Computer Controlled Thread Metering

(tension)..............................................................................19

How to modify top thread supply.

How to shirr and gather.

Problem Indicators..............................................................20

Fabric, Thread and Needle Table

How to Remove and Insert Needle

Straight Stitch......................................................................22

Back Tack..........................................................................23

Changing sewing direction/ pivoting.

Seam guides/ How to select needle positions.

Zigzag Stitch

How to adjust stitch width.

Manually adjusted stitch width vs. stitch length.

Overcasting (Overedging)...................................................25

Automatic Buttonholes...................................................26,27

Purl stitch buttonholes

Sewing Corded Buttonholes

Basting Stitch......................................................................28

Blindstitch

Attaching Buttons................................................................30

Four Direction Sewing........................................................31

Balancing Shape of Pattern

Pattern Sewing

How to select patterns. Pattern modifier keys.

Large Size Pattern Sewing

1 .Single pattern

2. Enlarge pattern

3. Reduce pattern

4. Mirror pattern

5.2-color pattern

6. Position pattern

7. Repeat pattern

.......................................................................

......................................................................

.............................................................

..........

............................................3

...................

.............................................

...................

.....................

......................................

....................................

...............................................

...............................................

............................................

16

17

18

21

21

28,29

31

32,33

34,35

24

28

Fun-face Pattern Sewing....................................................36

Regular Pattern Sewing......................................................37

How to use pattern modifier keys of regular patterns.

Alphabet Stitch Sewing.......................................................38

How to select letter of alphabet.

7

How to Combine Patterns...................................................39

Combine upper case and lower case.

Combination fun-face and alphabet.

How to Correct Patterns in Memory

How to Cut Cross-over Stitch

Free Arm Sewing

Circular Pattern Stitch.........................................................42

Heirloom Sewing (Using wing needle)................................43

Quilting (Using quilting guide).............................................43

Patch Work

Twin Needle Sewing

Pin Tucks............................................................................45

Darning/ Free-motion Embroidery

Rolled Hemming.................................................................47

Even Feeding......................................................................47

Inserting Zippers.................................................................48

Inserting Invisible Zippers

Manual Buttonholes............................................................50

Attaching Cords..................................................................51

Optional Accessories.....................................................52,53

Ruffler presser foot

PIntuck foot/ Open toe embroidery foot

Darning/Embroidery foot/ Quilter’s foot

Side cutter

Embroidery

Preparation for Embroidery

Attaching/removing embroidery bed.

Inserting/removing embroidery card.

Securing material in embroidery frame.

Attaching/removing embroidery frame.

Determining location of embroidery.

Letter embroidery guide

Initial letter embroidery frame

Sampler Card Patterns of Embroidery...........................58,59

Outline embroidery

Multi-color embroidery

Letters Card of Embroidery

Example (combination of sampler and

upper/lower case script)

Troubles in Embroidering....................................................63

If thread breaks during embroidering:

To re-embrolder troubled pattern from start:

Helpful messages given on LCD window during

embroidering:

Optional Embroidery Cards

How to Replace Light Bulb

Cleaning..............................................................................65

How to Replace Needle Threader Hook Holder

Performance Checklist

Part Number of Accessories...............................................68

.................................................................

.......................................................................

...........................................................

.......

....................................................................

.....................................................

..................................................

...................................

............................................

......................................

...........................................

54,64

...........................................

...........................................

................................................

.................................................

56,57

60,61

.................

66,67

40

40

44

45

46

49

41

62

64

65

65

Page 4

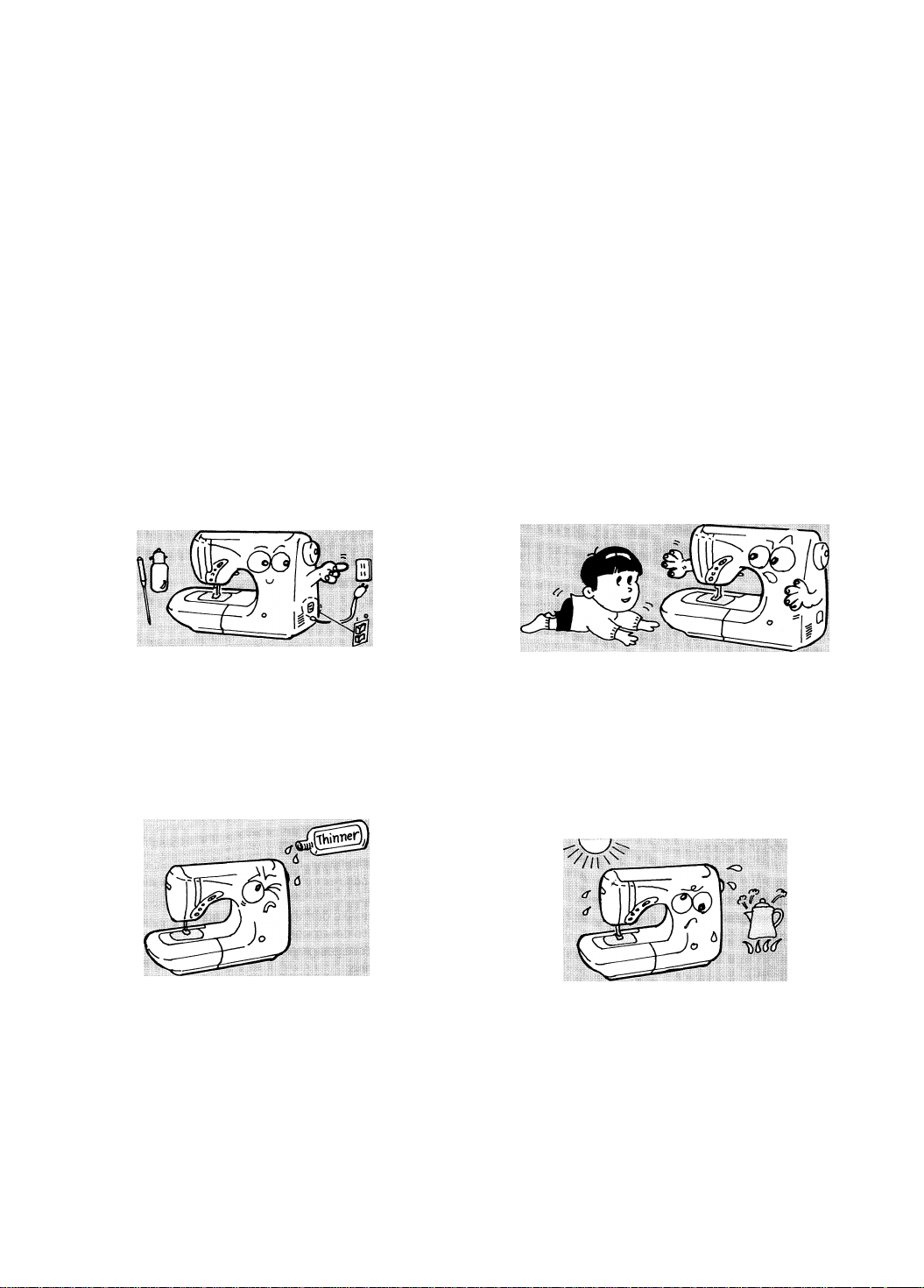

Be sure to turn power switch OFF before replacing sewing machine needle, or lubricating machine.

When not in use, be sure to turn power switch OFF and unplug machine.

Do not use thinner or other similar solvents to clean machine.

Do not expose machine to direct sunlight or humid atmos

phere.

This sewing machine uses a micro computer and precision electronic circuits consisting of semiconductor components, so

please observe the following precautions:

• Keep room temperature at 40°F to 100°F. If temperature of room where machine is used is too low, machine may present

problems such as failure to reach its normal sewing speed.

• Motor used in this sewing machine is electronically controlled. When the machine is operated for an extended period of

time at low speed, safety device will automatically turn machine OFF preventing motor from overheating. If motor should

stop while sewing, turn power switch OFF, and wait about 20 minutes. This will reset safety device.

Page 5

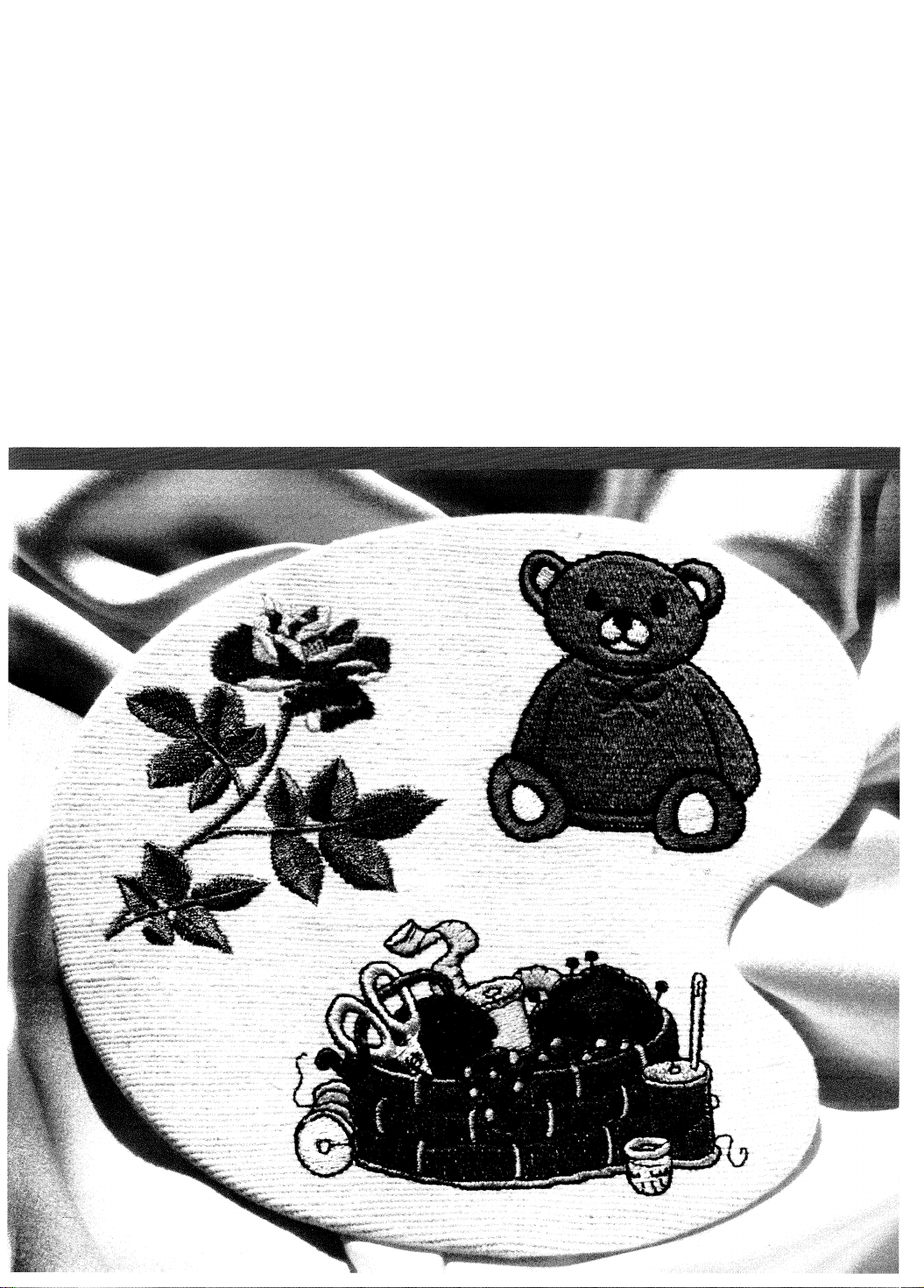

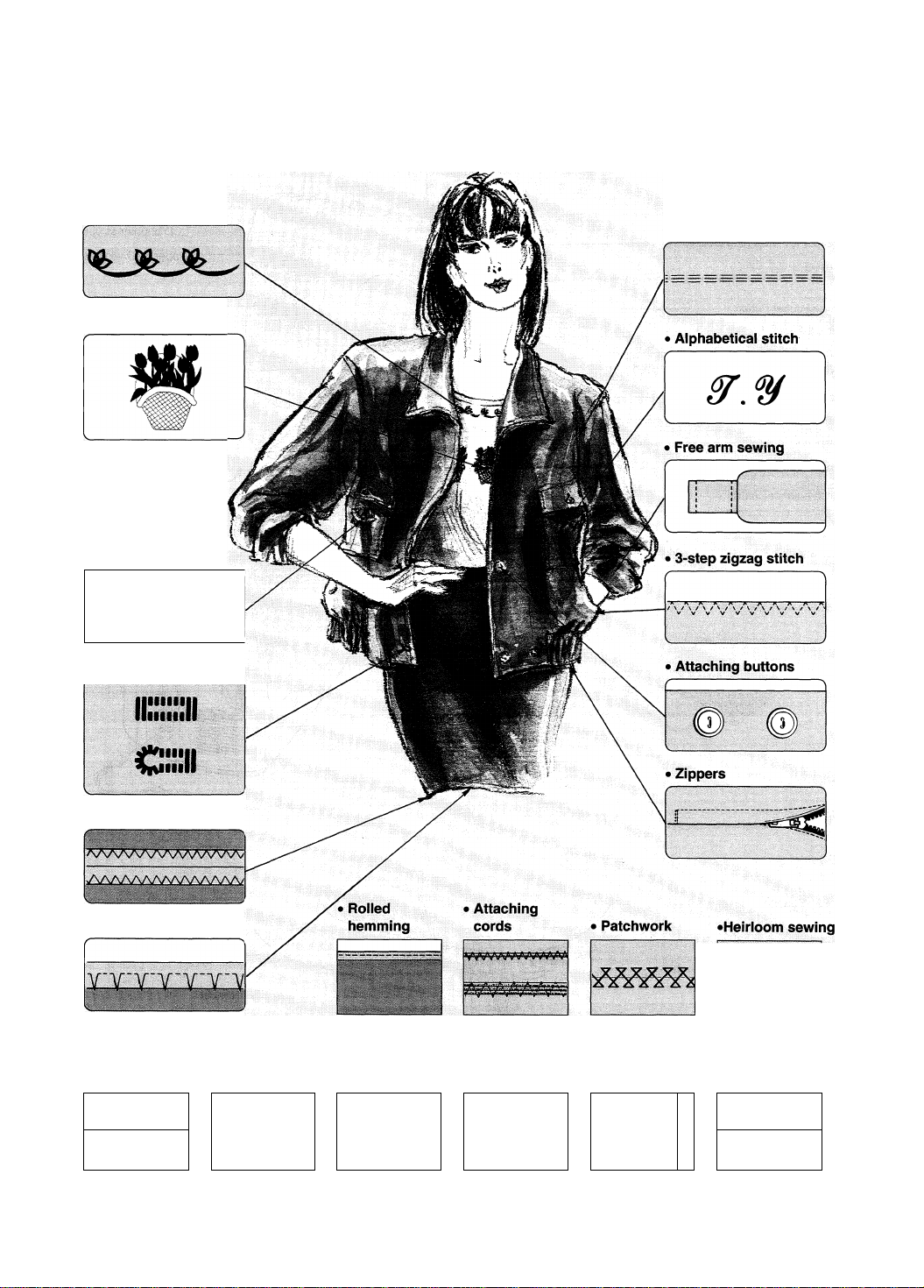

Various Types Of Stitches

• Pattern stitch

• Embroidery stitch

» Applique

• Buttonholes

r

• Reinforcing stretch

stitch

»Overcasting

» Blindstitch

• Circular

• Straight stitch • Zigzag stitch • Basting stitch pattern stitch • Quilting

aaaaa

rrrm“rrrrn

CCCCCCCOICO

Wing needle

► Pintuck

j s

AA/|\AA/^sAA^ A/

Twin needle

Page 6

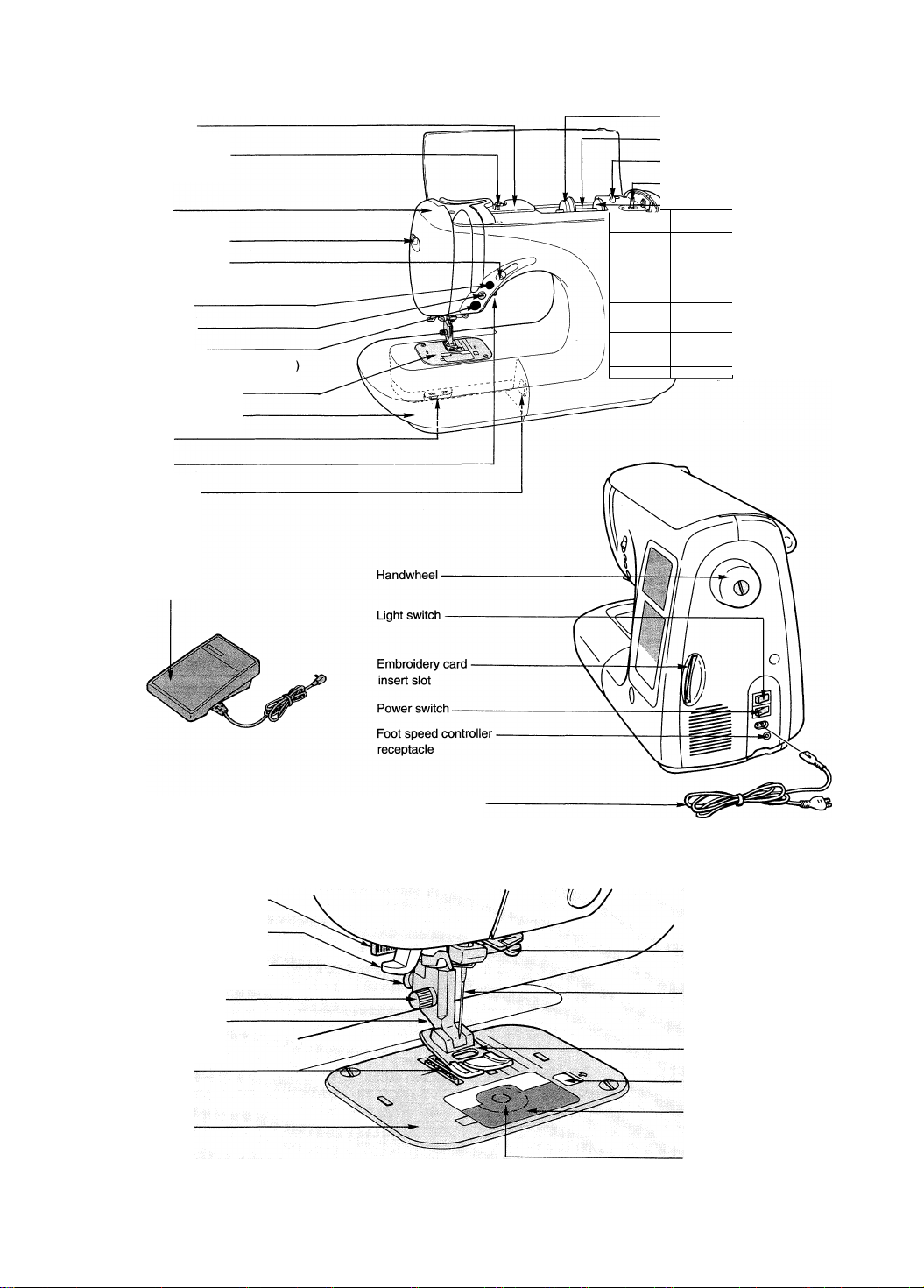

Principal Parts

Thread sensor guide

Bobbin winder thread guide

Face plate cover

Presser foot adjusting lever

Sewing speed lever

(When foot speed controller is not used.)

Thread cutter button

Back tack button

Start/stop button

(When foot speed controller is not used.

Needle plate

Auxiliary bed (Accessory box)

Drop feed lever

Presser foot lifter

Stitch balance control

Foot speed controller

\

--------

Thread spool cap

Spool pin

Bobbin thread cutter

Bobbin winder

Spool pin felt

LCD brightness control

Upper LCD window:

Lower LCD touch-screen

Function buttons

Utility pattern button

Buttonhole lever

Needle threader

Presser foot release button

Presser foot screw

Presser foot holder

Feed dog

Needle plate

Electric power cord

Needle clamp

Needle

Presser foot

Bobbin case cover button

Bobbin case

Bobbin

Page 7

Embroidery foot -

Converting machine to free-arm

Available spot for extra feet.

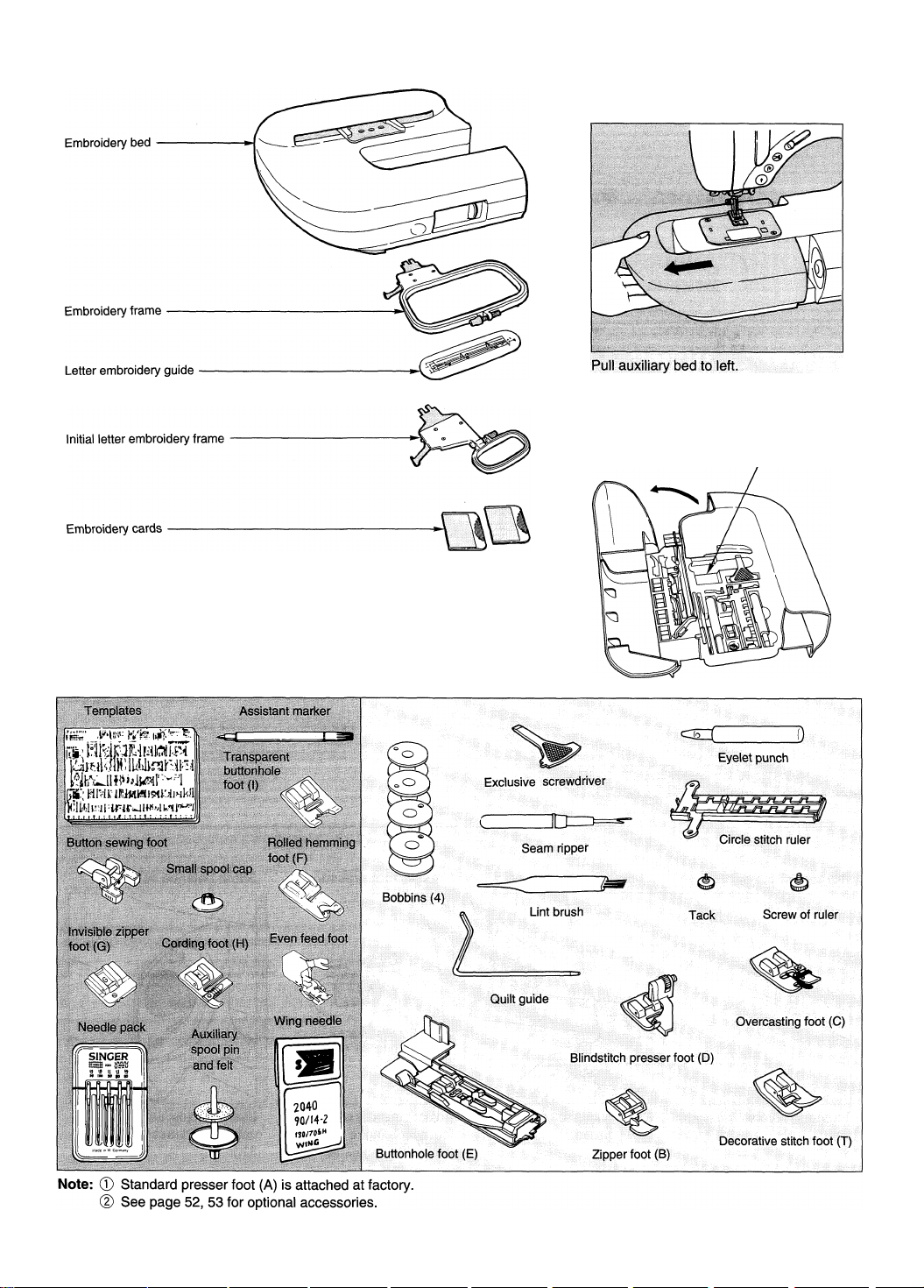

Accessories

d) See page 68 for part numbers of accessories.

Page 8

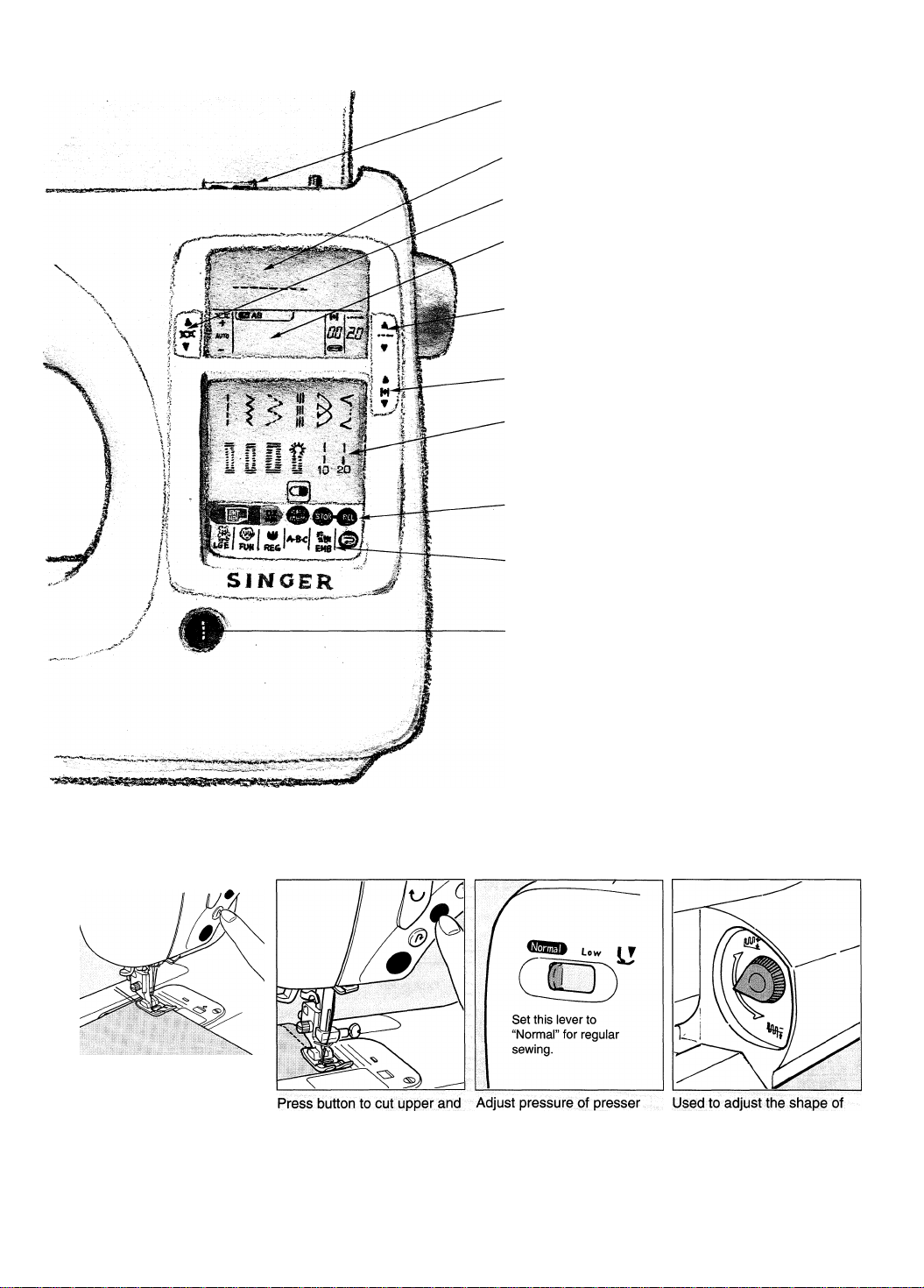

Major Functions

' LCD Brightness control:

Controls brightness and contrast of upper LCD window and

lower LCD touch-screen.

• Upper LCD window:

View stitch pattern graphics and problem indicators.

• Thread meter override buttons:

Increases and decreases top thread supply (tension).

• Liquid crystal display:

Indicates presser foot, stitch length, stitch width, tension, mirror

image, turn over, pattern repeat, small abc, two color patterns

and memory.

» Stitch length override buttons:

Increases and decreases stitch length.

► Needle position/stitch width buttons:

Changes straight stitch needle position and stitch width.

► Lower LCD touch-screen:

Indicates patterns which may be selected.

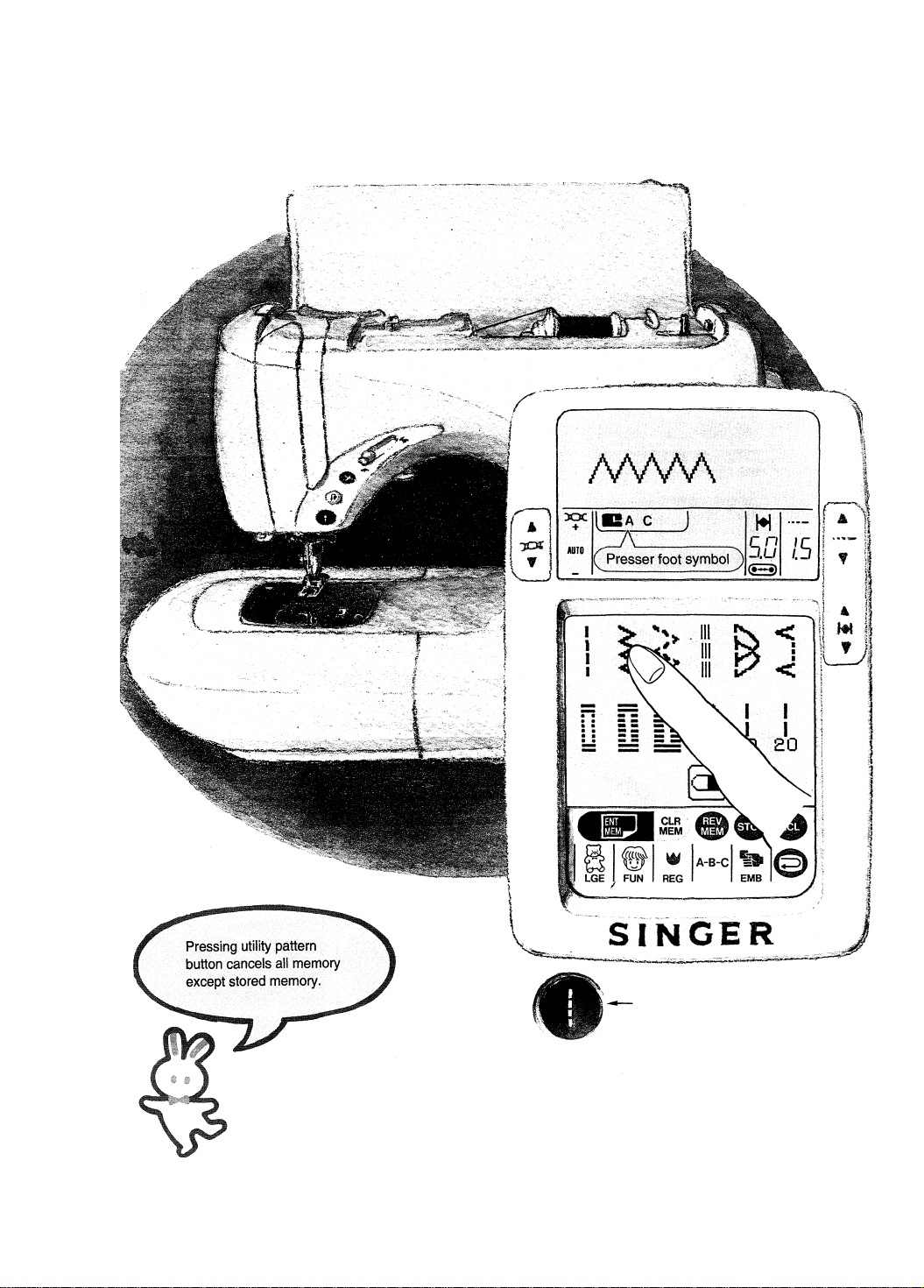

Memory buttons:

Memorize, clear, review, store and recall patterns.

' Pattern category buttons:

Used to select large motifs, fun faces, regular, alphabet or

embroidery category touch-screens.

Back tack button

Used to back tack beginning

and end of seam.

Utility pattern button:

Instant access to utility pattern screen

Thread cutting button Presser foot pressure

lower thread.

foot according to type and

thickness of material.

Stitch balance control

patterns. (Please see page

31.)

Page 9

Page 10

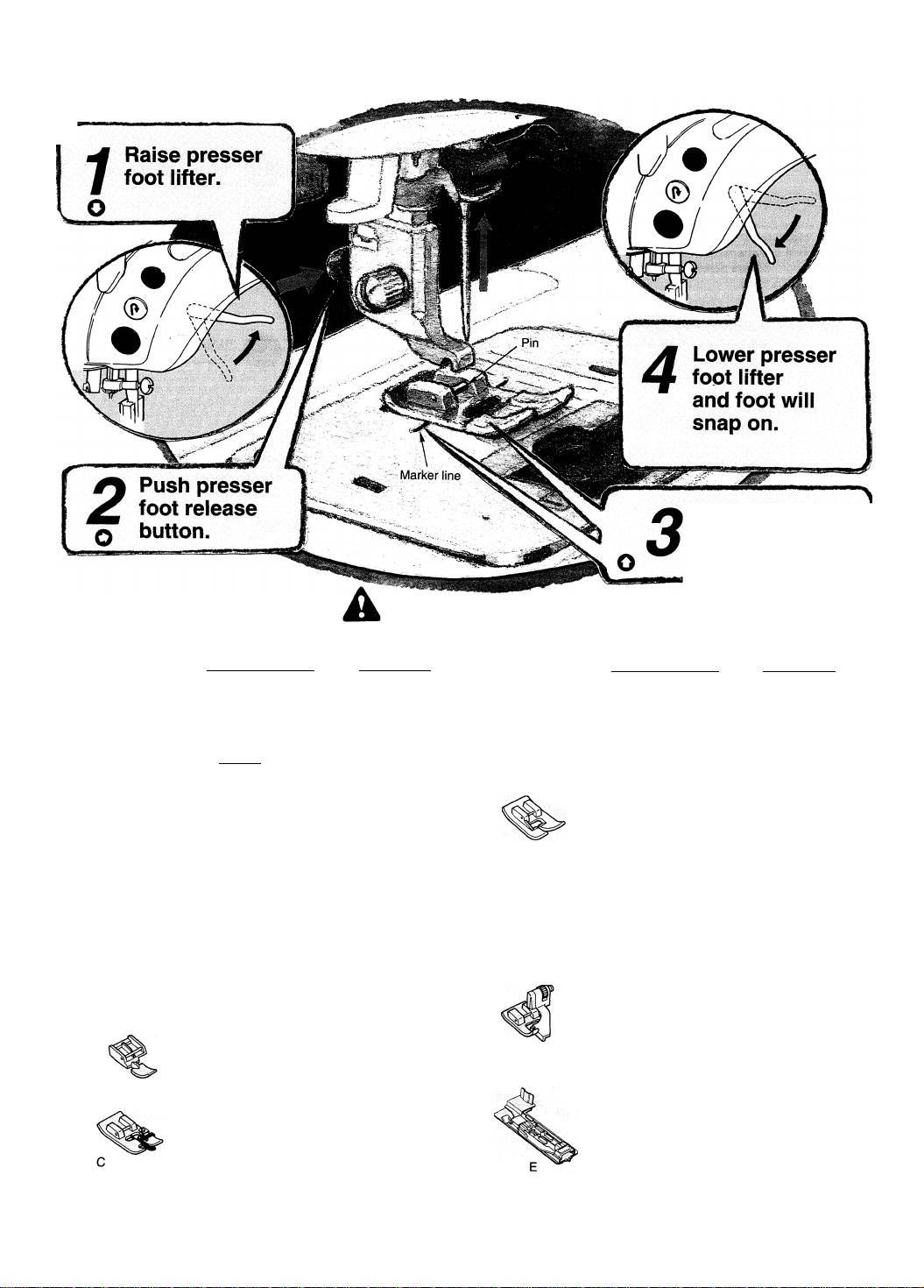

Changing Presser Feet

Place needle in highest position.

Align presser

foot pin with

marker line.

Types of Feet and Their Application

Typical applications

Standard presser foot

Zipper foot

B

Overcasting

Straight stitch

Quilting

Pintuck

Zigzag stitch

Applique

Quilting

Overcasting

3-step zigzag stitch

(elastic stitch)

Stretch

reinforcing stitch

Overcasting, etc.

Pattern stitch,

patchwork, etc.

Inserting zipper

Overcasting

(Overlocking)

CAUTION: When changing to feet which require removal and replacement of

presser foot screw it is mandatory screw is tighted with exclusive

screwdriver (see page 47).

Stitch pattern

Auto-matic

Decorative stitch foot

Blindstitch presser foot

w

REG

Buttonhole foot

Typical applications Stitch pattern

Large motif patterns

LGE

Fun Face

Patterns

Regular Patterns

Alphabet

Blindstitch

Automatic buttonholing

FUN

w

REG

A-B-C

<

<

O D D

ti

y

Additional and optional feet and applications are covered on pages 47 through 53.

Page 11

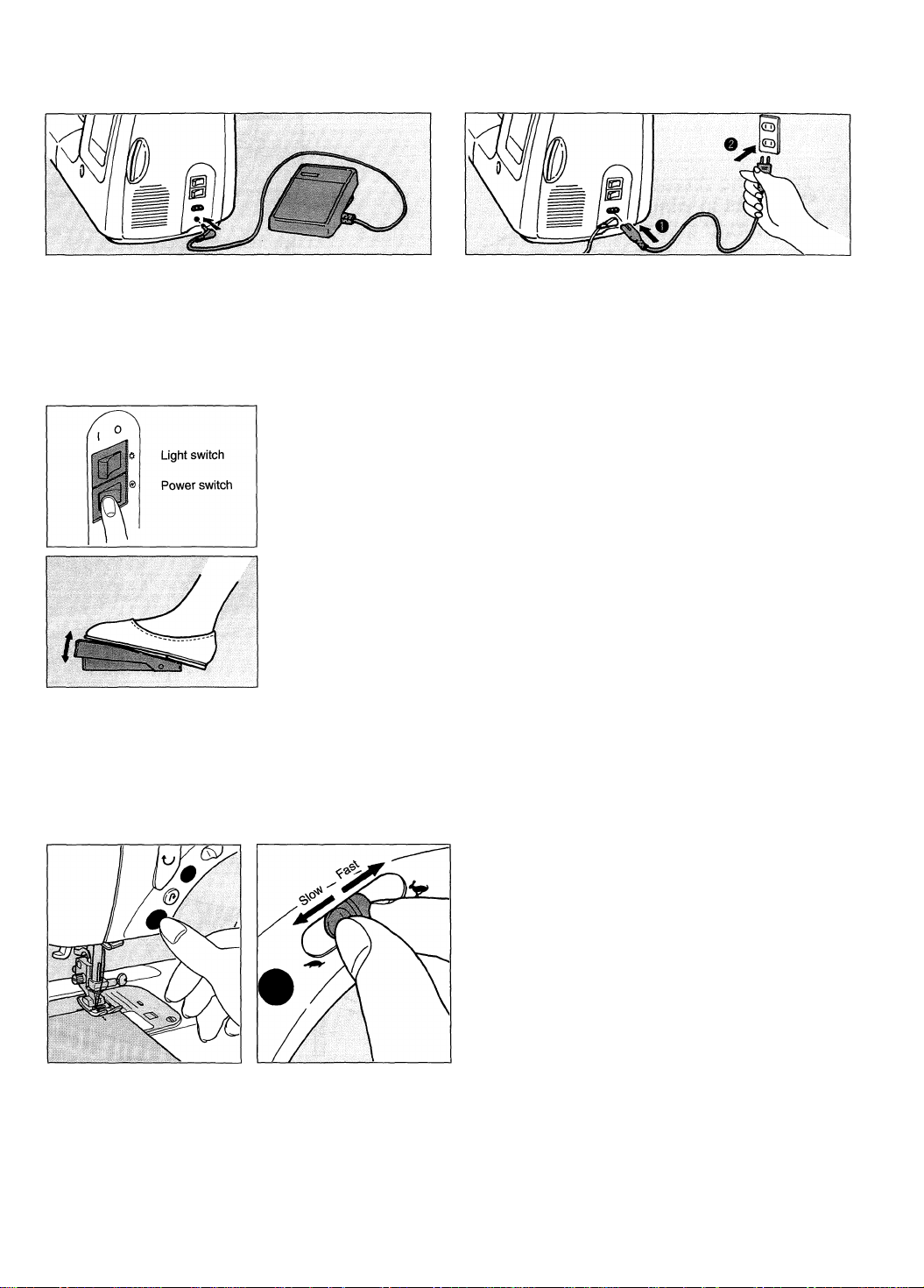

Connecting Machine

Push foot speed controller plug into lower receptacle at right

end of machine.

NOTE: If upper LCD window or lower LCD touch-screen is too bright or dark to see the stitch patterns, adjust LCD brightness

control (see page 15).

Push power cord plug O into upper receptacle at right end of

machine. Plug 0 into electric outlet.

Running Machine

Power/light switch.

- When ‘T’ side of power switch is pressed machine will be turned on.

- When “O” side of power switch is pressed machine will be turned off.

Note: Power switch must be on before light switch will operate.

To run machine press foot speed controller. The harder you press, the faster machine will

sew.

To stop machine, remove foot from controller.

Running machine without foot speed controiier

Foot control must be unplugged for start/stop button and sewing speed lever to operate.

Start/stop button

One press on button starts

machine, and another press

stops machine.

Note: #1.When foot speed controller is plugged In, start/stop button can only be used to stop machine.

#2. When foot speed controller Is plugged in, sewing speed lever will not operate.

Sewing speed lever

Sliding lever sets desired

sewing speed.

Page 12

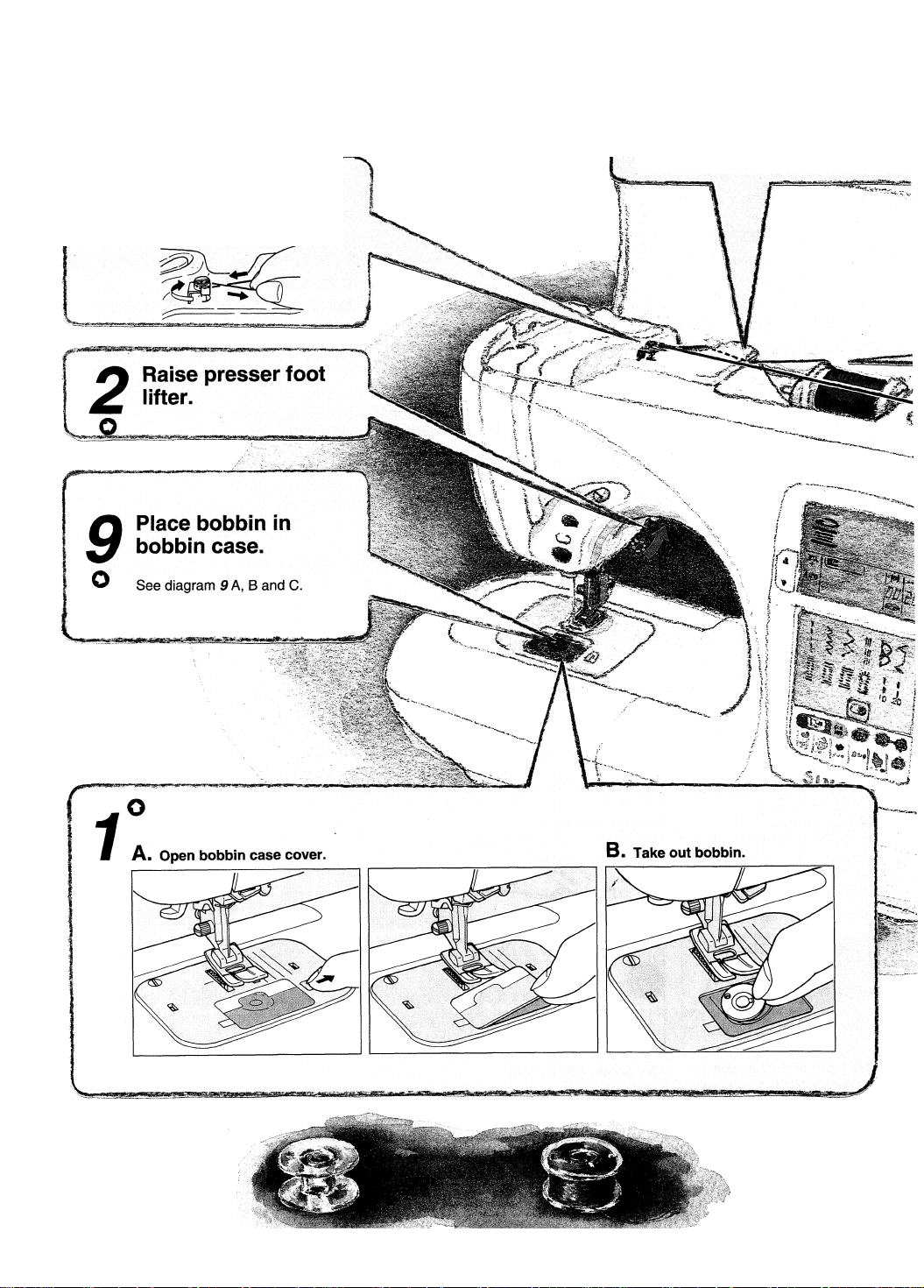

Winding Bobbin

To wind a bobbin follow steps 1 through 9.

Wind thread around

5

bobbin winder

Q thread guide.

Use both hands to

pull thread into

4

Q groove of thread

sensor guide.

10

Page 13

£% Place thread spool

and spool cap onto

- , . (2) Use cap to hold spool in

(1) Be sure notch on spool is i

on right side.

O spool pm. place

oUhread® large spool NOTE: Some size and style spools of

V—,i" " 11 '• I . TKiiiiiiiiiiiiiiiiJiiiiiiJiiiiiiiri

thread do not deliver thread smoothly with

horizontal spool and spool cap. In this

case use vertical auxiliary spool pin.

Place bobbin on bobbin

Bobbin

winding shaft

winding shaft.

Lead thread through one

of the holes in bobbin

from inside out.

• Press bobbin against winding regulator. \ regulator

• Hold thread while winding and trim flush with top of bobbin. J

Push bobbin back to left.

O t

Bobbin thread

cutter

Take bobbin off shaft

and cut thread.

Hold thread end, depress

speed controller to wind

bobbin. *

r

9

Place bobbin in case Pull thread Into grodS

with thread pulling off bobbin case and draw thread to

A. as illustrated. B. rear of machine C. Close bobbin case cover.

NOTE: Always use Singer 15 class bobbins!

Page 14

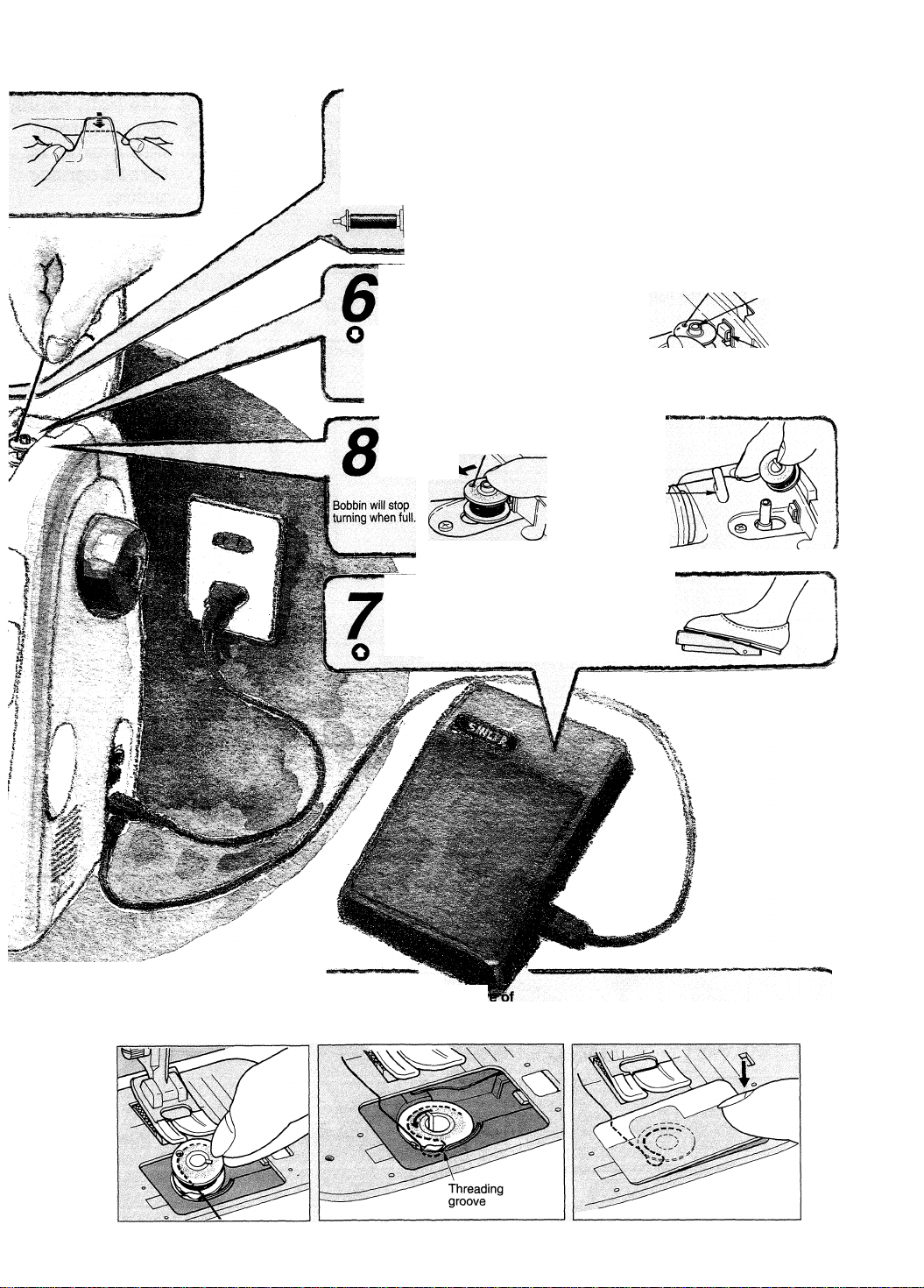

Threading Machine

To thread machine follow steps 1 through

Follow threading

path arrows on

4

Q machine. (4,5,6,7)

O Use both hands

^ to pull thread

Q into groove of

i I

thread sensor

guide.

12

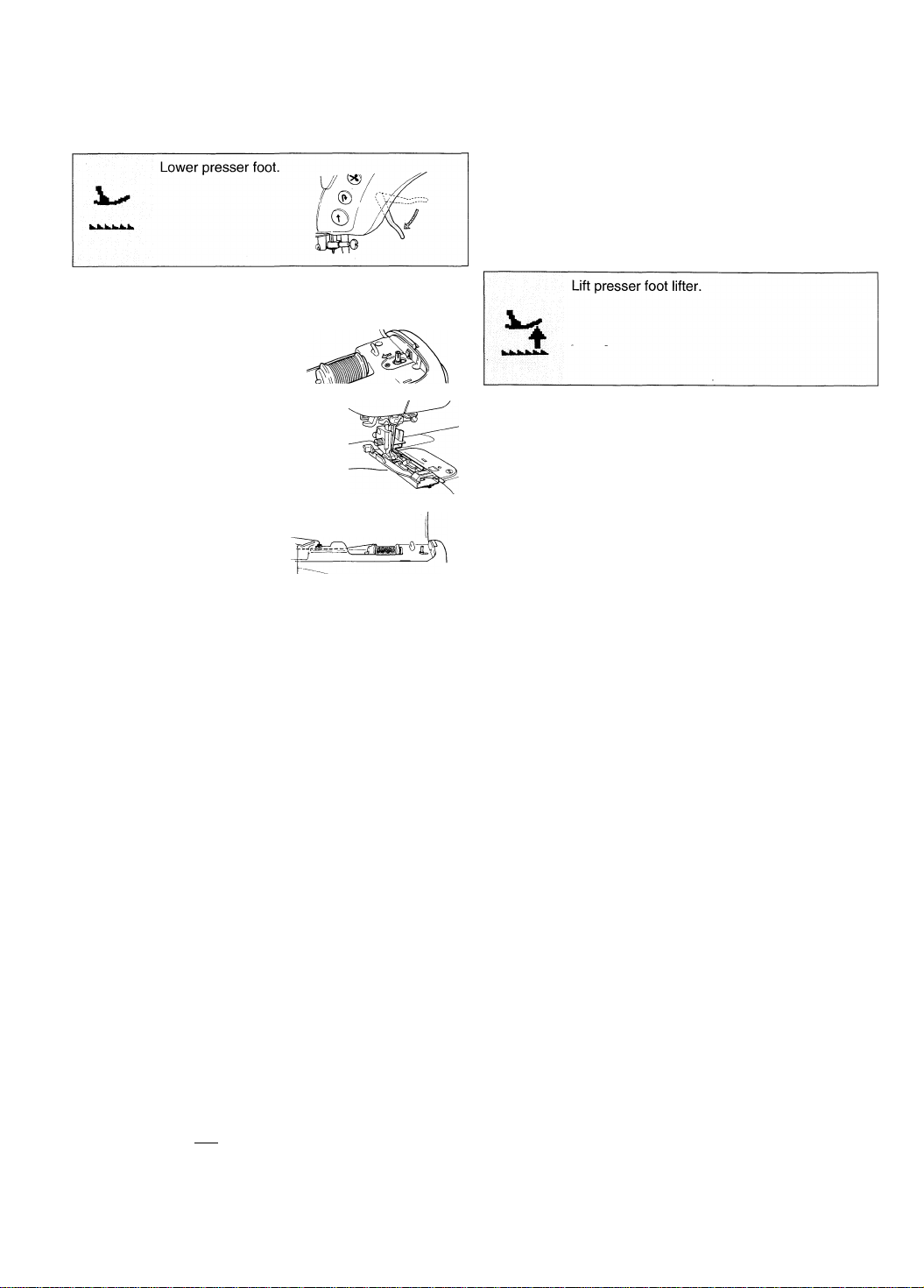

Automatic Needle Threading

A. Lower presser foot lifter.

Raise needle to highest position.

B. Push threading lever down. C. through eye of needle.

Place thread onto ®

' Push threading lever all the

way down and a hook will go

Pass thread in front of needle and

below hook.

Page 15

►• c»» 1^. *V>- *-vi s,..*jfj*, .

Turn handwheel,

__

counterclockwise to

Q raise needle to high

est position.

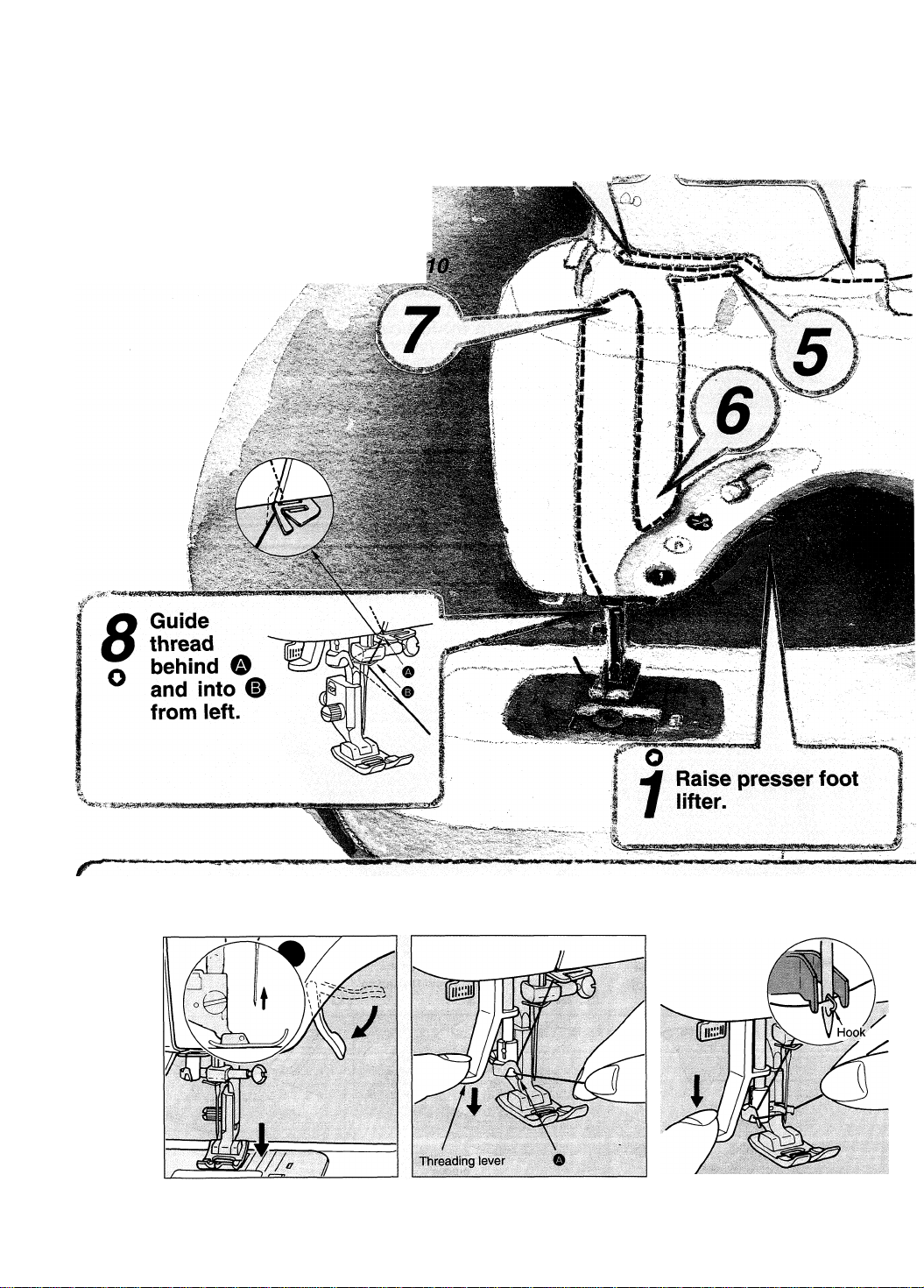

Pulling up Bobbin

10

Thread

Hold needle thread lightly with left

hand and turn handwheel

counterclockwise until needle

A. enters needle plate.

Continue turning handwheel while holding

needle thread until needle rises.

Tighten hoid on needle thread

B. until bobbin thread is pulied up.

D. Release needle threader.

Undo loop with fingers.

Pull both needle and bobbin

threads out about 4" and pass

them under presser foot to back of

C. machine.

Pull loop of thread that is at

back of the needle out about

E. 4".

-J

Caution:

1. Do not lower threading lever while sewing

machine is in operation.

2. Automatic needle threader will not work on

twin needles or wing needles.

13

Page 16

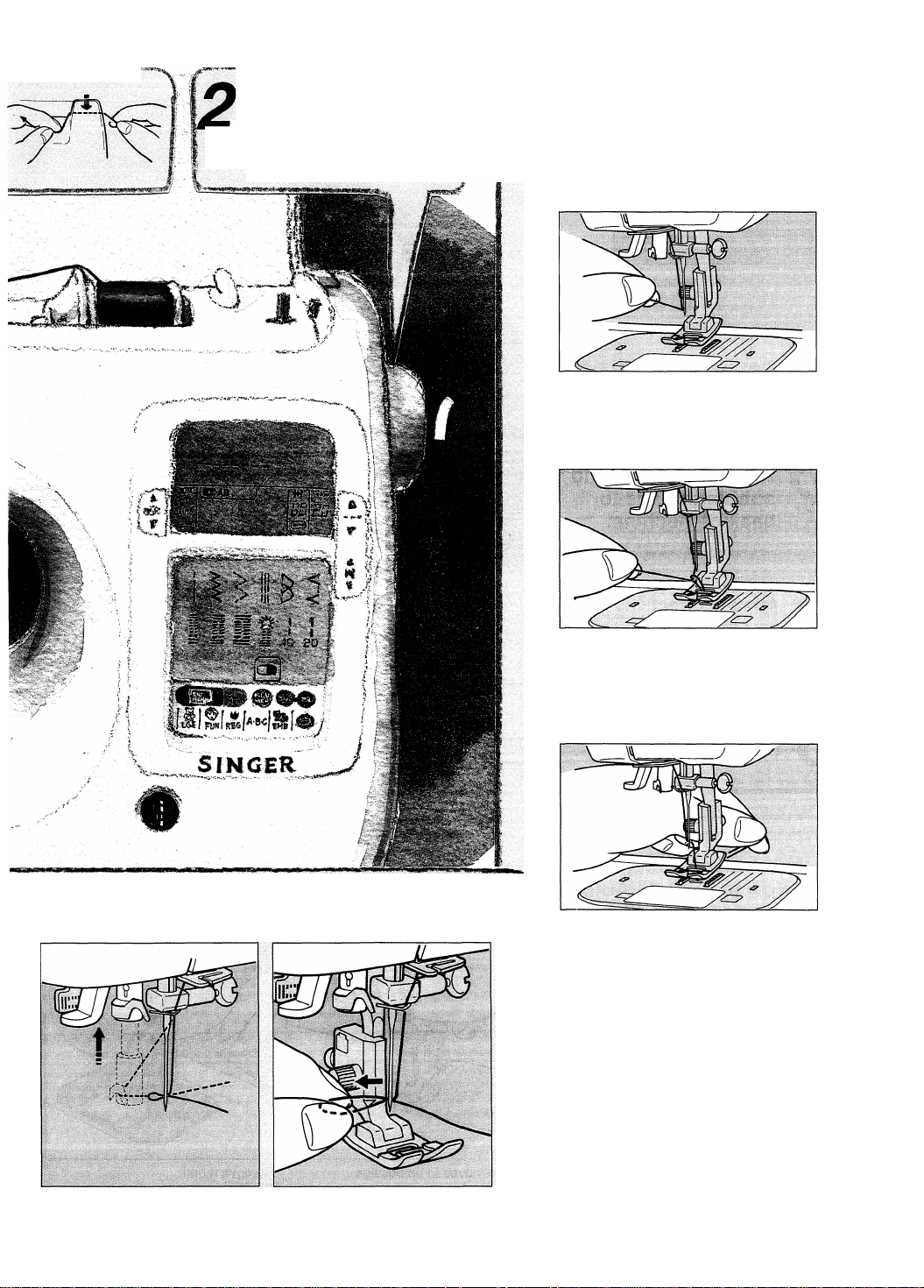

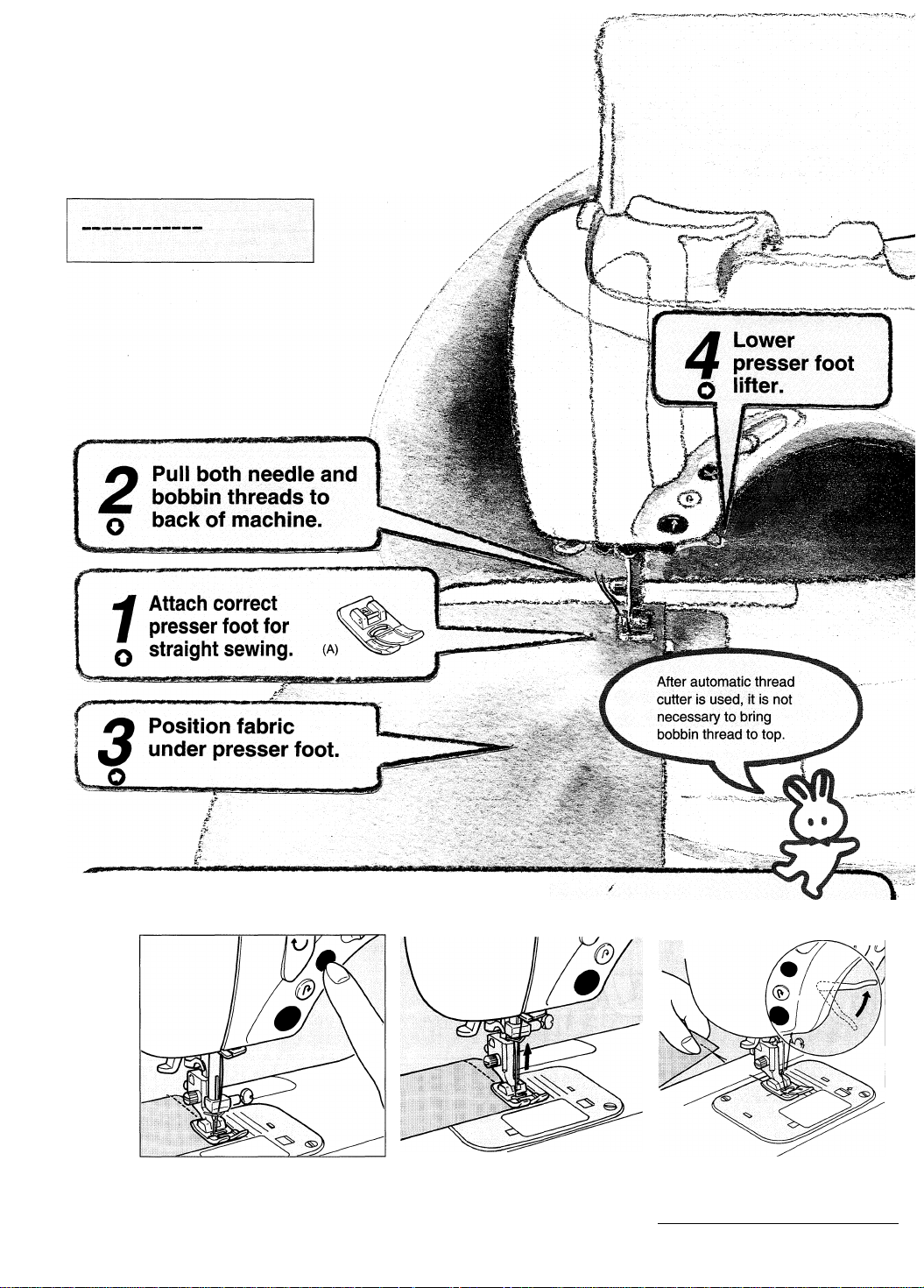

Trial Sewing!

When power switch is turned on utility touch-screen

illuminates and left position straight stitch is

automatically selected.

Upper LCD window

14

How to Operate Automatic Thread Cutter

Wait until needle stops _

A- completely in down position. B- Release button.

Press thread cutting button.

Needle moves to up position. Remove fabric.

C. Raise presser foot lifter.

NOTE: Use thread cutting groove

located at back of presser foot for

cutting thick or special types of thread^

Page 17

How to select needle position

(Only works with straight stitch)

Press needle position buttons to select from

among 22 possible needle positions.

M

nn

uu

M M

3.E

in

I.Lf

Full right

How to JH^^read Cutting Groove (How to Knot the Threads)

Remove material from machine.

After finishing a seam, raise needle and

presser foot, and slowly pull material from

under presser foot.

Note: It is advisable to use automatic thread cutter at end of a seam.

Use thread cutting groove located at back of presser foot for cutting thick threads or special types of thread.

^ Cut threads, using thread cutting

I groove.

Hold upper and bobbin threads together,

pull them out about 4" and cut them with

thread cutting groove located at rear of

presser foot.

^ Knot two threads on wrong side of O fabric.

Pull upper thread to wrong side of fabric,

and knot upper and bobbin threads. Cut

threads as close to knot as possible.

This technique is useful for securing

pattern stitches.

15

Page 18

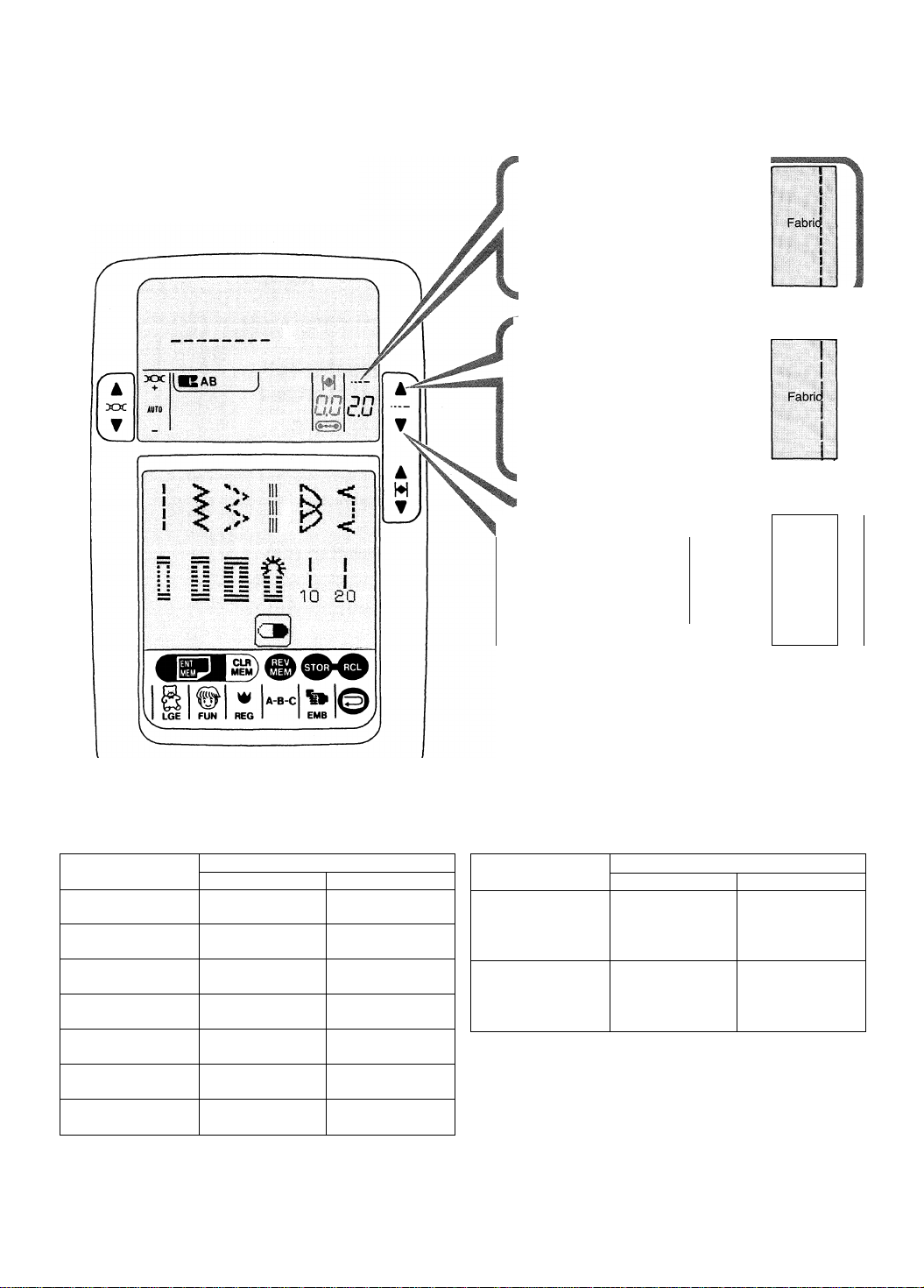

How To Select Utility Patterns

Touch utility pattern button , then touch desired utility

pattern. Upper LCD window will indicate selection.

№

*

16

Utility Pattern Button

Instant access to utility patterns

Page 19

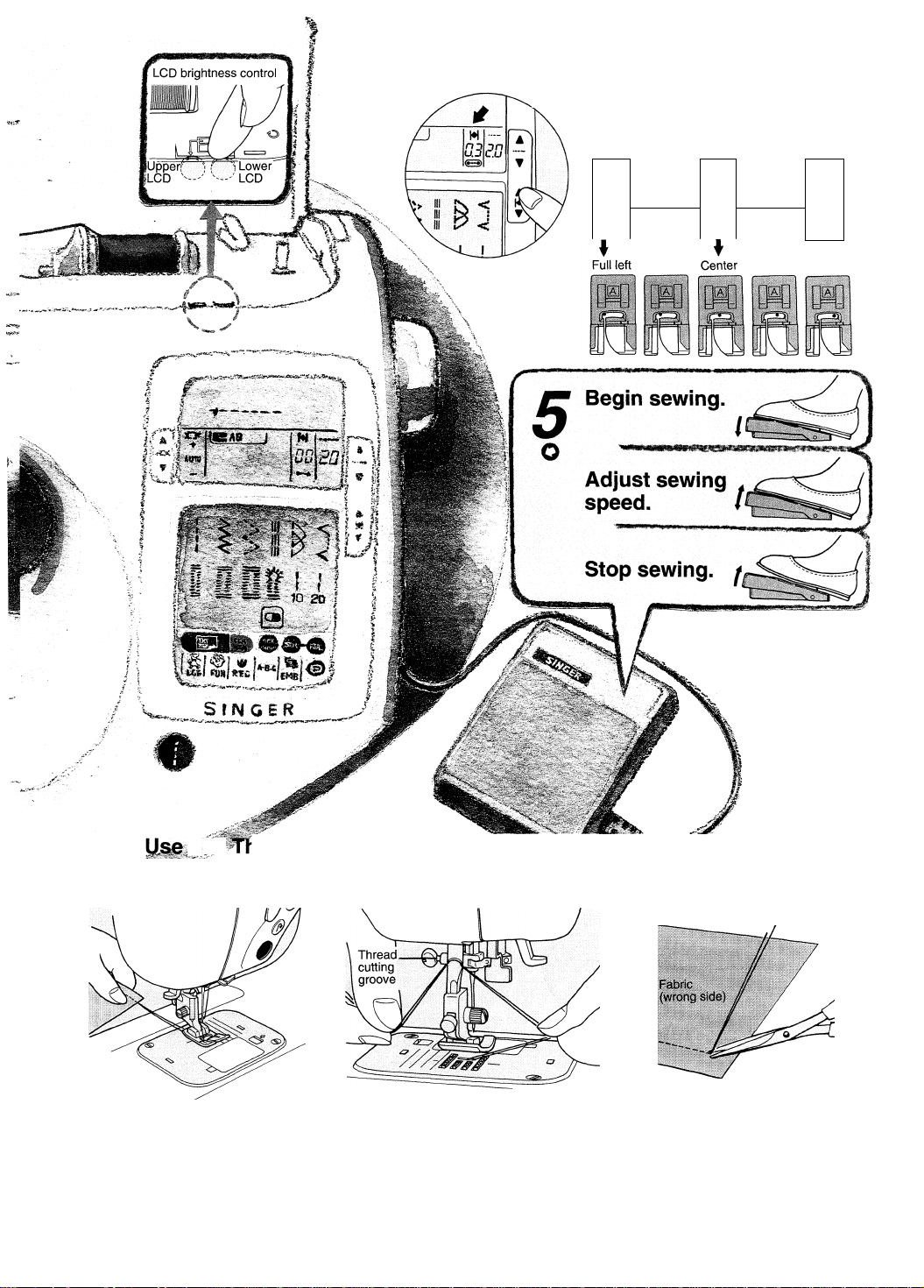

How to Adjust Stitch Length of Utility Patterns

Machine’s stitch patterns are automatically set to an optimum length.

By using override buttons pattern length can be adjusted as desired.

How to use stitch length manual

override buttons.

Example (Straight stitch)

¿0

(Automatic)

Example (Straight stitch)

Press this but

ton to increase

stitch length.

. Example (Straight stitch)

Press this but

ton to decrease

the stitch length.

40^

(Adjusted)

nc

(Adjusted)

Fabric!

inr

Stitch Length of Each Stitch Pattern

E'.O

1.5

1 n

i,U

J n

LJJ

Stitch length

Adjusted

LUJ UJ

LUJ UJ

LUJ UJ

LUJ UJ

LUJ I, LI

Stitch pattern

1

1

1

1

1

i ^

<

<

Q ODy

1 1

1 1

10 20

Automatic

Bartacked Keyhole

n C n c

U,J UJJ

n n

n n

n u n

n u n

! n

n u

LI, 1

n LI

IJ, 1

Stitch length

Adjusted

l~l u n

IJ,LI l,U

n u n

IJ,IJ l,U

Stitch pattern

))>

on W

1 LGE 1

1® % iP

1 ^ 1

on

1 REG I

NOTE: (—) indicates that pattern cannot be adjusted

using stitch length button.

When stitch length displays (- -) the pattern may be

adjusted with stitch balance control (see page 31).

Automatic

17

Page 20

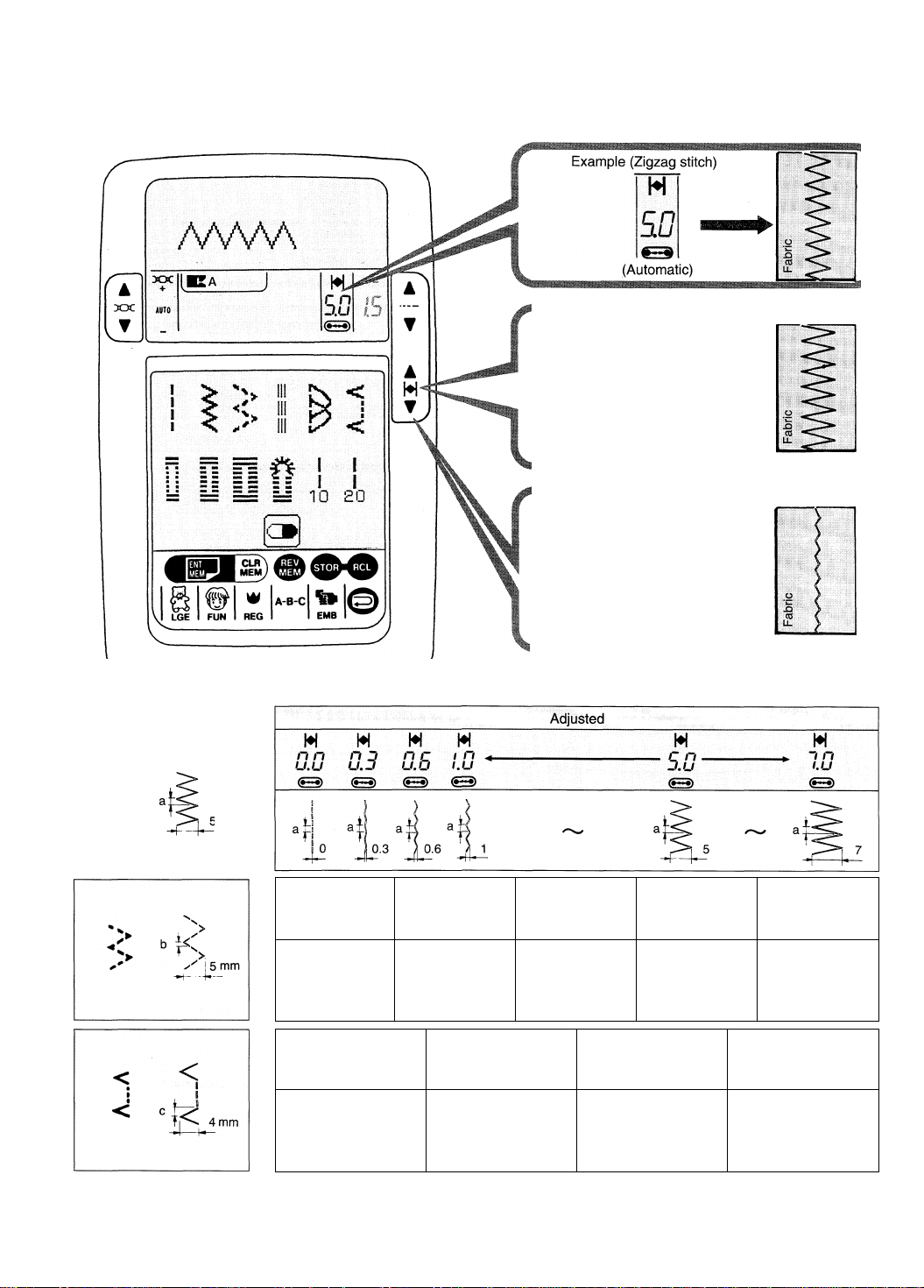

How to Adjust Stitch Width of Utiiity Patterns

After specifying pattern from among % : > 4 , if desired, the stitch width may

be adjusted by pressing stitch width buttons.

^ <

Example (Zigzag stitch)

Press this but-

ton to increase

stitch width.

Example (Zigzag stitch)

Press this but

ton to decrease

the stitch width.

M

Ì0

(Adjusted)

M

(Adjusted)

Automatic stitch width

5 mm

M

0 n

J.U

4Ì5

M

J n J

J.U ^

<

Stitch length a = 1.5 mm, b = 1 mm, c = 2 mm

w

1,U

j ^ 4

un ^

- 5.G -

M

u n J

IJJ

^3)

<

1

M ' w

. c n

5

.► C n

^ J.U

"lib

M

&>

<

O.U

^3)

W

c n

u.u

&>

M

nn

t.u

<^3>

18

Page 21

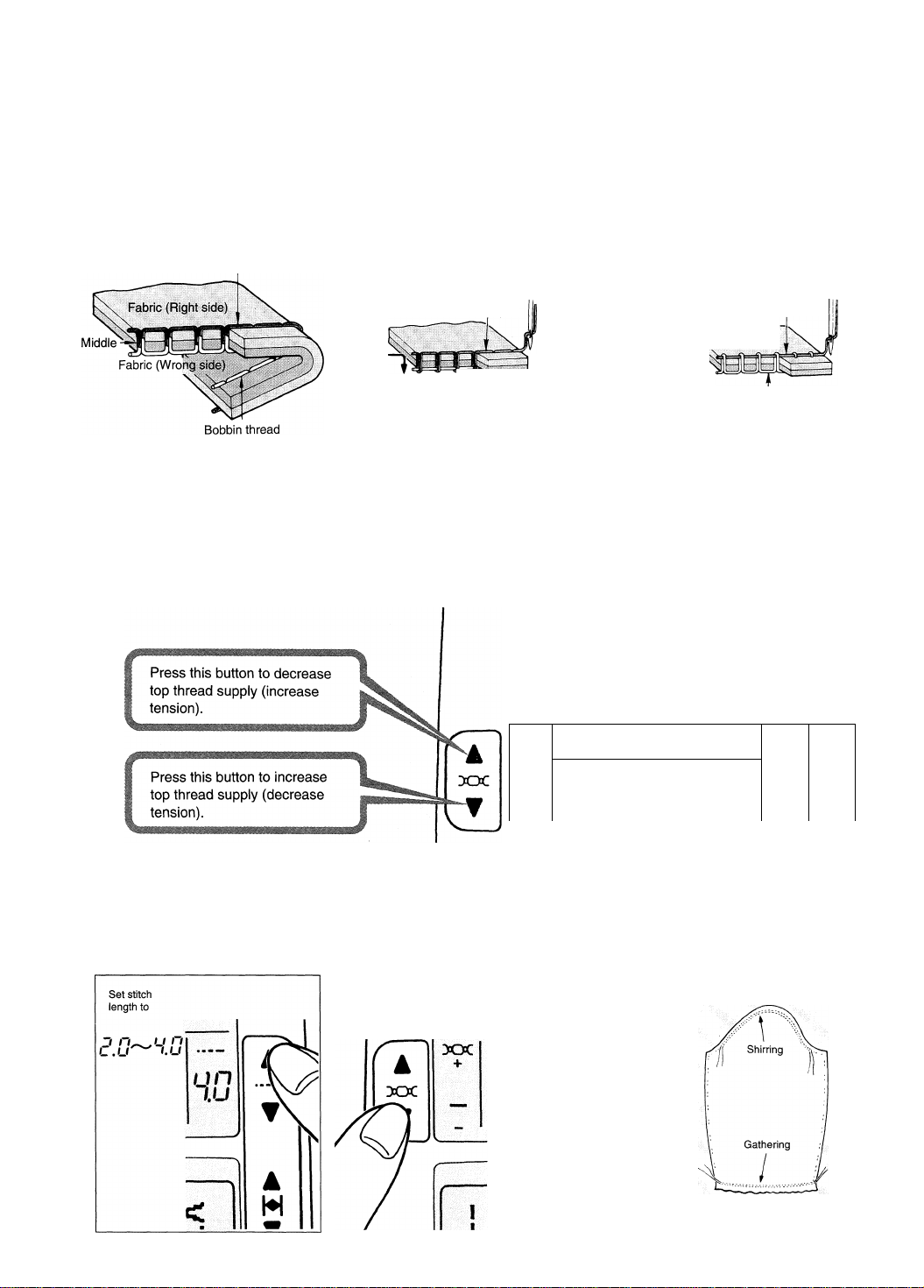

Automatic Computer Controlled Thread Metering (tension) System

Insteadof a mechanical tension system, which controls thread by squeezing it between 2 discs, the XL-100 controls thread by

computer. An automatic computer controlled thread metering system delivers the precise amount of thread for each needle

penetration to create the optimal appearance of each stitch. This makes possible, perfectly balanced straight stitch, plus no

pucker blind hemming, two color patterns without changing thread, multicolored embroidery without changing bobbin thread, and

decorative top-stitching and cross stitching that simulate hand sewn. An override control allows individual modification for

specialized effects.

Examples of Automatic Thread Metering:

Upper thread

Upper thread

Bobbin thread Fabric

Straight stitch: Upper and

bobbin thread join in middle.

Embroidery and decorative topstitch

patterns: Upper and bobbin thread

join on wrong side of fabric to

optimize top side appearance.

How to modify top thread supply.

Use thread meter override buttons to modify top thread supply (tension).

(Wrong side)

XX

+

AUTO-

[BAB J

----------------

Indicates that thread

metering (tension) is

automatic.

Upper thread

Fabric (Right side)

J

Bobbin thread

Two-color patterns: Upper and

bobbin thread join on right side

of fabric.

—

W

rin

u.u

C—

jn

L.U

♦)

How to shirr and gather.

When shirring an armhole or skirt waist, or gathering cuffs or yokes, sew with a long thread length, then pull bobbin

thread by hand to gather material.

Increase top

thread supply. "I

XX

XX

XX

+

19

Page 22

Problem Indicators

If machine has not been properly set to sew, a problem indicator will appear in LCD window advising where problem is located.

Problem indicators, cause & solution

• Bobbin winding shaft was left in right position

after winding.

• Move bobbin winding shaft back to left position.

Lower buttonhole lever.

Buttonhole lever has

not been pulled down.

(See page 26, 27.)

Check needle thread.

1) Upper thread has run out or broken or

2) Thread is not in thread sensor guide.

Select a pattern.

Select one of patterns shown on lower screen.

Problem indicators, cause & solution

Raise needle.

5t

Place embroidery frame on machine.

Place embroidery frame in position on machine.

Change to full size embroidery frame.

Embroidery card is not installed. Turn off power

and install card properly.

IÜ1

A

IMEWfl

Machine does not accept this operation.

Memory error

Memory is full.

Indicates pattern is being stored in memory

after key is pressed.

Indicates pattern is being recalled from memory

after mUk key is pressed.

This card cannot be used.

Change it with another one.

X

Deletg. pattern with clear key.

Lower presser foot lifter.

Change needle thread to a different color.

Qltilll

20

Page 23

Fabric, Thread And Needle Table

Your fabric will determine choice of needle and thread,

Always refer to it before a new sewing project. And be

Fabric

Fabrics below can be of any fiber, cotton, linen,

silk, wool, synthetic, rayon, blends. They are listed

as examples of weight.

Very Lightweight*Batiste, Chiffon, Organza, Voile.

Also all microfiber or microdenier fabrics.

Lightweight*Challis, Chambray, Charmeuse,

Crepe de Chine, Gauze, Handkerchief Linen, Silk,

Taffeta, Tissue faille.

Medium-weight*Broadcloth, Brocade, Chino,

Chintz, Corduroy, Flannel, Linen, Poplin, Satin,

Synthetic, Suedes, Taffeta, Terry, Velvet.

Medium to Heavy-weight*Coating, Damask,

Denim, Drapery Fabric, Fake Fur, Gabardine,

Ticking, Woolens. Long fiber polyester (two spun)

Heavy-weight»Canvas, Duck, Sailcloth, Upholstery

Fabric.

Leather

Knits*Jersey, Tricot, Single Knit

Sweatshirt-Double Knit, Swimwear, Sweater Knit

^ Use with standard sewing thread in bobbin.

The following table is a practical guide to needle and thread selection,

sure to use same size and type of thread in bobbin as in top thread supply.

Thread

Cotton-Wrapped polyester core

(extra fine)

Long fiber polyester (extra fine)

Cotton-wrapped polyester core

(all purpose)

Long fiber polyester (two spun)

Cotton-wrapped polyester core

(all purpose)

Long fiber polyester (two spun)

Cotton-wrapped polyester core

(all purpose)

Cotton-wrapped polyester core

(all purpose)

Long fiber polyester (two spun)

Cotton-wrapped polyester core

(all purpose)

Long fiber polyester (two spun)

Cotton-wrapped polyester core

(all purpose)

Long fiber polyester (two spun)

A

How to Remove and Insert Needle.

1 Removing needle

Attaching needle

2 (Needle cannot be inserted unless it is correctly positioned.)

Needles

Failure to use a Singer brand needle

may result in skipped stitches or

poor sewing performance.

TYPE

2020

red

shank

2020

red orange

shank

2020

red blue

shank

2020 16/100

red

shank

2020

red

shank

2032

leather

2045

yellow

shank

2045

yellow

shank

CAUTION: Make sure power/light switch is off

before inserting needle.

SIZE

9/70 or 11/80

orange

band

11/80

band

14/90

band

purple

band

18/110

11/80

orange

band

14/90

blue

band

position.

(2) Loosen needle clamp screw with

exclusive screwdriver.

it fully until it touches stopper pin.

21

Page 24

straight stitch

When power is turned on, full left position straight stitch is automatically selected. To move needle position see page 15 or 23.

a

-Automatic needle position

(Left needle position)

4 Begin sewing.

Seiect straight

1 stitch pattern.

2 Use correct presser foot.

Use presser foot bearing symbol

indicated on LCD.

* See page 8 for how to attach presser

foot.

5 Lightly hold material.

Position material, and lower presser

3 foot.

Place edge of material under presser

foot.

Pull upper and bobbin threads to rear of

machine and lower presser foot.

6 Adjust sewing speed.

22

force to material while sewing.

Cut thread.

(For automatic thread cutter see

8 page 14.)

Lift presser foot and remove

9 material.

Page 25

Back tack

Back tack is used at the

beginning and end of seam

to secure it.

O Press back tack button

for 3 needle penetrations

to lock off seam.

• The back tack button is only designed to be used for 3 needle penetrations at the ends of a seam.

• If you want to sew continuous reverse stitching, consult page 31 (Four Direction Sewing)

and use the continuous reverse stitch there.

• The sewing machine will back tack only while the button Is being pushed and stops when

the button Is released.

• The sewing machine runs at a slow speed when back tacking.

& Begin sewing.

© Press back tack button

again for 3 needle

penetrations to lock off

other end of seam.

Changing sewing direction/pivoting

Stop machine in desired position.

Lower needle into fabric. Lift presser foot,

and turn material in desired sewing

direction.

Lower presser foot and start sewing.

How to seiect needle positions

When power is turned on, full left straight

stitch is automatically selected.

Press needle position buttons to select

from among 22 possible needle positions.

Seam guides

Page 26

Zigzag Stitch ^ Select zigzag stitch

pattern. 2 Use correct presser foot. 3

How to adjust stitch width.

The sewing

method is the

same as for

straight stitch steps

3 through 9. (see

page 22)

symbol indicated on LCD.

After selecting zigzag stitch pattern, if desired, adjust stitch width by pressing

stitch width buttons.

Select from among 22 different stitch width possibilities.

NOTE: Stitch width can only be adjusted when sewing machine is stopped.

NOTE:

Automatic

stitch width

and stitch

length

5

Manually Adjusted Stitch Width vs. Stitch Length

^ See page 17 for how to adjust stitch length.

24

Page 27

Overcast! nqm(OveredgIng)

1 Select desired stitch pattern.

Used to prevent fabric from fraying.

There are three stitch types that can be

used for overcasting.

Select the one that is best suited for

material.

2 Use correct presser foot.

• Be sure to use the

standard presser foot for

zigzag and multi-stitch

zigzag sewing.

M

Standard presser foot A

• Overlock/overcasting

Overcasting foot C

Use presser foot which is indicated on

LCD.

edges.

Used for overcasting edge of fabric to prevent fraying.

This stitch may also be used to sew a seam that will not

be pressed open.

25

Page 28

Automatic Buttonholes

When sewing knit or other

stretchy materials, apply

interfacing to the material, and

set presser foot pressure

adjustment lever to “LOW”.

Be sure to sew a test

buttonhole first.

Automatic stitch length

(density) is 0.5 for bartack

buttonholes and 0.6 for

keyhole buttonhole. Adjust

buttonhole density by

adjusting stitch length (see

page 17).

Automatic buttonhole foot has an underplate for sewing

perfect buttonholes along edge of garments where fabric

layers are not equal. Underplate may be removed for

special applications such as a double-breasted coat.

For sewing small buttonholes on light

weight fabric

For sewing small buttonholes on light

to medium weight fabric

For sewing large buttonholes on

medium to heavy weight fabric

For sewing large buttonholes in thick

or heavy weight fabrics

Select desired style and

1 size buttonhole.

2 Change foot.

3 Position Needle and Bobbin threads.

bobbin thread between buttonhole foot and

underplate.

4 Place button in buttonhole foot. 5 Remove button.

Mark Buttonhole

6 Positions.

Button slide

After placing button in presser foot,

push slide to set buttonhole length.

Note: When sewing buttonholes be sure to support the weight of the garment

26

Page 29

Automatic buttonhole steps

12 3 4

► 1 J

^ ^

> 1

: ' ^ :

! I

I I

0

i ^ \

1 ^

i. 1 <

*• 1 *

r V 1

Tacking stitch automatically.

Purl stitch Buttonholes

Tacking stitch

:

At end of buttonhole

machine will sew a

tacking stitch, then stop

The bartack buttonholes and the keyhole

buttonhole can be used for purl stitch effect.

Select desired buttonhole and press 2-color

key CM .

• Finished appearance resembles a hand

sewn buttonhole.

7 Position material. 8 Lower buttonhole foot.

and underplate.

Attempting to sew without lowering the buttonhole lever, will cause problem indicator to flash on and off, and machine will not

start.

If buttonhole length is set wrong, or needle or bobbin thread runs out, restart buttonhole from beginning by pressing buttonhole

stitch pattern selection button once.

10 Begin sewing.

of needle hole in foot.

11 Press thread cutter button.

9 Lower buttonhole lever.

If problem indicator

comes on, buttonhole

lever has not been

lowered correctly.

When buttonhole

lever is fully lowered

problem indicator will

go off.

Open completed buttonhole, using seam

12 ripper.

ii Bartacked

Ü buttonholes

Straight pin

threads.

Ì

Seam ripper

ft Keyhole i l Eyelet

y buttonhole S—^ punch

Cut middle of buttonhole open using seam ripper,

being careful not to cut threads.

It is advisable to place a straight pin at end of

buttonhole to help prevent overcutting.

Use eyelet punch to cut out round portion of

keyhole buttonhole. It is advisable to place fabric

on old piece of wood.

27

Page 30

Sewing Corded Buttonholes

Sewing a cord into buttonholes will prevent them from becoming loose and they will last longer. Buttonhole twist thread may be

used tor cording.

How to set the cord

n n n

To sew buttonholes with cording, pass cord around end of buttonhole foot and

knot ends of threads at front. Then, attach buttonhole foot to presser bar and sew

buttonhole. Pull cording tight into sewn buttonhole and cut off excess cord.

Basting Stitch

Basting stitch seam

can be easily removed.

Blindstitch

Blind stitching provides

a durable way to finish

a hem. It takes

practice, however, so a

test sample is sug

gested.

1 Select desired length basting stitch.

Stitch

length

Select blindhem stitch

I

i

10

1

I

10mm

Use correct presser

2 foot.

Presser foot

symbol

I

I

20

20 mm

Standard presser

foot (A)

2 Use correct presser foot.

Use presser foot which has symbol

indicated on LCD.

28

Page 31

For blindstitching general fabrics or heavy-weight materials

Position folded edge against

1 Overcast material, and fold edge.

Refer to page 25 for overcasting.

Refer to page 28 for basting stitch.

2 guide and sew. 3 Turn fabric over.

For blindstitching light-weight fabrics

1 Fold the fabrics.

Position folded edge against

2 guide and sew.

How to adjust guide of blindstitching presser foot

• If stitches fail to reach folded edge:

• If stitches cover folded edge too much:

3 Turn fabric i

Fabric Fabric

(wrong side)

j

s

r

_ ,

(right side)

-

Turn screw counter clockwise.

This will move guide to right.

Place folded edge snugly

against repositioned guide.

You also may adjust stitch width to achieve a perfect blindstitch.

This will move guide to left.

Place folded edge snugly

against repositioned guide.

29

Page 32

Attaching Buttons

1 Use correct presser foot. 2 Lower feed dogs. 3 Select zigzag stitch pattern.

Í ©/

U® X

4 у

XX

XX

Авто

ЛЛЛАЛ

[■SA

штА

....

шш

D.UIS

The Zigzag stitch is

used to attach both 2

and 4-hole buttons.

The button-sewing foot

must be attached when

sewing a button.

supplied in accessory bag.

Press stitch width buttons to match holes in

button to be sewn.

NOTE: 3.0 mm width will generally sew all size

buttons.

I ''

Ж i=5

-----

,

^ у 7SS \ J

Place fabric on machine, and

Up Down Cl

Turn handwheel by hand to confirm

that needle exactly enters holes in

button.

6 Tack thread in place.

Press back tack button to

tacking stitches to secure,

sew 5

30

Slowly press on speed

controller allowing needle to

7 sew 8 to 10 stitches.

Caution: Due to irregular shape of some buttons button foot may not clamp securely.

Press reverse stitch button to sew 5

8

or 6 tacking stitches.

Do not attempt to sew these or buttons with a shank using sewing machine.

Press thread cutting

3 button, trim thread.

Page 33

Four Direction Sewing

1 Press LGE motif button

cs*

I r )

Select desired

2 pattern.

3 Use correct presser foot.

These four stitches

allow sewing sideways

(Zigzag/Straight stitch)

and forward or

backward, without

pivoting the fabric.

Follow steps O through O

o

O o

iDCaS!^)

|VW|

ŒI II

Balancing Shape Of Pattern

It is recommended that a test sample of pattern be sewn using same fabric and interfacing or backing before sewing on garment.

Depending on type of material, its finish, thickness and interfacing used, shape of pattern may be altered. If pattern is out of

shape sew trial sewing pattern to balance machine.

Press pattern category

> )

1 button. 2 Press trial sewing pattern . 3 Begin sewing.

4 Completion

g

LGE

FUN

When stitch length displays (— ), pattern

may be adjusted with stitch balance control.

(Except basting stitches)

NOTE: Trial sewing pattern may

also be used for darning.

A-B-C

REG

Machine may be balanced with trial sewing

pattern from any touch-screen.

How to adjust right side up

4-1 stitching

Incorrect balance

I. -K-

side

P

Turn stitch balance control up.

Correct balance

Horizontal

This will balance

all applicable

patterns in

machine.

How to adjust right side down

4-2 stitching

Turn stitch balance control down.

31

Page 34

Pattern Sewing

How to select patterns

1.

FUN

w

REG

A-B-C

Press desired pattern category button. Lower LCD

Touch-screen will illuminate to indicate selection.

Pattern Modifier Keys

sz

CO

CD

CO

CD

o

O

E

ra S'

_i«£

Enli

-

--------

arge siz<

s

3 key

2.

Touch desired pattern on lower LCD Touch-screen.

Selected pattern will appear on upper LCD window.

Presser foot

symbol

Decorative

stitch foot (T)

XX

fk'

30C

AUTO

1—^40353025201510• . . . 5 • • • • 0

....

III

JC

to CL

c £

1 ®

^ sy.

CL

CO

Ü

Ic

CL

2

O)

Q

O

-j

32

----------------------------------^ -------------------

4 Touch-screens

□Di©EI> )

m:

№11

00@h3@

IBI^l 1^1

I ^ 1 Touch-

I

FUN I screen

^ 6 Touch-screens

I REG 1

1 \ > 1

1 * ÿ f 3 ^

f Ov 1 TcORRT*^]’ 1

1 f*i ImemIrpt !♦

•=® 1 ^ > jg 1

1 fii lïÉSI^kNI^I

[ g g § II ^ ì

i È i E 1 0

S ,i § 1 b i

v^CQR^

Ilf ?; b 1

^ 1

1 B

--------------------------

^ 1 S 1 # # 1

1 1 1 i Î t

Î1 f M ê

1111 f

[CÓRRI fn^il

[wemI

îffoil

IBI 1^

-

2 Touch

ffis

:^/ii

Op

Si

«N

iS

YZ

°D

®4

^•2

®e

CORR

MEM

â:

%

fr %■

%Pb

%

?

^6-Fô^

a

CORRÎ^^'

IS!^/

ImemIrpt

1 "25f-

screens

is ii

mm

»

•'s

So

'****

RPT

1

*<0:1

?E:

M£m)

№

1:

i

g

Page 35

Reduce size key

Mirror (reversed image) key

Turn over key

W

Category button

I

REG I

'i:'

. M J

Pattern elongate key

Category button

I

REG

I

RPT

Repeat pattern key

Continuous pattern sewing

^ ♦

Pattern position key

Each press of

/v\ position key will

indicate a different

pattern layout.

Applicable 3 Touch-screens

memJ

Return key

(^3^ HAP

Needle will return to sewing

start point of memory

patterns.

Applicable 1 Touch-screen

or

/a.

Small alphabet key

Frames upper or lower case.

CORR

MEM,

Correction key

Corrects undesired pattern in

middle of memory sequence.

Pattern memory button

(to memorize pattern

selected)

40353025201510 • . • • 5 • • • ♦ 0

Indicates memory

capacity remaining.

NOTE: Indicator counts

down by 5 until 10

patterns remain at which

point it counts down one

by one.

CLR

MEM

Pattern clear button

(clears pattern that has

been memorized.)

Store button

Stores patterns in memory

even when power is OFF.

Review button

Reviews patterns in

memory one by one.

Recall button

Recalls stored memory.

33

Page 36

Large Size Pattern Sewing

It is recommended to make a sample using same fabric and interfacing or backing material before sewing on garment.

Note; Virtually all fabrics require interfacing to sew large size patterns properly.

When sewing pattern stitches or

alphabet stitches, be sure to use

decorative stitch foot (T).

Presser foot symbol

To determine pattern placement use It is vital fabric is kept square to

assistant marker and templates provided machine to assure proper pattern

with machine. formation.

Position fabric under decorative

stitch foot (T) where needle will

begin sewing pattern.

Patterns are stitched sideways, this

allows for easier sewing with freearm.

Decorative stitch foot (T)

How to select patterns of lower LCD touch-screens.

Press large motif category button...

1 - First press... 2- Second press...

How to select a pattern.

Touch desired pattern on lower LCD

Touch-screen. Pattern will appear on

upper LCD window.

1. Single pattern

Note: See template for additional

3- Third press...

(

i3Q'SEi> )

iDEï3S')

5. Fifth press... returns to first screen

instructions.

4. Fourth press...

[cörrT

[memI

34

XX

lE : tJ-

(k

XX

a¥o

1-V4035302520BIO« • • • 5 • • • « 0

M 1 -

asas

When one pattern is

complete machine will stop

automatically.

Page 37

2. Enlarge pattern.

1. Select pattern.

2. Press enlarge size key

3. Begin sewing.

3. Reduce pattern.

1. Select pattern.

2. Press reduce size key

3. Begin sewing.

4» Mirror pattern

y

1. Select pattern.

2. Press mirror key iXi .

3. Begin sewing.

* Pattern can also be enlarged or reduced.

5« 2-color pattern

These illustrated patterns can be sewn in two colors. This

unique technique is achieved by placing a different color

thread in bobbin than needle thread. Bobbin thread color is

sewn on right side of fabric, thereby sewing pattern in two

different colors.

On machine as shown on inside of top cover grey area of

pattern will be sewn with bobbin thread.

* Press 2-color pattern key IcTiJ.

6. Position pattern

In position pattern mode, machine is capable of changing

position of each pattern.

1. Select pattern.

2. Press position key

Continue to press position key to select from among 6

different positions as shown on upper LCD window.

3. Begin sewing.

4. Machine will continue to sew pattern until machine is

stopped.

NOTE: This is a repeat function and cannot be entered

into memory.

____

7. Repeat pattern.

1. Select pattern.

2. Press repeat key

3. Begin sewing.

stopped.

NOTE: To finish sewing to the end of patter

repeat key again.

Machine will stop sewing at end of pattern.

RPT

35

Page 38

Furi’face Pattern Sewing

Presser foot to be used

fl

Decorative stitch

foot (T)________j

1. Press the FUN button I .

2. Press |a| , (B) , © and @ key.

To change features from among 1920 possible

faces. Face changes appear on upper LCD

window.

Names of each key

Hair key

Advance

^/r •

f'^

(gv

, \ /r _ ^

df"©

[meîïiIrpt h

Kinds

(aKM frSl (n^

Chin key

Mouth key

Eye key

36

T

Back

(B)

(C

/ \ ¡¡J

J / 4

% ff

Q 0

if%

0 fl

/ Vi VJ

0 0 D r

/ 0

Page 39

Regular Pattern Sewing

1 - Press regular pattern button \ ^ \ .

2. Each time [^ \ button is pressed, lower LCD touch-screen will change.

I REG I

Presser foot to be used

Decorative stitch

ft

foot (T)

Single patterns

1

>1 5 > % ►

w >

Ì*

f 3 ^

> i ^

'I

^ g c?

S ^ I

NOTE: All regular patterns except top 3 rows of screen 1 must be balanced for perfect appearance, (see page 31). Use the trial

pattern from any of the 4 large touch-screens or from the fun-face touch-screen to balance pattern to fabric being used. Backing

fabric will enhance appearance of stitch patterns.

Continuous patterns

-

&

«L

n

-.L

o

J

u

1 n

1—1

fa

g

fa

i=0

c

corr'

Ì

MEM

J

.xO-

TO.

Û7

«6

SUS

li

>• ■•' 0

m

M

mem)

><

§ >-<

>k

mem]

§ i6.

C

mem)

»« ffS-..

ÎOÎ

CORR

MEM

n V^Vw

■jiSii ¥ -, .. ..

^ 111

a 4? 'Ÿ' y ^

ei

é

CORR

MEM

How to use pattern modifier keys of reguiar patterns.

1. Press regular pattern button *** .

2. Press desired pattern.

For example: Touch-screen 1

> 1

â S

w >

i *

J

W W %

y

^i‘

> ^ ►

\ ^ i

f 3 ^

IMS'

ifiS

___________

LGE I FUN I REG I I EMB l^y

3. Begin sewing.

Automatic Pattern

I REG I

|a-b-c| IÆ)

Name and function of modifier key

!dx

'i:'

i*i

♦♦♦♦

Pattern elongater key

Turn over key

Repeat pattern key

RPT

.A.

Pattern position key

Result

How to adjust width and length of regular patterns.

• The width on patterns of first 3 touch-screens may be adjusted from automatic width of 7mm to widths of 4 and 5mm (see page

18 for How to adjust stitch width).

• The length of the first 3 rows of patterns on touch-screen 1 may be adjusted for desired density (see page 17 for How to adjust

stitch length).

37

Page 40

Alphabet Stitch Sewing

1. Press alphabet button |a-b-c| .

First press

Ag

“n Op

Y-p

1

N

LGE I FUN I REG I

How to select letter of alphabet.

c>4

Ep

Qp.

®E]

^8

CORR

,MEM

CLn

I MEM

Oh

O'T

,RPT ,

^ |A-

'j a'

IJ,

• t

CrUR I

Second press

•M

%

% %

A

corr'

[mem,

№Ü

g)

^0

,RPT

A-B-C

D

^1©

Presser foot to be used

ft

V

em)

Decorative stitch

foot (T)

Space key

Period key [ |

Hyphen key | —[

Center point key [ ■ |

Apostrophe key □

• Pressing

Pressing key again will select

First time key is pressed: ^ ^

Second time key is pressed; ^ ^/^1/ / -► /

First time Y'ct

Second time ■:

key once will select ^

or key is pressed: ^ /^8

or key is pressed:

How to place letters or patterns into memory

• Press BBIl button and last selected letter or pattern

shown on upper LCD window will be placed in memory.

Press

placed in memory.

• Press button to delete a wrong letter or pattern in

memory.

• Press button to review patterns in memory one by

one.

• Use memory capacity indicator ( |mem) 40 35 30 25 20 15

10) to determine how much space is still available in memory.

button for every letter and pattern to be

► Press button to store letters or patterns in memory

even when power to machine is turned off.

» To recall stored letters and patterns from memory press LGE,

FUN, REG or A-B-C category button and then button.

After selecting (Q) , wait for beep and for sequence stored

to again show on LCD screen. This will assure storage.

' If new patterns are stored in memory, patterns which were

stored in memory before will be erased.

' To store in memory additional patterns with patterns already in

stored memory, first recall existing pattern to upper LCD

window, add additional patterns to memory sequence, then

store new pattern sequence in memory.

38

Page 41

How to Combine Patterns.

Combine upper case and lower case.

Up to 40 patterns may be entered into memory.

1 - Press alphabet button a-b-c twice.

2. Press . (Indicates ^ on upper LCD window.)

3. Press 4^81

4- Press M^i . (Indicates )

(Example)

11 . Press . (Indicates )

5. Press key. (Indicates

6- Press

button.

7- Press twice. (Indicates )

Combination Fun-Face and Alphabet

1 ■ Press Fun-Face button

2. Press desired |a| , (§)’■©

key to make face.

3. Press

button.

4. Press Alphabet button |a-b-c

5- Press j'-^|-|| twice. (H)

12. Press button.

13- Press twice. (Indicates )

14. Press SBQ button.

15 - Begin sewing.

D

11 . Press Op twice. (P)

12. Press ^iSil button.

13- Press V' 2;[ •

14- Press tfyn button.

15- Press pQ . (space key)

16. Press Iliiil button.

^ A

23. Press A-p twice. (T)

24. Press IjBIWl button.

25. Press |0}-^| twice. (H)

26- Press

I button.

27- Press jOpj twice. (D)

28- Press

I button.

6- Press button.

7. Press ^b| • (A)

Or

button.

twice. (P)

button.

8- Press

9. Press

10- Press

17. Press Aq| twice. (B)

18. Press HlBll button.

19- Press I i ,j| . (I)

20- Press ^^3 button.

21 - Press Op twice. (R)

29. Press ^ . (A)

30. Press button.

31 - Press "i"'' 2I • (Y)

32- Press lilBiJ button.

33. Begin sewing.

22- Press fl|Hl button.

Data which has been placed in memory can be cancelled with any of following three methods.

1. Press clear button to remove one pattern at a time or hold it down to cancel all memory.

Press Utility Pattern Button || . W,, ^^,3,

2. Press Utility Pattern Button || . | once.

Turn off power to machine then turn it back on. J Does not apply to stored data.

39

Page 42

How to Correct Patterns in Memory

When an undesired pattern has been

placed in memory.

• button will operate only when

button has been pressed.

• Pressing button will clear

patterns which have been selected.

• Memory of undesired patterns will be

cleared in order from pattern which was

selected last.

• Continue to press button and

all patterns which have been selected

will be cleared one at a time.

• Turning power switch off, or selecting

utility pattern button will clear all

data In memory.

• To clear reduced size or mirror pattern

press modifier key again.

When last selected pattern that

A has been placed in memory is not

IP a desired one.

Liquid crystal display window

ABC

XX

lE

AUTO

1^403530252015»

''’Vj

^7

1 .p.

When an undesired pattern is

selected in middle.

Up

o

'-^’4

Tj(3>a W

....5....0 <S)

Ep

Qr

Bq

cor r'

,RP T ,

MEM,

^ lA-B-Cl

REG I I EMB

Li,,

8p

'j

Tlx

to©

EMB

u'

\A.'x

MEMjj

► When memory is not full, it will be

indicated on LCD and patterns may

continue to be added.

• Before selecting a new set of patterns,

•—

be sure to clear all memorized patterns.

Memory Capacity Indicator (^) will not

show on LCD.

» 40 patterns can be stored in memory.

Memory Capacity Indicator Pointer ^

indicates how much space is available

in memory.

last pattern will be deleted.

2. Select correct letter (C.)

3. Press Pml button.

I

L

______

-__J

are the desired patterns.

I

------------

are selected by mistake.

1

1. Press button twice.

2. Press key and button.

Press iSfi? key and select

3.

WcM

correct letter (B.)

4. Press ^IBU button.

Press button twice.

5.

Indicated on

upper LCD window

EC

f

■=>

G

|"bc

/

■=>

ABC_

Page 43

Free Arm Sewing

Application examples

Sewing hard-to-reach garment areas is

made easier by using free-arm sewing

capability of sewing machine.

Note: See page 5 for converting machine

to free-arm.

/

Hemming

41

Page 44

Circular Pattern Stitch

sewing outside

periphery of coasters

and emblems.

Circular ruler allows

machine to sew circular

patterns of 3 to 10 cm

radius.

Attach circular pattern

3

stitching ruler.

Left-hand side:

Suited to sewing of large circular

patterns

4

Move sizing lever by

firmly pushing from

slot.

Select pattern as

1 desired.

Select patterns from

IRK I category.

If single pattern is selected

press I Rpj key.

Move sizing plate to

5

desired position.

Attach decorative stitch

2

foot (T).

Push sizing lever into

6 slot.

Right-hand side;

■ Suited to sewing of small

circular patterns

Attach circular pattern stitching

ruler to left- or right-hand side of

Needle plate using screw supplied

with machine.

Place material on machine and

hold in position using tack sup-

7

plied with machine.

42

Page 45

Heirloom Sewing (Using wing needie)

☆ When using wing needle, do not use thread cutter (needle may bend).

Quilting (Using Quilt guide)

1

Select pattern as desired. 2 may use stitch width.

CAUTION:

Use correct presser

2 foot

When using zigzag stitch

Make sure power/light switch is off before changing needle.

Automatic needie threader

3 cannot be used. 4 patterns from category.

Select one of five

REG

ZJ -L i"~i r~

••1*.

_J _L U ^

^ Pattern

pattern so press

3

Use correct presser foot.

is single

RPT

are joined together with

parallel rows of

stitching. Batting is

usually placed between

layers of material,

which is used for

protection against cold

or for decoration.

4

Attaching quilt guide.

Insert quilt guide into hole in presser foot holder.

desired.

Sew quilting on material using quilt guide to

5

trace pattern previously sewn.

Spacing between lines of stitching may be adjusted

by moving quilt guide.

43

Page 46

Patch Work

With pattern stitches,

fabrics can be joined

together to form a

strong seam.

Overlapping Patch

1

1

Select pattern.

Press ^ button, and select

I REG I

desired pattern.

Choose one of above three

patterns.

2

Use correct presser foot.

Basting stitch

5/8"

\ ,^iii

N

Fabric (wrong side)

I

I

Place two pieces of fabric right sides together and sew a

basting stitch. Press seam to one side.

Open Patch

1

Fabric (wrong side)

^ Seam

Place two pieces of fabric right sides together and sew a

basting stitch. Press seam open.

44

Sew a pattern stitch on top of seam. Remove basting stitch for

open fagotted appearance.

Page 47

Twin Needle Sewing

- With machine turned off, insert twin needle into needle clamp, and thread machine as for single

needle sewing through left needle eye.

- Attach auxiliary spool pin into hole by bobbin thread cutter. Place second spool of thread on it; and,

again, thread machine as usual except as noted in point 4 below. The second thread will thread

through right needle.

Attaching

1 twin needle.

Twin needle sewing

produces two parallel

lines of closely-spaced

stitching.

Attach

Use correct presser foot.

auxiliary

3 spool pin.

4

Thread machine.

NOTE:

needle threader and

automatic thread cutter

cannot be used.

IMPORTANT: Use only

Singer branded twin

needle style # 2025.

5

Patterns for twin needle sewing.

Select straight or zigzag patterns. Patterns

illustrated on right are designed for twin

needle sewing.

Automatic

Straight stitch

Adjusted needle

position (center)

M

3.E

foot (A) or decorative

stitch foot (T).

Zigzag stitch

AW

Adjusted stitch width

M

S!/7

Caution:

Pin Tucks

1

Select straight stitch. 2 Use correct presser foot.

Put right needle thread into outer slit,

by-pass final thread guide and then

through right needle.

Press the ^ button.

CAUTION: Do not select any

pattern which cannot be

adjusted to 4 mm stitch width.

I REG I

* If sewing with twin needle, never press the elongate or

position key (since the needle will hit the presser foot).

* Sew at low or medium sewing speed.

* Do not use reverse stitch.

Make folds on material for

pin tuck using an iron so

that they are neatly

finished.

A type of fabric decoration.

Commonly used in French

sewing.

Traditionally, pin tucks are

formed by stitching very

near a folded edge, as

shown in steps 1 through 5.

You can also sew pin tucks

with a twin needle.

Twin needle tucks are

always even as they are

formed by two parallel needles.

Decreasing top thread supply

(increasing tension) will result

in a more pronounced pin tuck.

After finishing sewing, tilt pin tuck to

one side and press.

Sew folds taking care not

to stretch them.

A blindstitch presser foot

guide will help finish the

folds more beautifully.

Application examples

• Blouse

* Apron

Page 48

Darning/ Free-motion Embroidery

Remove presser foot

1 holder.

' Before removing presser

foot holder, be sure to turn

off power to sewing

machine.

2 up to down.

Move drop feed lever from

3 Select zigzag stitch pattern.

AWV\

-------

XX

'

A

yoc

UTO

-

cn

D.U

M

4 Select stitch width.

Set stitch length to 4.0 to

5 increase thread suppiy.

Set embroidery hoop in

6 place.

Lower presser foot lifter and start

sewing.

NOTE: It is possible to sew without embroidery hoop if optional Darning/Embroidery foot is used.

See page 53 for further information.

46

Page 49

Rolled Hemming

Material edge is hemmed while rolling it

under.

Used for finishing bottom of shirts and

blouses and edges of frills and handker

chiefs.

Select desired stitch

1 pattern.

2 Change foot.

in accessory bag.

NOTE:

needle position may

be adjusted for perfect

sewing position, (see

page 15 or 23)

Straight stitch

work easier.

Insert material into spiral groove in hemmer foot

until needle position is reached.

Even Feeding

To prevent slippage of material, use even

feed foot.

* For matching plaids and designs,

* To prevent slipping, stretching or

sticking when sewing fabrics such as

synthetic suede, sheers, heavy knit and

quilted.

Select straight

1

stitch.

2

Remove presser foot holder.

Drawing ends of needle and bobbin threads, turn

handwheel 3 or 4 turns by hand to guide material

to hemmer foot.

Use even feed foot only for forward stitching.

* Do not use it for any patterns which feed sideways or feed

both forward and reverse.

3

Attach even feed foot to machine.

When power switch is

turned on, straight stitch

is automatically selected.

Lift presser bar, remove presser foot clamp screw

and remove presser foot holder.

' Sew at low or medium sewing speed.

' To sew elastic materials such as knits and jersey, set presser foot adjusting lever to "LOW.”

Put forked section of actuating lever around

needle clamp, attach to presser bar and securely

tighten presser foot clamp screw.

47

Page 50

Inserting Zippers

1

Select straight stitch.

Zippers may be inserted in

several ways. Type and

location of zipper will help

select right method.

Lapped

inserted in side seam of the

garment.

Centered

centered in opening, and

are suitable for almost all

fabrics.

zippers usually are

zippers are

Lapped Insertion

o

XX

IBAB J

+

XX

AUTO

•vT

When power switch is

turned on, straight stitch is

selected automatically.

Use correct presser

2 foot.

machine. Zipper foot can be

put on to left or right of

needle, depending on where

bulk of garment is placed.

side of zipper foot goes on shank.

If zipper is to right of needle, right

side of foot goes on shank.

A zipper is lapped when one edge of

fabric opening overlaps and conceals it,

allowing only one stitching line to show.

* Machine-baste zipper opening together

on seamline, and press open seam

allowance.

* Attach left side of zipper foot to shank.

O

* Pin or machine-baste zipper to garment

from wrong side, through zipper tape,

seam allowance, and front of garment.

* Turn garment right side out.

* Attach left side of zipper foot to shank.

* Stitch across lower end of zipper and up

to waistline. Use basting stitches as a

guide.

* Remove basting and press.

48

* Open zipper and flatten back seam

allowance, as shown, with zipper face

down and edge of teeth following seam

line. Zipper’s top should fall between

1/8" and 3/8" below garment top seam.

* Stitch zipper to seam allowance from

bottom to top.

Centered Insertion

m

seamline, and press open seam

allowance.

' Place open zipper face down on seam

allowance with teeth against seamline.

^ Stitch zipper to seam allowance from

bottom to top.

^ Close zipper and turn it face up.

^ Smooth back seam allowance at edge

of zipper.

^ Stitch zipper from bottom to top, as

shown, near seam allowance folded

edge.

allowance and garment exterior.

' Turn garment right side up and topstitch

it to zipper, sewing through all layers.

' Remove basting and press.

Page 51

Inserting Invisible Zippers

Since a seam does not

appear on right side of

material, opening can be

finished with material edges

neatly butted.

4

1 Select straight stitch. 2 Change foot.

When power switch is

turned ON, straight stitch is

automatically selected.

Attach invisible zipper foot

supplied in accessory bag.

Set center of Invisible zipper on seam.

on seamline, and press open seam

allowance.

After fitting teeth of zipper to groove on invisible

zipper foot and raising teeth with fingers, sew

zipper tape on seam allowance from opening

end by forming seam along edge of teeth.

Baste zipper to seam allowances.

Undo basted seam up to opening end

shown and open zipper.

Sew other side of zipper tape on seam allow

ance using same procedure.

49

Page 52

Manual Buttonholes

Automatic foot can make buttonholes up to 1 1/2:

use transparent foot to create larger buttonholes.

^ To make ribbon casings

Other uses for Transparent foot I.

' For french machlne-sewing:mock whip and roll,

pin-tucking and entredeux, are better controlled

because there is a groove In bottom of foot.

' For satin stitching

Select desired stitch

1 pattern.

2 Change foot.

Mark rnaterial to indicate buttonhole

placement.

Lower buttonhole foot so that mark is at

center of needle hole in foot.

Lower buttonhole lever.

When needle reaches end of marker line,

slightly press buttonhole lever towards

rear of machine.

Start sewing while slightly pulling

buttonhole lever towards front of

7

machine.

slightly pull lever towards front of

machine.

* Machine starts straight stitching on

right-hand parallel section of button

hole.

If sewing machine does not operate as described above, stop machine and press buttonhole pattern key again. It will start

buttonholing from beginning.

slightly press buttonhole lever towards

rear of machine.

* Machine starts zigzag stitching on right-

hand parallel section of buttonhole.

8

When needle reaches beginning of mark,

slightly pull lever towards front of

machine and sewing machine will start

bartacking, perform fastening stitching

and stop.

50

Page 53

Attaching Cords

Gathering and shirring

Place pearl cotton into center of foot and zig-zag

over it.

Secure one end of pearl cotton and pull other

end to gather.

Use same method with elastic threads to create

shirring.

' Decorative shirring

Experiment with decorative threads, like ribbon

thread or metallics.

Place cording into slots and stitch using multi

stitch zigzag.

^ Applying trims

1

Select desired stitch pattern. 2 Change foot.

i=> For one cord

(Manual zigzag stitch

width 1.0-2.0)

Multi-stitch

zigzag stitch

O For three cords

Sewing one cord

For sewing one cord, pass cord through center

spring of cording foot, fit top end of cord in groove

on sole of cording foot, then lower cording foot.

Sew cord on material using zigzag stitching

function with zigzag width reduced (stitch width

1.0-2.0).

Make fastening stitches at beginning and end of

seam by pressing reverse button.

Sewing three cords

For sewing three cords, pass cords through all

springs of cording foot and fit cord ends in groove

on sole of cording foot as in case of sewing one

cord. Then, lower cording foot.

stitch pattern.

As in case of sewing one cord, make fastening

stitches, draw cords out on wrong side of material

and make a knot. Then trim cords.

* To sew two cords, pass cords through rightmost

and leftmost springs.

51

Page 54

* Always use Singer genuine accessory feet.

^ . I - > Off brand or generic accessories may cause poor performance, damage to sewing

Optional ACCGSSOriGS machine or injury.

Ruffler presser foot (Pan No.saeoas)

Ruffler quickly & easily produces

professional looking ruffles on

garments and home decorating.

' Be sure to turn power off before Select straight stitch pattern and

Attaching ruffler.

® Remove presser foot.

@ Raise needle bar to highest position.

(D Fit ruffler fork onto needle clamp screw and attach to presser bar.

® Tighten presser foot screw with exclusive screwdriver.

removing/attaching ruffler adjust needle position to 1.0 (This is

presserfoot. very important).

Ruffling.

(1) Determine number of ruffles.

• Ruffles

every

stitch.

(3) Place fabric under ruffler foot.

*Note: Sew test swatch before sewing on project.

• Ruffles

every six

stitches.

®

O

• Ruffles

every 12

stitches.

........

-

Fabric

(2) Adjust overlapping width of ruffles.

Straight

stitch

(4) Lower ruffler presser (5) Lightly push cloth feed plate towards

foot.

'< edge

badk of machine.

(6) Turn handwheel counter clockwise to

lower needle into fabric until fabric begins

to fold.

Ruffle overlap

width increases.

Ruffle overlap

width decreases.

52

(7) Start Sewing.

Through 25mm

Page 55

Optional Accessories

PintUCk foot (Part No.386022)

Uses:

- Sews evenly spaced plain twin needle pintucks.

- Sews evenly spaced corded twin needle pintucks.

Procedures:

Plain pintucks

1) Insert twin needle and thread machine with two

spools of thread, using auxiliary spool pin. (See page

45)

2) Select straight stitch pattern and adjust needle to

center position (3.6).

3) Mark straight line for first pintuck.

4) Stich along marked line. Increase tension as desired,

to make pintucks stand up.

5) Place first tuck into desired groove on bottom of

pintuck foot. Stitch, allowing groove to guide fabric for

evenly spaced tucks.

Corded pintucks:

Follow procedure above, but place cording under fabric.

Lower twin needle by hand to ensure cording is centered

inbetween stitch, being sure to catch cording between

needles.

Darning/embroidery foot (PartNo.3860i7)

Uses:

- For free-motion embroidery, darning & monogramming.

Procedures:

1) Drop feed dog.

2) Place fabric into embroidery hoop (optional).

3) Attach foot and tighten presser foot screw with

exclusive screwdriver. Begin stitching, moving hoop

as you stitch. If not using hoop, grasp fabric firmly

with two hands and hold taut.

Sew at slow to medium even sewing speed.

Quilter’s foot (Part No.386005)

Open toe embroidery foot (Part N0.386023).

Uses:

- For satin stitching.

- For applique.

- For machine embroidery, cutwork and fagoting.

Procedures:

- This foot allows a clear view for sewing above tech

niques.

- Follow instructions found in Singer Sewing Reference

Library Series.

Uses:

- To sew perfect 1/4" seams for piecing quilt blocks.

- To sew narrow seams, such as those In doll clothes.

Procedures:

- Use in place of A foot.

- Select straight stitch pattern full left (automatic)