Page 1

REX

BLINDSTITCH

SEWING MACHINES

INSTRUCTION

BOOK

MODELS

lOl-l • 101-2 • 101-3 • 101-1 PB

REX TRADING CORPORATION

278 — I5lh AVENUE, NEWARK, N. J. 07103

Afe« Corfa 2§| —. 242-84SS Cabk Arfdrcni REX . NEWARK, N. i.

Page 2

INDEX

PAGE

Changing 1-1 and 2-1 Ratios........................................................ 3

Knee Lifter Adjustment..................................................................... ^

Mounting Machine ........................................................................... 5

Oiling Instructions ............................................................................ ^

Threading Chart ...........................................................................

Needle Setting ................................................................................. 8

Needle Changing ............................................................................. 8

Hew to Sew.................................................................................... 10

Tension .......................................................................................... 10

Proper Stitching ........................................................................... 1 1

Part Numbers and Illustrations

.....................................................

12

Hemmers ....................................................................................... 80

Copyrighted 1964

By Rex Trading Corporation

Printed U.S.A.

Page 3

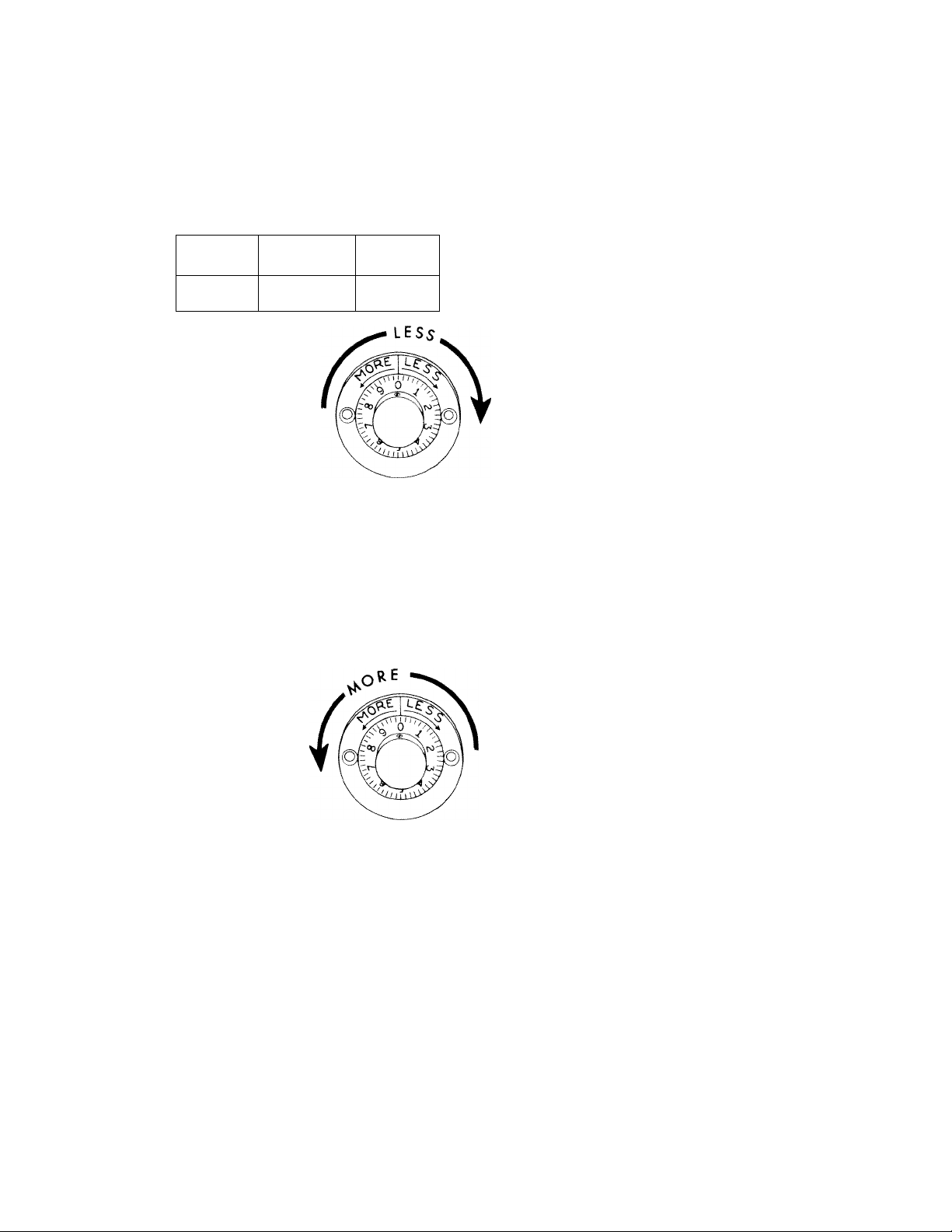

REX BLINDSTITCH RATIO DIAL

¡LOCATED IN REAR OF MACHINE)

RATIO 1-1 to catch every stitch

RATIO 2-1 to catch every other stitch

WHEN CHANGING FROM 1-1 TO 2-1 RATIO

TURN RATIO DIAL

lllh. '*

FROM

TURN PENETRATION DIAL

ONE COMPLETE TURN

TOWARD LESS

1-1

TO

llll.....

2-1

-

WHEN CHANGING FROM 2-1 TO 1-1 RATIO

TURN RATIO DIAL

FROM

TURN PENETRATION DIAL

2-1

TO

1-1

RATIO

RATIO

ONE COMPLETE TURN

TOWARD MORE

Page 4

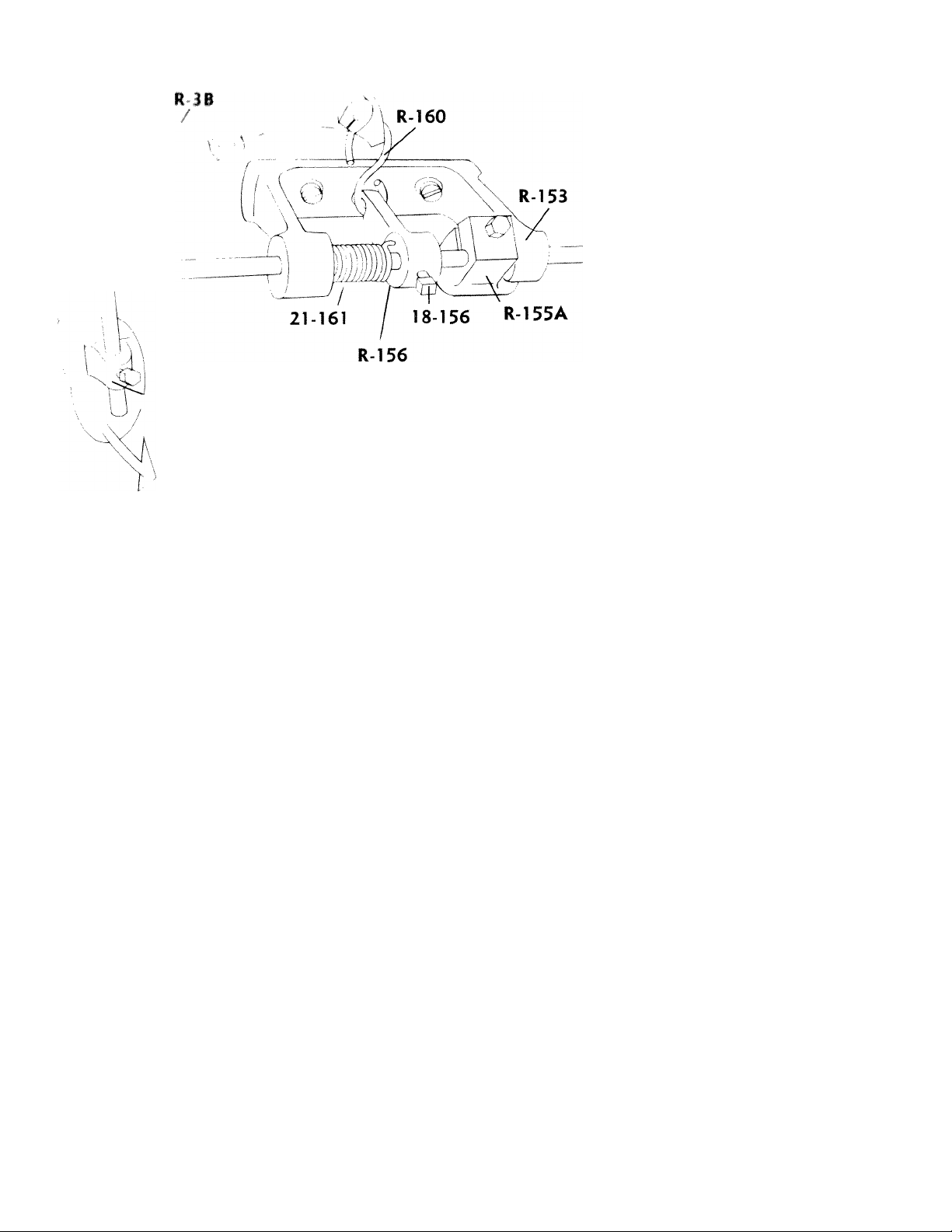

iviNCi: LiricK Mwjua I mcM I

r R-152

If spring

place . . .

1 Loosen set screw ( I 8-156) and disconnect "S"

hook (R-160) from lever IR-156).

2 Wind spring 121-161) by turning lever

(R-1 56) when machine is not fastened to table.

2 When spring is wound, tighten lever set screw temporarily,

^ Attach “S" hook (R-160) back to lever (R-156).

5 Adjust knee lifter to comfort of operator by loosening lever set screw. When

in desired position, tighten set screw (18-156) securely,

g With knee, press knee lifter to right to bring lever (R-1561 down to bottom

of "S" hook (R-160). While in this position, loosen screw on stop bracket

(R-155A), bring stop firmly up to bottom of knee lifter bracket (R-153)

and tighten screw securely. If properly done, it should look like illustration.

-] IMPORTANT STEP:

For the final operation, tap knee lifter (R-152) slightly to the LEFT, This

little “give" should relieve tension of hook (R-160) allowing it to ploy

freely between feed frame (36) and lever (R-156). Keeping this slack is

all important for proper operotion.

WHEN MACHINE IS WORKING, KNEE LIFTER (R-152) WILL NOT SWING

BACK AND FORTH, IF PROPERLY ADJUSTED.

(At no time, should the operator's knee be in contact With the knee lifter when

machine is in operation).

(21-161) is out of

rewind as follows:

Page 5

MOUNTING MACHINE

I ^ Fasten machine to table using felt pad. Tighten screws

evenly, turning each a little at a time.

When an individual motor and clutch unit is employed,

it is recommended that the motor be rated at 13 HP and

1725 1750 RPM. On all standard models, use a 3’/2"

outside diameter pulley. On models intended for altera

tion, use a 2’/2" outside diameter pulley.

When the machine is mounted on a power table, a 4"

pulley should be used. If possible, when using such

stands, the machine should be mounted TO AVOID

CROSSING THE BELT.

The maximum machine speed recommended for any

installation is 3000 RPM, unless otherwise specified.

2 The handwheel's direction of rotation is away from the

operator. It rotates in a clock-wise direction when looking at

the face of the wheel pulley, as shown by the arrow.

Either V-belting or round leather belting may be used. Ex

cessive tension of belt will cause over-heating and freezing

of bearing at handwheel.

Page 6

OILING INSTRUCTIONS

CAUTION: BEFORE operating machine, lubricate

' IN ACCORDANCE WITH INSTRUCTIONS.

REFER TO OIL CHART.

Place a few drops of oil at all points shown on the oiling

chart. All moving parts MUST be oiled.

2 In production use, the machine should be oiled twice daily

Page 7

THREADING CHART

1 Use any type thread which is suitable for the fabric being

’ sewn. This includes mercerized, 00, silk and synthetic

threads.

2 The thread is passed through rear thread guide A, then slides

between two tension discs, B under pin C, through front

thread guide D , . . then down through needle clamp guide

hole E . . . and entering from the underside of needle hole F.

3 Leave thread about 2 to 3 inches past needle hole.

THREADING NEEDLE

I To thread needle at point F

Swing work plate out of way

a.

Depress cylinder out of way

b.

with knee lifter (R-152)

Hold thread between index

c.

finger and thumb

End of thread must be stub

d.

not feather edge.

Page 8

NEEDLE SETTING AND CHANGING

THE MACHINE SHOULD BE CHECKED TO INSURE CORRECT

NEEDLE SETTING TO PREVENT DAMAGE TO NEEDLES.

Depress knee lifter (R^152).

2 Turn hand wheel CLOCKWISE until eye of needle is at slot

in presser foot shoe (R-49A).

3 Slowly release knee lifter . . . the rib (R-612) should JUST

' TOUCH THE NEEDLE.

4. If rib IS pressing up against needle iFig. 1), turn dial

(R^57N) toward "LESS" until rib just touches needle.

If rib is away from needle (Fig. 2), turn dial toward

"MORE" until rib just touches needle.

Fig. 1

47...

v'i.

Fig. 2

Page 9

When needle just touches rib (Fig. 3), machine is set

to test.

“7, To test machine, when ratio is set 2 to 1 ratio — take single

layer of materiel, place in machine and turn machine by

hand. If machine catches once, then does not catch on

next stroke, machine is ready to work.

Keep dialing "MORE" or "LESS" until above results are

obtained on silk or any thin goods.

9. On heavy goods, it should catch on each stroke of needle.

10. You ore now ready to thread machine. Refer to threading

instructions.

CHANGING NEEDLES

If, after turning your dial several times, you experience difficulty

in catching the lower layer of goods, examination may disclose

a BENT or BURRED NEEDLE ... The needle should be changed

immediately.

IMPORTANT — To test if needle is bent, needle must rest on

needle guide R-47. To test if needle is burred, rub fingernail

across point of needle.

THE MACHINE SHOULD BE CHECKED TO INSURE CORRECT

NEEDLE SETTING TO PREVENT DAMAGE TO NEEDLES.

VERY IMPORTANT

Use only genuine REX needles. Accept no others. REX needles

cost no more than cheap imitations, and are ALWAYS available.

Standard Si*e Needles: #10 - #15 - #20 - #25 - #30

Mochines equipped with #25

Page 10

HOW TO SEW

1 With hands 12 inches or so apart, hold hem firmly. Depress

knee lifter, place hem in machine parallel with, and up under

presser foot.

2 Place edge of hem in slot of R-49A, and at edge of gauge

■ (R^125).

3 Start sewing. IMPORTANT: Keep edge of hem lightly, but

' firmly against gauge, keep material parallel to gauge by

KEEPING EYES ON GAUGE ONLY , , . NOT ON NEEDLE

OR SEWING.

TENSION

If material puckers, loosen tension.

If thread is loose, make sure thread is down in tension, then

tighten accordingly. Do not hesitate to turn tension nut several

times as needed.

On thin goods, a light tension is required. On heavier goods,

a tighter tension is necessary.

IMPORTANT: Unlike a regular machine, this machine requires

very little tension.

CHANGING FROM RATIO 1-1 TO 2-1

1 Turn Ratio Dial to 2-1 ... to CATCH every other stitch when

' working with silk or other thin fabrics.

2 Turn Penetration Diol (R-57N) one complete turn toward

■ LESS.

CHANGING FROM RATIO 2-1 TO 1-1

1 Turn Rotio Knob to 1-1 to catch EVERY STITCH.

2' Turn Penetrotion Dial (R-57N) one complete turn toward

■ MORE.

10

Page 11

START SEWING

1 On thin goods or ribbon gauge (R-125) should be set utmost

' at extreme right side of machine and should obtom results

shown in Fig. 1 ,

2 For heavier goods, bring gauge to the left as necessary,

3 Do not pull material to help feeding, do not hold material

back, just hold firm but lightly.

PROPER STITCHING

I Proper stitching.

^ Catches on thin fabric every

other time. (Provided needle

is good.)

2 Material running

off. Bring gauge

over a little to left.

3 Gauge too for to

left, Move gouge

over to right.

5^ If catching each time on light

fabric, turn dial to "LESS" until

it looks like Fig. 4.

1 1

Loading...

Loading...