Page 1

WHITE

SUPERLOCK

OWNERS WORKBOOK

2000 ATS

Copyright 1995

Education Department

White Sewing Machine Company

11760 Berea Road

Cieveland OH 44111

Page 2

TABLE OF CONTENTS

INTRODUCTION

SECTION I - Know Your Machine - Model 2000 ATS

Accessories

Superlock Set Up and Maintenance

Foot Control

Power/Light Switch

Opening Front Cover

Closing Front Cover

Opening Swing-Away Side Cover

Handwheel

Presser Foot Lift

Changing Presser Foot

Adjustment of the Presser Foot Pressure

Disengaging Upper Cutter

Exclusive Built-in Thread Cutter

Adjustable Fabric Guide

Waste Tray

Oiling

Cleaning

Storage

Hints for Successful Stitching

Needle Replacement

Needles, Thread & Fabric Chart

3

4

5

5

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

9

10

11

SECTION II - Threading & Tension

Preparation for Threading

Spool Holders

Spool Caps

Spool Nets

Threading Upper Looper

Threading Lower Looper

Threading Needles

Needle Threader

Helpful Hints - Changing Thread

Testing Stitch

Thread Tensions

Adjusting Thread Tension

SECTION III - Basic Sewing Techniques

Superlock Seams & Seam Finishing

Adjusting Stitch Length

Adjusting Cutting Width & Balance of Stitch

Adjusting Cutting Width

Securing Beginning & End of Seam

Outside Corners

Inside Corners

Corded Overlook

Ribbing

Casing or Hem Fold

12

12

12

12

12

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Page 3

SECTION IV - Differential Feed

Positive Differential Feed

Minimal Differential Feed

Normal Differential Feed

Serging Lightweight Fabrics

Serging Stretch or Bulky Knits

Gathering

33

34

34

34

35

36

37

SECTION V - 3-Thread Sewing Techniques

3-Thread Seam or Edge Finish

Rolled Edge

Picot Edge

Spaghetti Straps

Slit or Placket

Rolled Edge - "Pokies"

Narrow Edge

Safelock

Decorative Edges

Decorative Braids

Flatlock/Ladder Stitching & Seams

Flatlock Technique - Lace Application

Flatlock Technique - Lingerie Elastic Application

Flatlock Technique - Fringe

Rolled Edge - Novelty Threads

Rollled Edge - Fishline Ruffles or Wire Edges

Narrow or Shell Edge

SECTION VI - 2-Thread Sewing Techniques

Threading for 2-thread Sewing

Two Thread Overcast

Two Thread Flatlock

Two Thread Wrapped Edge

Two Thread Rolled Edge

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

56

57

58

59

60

SECTION VII - Optional Accessory Feet

Blind Hem Foot

Piping/Cording Foot

Elastic Foot

Shirring Foot

SECTION vm - Special Hints

Puckery Fabric

Skipped Stitches

Stitiches Show Through on the Right Side of Seam

Thread Continues to Break

Cannot Get a Tight Stitch at the Cut Edge of the Fabric

Adjusting Tensions

Machine is Jamming

INDEX

61

61

62

63

64

65

65

65

65

65

66

66

66

67-69

II

Page 4

tNTRODUCTtON

Welcome to the world of easy, speed sewing. The White Superlock was designed with

the home sewer in mind. It is simple to thread, simple to change from regular sewing to specialty

sewing, such as flatlock and rolled edge. The automatic thread tension release will help you

in easy removal of your projects and creative sewing. This workbook is compiled in a method

so you will thoroughly understand the machine and its potential. After following these

instructions, you will marvel at how easy your new White Superlock is to operate.

Page 5

SECTION I

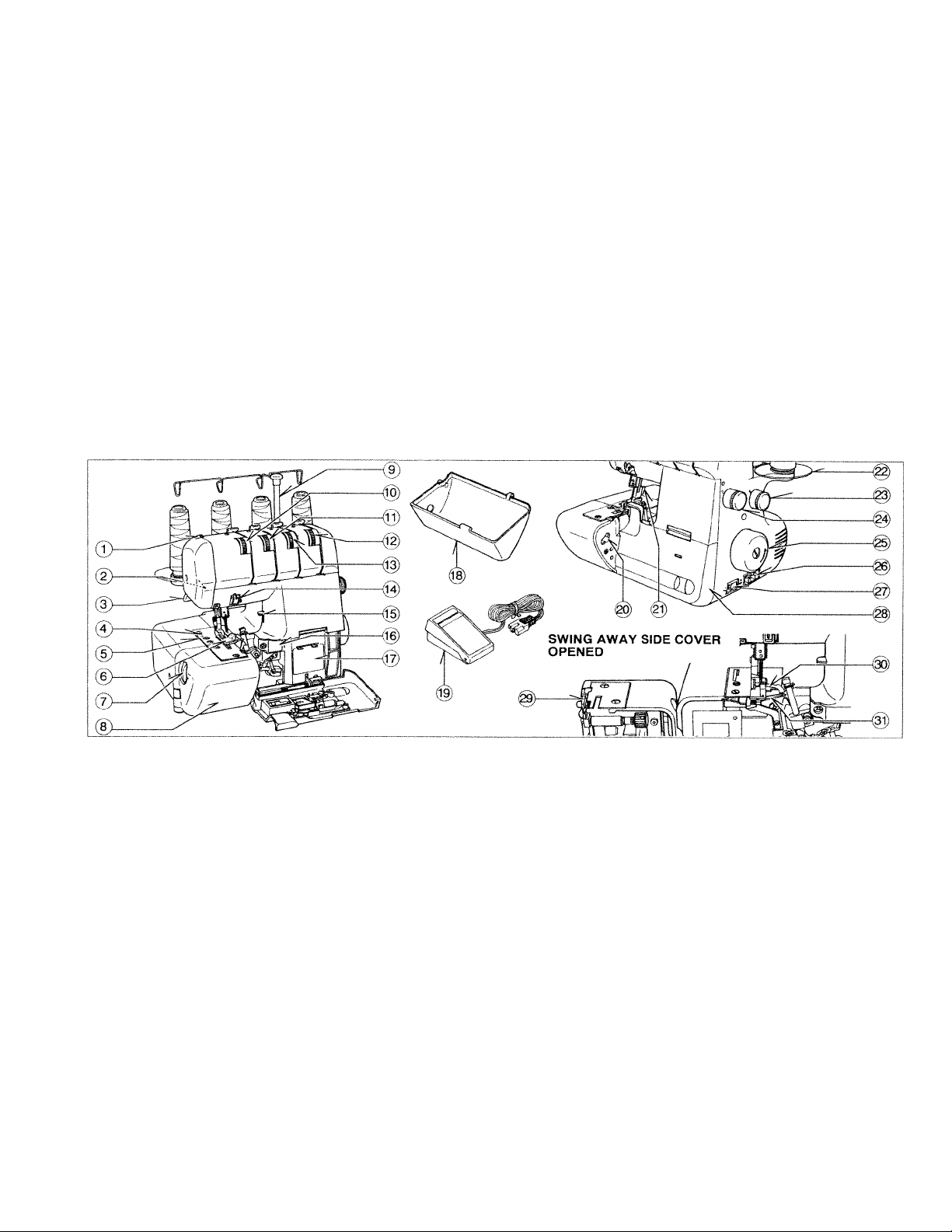

KNOW YOUR MACHINE - MODEL 2000 ATS

Top of the line Superlock model 20CXÌ ATS is a 2/3/4 thread serger with adjustable

cutting width, built in rolled edge and differential feed. It is capable of two, three or four

thread sewing plus many decorative and specialty applications. A section of this workbook

outlines many different techniques, specialty feet, and simple quick projects for you to try

on your new Superlock.

1. KNOWING YOUR MACHINE

IDENTIFICATION CHART

1. Foot pressure regulator

2. Sewing light

3. Presser foot lift lever

4. Thread cutter (Model 2000 only)

5. Needle plate

6. Presser foot

7. Overedge cutting width dial

8. Swing away side cover

9. Thread guide pole

10. Left needle thread tension dial

11. Right needle thread tension dial

12. Lower looper thread tension dial

13. Upper looper thread tension dial

14. Needle thread guides

15. Thread cutter lever (Model 2000 only)

16. Two thread convertor Instruction

17. Threading chart

18. Waste tray (Model 2000 only)

19. Foot control

20. Release lever side cover

21. Foot release lever

22. Thread extension plate

23. Differential feed control dial

24. Stitch length dial

25. Hand wheel

26. Plug connector socket

27. Light and power switch

28. Front cover

29. Moving cutter

30. Upper looper

31. Lower looper

(Model 2000 only)

Page 6

ACCESSORIES

All parts listed may be obtained from your nearest dealer.

(D (D

^

P

I I

*

1. Two-thread convertor

(Model 2000 only)

2. Needle set

3. Brush

4. Screwdriver (small)

5. Needle threader

6. Machine cover

7. Screwdriver (large)

8. Oiler

*Only Model 2000 has storage of accessories at the back of front cover.

9. Moving cutter

10. Spanner

11. Thread net

12. Tweezers

13. Thread extension plate

14. Cone holder

15. Cord guide

16. Accessory bag

Page 7

SUPERLOCK SET UP & MAINTENANCE

1. Set your Superlock on a sturdy, flat surface.

2. Your Superlock has been thoroughly oiled at the

factory so be sure to wipe the needle and bed

plate areas carefully before sewing a garment.

Practice on a scrap of fabric so any surplus oil

is absorbed.

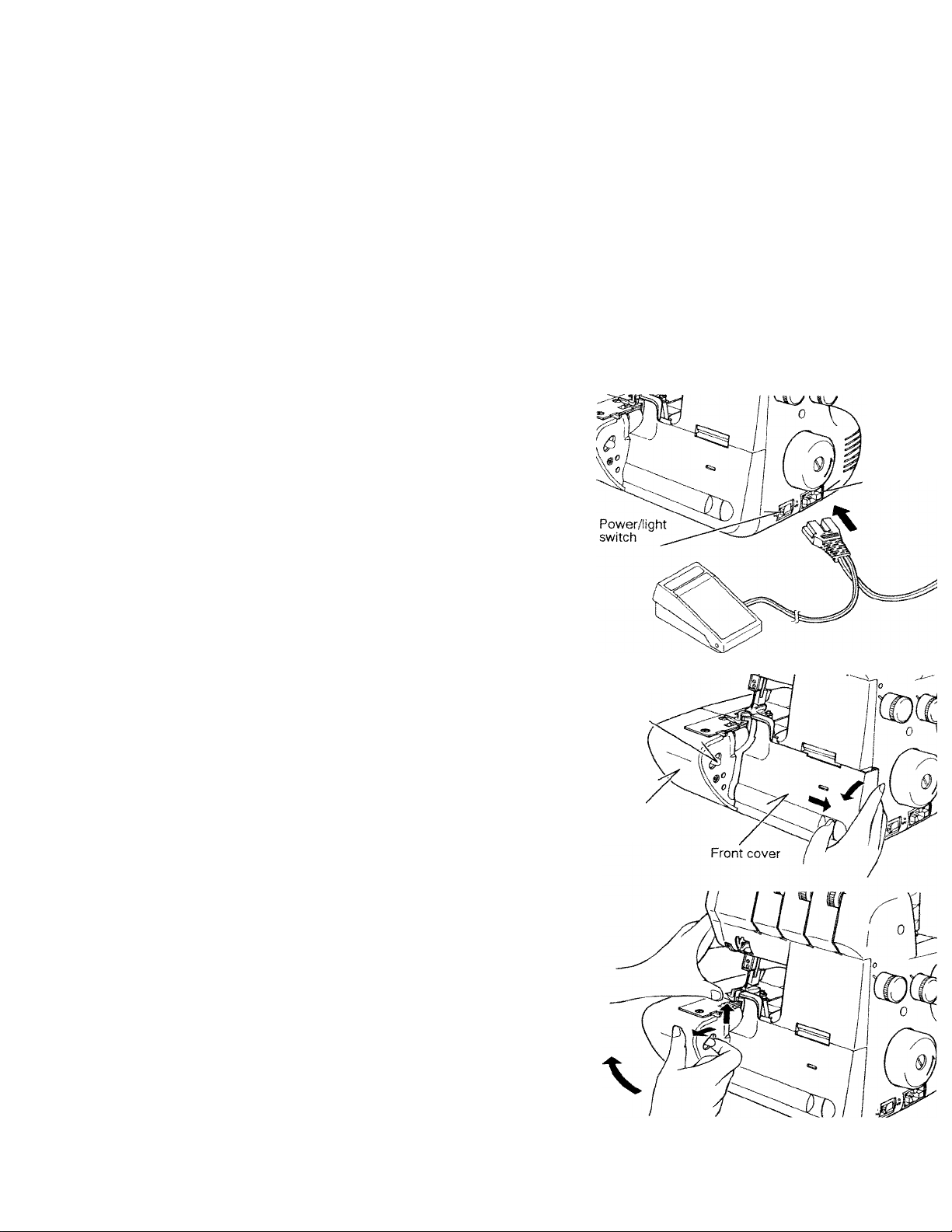

3. FOOT CONTROL

Push foot control plug into the connector socket

at the bottom right side of your Superlock.

4. POWER/LIGHT SWITCH

To operate your machine, turn the power switch

on. It is located at the bottom right hand side.

The same switch controls both power and light.

If leaving your Superlock unattended, turn

switch off.

Connector

socket

5. OPENING FRONT COVER

To open front cover, push part B of cutter cover

to right and pull the cover down toward you.

To open the side cover, press down on the

silver knob located to the inside of the side cover,

and swing the lower left portion of the Superlock

to the left.

6. CLOSING FRONT COVER

Push part B and lower left cover toward the

center of the front to close it.

Note: Always close front cover when sewing.

7. OPENING SWING-AWAY SIDE COVER

To open side cover, pull the release lever toward

you with your right hand and swing out to left.

NOTE: Always close side cover when sewing.

Release lever

Swing away

side cover

Page 8

8. HANDWHEEL

Always turn handwheel toward you.

9. PRESSER FOOT LIFT

Raise the presser foot lift to lift up the

presser foot.

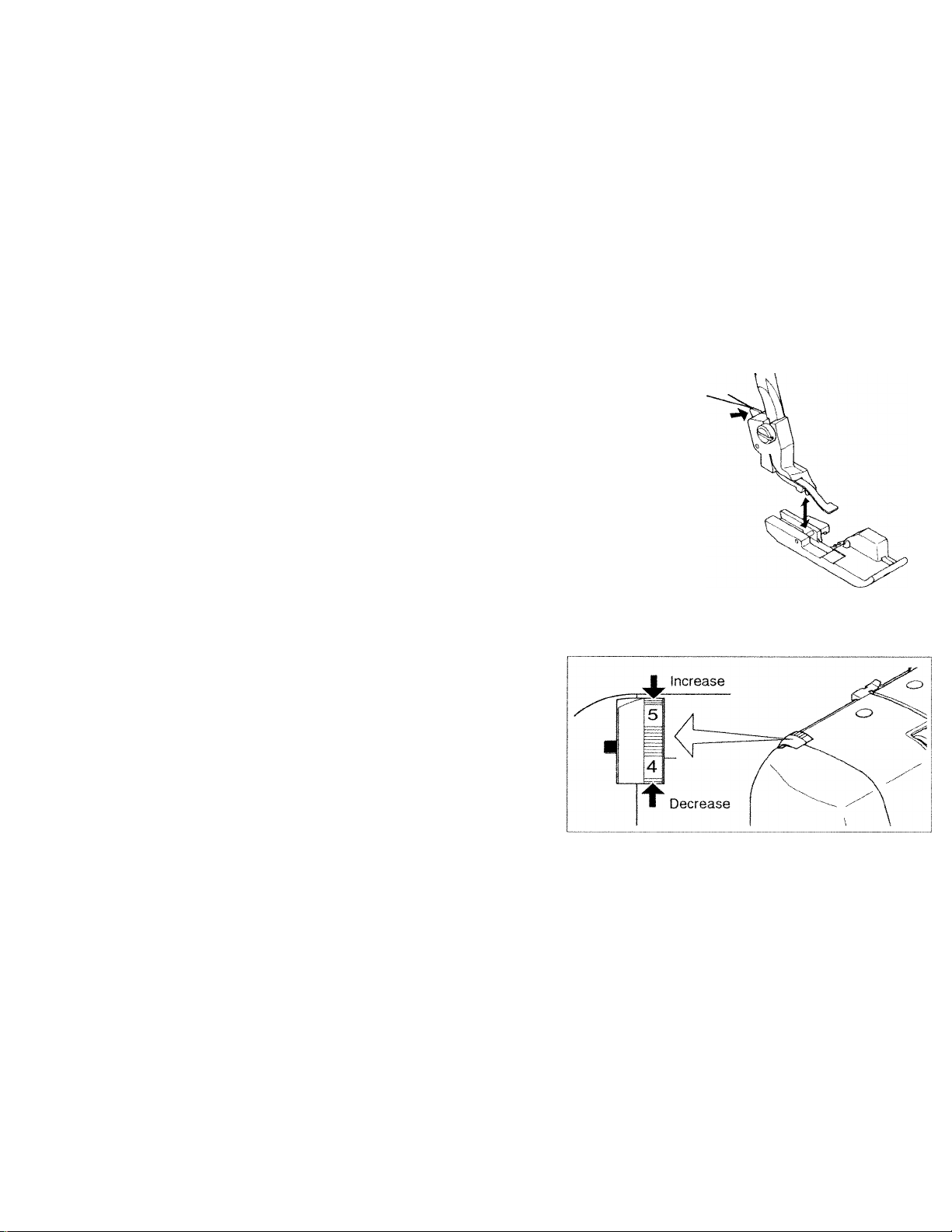

10. CHANGING PRESSER FOOT

Switch off your Superlock.

Raise presser foot.

Raise needles to their highest position by

turning handwheel toward you.

Push lever A and foot will come off.

Position the new foot with pin right under

the groove of the ankle. Lower presser foot

lift so that holder catches the presser foot.

11. ADJUSTMENT OF THE PRESSER

FOOT PRESSURE

The presser foot pressure is pre-adjusted

for materials of medium thickness.

Adjustment is necessary only when

you work on very thin or very thick

materials. Accordingly, sew thinner

materials with less pressure (2 - 3)

and thicker materials with more pressure

(4 - 5). Increase the pressure of the presser

foot by turning the dial to the desired number.

Foot release lever

Page 9

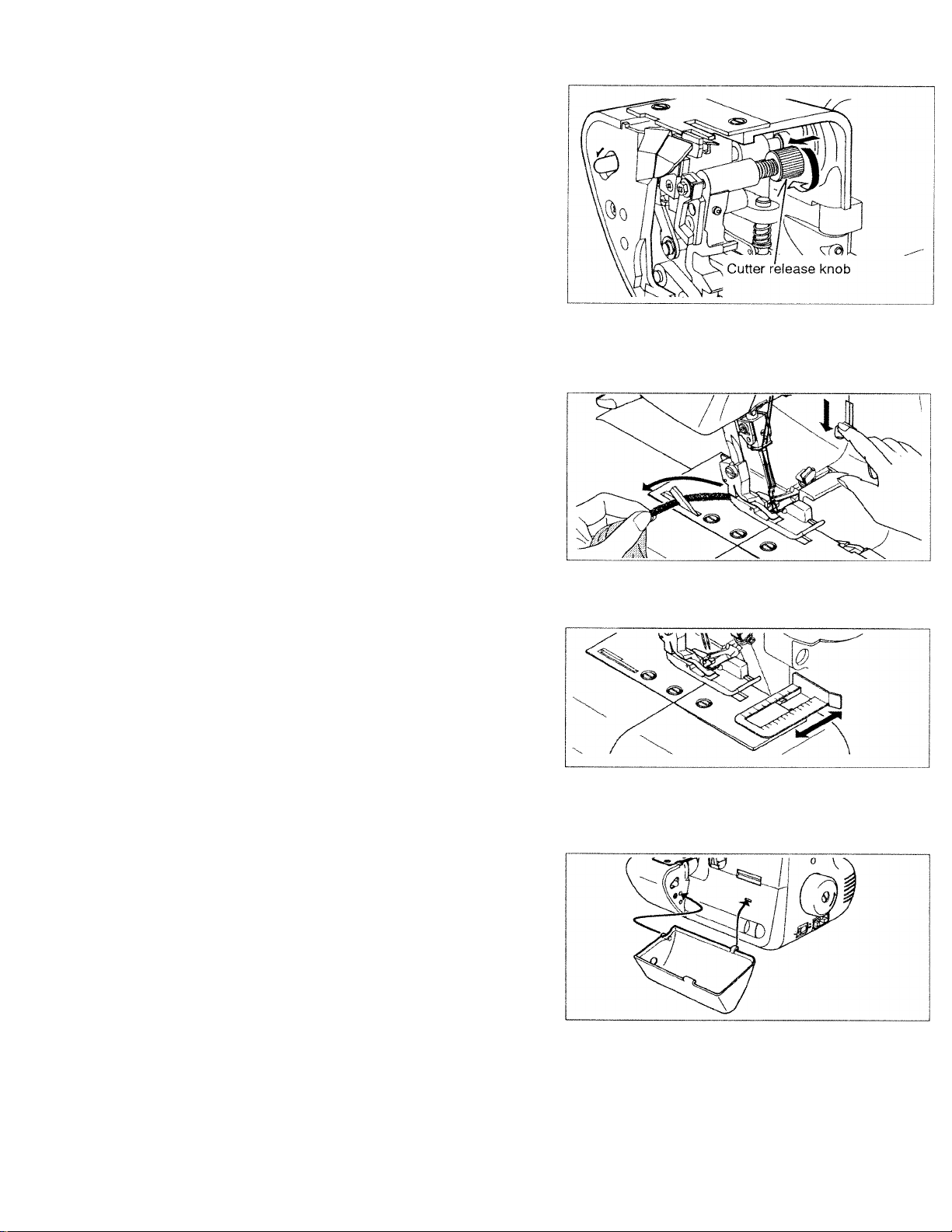

12. DISENGAGING UPPER CUTTER

To lower the upper cutter, open the left

front cover and turn the cutter knob toward

you until the cutter is all the way in the

down position. BE SURE TO PUT CUTTER

BACK UP BEFORE SEWING.

13. EXCLUSIVE BUILT-IN THREAD CUTTER

The built-in scissor conveniently cuts your

thread tail simply by pressing down on the

lever as illustrated, then releasing to cut.

14. ADJUSTABLE FABRIC GUIDE

The adjustable seam guide can slide to the

left or right as needed to keep fabric straight

while serging seams.

15. WASTE TRAY

Place the large waste tray on the front of

your Superlock by hooking over the slot on

the right front cover and inserting the peg

on the left into the hole on the side cover,

as illustrated.

Page 10

16. OILING

Lubrication is not required often for

this machine since the important parts are all

made of a special oil impregnated sintered

metal. You will want to occasionally put one

or two drops of oil on moving metal parts will

increase durability.

17. CLEANING

First disconnect machine from power supply

by removing plug from the electric outlet.

Open front cover and side cover (see pg. 3).

Using the brush provided, remove all the dust

and lint that has accumulated. Remember to

also clean between the cutters often.

18. STORAGE

When the machine is not in use, disconnect

it from the power supply by removing plug

from the electric outlet.

Using the vinyl cover provided, cover

your machine when not in use.

8

Page 11

)

HINTS FOR SUCCESSFUL STITCHING

An understanding of the following variables will make your Superlock run smoothly and

your work will look professional. Before sewing, always test the compatibility of your fabric,

thread, pressure, stitch length, and tension.

Thread Selection

When selecting the proper thread, choose one that is compatible with the fashion and

the fabric. Polyester threads (or polyester based) are most commonly used for general

sewing purposes. Threads of different fibers (cotton, rayon, silk, etc.) are available for

special sewing.

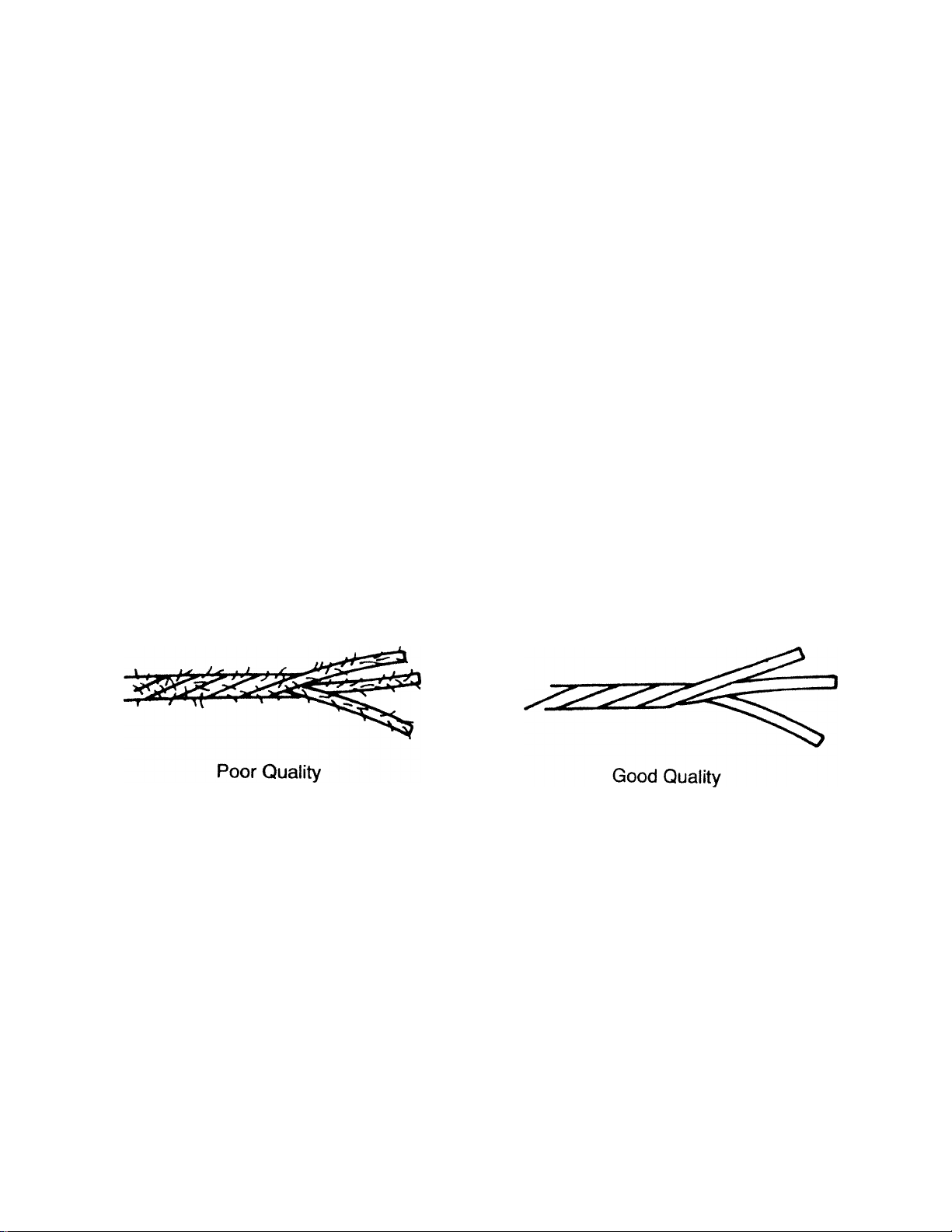

Quality is a very important consideration when selecting a thread. A thread of poor

quality will result in operating and stitching problems on any type of sewing machine. Syn

thetic threads are made by twisting filaments together. Lower quality synthetic threads are

made by twisting short, leftover filaments of polyester together. The result is a "hairy*

appearance and a weaker thread. Better quality threads are made by twisting long continu

ous filaments together. This thread is stronger and smoother, thus fewer operating prob

lems will occur. Brand name and price do not necessarily represent quality in a thread.

The only true test of thread quality is close examination.

A variety of threads are available for overlooks. They may be of cotton, cottonwrapped polyester, polyester or nylon (Wooly Nylon®). These are most often put up on

cones or tubes. Threads for the overlock are generally finer and lighter in weight than

standard sewing machine thread. This is because of the large amount of thread that builds

up in an overlook seam. Finer thread makes for a less bulky seam. Your Superlock will

handle thread on cones or spools. Many decorative threads will be discussed later in this

workbook.

Page 12

■»

NEEDLE REPLACEMENT

Replace needles in the following way:

1. Bring needles to their highest position by turning handwheel towards you.

2. Lower presser foot.

3. Open front cover: the screwdriver and needles are located inside the handy storage

area.

4. When replacing right needle, loosen right needle clamp screw, marked "R", and remove

needle. Be sure to store extra loose needles in needle cushion.

To replace left needle, loosen left needle clamp screw.

5. With the flat side away from you, insert the new needle into groove of needle bar as far

as it will go. Use an Organ brand HA x 1SP. These are standard needles used for home

sewing.

Change needles after each garment for best results.

10

Page 13

NEEDLES, THREAD & FABRIC CHART

Needles

Proper needles are important when using your White Superlock. A standard sewing

machine needle of good quality, Organ brand HA X 1SP, can be used on your

Superlock. Change needles often for best results.

Caution: Do not used banded needles (i.e., yellow band) on your White Superlock.

These can cause skipped stitches and possibly bend or break needles or damage

loopers.

Threads

Any good quality cotton, polyester, silk, synthetic threads, etc., can be used on your

Superlock. Wooly Nylon®, a stretchy, yarn-like thread, is recommended in upper

and lower loopers for rolled edge and lingerie sewing.

COTTON

LINEN

WOOL

SYNTHETIC

FIBER

KNIT

Fabric

Lightweight:

Organdy, Lawn, Calico

Heavyweight

Oxford, Denim, Corduroy

Lightweight:

Tropical, Wool, Poplin

Mediumweight:

Gabardine, Flannel

Heavyweight:

Velours, Camelhair

Lightweight:

Georgette, Crepe, Voile

Heavyweight:

Taffeta, Twills, Denim

Tricot

Thread

Cotton #80

Polyester #60 - 50

Cotton #60

Polyester #80

Cotton #60

Polyester #80-60

Cotton #60

Polyester #60-50

Cotton #60

Polyester #100-80

Cotton #120-80

Polyester #60

Cotton #60

Polyester #80-60

Cotton #80-60

Needle

90 (14)

for general

sewing

75(11)

for light

weight

fabrics

Jersey, Interlock

Wool

Polyester #60-50

Cotton #60

Polyester #60-50

Wooly Nylon

11

Page 14

SECTION II - THREADING & TENSION

Spool cap

Preparation for Threading

Spool Holders

For large cones of thread, use the black plastic

cone holders. This will help hold the cone of

thread in place.

Spool Caps

When using small spools, remove the

plastic cone-spool holders (a drop of oil will

make the holder slide off easily), and place the

spool directly on the spool pin. Use the spool cap

to keep the spool in place and to prevent the

thread from catching on edges of the spool.

Spool Nets

Spools of specialty thread sometimes work loose

from the spool during sewing, causing tangling or

irregular thread feeding. To prevent this use the

spool net provided as shown.

Extension plate

Domestic cotton reel

Cone type thread

Cone holder

▼ .4'

Thread comes off the top

Net

I

Net

m

.Turn up

\

Spool

NOTE: Specialty threads, such as fine perle cotton. Designer 6 by YU®, Ribbon Flos^,

and Pearl Crown Rayon® by YU may be used in the loopers of your Superlock.

For successful stitching be sure these threads feed off their spools or skeins easily.

Spool

12

Page 15

Your White Superlock is very easy to thread. With some practice you will be

able to thread it in a few minutes without using any tools. Master the correct

threading before starting your first project.

To become familiar with your Superlock, practice on scrap fabric with different

color threads to identify placement and function of each thread.

Threading must be carried out in the following sequence for total ease of

operation: upper looper - lower Looper - right needle - left needle.

Extend the thread pole to its highest point, then turn it until the shaft clicks

into its locked position. Place threads on spools and draw ends through the

guides from rear to front.

Your Instruction Manual shows threading the lower looper first. We have

found that threading your upper looper first is easier and will allow your

threads to lay in the correct order for a proper stitch.

13

Page 16

THREADING UPPER LOOPER

Open front covers.

Bring the upper looper to its lowest position by turning the handwheel toward you

Draw thread from spool and pass it through the thread stand (back to front), under

thread clip guide (1) and then, in order, through guides 2-4 as illustrated below and

inside the front cover of your Superlock.

With the presser foot raised to release tension, lay thread between

thread tension discs. (2) Be sure thread is all the way into the tension discs.

Snap thread into guide A, B, and C (illustration 3), then thread the hole of the upper

looper (4) using the tweezers provided if necessary.

Bring thread tail under foot and toward back left corner of your Superlock.

14

Page 17

THREADING LOWER LOOPER

Bring the thread from the spool through thread guide back to front of the thread stand

under (1) and then, in order, through guides 2-4 as illustrated below and inside front

cover of your Superlock.

With the presser foot raised to release tension, lay thread between thread

tension discs. Be sure thread is seeded all the way into the tension discs.

Bring the lower looper to the far left position by turning the handwheel toward you.

Snap thread into thread guides A, B, and C (illustration 3), then hook the thread guide

onto the lower looper thread guide D (Figure 3).

Then move the lower looper slightly to the right by turning the handwheel toward you.

Thread the eye of the lower looper D (Illustration 3). You may wish to use the tweezers

provided.

Bring thread tail under foot and toward the back left corner of the Superlock.

15

Page 18

)

THREADING NEEDLES

Raise the needles to their highest position.

Bring the thread from the spool and pass it through the guides on thread stand (back to

front), then under thread clip (1).

Lay thread between thread tension discs (2). Be sure thread is seeded all the way into the

tension discs.

Pass thread through guides A and B for each needle.

Thread each needle(s) eye (4) using your needle threader found in the storage area of the

right front cover.

To thread right needle, lower presser

foot and raise needles to their highest

position. Follow illustrations 1-6 (next

page) inserting left peg of needle threader

into hole on right side of needle bar, then

sliding wire of needle threader through eye

of needle (back to front).

Hook thread under wire hook an dull needle

threader straight back to pull thread through

eye of needle. Place thread tail under presser

foot and toward back left corner.

Thread left needle in same manner, following

illustration Slide right peg of needle threader

into slot on left side of needle bar and continue

same as for right needle. Be sure to put needle

threader back into the built-in accessory

compartment.

16

Page 19

(For right needle)

NEEDLE THREADER

17

Page 20

HELPFUL HINTS - CHANGING THREAD

The following steps may be helpful when changing your threads.

•Cut off threads that are on your Superlock

near the spools and replace the

spools with new ones. Tie new thread on

to old threads with overhand or square

knot.

•Raise presser foot and cut the needle

thread(s) right above the needle eye.

•Lower needle bar to its lowest position

by turning the handwheel. With the

presser foot in the highest position, pull

the looper threads until the knots are

about 4" past the presser foot.

•Rethread your needle(s).

18

Page 21

TESTING STITCH

After threading is completed, test your Superlock stitch in the following order:

1. Be sure both front cover and side cover are closed.

2. Without fabric under the presser foot, lower

presser foot. Pull the ends of the threads

gently with your left hand toward the rear

of the machine, turning the handwheel toward

you a few times to make sure the stitch forms

on the stitch finger (figure 1).

. Sew on scrap fabric. When you reach the end

of the fabric, raise the presser foot and remove

fabric from your Superlock. Use the handy

thread cutter (figure 3) on your Superlock to cut

your threads. Use the illustrations on the

following pages to check the stitch formation

produced to see if it is uniform. If not, you will

need to adjust tensions and/or recheck threading.

19

Page 22

THREAD TENSIONS

Thread tensions will vary according to the type and thickness of your thread and fabric.

In most cases these tensions will only vary slightly. Turning the tension dial to a lower

number gives you less tension. Threading your Superlock with four different colors of

thread will help you identify the placement and function of each thread.

Upper Looper Thread should be flat on the top side of fabric and lock with the

lower looper thread on the edge.

Lower Looper Thread should be flat on the underside of fabric and lock with the

upper looper thread on the edge.

The needle threads should lay mainly on the top side like rows of normal straight

sewing. The left needle will form a line of sewing along the left edge connecting the

two looper threads and the right needle acts as a "safety stitch"-forming a line of

stitching through the upper looper thread.

Set your Superlock according to the tensions recommended below. Try test sewing on

a piece of medium weight fabric. If you need to change the tensions mark them down

for future reference.

Left Needle (LN)

Right Needle (RN)

Upper Looper (UL) __4

Lower Looper (LL)

We will refer to these tensions as normal.

These tension recommendations are for average strength thread tension. It may be

necessary to adjust the thread tension(s) slightly as different weights of fabric and

thread can make a difference. Your tensions should remain in the outlined area on the

tension dial.

____

___4__

___

4__

__

4__

20

Page 23

ADJUSTING THREAD TENSION

#

Just Right

Left Needle Thread Loose

and visible on undereide of

fabric.

Upper Looper Thread

Pulled to the Underside

Increase upper looper thread

tension and/or decrease lower

looper tension.

Right Needle Thread Loose

and visible on underside of fabric.

Lower Looper Thread

Pulled to the Top Side

Under side

, J ' tooper

i Top side'

Increase lower looper thread

tension and/or decrease upper

looper tension.

j ' thread

^ Lower

Top skte It

Increase left needle tension

and/or cteaease both loopers.

Increase right needle thread tension.

I-

21

Page 24

SECTION III

BASIC SEWING TECHNIQUES

Sew samples for the next section of this workbook, and record your

tension settings on each page for future reference.

22

Page 25

SUPERLOCK SEAMS & SEAM FINISH

Seam and overcast all in one step. Your Superlock produces fast, professionally-

finished garments.

Machine Setting

Stitch Length: 2-3

Stitch width: 6

Fabric

Medium weight woven

Tension Setting

Set your tension to normal setting and note.

Left needle (LN) - 4 Right needle (RN)-4Upper looper (UL)-4Lower looper (LL)-4-

To Seam & Overcast

•Fold fabric in half.

•Place under presser foot with folded edge to be trimmed to the right.

•Use your 5/8* seam allowance as a guide.

•Serge seam.

•Lift the presser foot, and pull your sample away. And cut the threads

using the thread cutter.

To overcast raw edges for conventional seaming - Serge one edge of above

sample to finish raw edge. Mount your sample on the facing page.

23

Page 26

ADJUSTING STITCH LENGTH

Turn the stitch length dial (located on the right side of your Superlock) until the

required length is at the guideline. The higher the number, the longer the stitch.

With the dial you can adjust the stitch length from R for rolled edge to 5mm.

Stitch Length Sample

Machine Settings

Stitch length: 1 - 5 (see illustration)

Stitch width: 6

Fabric Medium weight woven

Tension Settings

Normal

LN

RN -4UL -4LL - 4-

-4-

Serge

•Fold fabric in half.

•Set stitch length to 5mm.

•Stitch along edge stopping every inch and

decreasing stitch length to 4, then 3, etc.

24

Page 27

ADJUSTING CUTTING WIDTH &

BALANCE OF STITCH

The cutting width can be adjusted from 4mm to 7mm by simply turning the cutting

width dial according to the type of fabric you are working with. This fine tune adjustment

allows you to achieve the best stitch possible on all fabric types.

The normal setting for the cutting width is 6mm.

Adjust the cutting width by turning the dial on the left side of the Superlock. If the cutting

width is narrower than the stitch width, leaving loops off the edge of the fabric, turn the

cutting width adjustment dial toward 7.

If the cutting width is wider than the stitch width causing a pucker within the overlock

seam, turn the cutting width adjustment dial toward 4.

25

Page 28

ADJUSTING CUTTING WIDTH

The cutting width can be changed for different techniques and types of fabric.

Loosely woven or heavy knit fabrics require a wider width and lighter weight

fabrics require a narrower seam width.

Machine Settings

Stitch length: 2.5 - 3.0

Stitch width: 6

Fabric

Medium weight woven

Tension Settings

Normal

Serge

Serge along one edge with the stitch width on 4mm. Serge along the

other edge with the stitch width at 7mm.

For a narrow or wide stitch width, see three thread sewing techniques on pages

38 and 39.

26

Page 29

SECURING BEGINNING & END OF SEAM

As most ends of seams and finished edges are later stitched over during garment

construction, it is often not necessary to lock ends. When needed, use one of the

following methods.

Machine Settings

Stitch Length 2.5-3

Stitch width 6

Fabric

Medium weight woven

Tension Settings

Normal

(LN) - 4 (RN) -4(UL) -4(LL) -4-

Securing Beginning of Seam

•Fold fabric in half

•Stitch 2-3 stitches into fabric, then stop sewing.

•Raise presser foot. Bring chain around left side

of foot and under front of cutter.

•Lower presser foot and sew, cutting off excess chain.

Securing End of Seam

•Sew to end of fabric.

•Raise presser foot to release thread tensions and pull fabric 1" from foot.

•Reinsert fabric under foot about 1" from end and serge over

previous stitching.

•Raise presser foot and pull sample out.

Use thread cutter to cut threads.

Optional Securing Methods

•You may tie a knot in the thread ends. This method requires about three

inches of extra thread. After tying knot, trim ends.

•Use a small amount of Fray Check^” at the ends.

•Thread ends into the finished seam. This requires one or two

inches of thread at the end and is usually the best choice for decorative finishes.

27

Page 30

OUTSIDE CORNERS

You can stitch neat outside corners with little practice on your Superlock.

Machine Settings

Stitch Length: 2.5 •

Stitch Width: 6

Fabric

Medium weight woven

Tension Settings

Normal

(LN) -4(RN) -4(UL) -4(LL) -4-

3.0

Serge (Sew along edge of fabric; do not trim.)

•Sew along one side of fabric to the end.

•Raise the needles and presser foot.

•Gently slide the threads off the stitch

finger of the needle plate by pulling fabric toward back of Superlock.

•Grasp the fabric gently and turn the corner.

•Realign the edge of the fabric and put the cut edge of the fabric against the cutter.

•Pull up slack in threads.

•Lower presser foot.

•Serge the edge. Repeat for the remaining corners.

28

Page 31

INSIDE CORNERS

Practice the inside corner technique for perfect inside corners or curves such as for

Christmas stockings, oven mitts or kick pleats on skirts.

Machine Settings

Stitch Length: 2.5 - 3

Stitch Width: 6

Fabric

Medium weight woven

(Cut a square out of one corner.)

Tension Settings

Normal

(LN) -4(RN) -4(UL) -4(LL) -4-

Serge

•Align the edge with the inside edge of cutter, with bulk of fabric to the left.

•Serge up to 1/2" from the inside corner.

•Careful! Your cutter is 1/2" in front of the needle so you must fold

fabric away from the cutter before the corner reaches it.

•Pull fabric into a straight line and align the unfolded edge against the

inside edge of the cutter. There will be some tucks in the edge.

These should lay flat after stitching.

•Continue to serge along the edge.

Sleeve Placket

•Cut a 2 1/2" slit in a second piece of fabric.

•Cut a strip of fabric 1" x 5*.

•Fold strip in half lengthwise, wrong sides together.

•Lay strip on slit right sides together.

•Using inside corner technique, stitch strip to opening forming a placket.

29

Page 32

CORDED OVERLOOK

The Specialty Technique Guide consists

of the snap on cord guide (1) found in your

accessory pouch, the guide above the

needles (2) and either hole in the presser

foot (3).

The Specialty Technique Guide guides cord

through the foot and then is covered by the upper

looper thread or is caught by the right needle,

depending on the size of cord you choose. Ribbon

or Cording can be used to stabilize where stress

occurs: joining shoulder seams, sleeves, side

seams, etc. You can also use it for a decorative

look in the areas that are visible. Use filler cord,

perle cotton, twill tape, gimp, wool yarn, elastic

thread, polyester ribbon, etc.

Machine Setting

Stitch Length: 2.5 - 3

Stitch width: 6

Fabric

Sweatshirt Fleece & 1/8*

Tension Settings

Normal

(LN) - 4 (RN) -4(UL) -4(LL) -4-

•Feed ribbon through guides and front hole on foot.

•Fold fabric in half.

•Serge with four thread seam to stabilize seam.

•Use the back hole in foot for cording, fishline, etc.

3/16' Ribbon

Slide ribbon under foot to needles.

30

Page 33

RIBBING

Your Superlock will finish, trim and allow the material to stretch while retaining its original

shape.

Machine Setting

Stitch Length: 2.5-3

Stitch Width: 6

Fabric

Sweatshirt fleece and ribbing

Tension Settings

Normal

(LN) -4-

(RN) -4(UL) -4(LL) -4-

Serge

•Cut a curved neckline in fabric.

•Fold ribbing in half lengthwise.

•Place ribbing on neckline with raw edges even.

•Serge, stretching ribbing to meet neck edge.

•When attaching ribbing in a circle such as around the neck, serge around

until your stitches overlap one inch. Raise the presser foot and pull your work out, and

31

Page 34

CASING OR HEM FOLD

Try this easy technique for T-shirt hems, elastic and drawstring waistbands or curtain

rod casings.

Serge

•Measure and fold the desired depth for the casing.

•Hold the folded fabric with wrong side facing you.

•Turn the casing underneath so that the fabric now has an *S" shape.

•Serge along the fold with the wrong side up catching both needles into fold of fabric.

32

Loading...

Loading...