Page 1

Instruction Book

3 / 4 THREAD OVERLOOK

MODEL 7234.

Page 2

POLARIZED PLUG CAUTIOIJI

To reduce the risk of electric shock, this appliance

has a polarized plug (one blade Is wider than the

other). This plug will fit in a polarized outlet only

one way. If the plug does not fit fully In the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to Install the proper outlet. Do

not change the plug in any way.

OVERLOOK SEWING MACHINE

Record in space provided below the Serial No.

and Model No. of this appliance.

The Serial No. is located Rear of arm.

The Model No. is located Rear of arm.

Serial No. _________________________________

Model No. 7234

Retain these numbers for future reference.

Foot Controller Model YC-482E for use with Overlooking machine Models SL-1A,

SL-2, 634, 634D, 634DE, 834DW, 3000, 3400, 3400D, 3404, 3404D, 6300, 6600,

and 6700.

This sewing machine is for Household Use

Page 3

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be

followed, including the following:

Read all instructions before using (this

appiiance).

DANGER —^To reduce the risk of electric shock:

An appliance should never be left unattended when plugged in. Always unplug this

appliance from the electric outlet immediately after using and before cleaning.

WARNING --To reduce the risk of burns, fire,

electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this appliance

is used by or near children.

2. Use this appliance only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the

appliance to the nearest authorized dealer or service center for examination, repair,

electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation open

ings of the sewing machine and foot controller free from the accumulation of lint,

dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is

being administered.

8. To disconnect, turn all controls to the off ("0”) position, then remove plug from

outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

DANGER

1. Always unplug before relamping. Replace bulb with same type rated 15 watts.

2. Do not reach for an appliance that has fallen into water. Unplug immediately.

3. Do not place or store appliance where it can fall or be pulled into a tub or sink.

Do not place in or drop into water or other liquid.

Page 4

WARNING

I. Kiip Iffi0«rt away from all moving parts. Special care is required around the sewing

mmlilm rwèdlt.

t, Alwip um Ih» proper needle plate. The wrong plate can cause the needle to break.

a 0# lloHis# bent needles. ^ _

4. Oft not pull or posh fabric while stitching. It may deflect the needle causing it to

br**k.

pr*»t#r foot, etc. . ^

Instruction manual. ^ ,

?, Never operate on a soft surface such as a bed or couch where the air openings

may be blocked.

i. Switch Ih« sewing machine off (“0”) when making any adjustments in tne needle

9féà, inch as threading needle, changing needle, threading bobbin, or changing

§, Always unplug sewing machine from the electrical outlet when removing covers,

lubricating, or when making any other user servicing adjustments mentioned in the

SAVE THESE INSTRUCTIONS

Page 5

CONTENTS

1. NAMES OF PARTS..................................................................................................................................................... ^

2. PREPARATION FOR SEWING.......................................................................................................................... 2

2-1. Connecting Power Cord............................................................................

2

2-2. Setting Telescopic Thread Stand........................................................................................ 2

2-3. How to Change Threads.................................................................................................................................

2-4. Replacing Needles........................................................................................................................................... ^

2-5. Threading.................................................................................................................................................................. ^

2- 6. Preparation for Sewing and Checking........................................................................................ 6

3. FOUR THREAD OVEREDGING STITCH USING 2 NEEDLES

....................................................

3- 1. Before Sewing...................................................................................................................................................

3-2. Presser Foot Lifter.............................................................................................................................................

3-3. Beginning and Ending of Sewing.......................................................................

7

3-4. Adjustment of The Presser Foot Pressure.................................................................................. 8

3-5. Thread Tension Adjustment.................................................................................................................... g

3-6. Adjustments for Size of Bight............................................................................................................ .j.,

3-7. Stitch Length Adjustment...........................................................................................................................

3-8. Sewing for Curved Seams....................................................................................................................... .J

4. THREE THREAD OVEREDGING STITCH USING ONE NEEDLE

.......................................

3

....

^

y

.|2

2

13

5. ROLL HEMMING

6. CORDED OVERLOOK

...............

.......................................................................................................................................14

.......................

7. REPLACING THE CUTTING KNIVES...

8. CHANGING THE LIGHT BULB

9. LUBRICATION....................

0. TABLE OF SEWING MATERIALS, NEEDLES AND THREAD

1. ACCESSORIES

.........

2. SPECIFICATIONS......................................................................................................................................................... _

.........................................................................................................................................16

.................................................

j..............................

.

.........................................................................................

19

17

Page 6

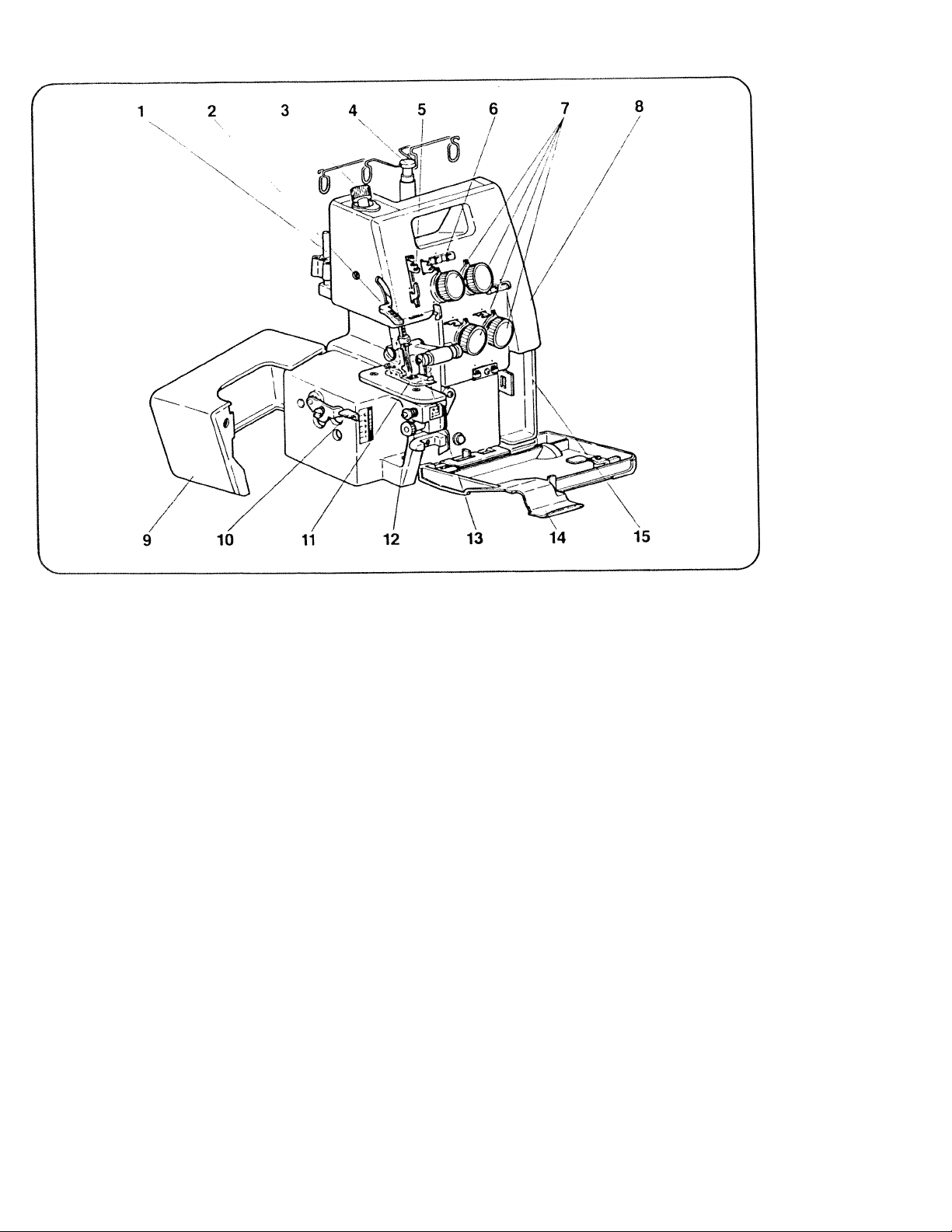

1. NAMES OF PARTS

1. Spool pin

2. Presser foot lifter

3. Pressure regulator screw

4. Telescopic thread stand

5. Thread take up lever

6. Thread tension support

7. Thread tension dials

8. Front panel

9. Side cover

10. Stitch length adjuster

11. Presser foot

12. Bite width adjusting dial

13. Upper knife

14. Front cover

15. Handwheel (Right side of machine)

Page 7

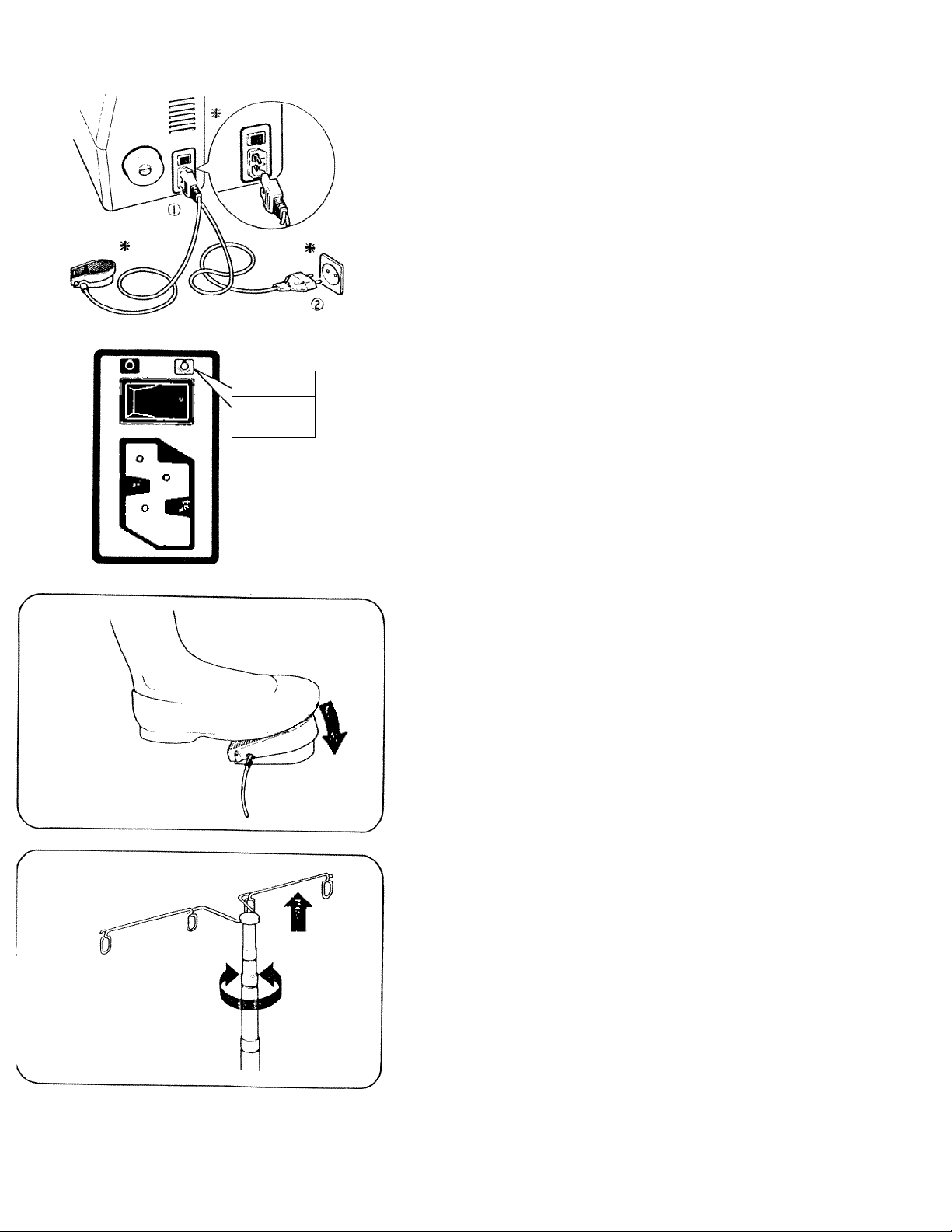

2. PREPARATION FOR SEWING

2-1. Connecting Power Cord

Connect foot controller and power cord ® ®.

Before plugging in your machine, be sure that

voltage is same as that of your machine.

(written on a plate at back of machine).

* Specifications vary from country to country.

V_

V.

/

OFF

13 a

V

ON

J

Put power switch on machine and turn on sewing

light.

J

Always switch off or unplug machine when not in

use.

J

The more you press foot controller, the faster the

machine runs.

When the power switch is turned off, the machine

will not operate even by pressure on the foot

controller.

2-2. Setting Telescopic Thread Stand

Extend the telescopic thread stand to its full

height, then turn it until the shaft clicks into its

locked position.

Page 8

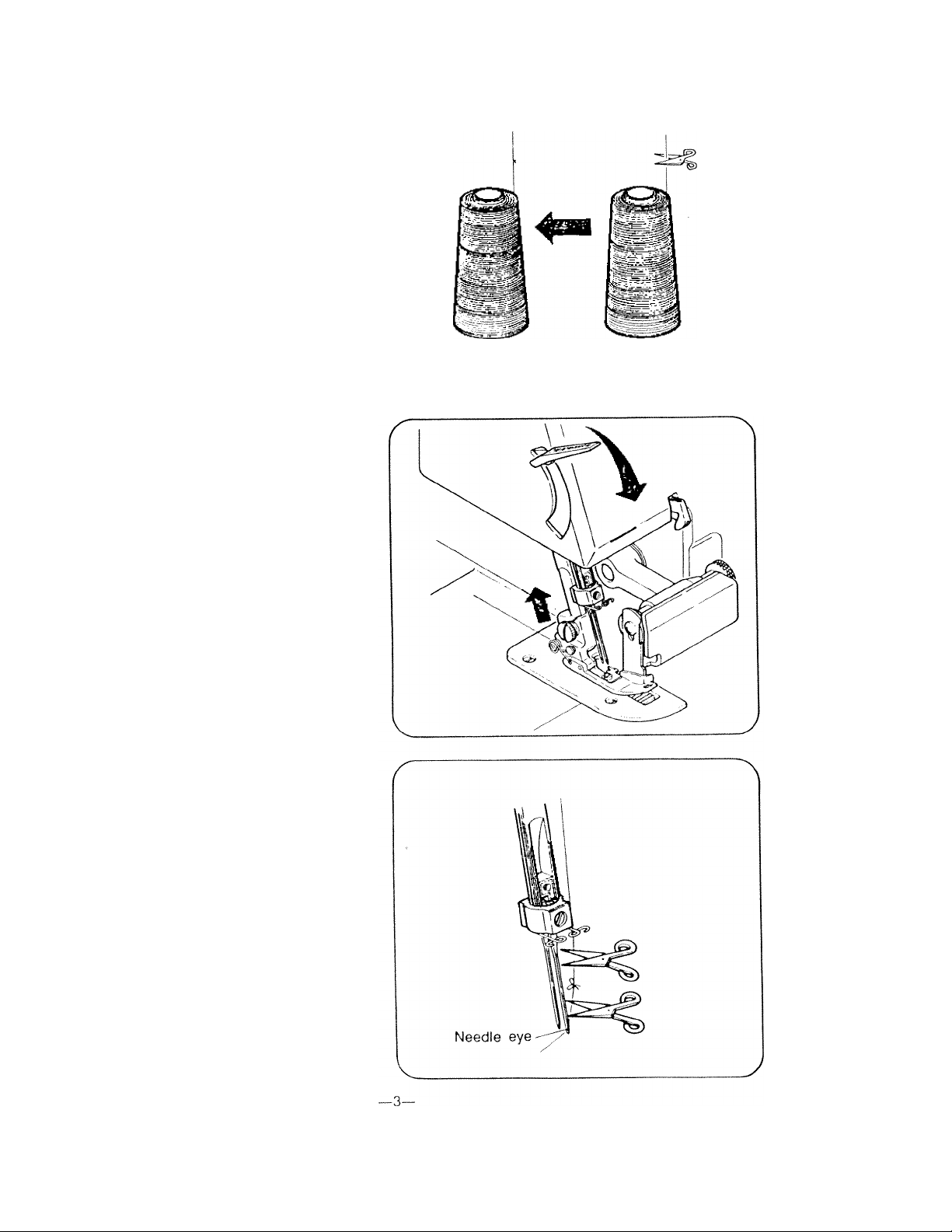

2-3. How to Change Threads

The machine is supplied with thread but the fol

lowing is an easy way to change them:

(1) Cut the thread in use near the cone spool

(behind the telescopic thread stand). Place the

new thread on the spindle and tie it to the end

of the original thread.

Tie threads

Cut thread

(2) Lower the presser foot lifter to lift up the press

er foot.

(3) Set tensions to 0 so that the thread knot can

pass through smoothly, draw out the looper thread

until the thread knot comes to about 10 cm past

the presser foot.

(4) When changing the needle thread, cut off the

thread knot before it reaches the eye of the nee

dle to avoid bending the needle as the knot is

pulled and caught in the needle’s eye.

To make the above threading easier, use tweezers.

V

J

Page 9

Cover the spool \with the “NET” as chemical

fibers (fibres) and the like are easily frayed.

When using a real type thread spool, insert the

spool adapter (supplied with the machine) (as

shown).

2-4. Replacing Needles

Replace needles in the following way:

Note: be sure to take out the power supply plug

before replacing needles.

(1) Bring needles to their highest position by

turning handwheel towards you.

(2) Loosen the needle clamp screw and remove

the two needles together.

(3) With the flat side away from you, insert the

new two needles together into the groove of

needle bar as far as it will go.

Use "HA X ISP (705/130)" m(80) or #14(90) or

ones the same as for home-use sewing machine.

Page 10

2-5. Threading

When threading the machine from the beginning,

threading must be carried out in the following

sequence:

First: Lower looper threading (A)

Second: Upper looper threading (B)

Finally: Needle threading (C, D)

(1) Lower looper threading (A)

Push the front cover to the right, and fold it down

towards you.Take the thread drawn from the spool

and pass it, through guide D of the thread stand

and then, in order, through guides'!) ® (s^ and thread

tension dial '6 . (Fig. A)

Pass the thread through guides® ® ® and is.

Bring the lower looper to the far left position by

turning handwheel towards you, and pass the

thread through lower looper thread guide 11 .

Then, move the lower looper slightly to the right

by turning the handwheel towards you, (Fig. B)

To thread the hole of lower looper :i|, insert the tip

of the looper threader into the looper slot from

the righ of the lower looper, hook the thread onto

the threader and draw it through the looper in the

direction of the arrow. Then thread the hole of

lower looper)iusing tweezers.

Cut the thread leaving about 10cm (4"’) of spare

thread. (Fig. C)

Page 11

(2) Upper looper threading (B)

• Bring the upper looper to its lowest position by

turning handwheel toward you.

• Draw thread from spool and pass it, through

guide ® of the thread stand and then, in order,

through guides ® ~ ® (Fig. A).

• Thread the hole of upper looper(TJjusing tweez

ers. Cut the thread leaving about 10cm (4") of

spare thread (Fig. D).

• Close the front cover.

(3) Right needle threading (C)

• For ease in threading, push the upper knife

holder screw from A, side with the forefinger of

your left hand * and grasp the right end of the

holder ijC and turn it in the direction of arrow b

with your right hand. (Fig. E)

• Take the thread drawn from spool, and pass it

through thread guide ®~(D, then thread to

the right-hand needle’s eye® from front to

back.

Cut the thread leaving about 10cm (4") of spare

thread. (Fig. A)

(4) Left needle threading (D)

• Take the thread drawn from spool, and pass it

through thread guides 'Z)~^4), ©-is), and thread

the left-hand needle's eye f£) from front to back

(Fig A. E). "

2-6. Preparation for Sewing and

Checking.

• Check that no thread slips off or snaps.

• Confirm that the upper knife moves against the

lower knife correctly by turning the handwheel

slowly towards you. If it is not correct, check if

there is any fabric or waste thread between

knives.

• Turn the handwheel towards you with your right

hand to check that the thread winds around the

stitch finger of the needle plate.

If the thread doesn’t wind around the stitch finger

of the needle plate, check if any threads are

threaded incorrectly.

Page 12

3. FOUR THREAD OVEREDGING

STITCH USING 2 NEEDLES

3-1. Before Sewing

After threading is completed, and when the threads

are not wound around the stitch finger, gently

draw out the four threads under and behind the

presser foot, and turn the handwheel towards you

by hand two or three times to make the thread

wind on to the needle plate.

3-2. Presser Foot Lifter

For setting average material, there is no need to

lower the presser foot lifter.

When beginning to sew. push the material just in

front of the presser foot and it will be fed through.

For the thick material, lower the presser foot lifter,

place the material under the presser foot, then

raise the presser foot lifter.

3-3. Beginning and Ending of Sewing

(1) Beginning to sew

Just put your left hand on the material to push

it slightly until the tip of the fabric comes exactly

behind the presser foot.

Page 13

(2) Ending of sewing

Make chain-stitches at the end of the sewing to

prevent the thread from untying and to prepare for

the next sewing.

Draw the finished fabric gently backwards and to

the left as the machine is operating and make

chain-stitches. This is called chain-stitch sewing.

Then cut the thread 2 ~ 5cm (1-2") from the pres ser foot.

* Do not pull it out roughly as the needle will

bend and break.

3-4. Adjustment of the Presser Foot

Pressure

The presser foot pressure is pre-adjusted for

materials of medium (standard) thickness.

Adjustment is necessary only when you work on

very thin or very thick materials.

Accordingly, sew thinner materials with less pres

sure and thicker materials with more pressure.

Increase the pressure of the presser foot by

tightening the adjustment screw.

Page 14

3-5. Thread Tension Adjustment

Set the balance of the tension as weak as possible.

Balance of the Loopwer thread;

When the lower looper thread is pulled to the

top of material, loosen tension dial (|, counter

clockwise. (or tighten tension dial (4) clockwise.)

When the upper looper thread is pulled to the

underside, tighten tension dial ^ clockwise, (or

loosen tension dial % counter-clockwise.)

(1) Correct tension.

• Lower looper thread and upper thread should

be well balanced with same tension. (Both loop

er threads should make crosses at the edge of

the fabric.)

• Needle thread should not be slacken, or pulled.

(2) Unbalanced upper looper thread wraps

round and over the back:

Tighten the thread tension of the upper looper

( Dial %) or loosen the thread tension of the lower

looper (Dial. < ).

Page 15

(3) Unbalanced lower looper thread wraps

round and over the face:

Tighten the thread tension of the lower looper

(Dial 4 ) or loosen the thread tension of the

upper looper (Dial 3 ).

(4) Unbalanced left needle thread too loose:

Tighten the thread tension of the left needle

(Dial T)) or loosen both looper thread (Dial ®

and "4)).

(5) Unbalanced right needle thread too loose:

Tighten the thread tension of the right needle

(Dial 2.).

Page 16

3-6. Adjustments for Size of Bight.

• Adjust the size of the bight from 4.2mm (0.16")

to 6.0mm (0.23") according to the kind of

material.

• The standard bight size is 4.5mm (0.17")

• Open the side cover to adjust the bight size.

(1) If the cutting width is narrower than the bight

size, turn the bite width adjusting dial to the direc

tion of arrow. (To bigger number)

(2) If the cutting width is wider than the bight size,

turn the bite width adjusting dial to the direction of

the arrow, a smaller number)

The right figure shows that the size of the bite

between the left needle and the edge of the

material 4.5mm.

D

4

-----------

cr

1

Page 17

3-7. How to Adjust Stitch Length

The machine is pre-set to a 2.5mm stitch length

for regular seaming and overedging. You may

adjust the stitch length from 1mm (Narrow rolled

hemming) to 5mm by one-touch of the stitch length

adjustment lever.

^ For normal overedging set the stitch length

from 2.5mm to 5mm. A stitch length less than

2.5mm is used only for rolled hemming.

V

J

3-8. Sewing for Curved Seams

For a neat and clean finish of curved seams;

For inside curves, guide the fabric gently with

the trimming line of the fabric under the right

front of the presser foot, applying pressure to

the fabric with your left hand, at the same time,

apply a little pressure in the opposite direction

with your right hand as shown.

For outside curves, apply pressure in the opposite

directions of the above.

Page 18

4. THREE THREAD OVEREDGING

STITCH USING ONE NEEDLE

Though this machine is made mainly for 4 thread

stitch overedging using 2 needles, three-thread

stitch overedging using 1 needle can be easily

operated by just removing 1 needle.

(1) By removing the right needle.

Three-thread overedging stitch using 1 needle for

as wide as a 4-thread overedging stitch using 2

needles can be achieved.

Use the left thread tension. (Dial CD ). The bite

width is normaly 4.5 mm.

(2) By removing the left needle.

The right needle sews with a narrow width bite.

Use the right thread tension. (Dial 2,; ) The bite

width is normaly 2.5 mm.

Page 19

5. ROLL HEMMING

Roll hemming is achieved by adjusting the thread

tensions so that the fabric is overlocked, and

folded under to 1.5 mm in width.

It is ideal for use with thin materials.

(1) Remove the left needle. (Sew only with the

right needle)

(2) Change the presser foot and the needle plate

for roll hemming.

For roll hemming sewing, use the presser foot

marked “B” and the needle plate "B”. (The presser

foot "A” and the needle plate “A” are for normal

sewing).

(3) Set the bite width between 45and 5.5.

(4) Set the stitch length adjuster to 1.

(5) The standard thread tensions are as follows;

Dial®; Needle thread

Dial (3): Upper looper thread

Dial®: Lower looper thread

............................

..............

.................

1 -4 tension.

1 ~ 4 tension.

5~8tension

For roll hem sewing, pass the nedle thread to

the left side (solid line) of thread

guide @ illustrated. [For normal sewing, pass

it to the right side (dotted iine) of thread

guide @.]

At the begining of sewing, gently pull the end of

the thread chain.

For roll hem sewing, pull the material gently

towards the rear of the machine, and you’ll get

the neater stitches.

Page 20

6. CORDED OVERLOOK

Corded overlook can be used to strengthen stitches

when joining elastic materials such as knitted

fabrics.

There are two ways of corded overlock.

(1) Place the slightly wide cord (about 3mm) under

the right needle, and sew on.

(2) Sew a narrow cord, positioning it on the edge

of the overlooked stitch.

7

. REPLACING THE CUTTING KNIVES.

The upper knife and lower knife are made of a

special long-lasting steel and will seldom have to

be replaced. However, when they do not cut the

fabric even though they are set in the right posi

tion. replace them in the following way;

Before replacing the knife, be sure the power

supply plug is take out.

Move the front cover to the right, then open it

toward you.

(1) Replacing the lower knife:

Loosen the lower knife clamp screw and change

the knife for a new one. Align the top of the lower

knife with the top of the needle plate.

(2) Replacing the upper knife:

Move the upper knife to its lowest position by

turning the handwheel towards you.

Loosen the upper knife screw, while holding the

upper knife. Change the knife for a new one.

Check if the biting position (A of upper knife is

positioned downwords 0.5-1.0 from the top of

biting position of lower knife.

Tighten the upper knife screw.

Page 21

8. CHANGING THE LIGHT BULB

9. LUBRICATION

CLEANING

First disconnect machine from power supply by

removing plug from the electric outlet.

1. Open front cover and side cover. (See Page 3)

2. Using the brush provided, remove all the dust

and lint that has accumulated.

STORAGE

1. When the machine is not in use, please

disconnect it from the power supply by

removing plug from the electric outlet.

2. Using the vinyl cover provided please cover

your machine when you finish your sewing.

3. Store away from bright and damp places.

SERVICING

Any questions regarding service and or operation

is to be addressed to the store where the machine

was purchased.

Page 22

10. TABLE OF SEWING MATERIALS NEEDLES AND THREAD

HAxiSP

Needle HAxIT

(705/130)

(For home-use sewing

machine)

Thread

Thin material

(crepe, georgette)

#11

(80)

Polyestel (spun, filament)

#60/2 Twisted thread

~#80/2 twisted thread

(#80/3 Twisted thread

~ #100/3 twisted thread)

(Three-thread overedging

stitch).

Medium to thick

material

(Serge, gabardine, etc.)

#11 #14

(80) (90)

#60/2 Twisted thread

(Three or four-thread

overedging stitch).

Thick material

(thick denim)

#14

(90)

#50/2 Twisted thread

-60/2 twisted thread

(Three or four-thread

overedging stitch).

Thread tension

(Needle thread)

Overedging width

(Between left needle and

edge)

Stitch length

Use ball point needles for Man-Made fibers

Loose

4.2 ~ 4.5mm

2 ~ 2.5mm

(Set the

Medium

balance of looper tensions w

4.2 ~ 4.5mm

2.5 ~ 3mm

Tight

eak).

4.5 - 5mm

2.5 - 3mm

Page 23

11. ACCESSORIES

Page 24

12. SPECIFICATIONS

Number of threads

Number of needles

Needles

Width between two needles

Overedge width

Size of bight

4 Threads (3 threads)

2 Needles (1 needle)

Standard HAxISP or HAxIT (705/130) #11 (80)

2mm

Standard 4.5mm (Range 4.2-6mm)

Stitch length

Maximum sewing speed

Machine dimensions

Weight

1 ~5mm

1500 RPM

Width 300mm (Max. 330mm)

Depth 220mm (Max. 220mm)

Height 290mm (Max. 330mm - 570mm)

7.5kg

-19-

Loading...

Loading...