Page 1

штштш

. Ч '-Ч:

''Ч:,, '5,

,v\,:'' -,'Ч;

Page 2

INDEX

Features and parts

Needle and Thread size ...

Inserting the needle .

Winding the Bobbin

Threading the Bobbin case

Placing Bobbin case in shuttle

Upper Threading

.........

Adjusting the tensions

Setting the stitch Length

Sewing in Reverse

Adjusting pressure and Feeding of Fabric

Sewing Thin or Light weight Fabric

Darning and monngramming

Straignt stitching ..

Zgzag Stitching

.......................

PLacing of pattern cam

for Embroidry Sewing

Sewing Pattern

...............

Page

.....

.....

..... 5

.... 7

.... 7

.... 8

.... 9

10

10

,. 11

.. 12

Page

2

3

4

5

6

7

Blind Stiching

Sewing on Buttons

Making Buttonholes 1 s.

Embroidering with a hoop

The Adjustable cording and zipper Foot

Cording . .

Sewing in zipper

Narrow Hemmer ....

Quilting Guide. .

Seam Gauge or cloth Guide

Care and maintenance of your manhitip

Cleaning and Oiling Hook Assembly

Check up for Smooth Sewing

Accessories ...

Instructions for Portable Installation

..........

Instructions for Cabinet Installation

To Assemble Legs on KD Cabinets

~16

. 17

17

18

19

19

20

21

22

2.3

24~25

26

27

Page 3

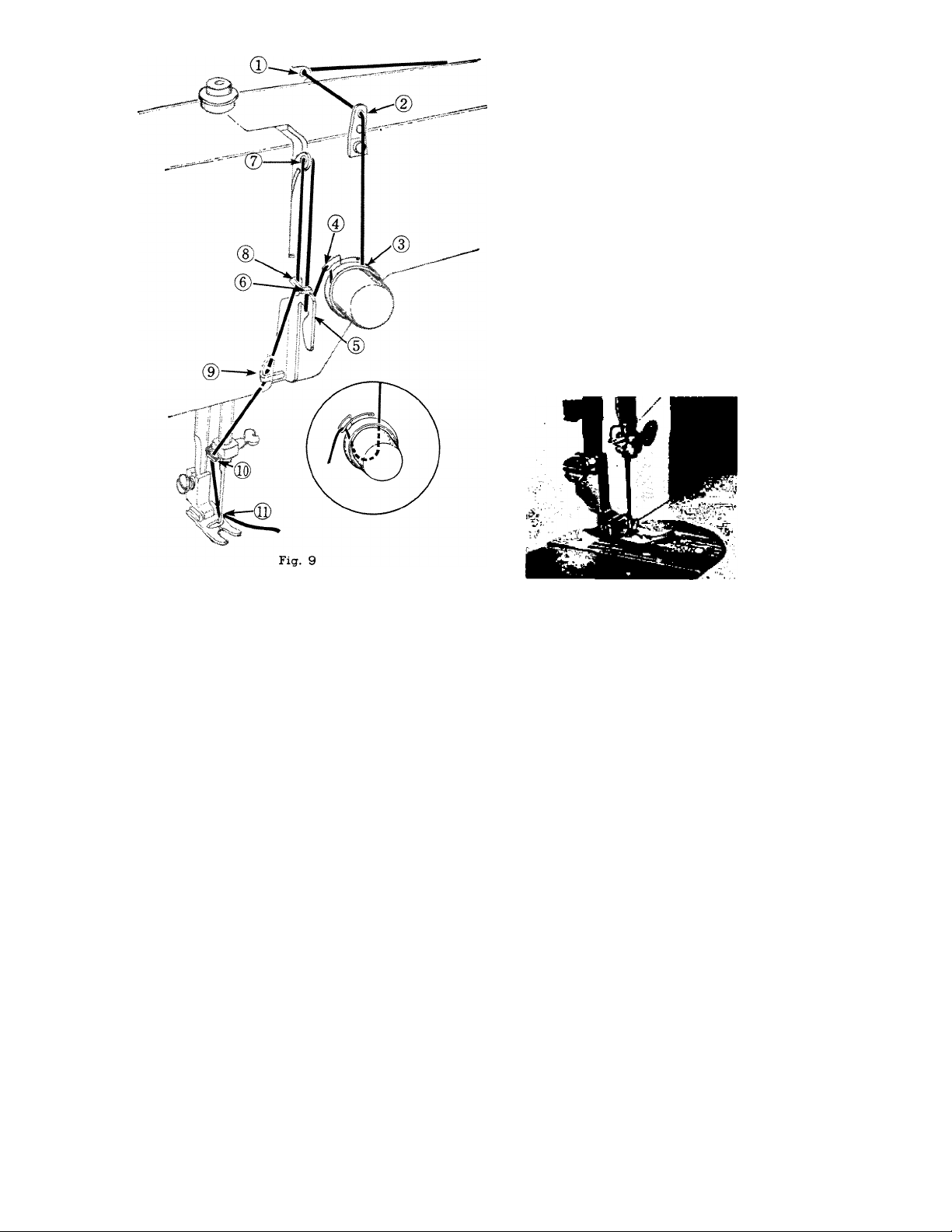

FEATURES AND PARTS

1. Thread Take-up Lever

2. Pressure Release CDarning)

3. Top Plate Thread Guides

4. Zigzag width control Dial

5. Top Plate

6. Needle Positioning Lever

7. Buttonholer Control Dial

8. Bobbin winder Spindle

9. Hand wheel

10. Stitch Length Control Dial

11. Drop Feed Dial

12. Push Button Reverse

13. Tension Regulator Dial

14. Needle Clamp Screw

15. Needle Plate

16. Bobbin Cover Plate

17. Pressure Foot

18. Pressure Foot thumb screw

19. Thread cutter

20. Thread Bar and Guide

21. Lamp Switch

22. Face Plate

23. Cam Cover

24. Pressure Bar Lifter

25. Feed

26. Head Hinge Mounting Holes

27. Motor Belt Cover

28. Spool Pins

29. Clutch Release

Page 4

NEEDLE AND

THREAD

SIZE

Fabric

Extremely heavy

tarpaulin, sacking.

canvas, duck, ete.

Heavy upholstery

fabric, ticking.

denim, leatherette

Medium heavy drapery

fabric, velveteen.

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen.

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn.

dimity, crepe,

handkerchief linen.

plastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marquisett, etc.

15x1

Needle

No.

Machine

Stitches

Per Inch

6

19

18

16

14

11

&

Ball Point

r^eedie CPlastic film)

9

&

BaU Point

Needle

to

8

to

10

10

to

12

12

to

14

14

to

16

8 to 10

16

to

20

Cotton

Thread

10

8

to

30

30

to

40

40

to

60

60

to

80

80

to

100

100

to

150

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk

or

Nylon

E

Twist

D

Twist

c

Twist

A&B

Twist

O

Twist

OO&OOO

Twist

Page 5

INSERTING THE NEEDLE

See Fig. 2. Raise the needle bar ® to its highest point, turning

hand wheel toward you by hand. Then loosen the needle clamp

screw (D and the needle can be inserted into clamp

Place needle (Fig.3, FLAT SIED TO RIGHT) in the needle ckmp

and push it upward as far as it will go into the needle clamp ho e,

tightening the needle clamp screw securely with a screw driver.

After changing the needle, make one complete revolution of the

hand wheel by hand to be sure the needle is in the correct position.

®.

Fig. 3

Fig. 2

WINDING THE BOBBIN

Disenaaae the hand wheel C®, Fig. 4) from the stitching

Disengag _i„trh

mechanism by turnmg the clutch CU< y lead

oloctwi^. ..pool of to...! »“ol

thread around one set of arm thread guide (®, Fig. 4). Run en

thread through a hole in the bobbin edge and place

spindle of bobbin winder (®, Fig. 4) fitting the ^°tch^ bobbm

over small pin on spindle. Push bobbin ^^wly

against bobbin. Hold thread end loosely and start machine slo y

Bobbin will stop winding when it is filled.

Tu^ clutch away To reengage stitching mechanism turn clutch

(®,Fig.4) clockwise.

C(i)

Fig 4) toward you or counter

Page 6

Fig. 3

Fig. 8

THREADING THE BOBBIN CASE

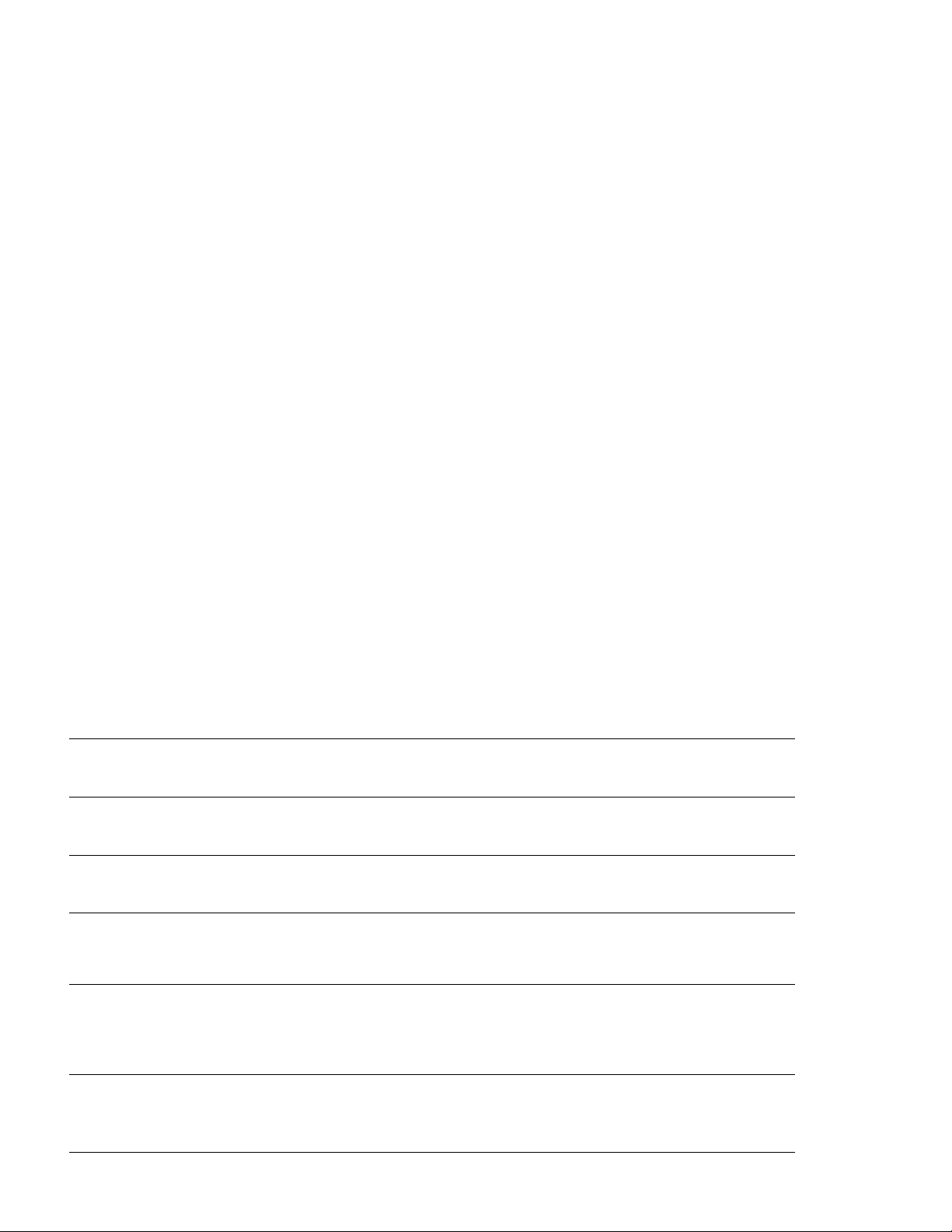

Step 1 (illustrated in Fig. 5) Hold bobbin case between thumb

and forefinger of left hand, so that the slot in the edge of the

bobbin case is on top. Take the bobbin between thumb and

forefinger of right hand so that the thread on top leads from left

to right. Step 2. Insert bobbin into bobbin case, pull the thread

into the slot of the bobbin case as shown in Fig. 6, and draw it

under the Tension spring and into the fork-shaped opening of the

spring as shown in Fig. 7.

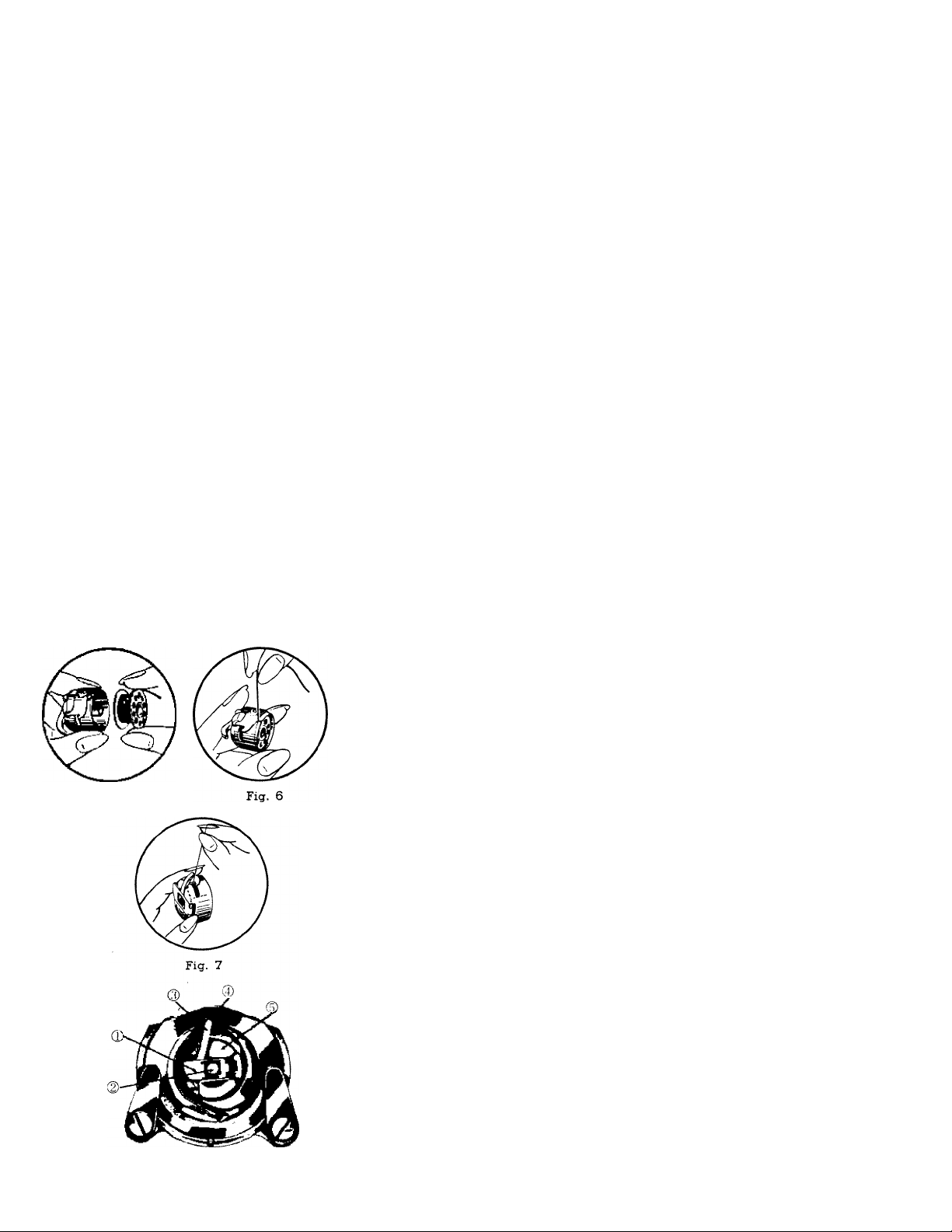

PLACING BOBBIN CASE IN SHUTTLE

Open bobbin case cover plate left of the needle. (@, Fig. 1)

See Fig. 8. Hold the bobbin case latch, ®, between the thumb and

forefinger of the left hand with at least three inches of thread

running from the top of the bobbin case to the right. Insert and

center the bobbin case on the stud of the shuttle hook ®. Be sure

the bobbin case finger (S) is inside the shuttle race notch ®.

Press the bobbin case ® into the shuttle as far as possible until

latch catches on the center post of the shuttle. Then release the

bobbin case latch ®. Press bobbin case again after latch has been

released to make sure the bobbin case is locked securely in place.

Close the cover plate.

Page 7

Turn hand wheel toward you to raise the

UPPER THREADING

take-up lever and needle to their highest position.

Place spool of thread on spool pin and lead

thread through top plate thread guide® and®.

Down and between tension discs® from right

to left.

Up and over the tension spring® then down

under the thread bar®

Up though thread bar guide® and into take-up

leverr® from right to left.

Down through thread bar guide® again and

into face plate guide® and needle clamp guide®.

Thread needle from left to right pulling three

to four inches of thread through needle.

Hold the end of the upper thread loosey and

turn hand wheel toward you until the needle goes

all the way down and comes back up bringing with

it the bottom or bobbin case thread.

Place both threads

(upper and lower)

imder the slot of the

Presser foot and place

toward the back of the

machine, leaving both

threads three to four

inches long.

Fig, 10

Page 8

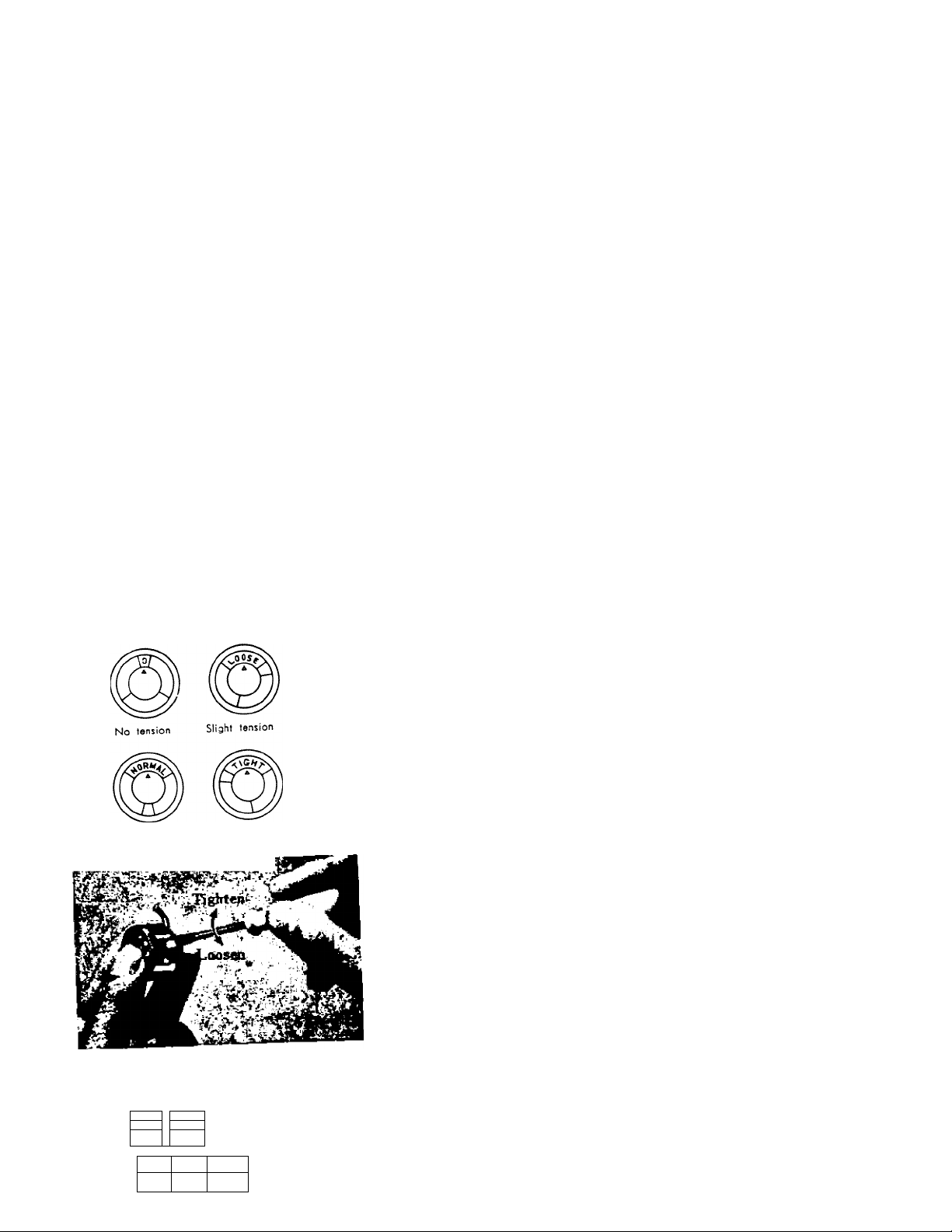

Normol tension Tijht tension

Fig. 11

ADJUSTING THE TENSIONS

A correct stitch can be obtained by varying the tension on the

needle thread. To adjust the tension of the needle thread, Lower

the pressure foot.

Adjust the tension regulator as the case demand, by reffernng

to iUustration. (Fig.ll) The quality of sewing depends on the

tension of thread. Therefore, it is necessary for the user to

become fully familiar with the correct tensions through practice.

Before adjusting lower tension be sure that the machme is

threaded properly. When necessary to change the bobbm te^n,

turn small screw (Fig. 12) on side of the bobbin case clockwise

to tighten, counter-clockwise to loosen.

When the upper and lower tensions are properly balanced,

perfect stitch will be formed with both threads interlocking in

fabric (Fig. 13). , , . n j

When the upper tension is too tight, thrLbric^^g

up over the upper thread which is lymg flat on the fabric C^g.

ph ..1

■ M.

Fig. 12

,

"-'v

g Fig. 14

S Fig. 15

14).

13

When the upper tension is too loose, the upper thread forms

loops over the lower thread lying flat under the fabric (Fig. 15).

Page 9

-:--r

Fig 16

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the stitch length control

dial C@, Fig. 1) Near 0 is the shortest stitch and 5 is the longest.

But the control may be set at any spot between marking for a

variety of lengths. Turn the control dial to the right to lengthen

and to the left to shorten the stitch.

STITCH LENGTH CHART (Approximate)

Figures on indicator

Number of stitches par inch

0 1 2 3 4 5

No Feeding 30 15 10 7 6

SEWING IN REVERSE

When you wish to sew backward to tie the threads at the

beginning or end of a seam, press in the push button (@, Fig. 1)

as far as it will go. The machine will sew backward as long as the

button is held in.

ADJUSTING PRESSURE AND FEEDING

OF FABRIC

GENERAL SEWING. For normal straight stich and zigzag

stitching, the pressure bar cap or darner release, Fig. 17 and

18 is at its lowest position and the drop feed dial Fig. 16 is

set to "UP" position.

Page 10

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter pressure is required to sew satisfactorily on thin

silk or filmy material, the pressure cap should be about halfway

down.

Release all the way by pressing the snap look, C®, Fig. 17)

and then press cap C®, Fig. 18) down again to halfway spot.

DARNING AND MONOGRAMMING

In order to move the fabric freely in any direction for darning,

mending and certain kinds of free-hand embroidery, release the

cap C®, Fig, 18) completely by pressing down on the snap lock,

C®, Fig. 17). Set the drop feed dial (Fig.l6) to "DOWN." which

drops the feed well below the needle plate. To return feed to

normal, set to "UP", push cap down (Fig. 18).

Page 11

10

1» /

Fig. 19

STRAIGHT STITCHING

® Set needle position lever to L position.

(D Set Buttonhole disc ((D) indicator on M position.

(D Set zigzag width contrl dial ® at "O" Position. _ „

® Select desired stitch length by turning stitch length dial ® 0 5^

For more precise straight stitching on special fabrics this machme

eqX^rwith a straight stitch needle plate (#10 page23) and straight

stUch^resser foot (#11,Page 23) please note both accessories have

a small round hole instead of the wide slot as used for zigzag

The crosswise slot-needle plate and prsser foot-allow t e ®

sideways (zigzag) while moving up and down. A cam is not required

for straight stitching. , , .

To change needle plate, remove the setting screws on the plate.

replace with straight stitch needle plate and tighten screws securely.

When straight sewing with the regular zigzag needle plate and^^^^^^^

presser foot the needle can also be positioned in the M (middle)

piosition.

ZIGZAG STITCHING

® Use regular zigzag presser foot and needle plate.

(2) Cams are not required for normal zigzag sewmg.

® Set needle position lever to L, M or R position, preferably L.

® Set buttonhole dial to M position on panel.

® Select width desired from 0 to 5 on zigzag width knob.

® Length of zigzag stitch can be varied by increasmg the size of

©M^tSf virinces are possible by changing needle position,

stitch widths and stitch lengths.

Page 12

4ft:

Pattern Cam and box

s

©

PLACING OF PATTERN CAM FOR

EMBROIDERY SEWING

1) Use regular zigzag pressure

foot and needle plate.

2) Open the cam cover lid ®.

Fig. 20.

3) Set buttonhole dial to M

position on panel.

4) Turn zigzagicontrol diallto

position 5 this permits the

insertion of cam on to the

spindle ®. Revolve cam, pressing

down slightly tmtil hole in bottom surface is fitted over pin

5) Close cam cover lid and return zigzag Control dial to "0"

position.

6) Set stitch length between O and 1 for effect desired the shorter

the stitch length the greater the density of pattern sewn.

Needle position can be set at left (L), middle (M) or right (R).

Each position alters the basic stitching line and designs sewn.

IMPORTANT When using Cam |20 (blind hem cam) for blind

hemming, set needle position lever to "R" position.

Fig. 20

®,

11

Page 13

12

SEWING PATTERNS

Page 14

STEP 1

BLIND STITCHING

1. Use regttlar zigzag pressure foot and needle plate.

2. Insert Cam No. 20 into tlie machine.

3. Set needle position lever to "R" position.

STEP 2

4. Select stitching length desired.

5. Buttonhole dial must be set on "M" position.

Blind stitch hems provide a durable hem finish that is almost

invisible and comparable to hand sewing.

Prepare the garment in the same manner as for hand hemming.

Step 1. If hem with folded edge is used, make first fold 3/8

deep.

Step 2. Turn hem the depth desired and baste 1/4 from upper

edge. Press into place.

Step 3. Fold hem back toward right side of garment leavmg 1/4"

extended.

Step 4. Place garment under pressure foot and sew blind hem.

Fig. 21

Page 15

14

Fig. 22

SEWING ON BUTTONS

1. Use button sewing foot and zigzag needle plate.

2. Set drop feed dial to "EXDWN" position.

3. Set the needle positioning lever to "L" position.

4. Move zigzag width control dial to "0" position. Place the button

so that its left hole comes directly under the needle, then gently

lower the presser foot. Move the zigzag width control dial to the

right until the needle comes exactly over the right hole of the

button. Turn the hand wheel slowly by hand to be sure the needle

clears both holes of the button.

5. When needle goes into the center of each hole, run the machine

at medium speed, making five or six stitches, stopping with the

needle in the left hole.

6. To lock the zigzag stitch and prevent ravelling, set the zigzag

width control dial at 0, and take a few stitches in the same

hole. If you wish, you may place a roimded toothpick over

the button between the two holes, and sew button to fabric in

regular way. Remove the toothpick and wind thread under

button, forming a shank. Fasten. ,

If a four hole button is to be sewn, follow the same procedure

as above for the two hole button. Now lift pressure foot slightly

and move fabric to permit stitching the remaining two holes.

Hooks, snaj», etc. are sewn to the fabric with the same proce

dure as for sewing two hole buttons.

Page 16

MAKING BUTTONHOLES

A buttonhole can be made in any length within the range of

limited width.

1. Use special purpose buttonhole foot (Fig. 23) an igzag

needle plate.

2. Mark the beginning and end of the buttonhole on fabric with a

basting line or tailor's chalk. Make one on scrap fabric followmg

directions below to be sure machine adjustments are correct.

i-

3. Set the needle positioning lever at "L" position, and zigzag width

indicator at "0" position and stitch length indicator between

-Cam

Fig. 23

4 Steps in

Making

Buttonhole

Fig. 24

"0" and "1" position. , , , ,

4 Turn hand wheel imtil needle is out of fabric. Turn ut on o e

control dial to No. 1 position. Sew left hand side of buttonho e.

(Forward stitching)

5. With needle out of fabric, turn dial to No. 2 position an se

4 or 5 stitches. (Bar tack)

6. Wltk «e«iU 0.1 of tho Olotl., tom di.l to No. 3 po.ltio. ood

aew right hand aide of buttonhole. (Reverae stitching)

7. With needle out of the cloth, turn dial to No. 4 position and

sew 4 or 5 stitches. (Bar tack)

Page 17

8. Slit the buttonhole between the two rows of stitching with

the buttonhole cutter or seam ripper. Be careful not to cut

the stitching or the bar tacks.

If you plan to make buttonholes on sheer or soft material,

place tarlatan or paper, which can be torn away after

stitching under the fabric.

NOTE; When the left side pitch is different from the right side

pitch, adjust the pitch by means of the stitch length

control, so that pitches on both sides will be the same.

EMBROIDERING WITH A HOOP

^ It is easy to follow a stamped design or to work free

hand when embroidering or monogramming. Release the

pressure from the foot by pressing down the snap lock on the

darner. Drop feed dial to "DOWN" position. Then hang the

upper end of the embroidery spring on the needle clamp.

(See Fig. 25).

Stretch the fabric in an embroidery hoop, and place under

the needle after removing the pressure foot. Set the zigzag width

at the size you prefer and lower the pressure bar lifter. Then

operate the machine at a rather high speed while moving the

hoop slowly with both hands. Work carefully and be sure to

keep fingers out of the needle.

FOR BEST RESULT A WOODEN HOOP WITH TENSION

ADJUSTMENT IS RECOMMENDED"

Page 18

THE ADJUSTABLE CORDING AND ZIPPER FOOT

This attachment is used to make and insert

covered cording, and to sew in zippers.

Loosen thumb screw (Fig. 26) to slide foot

to either right or left of needle.

CORDING. Fold bias strip of fabric over

cord. Loosen thumb screw and set foot so

needle is centered in needle hole. Machine

baste cord in place (Fig. 27. ).

To sew covered cord to material, reset adjustable foot so

needle stitches closer to cord and on edge of base fabric.

SEWING IN ZIPPER

Loosen thumb screw and slide foot so needle enters center of

needle hole. Guide metal of zipper along edge of foot (Fig. 28).

17

Fig. 28

Stitching should be close to zipper to allow easy opening and

closing. Adjust to sew from either right or left side, whichever is

more convenient.

Page 19

18

NARROW HEMMER

With the needle at its highest position, replace regular

presser foot with narrow hemmer (Fig. 29) For a plain

narrow hem, make a 1/8 inch double fold for about two

inches along edge of fabric. Hold each end of the two

inch fold, slip undereneath hemmer. Bring fold up into

the scroll of hemmer, draw forward to end and fasten with

point of needle. Lower presser bar lifter. Gently pull ends

of thread as you start stitching.

Guide material slightly to right, and it will take a

double turn through scroll.

Trimmed Hem To sew a narrow hem and attach

lace in one stitching, insert lace in the slot next to needle

(Fig. 30). Sew hem as above, guiding lace under needle

and hem into scroll.

Lace Edge with Invisible Stitching Hold lace 1/8 inch

from raw edge on right side of fabric. Insert both inscroll

as for plain narrow hem (Fig.31). Let hem roll over and

sew in lace, press lace out flat along edge with hem

turned up.

It is possidle to have a little fullness in lace by feeding

it freely under scroll.

French Seam With right sides together, place top piece

of material 1/8 inch inside edge of lower piece.

Insert in hemmer scroll, allowing hem to roll over and

sew in too fabric, makincr French seam.

Fig. 29

Fig. 30

Page 20

QUILTING GUIDE

Tlus guide for making parallel rows of stltcliing is

attached by placing the pronged holder between the pressure

foot and the pressure foot clamp screw (Fig. 32). Adjust the

curved bar to press lightly on the fabric. By letting the guide

ride on the first stitching line, successive rows will be an

equal distance apart. When the bar is attached so that the

curved part is to the right of the needle, it may also serve as

a seam width guide.

SEAM GAUGE OR CLOTH GUIDE

Ig

Fig. 32

Use the seam gauge as a guide for straight seams and

even rows of top stitching along edges of fabric.

Fasten gauge with accompanying screw in threaded hole in

bed of machine (Fig. 33). Adjust to seam width desired.

Page 21

20

CARE AND MAINTENANCE

OF YOUR MACHINE

HOW TO OIL YOUR MACHINE

Your machine should be oiled occasionaUy to

keep it operating smoothly. How often depends

Fig. 34

Fig. 35

on the amount of sewing you do.

Before oiling the upper part of the sewing

unit at points indicated by arrows in Fig. 34 turn

hand wheel toward you until the take-up lever is

at its lowest point.

Avoid over-oiling. Only a drop is needed at

each point.

To oil parts under the bed of the machine,

tip the unit back on its hinges and apply a drop

of oil at each point indicated in Fig. 35.

To oil moving parts inside the face plate

which only rarely require oiling, open plate and

oil at spots indicatad in Fig. 36.

Page 22

Fig. 36

21

CLEANING AND OILING HOOK ASSEMBIY

If machine binds, clean hook assembly as follows.

1. With take-up lever in highest position, tilt head back on

hinges and remove bobbin case.

CASE

LATCH

2. Turn clamps outward and remove race cover.

3. Remove hook.

4. Clean thread and lint from all parts, including race.

5. Run a drop of oil along rim of hook.

6. Replace hook, then race cover. Snap clamps into place.

7. Grasp threaded bobbin case by latch and replace, fitting

tongue into notch of race cover.

Page 23

22

CHECK UP FOR SMOOTH SEWING

Although your sewing machine is designed for maximum efficiency should any of the following

difficulties occur they can be remedied with minor adjustments.

Upper Thread Breaks

Be sure needle is inserted properly.

Check on correct way to thread machine.

Use correct needle size for thread.

Do not have upper tension too tight.

Lower Thread Breaks-------------

Check correct method of threading bobbin case.

Be sure lower tension is not too tight.

Needle Breaks

Do not tug or pull on the fabric while sewing as this will bend and eventually break the needle.

Be sure pressure foot is firmly attached to bar.

Skipped Stitches

Do not use a blunt or bent needle.

Insert needle correctly.

Use correct needle size for thread.

Be sure pressure on foot is sufficient when sewing heavy fabrics.

Stitches Loop

Make sure tetiginug are properly balanced and that machine is threaded, correctly.

Machine Binds------------

Clean thread, dust and lint from body, shuttle and rece.

If condition ontinues, it may be that the machine is gummy with oil. Apply kerosene to oil holes,

run rapidly for a while, and wipe dry. Then lubricate again with fine sewing machine oil.

------------

-------------

------------

------------

Page 24

accessories

1. Ripper (Buttonliole Cutter)

2. Small Driver

3. Large Driver

4-, Plastic Oiler (Sealed and. Filled)

5. Bobbins

6. Felts for Spool pin

7. Needles (Regular and Ball Point)

8. Quilting Guide

9. Clotb Guide and Thumb Screw

10. Needle plate for Straight Stitch

11. Straight Stitch Presser Foot

12. Embroidery Spring

13. Button Sewing Foot

14. Buttonhole Foot (Plastic)

15. Narrow Hemmer Foot

16. Zipper Foot

17. Roller foot

The roller foot and the ball point

needles in your accessory box will

help you in sewing on the new

synthetic materials now on the

market.

23

Page 25

24

INSTRUCTIONS FOR PORTABLE INSTALLATION

Please read these imporlarrt instructions which were wrrtten to aid you in placing your new

^lfUr".i”fi"iwtg"rnTchi^^ en.t,be.ng certain to tahe out the instruct.on booh,

JrZJL accessory bon, lay the unrt lace down on a table. You will see two clanrp.ng

screws A entering head hinge holes B on the underside of the back. ,, K =

On the base you will find two head hinges C which will fit into holes B. Lower the base

onto the sewing machine fitting hinges C into holes B. Tighten screws A securely with a screw

‘'with machine in sewing position attach plastic clamp D to top of partition with screw

prrvlded so that it may be turned across the bed of the machine, to hold it down. (On some

Vyflqes the clamp may be positioned in the proper spot).

To make the elecLcal connection draw the two wires through the slot rn the padition of

the base. Plug the cord labeled "Motor" into the receptacle marked ~

attached to the outer section of the base. Then insert the other cord into the Lrgh ecep ^

Place the foot control on the floor, insert plug into a wall outlet (110-115 vol s) and y

arfready to sew. But first read the instruction book to become familiar with the threading of

the machine, tension adjustments and all the other features designed to make sewing a pleasur .

Page 26

25

Page 27

BACK OFF

SET SCREW

TO CLEAR

HINGE HOLE

X

HEAD HINGE SET

SCREWS

LIFT FLAP

TO LOWER

HEAD INTO

CABINET

INSTRUCTIONS FOR CABINET INSTALLATION

1. Loosen head hinge set screws until

head hinge hole is clear.

2. Tilt head hinge tongues up and back

as far as they will go.

3. Carefully slip head onto head hinges

making sure tongues are inserted as

HEAD HINGE

HOLES

HEAD HINGES

HINT; STRETCH

A RUBBER BAND

ACROSS THE TWO

HINGES TO HELP

HOLD THEM UP.

RIGHT WHILE

MOUNTING THE

SEWING HEAD.

far as they can go into head hinge

holes.

4. Allow the head to rest in its tilted

back position.

5. Tighten both set screws securely with

screw driver.

6. Plug electrical leads into sockets

located inside cabinet. Cord identified

with "motor" tag must be plugged

into socket marked "motor". Untagged

cord goes to "light" socket.

7. If your machine begins to run automatically

without the use of the knee, control, this

indicates that the motor plug and light

plug are in the wrong sockets and should

be reversed.

Page 28

TO ASSEMBLE LEGS ON KD CABINETS

1. Place cabinet body upside down on

smooth level surface (use packing

material as cushion to prevent marking

top.)

2. Select each leg by its corresponding

number on cabinet body corner to

insure proper match and fit.

3. Slip leg into position between corner

blocks and down as far as it will

go with stud fitting into slot or hole in

metal bracket.

27

4. Add wing nut and tighten securely.

Loading...

Loading...