Page 1

R, F.

BOOK 10

DIRECTIONS

For Using the

White Rotary Sewing

Machine

MANUFACTURED BY

White Sewing Machine Company

Cleveland, Ohio, U. S. A.

Page 2

When writing for information regarding parts or anything per

taining to your machine, be sure to mention style of machine,

whether Vibrator or Rotary shuttle, also give the plate No. which is

stamped on bed of machine at foot of arm.

By giving full information it will save time and expense.

Instructions for operating the WHITE supplied in English, Ger

man, Spanish, Portuguese. French, Bohemian, Swedish, Danish, Dutch.

Italian. Polish, Finnish, Hungarian and Russian.

Page 3

iNSTRUCTiONS

FOR USING THE

White Rotary Sewing Machine

MANUFACTURED BY

White Sewing Machine Company

Cleveland, Ohio, U. S. A.

Never run Machine ivitJi needle threaded toithout goods under

p7'esser-foot. Run Machine so that upper side of hand tvheel moves

from you,

TO SET NEEDLE

Raise the lieedle-bar to its highest point; loosen the thumb-screw

and press it to the left to permit the shank of the needle to pass up

between the clamp and needle-bar as far a sit will go, flat side to the

RIGHT—the NEEDLE being flatened on one side so it will set itself per

fectly, then fasten securely by tightening thumb-screw.

To avoid loosening of the needle, ahoays use a screw driver to

fasten the same, the needle nut bemg slotted for that purpose.

The needle, when descending, should pass central in the needle

hole from front to rear, but close to the right side of the hole, as it

prevents the needle from glancing into the race and being caught by

the shuttle.

NEEDLES AND THREAD TO BE USED

The MOST IMPORTANT consideration is to buy and use perfect nee

dles—not bent, nor blunt points.

When ordering needles for this machine, be sure to ask for the

genuine White Rotary flat shank needles which are stamped on the

shank “White F. R.” Imitation or “just as good” needles will cause

trouble. Get the genuine White.

Cut of White Rotary flat shank needle

showing exact length.

iize of the needle sh

and both be suitable to the material sewed. Use as fine a needle as

will permit the thread to pass freely through the eye.

The following index will show the size of needle, thread and silk

to be used.

For colored thread use needles one size larger than given in in

dex above.

г'П'Г'глАт 'TKT3F

150 to

300

150

90 to

70 to

50 to

30 to

. 20 to

90

70

50

30

SILK THREAD

000

00

0

A & в

c

D

NO. OF NEEDI '

00

0

1

2

8

4

Page 4

TO REMOVE BOBBIN CASE

FROM SHUTTLE

Raise the take-up to its highest

point. With the thumb and second

finger of left hand clasp bobbin case

as shown in cut, then lift latch S

with the third finger, when bobbin

case may be readily withdrawn

from shuttle

TO REMOVE SHUTTLE FROM SHUTTLE RACE

First remove the bobbin case. Turn the machine back on its

hinges, then turn the machine in the same direction as in sewing

until the point of the needle just enters the needle plate hole; push

on rear end of latch G and at the same time pull shuttle race cover

away from shuttle and toward latch G from under pin H; the shut

tle can now be removed.

When shuttle has been removed from race be sure to clean both,

and oil the race slightly before replacing. Occasionally oil slightly

in hole on race cap marked V above and pin W in shuttle, see page

5 fig. 9. 4

F. See page 5,

Page 5

4 •• •e4eewe* *i&

lU KtrL-AUli I Mt SMU l i Lt

Turn the machine in direction for sewing until the point of the

needle just enters the needle plate hole; take the shuttle by the

center pin W with the left hand and place it in the race, so that

point of shuttle will be fi’om you and over arrow on thread cast off,

so that the holes in the shuttle will drop on to driving pins in race,

then replace the shuttle race cover.

DO NOT FORCE the shuttle into race. It will enter readily

wllPTI in -nnAnAT* nn.dlfin'n

' ' t' * -

---

-

Should the machine at any time act badly in sewing or running

it would be well to remove shuttle and clean it and the race, which

is but a moment’s work.

To replace the bobbin case, it need not be held as when remov

ing, but simply slip it on the pin in shuttle, with the tension project

ing upward, and push it into shuttle as far as it will go, when the

spring latch will pass over and retain it in that position.

The thread should be allowed to project about one inch from

TO WIND BOBBIN ^

Place spool on spool pin, pass the thread down ^

through the rear hole in arm of cover plate, then to

_

____3 _

_______

_____

______

uie leiir uuuer aiiu over tue ¿inu uuwii uixougu i.xuuu

.¿.г.J

__________

__

hole. Put the end of thread through hole U in bobbin S

from inside out, place bobbin on

bobbin winder spindle, raise winder

so belt will drive it, loosen thumb % Bobwn

screw in hand wheel, run the machine as in sewing,

holding on to the end of thread until winding is

started, then break off thread and finish winding.

LOWER TENSION

Pig. 8 represents the bobbin case. To regu

Fig. S, Bobbin Case

late the lower tension, turn the screw T to the

right to tighten, and to the left to loosen the same.

TO THREAD BOBBIN CASE TENSION

Place bobbin in case so that thread will come from bobbin on

same side as hole B in bobbin case; pass thread through slot A to

hole B thence across opening, drawing it down under lip C then

pull it up until thread passes out under tension spring D.

The tension on bob

bin case should be the

same as the upper ten

sion.

Fig. 9, Shuttle

Fig, 10, SHrattle H»«e Cove»

Page 6

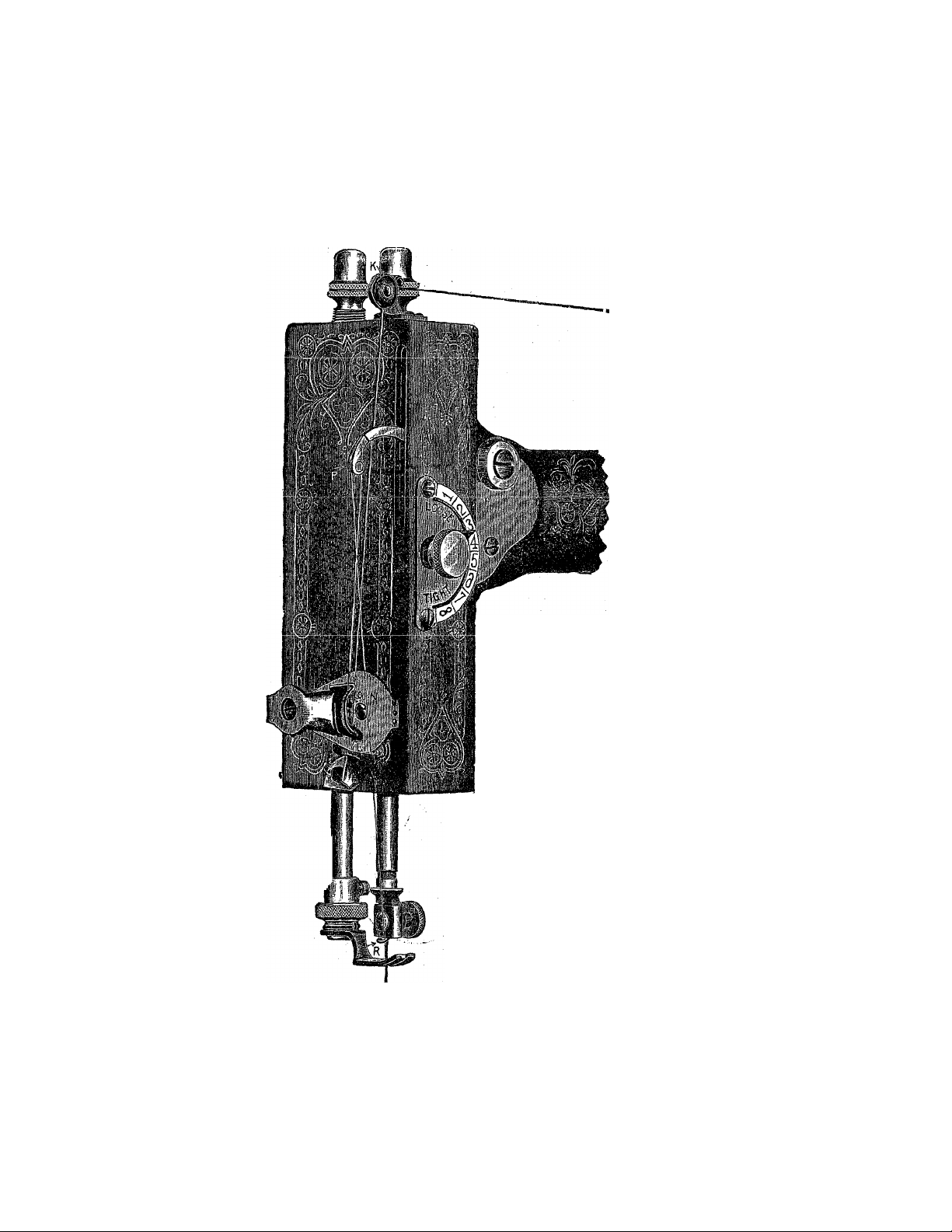

i>lMctiONS FOR THREAbiNd

Place the spool on spool pin, take the thread in your left hand

holding it taut with the right during the whole threading operation.

Pass thread from

spool over check

spring K at top of

face and down

under point L

now pull thread

upward until it

passes through

the eye of spring

N and into notch

O, then into end

of .take-up pthen

down through slot

R in end of needle

UCli ctliU

eye of needle from

left to right, al

lowing about 3

inches of thread

when take-up is at

its highest point.

To draw up the lotver thread, r&ise

the presser-foot, take hold of end of

upperthread and turn, the handw;heel

once around, (moving upper side of

wheel from you,) which will drawthe

lower thread up through needle hole.

Pass the ends of both threads

under the presser-foot and you will

be ready to sew.

Note.~T}o not run the machine with

the presser-foot down on the feed without

cloth under it. Do not pull cloth cc or from

you in such a manner as to bend the needle.

THE TENSION

The illustration above represents the Ten

sion Regulator and Indicator for the upper

thread, an entirely new and useful device:

The half circle is marked with a scale run

ning from 1 to 8, with the word “loose'’ at

Ä

_____

-t

____

Jf TWT-.

Ki- 12

ngUre X auu ugiit at inu. 8, No. 1 being

the slack and No. S the tightest tensior

Page 7

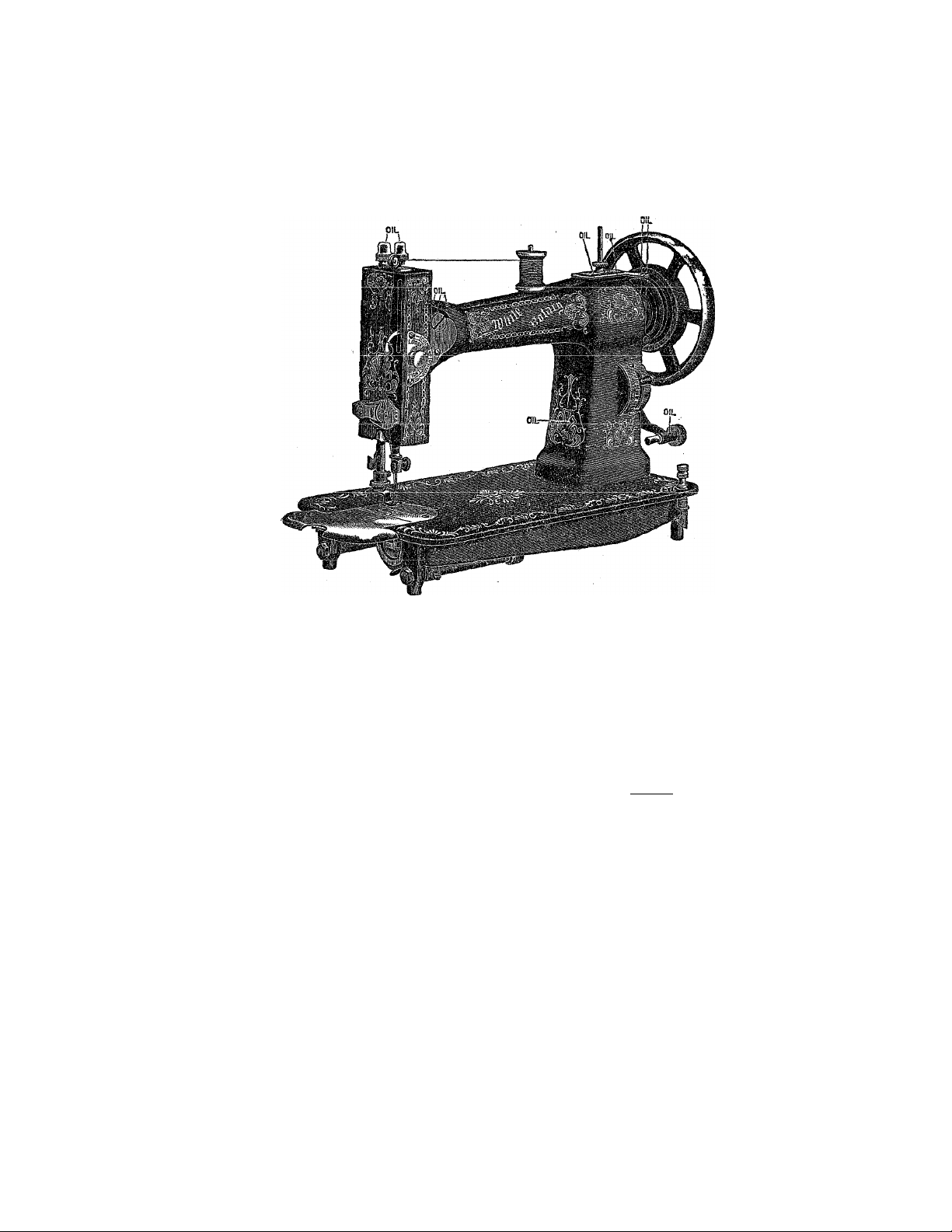

OIL PLACES AS INDICATED BELOW

The regulator is located at the right end of machine on the front side or

•arm. TO SHORTEN stitch more the lewr down. TO LENGTHEN stitch

move lever up. No. 1 indicates the shortest, and No. 7 the longest stitch.

TO CHANGE THE LENGTH OF STITCH

TO REGULATE THE TENSION

To loosen the tension, turn the thumbscrewon the dial to the left

n-xrVn tTr4 11 -Art»TTi«zi

VV .iI.J.V/i.1. VV iXA AAIV,# V ^ L/AA\P JjJV/AAA UW¥ CU.X VAO AAg VAA W 1.

4'n■?4' 4*nT»v» 4-/%

A. \J V/A^AAWC^AX Ml/f VUXAA \j\J

the right, moving the pointer towards No. 8. By this means the

;same tension can always be duplicated, thus obviating the necessity

•of experimental trials, as is the case with other machines. If a tight

tension is desired, both upper and under threads must necessarily be

tight. If the upper thread is tight and the lower thread loose, the

upper thread will be drawn to the top thus: If the

lower thread is too tight, it will be drawn straight on the bottom of

goods, thus: \ When you desire the goods to look alike

nn both sides, and be elastic, balance the tension thus:

THE TENSION RELEASER

, The tension releaser is operated by the presser-bar lifter. By

means of it, all tension is taken off the upper thread when the

presser-f oot is raised, and the work can be taken out without pulling

the thread down by band.

^PARTICULAR NOTICE—The tension cannot he regulated when the lifter

is up because the Releaser is operated by the presser-bar lif ter,

7

Page 8

TO COMMENCE WORK

In tiireRdin" the needle mid bobbin case rt.speclively.yt'U .shoidd

leave an end of thread about two inches in lenjfth to cacli. ilold the

end of the upper thread loosely in the left hand, and with tlie right

hand pontlyrevolve the hand-wheel until the needle passes to its low

est point and rcUinis. a loop will be foniK.-d through wijich the shut

tle will pass, and. as the needle ascends it will draw up the Icrvor or

shiittlc thread, and the machine is ready for praclicrd operation.

TO REMOVE WORK

Step the machine with the take-up at its liighesl point J riUjsG the

prts.sci’-foot with the lifter which slackens the upper liiread; then

lake hold ofynur work with your left hand and pul! it direct'.y from

you, keeping the top thread in the slot of the presser-foot, '.vhici'. wiÜ

prevent bending ihe needle. Now raise the work and draw the

threads into the tliread cutter on the pressor-bar and indl dovnward, which wil! cut the ilireafis iiie proper length to com.Tiente

wi>rk again.

EXPLANATION OF DIFFICULTIES THAT SOMETIMES

OCCUR WITH BEGINNERS

If the t'jip^r Hrrio.f.l brrul:-'-'. it may be caused by the needle not

is.ing properly .sot. or the itn-.cldne no: tht-'-aded correct iy, or the

u]iper ten.-ioa loo tight, or the thread une'on and the nocdl... p,.-;

.small J'i>r it, or the needle eye to.,» .sharp, or the presser-i'ool attached

to the machine so that the needle rubs it iti pa.-sing.

If liu ni'-<h i‘ iln rm! hi i'i!:.'!. it may be ca.useii by the bo'oi.'in ca;.c

i.'cing improperly Ihreaded. or too much Un.sion upon it, or by the

bobbin being wound loo full .so that the thre.-id slips ovf-r the ends of

the bor>bin in the oe'hbi.n case.

If flic nx.dfc breahK. it is more than likely your oun fault,

cau.sed by pulling the goods to or from you in .such a rnanner Und

the needle .«irijces the Ihro.at plate atul is botuid to break. Tin? nf.-odle

nu'-y however, break in trying to sew cxlra.ovdin.avy heavy sejun.-;

when the pressure on Ihr- presser-foot is no: lieavy enough.

To create more pressure upon the goods turn the pro.ss.or-bar

nut on top of the prosser-bar to the risriit : to derr-cise ihe pre-sore

Tarn it to the left.

If it makes loop stiUrhe.s, it is most sure to be cau.sed 'ny t ]oc-.,o

!( nsion both top and bottom.

If ihf y!:ipf> .'■f-ichcs.ih^ ri'.edie i - either btu:! cr me in

right position.

I f the sHli.lii’s lire i”if (. I I /?, it may h-.- caused by the pres-or-''c't

not resting evenly upon the fabric sewed, or b'e the feed n')l being

nigli enou.gli. or by the stitch being too sh u-t. or l;y pulling tlie clo^h

(■■r by using too fine? a nedlie with too coarse or urseven thi’oad.

Tf i.he machine should be run without .sewing and thread get in

!lic shuttle race making' the ■/><:■ rnn heui'ii. lake out bobbin cas-.-

.'ind runtho machine in Ihewj’ong directio:, ;itwill cut the thrciid oub

-Vij.'iVf- Tl-n ic-ii'iu!!' liaivl i'houid idwav-' \ e ti:;'?!'. eaouvr’ii ns; to slie. if ¡',

'Pj’S or does Tie* fo;'ce ti:e m-(-d!e ti'-rouch thick gonds, cut oif a vi '-v shorr n!,;cc

and re ailju.-r t’nr ends. The belt should rot Vo so ticht a; to p'-rvont au (.‘■.vS;’

niotifn o' liic onichiac.

C:

i-

Page 9

ulKtuiUJiN::» tuK u;3j;nu injc. a 11 ACnm£.iN i :>

*

^ ■ -..■■■ ■ --. = ---

?S==S~^^====B=

' -

Hemming

Raise the lakc-up to iis liigliest poini. remove the presser-fuot and

in its place attach the hcnimcr. Trim the cdj,‘e of doth on a curve

and insert in hcimner far criougii to permit the needle to enter the

cloth at its extreme edije, (See Fiy. 2 above), then proceed to sew.

keeping the edge turned as it feeds through.

Felling

Tiic hommer is also the feller. Sc'.v together two piece.s of clotlt

with tlio under edge projecting be-iwecn .'.■ and '■ ! inch beyond the

tipper edge; then trim the edges if necessary and opcii the work; oat

\^roiig -ide up. and fold down the wider edge, toward the left, over

tl'ic narrow edge, and then pass the ¡folded edge info the feller the

same as in orrlinary hemming.

lihistration above represents an oj»erator in the act of compietuig

Page 10

lie s

Zs:

Page 11

No.

14® Take up roller stHd

141 Take up roller ...

Take up screw lor хз

2T9

263 Screw to fasten stitch Indicator

264 Screw to fasten attachment holder

266 Screw to fasten rear feed rock arm

267 Screw for head of main connection

268 Screw to bind screw 760 in shuttle

210 Screw to fasten face

215 Screw to fasten -presser bar lifter

233 Qullter .............................................................

234 Screw to fasten qullter and thread

345 Gauge screw

271 Presser bar lifter washer

276 Screw to fasten S33 to face

279 Needle bar bushing

280 Needle screw and clamp ........................

281 Needle screw nut

341 Washer for 72S ...............................................

342 Attachment holder complete............................

343 Presser foot

345 Hemmer

347 Presser bar lifter and releaser cam.

348 Presser bar lifter screw

355 Tension indicator -complete

357 Tension disc ......................................................

359 Screw and nut to connect 35S and

360 Guide pin In slot of tension plate.785

363 Screw to adjust lower end of face..

364 Screw to clamp feed bar centers 726

see Thread cutter

369 Needle bar .........................................................

452 Head latch guide washer

153 Head latch spring

154 Head latch nut .................................................

536 Lock nut for 758 ..............................................

540 Screw to fasten 767 in arm

542 Head latch .......................................................

543 Washer for head latch sprmg...........................

548 Foot gatherer

593 Stud for revolving spool standard ..

594 Sleeve for revolving spool standard.

595 Screw to fasten 593 in arm..............................

617 Bobbin winder pulley

701 Screw to bind needle bar link screw

702 Screw to fasten feed cam 763, and to

704 Screw to fasten main connection stud

705 Center for feed rock shaft 72i and

706 Nuts for 705 and 797 ......................................

707 Screw to connect 714 with 723 and

708 Nut for 707 and 721 .,i...........

710 Pin in feed fork for shifting block

711 Shifting block In feed connection 714

714 Peed connection

715 Peed connection link

716 Pin for feed connection link 719 . ■ . ■

717 Stitch adjusting lever.......................................

718 Stitch adjusting stud ^

719 Friction washer for 717

720 Sleeve for 71S

.............................................................

plate 722 take up plate 798, check

spring bracket 794 ......................................

342 to presser bar 775

723 to rock shaft 724 and thread

pull o£E rock arm 755 to rock shaft

758 ..............................................................

747 ...................

race .............................................................

block 779 and guide 780 to presser

bar 775 ........................................................

cutter ...........................................................

.....................................................

.....................................................

............................................................

858 Tension spring on inside of face ...

7S5 ..............................................................

In feed rock shaft 724

.....................................................

...............................................

784 In take up cam 762

locate take up cam 762

708 Screw to tighten take up cam 762 on

shaft 761 and to fasten 842 in arm

751 In

....

thread pull off rock shaft 756 .. .

754 W'ith 756 and to fasten bobbin

winder to arm .............................................

711 ......................................................... ■ ■

................................................

ed! e 'jar bushing

................................

......................................

............

.............................

....................................

...............................

.........................................

............................................

...................................

.............................

.............

...................................

............................................

...............................

.......................................

...............................

...............................

................................................

.........

....................................

...........

...........................

.....................................

...................................

....

...............

..

■

No. Price

Price

721 Screw to connect 715 to 717........................... 06

$0 05

722 Stitch Indicator .plate

10

723 Eock arm on rear end of feed rock

02

02

02

02

03

02

03

02

10

02

05

f)l

02

06

10

05

01

40

25

40

15

02

50

03

05

06

01

02

02

02

25

02

ПЯ

05

02

02

05

02

S.j

05

05

02

08

02

02

02

02

06

03

06

02

03

07

26

13

05

12

15

02

03

shaft 72» .................................................... 13

724 Feed rock shaft................................................ 50

725 Feed bar .......................................................... 50

726 Centers for feed bar 725

727 Feed

728 Screw to fasten feed 727 to feed bar

729 Spring washer tor bobbin winder

730 Shuttle race

731 Latch to hold shuttle race cover 834

732 Spring for 731

733 Pin for 731....................................................... 01

7S4 Spring pin to hold shuttle race cover

735 Spring for 734 ................................................ 02

736 Washer on 734

738 Thread guide plate on S34

739 Screw to fasten 738 to 834

744 Bobbins

746 Crank on rear end of shuttle shaft

747 Main connection complete

745 Main connection roil

749 Screw to adjust main eoimectlon to

750 Main connection slide block

731 Main connection stud ....................................... 15.

752 Feed raising and thread -pull off cam 20

753 Screw to fasten 752 to 80S

754 Eccentric connection for thread null

755 Thread -pull off rock arm

736 Thread puli off rock shaft.................................. 25

757 Thread pull off ................................................ 59

758 Screw to connect 757 to 755 .......................... Ó2

750 Thread pull off slide block

760 Screw to connect 759 to shuttle race

761 Upper shaft

702 Take up cam ..................................................... 50

763 Feed cam.......................................................... 25

764 Screwtogoinrearendof 7éí

765 Forward hushing for upper shaft 761 25

768 Screw to fa-sten 765 in arm S14 and

767 Rear bushing for upper shaft 761.. 20

770 Needle Plate

771 Screw to fasten 770

772 Bobbin winder complete

775 Presser bar ;..................................................... 15

776 Presser screw .................................................. 15-

777 Needle bar cap ................................................ 15

7TS Presser bar svjring

779 Presser bar lifter block

780 Presser bar guide

781 Needle bar link

782 Needle bar block ............................................. 15

784 Screw to connect T81 to take up cam

785 Tension plate

788 Auxiliary spring ................................................ 12

787 Adjusting washer for 786

759 Screw to connect 8.39 to S3i and

790 Take up complete

701 Take up screw.................................................... lo

792 Spring for latch 839

793 Take up cover plate

794 Check spring bracket ...................................... io-

793 Rear spool standard

796 Rear cover plate ................................................ 08

797 Table hinge compiete ..........................

799 Washer for 797

...............................................................

725

........................................................

frame .......................................................... 01

on race 730

834 on race 730

..........................................................

80S ............................................................. 25

slide block 750

off

..............................................................

730 ............................................................. 03

782 to 309

762 06

to Inside of face 813

(Continued on next .page.)

..........

........................... 10

.................................

....................................................

................................................

................................................

.........................................

......................

....................................... . 02

.....................................................

..................................................

...................................................

...........................................

............................................

........................

...................................................

.............................................

..........................................

.......................................... 02

...........

.............................

............................

.............................

......................................

...........................

.............................

...............................

...............................

................................

........................................

................................

...................................

..................................

...................................

.......................................

........................................

11

.............

......................

...........

05 ,

b‘0

02

1 25

08

02

05

01

07

02

S8

75

10

15

02

15

15

10

1 50

¡0

02

40

02

33

19

25

15

25

So

02

02

40

02

0.5

08

SO'

Page 12

No.

802

Strew to locate needle bar block 782 02

SOi

807

80S

^809

Í813

*814

815

820

821

822

823

824

82G

827

S2S

829

S.30

831

832

833

834

835

836

837

838

Screw to clamp shuttle race 730 anti

shaft 808 ......................................................... 02

Gauge ...................:.......................................... 05

Shuttle shaft driver and thread cast

off complete................................................... 1 00

Screw to adjust auxiliary spring 7S6 02

Bed

Arm .................................................................... 2 73

Pace .................................................................. 1 23

Screw to fasten tension Indicator

355 to 813.......................................................... 02

Washer on auxiliary spring 786.... 01

Washer under latch S39 ........................................ 01

Stud for lower end of main connec-

aon 747 ............................................................. 03

fetén S42 in arm................................................. 03

Plate for 725

Sirort rivet for S26

Long rivet for 826

Screw to fasten hed to arm .............................. 02

Hand hole cover complete

Lfltoh for cover 830

Spring for latch 831

Catch on lower end of face to retain

cover 830 when raised

Shuttle race cover .............................................. 1 00

Shuttlé

Bobbin case complete ........................................... 60

Bobbin case tension spring ........ 07

Bobbin case tension screw' ................................... 02

to take up rear bearing of shuttle

....................................................................

Screw to fasten crank 746 on rear

end of shuttle shaft SOS and to

........................................................

................................................

................................................

............................

..............................................

...........

................................... 03

.....................................

..............................................................

Numbers preceded by a star (*) are not illustrated

Price

2 75

02

05

02

1 00

20

03

1 50

No.

So9

Latch to retain bobbin ease 836.... 10

840

Auxiliary cam

Feed fork and stud complete

841

Bearing for feed fork stud

842

Screw in end of feed fork stud .... 05

843

*84, .5

Loose pulley on hand wheel

846

Wire retainer for 845

847

ffhumb screw in hand wheel.

848

Ijock washer for 847

852

Screw to fasten hand wheel toupper shaft 04

*8 5 3

Hand wheel

855

Bobbin winder center

..................................................

......

................................................

............................

................................

............................

.......................................

...........................

......

..................................

......................................

Price

' 05

3.5

15

SO

- 06

OS

02

2 00

OT

DIRECTIONS FOR USING THE FOOT GATHERER

Remove the presser-foot and replace with the Gathering Foot

TO GATHER, PUFF OR SHIRR

Place the goods under the foot the same as in ordinary sewing.

For fine gather use a short stitch. To increase the fullness lengthen

the stitch. For greater fullness tighten tension.

12

Page 13

HEMMING AND SEWING ON LACE

ONE OPERATION

Our hemmer and feller which accompanies each machine, is

now made with a slot—6. (See illustration above.) In this sloB

place the edge of the lace and sew it on at the same time as In

ordinary hemming.

WIDE HEMMING

Any width hem can be made with the hemmer and feller upo»

thin fabrics by simply folding the goods the desired width of hem

and then passing the edge through as in narrow hemming,

13

Page 14

Cl«.* •

Draw out slide of machine

about half way, insert ear of

shirring plate into gauge screw

hole in needle plate, and holding

down the shirring slide, push

slide up in its place, and fee

shirring slide will be held firmly

in that position.

Loosen screw 6 (see page 16)

and remove separator, placing

the goods to be shirred between

the blades, and shirr at any de

sired distance. ^

Be careful not to use rufiier without separator or shirring blade

and cloth above,

for in so doing the rufiier teeth will be broken or

injured.

To Put Ruffling on a Band Edge Stitched With

or Without Piping.

Take striped calico or plain colored goods, cut on the bias in

strips full one half inch wide, folding in center. Place the piping

in guide 7 with folded edge to the right, then take the band and turn

down on edge a quarter of an inch and place in guide 8 having both

ends down under foot. The guide can be adjusted to right or left by

loosening screw 9. Place the ruffling to the right between the blades

and in guide 4; if wider ruffling is desired remove separator and us€

shirring slide. To use facing with shirring slide place facing unde:

shirring blade 1 and in guides 2 and 4.

To Make Heavy Pleating.

Cut Lonsdale cambric in strips one inch wide lengthwise of the

goods, fold in the center and press the folded edge down smooth.

Adjust the goods with folded edge to the left and between the

springs of>ruffler, then in gauge 4 (see page 16). Set a long stitch,

turn adjusting nut 5 to No. 4 on gauge, placing the band in guide 8

in the same manner as when using piping. This will make a very

large sized pleat and be stitched on the band.

To Make Scallop Ruffling.

Place the goods in rufiier just the same as for making large'

pleats, except to remove guage 4 from rufiier and shorten the stitch

of machine. While sewing, move the goods to the right and lef^

alternately and far enough to make the scallops of desired depth

Scallops can be made of uniform length by counting the same num. '

ber of stitches between each alternate movement to the right or left.

17

Page 15

OIL PLACES INDICATED BELOW

KEEP MACHINE WELL OILED

Oil in the all the places indicated on page 7. To oil the under

side of machine, slip the belt off the balance wheel and turn the

machine back on its hinges and oil in places indicated above.

THE IRON STAND

Oil occasionally the treadle centers, upper and lower end of pit

man and the balance wheeThub bearings. Whenever you oil the

machine work it a little to distribute the oil. After standing a few

moments take a soft cloth and clean the superfluous oil from the

Japaned parts of machine.

TO CLEAN MACHINE

If the machine is dirty or gummed up with poor oil, oil thorough

ly in places indicated above and on page 7, using Kerosene (coal oil)

run the machine for a short time, wipe dry and oil with good sewing

machine oil.

18

Page 16

Hemming

We furnish with each machine five

assorted widths of hemmers. Select

the width desired and substitute it for

the presser-foot. Take the cloth in

both hands, the right hand in front

of the hemmer and the left behind.

Place the edge of the cloth in the hemmer drawing it back and forth until the hem is formed, stopping with

the end under the needle. Drop presser-foot and commence to sew

Guide the cloth so as to keep the hemmer full. To change stitching

near or far from edge, loosen thumb screw and move hemmer to

right or left as desired and tighten screw.

Binding

Remove the presser-foot and sub

stitute the binder. Cut the binding yi

inch wide (on the bias if convenient).

Pass the binding through the scrolls

\ of the binder and under the presser-

■ r

cloth with the left hand, and let the binding glide easily through

the fingers of the right. To change the stitching near or far from the

edge, move binder lug A to right or left as desired.

foot. Place the edge of the goods to

be bound between the scrolls of the

binder, drop presser-foot, guide the

Under-Braider

Substitute the under-braider foot

(which is found in the box of attach

ments) for the regular presser-foot.

Place under - braider on machine

same as the shirring plate; draw the

braid under and through the tube

and a httle past the needle. The

pattern to be braided should be

stamped on the wrong side of the cloth. Place the goods under the

presser-foot same as in regular sewing, following pattern carefully.

This stitches the braid on the cloth from the underside.

19

Page 17

Stand for Nos. 74, 75, 76, and 85

T 623

2Q

Page 18

Parts for White Sewing Machines may be

Secured Anywhere

list of stand Parts for Ball Bearing Stan&,White Box Top, White Automatic Swing J>ropa

Nos. 70. 74. 75, 76, 77. 80 and So and CabiiketaNos. 72,and 78

206

207

209

211

223

Stand caster ......................................................

Pin in stand caster

224

225

Stud in treadle, for pitman.

231

309

Pelt head tack ........................................

364

379

*384

Brace for box top

*385

Dress ^ard for box top

Rest pin in table for box top.................................

*389

437

Pin in head carrier for slotted stop

513

Screw to connect cable to lid

516

Screw to connect cable to lever

517

Nut for adjusting stud...........................................

519

Drip pan for Nos. 70, 74, 75, 76, 77,

*530

Spring for swing bottom

531

532

Eyelet for 531 — . ...............................................

Drip pan for Nos. 72 and 78

*533

Latch plate for head carrier........................

544

Treadle for No. 80 drop........................................

*550

Treadle support for No. 80 drop

*552

553

Caster for No. SO drop

563

Screw to fasten treadle support to leg...

564

Treadle for Nos. 72, 74, 75, 76, 77, 78,

565

566

Treadle center ......................................................

567

568

Dress guard for Nos. 70, 72, 74, 75, 76,

569

Screw to fasten link No. 621 to plate

No. 630 ............................................................

Adjusting screw in lower end of pitman

Screw to fasten stud in treadle, treadle

pin in balance wheel

centers in treadle support and crank

Screw to fasten dress guard and brace to

leg

...................................................

Wood screw to fasten swing drawer to

table .................................................................

Set screw to tighten balance wheel cone

573 and crank pin cone 577

Balls for balance wheel and pitman, per

100 ................................................

Brace for Nos. 74, 75. 76 and 85 drops..

80 and 85

Treadle support for Nos. 74, 75, 76 and

85

...

.................................................................

and 85

Pitman for Nos. 70, 74, 75, 76, 80 and

85 drops

..........................................................

Balance wheel for Nos. 70, 72, 74, 75, 76,

77, 78. 80 and 85

77, 78, SO and 85

.......................................

................

...............................................

..................................

........

..................

.........................................

......................................................

......................................

................................

........................................

.......................................................

...................................

..........................................

..............

....................

...............................

...........................

..........................

..

..................

.......................

..

..

..

Numbers preceded by a star (*) are not illustrated.

Where the parts such as pitman, treadle rod, etc. are ordered to be sent by mail,

postage will be charged thereon, '

570 Stud in dress guard for balance wheel

.02

.03

.02

.02

.05

.02

.02

.06

.02

.02

.50

.60

.50

.05

.60

.01

.02

.02

.02

.25

.06

,01

.25

.04

.75

.50

.10

.50

.03

.50

1.50

1.00

.10

.06

568

571 Nut to fasten stud 570

572 Rear cone for balance wheel stud 570... .05

573 Front cone for balance wheel stud 570.. .08

574 Ball race in balance wheel hub

575 Bail retainer for ball race 574.

576 Crank pin in balance wheel, for pitman

577 Front cone for crank pin 576

578 Ball cage for crank pin balls, with balls .08

^579 Pitman for No. 77.................................................... 50

*580 Treadle suppoii; for No, 77..

*581 Right leg for No, 77

*582 Left leg for No. 77

*583 Pitman for box top......................................................50

*584 Treadle support for box top........................................50

*585 Right leg for box top

*oS6 Left leg for box top

*587 Balance wheel for box top.................................... 1.50

*588 Stud in leg for balance wheel 587...... ,15

*589 Treadle support for Nos. 72, 78 and

#590 Pitman for Nos. 72,. 78 and cabinets. .50

*592 Treadle for box top.....................................................75

599 Wire bail for belt grip................................................08

600 Clip for 599 ........................................................... .02

601 Spring for 599........................................................ .05

*603 Treadle for No. 70................................................... .60

*604 Treadle supnort for No. 70

*605 Brace for No. 70........................................................ 60

619 Cable adjusting lever

620 Adjusting stud and plate for cable lever. .15

621 Link to connect swing fi'ont to head

622 Cable (20 in. long) for Nos‘ 70, 72, 74,

623 Cable guide ..............................................................30

624 Swing cover for corner of head carrier.. ,30

625 Eight kg for Nos. 70, 74, 75, 76 and 85. 1.75

626 Left leg for Nos. 70, 74, 75, 76 and 85.. 1.75

#627 Brace for No. 77.,

630 support for cable adjr^ting lever No. 619 .10

631 Head carrier hinge ....................................................06

632 Pin for head carrier hinge No. 631...,. .02

.....................................................................

(including rear cone) .......................................

cabinets * • 50

carrier ............................................................... .29

75, 76, 77, 78, 80 and 85...........................20

.........

......................................

.................................

..................................

......................................

......................................

...............................................

.................................................

..............................................

.................................................

.......................................

................................................

....................................................

15

.12

1,75

1.75

1.75

1.75

60

08

02

50

60.

03

08

20

f{0

21

Page 19

TUST one more tíme saver which the busy user wili eagerly

welcome—a Scissors Gauge with which one can easily and accu

rately cut bands of various widths, either straight or on the bias.

It’s an attachment, the value of which will be grasped on sight

by every sewer and highly appreciated for its thorough utility.

This attachment is included free with the attachments supplied

with this machine.

THE SCISSORS GAUGE

The Scissors gauge is for cutting bands qf various widths, either

itraight or bias. The sliding scale is adjustable for the widths of

band desired.

Place the gauge upon the scissors, as shown in the illustration,

slip the edge of the cloth in the gauge and proceed to cut the band.

The tape for the Binder should always be cut on the bias, also th©

piping which is used with the Ruffler.

The letter P indicates the proper width for

a bias fold, which is to be one-half of an inch

wide when finished.

The Scissors Gauge »fhe letter B indicates the width for cutting

bias bands which are used with the binder.

C is for corded or plain piping. The piping is cut bias and

. folded double to use with the ruffler.

With the aid of this gauge any

number of folds may be cut of

exactly the same width. Those

who have tried know the difficulty

of doing this with the scissors

alone. Everyone who uses a bias

gauge is delighted with it.

O

rlaoing the Gauge Ou the Scissors

Buy a yard of 44 inch lawn.

Cut it into bias strips % to 15-16

of an inch wide. Roll it on card

board and keep it in the machine

drawer. It will furnish the bind

ing for the inside seams of the

>£white se wing for months to come.

22

ti

©

Cutting a Bias Band with the help of the Gaug«

Page 20

THE EDGE-STITCHER

A Combined Edge-Sdtching, Lace-Joining and Piping Attachment

HE EDGE-STITCHING ATTACHMENT is fastened to the

machine in the same manner as the Presser-Foot. The

T

different slots which are numbered from 1 to 5 in the illus

tration serve as guides for sewing together laces, insertions, em

broideries, sewing in position folded or hemmed edges, bias-folded

'•tai*

material or piping, etc.

This Attachment is very useful in trimming such articles

of clothing as aprons, women’s and children’s dresses and under

wear, shirtwaists, silk blouses, boys' rompers and suits, or for articles for household

decoration such as fine bureau scarfs and thin curtains, baby carriage covers and

doillies.

Very beautiful effects may be

obtained in yokes, guimpes, sleeves

collar and cuff sets, vestees, fich

us, lace waists, camisoles, etc. by

joining rows of lace insertion alter

nate rows of lace and embroidery

insertions, or alternate rows of

tucking and lace insertions.

The folded tape, whidh may be

purchased in any department store

in all colors, qualities and widths

is indispensable to use with this

Attachment. The folded piping,

which may also be purchased

ready turned, will exactly fit the

piping slot in this Attachment.

How to Adjust the Edge-Stitcher

To adjust, move the lug A (see illustration) at the left of the attachment to

the right or left until the desired adjustment is obtained. When sewing two pieces

of lace together, it is very necessary that the attachment is adjusted to stitch ex

actly on the edge, so that the edges will not fold over when laundered.

When sewing laces or soft materials together, it is better to hold the edges

slightly overlapped. This will prevent the lace from feeding away from guide.

When the attachment is properly adjusted, the most inexperienced operator

may sew yards of lace or material together with no difficulty. '

Practical Uses of the Edge-Stitcher

1. Sewing lace and insertion together.

2. Sewing lace and embroidery insertions together.

3. Piping plaits and belts for children’s clothes.

4. Sewing tape to top of stocking to prevent "runners” (patented). -

5. Sewing insertion on material—afterward cutting material away and turning

edges back.

6. Sewing lace on edge of hem.

7. Setting in insertion with edges edge-stitched.

8. Sewing lace and ribbon together.

9. Covering seams with bias bands or finishing braids.

10. Sewing braid on heavy suits and dresses.

11. Sewing on bias bands for trimming—straight or curved. ,

13. French seaming.

23 , V

ipia

Page 21

Practical Buttonholes made with the Binder and Hemmer

It is the desire of every -women to understand the art of rnaking fine buttonholes,

but many women do not have the time to spend working them, even though they

are skilled in the art.

Good practical buttonholes can be made on the sewing machine with the help

of the Binder and Hemmer. These buttonholes are strong and durable and will

wear as long as the garment. They are neat and good looking and a dozen can be

made in a fraction of the time it takes to make one by hand. These buttonholes

are especially practical for children’s underclothes, rompers, dressses and for the

backs of Princess slips.

Directions for Making

If the buttonholes are to be two inches apart, take a strip of material two inches

wide and bind it as shown in B. The marks show this strip divided into sections.

Each section is one-half inch wider than the button. If your button is one-half inch

across add one-half inch, thus cutting your strip into pieces 1 inch wide. If the

button is three-quarters of an inch wide, add one-half inch and cut strip into sec

tions one and one-quarter inches wide.

1

C

A ft^r ■yriur !e+riT\

the presser-foot. Bind the edges with bias binding as shown in D. This makes a

finished strip of buttonholes which are strong and practical for children’s clothes.

E shows the same idea worked out with finer materials; the Foot Hemmer in

stead of the Binder is used to finish the first strip, in order to get an effect dainty

enough to use with dimity, batiste, etc.

E also shows the edges sewn to another piece of cloth, which in Hte case of

practical sewing would be the garment. This is done when they are in the stage as

shown in C, binding the edge of the garment in with the row of buttonholes, then

stitching the free edge of the binding flat on the garment, using the presser foot.

rse eoTir i ■i-a

k.'V'V/ka

iC.i: bv/gCvxxvyS wxxw tt a.4 ix*. v^>

26

j

Page 22

■

■,;.V-i- .■< '. -.--■i.-'- '--.V'V '.■ ;..

WHITE SEWING MACHINE FACTORY, CLEVELAND. O., U. S. A.

■

Loading...

Loading...