Page 1

:Íliá:'?>

:^т,>уЩ^\.

С ■ ''Х'й-.'Ч’/

• • «Ш&г ■

Mf I

-:Л' H í *

nvnNVIAl NOUOntaSNI

I.-JX lunfuen^

/(

ì

О

Page 2

CONGRATULATIONS

..on the purchase of this now Singer* electronic sewing machine. To achieve

the most enjoyment and satisfaction from this product, it is recommended

that the instruction manual be read through step by step while seated in

front of the machine. This will help the operator get to know all of its parts

and capabilities.

INSTRUCTION BOOK SINGER* quantum XL 1

The manufacturer reserves the right to change the appearance, design, or

accessories of this sewing machine as considered necessary without any

notification or obligation.

*A trademark of The Singer Company

Copyright 1989 Singer Sewing Machine Company.

All rights reserved throughout the world.

Page 3

CONTENTS

Accessories.............................................................................. 1

Principal Parts

Major Functions.........................................................................3

Important Safeguards................................................................4

Connecting The Machine

Winding The Bobbin

Threading The Machine.........................................................8, 9

Automatic Needle-Threader

Changing The Sewing Feet.....................................................10

Type Of Feet And Their Applications

Stitch Length Of Each Stitch Pattern

Automatic Thread Tension Control..........................................12

Indicator Lights........................................................................13

Fabric, Thread And Needle Table

How To Remove And Insert The Needle

Various Types Of Stitches.......................................................15

Straight Stitch..........................................................................16

Reverse Stitch....................................................................... 17

Shirring And Gathering............................................................18

How To Operate The Automatic Thread Cutter

How To Use The Thread Cutting Groove................................18

ZigZag Stitch

Automatic Buttonholes.......................................................20, 21

Free-Arm Sewing

Overcasting (Overedging)

..........................................................................

..........................................................

..............................................................

......................................................

...

..................................

.................

...........................................

...........................................................................

....................................................................

.......................................................

.....................

...............................

.....................

6, 7

10

11

14

14

18

19

22

23

Pattern Sewing.................................................................. 24-33

2

5

9

Information Indicated On The Liquid Crystal

Display Window...................................................................24

Relationship Between Patterns And Buttons ......................25

Large Size Pattern Sewing (1 )

Single Pattern Stitch

Reverse Pattern Stitch

Reduced Pattern Stitch

Repeat Pattern Stitch

Large Size Pattern Sewing (2)

Alphabet Stitch

Continuous Pattern Stitch

How To Combine Patterns

Balancing The Shape Of A Pattern

How To Cut The Cross-Over Stitch........................................31

How To Correct Patterns In Memory

Four Direction Sewing ............................................................34

Attaching Feed Cover

Darning Stitch..........................................................................36

Twin Needle Sewing

Pin Tucks

Blindstitch

Patchwork

Inserting A Zipper

Optional Accessories

How To Adjust The Bobbin Case............................................42

How To Remove The Face Cover ..........................................43

Lubricating The Machine

Performance.......................................................................44, 45

................................................................................

...........................................................................

...............................................................................

.............................................................

..............................................................

...................................................................

..............................................................

.........................................

..........................................

................................................

....................................

.................................

........................................................

26, 27

28, 29

30, 31

30, 31

32, 33

38, 39

35

37

37

40

41

42

43

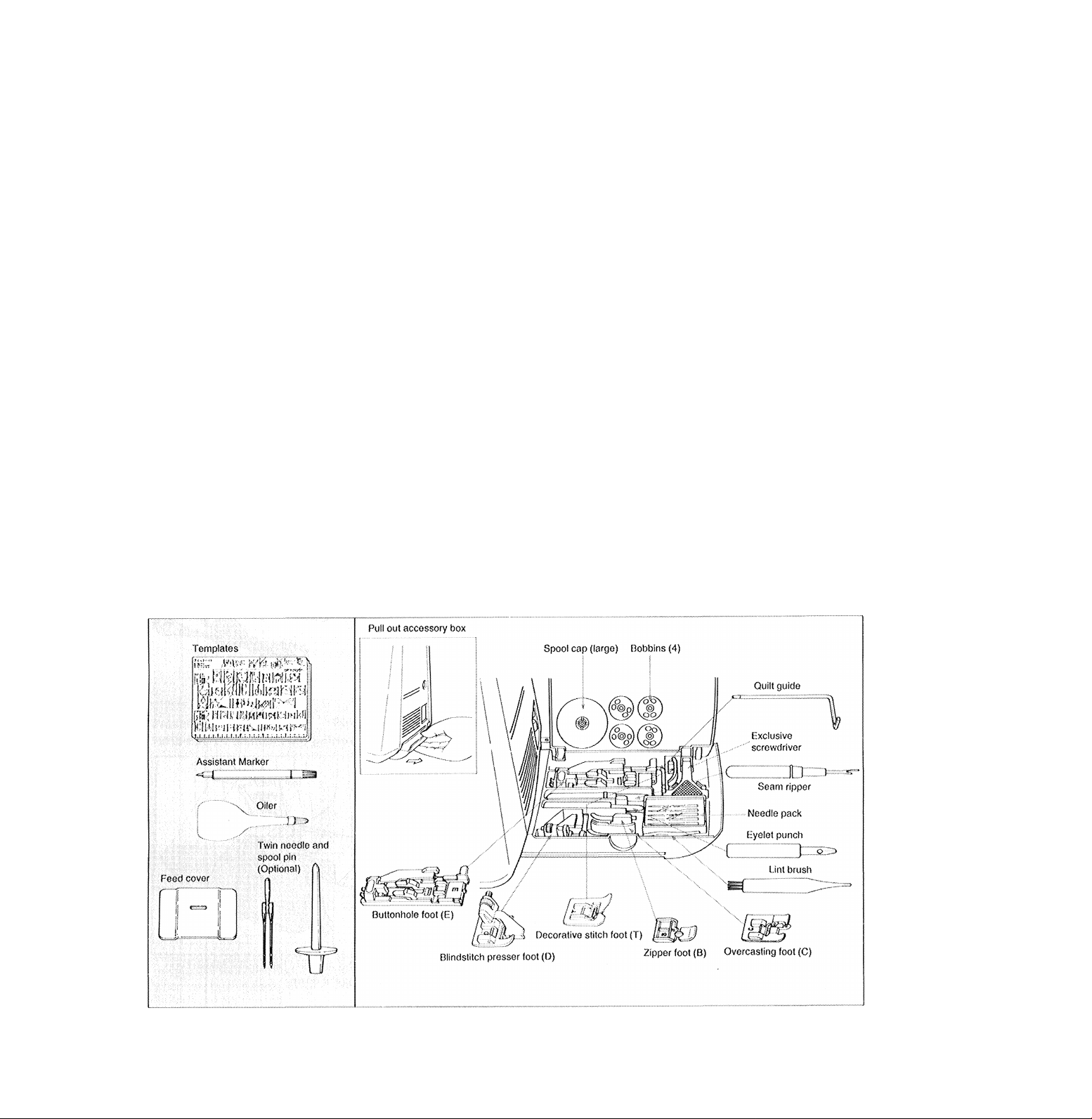

Accessories

Note; Standard presser foot (A); The sewing machine is shipped from the factory with this presser foot attached.

Page 4

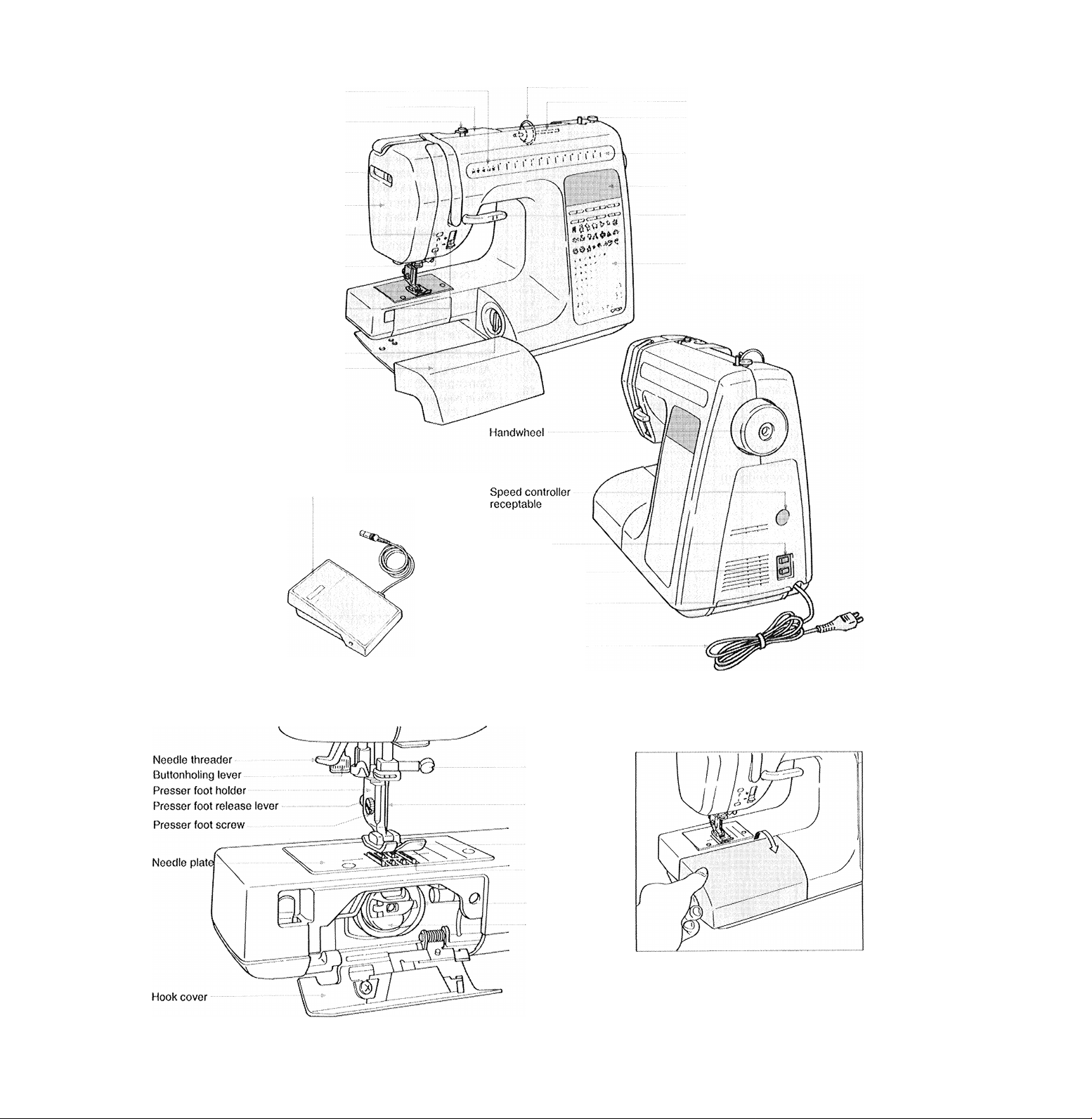

Principal Parts

Indicator lights

Thread sensor guide

Bobbin winder thread guide

Pressor foot adjusting lever

Face plate cover

Reverse stitch button

Start/stop button

(When speed controller Is not used.)

Sewing speed setting lever

(When speed controller is not used.)

Stitch balance control

Auxiliary bed

Thread spool cap

Spool pin

Bobbin winder

Instant pattern button

Liquid crystal display

Presser foot lifter/thread cutter lever

Pattern display panel

Speed controller

Light switch

Power switch

Accessory box

Electric power cord

Converting the machine to free-arm

Needle clamp

Needle

Presser foot

Feed dog

Hook

Bobbin case

Lift the auxiliary bed, pull it toward you.

and pull it down.

Page 5

Major Functions

Indicator lights:

One or more of those will light up to indicate

cause of problem.

F^attern (Number) selector buttons:

Use this button to select a desired pattern. I he

left button is for the tens digit of the patterns.

The figtit button is for the units digit of the

patterns.

Presser foot symbol

These buttons are for selecting the

functions for pattern stitching;

Iteducing the siito of patterns, to reverse

patterns, to memorize patterns selected, to

clear the patterns memorized, and to repeat

stitct) patterns.

Instant pattern buttons:

When you press the desired stitch pattern button

the light beside the pattern will come on to indicate

your selection.

<

Í

<

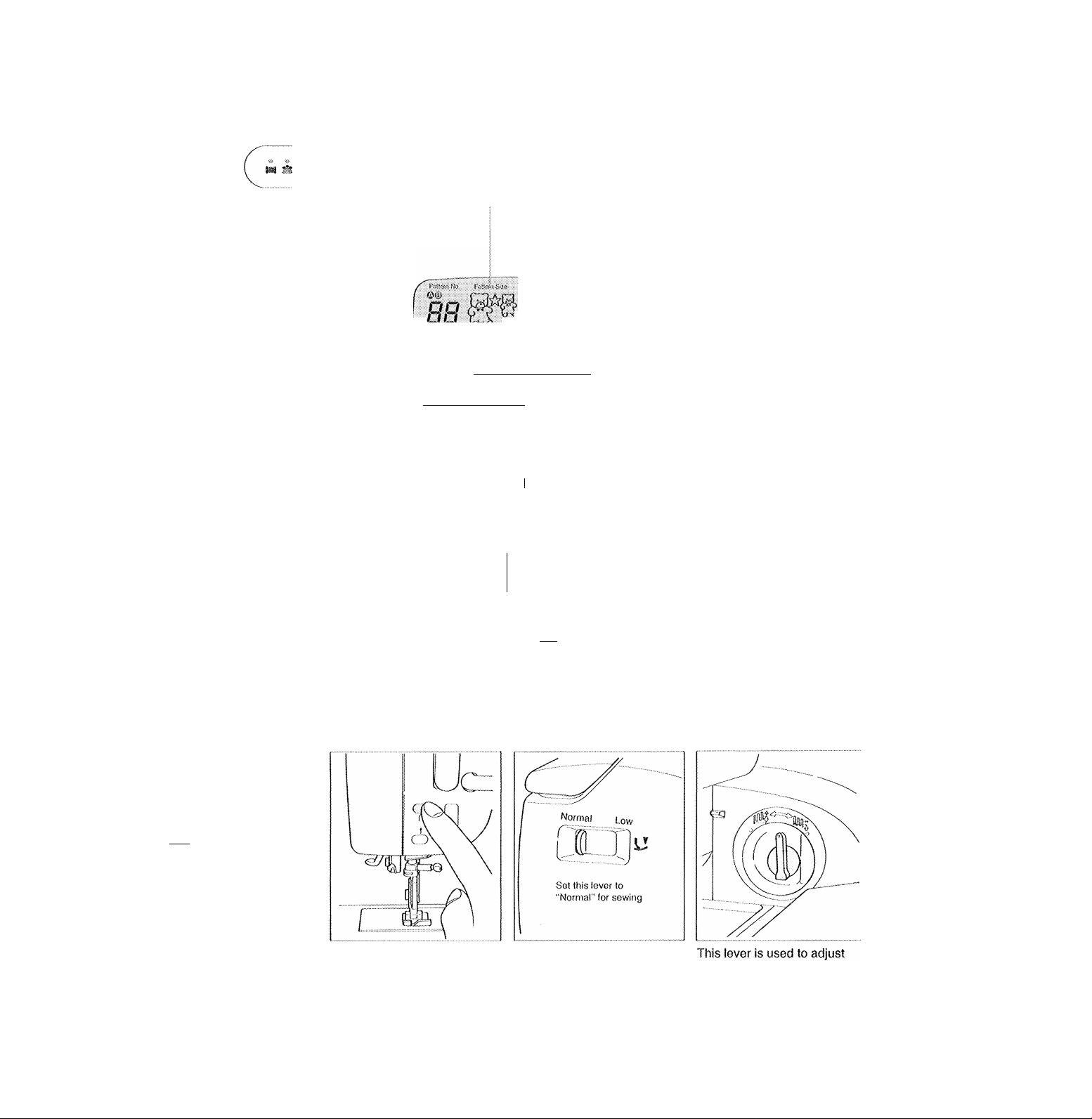

Liquid crystal display:

When you press the button below, the following information can be

monitored on the liquid crystal display: (1) Mark symbolizing the size of

patterns, (2) f teduced size, (3) Reverse pattern, (4) Pattern repeat, (5)

Memory, (6) Stitch length, (7) Indication of thread tension by MANUAL

override or AUTOMATIC.

. ■?

. i

B

a:

K]

;u.

Tí'’

1 C ) ■

3

X •M

31 iz

Y iW; Ixí

t\

T7 'a'’

a"

► Ï W I

<> T ( ^ 1

I, :

..

LMKJ C 'il..Tí:..

■ iî

l

í • ;

'ív

a

;;./

í< ■

.o]

'Û

« ’ 55

. \

./

17

n '

•'■■15

PiXLH!

ly.

0

'2S'

u

n

’Ni

XT

P:.

iVj

a

Xt '

.Q\

â.

a/

i-i iy

T'

n î-î '>7 i'i 5î

n

\zí XT

a

O

' îi

n ■

n] ■XI

X

'tï

Í ,í.

11

15

n

\u\

H iî'

'u ■f5‘

a

n

[d]

n

rr]

■ , :

55'

Indicator light

Pressor foot symbol

Stitch length override buttons:

fTessing increases the upper thread tension,

and pressing decreases it.

Thread tension override buttons:

Pressing ^ increases the stitch length, and

pressing sx decreases it.

Pattern panel

Patterns on A or B sl|fe will appear in

openings of panel/ ^

Presser foot lifter/threac) cutting lever

Pressor foot

goes up.

/ / Y

/ /\ \

Presser foot

/ / \

comes down.

I Thread

cutting

When you push the lever up,

the presser foot goes up,

when you push it down, both

threads are cut and the

needle will automatically go to

its highest position.

'n'

n

fi"

é-:

i

íí

íí 51

;>;

V:

a

ÎÎ

T

i "'i

53 U

Reverse stitch button

The reverse stitch is engaged

only while you continue to

press the button.

XT

/5'

XT Xi'

'75'

U

a

'a'

J.

55

35

j>'

X.t"

.KK

XT

« a

Presser foot pressure

This lever is used to adjust

the pressure of the presser

according to the type and

thickness of the material.

A, B side selection lever:

o When you shift the lever to the left, patterns

on A side will appear.

o When you shift the tever to the right, patterns

on B side will appear.

Stitch balance control

the shape of patterns. (Please

see page 30 and 31.)

Page 6

Important Safeguards

Disconnect the powerltne plug from the electrical outlet when changing needles, feet, or needle plates, or when leaving

machine unattended. This eliminates the possibility of starting the machine by accidentaliy pressing the speed controller.

Before removing the bobbin case, disconnect the powerline plug from the electrical outlet.

2,

Because of the up and down movement of the needle, work carefully and watch the sewing area when operating the

3.

machine.

Do not pull the fabric while stitching as this may deflect the needle, causing it to break.

4.

Before cleaning the machine, disconnect the powerlino plug from the electrical outlet.

5.

Do not attempt to adjust the motor belt. Contact the nearest service center or an authorized dealer should any adjustment be

6.

required.

Before changing the light bulb, make sure the poweriine plug is disconnected from the electrical outlet. Be sure to replace the

face plate which covers the light bulb before operating the machine.

This machine is designed to use a 5 watt maximum light bulb only.

8.

This machine is double insulated. When servicing product, use only identical replacement parts.

9.

This product is suppressed for radio and television interference with the International Electro-technical Commission requirements

of the CISPR.

Be sure to turn the power switch OFF before

replacing the sewing machine needle, or lubricating

the machine.

Do not use thinner or other similar solvents to clean the machine.

When not In use, be sure to turn the power switch OFF and unplug the machine.

Do not expose the machine to direct sunlight or humid atmosphere.

This sewing machine uses a micro computer and precision electronic circuits consisting of semiconductor components, so

please observe the following precautions;

• Keep the room temperature at 40T to 100T, If the temperature of the room where the machine is used is too low, the

machine may present problems such as failure to reach its normal sewing speed.

• The motor used in this sewing machine is eiectronically controlled. When the machine is operated for an extended period of

time at tow speed, the safety device will automatically turn the machine OFF preventing the motor from overheating. If the

motor should stop while sewing, turn the power switch OFF, and wait about 20 minutes. This will reset the safety device.

Page 7

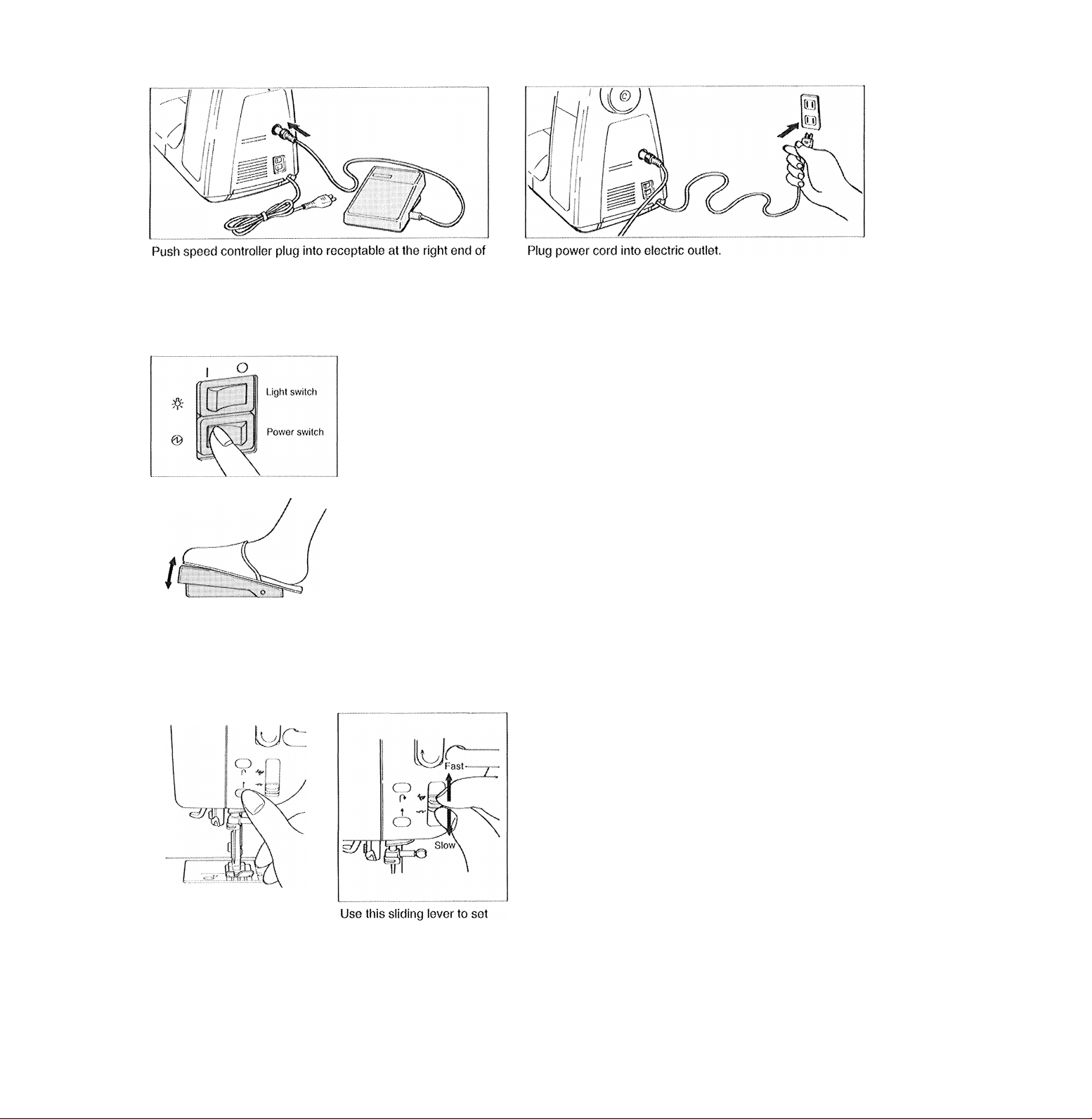

Connecting The Machine

the machine.

Running The Machine

Power/Hght switch

■■ When the “1" side of the power switch is pressed the machine will be turned on.

- When the “O” side of the power switch is pressed the machine will be turned off.

Note: The power switch must be on before the light switch will operate.

To run the machine depress the foot-operated speed controller. The harder you press,

the faster the machine will sew.

To stop the machine, remove your foot from the controller.

Running the machine without foot control

The foot control must be unplugged for the starf/stop switch and sewing speed setting lever to operate as described.

Start/stop switch Sewing speed setting lever

One press on the switch

starts the sewing machine,

and another press on the

switch stops the sewing

machine.

the desired sewing speed.

Note: #1. When the foot control is plugged in, the start/stop switch can only be used to stop the machine.

#2. When the foot control is plugged in, the sewing speed setting lever will not operate.

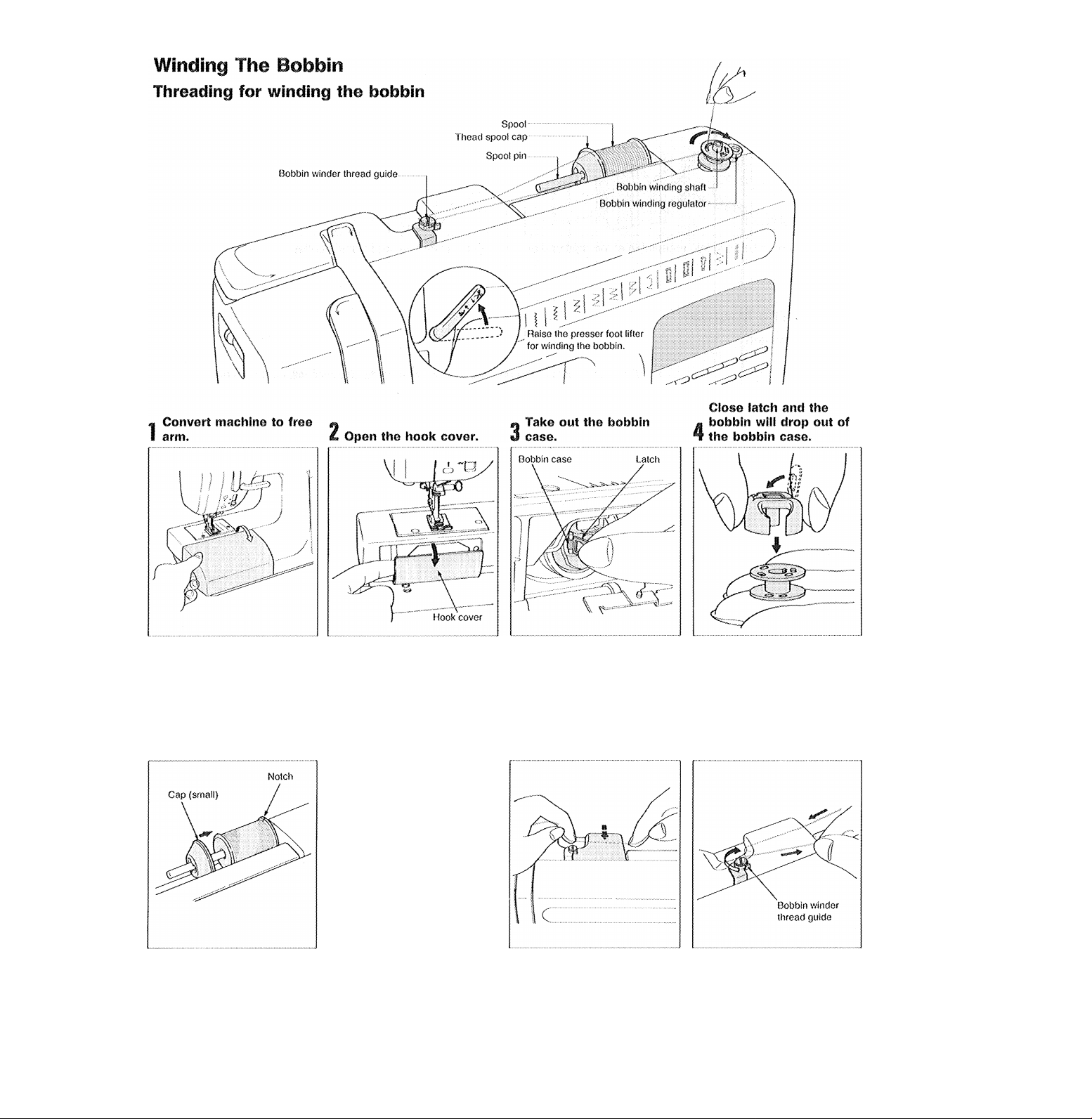

Page 8

(1) Bo sure that the needle is up.

(2) Open the latch of the

bobbin case, and remove.

Piace the spool onto

5

the spool pin.

(1) Be sure that the notch on

the spool is on the right

side.

(2) Use the cap to hold the

spool in place.

(3) Refer to the following

instructions for the proper

use of the large and small

thread spool cap.

Puli the thread into the

groove of the thread

sensor guide.

Hook the thread onto

the bobbin winder

thread guide.

Page 9

Thread spool cap (small) spool

i

c.

Thread spool cap (large)

Place the bobbin on the bobbin

8

winding shaft.

targe spool

I

Use the smait cap for

a small spool, anci the

large cap for a large

spool.

Depress speed controller

9

to wind bobbin.

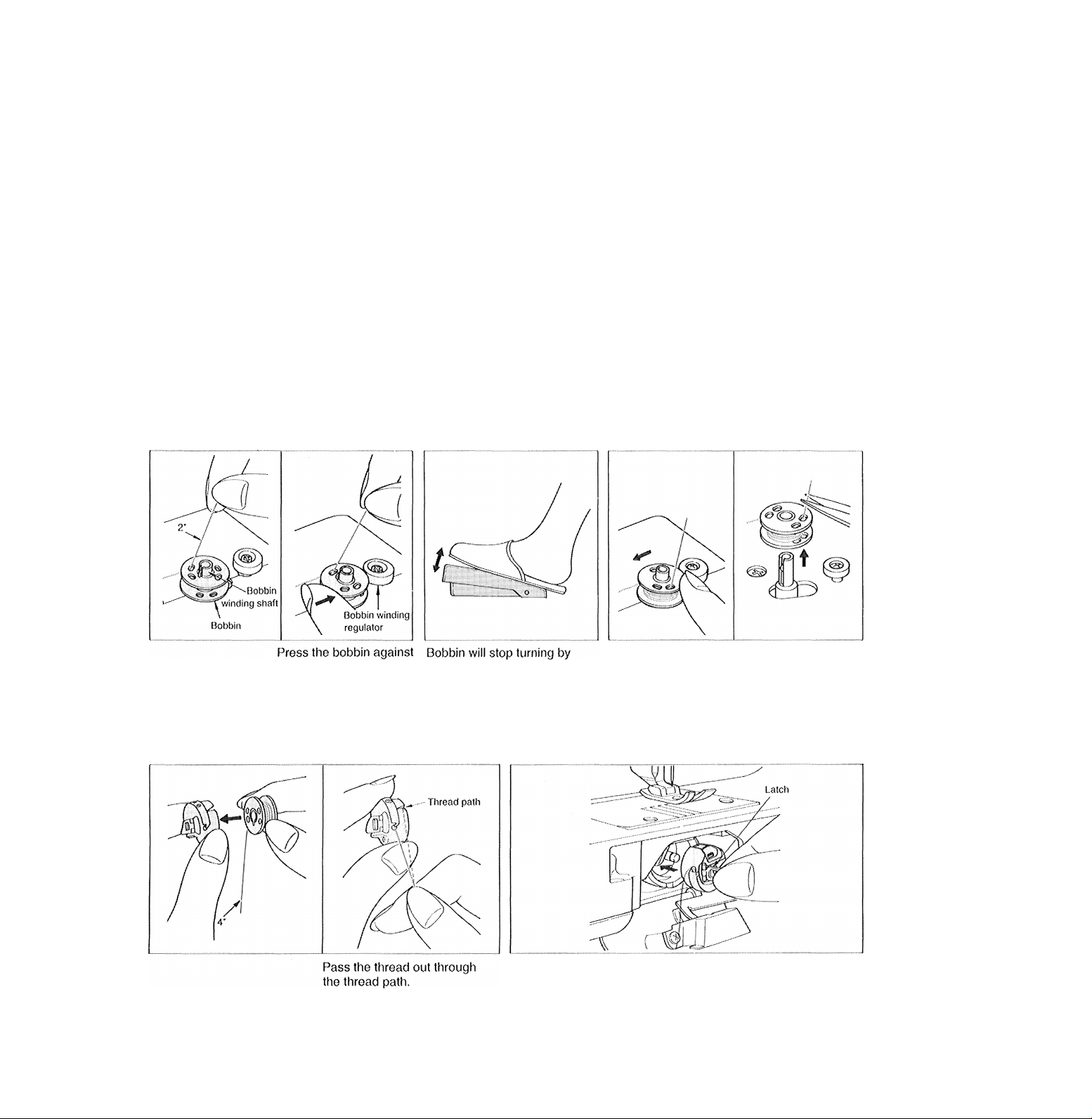

Tension screw ^ l^fdad path

Thread tension spring

The bobbin case furnished with the

machine is factory-adjusted to provide

the proper thread tension, so do not

tamper with the tension screw.

10

'

....

Push the bobbin back to the left.

the winding regulator. itself when full.

Place the bobbin in bobbin case.

11

Cut the thread and take

the bobbin off the shaft.

Replace the bobbin case into machine.

12

(1) Fully open the latch, and securely fit the bobbin case into

the hook.

(2) Snap the latch closed on the bobbin case.

(3) Close the hook cover.

Page 10

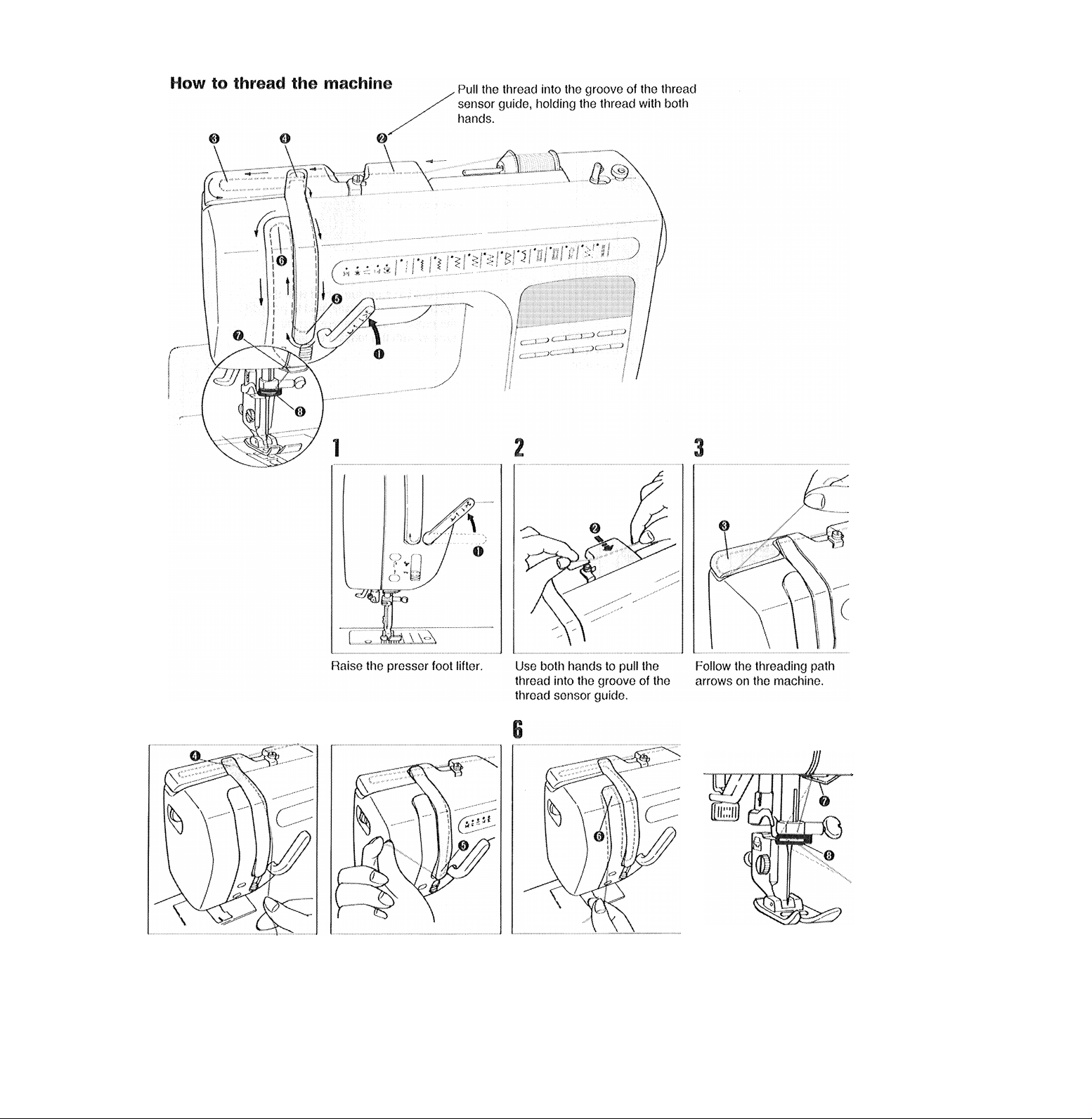

Threading The Machine

Pass the thread down from

e

8

Hook the thread onto ®

before routing the thread

upward.

1

Turn the handwheel to move Hook the thread in © and @

the needle to its highest from the left,

position before passing the

thread over ®.

Page 11

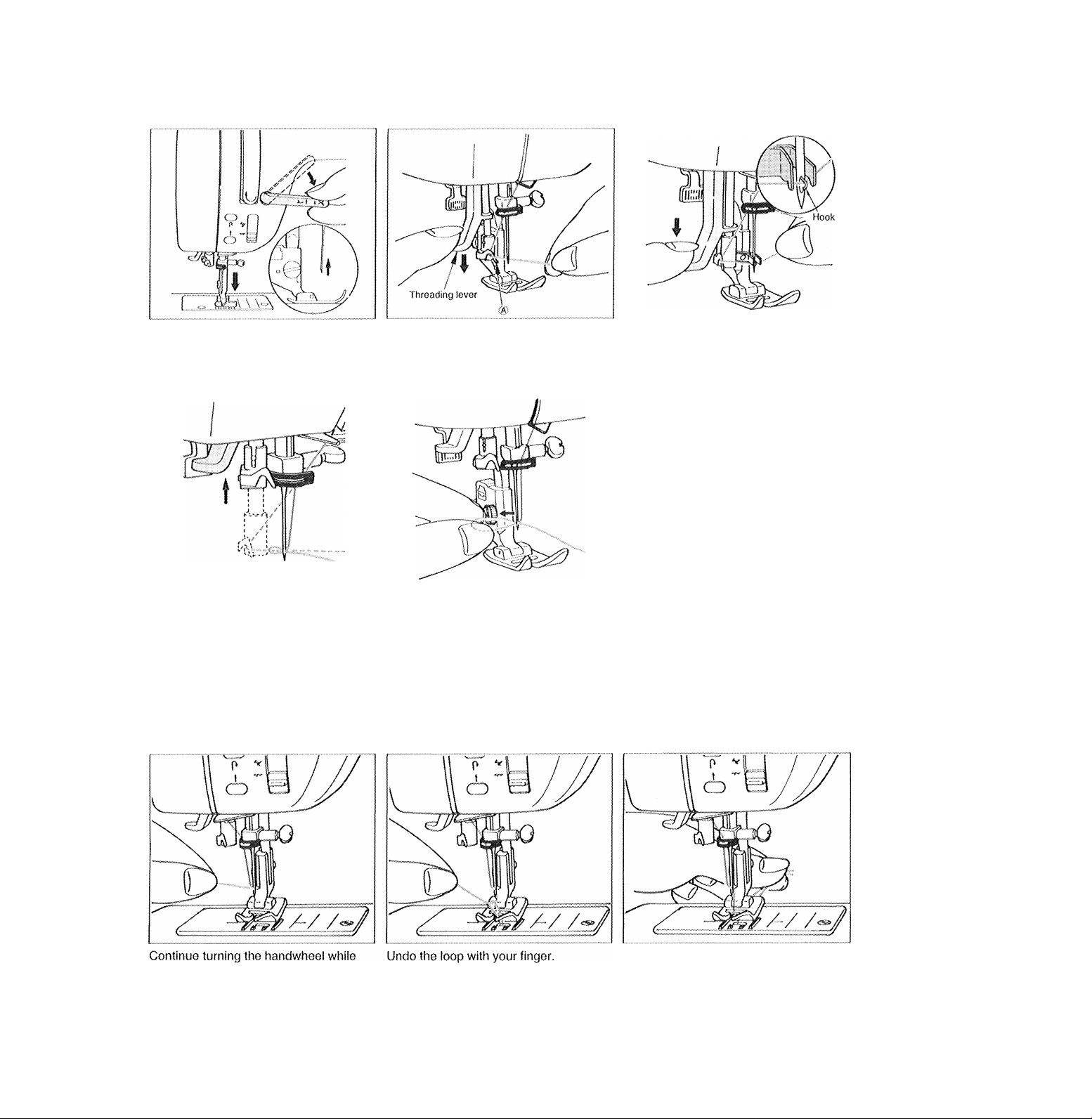

Automatic Needle Threading

Lower the presser foot lifter.

Push the threading lever down.

Push the threading lever all the

way down and a hook will go

10

through the eye of the needle.

The needle should be in the highest

position.

n

Release the needle threader and it will Pull the loop of thread that is at the

return to its original position back of the needle out about 4".

Lower the threading lever and hook the Pass the thread in front of the needle

thread onto (a). and below the hook.

12

Pulling Up Th© Bobbin Thread

Hold the needle thread lightly

with the left hand and turn the

handwheel toward you until

« m the needle enters the needle

IJ plate.

Drop the bobbin thread and

tighten the hold on the needle

»m thread until the bobbin thread

Is pulled up.

Caution:

1. Do not lower the threading lever

while the sewing machine is in

operation.

2. The automatic needle threader will

not work on twin needles.

Pull both needle and bobbin

threads out about 4" and pass

• I. them under the pressor foot to

13 the back of the machine.

holding the needle thread until the

needie rises.

Page 12

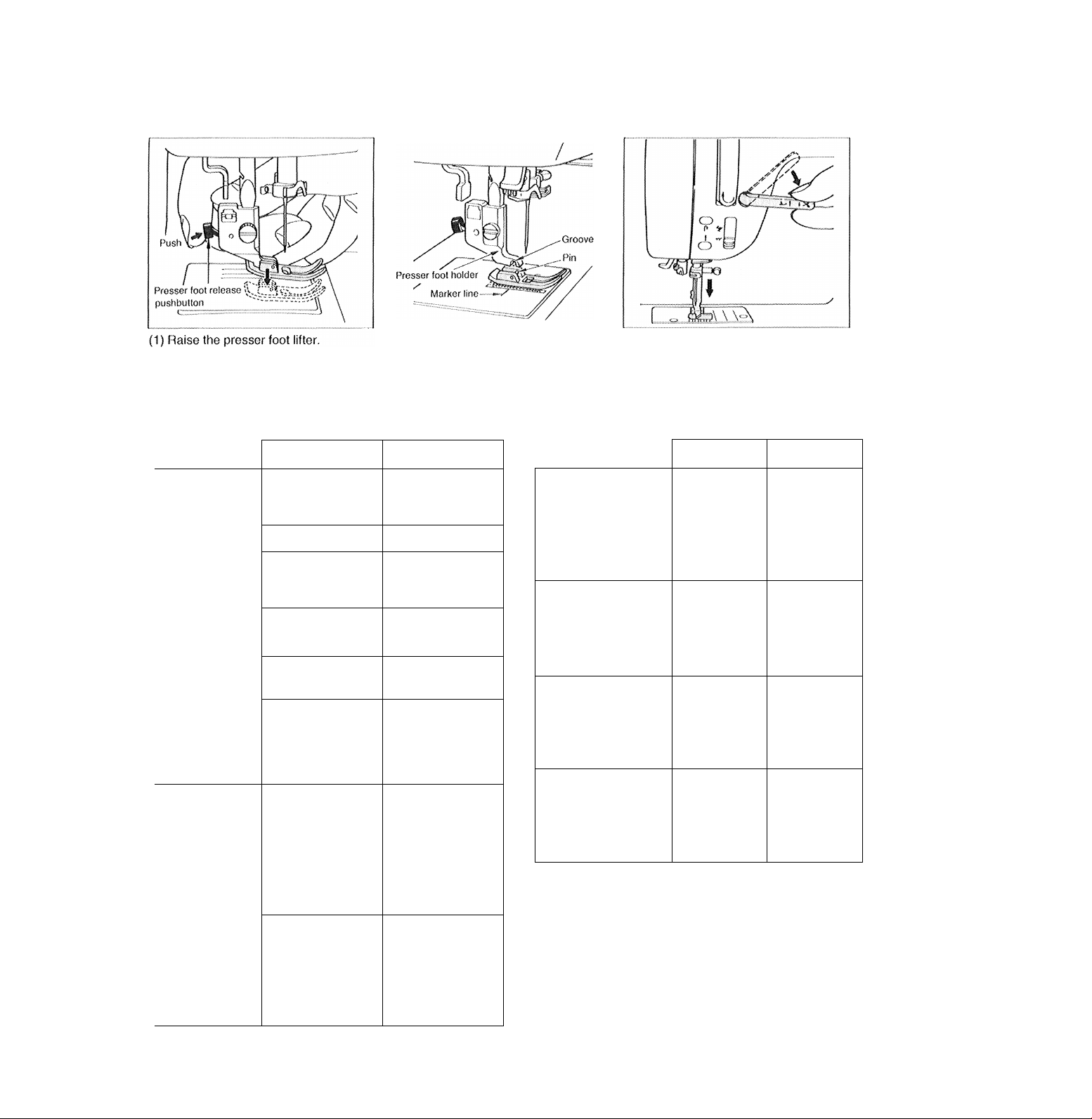

Changing The Presser Feet

Align the presser foot pin with

1 Remove the presser foot.

2

the marker line.

(2) Push the presser foot release push

button in the direction of the arrow.

Types Of Feet And Their Application

Standard presser foot

A

Typical

applications

Straight stitch

Quilting

Pintuck

Stretch

reinforcing stitch

Zigzag stitch

Applique

Quilting

Overcasting

3~step zigzag stitch

(elastic stitch)

Overcasting, etc.

Pattern stitch,

patchwork, etc.

Stitch pattern

!

*

H

Mill

Patterns on A side

1

93 97

Move the presser foot lifter

down to the horizontal position

and the new foot will snap on.

3

(When the presser foot lifting lever is set

in the horizontal position, the presser

foot is lowered.)

Zipper foot

B

Overcasting

c

Biindstitch presser foot

D

Buttonhole foot

Typical

applications

Setting zipper

Overcasting

(Overlocking)

Biindstitch

Stitrfi pattern

1

Stitcti width 5

Decorative stitch fool

T

10

Large size pattern figure

stitch

Large size alphabetical

stitcti

Large size continuous

pattern stitch

Standard pattern stitch

Patterns on A side

No. 00-19

Patterns on A side

No. 47-75

76-79

86-89

Patterns Ofi A side

No. 20-47

80-86

90-97

Patterns on B side

No. 20-79

82-97

Automatic

buttonlwling

If ü Û

vS M U

E

Page 13

stitch Length Of Each Stitch Pattern

The machine’s stitch patterns have been preset to an optimum length,

can be changed to suit your needs.

By using the manual override buttons the pattern length

Stitch pattern

\

%

\

\

1

1

1 1 fl

3

i ^

Patterns on A side

) I ^ >

80 81 U 83

Patterns on B side

Stitch length

Programmed

3 n

CXJ

in

in

IS

¡5

nn

Bartackod Eyelet

03

0.5

nn

in

0.S nn

Manual override

nn - on

on - on

nn - on

nn - on

nn - on

nn - on

on - in

nn - on

on

--

on

-

on

* The two lines (-----------) indicate that the

pattern cannot be altered using the stitch

length button.

nn

ao 81

i^atte rn f Igu re s 00--19

Patterns on A side ^4,9-^

Patterns on B side 02->97

20-79

20-79

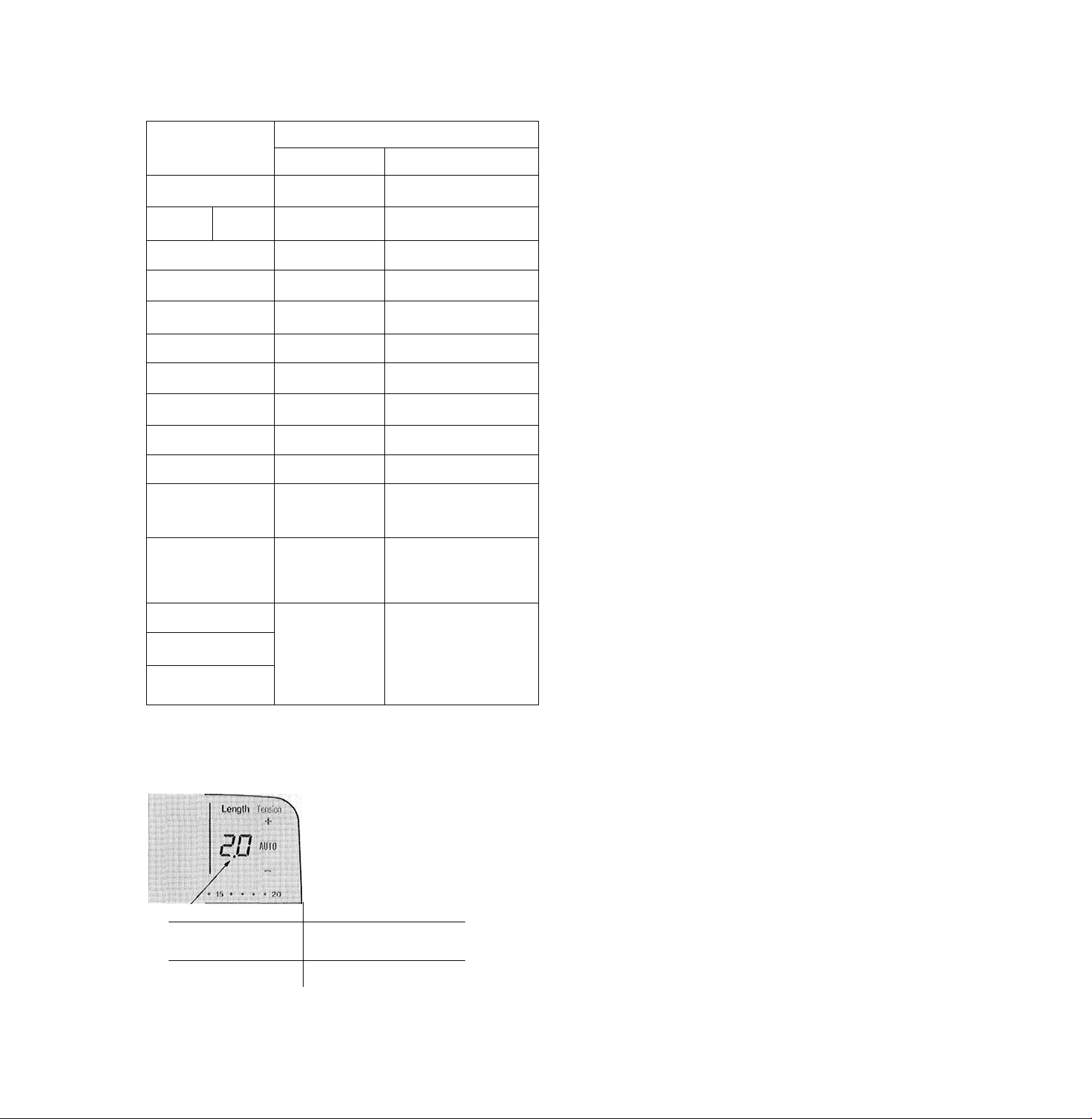

How To Adjust The Stitch Length

Digital display

..

'^'1

■jf

How to use the stitch length manual override buttons

Manual override range

nn un f 0.0, 0.2. 0.3. 0.4, 0.5, 0.6, 0.7, 0.8, 0.9,1.0,1.'

U.U --- 'T.u ^t.5^2.0, 2.5,3.0,3.5, 4.0

on - on

Press this button to increase the stitch length.

Press this button to decrease the stitch length.

11

Page 14

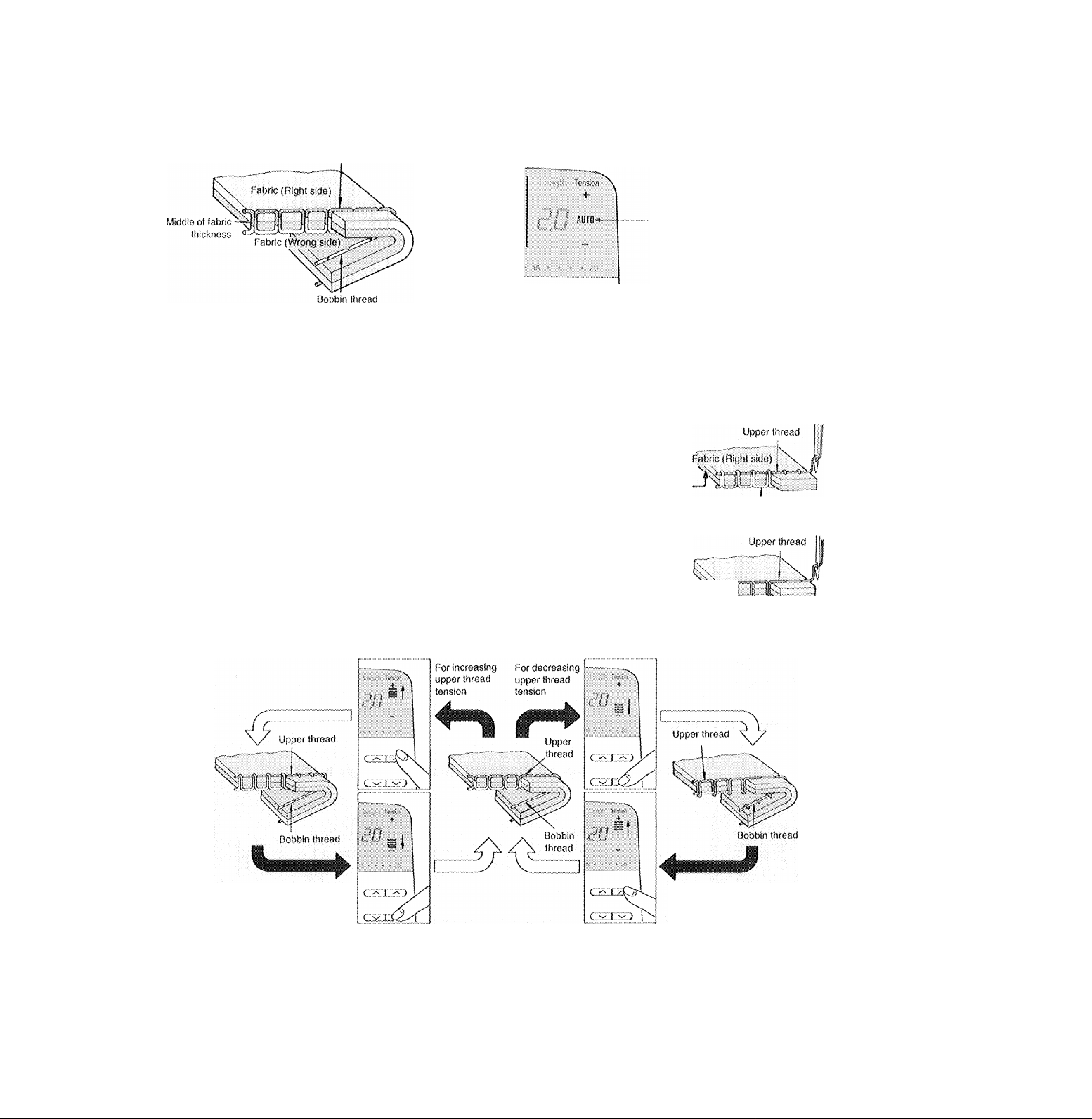

Automatic Thread Tensiori Control

The thread tension is automatically computer controlled.

The upper thread and bobbin thread should interlock at the middle of the fabric thickness as shown bellow.

The thread tension control is set to “AUTO” whenever the power switch is turned ON or a stitch pattern is selected.

Upper thread

■Indicates that the automatic tension control is on.

How to adjust thread tension

Use the thread tension manual override buttons to change the thread tension.

if the bobbin thread of the

ao g

-----

Press this button to increase

thread tension.

Press this button to decrease

thread tension.

formed stitches is seen on the

right side of the cloth as

illustrated, it means that the

upper thread tension is too

high.

If the upper thread of the

formed stitches is seen on the

wrong side of the cloth as

illustrated, it means that the

upper thread tension is too low.

Bobbin thread

1» . V

Bobbin thread Fabric

(Wrong side)

For decreasing

upper thread

tension

For increasing

upper thread

tension

Note: When you select a combination of patterns from No.OO to No.98, use the thread tension override button on the first pattern.

The thread tension which has been set once will automatically apply to the all of the following pattern stitches.

12

Page 15

Indicator Lights

If the machine has not been properly set to sew, an indicator light will come on to tell you where the problem is located.

Upper thread indicator light

Bobbin winder indicator light

Prosser foot lifter/thread cutter lever indicator light

Buttonholing lever indicator light

Low bobbin thread indicator light

Solution

Indictor

light

Problem

Cause

(When the following corrective

action is taken, the indicator light

will go OFF.)

1

№■)

When the speed controller or

start switch is pressed and the

machine will not sew.

The machine forms one stitch

then stops.

Mote: The bobbin winder is

turning.

The indicator light flashes ON

and OFF, and the machine

stops after it produces only one

stitch.

1 -'ff ^ \

1) The upper thread has run out or

broken,

or

2} The thread is not in the thread

sensor guide.

Bobbin winding shaft

The bobbin winding shaft was loft in

the right position after winding.

The presser foot is up, and the

thread cutter is in position.

____

\

V

1) Replace the empty spool arid

rethread machine.

2) Place thr'ead correctly in thread

sensor guide.

Move the bobbin winding shaft back

to the left position.

„iCCX

О

‘î; у

-i ^ '■

..

Push the presser foot lifter/thread

cutter lever down to the horizontal

position.

w

.f )

The indicator light flashes ON

and OFF, and the machine will

not sew a buttonhole.

The indicator light will blink

when the bobbin thread is low.

The thickness of thread

detemiines the remaining

amount on the bobbin.

Bultonhofing leverAi yii T X '"

The buttonholing lever has not been

pulled down.

Note; When using transparent

thread the machine cannot detect

i the remaining amount of thread on

the bobbin and the indicator light

will blink even when the bobbin Is

full.

о

Bring the buttonholing lever down.

(See page 20.21)

UH Wind a new bobbin.

Important

Please Keep

^*tis area of the

j machine clean

' fhK. vV to allow the low

bobbin thread

sensor to work

properly.

13

Page 16

Fabric, Thread And Needle Table

Your fabric will determine the choice of a needle and thread. The following table is a practical guide to needle and thread

selection. Always refer to it before a new sewing project. And be sure to use the same size and type of thread in the bobbin as in

the top thread supply.

Fabric

The fabrics below can be of any fiber, cotton,

linen, silk, wool, synthetic, rayon, blends. They

are listed as examples of weight. sewing performance.

Very Lightweight • Bastiste, Chiffon, Organza,

Voile, (extra fine) red orange

Cotton-Wrapped polyester core 2020 9/70 or 11/80

Long fiber polyester (extra fine) shank

Thread Needles

Failure to use a Singer brand needle

may result in skipped stitches or poor

TYPE SIZE

band

Lightweight • Challis, Chambray, Carmeuse, Cotton-wrapped polyester core 2020 11/80

Crepe de Chine, Gauze, Handkerchief Linen, (all purpose) red

Silk, Taffeta, Tissue faille.

Medium»w@lglit» Brocidcloth, Brocade, Chino, Cotton-wrapped polyester core

Chintz, Corduroy, Flannel, Linen, Poplin, Satin,

Synthetic, Suedes, Taffeta, Terry, Velvet. Long fiber polyester (two spun)

Medium to Heavy-weight • Coating, Damask,

Denirn, Drapery Fabric, Fake Fur, Gabardine,

Ticking, Woolens. Long fiber polyester (two spun) shank band

Heavy-weight • Canvas, Duck, Sailcloth,

Upholstery Fabric. (ail purpose)

Leather

Knits * Jersey, Tricot, Single Knit.

Sweatshirt • Double Knit, Swimwear, Sweater Cotton-wrapped polyester core

Knit. (all purpose)

*Use with standard sowing thread in bobbin.

Long fiber polyester (two spun)

(all purpose)

Cotton-wrapped polyester core

(all purpose)

Cotton-wrapped polyester core

Long fiber polyester (two spun) shank

Cotton-wrapped polyester core

(all purpose)

Long fiber polyester (two spun)

Long fiber polyester (two spun)

shank band

2020

red

shank

2020 16/100

red purple

2020

red

2032

leather

2045

yellow

shank band

2045 14/90

yellow blue

shank

orange

14/90

blue

band

18/160

11/80

orange

band

How To Remove And Insert The Needle

Attaching the needle.

Removing the needle.

highest position.

(2) Loosen the needle clamp screw.

2

(The needle cannot he inserted unless it is correctly positioned.)

fully until it touches the stopper pin.

CAUTION: Make sure the power/lighi switch is off

before inserting the needle.

screwdriver furnished with the

machine.

14

Page 17

Various Types Of Stitches

You can perform various types of stitching such as straight stitcii,

buttonhole, applique, blindstitch and free arm sewing.

/vWxA

ilililllll

Ty/in Needle (Oi)tioiial)

iiiii

■

i:|i 8

i ■■ A

lii-ill'

16

Page 18

straight stitch

„,L„

When the power switch is turned on, the straight stitch is automatically selected and the needle will

be in position at the left of the pressor foot (A).

To move the needle position use patterns 80, 81 on B side of pattern display panel.

Needle entry position

(left needle position)

Stitch produced in

automatic setting.

The straight stitch is

the basic stitch.

Begin sewing.

Select

a stitch pattern.

{ndicator light

Make sure that the presser foot

2

is correct.

Presser foot

symbot

Standard presser foot A

Use the presser loot bearing the symbol

indicated on the instant pattern button,

*See page 10 for how to attach the

presser foot.

Ig Lightly hold the material with

3 your hands.

Set the material, and lower the

3

presser foot.

Place the material under the pressor

foot so the needle will enter the sewing

start point of the material. Pull both the

upper and bobbin threads to the rear of

the machine and lower the presser foot.

Adjust the sewing speed.

6

7

Stop sewing.

16

Be careful not to apply excessive pulling

force to the material while sewing.

Cut the thread.

(For the automatic thread cutter

g

see page 18.)

thread cutter lever until the needle

moves. This will cause the upper and

bobbin threads to be cut at the same

time.

Lift the presser foot and remove

9

the material.

position, raise the presser foot lifting/

thread cutter lever and remove the

fabric.

Page 19

Reverse stitch

I he reverse stitch is used at

the beginning and end of a

seam to secure it<

Press the reverse

W stftoh button.

@ Begin sewing.

Press the reverse

® stitch button.

e The sewing machine performs reverse stitching only while the reverse stitch button is

being pressed.

# The sewing machine runs at low speed when sewing in reverse,

o When sewing pattern stitches such as a zigzag stitch, the machine will perform

tacking stitching instead of reverse stitching.

Changing sewing direction.

Stop the machine in the desired

position. Lower the needle into the

fabric. Lift the presser foot, and turn the

material in the desired sewing direction.

How to select needle entry

position.

Center position

Select B side No.BO

stitch pattern

night side position

Select B Side No.81

stitchpattem

See page 24-31 tor how to select pattern stitch.

Lower the presser foot and start sewing.

17

Page 20

Shirring And Gathering

How to perform shirring and gathering

When shirring an arriihoie or skirt waist, or gathering cuffs or yokes, sew with a leng thread length, then pull the bobbin thread by

hand to gather the rnateriaL

Reduce the ypp0f 1 3 4

thread tension. Tension Tension Tension Tension

How To Operate The Automatie Thread Cutter

Note: it is advisable to use the automatic thread cutter at the end of a seam. Use the thread cutting groove located at the back of

the presser foot for cutting thick threads or special types of thread.

tivnCii-:-

Upper thread tension

decreases gradually

between four steps.

Lower the thread cutting fever.

At the end of a seam pusii tho thread

cutting lover completely down.

The indicator will light up.

★ After tho automatic thread cutter Is used, you can begin sewing oven if the bobbin thread is not on the needle plate.

Needle up.

Release tho thread cutting lever and the

needle will go up, and the upper and

bobbin threads are cut. The needle

stops in the up position.

How To Use The Thread Cutting Groove (How to knot the threads)

Remove the material from the machine.

Cut the threads, using the thread

cutting groove.

rhroad cutiinp

groove

Raise the thread cutting lever.

After confirming that the needle has

completely stopped, lift the thread

cutting lever all the way up and the

presser foot will be raised.

Knot the two threads on the

wrong side of the fabric.

After finishing a seam, rai,se tho needle

and the presser foot, and slowly pull tho

material from under the presser foot.

18

I iold tho upper and bobbin threads

together, pull them out about 4" and cut

them with the tliread cutting groove

located at the rear of the presser foot.

Pull the upper thread to the wrong side

of the fabric, and knot the upper and

bobbin threads. Cut the threads as

close to the knot as possible.

This technique is useful for securing the

pattern stitches.

Page 21

Zigzag Stitch

I

Stitch width vs. stitch length

Stitch

pattern

selection

button

Select the desired stitch pattern.

Indicator light

y

\ ;; <

Presser

fool

symbol

Select from the zigzag stitch

patterns.

Check that the presser

2

foot is the correct one.

Be sure to use the foot

indicated on the instant

pattern button.

* See page 10 for how to

attach the presser foot.

3

The sowing method is the same as for

straight stitch.

Refer to pages 16 and 17.

Stitch

width

Automatic

stitch

length

( n I /

f.U i>

I n <

I.U )

Manual

override

stitch

length

n J

u.c

u n

n.i -

u

ü£ HD

n ^ Lj n

Use the thread tension manual override buttons when you need to change the thread tension.

upper tliread

V

To decrease the

upper thread tension

Bobbin thread

To increase the upper

thread tension.

19

Page 22

Automatic Buttonholes

® When sewing knit or other stretchy

materials, apply interfacing to the

material, and set the presser foot

pressure adjustment dial to “LOW’’.

# Be sure to sew a test buttonhole first.

For sewing small buttonholes in shirts,

blouses, children’s clothing, etc.

For sewing large buttonholes in coats, etc.

For sewing large buttonholes in thick

feibrics, etc.

Select the desired stitch

pattern.

Indicator light

Change the foot.

n

Pressor foot

symt)ol

Of the three types of

buttonholes, select the one

suited for your particular need. ‘Refer to page 10 for how to attach the

Place the button in the buttonhole foot.

Attach the buttonhole foot with its symbol

located away from you.

presser foot.

F*uil out the upper and Bobbin

3

threads.

Pass the upper thread under the buttonhole

foot.

Remove the button. U Mark the material.

6

20

Mark

has been determined, take indicate the buttonhole

the button out of the foot. placement.

Page 23

Automatic buttonholo stopé

Lower the buttonhole foot.

7

1

1

2 3

« i v <

it •*

I

Lower the buttonhole lever

5

ti

Tacking stitch

Tacking stitch

At the end of the buttonhole the machine will

sev/ a tacking stitcti, then stop automatically.

Begin sewing.

9

If the indicator

light comes on the

buttonhole lever

has not i s

been

lowered correctly.

Lower the buttonhole foot so that the mark is at When the buttonhole lever is fully lowered, the

the center of the needle hole in the foot. indicator light will go OFF,

* If you try to start sewing without lowering the buttonhole lever, the indicator light will flash ON and OFF, and the machine will not

start.

‘ If you set the buttonhole length wrong, or the upper or bobbin thread runs out, you can restart the buttonhole from the beginning

by pressing the stitch pattern selection button once.

At the end of the buttonhole cut

Ш

the threads.

« I Open the completed buttonhole,

I I using the seam ripper.

Barfacked

buttonholes

Keyhole I ! Byelel

\ buttonhole

O

i

punch

Straight pin

c: .V

:.=C

Seam upper

Cut the middle of fhe

buttonhole open using the

seam ripper, being careful

r

not to cut the threads. It is

advisable to place a straight

pin at the end of the

buttonhole to help prevent

overcutting.

1/

Lower the thread cutting lever to cut the

threads.

* Lift the presser foot, and then lower it

so that the second buttonhole mark is

set at the center of the needle hole in

the presser foot.

21

Page 24

Sewing Corded Buttonholes

If you use cording for buttonholing, it will prevent them from becoming loose and they will last longer. Buttonhole twist thread may

be used for cording.

How to set the cord.

n rr: : : |

f Ì

/

"Cord

(front) (back)

Free Arm Sewing

Application examples

When you sow buttonholes with cording, pass the cord through the end of the

buttonhole foot and knot the ends of the threads at the front. Then, attach the

buttonhole foot to the presser bar and sew the buttonhole. Pull the cording tight

into the sewn buttonhole and cut off the excess cord.

Sewing harcf"tO“reach garment areas is

made easier by using the tree-arm sewing

capability of your sewing machine.

Note: See page 2 for converting the

machine to free-arm.

Topstftchlng

M-f-

22

Collar sowing

Cap

/■■■

Hemming

Page 25

Overcasting (Overedging)

Used to prevent fabric from fraying.

1

Select the desired stitch pattern.

Stitch width 3

Presser toot

symbol

Stitch width 5

c

Pressor foot

symbol

There are four stitch types that can be

used for overcasting.

Select the one that is best suited for

your material.

Replace the presser foot.

2

• Be sure to use ihe standard

pressor foot for Ihe stitch width

3 and 3“Step zigzag sewing.

Standard pressor foot A

# Stitch width 5

# OverlocK/overcasting

Overcasting foot C

Use the presser foot which is indicated

on the instant pattern button.

* See page 10 for liow to change the

foot.

Used for overcasting light-weight material with curly

edges.

Used to prevent cloth edges from fraying. Place the

fabric against the foot guide so that the needle sews

close to the edge.

Used for stretchy material or fabrics which tend to fray.

For overcasting the edge of a fabric to prevent it from

fraying. This stitch may also be used to sew a seam that

will not be pressed open.

23

Page 26

Pattern Sewing

Uguid Crystal

And Name Of Each Button

liquid crystal display

i^altef« No.

©d)

00

Paiten) Size

'iM

OS

'm

1 II I

ERROR

F^ress this button once and 00

will appear in the liquid crystal

display under pattern No. unit.

Information Indicated On The Liquid Crystal Display Window

/N j .A. y C^’** F ### I ^ ^ ✓ V ¡ ^ )

< >", I N/ ) (. Mm.)

lens unit One unit

Pattern No. selector clear a pattern that has

button

F^atteff) clear button

been niernofized)

AUTO

Reduced size button

Re()eat pattern button

Iteversed in>age button

l-^attern rnernofy button

(to memorize the pattern

selected)

owhen you select a pattern number.

Í When you change the number or the

display to patterns on A side.

^When you change the numbers or the

display to patterns on B side.

A

You can stitch "A".

^ When you select a large ® When you press the reduced size button # Wtien you select a standard ® When you press ttie reverse image

size pattern. alter you have selected a large size size patterr) stitch, button,

Paiiem Size Paitern Size

A large bear will appear. A small bear v/ill appear to indicate that the A star will appear to indicate the The ()atiern will be sewn ir> reverse,

^ When you press the repeat button the ^ When you press the

pattern or pattern sequence will continue memory button,

to sew until the machine is stopped.

pattern stitctc

€S

pattern will be sewn smaller. pattern cannot be altered in size.

^When a pattern is

rnomorized

® When you make a selection that the machine will

not accept the word El tF^OF^ will appear.

ERROR ' When you select a pattern which cannot

This indicates that

The above symbol will

appear.

patterns are storert

in the memory.

be reduced or reversed.

*When you attempt to memorize more

than 21 patterns.

^Ttu) {Uimber of patterns stored in memory is indicated by the pointer.

» 9 B * • ♦ 10 ♦ * * ♦ 15 ♦ * * * 20

To clear any pattern selection from the liquid crystal display press any of the instant pattern button or turn the power switch off

then on.

24

Page 27

Relationship Between Patterns And Buttons

Large Size Patterns

Patterns on “A” Panel.

Pattém Figuras

Block Alphabet

Large Script

n

Ü

06

13

(Al

21

20

(Kl

31

30

lui [Vi

41

40

1 1

! 1

50

51

f 1

:-J

61

60

1 ''1

71 72

70

iBi

[Q

i 1

1 ]

1 j

00 ' '01 ■'

07

14

: [D]

22

H El

32 38

11 [X]

42 43

I'i

52

f ' !

i -j

62

{

...

1

^02

/ i i.. i

' 09 10

08

1?

16 •

15

1 (Fi

lE'

24 25 26

28

1 (Pi (Ql

[Ql

34 35 36

[y 1 [ZJ

45

44

M581 1

! "1

73

[ 1

54

55

f-yyi

i '1

i

[' 1

64

65

f

...

i 1

1

i 1

|y

74 '?5 47

t

(Gl El

46

ÎU

58

! 1 66i '1

Function Buttons

04

11

19

[I] yj

26 29

(S|

48

l-''l

5$

!n]

46

05

^ i

12

39

i ■' ]

59

^69^

49

C

...

i

m

i ;

[ ]

............1....

c

....

i:LH ! MEM 1

r

.....

CiU' r MEM 1

MEM 1

03

18

27

[R]

37 38

lui

i

...

I

47

!U

57

67 66

! i

Patterns on “B” Panel.

Large

Continuous

Patterns

Continuous

Patterns

Standard

Patterns.

' I i '' i

76 77 78

86 8? 88 89

80 8i 82 83 84 85

M M 1*11*1 111 I“11

50 81 92 33 94 95 9$ 97

I

iP] [IJ fa] (3j (41 (51 [B] (7) [8J (9j

20 21 22 23 24 25 26 27 28 23

m m

ffj m Wi (1 1^1 1^1 (il 0 13 0

ao

(fi ill [s @ (11 11 ti] 0

30 3Ï 32 33 34 35 38 37 38 39

1 41 42 43 44 45 46 47 48 49

50 51 52 53 54 55 58 57 58 59

60 61 62 63 64 65 66 6?

m |t

J

70 71 72 73 74 75 76 77 78 79

ia

...................

81 82 83

\P

i.a;i

3 iHi

ÿ y 0 § S E

85 86 87

5j (01 111

^ n

?3

C, .ill: I MEM 1

69

1 01 92 93 34 35 96 9?

See page 30 on how to adjust. If pattern you are sewing is not balanced see page 30.

OCC5ZZD®

25

Page 28

Large Size Pattern Sewing (1)

It is recommended to make a sample using the same fabric and interfacing

or backing materia! before sewing on the garment.

Large size patterns

When you sew pattern stitches or alphabet stitches,

be sure to use the decorative stitch foot (T).

Select a pattern, and check the pattern number.

Select a pattern, and check the

pattern number.

To determine the pattern placement use

the assistant marker and templates

provided with the machine.

Position the fabric under the decorative

stitch foot (T) where the needle will

begin sewing the pattern.

Patterns are stitched sideways, this

allows for easier sewing with the free-arm.

Note: See template for additional

instructions.

m Select a pattern, and check the

I pattern number.

Select a pattern, and check the

pattern number.

26

Page 29

2

Select pattern No.

button, the pattern number and bobbin thread together, the machine will stop

will appear on the liquid

crystal display.

Select pattern No.

2

Begin sewing.

lower the presser foot, begin automatically,

sewing.

Press reverse button, nt Begin sewing.

Completion.

Completion.

Select pattern No.

Select pattern m Press repeat

sen

2

No. button.

The reverse symbol will

appear on the liquid crystal

display.

Press reduce button.

appear on the liquid crystal

display.

4

Begin sewing.

the machine will stop

automatically.

Begin sewing. Completion.

When the pattern is complete,

the machine will stop

automatically.

Completion.

The repeat symbol will appear

on the liquid crystal display.

The machine will continue to

sew the pattern until you stop

the machine.

27

Page 30

Large Size Pattern Sewing (2)

^Alphabet Stitch

Types Of The Large Sisge Alphabet

Set the pattern display panel to patterns on A side.

47

-1

50 51

[:;1 l-l

60 61

70 71 72 73 74 75

The reverse stitcli button will not function on the alphabet pattortrs.

53 54 55 56

52

[^l

62

63 64 65 66

V,

5?' 58

67^

Pi

48

I - I

1 1

(' ■]

68

1 i

f .

l-:_

69

49

59

Select a pattern, and check the

1

pattern No.

Select a pattern, and check the

1

pattern No.

Continuous Pattern Stitch

Types Of Large Size Continuous Pattern Stitch

Set the pattern display panel to the patterns on A side.

76 77 78 79

86 87

The reverse, reduce size and

memory buttons will not function

on these patterns.

Select a pattern, and check the

1

pattern No.

28

Page 31

Select the pattern No. y Begin sewing.

Select pattern No. 50 of

patterns on A side.

Press reduced size

3

Select the pattern No.

button.

Completion.

completed, the machine will

stop automatically.

Begin sewing.

Completion.

The reduce symbol will

appear on the liquid crystal

display.

Select the pattern No. «1 Begin sewing.

4

Completion.

The machine will continue to

stitch the pattern until you

stop the machine.

When the pattern is complete,

the machine will stop

automatically.

29

Page 32

How To Combine Patterns (Example)

Check the pattern

1

Select a combination of pattern.

2

numbers.

Select the number

for PJ (69).

Press memory button.

For example (combination of two

alphabet stitches)

For example (combination of the large size pattern figures)

Reverse

Pauern No. 06

Patterns on A side

69 49 74

Reduced size

Pattern No, 07

Reduce and

reverse

1x

cso... J

Regular direction

Pattern No.

nr

nn*

MEM

)

..

:>

For example (combination of large size pattern figure and patterns on

A or B side)

I I:

l.„ Q V

Pattern No. t4

A Side B Side A side A side

31 66 41 24

13

Balancing The Shape Of A Pattern

I Select the trial sewing m

I pattern No. 98. L Begin sewing.

It is recommended that a test sample of

the pattern is sewn using the same fabric

and interfacing or backing before sowing

on the garment.

Depending on the type of material, its

finish, thickness and interfacing used, the

shape of the pattern may be altered. If the

pattern is out of shape sew the trial sowing

pattern to balance the machine.

Pattern No.

Completion.

Correct balance

The normal

stitching.

•' '' Horizontal

30

The pattern can be

selected from A side or

B side.

The machine will continue to

sew the pattern until you stop

the machine.

Page 33

1» Select the number

3 for y (49)

» Press memory

D button.

^ Select the number

I for ^ (74).

Press memory

button.

8

9

Begin sewing.

/ © ^

No. Si20

o ®

U€3 cPi

.♦*♦$**** to*»* *t

& * —»

1 1 T ^ >

r^”rr^ cw^rm

1

With using the memory button

you may stitch the same

pattern up to 20 times.

Reverse

06 will be on the liquid crystal

display window.

I O

Reduced size

Pattern No.

n

I#. PoUem Suo

IH o

S -----------------------

................

(S-I

■ ^ pn

--

When the patterns ^ ^

are complete, the machine

will stop automatically.

Reduce & Reverse

Begin sewing

07 and reduce will be on the

liquid crystal display window.

Pattern No.

«»I I ©fiMeM

on A side

a How to adjust the right side

4

~ I up stitching.

Turn the stitch balance control to the

left.

Pattern No.

©

ii ti

on B side

V

Pattern No.

Q

Lj ¡.^

on A side

©CSSHI)©

M How to adjust the right side

4

down stitching.

Turn the stitch balance control to the

right.

Begin sewing.

Pattern No.

'

...

N ~ •’

How To Cut The Cross-Over Stitch

Unnecessary cross-over

stitches on the right side

of the fabric should be

cut with a pair of

scissors.

31

Page 34

How To Correct Patterns in Memory

When an undosired pattern has been placed in memory in a combination of pattern stitches.

* The clear button will operate only when the memory button has been pressed.

* Pressing the clear button will clear the pattern numbers which have been selected.

* Memory of the undesired patterns will be cleared in order from the pattern which was selected last.

‘ Continue to press the clear button and all the patterns which have been selected will be cleared one at a time.

* Turning the power switch OFF, or selecting a pattern from the instant patterns, will clear tire memory.

‘ To clear the reduced size or reverse pattern press the button again.

When the last selected pattern number ttiat has been

placed in memory is not a desired one.

Press the clear button once.

1

i O !

{

.........

A

20

21

are the desired patterns.

/r J

^ 22 *

t

___

r::... ...i

f

..................

I

The last pattern number selected (24) Is cancelled.

A

20

mmS

21

1

.....

are selected by mistake

...........

]

Pattern No. 21 (B) which has been set in the second place

will be on the liquid crystal display.

When an undesired pattern number is selected in the middle.

V

...

.............

1 t

A

20

A

1 }

1 21 i

t ^

20

}

c

i {

1 j

1

22

Ip 1

f i

1 22 ^

u .......... j

.

...... ..... ...t

are the desired patterns.

are selected by mistake.

1 Press the clear button twice.

32

Pattern No. 20 (A) which was selected first will be on the

liquid crystal display.

Page 35

Liquid crystal display.

PiiUcm Ho. PaUefo

©

☆

czo::5D csMiTiD

C2:i::^ oiia:j5M.3 CNi..i..v>

Select the correct pattern number (22).

2

4-

«* «. iBTO

Press the memory button.

• When the memory is not full, it will be indicated on the

display and you can continue to add patterns.

• When you select a new set of patterns, be sure to dear all

of the memorized pattern numbers including the memory

indicator from the liquid crystal display.

number of patterns stored in memory is indicated hero.

When the % mark is not indicated on the scales of theEP, the

pattern number displayed is not stored in memory.

Select the correct

2

pattern number (21)

.......

P I

☆

t

► »0 * * ♦ « » X

imuD c

c:v.;

Press the memory

3

button.

Select the pattern

4

number (22) or C.

Pattern C was cancelled and

has to be placed in memory again.

Press the memory button.

I

33

Page 36

Four Direction Sewing

Those four stitches allow

you to sew sideways and

forward or backward,

without pivoting the fabric.

Right side

O straight stitch.

© feed stitch.

O Reverse straight stitch.

Check that the presser

foot is the correct one.

O Left side feed stitch.

34

Page 37

Attaching Feed Cover

For darning and frec-motion

embroidery, ttic food cover prevents the

feed from moving the material.

Attach it as follows:

Remove the presser holder

and set the feed cover

in place.

Set the feed cover on the needle Select a zigzag pattern from the five

plate while aligning the pin of the different patterns available,

feed cover with the hole in the

needle plate.

‘Before removing the presser holder,

be sure to turn OFF the power to the sewing machine.

Set the stitch length to 4.0.

Select the pattern

2

as desired.

A < A

Set the embroidery hoop in

4

place.

Set the stitch length to 4.0 using

the manual key.

Lower the presser bar lifting lever

and start sewing.

35

Page 38

Darning Stitch

Push pattern panel to

I

side B.

Select the pattern No.

Attach the decorative

3

stitch foot (T).

* See pages 30 & 31 for how to balance the shape of a pattern.

Begin sewing.

Patterns on B side

75 pattern No.

Select pattern No. 75 from

patterns on B side.

To sew 8 wider darning stitch, begin sewing after

the needle entry position has been set so that the

pattern can be continued after the previously

5 stitched pattern.

Needle entry •

\ position I

’"11--

H

n

Starling position

/

Siitch foot symbol

:.T„

Decorative stitch foot (T)

The machine will stop automatically

when the sewing of one pattern is

complete.

Use four direction sewing for free-arm sewing.

Select pattern No.94 Begin sewing and

from the patterns on n stop at the desired

I

A side. £ point.

Set right direction cross-feed.

Select pattern No.93

from the patterns on

3

A side.

Set left direction cross-feed.

Begin sewing and

stop at the desired

point.

A part is fed manually.

Sew as illustrated

1« in the Fig. 1 and

3 Fig. 3 alternately.

limi]

f • U 4 i ' f f » * j

i X i i i. i

% i M i M

1 4 i i i : J 1 n 4 i

i i V i i i ¥ i

4 ' i i i ! 4 . i > i

4 4 4 i i : 4 : : # i 4

’ < i i n • i

i 4 4 i < : 4 : ¡fit

4:444:4:4 4 4

i i i 1 1 Ä i

% i ¥ t % Ä i

¥ i i

> i . ¥ ¥ i i

^ i ! i i i i

i • i > : i i

4 4! 4 4 4 i 4 4: 4: 4 4 4

444 4 4:4 4 4 44

4 4 4 4 4 : 4 : Ì 4 4 4

4 4 4 ;4 .4 4i 4 4: 4: 4 4

4 ^ j > 4 4 . w > 4

i 4 i 4 S ? i 4 4 i 4 I

4 > 4 : : 4 4 4 4 4 4

4 4 4 i i 4 4 4 4 4 4

4 4 4 4 4 4 4 4 4 4 4 4

? % i i t ¥ Ä i

36

Page 39

Twin Meedle Sewing (Optional)

Twin needie sewing produces two parallel lines of closely-spaced straight stitching. You must sew with

center position straight stitch No. 80 8 side. Any other stitches will cause breakage of the needle.

- With machine turned off, insert twin needle (optional) into needle clamp, and thread machine as for

single-needle sewing and through right needle eye.

- Attache extra spool pint (optional) to bobbin winder shaft, place second spool of thread on it; and,

again, thread machine as usual. Pass second thread through eye of left hand needle.

Check that the

presser foot is the Attache extra

correct one.

Attaching

the twin

I

needie.

I

t %

2

Select

pattern

No.80 of

patterns on

B side.

Patterns

on B side

ec <D

Pin Tucks

.. i.

.......i.....

A type of fabric decoration.

It is commonly used in

French sewing.

Traditionally, pin tucks are

formed by stitching very

near a folded edge, as

shown in steps 1 through 5.

You can also sew pin tucks

with a twin needle.

Twin needle tucks are

always even as they are

formed by two parallel

needles.

Increasing tension will result

in a more pronounced pin

tuck.

*You cannot use the automatic needle threader

and the thread cutter.

Select the pattern you

1

wish to make.

Inclicator lamp

■ Symbol forth©

presser foot

When the power to the Use standard presser foot (A) or

sewing machine is turned ON, biindstitch presser foot (D).

the machine automatically *Refer to page 10 on how to attach

selects runstitching. the presser foot.

5 Application examples

Check the presser foot

2

selected.

® Blouse

Symbol for the

Make folds on the

3

material for the pin tuck

using an iron so that

they are neatly finished.

Sew the folds taking

care not to stretch

them. A biindstitch

pressor foot guide will

help finish the folds

more beautifully.

# Apron

After you have finished sewing, till the

pin tuck to one side and press them to

make them neat.

37

Page 40

Blindstitch

Select the bllndhem stitch

pattern on the instant pattern

1

panel.

Indicator light

■ ^ <

Change the presser foot.

Blind stitching providens a durable way

to finish a hem and is presented as an

instantly selectable pattern as a

convenience. It takes practice, however,

so a tost sample is suggested.

When the desired stitch pattern

selection button is pressed, the

stitch pattern is selected and the

indicator light is ON.

0<i

For blindstitching general fabrics or heavy-weight materials

Position the folded edge

1Overcast the material, and fold the edge.

against the guide.

- Presser foot symbol

Use the presser foot which has the

symbol indicated on the instant

pattern selection button.

‘Refer to page 10 for how to attach

the presser foot.

Turn the fabric over.

3

For blindstitching light-weight fabrics

1

Fold the fabrics.

7/16'~5/8'

1/8'~5/32*

38

presser foot guide, and sew the

material.

Position the folded edge against

2

the guide.

Place the folded edge against the

presser foot guide, and sew the

material.

fabric over.

Turn the fabric over.

Fabric

{wron^ eide)

After sewing the seam, turn the fabric

over.

Fabric

(right side)

Page 41

How to adjust the guide of the biindstitching presser foot

If the stitches fall to reach the folded edge:

if the stitches cover the folded edge too much:

........................£=

Turn the screw toward you.

This will move the guide to the right.

Place the folded edge snugly against

the repositioned guide.

Turn the screw away from you.

This will move the guide to the left.

Place the folded edge snugly against

the repositioned guide.

J

39

Page 42

Patch Work

Select a pattern.

Make sure that the correct foot

2

is attached.

With pattern stitches 90 and 92 from A

side and 93 and 97 from B side of the

pattern display, fabrics can be joined

together to form a strong seam.

Overlapping Patch

1

Basting stitch h

........................____

Fabric (wrong skle)

5/B'

L

\ ;

N

Fabric (wrong side)

Patterns on A side

©C£sx:>©

90 ^

Choose one of tho four patterns.

patterns on B side

0

93 97

rabric (right side)

Use standard presser foot (A).

‘See page 10 for how to attach a

presser foot.

,!><J

Fabric (right side)

illllllilliiiiiiiiiiiiiiilllll

Soam

Place two pieces of fabric right sides together and sow a

basting stitch. Press the seam to one side.

Open Patch

1

Place two pieces of fabric right sides together and sew a

basting stitch. Press the seam open.

ii

Sew a pattern stitch on top of the seam.

>1-

Pabric (fight side)

Sew a pattern stitch on top of the seam.

l><=

l><

N

Fabric (fight side)

40

Page 43

Inserting Zippers

Zippers may be Inserted In

several ways. The type and

location of the zipper will help you

choose the right method.

Lapped zlppQts usually are

inserted in the side seam of the

garment.

Centered zippers are centered in

the opening, and are suitable for

almost all fabrics.

Lapped Insertion

#

Select a stitch pattern.

Indicator light

' Pressor foot

symbol

When the power switch is turned

ON, the straight stitch is selected

automatically.

M Change the presser

L foot.

Attach zipper foot В to machine.

The zipper foot can be used

either to the left or right of the

needle, depending on where the

bulk of the garment is placed.

#

3

‘If the zippers is left of the needle, the

loft side of the zipper foot goes on the

shank.

*lf the zipper is right of the needle, the

right side of the foot goes on the

shank.

A zipper is lapped when one edge of the

fabric opening overlaps and conceals it,

allowing only one stitching line to show.

*Machine-baste the zipper opening together

on the seamline, and press open the seam

allowance.

^Attach the left side of the zipper fool to the

shank.

0

*Pin or machine-baste the zipper to the

garment from the wrong side, through

zipper tape, the seam allowance, and the

front of the garment.

*Turn the garment right side out.

‘Attach the left side of the zipper foot to the

shank.

‘Stitch across the lower end of the zipper

and up to the waistline. Use the basting

stitches as a guide.

‘Remove the basting and press.

*Open the zipper and flatten the back seam

allowance, as shown, with the zipper face

down and the edge of the teeth following the

seam line. The zipper's top should fall

between 1 /8" and 3/8’ below the garment

top seam.

‘Stitch the zipper to the seam allov/ance from

bottom to top.

Centered Insertion

n

‘Machine-baste the zipper opening to the

seamline, and press open the seam

allowance.

‘Place the open zipper face down on the

seam allowance with the teeth against the

seamline.

‘Stitch the zipper to the seam aliov/ance from

bottom to top.

shank.

^Close the zipper and turn it face up.

‘Smooth back the seam allowance at the

edge of the zipper.

‘Stitch the zipper from bottom to top, as

shown, near the seam allowance folded

edge.

‘Baste through the zipper tape, seam

allowance and garment exterior.

‘Turn the garment right side up and top-

stitch it to the zipper, sewing through ail

layers.

‘Remove the basting and press.

41

Page 44

Optional Accessories

Transparent buttonhole foot

For sewing buttonholes and

overlapping seam allowances.

Cording foot

For attaching embroidery floss,

buttonhole twist and other cords to

clothing or craft items.

Invisible zipper foot Rolled hemming foot

For sewing invisible zippers.

Even feed foot

For even feeding of hard-to-feed

materials such as knits, jersey,

quilting, vinyls, leathers, and for

matching of plaids.

For narrow hemming the bottoms of

shirts and blouses, and the edges of

scarves and ruffles.

Twin needle/Spooi pin

For stitching parallel rows of

straight stitching.

ir

How To Adjust The Bobbin Case

The bobbin case furnished with the sewing machine is

factory-adjusted to give the proper bobbin thread tension.

Therefore you need not adjust it. However, if it is necessary

to adjust the bobbin case, do as follows:

42

incroaso

Turn the tension screw of the bobbin

case clockwise to increase the bobbin

thread tension or counter-clockwise to

decrease it.

Page 45

,'\i-

‘ CAUTION: Be sure to disconnect the plug from the wall outlet before opening the cover.

How To Remove The Face Cover

Using the exclusive screwdriver, loosen Remove the lamp cover. Push the lamp upward and

the setscrew at the rear of the face

cover by about two turns, and pull the

cover off sideways.

'> CAUTION: Be sure to disconnect the plug from the wall outlet before cleaning

Cleaning

Removing the lint and dust

Accumulation of lint or dust may cause

problems. Always keep your sewing

machine clean.

turn in the direction of the

arrow.

and lubricating the machine.

CAUTION: Contact the

dealer in your area for the

correct light bulb

replacement.

The power consumption of

the light is 5 watts.

and clean the area between the feed clean,

dog teeth and the slots in the throat

plate, using the brush furnished with the

machine.

Lubricating The Machine

Be sure to only use sewing machine oil on the machine.

This sewing machine uses special bearings, and requires no lubrication in normal use. However, if the machine is operated for an

extended period of time or if it has not been used for a long time, lubricate the points indicated by the arrows shown below.

1. Open the hook cover, remove the bobbin case, and

lubricate the hook.

2, Open the face cover, and lubricate the tops and bottoms

of the needle bar and the presser bar as indicated by the

arrows.

43

Page 46

Performance Checklist

If sewing difficulties occur, make sure the instructions are correctly followed. If a problem still exists, the reminders belew may

help solve it.

—'U

f.fV

lihl |:5*i

,:rJ

Problem

The sewing machine suddenly

stops during sewing.

The light is on, and the

handwheel can be turned by

hand smoothly.

The needle will not move.

The sewing machine will not

run.

The thread breaks.

Skipped stitches.

Stitches are not formed

properly.

Cause (Reason)

The sewing machine has been Turn the power switch OFF, and

run at low sewing speed for an

extended period of time.

The machine is designed to

automatically turn the motor

power OFF to prevent it from

overheating.

The upper thread has run out.

The pressor foot lifter/thread

cutting lever is up.

--Tho bobbin winder shaft was left

in the v/inding position.

■ The buttonholing lever v/as not

lowered when the machine was

placed in the buttonholing

mode.

- The remaining amount of the

bobbin thread is not enough.

The pressor foot is not to the

correct one, and the needle hits

the pressor foot.

The needle has come out and is :

In the hook of the machine.

The sewing machine was

started without the bobbin case.

(The thread is entangled onto

the hook shaft.)

The thread has been caught in

the hook.

Threading is not correct.

The thread has a knot in It.

The thread tension is not

correct.

The needle is bent or Is blunt. Replace the needle. 14

The needle has been inserted

wrong.

The bobbin base has not been

fully inserted in the hook.

The bobbin case has been

incorrectly threaded.

The bobbin does not turn

smoothly in the bobbin case.

The needle and the threads do

not match.

The thread take-up lever has

not been threaded.

The thread has not been pulled Fully pull the thread Into the

into the thread sensor guide.

Threading is not correct.

The bobbin case has been

threaded wrong. case.

The bobbin case has been

adjusted wrong. case.

The spool cap is the wrong size Replace the cap with the correct

for the thread spool.

Action to be taken

wait for about 20 minutes. The

safety device will be reset,

making and the machine will be

ready to operate.

Replace the empty spool, and

thread the machine.

Lower the pressor foot lifter/

thread cutting lever to the

horiiiontal position.

Move the bobbin winder shaft 13

back fully to the left.

Lower the buttonholing lover.

Wind a new bobbin.

Replace the pressor foot with

the correct one.

Remove the needle and insert a

nev/ one.

Cut the thread entangled on the

shaft and remove It before

inserting the bobbin case In the

hook.

Lubricate the hook, turn the

handwheel back and forth

several times, and remove the

thread.

Correctly thread the machine. 8,9

Remove the knot.

Correct the thread tension.

Properly insert the needle.

Securely set the bobbin case

into the hook.

Correctly thread the bobbin 7

case.

Check to see that the bobbin

has been wound evenly.

Use proper thread or needle.

Check the threading order.

thread sensor guide.

Correct the threading.

Correctly thread the bobbin

Correctly adjust the bobbin

size.

Page

13

13

13

13

10

14

7

6,7

14

8

8

8,9

8,9

42

7

44

Page 47

' ii M

{V VjH V V

/ .

u

Problem

Fabric puckers.

Cause (Reason)

The stitch length is too long for

the material.

The needle point Is blunt.

Action to be taken

Decrease the stitch length.

Replace the needle.

Page

11

14

ÍF

::Q

........

()

The needle breaks.

l.oud noise is heard.

.if Ì

4

The handwheel cannot be

turned.

The machine does not feed the

material.

A thin needle was used for

sewing heavy~v/eight material.

The needle has not been fully

inserted into the needle bar.

The needle clamp screw is

loose.

The presser foot is not the

correct one.

Dust has accumulated on the

feed dog.

The machine is in need of

lubrication after an extended

operation.

The machine has been

lubricated with an oil other than

machine oil.

Lint is in the hook.

The hook is entangled with

thread.

The stitch length has been set

to zero.

The presser foot pressure is too

low.

Use the correct size needle.

Properly insert the needle.

Securely tighten the needle

clamp screw.

Use the correct presser foot.

Clean the machine.

Lubricate the machine.

Use the machine oil.

Clean the machine.

Turn the handwheel back and

forth several times to help

remove the thread.

Reselect the desired stitch

pattern, and the proper stitch

length will be set.

Set the presser foot pressure

adjustment lever to

“Normar.

14

14

14

10

43

43

43

11

Threading cannot be done.

tvis;'*\55

niiW'-

If any of the above problems should still remain after you have tried the above suggestions. Please contact a service center or the store

where you purchased you sewing machine.

The needle threader will not

turn.

The threading hook will not

enter the needle eye.

The needle threads cannot be

returned, and the sewing

machine stops.

The threading hook is left in the

needle eye.

The sewing machine will not

start when the start button is

pressed.

The sewing speed remains

unchanged even when the

sewing speed adjusting lever is

moved while sewing.

The needle is not in the highest

position.

The needle threader is designed

not to turn to protect itself if the

needle is not up.

The needle has not been fully

inserted into the needle bar.

The sowing machine was

accidentally started while the

threading hook was still in the

needle eye (during threading).

The speed controller has been

plugged in.

Turn the handwheel until the

needle reaches its highest

position.

Properly insert the needle.

Slightly turn the handwheel by

hand av/ay from you (In the

reverse direction).

Unplug the speed controller.

14

45

Page 48

Pari No. 283433 Png.

Pftnled In Japan

Loading...

Loading...