Page 1

[LOO[}C

Page 2

This booklet has been written for you, to help you use and

enjoy fully your overlooking machine.

Before you start to use this machine, please take a few

minutes to study this booklet. You will find it will be time

well spent in understanding your machine.

If you have any questions regarding the use of your

overlooking machine please do not hesitate to contact

your dealer or ourselves.

WHITE SUPERLOCK SEWING MACHINE

Record in space provided below the Serial No. and Model

No. of this appliance.

The Serial No. is located Rear of arm.

The Model No. is located Rear of arm.

Serial No

..................

——

------------—-------------------------

--

Model No. 216

Retain these numbers for future reference.

WHITE SEWING MACHINE CO.

Cleveland, Ohio 44111

TABLE OF CONTENTS

1. KNOWING YOUR MACHINE

Identification chart................................................................

Specification of machine

Foot control, Power/light switch, Adjusting machine

balance ^ y

Preparation for threading.........................‘

Opening front cover. Opening side coyer, Thread

guide pole. Spool holders. Spool caps,^ Spool nets

Fitting the needle, Needle, thread and fabric chart

.........................................................

..................

2. STARTING TO SEW

Threading your machine i { ^

Threading upper looper.......................................................

Threading lower looper............................— ■ • • ■ ■ v—

Threading needle.................................................................

Changing threads. Cutting off needle thread _

Testing stitch

Overlook stitches. Double-chain stitches with

trimming fabric ,g -y

Adjusting thread tensions

Adjusting stitch length............................................................... „

Needle plate.............................................................

Changing needle plates

Presser foot..............................................................................

Changing presser foot

Stitch applications „„

Overlockstitches

Hem stitching. Pin tucks. Decorative braids.

Narrow hems. Rolled hems. Shell hems oa

Double-chain stitches without trimming fabric

Safety stitches

Basic techniques „g

Outside corners....................................................................

Inside corners.......................................................................„„

Inward curves

Outward curves....................................................................

Finishing seam ends

Removing stitches from fabrics............................................

3. CHECKING PERFORMANCE PROBLEMS....................29

..........................................

...............................................

.......................................

......................................................................

...........................................................

....

.........

....................

.....

..............

......

“ 18

................

4. CARING FOR YOUR MACHINE

Replacing moving cutter

Changing light bulb

Cleaning and oiling........................................

5. OPTIONAL ACCESSORIES

..........................................................

..........................................

.........................

......

................32 -33

^

o

....

■ “

11

^i

..

_

..

Page 3

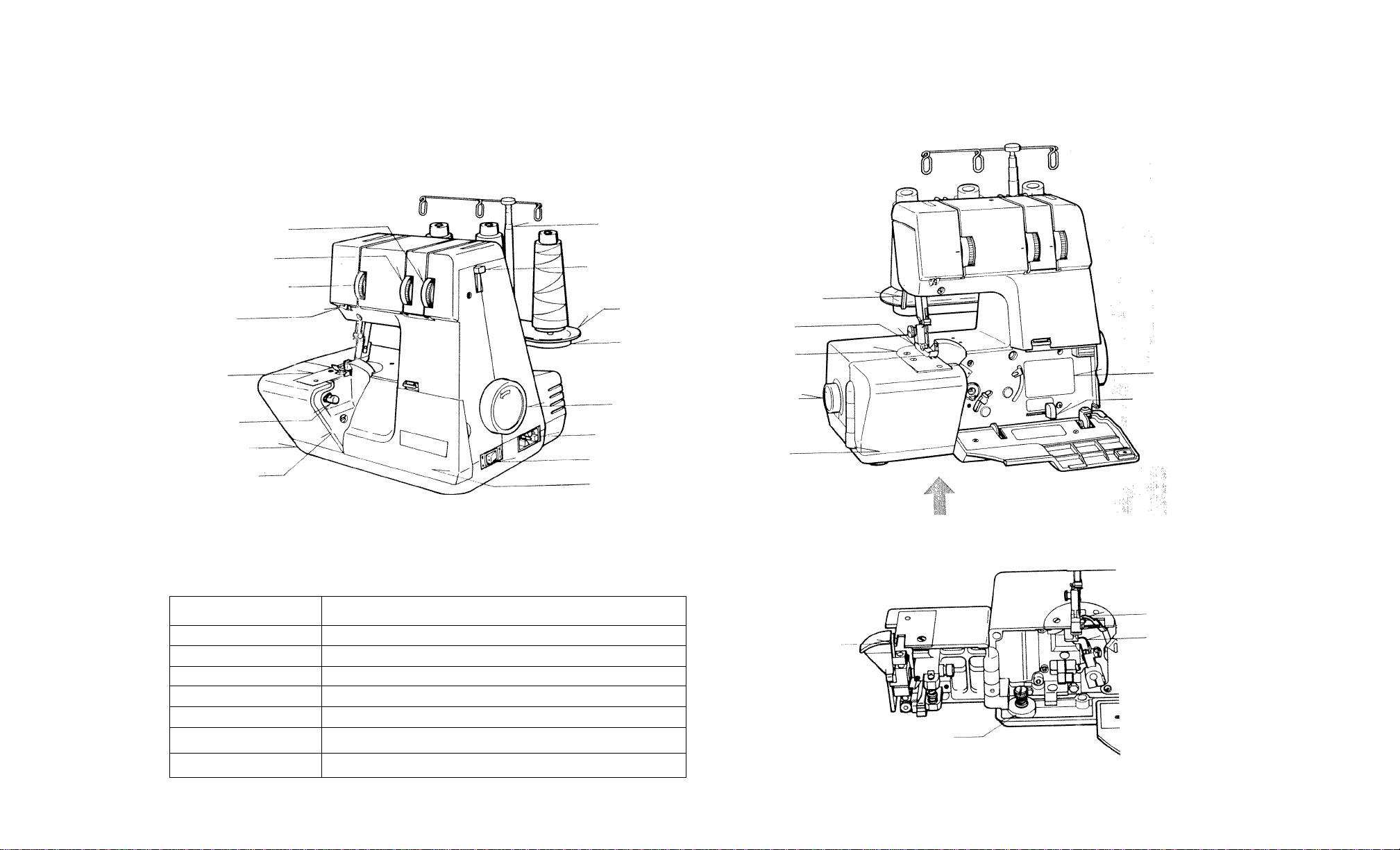

dentification chart

Lower looper thread

tension dial

Upper looper thread

tension dial

Needle thread tension

dial

Thread guide

Cover plate

Release lever

Base

Protection cover

____

SPECIFICATION OF MACHINE

ITEM

Number of Threads

Overedge Stitch Width

Needle

Stitch Length

Stitching Speed

Dimensions

Weight

SPECIFICATION ..............................................................^

2 or 3 Threads

3 5 mm Narrow 12 mmi and Rolled Hems

HA X ISP, HA x 1 (130/705 H)

1 — 5 mm

Ud to 1500 stitches per minute

325 mm(W) x260 mm(D) x275 mm(H)

9.2 Kg. ..............................................................

Thread guide

pole

Tension release

lever

Extension

plate

Spool pin

base

Hand wheel

Plug connector

socket

Light and power

switch

Front cover

----------------

_________________________________________

_____________________________________________—

......................................

Presser foot lever

Presser foot

Needle plate

Stitch length

dial

Side cover

FRONT COVER OPENED

Moving cutter

Bolt for adjusting machine balance

Threading char

Stitcfi selector knot

Upper looper

Lower looper

Page 4

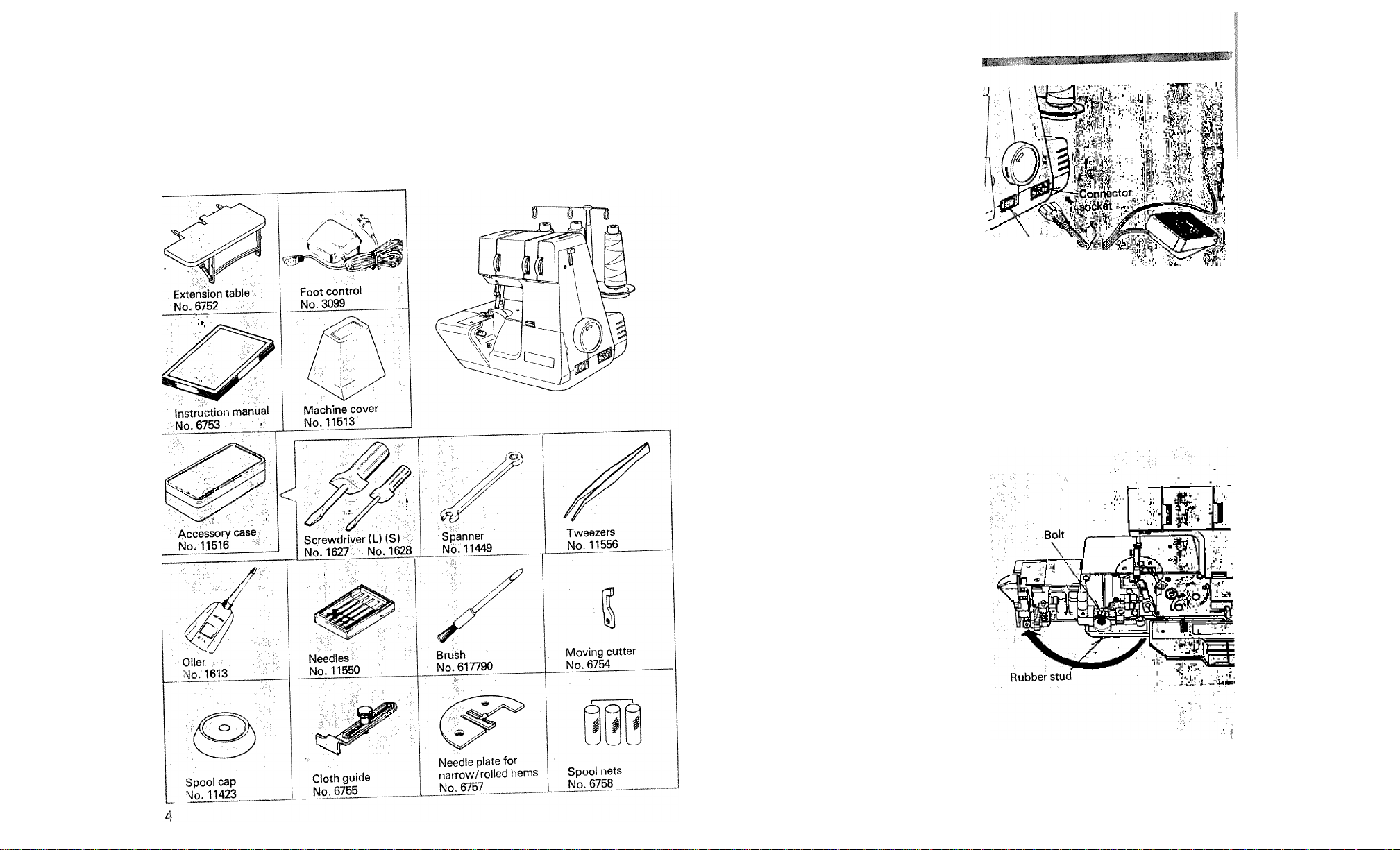

CCESSORY

1 parts listed may be obtained from your

¡arest dealer.

hen ordering, please give;

1. Part number and description.

2. The model and serial number of your

machine, which you will find on the

identification plate, at the back.

;

SETTING UP YOUR MACHINE

Set your sewing machine on a sturdy, fiat

surface.

Your sewing machine has been thoroughly

2.

oiled at the factory. Be sure to wipe off

the needle plate area and bed plate

carefully before sewing a garment. It is

wise to practice on a scrap of fabric so

any surplus oil is absorbed.

3. FOOT CONTROL

Push foot control plug into the connector

socket at the bottom right-hand side of

the machine.

4. POWER/LIGHT SWITCH

Your machine will not operate unless the

power/light switch is turned on. This

same switch controls both the machine

power and sewing light. When leaving

your machine unattended, the machine

MUST be switched off or the plug

removed from the socket-outlet.

When servicing the sewing machine, or

when removing covers or changing

lamps, the machine MUST be discon

nected from the supply by removing the

plug from the socket-outlet.

5. ADJUSTING MACHINE BALANCE

In order that you may be able to

compensate for any uneveness on your

working surface, the machine is fitted

with an adjustable rubber stud.

(1) Push release lever towards you to

open side cover.

(2) Adjust the height of the rubber stud

by turning the bolt.

In order to withdraw the rubber stud,

turn the bolt counter-clockwise.

Power/light

switch' : ■ ',jj ;i fi. ■ 'i?

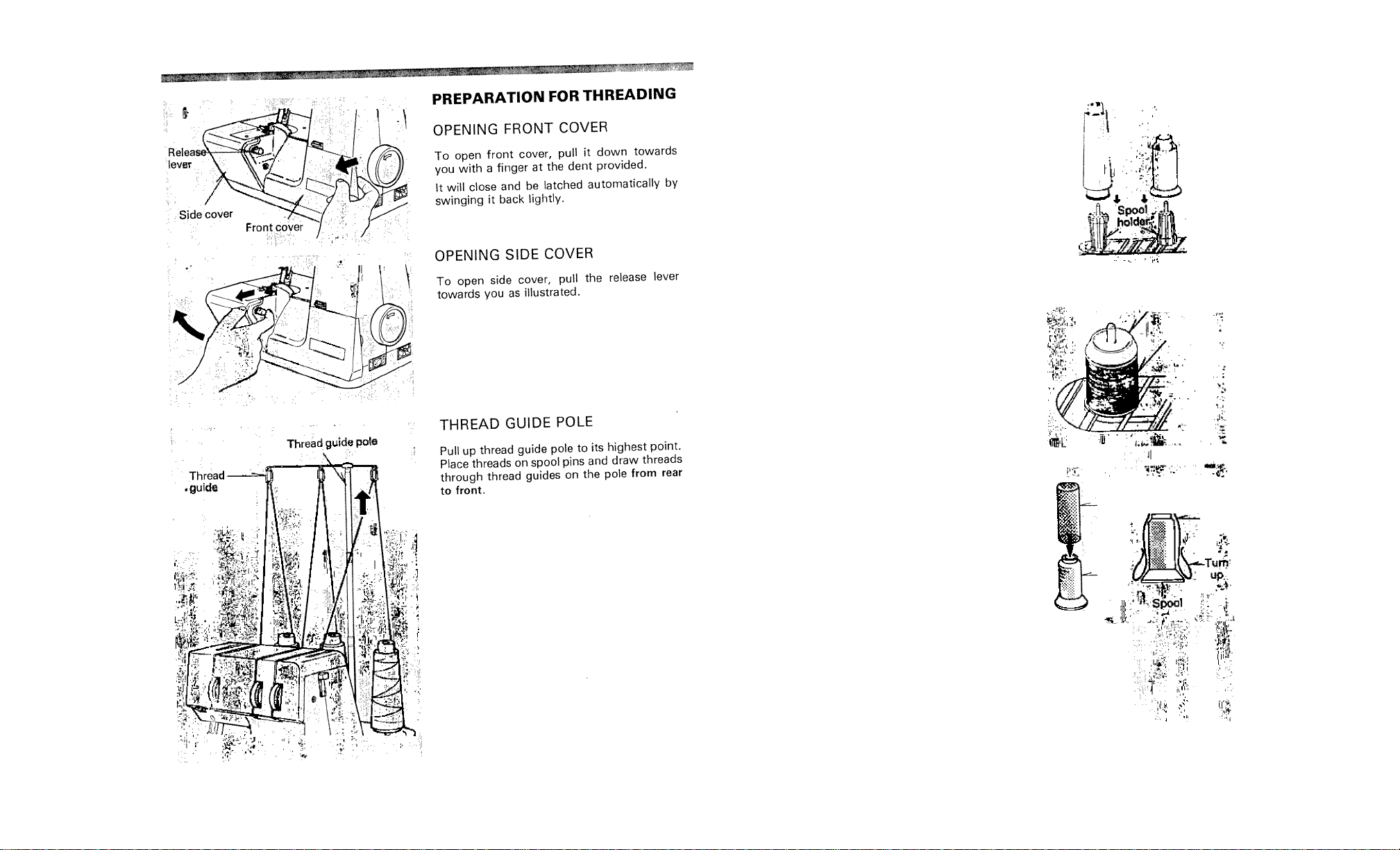

Page 5

SPOOL HOLDERS

For large diameter cone spools use the

rubber spool holders with the large end at the

top, and for small diameter ones, use the

same rubber spool holders with small end at

the top.

Always use the extension plate with spool

holders.

Cone type thread '■

Extension

plate

SPOOL CAPS

When using reel type thread spools, remove

the spool holders and place spool caps over

the thread spools.

SPOOL NETS

Polyester (filament) threads, or bulk nylon

threads are likely to loosen off the spool while

unwinding, causing thread tangling or inter

mittent irregular thread feeding. To keep

consistent unwinding of such threads, hence

constant balancing of thread tensions on

stitches, utilize the spool net supplied in the

accessories, by sleeving it over the spool as

illustrated.

Reel type thread

"T ■ ' *

TSpopl cap V

, ThPWd comes;-

,. ..voff^e.top ,i¡^.

Net

■ ■" Net'

Spool

'*5!

rííJW'

Page 6

Needle clamp

screw

FITTING THE NEEDLE

Raise needle bar to its highest point by

turning hand wheel towards you, but leave

presser foot down.

Loosen needle clamp screw to remove old

needle. Place new needle with FLAT SIDE

AWAY FROM YOU, up into the groove of

the needle bar, ensuring that it is inserted as

far up as it will go. Re-tighten the needle

clamp screw securely.

THREADING YOUR MACHINE

Wrong threading may cause skipped stitches,

breaking threads, or other problems.

Try to learn the correct threading at this stage

before moving on to test the machine

stitches.

Threading must be carried out in the

sequence of Upper Looper — Lower Looper—

Needle, in this order.

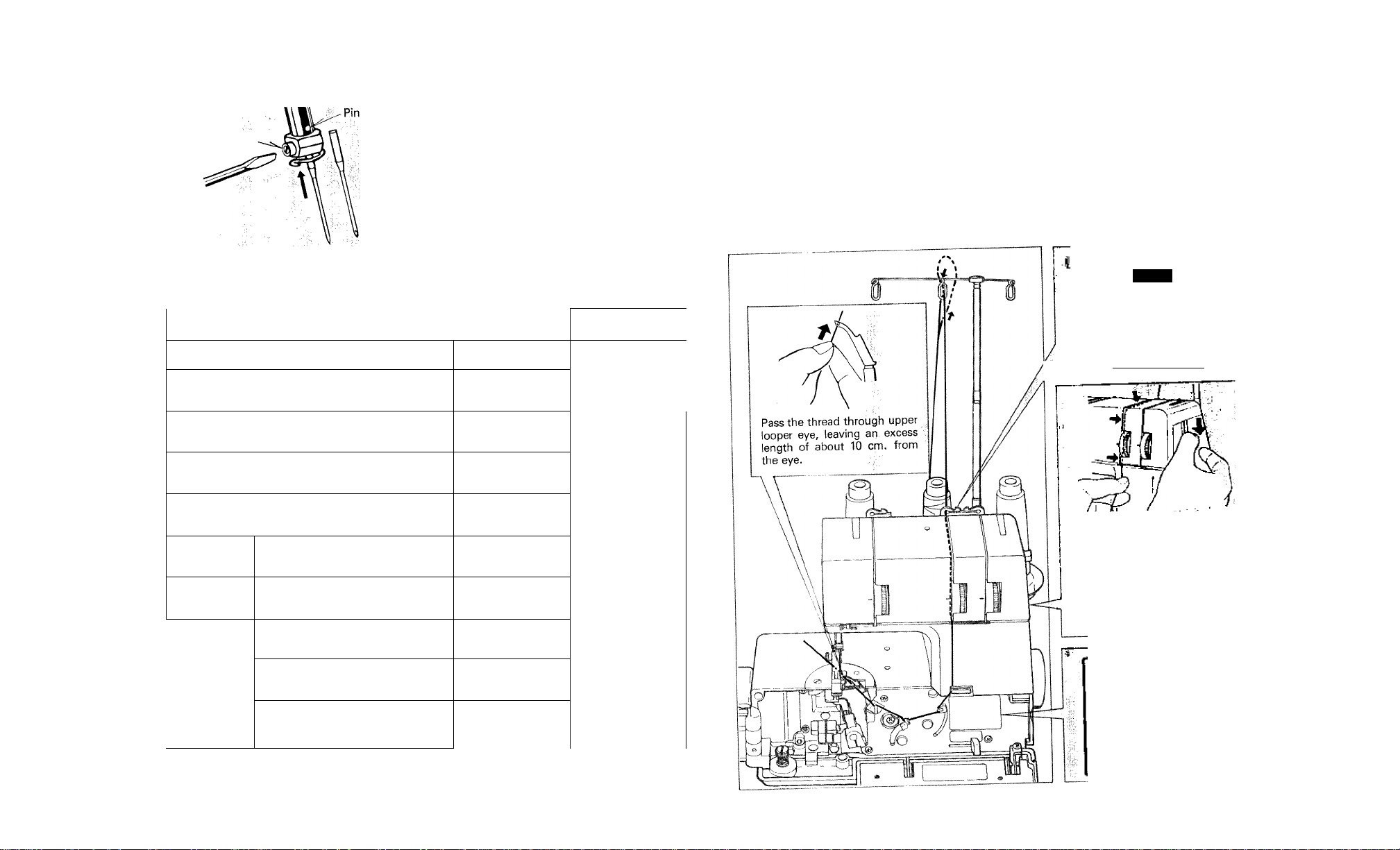

THREADING UPPER LOOPER

Whenever it becomes necessary to re-threac|

lower looper while sewing, remove needlq

thread out of the needle eye first, and

re-thread the lower looper, in order to keed

the threads from tangling each other.

Open the front cover and the side coverj

beforehand.

Raise needle bar to its highest point by

turning hand wheel towards you by hand.

NEEDLE, THREAD AND FABRIC CHART

Use HA X 1 bP, P

'T ' M:!

!■ :,v.

AX ! UOU//UDn/ i>iccuico.

Light Weight:

Oroandie, Lawn, Gingham

Heavy Weight:

Oxford, Denim, Cotton Gabardine

Light Weight:

Tropical, Wool, Poplin

Serge, Gabardine, Flannel

mm

Heavyweight:

Velours, Camelhair, Astrakhan

Lightweight:

Georgette Crepe, Voile, Satin

Heavyweight:

Taffeta, Twills, Denim

Tricot

.H

Jersey

»'1

Wool

f'. ;;t

■ ! U.'

1 .V: . - ■ fu

byninetic mredub die

very useful for different types of fabne.

Cotton No. 100

Polyester

No. 60 - 50

Cotton No. 60

Polyester

No. 80

Cotton No. 60

Polyester

No. 80-60

Cotton No. 60

Polyester

No. 60 - 50

Cotton No. 60

Polyester

No. 100-80

Cotton No. 120-80

Polyester

No. 60

Cotton No. 60

Polyester

No. 80-60

Cotton No. 80 - 60

Polyester

No. 60 - 50

Cotton No. 60

Polyester

No. 60 - 50

Bulk Nylon

100(16)

for heavy weight

fabrics: denim

90(14)

for general sewing

75(11)

for light weight

fabrics

J

».ss

r

Feed . the ■Mlipótìti ’ the

PL gutdd|a^;Illu5tfàtBd;

Press: dowii;'‘tension- rtìease

lever with ^irr righfc-.thuftib.

Holding th0,;i^er et its' down

position, lead the uppar'tiiifd«d

through th&i cenere’slot by

pulling it bet^n theTte^ton

disMto roceiya^tdnsta^pmjiBr

. tension while séwing.y

j

_______

tSJ I

I

I

1

Page 7

HREADING LOWER LOOPER

Pass the thread

through lower

looper eye, and

hook it around

part A as indh

cated by an arrow

on illustration.

Leave about 10

cm. extra thread

from looper eye.

w

/7

Feed the thread through the

thread guide as illustrated.

I -♦?

/

While pressing down and hold^

ing tension release lever with

your right thumb, pull the

lower thread passing through

right-hand tension slot with

your left-hand.

THREADING NEEDLE

.‘•I

7v-lni

-■V .It*- I

Feed the ,

thread ouidé;iis“Ìlltistratecirn r^;.

While pressing down and hold

ing tension relaase/léver^t its

dowp position, draWtha lieodle

thread passing ;

hand tenslori sldji' to ta^sure

positive engagement of the..it

thread with tension fdiscs

inside.

1

Raise the needle to its

highest position. Thread

the needle from front to

back through needle eye,

pull the thread backwardly

together with looper

threads passing along the

right side of presser foot,

and turn around towards

left under the rear edge of

the foot, leaving an extra

length of about 10 cm.^

Dravy the thread over

thread guide as illustrated.

ÜSiSi?

the

Page 8

HELPFUL HINTS

REPLACING THREAD SPOOLS

When replacing thread spools, the following

steps may be helpful for guick changeover.

Cut off existing threads in the vicinity of

1.

spools and tie-connect the cut ends (not

spool side) with the threads from new

spools.

Raise presser foot.

2.

Lower needle bar to its bottom position

3.

by turning hand wheel counter clockwise

by hand. Pressing down and holding

tension release lever, carefully pull the

existing looper threads until the connect

ing knots come under the presser foot.

As for the needle thread, stop pulling the

thread when the knot approaches to

needle eye, cut off the knot and thread

the needle with new thread.

TESTING STITCH

OVERLOCK STITCHES

After threading is completed, test the the

machine stitch in the following order.

1. Lower the presser foot. Lightly pulling all

the threads towards left, rotate the hand

wheel towards you a few times by hand,

and see if the lock stitches are properly

formed.

Check and confirm balance of thread

2.

tensions through test sewing with spare

fabric that you plan to sew. Start to run

the machine at low speed and feed in test

fabric under the presser foot, by slightly

pushing it forward. (This can be done

with the presser foot down on most

fabrics except bulky materials,) Guide the

fabric with light touch of your hand, as

machine automatically feeds the material.

CUTTING NEEDLE THREAD

Raveled, or loose end of the thread may

cause difficulty in needle threading. To

obtain clear-cut end, draw the thread passing

under the moving cutter and cut it by turning

hand wheel manually towards you, or by

using scissors.

3. On reaching fabric end, continue running

machine at low speed, gently pulling the

fabric rearwardly, until extra lock stitches

in length of about 5 to 7 cm are produced

without fabric.

Cut it off at the center with a pair of

scissors, or using thread cutter on the

presser bar.

13

Page 9

DOUBLE-CHAIN STITCHES

Double-chain stitching can be

performed either with trimming

the fabric or without trimming.

Double-chain stitches with

trimming fabric

ADJUSTING THREAD TENSIONS

Thread tensions will vary according to the

type and thickness of both thread and fabric.

Turning tension dial upwards gives a tighter

thread tension.Turning tension dial down

wards gives a looser thread tension. The

higher the number, the tighter the tension.

Test each thread tension on a spare piece of

the fabric you propose using.

* Set up each thread tension according to the chart provided below

MACHINE SETTING

1. Open the front cover and the

side cover.

2. Manually turning the hand

n

1

—

J

(

wheel towards you, set lower

thread guide at its lowest point.

Set the stitch selector lever at

its extreme left-end position for

double-chain stitching.

3. Close the front cover and the

side cover.

1. Set the stitch length control at 3. Raise

the presser foot, place a spare piece of

fabric under the foot, and lower the foot.

Attention: This model does not produce

chain stitches without fabric.

Be sure that fabric be placed

under the needle before start

ing to run the machine. The

upper looper thread is not used

to form double-chain stitches,

so remove the thread from

upper looper.

Start sewing at low speed, lightly guiding

the fabric by hand as machine feeds it.

2. On reaching fabric end, stop machine and

bring needle bar to its highest point by

manually turning hand wheel towards

you. Raise Presser foot. Pressing down

and holding tension release lever, remove

the fabric by left hand.

For double-chain stitches without trim

ming fabric, see page 24 - 25.

Try test -sewing with a piece of actual fabric you use and find the best

dial settings.

Page 10

"I

ADJUSTING THREAD TENSIONS

ust right.

If threads do not appear as above, identify it and make the correction to obtain the correct tension,

referring to the illustrations below.

1. Upper looper thread pulled 2. Lower looper thread pulled

to under side. to top side.

OVERLOOK STITCH

UPPER LOOPER THREAD should lie flat on the

top^side of fabric and lock with the lower looper

thread on the edge of the material.

LOWER LOOPER THREAD should lie flat on the

underside of fabric and lock with the upper

looper thread on the edge of the material.

NEEDLE THREAD acts as a 'safety stitch' and

should lie mainly on the top side dike a row of

normal straight sewing! on the left hand side of

the upper looper thread, and just visible in the

lower looper thread on the underside of the

fabric.

3. Needle thread loose and

visible on under side of

fabric.

" . i.'O'

Lower

looper

thread

DOUBLE CHAIN STITCH

* If threads do not appear as illustrated on the left, adjust tension as described below.

Just right.

NEEDLE THREAD should lie mainly on the top

side (like a row of normal straight sewing) and

just visible on the underside of the fabric. Needle thread too loose.

Adjustment:

Increase needle thread tension.

vll:

U ft

Adjustment;

Increase upper looper thread

tension and/or decrease lower

looper tension.

Adjustment:

Increase lower looper thread

tension and/or decrease upper

looper tension.

Adjustment:

Increase needle thread tension

and/or decrease either or both

looper threads.

,y|:

"■V ■

W-

«' I

it

1:

-A ,

Page 11

ADJUSTING STITCH LENGTH

Turn the stitch length dial with your left hand

until it comes to your required length at the

guideline.

The higher the number, the longer the stitch.

This dial allows for adjustment of stitch

length from 1 to 5 mm.

RECOMMENDED STITCH LENGTH SETTING

Regular hem

Narrow hem

Rolled hem

1 to 5 mm

3 mm ¡standard setting)

1.5 to 2 mm

1 to 1.5 mm

NEEDLE PLATE

When first delivered, your machine will be

fitted with the standard 3.5 mm needle plate,

which will be found suitable for most general

stitching requirements.

Your machine is also supplied with another

needle plate for narrow and rolled hems. This

will be found in your accessory box.

Needle plate for narrow jjiS i;.

and rolled herns,' ^ ^

Shell hem

Double Chain

Stitch

When sewing on 'stretch fabrics' or 'knits' it

may be advisable to adjust the stitch length

to quite different settings to those shown

above. Because of the wide range of these

fabrics which are now available it is not

possible to give specific settings. It is

suggested, therefore, that you make several

sewing tests, with various settings to

determine the most suitable for the particular

job in hand.

3 to 4 mm

2.5 to 5 mm

CHANGING NEEDLE PLATES

First disconnect machine from power supply

by removing plug from socket outlet.

1. Lift up presser foot, and raise needle bar

to the top position by turning hand wheel

manually towards you. Open side cover.

2. Using screw driver(L) in the accessories,

remove set screw and take out needle

plate sliding away from you as illustrated.

3. Place new needle plate in position, by

sliding it towards you, and secure it with

the set screw.

Page 12

.........

PRESSER FOOT

Your machine is equipped with standard

presser foot for general use when delivered.

Specially designed blind hem foot and an

elastic foot are available as optional extra.

(See page 32, 33)

CHANGING PRESSER FOOT

1. Lift up presser foot, and raise needle bar

to the top position by turning hand wheel

towards you by hand.

2. Loosen set screw by turning it anticlock

wise with screw driver (L), and remove

the existing foot as illustrated.

3. Set new foot in position and tighten set

screw with the screwdriver by turning it

clockwise.

CAUTION: In the case a blind hem foot, or

an elastic foot is set on the

presser bar, the following care

must be exercised when you are

going to open machine side

cover.

(1) Lower needle bar to the bottom

position, by turning hand wheel

towards you by hand.

(2) Raise presser foot. Lift up and

hold front edge of the foot with a

finger, and open the machine side

cover.

STITCH APPLICATIONS

OVERLOOK STITCHES

The basic stitches applicable on wide range in

variety of fabrics from shear textiles upto the

heavy duty bulky webs. Among its versatile

applications, pin tucks and decorative braids

are well accepted, besides the professional

hem stitching work.

Remove the extension table, if

assembled for double-chain

stitching, by pulling it off the

machine base. Remove the

thread from lower looper,

thread upper looper according

to the instructions on page 9,

and re-thread the lower looper.

Manually turning hand wheel

towards you, bring the lower

thread guide to its lowest

point. Bring the needle to its

lowest position.

Set the selector knob at its

extreme right end for over

looking position.

To change machine settings from double

chain stitching (without trimrning) into over

looking, follow the instruction below.

...

OJ \

V

-

k

■f:f

mm

. 'fev

21

Page 13

1. НЕМ STITCHING

Machine trims and overlooks

fabric edges simultaneously,

to' produce neat, reinforced

hem.

PIN TUCKS

Pin tucks are used for

decorative appearance, or,

purposely applied in the area

necessary to reduce fabric

width partially. When sewing

along the pre-folded line, pay

attention to keep fabric off the

moving cutter blade to avoid

damage on fabric.

decorative braids

Sew over the braid in width

suitable for overlook stitch

width, giving it proper tension

with your hands.

Triple-twisting of the finished

braids in selected color

combination will add fabulous

decorations to your garment.

4. NARROW HEMS

Narrow hems are formed by overlooking

in width of about 2 rnm over the

automatically turned-up edges, and are

widely accepted for finishing edges on

shear fabrics, like georgette de Chine

silk etc... not recommended for use on

heavy materials on account of its limited

stitch width.

* Replace regular needle plate with

narrow/rolled hem needle plate.

* Set stitch length control at 1.5 to 2 mm.

* Use Tetron No. 50 thread for needle

and woolly nylon (less stretchable;

threads for both loopers.

5. ROLLED HEMS

With the same stitch width of about

2 mm, as for narrow hems, fabric edge is

further rolled in by more concentrated

stitches, which produce additional

strength to the edges and provide

different decorative appearance best

suitable for finishing edges on frills.

* Replace regular needle plate with

narrow/rolled hem needle plate.

* Set stitch length control at 1 to 1.5 mm.

* Use Tetron No. 100 thread for needle,

and woolly nylon threads (less stretch-

able! for both loopers.

SHELL HEMS

Sewing on shear fabrics with the same

thread tensions as for roll hemming, but

with a longer stitch length, will produce a

shell-tuck effect, so-called PIQUE, which

is most suitable for edge decorations on

scarves and others made of thin materials.

* Replace needle plate with the narrow/

rolled hem needle plate as supplied with

other accessories.

* Set stitch length control to produce 3 to

4 mm stitches.

* Use Tetron No. 100 thread for needle

and woolly nylon, or bulky nylon thread

(less stretchablel for both loopers.

* See page 15 and 16 for adjusting thread

tensions.

z

Page 14

7j^-rriwggam«aa^M>:'~

..................

double-chain stitches

The double-chain stitches present

appearance like conventional

straight stitches on surfaceof fabric,

and chain effect on the back

-suitable for sewing a single, or

multiple layers of stretchable fabrics.

Upper looper thread is not used in

forming the stitches.

Double-chain stitching can be

performed either with trimming the

fabric, or without trimming.

Double-chain stitches without

trimming fabric

MACHINE SETTING

1. Open the front cover and the side

cover. (See page 6.)

2. Manually turning the hand wheel

towards you, set lower thread

guide at its lowest point. Set the

stitch selector lever at its extreme

left-end position for double-chain

stitching.

3. Assemble the extension table

onto the machine.

ASSEMBLING TO MACHINE BASE

Assemble the extension table with turned-up

legs, by pushing in the two studs on the rear

edge to the holes provided on machine base.

Attention: When assembling the extension

table to machine base, care must

be exercised to keep both upper

and lower looper threads un

touched and free from any ob

struction on thread paths.

Use the cloth guide to be attached to the

extension table.

The cloth guide helps feed the fabric straight,

or when sewing along at a fixed distance

from the fabric edge.

Graduations are marked on extension table

for guide reference.

Place the cloth guide at the desired positioti,

and secure it tightly onto the extension table

with thumb screw.

CHANGING SEWING DIRECTIONS WHILE

DOUBLE-CHAIN STITCHING

To change sewing directions while sewing

with double-chain stitches, stop the machine

with needle at its lowest position piercing

through the fabric, raise presser foot,

carefully turn around the fabric to the desired

direction, lower the foot, and start sewing in

the new direction.

Connecting holes,

1

Pins

■; '.i • 1 (,* ■ . 1

'ft:*

№

1 %

-1

■■ f i

i;y'

ii

-’’■TV;

24

Jo’nt

PUTTING UP THE LEGS

Pushing up support links at the joint

with a finger, as illustrated, will turn

up the front legs and lock them in

position.

SAFETY STITCHES

So-called safety stitches are formed in

combination of double-chain stitching and

overlooking, for the purpose of reinforcement

on seams.

Finish the double-chain stitching first, and

overlock the seam preferably 2 or 3 mm apart

from the double-chain stitching line.

Page 15

BASIC TECHNIQUES

Sewing off and back on creates extra thread

which must be disposed of and tied off.

INSIDE CORNERS

You may either cut your fabric to desired size

or mark your fabric and carefully follow your

line and trim off excess.

OUTSIDE CORNERS

To attain a neat outside corner, do the

following:

1. Sew one side of the fabric to end.

2. Carefully raise the needle and presser

foot.

3. Grasp the fabric gently and rotate the

cloth.

4. Slide the threads off the seam forming on

the tongue of the needle plate, while

pressing the tension release lever down

with your right hand.

5. Realign the edge of the fabric and put the

cut edge of the fabric against the cutter.

6. Align the needle back into the needle line

instead of the edge of the fabric.

7. Overlook the edge as needed, repeat for

other corners.

Align the fabric edge with the inside edge

1.

of cutter.

Overlook stitch to the inside edge,

2.

allowing your cutter to make one cut into

the inside corner.

3. CAUTION: Your cutter is approximately

4. Raise up presser foot and needle, pivot

in front of the needle, so you must

fold your material away from the cutter.

Sew to the corner and stop.

material, align the fabric edge against the

inside edge of cutter.

5. Slide the thread off the seam forming

tongue of needle plate.

6. Align needle to form a square corner and

sew the balance of your seam.

UNCUT MATERIAL: Follow the same

procedure, but you must carefully follow

your mark. Always consider that you will

have excess cut-away material to handle.

Page 16

I:

INWARD CURVES (Concave)

When sewing on inward curve, guide the

fabric gently in the way that the seam line is

passing through under the front right edge of

presser foot (or a bit inward towards left),

constantly applying light pressure by left

hand at point A and by right hand at point B,

in the directions as indicated by arrows on

illustration.

OUTWARD CURVES (Convex)

Do the same way as for sewing on inward

curve, but applying pressures in the opposite

directions at points A and B respectively, as

indicated by arrows.

FINISHING SEAM ENDS

When sewing work has been done, it is

recommended that both ends of the seams

be finished with a little extra work.

3. CHECKING PERFORMANCE PROBLEMS

iirPRdfeLEM ' Ü' .

Irrediilar,

S -BfeaKing.j i

[t- Skipping'*':

%

y^S'raoking', ^

vThfeads-^- w

■ lncPr№c.t\f™

' l'ncôïfècwz^^eeaw,,.

iliTipropdr

l.Ldos'e PriK^^QOtiJ

^Incorrect

: Incorrect¿.r

ihfelii. ft Reset Thread Tension(s). : ' ^ .

Loosia Pres^.E^PO^»''

’I nbdtreclSri^icf _

I'irdjpropor fhrMdlngiw-

.i-THrééd TwaM^ltP^B^^

’il hcOirect Mtd™ 9,f

Tlviedd'Si№!;Mh9l^i^

iThread, Sujÿe'Pbtelr^B^de^

t- - - ÇOWWËCTION

■'fe Choose correct size Needle for Thread

' v-W '■ Pahrin

and Fabric.

Re-thread Maichinaii.^

Do not pull Fabric; guloeft gently.

Reset Presser Foot. ■

Do not pul! Fabric; guide it gently.

Choose correct size Needle for Thread:

and Fabric.

ResetNeedle. , n "■

Reset Presser Foot.

Reset Thread tension'ls).;,;

insert new Needle. ‘ v

Reset Presser Foot. ,

Re-thread Machine. . (

Choose correct size Needle for Thread

and Fabric. .t' ,,

Insert new Needle. _

Reset Needle;

Re-thread Machine: ^ " ’^111

1 nsert new Needle.. ^ ^

Reset ThreadTenaionlsV. ■ >1,^'■

„ResetNeedle.- .'iiV

Reset Spool properly.,, I

Fully extendpuide Pole-: ?(: ■ .a-iK

LOCK STITCHES

Using an embroidery needle, bring back 2 or

3 cm of extra chains through the lock stitches

already made on the fabric as illustrated.

DOUBLE-CHAIN STITCHES

Make a knot with lower looper thread and

needle thread at both ends of the seam.

REMOVING STITCHES FROM

FABRICS

To remove the stitches already sewn on

fabrics, wherever necessary, snip off needle

thread at intervals and pull off looper

thread(s).

Page 17

4. CARING FOR YOUR MACHINE

REPLACEMENT OF MOVING CUTTER

Should it become necessary to replace

moving cutter, due to it becoming blunt,

apply the following procedure. A spare cutter

will be found in your accessories.

NOTE: You should not need to replace fixed

cutter, which is made of a special

hard alloy material.

FIRST REMOVE THE POWER PLUG FROM

THF SUPPLY^SOCKET^OUTLET.

Side cover

Release lever

Open side cover. Loosen set screw for

protection cover with screwdriver in the

accessories. Loosen release lever with

spanner in the accessories, and take out

protection cover.

While keeping set screw of moving cutter

from rotating with screwdriver, loosen

nut on the other side with spanner, and

take out moving cutter.

Set the replacement cutter in positon,

and secure it with screw and nut.

Assemble protection cover in the reverse

way as described in step 1 above.

CLEANING AND OILING

To keep you machine running smoothly, it is

necessary to keep it clean and lubricated at

ail times.

FIRST DISCONNECT MACHINE FROM

POWER SUPPLY BY REMOVING PLUG

FROM SOCKET-OUTLET.

1. Open both front and side covers. Using

the brush provided, remove dust and lint

that have accumulated around the whole

exposed area.

2. Lay the machine on its back and take off

the lint tray by removing the single

securing screw.

Using the brush provided, remove any

dust and lint that may have accumulated

in the tray and bottom of the machine.

Replace the tray and secure by re-tighten-

ing the screw.

3. Apply a few drops of oil to the points

indicated by arrows.

ALWAYS USE A GOOD QUALITY

SEWING MACHINE OIL.

4. Wipe off any stains with a soft cloth.

30

Light cover

CHANGING LIGHT BULB

The sewing light is located under the

machine arm, as shown, and illuminates the

sewing area only.

DISCONNECT MACHINE FROM THE

POWER SUPPLY BY REMOVING PLUG

FROM SOCKET-OUTLET.

DO NOT REPLACE BULB OF MORE THAN

15 WATTS MAX.

To change bulb, pull down light cover,

remove old bulb by unscrewing. Replace

with new bulb.

Page 18

5. OPTIONAL ACCESSORIES

Optional Accessories described in this section

are not supplied with this Machine as

standard equipments, but can be obtained

from the Dealer who supplied your Machine

or by contacting us direct.

ATTACHING ELASTIC TAPE

USING ELASTIC FOOT

1. Replace regular foot with elastic foot.

2. Set stitch length to about 4.

3. Slightly raise the roller portion of the foot

and insert elastic tape between the roller

and the lower support bar as illustrated,

until the edge of elastic reaches the feed

dog teeth. (It may be necessary to loosen

the Tension Control Screw on the Roller

to feed the Elastic through).

4. Sew the elastic tape for about one inch or

so to confirm the tape is being properly

sewn.

5. Place the fabric under the foot and sew

together with the elastic tape.

6. Check that the Stitch formation is

uniformally balanced and if necessary

adjust the Thread Tension Controls.

7. Adjust the Tension Control Screw of the

Roller so that the desired finish can be

obtained.

a. Tighter tension of the Roller gives more

elasticity of the fabric after it is sewn.

b. Looser tension of the roller gives less

elasticity of the fabric.

32

Loading...

Loading...