Page 1

HOW TO USE AND CARE FOR YOUR

ZIG ZAG

MODEL K-lOO

SEWING MACHINE

IMC^TRlirTION RnniC

Page 2

CO NTENTS

1.

MACHINE AND FEATURES

2.

BELT ADJUSTMENT ..

3.

REPLACING NEEDLE ..

4.

REMOVING BOBBIN CASE

5.

WINDING BOBBIN

6.

ADJUSTING BOBBIN WINDER

7.

THREADING BOBBIN CASE

8.

REPLACING BOBBIN CASE

9.

THREADING MACHINE

10.

PREPARING TO SEW

11.

ADJUSTING UPPER THREAD TENSION

12.

ADJUSTING BOBBIN THREAD TENSION

13.

ADJUSTING FABRIC FEEDERS

14.

ADJUSTING PRESSURE OF THE PRESSER FOOT

15.

regulating STITCH LENGTH

16.

ZIG ZAG SEWING

. (Front)

(Back)

..........

............

Regulating Width of Stitch .......................................

Locking Zig Zag Regulating Lever

17.

STRETCH STITCHING

18.

CLEANING SHUTTLE AND RACE ASSEMBLY

19.

OILING THE MACHINE ......................................

20.

BUILT IN LIGHT ..................................

21.

ACCESSORIES ..............................................................................

A. Presser Foot for Straight Sewing

Making Patterns

B. Cloth Guide

C. Zipper Foot

.........................

..............................

D. Buttonhole Foot

22.

BLIND HEMMING

23.

APPLIQUEING .................................................

24.

EMBROIDERING AND MONOGRAMMING

25.

DARNING ...............................................

26.

SEWING ON BUTTONS

27.

CAUSES OF COMMON DIFFICULTIES

..............................’.........

............................

.............................

................................

..........................................

........................

................................

' .

.......................

........................................

........

J3

'

.......................

" 19

.....................

.............

.....................

....................

....................

.....................

.......................

.......................

Page

1

2

3

3

3

4

5

5

6

6

7

9

9

10

11

12

& 14

15

16

17

17

18

19

20

21

21

22

22

23

24

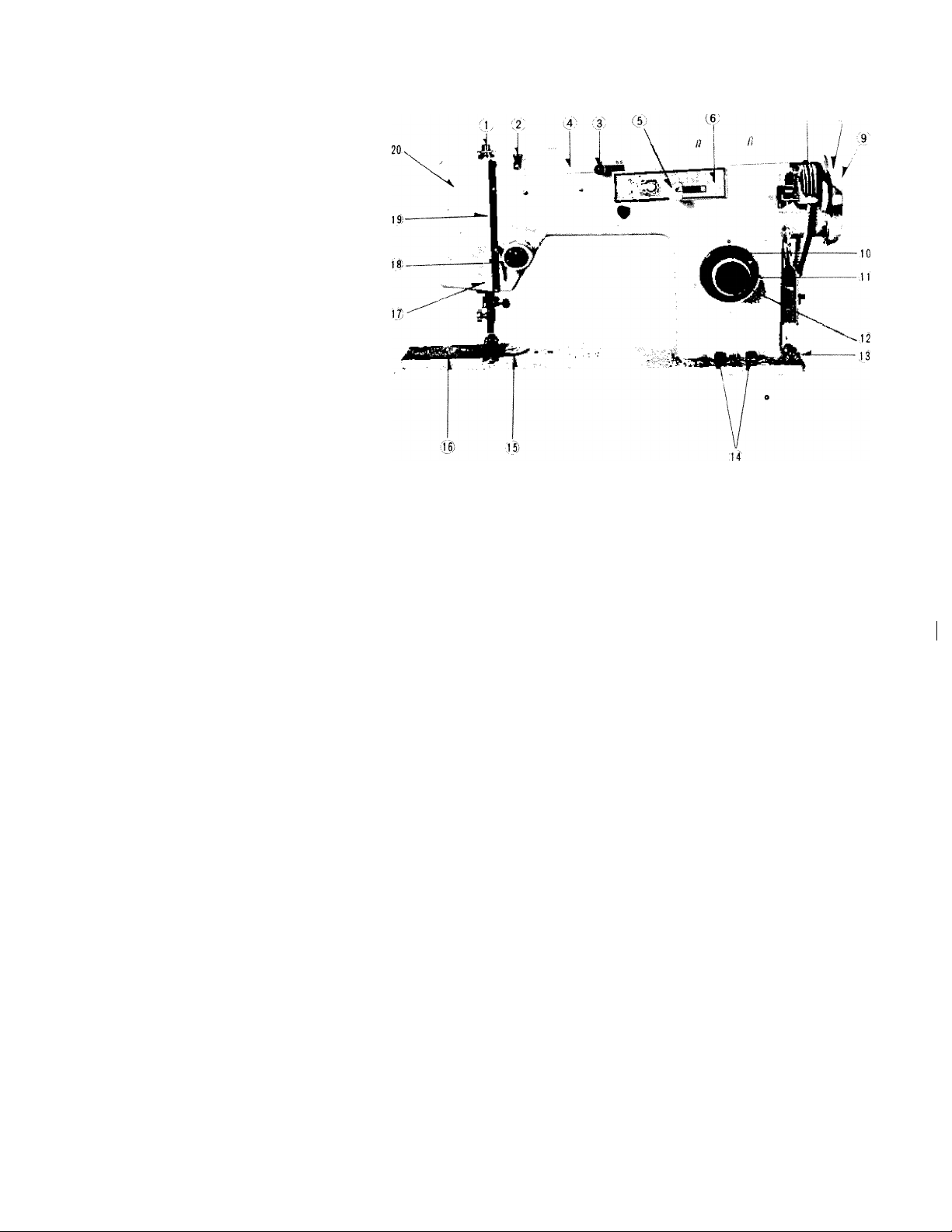

Page 3

1 . MACHINE AND FEATURES

Fig. 1

.7 ;8

FRONT

1. Pressure release (darning)

Thread guide for top cover

2.

3. Stretch stitch control

4. Top cover

5.

Zig zag width control

6.

Zigzag indicator

7. Bobbin winder

Fly wheel

8.

Clutch nut

9.

10. Stitch length indicator

11.

Stitch length control dial

Reverse button

12.

13.

Bobbin winder .tension

14.

Drop feed buttons

15. Needle plate r

16. Cover plate (Slide plate)

17.

Thread guide

18. Tension

19. Take up

20. Face plate

4‘

1

1

1

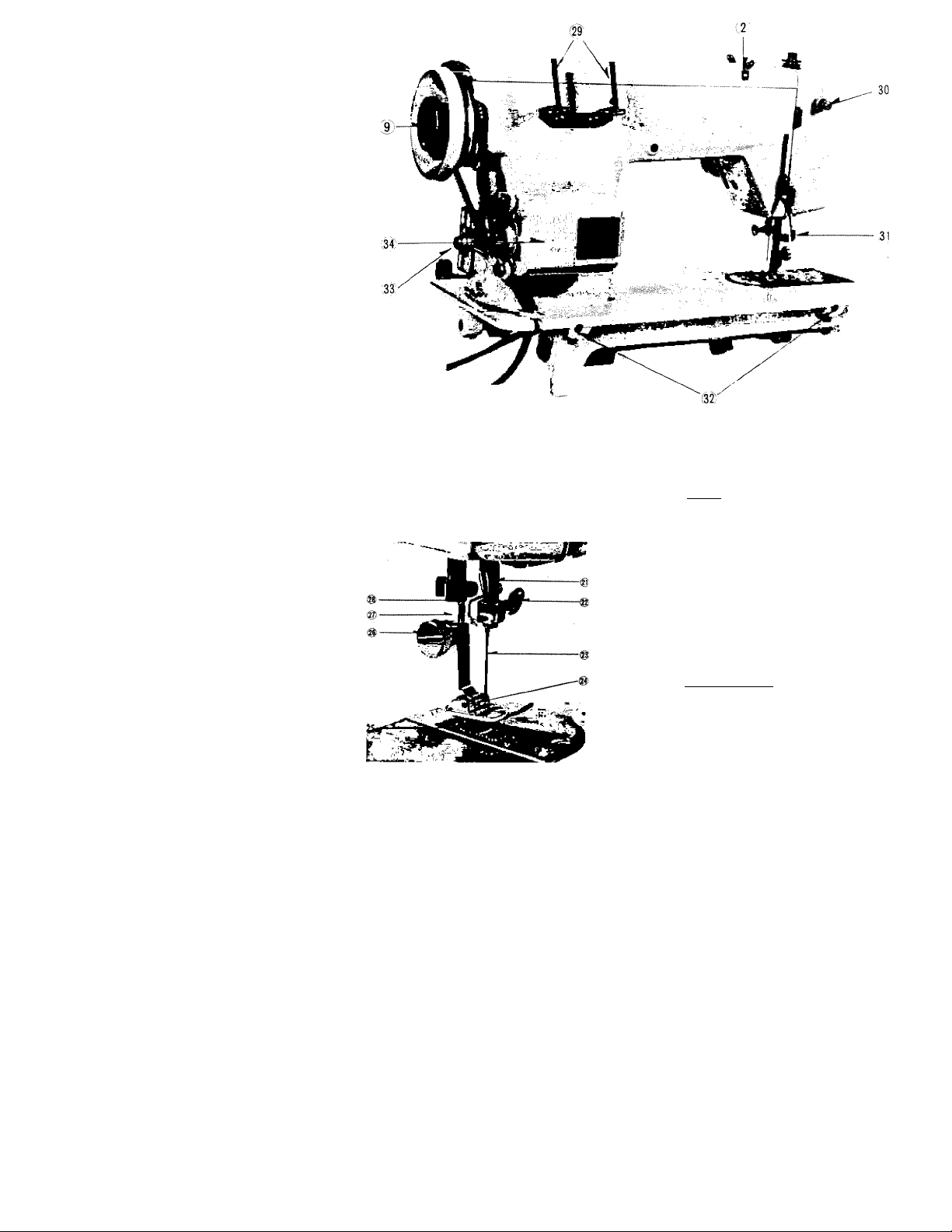

Page 4

Fig. 2

Fig. 3

Fig. 2

21. Needle bar

22. Needle clamp

23. Needle

24. Presser foot

25. Fabric feeders

26. Presser foot clamp screw

27. Presser bar

28. Thread cutter

BACK (Fig. 3)

29. Spool pins

30. Light switch

31. Presser bar lifter

32. Head hinge mounting holes

33. Motor set screw

34. Motor

Page 5

Fig. 4

2. BELT ADJUSTMENT

Loosen motor bracket screw (A).

Slide motor bracket down to tighten

— up to loosen.

CAUTION : Do not tighten belt

too tight.

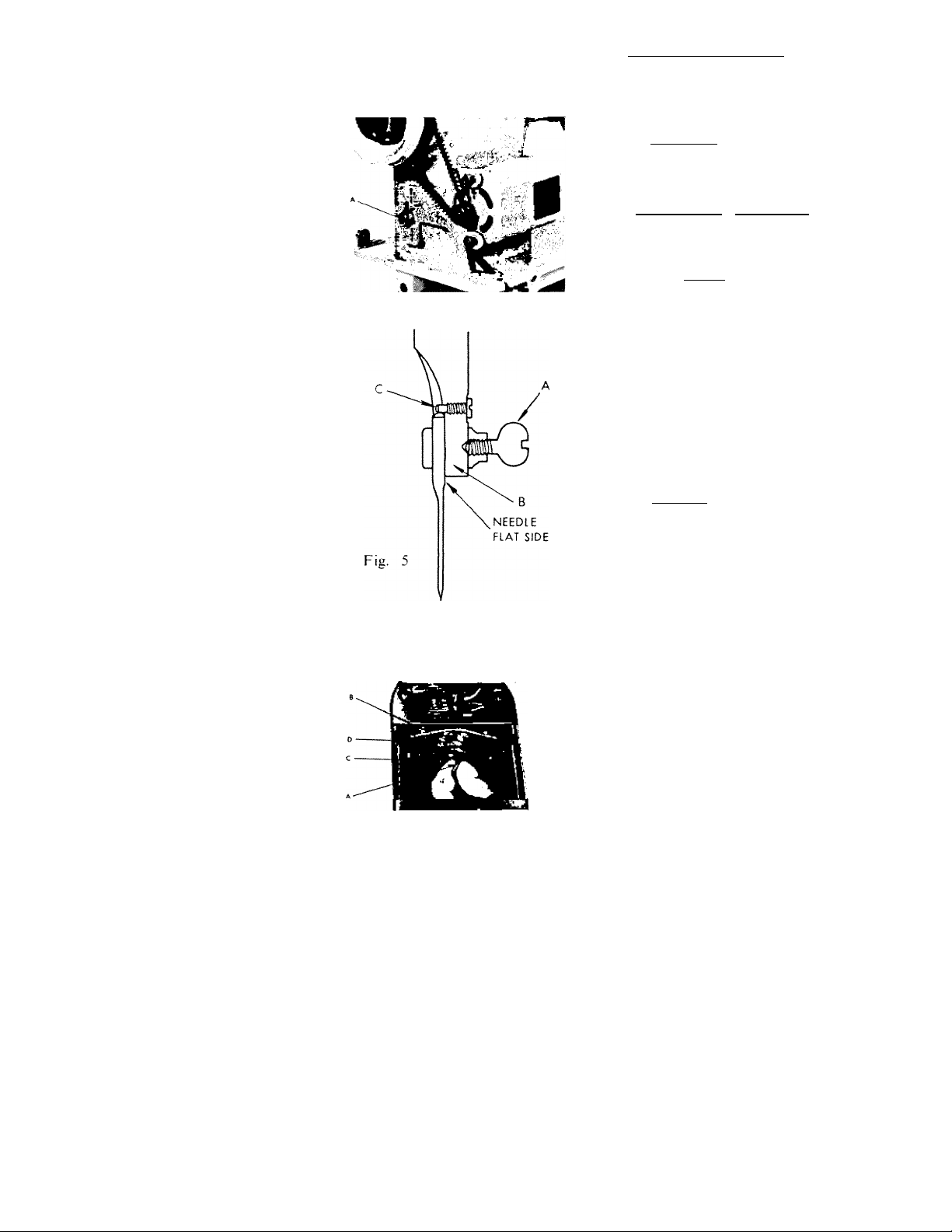

3 , B E P L A C m e W EED L E

1. Raise the needle bar to its highest

position. (Turn the fly wheel by

hand toward you.)

2. Loosen needle clamp screw (A) and

remove old needle.

3. Insert the needle into needle bar (B)

with the flat side of the needle tow'ard

the fly wheel.

CAUTION : Be sure the needle is

all the way up. It should rest against

the needle stop pin (C).

4. Tighten the needle clamp screw se

curely with screw driver.

CAUTION ; Check needle and make

sure it is not bent or dull.

Fig. 6

4. REMOVING BOBBIN CASE

1. Raise the needle bar to its highest

position. (Turn the fly wheel toward

you by hand.)

2. Open slide plate. With the left

thumb and forefinger, open the latch

(A) of the bobbin case (B).

3. Remove bobbin case from the spindle

post (C). (PuU to the left.)

NOTE : With the latch held open,

the bobbin is locked inside the

bobbin case. To remove bobbin from

the bobbin case, release the latch.

Page 6

Fig. 8

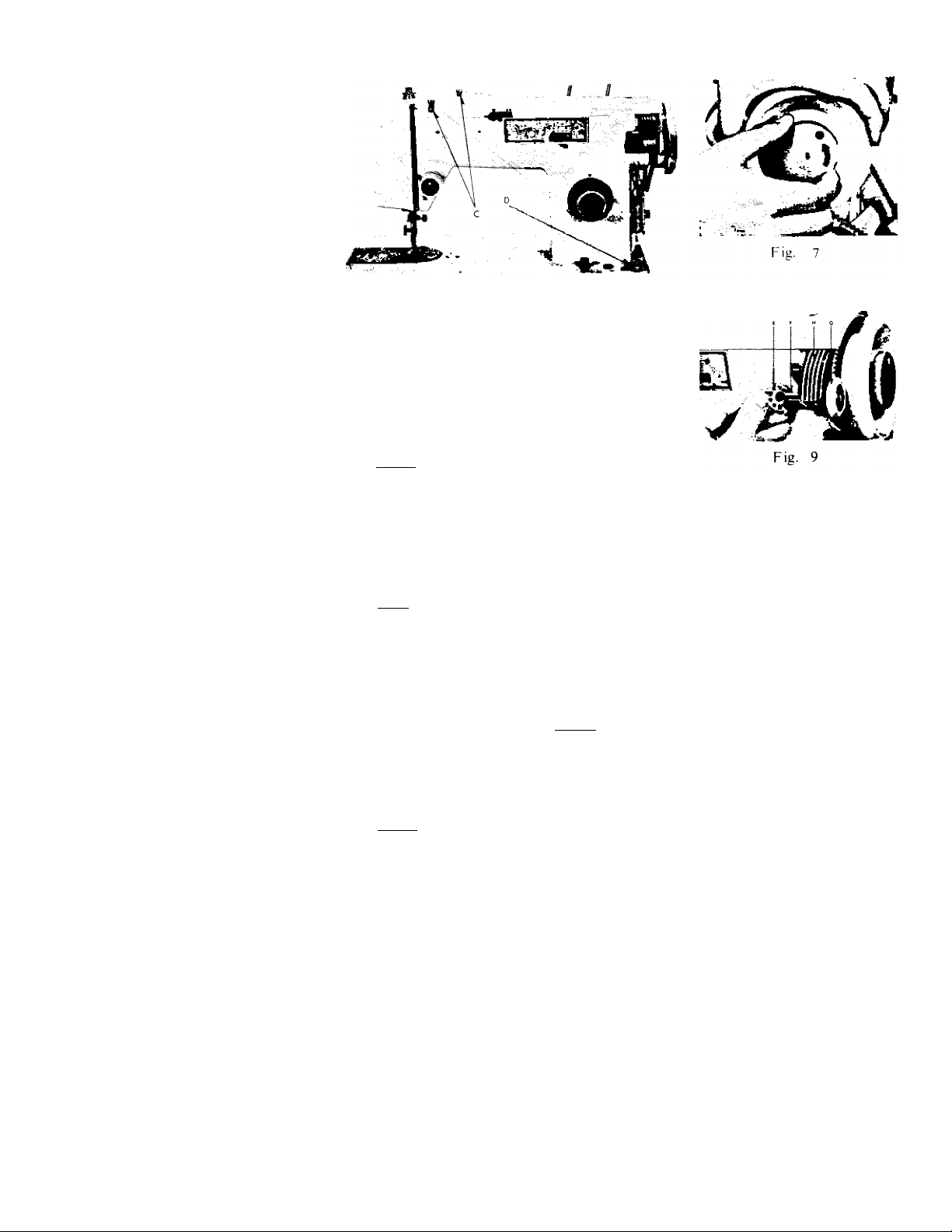

5. WINDING BOBBIN

1. Hold the fly wheel (A) Fig. 7 with the left

hand and turn the cluch (B) Fig. 7 toward

you to release the clutch. By doing this, the

fly wheel turns freely.

NOTE : If the needle moves, the clutch is

not completely released.

2. Place thread on the spool pin and guide the thread through the upper thread

guide (C) Fig. 8. Then bring the thread across the machine and under the

bobbin winder thread guide (D) Fig. 8.

3. Wind the thread several times on the bobbin (E) Fig. 9. Now place the bobbin

on the spindle (F) Fig. 9 of the bobbin winder.

note : The lock spring on the spindle must fit into the slot in the bobbin.

This is done by holding the rubber ring (G) Fig. 9. with the right hand and

turning the bobbin with the left hand until the lock spring slips into the slot

of the bobbin.

4. Push the cover (H) Fig, 9, of the bobbin winder down until the rubber ring

(G) Fig, 9 is brought in contact with the fly wheel.

5. Turn the fly wheel slowly, toward you; then operate the machine as in sewing.

When the bobbin is full, it will stop.

6. Remove the bobbin from the spindle, then re-engage the machine by holding

the fly wheel with the left hand and with the right hand turn the clutch away

from you.

NOTE : Make sure you tighten firmly.

Page 7

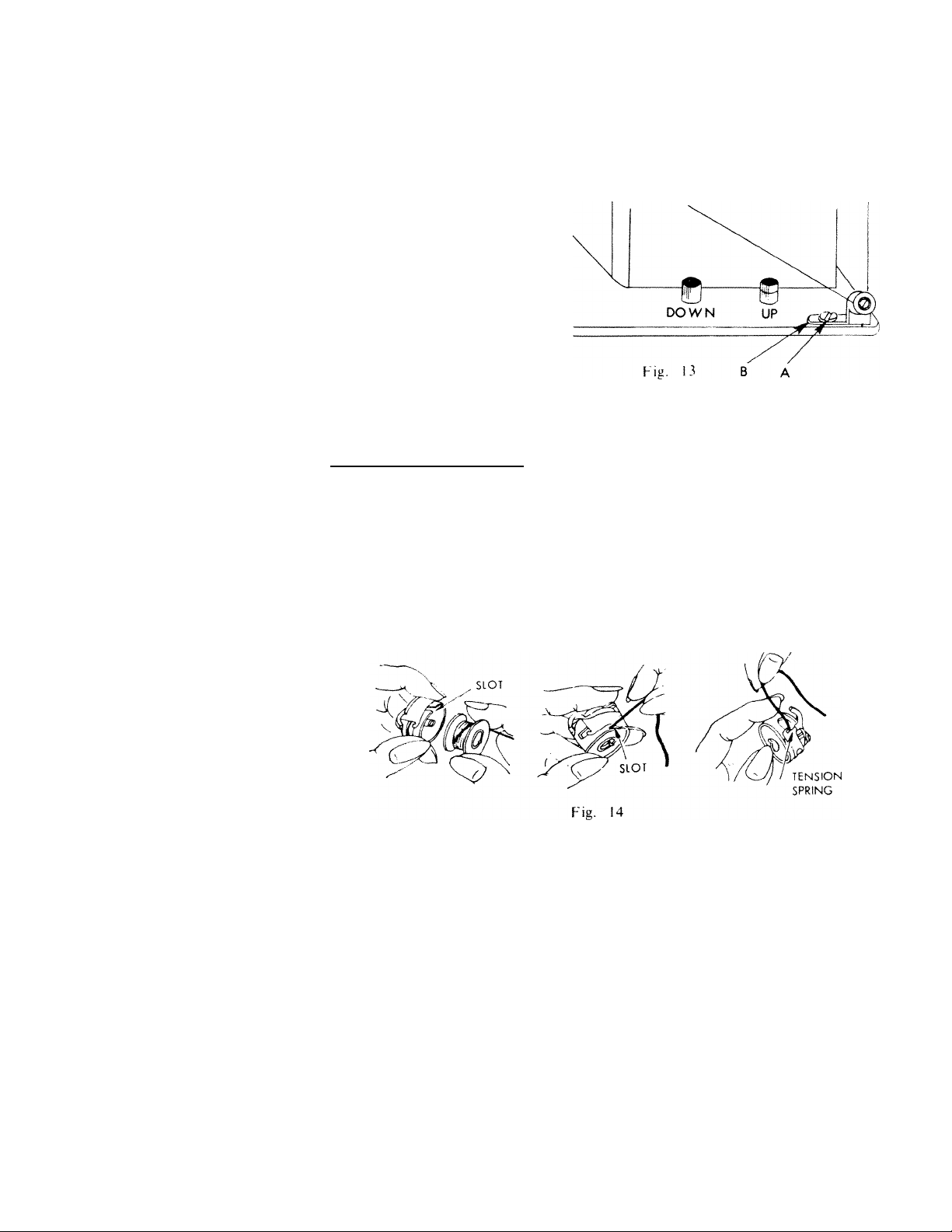

6 ADiUSTINO BOBBIN WINDER

]. If the thread winds unevenly on the bobbin as shown in Fig. 11 and 12, loosen

screw (A) Fig. 13 and adjust the bobbin winder thread guide bracket (B) Fig. 13.

2. If the thread winds as in Fig. 11, move the bracket slightly to the left. If the

thread winds as in Fig. 12, move the bracket slightly to the right.

Fig. 10 Fig- 11 P'K- 12

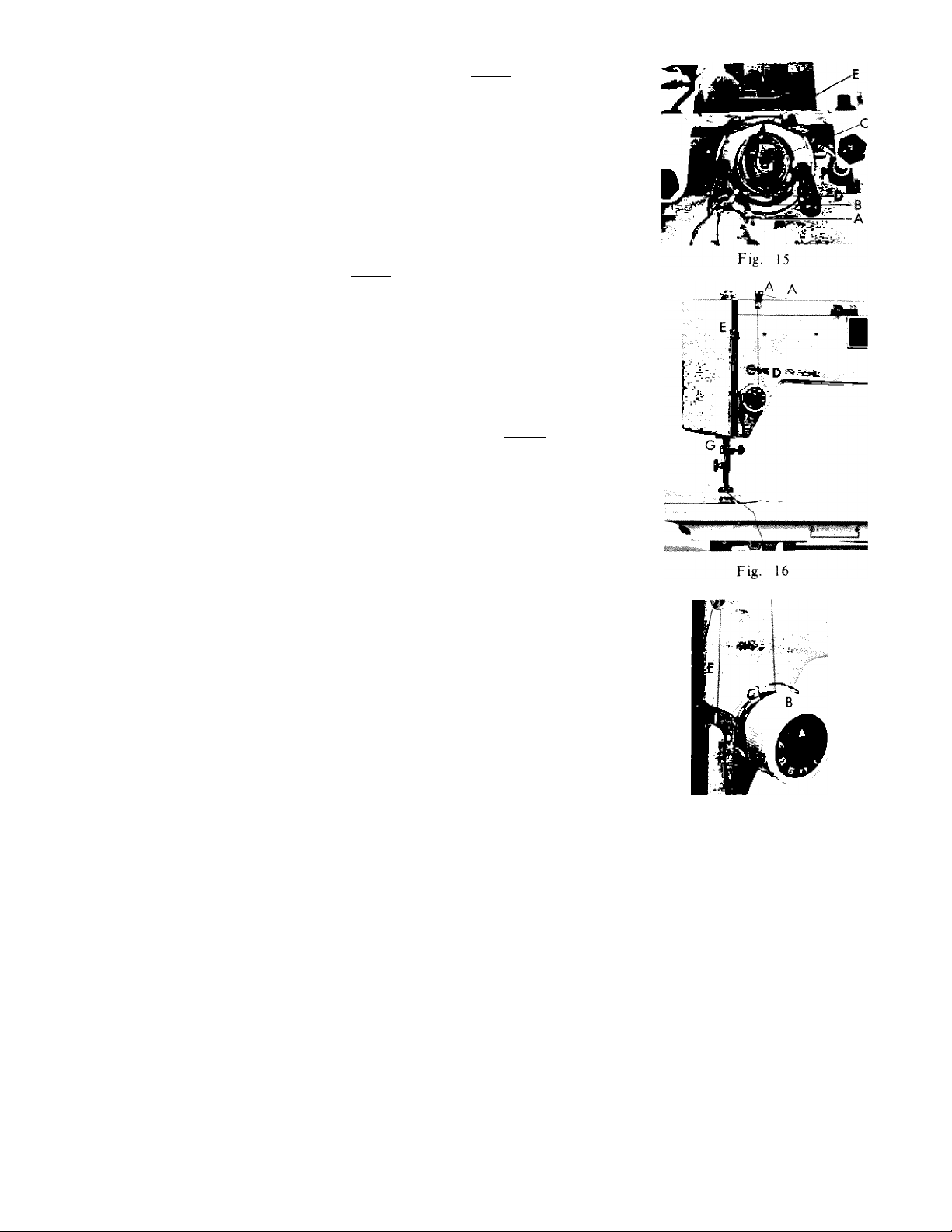

7. THREADING BOBBIN CASE

1. Hold the bobbin case between the left thumb and forefinger with the slot up.

With 5 or 6 inches of thread trailing in the palm, hold the bobbin between

the thumb and first two fingers of right hand.

2. Insert the bobbin into the bobbin case, then pull the trailing thread into the

slot, up to the left until it enters the delivery eye under the tension spring.

There should be a slight tension on the thread as it pulls through the delivery eye.

Page 8

8. REPLACING BOBBIN CASE

1. Turn fly wheel toward you by hand

until the needle bar is at its highest

position, and open the slide plate.

Draw about 3 inches of thread from

the bobbin and let it hang loosely

from the bobbin case.

2. With the left thumb and forefinger,

hold the latch (A) of the bobbin case

(B) and place it on the spindle post

(C) . (Fig. 6)

NOTE ; The protruding finger (D)

must slide into the delivery eye (E)

at the top of the shuttle.

3. Release the latch and press the bobbin

case to the right until it catches the

groove on the spindle post.

9. TH R EA D IN G M A CH I NE

1. Turn the fly wheel toward you and

raise the take up lever (E) to its highest

position. Place thread on the spool pin

and bring the thread through the upper

thread guide (A).

2. Bring the thread down through the

thread guide to the tension disc (B)

from right to left and up. Then pull

the thread up through the thread take

up spring (C).

3. Bring the thread under the thread

tension guide (D) and thread the take

up lever (E) from right to left.

4. Bring thread down through the thread

guide (F) at the opening in the face

plate, and through the needle bar

thread guide (G) from behind. Thread

the needle from left to right, leaving

about 5 or 6 inches of thread.

Fig. 17

Page 9

10. PREPARINO TO SEW

Fig. 18

1. Hold the loose end of the needle thread

in your left hand, and turn the fly

wheel toward you by hand until the

needle moves down through the needle

plate and up again to its highest position.

Pull the needle thread gently, and the

bobbin thread will come up with it

through the hole in the needle plate.

Then place both ends of the thread

back between the toes of the presser foot.

NOTE : If the bobbin thread does

not rise, check to see if there is at

least 3 or 4 inches of bobbin thread

hanging loosely from the bobbin case.

2. Pull the two threads at least 5 inches

behind the presser foot. Place material

under presser foot, and lower the foot

with the presser bar lifter. Regulate

the stitch to the desired size and sew.

TO REMOVE MATERIAL, raise the

needle to its highest position and raise

the foot with the presser bar lifter, then

pull the fabric back and to the left.

Cut the thread with the thread cutter

behind presser bar, leaving a few inches

of thread behind the presser foot.

Fig. 19

Page 10

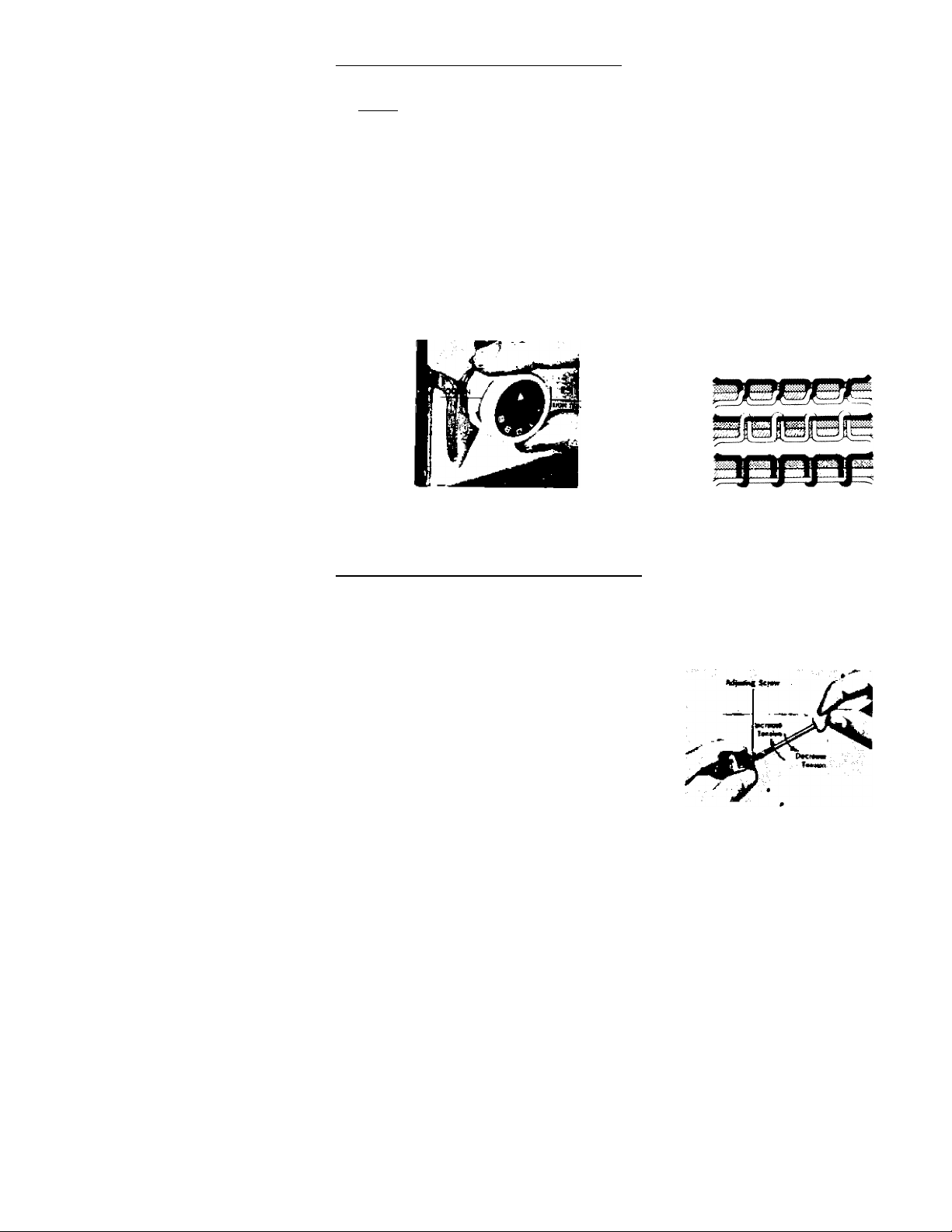

11. ADJUSTING UPPER THREAD TENSION

The correct stitch can usually be obtained by varying the upper thread tension.

NOTE : TENSION ADJUSTMENT SHOULD BE MADE WITH THE

PRESSER FOOT DOTO.

To increase the tension, turn the tension dial clockwise (Fig. 20). To decrease

the tension, turn the tension dial counter clockwise (Fig. 20). When the tension

is properly adjusted, the upper and lower threads will cross in the center of

the material (Fig. 21-A).

When the upper thread tension is too tight, or the bobbin tension is too loose,

the lower thread will lay flat along the top of the material (Fig. 21-B).

When the upper thread tension is too loose or the bobbin tension too tight, the

upper thread will lay flat along the bottom of the material (Fig. 21-C).

The tension should be adjusted little by little until the desired tension is obtained.

0

Bj

Fig. 20

Fig. 21

12. ADJUSTING BOBBIN THREAD TENSION .

1. The bobbin thread tension on your machine is correctly adjusted before leaving

the factory. Therefore, it is seldom necessary to alter the bobbin thread tension.

Should it become necessary to do so,

the adjusting screw of the tension spring

on the outside of the bobbin case can

be tightened or loosened to increase or

decrease the tension of the bobbin

thread.

2. To increase the bobbin thread tension,

turn the adjusting screw clockwise.

To decrease tension of the bobbin

thread, turn the adjusting screw counter

clockwise.

Fig. 22

8

Page 11

13. ADJUSTING FABRIC FEEDERS

By using the push buttons you can adjust the fabric feeders for sewing different

types of materials and other special sewing, such as emitroidering or darning.

1. For ordinary sewing, press “UP” button all the way down. (This raises the

fabric feeders to the up position)

2. For sewing very light fabrics, press “DOWN” button half way down so that

the center line of the “UP” button appears on the plate.

3. To lower the fabric feeders below the surface of the needle plate, press the

“DOWN” button all the way down. The fabric feeders are now in the down

position, and you will be able to move your material freely in any direction,

such as when you desire to embroider or darn. When embroidering and darning,

remove the presser foot and use an embroidery hoop.

“UP” Position

Normal Fabrics

DOWN

“MEDIUM” Position

Lightweight Fabrics

DOWN

“DOWN” Position

Embroidering & Darning

DOWN

Fig. 23

&

UP

UP

UP

Fig. 24

14. ADJUSTING PRESSURE OF THE PRESSER FOOT

1. To release the pressure on the material, press down on the curled ring (A). (This

will allow the built-in darner (B) to raise, thus releasing the pressure on the

material.)

2. To increase the pressure on the material, press down on the built-in darner (B).

note : The built-in darner will stop.at any position you desire.

3. For normal sewing, push built-in darner all the way down.

4. For darning and embroidering, release the built-in darner.

CAUTION : Even though the presser foot is removed, make sure the presser

bar lifter is in the down position. ^

5. Adjust the built-in darner to the proper position according to the thickness of

the material you are using.

Page 12

Fig. 25 Fig. 26

15. REGULATING STITCH LENGTH

SEWING FORWARD

The length of the stitch is regulated by the dial, shown in Fig. 27. Near O is the

shortest stitch and 4 is the longest, but the control may be set at any spot between

the marking for a variety of lengths. Turn the dial to the right to lengthen and to

the left to shorten the stitch. The number stitch length you choose is indicated by the

pointer.

SEWING BACKWARD

When you wish to sew backward to tie the threads at the beginning or end of a

seam, press in the button (Fig. 28) as far as it will go. The machine will sew backward as

long as the button is held in.

CAUTION : When the dial is set on the number “O’,’ neither forward nor backward

stitch can be made. This will cause the machine to break the thread.

Fig. 27

Fig. 28

10

Page 13

16. ZIG ZAG SEWING

Fig. 29

REGULATING WIDTH OF STITCH

The zigzag, regulating lever (A) controls the width of the stitch. When you move

the zigzag regulating lever, you will notice that the zigzag indicator (B) moves troiii “O”

to the numbers 1,2, 3, 4 on the zigzag indicator plate (C).

When the zigzag indicator moves the zigzag regulating lever from "0 tow'ard

the numbers 1, 2, 3, 4, the width of the stitch will become progressively wider.

The larger the number the wider the stitch.

note : The zagzig regulating lever returns to the straight stitch position when

released.

11

Fig. 30

Fig. 31

Page 14

L0CKIN6 ZIG ZAG REGULATING LEVER

To lock the zigzag regulating lever

so tliat the machine sews a uniform stitch

width, first move the zigzag regulating

lever until the zigzag indicator is under

the number on the zigzag indicator plate

that you desire.

Turn the zigzag lock coickwise to lock

the position.

CAUTION : Do not release the zig

zag regulating lever until after you have

released the zigzag

screy^

You will notice that the zigzag indi

cator is locked on the number which the

zigzag indicator was set under. If the

zigzag indicator is locked under any

number larger than “O” up to “3M”, you

will notice that when the zigzag regu

lating lever is moved from side to side,

the zigzag indicator will move from that

number to # 4. When the zigzag regu

lating lever is released, the zigzag indi

cator will return to the number under

which it was locked. To release the zig

zag regulating lever, turn the zigzag lock

counter clockwise.

CALJTIOJ^ ; When you turn the zig

zag lock and release screw, do not

hold the zigzag regulating lever.

(Fig. 33)

_____

1 pc^ and release

Fig. 32

Fig. 33

12

Page 15

MAKING.PATTERNS

By moving the zigzag regulating lever front 0-4 as you _are sewing, the pattern

formed will be as in Fig. 34. When you slowly release the zigzag regulating lever

back to its “0” position, you will form the pattern as in Fig. 35. By moving the zigzag

regulating lever slowly from “0” to “4” and slowly back to “0” as the machine is sewing,

you will form the pattern as in Fig. 36.

..

0 12 3 4

Fig. 34

START HERE

You can form the pattern as in Fig. 37 by holding the zigzag regulating lever # 4.

note : The zigzag indicator will be on # 4. You may lock the zigzag regulating

lever in this position (Page 12)

You can form the pattern as in Fig. 38 by moving the zigzag regulating lever

until the zigzag indicator is on # 2. (You may lock the stitch in this position.

See Page 12.)

In order to form the pattern as in Fig. 39, first lock the zigzag indicator on # 2,

then move the zigzag regulating lever so that the zigzag indicator is on * 4. Sew

the desired number of stitches and while the machine is still running, quickly release

the zigzag regulating lever. The machine will now sew a * 2 zigzag stitch. Sew the

number of stitches desired and quickly move the zigzag regulating lever to » 4.

Sew the number of stitches desired and repeat.

0 12 3 4

0 12 3 4

01234 0 1234

mfmmmmmm

13 Fig- 37

Fig. 38

Fig. 39

Page 16

17 . S T RE T CH ST I TC H IN 6

Fis- 42-!

This IS a helpful stitch developed to ada elasticity and strength when sewing on fabrics

III as

It adds triple strength to straight or zigzag stitching. For a triple strength straight st, c -

1. Set stretch control lever “A” at the SS (stretch stitch) position.

T Set ZigZag width control “B” at “0” position.

3 Set stitch length control “C” at * 4- the longest possible stitch. ^ .

To sew multiple zigzag stitches simply engage the zigzag width lever ^e d®sir d

width This zigzag stitch can be used for overcasting, applying elastic waist bands, etc^

Thert are many Ler uses for these stitches which will become apparent as you use

the (M) manual position.

knhs jerseys, etc. It reinforces the garment particularly in stress or strain areas.

to'normal straight or zigzag stitching, move the stretch stitch lever back to

stitch conttoU both the fotward and te.etse stitch length

length control “C” is not set at number 4, the machine will be noisy and the mater

w-ill feed in reverse.

Page 17

You can ronii the pattern as in Fig. 40 by slowly moving the zigzag regulating

lever as the machine is running until the zigzag indicator is on # 4, then quickly

release the zigzag regulating lever and again slowly move the zigzag regulating

lever to « 4, Repeat as often as desired.

In order to form the pattern as in Fig. 41. first move the zigzag regulating lever

to # 4, and while running the machine slowly release the zigzag regulating lever

until the zigzag indicator is on “0”. When the zigzag indicator reaches “0”, quickly

niovc the zigzag regulating lever to # 4. Repeat as often as desired.

In order to make the pattern as formed in Fig. 42. with the zigzag indicator

on “0”. sew a straight stitch for the length desired; then while the machine is still

running, quickly move the zigzag regulating lever to 4. Sew the number oi stitches

desired and then quickly release the zigzag regulating lever. Repeat as often as desired.

0 12 3 4

0 12 3 4

4 0 4 0 4 0

Fig. 42

Fig. 40

note : The above patterns arc just a few of the numerous patterns that you

will be able to make with your machine. By varying the speed with which you

move the zigzag regulating lever and releasing the zigzag regulating lever at the

same time varying the stitch length and; the number of stitches made, you will be

able to create hundreds of different patterns.

CAUTION : When the machine is not sewing, do not move the zigzag regulating

lever unless the needle is raised out of the material. When making patterns, for

best results, the machine should be sewing at a moderate rate of speed.

14

Page 18

18. CLEANING SHUTTLE AND RACE ASSEMBLY

In order to obtain the best possible performance from your machine, it is

necessary from time to time to clean and oil the shuttle and race assembly.

¡removing shuttle

needle, presser foot and needle plate. (See Page 1)

Raise the needle bar to its highest position and remove the bobbin case.

Release knobs (A) on the both sides of the race assembly, by opening them to both

sides and remove shuttle cover (B) from the race assembly.

Take hold of the holder post (C) of the shuttle, and remove the shuttle from

the race assembly.

Carefully clean the race assembly, making sure that you remove any thread

or lint that may become trapped in the shuttle and race assembly. Also thoroughly

clean the fabric feeders (D). This can be done with a stiff brush.

Fig. 44

Fig. 43

REPLACING SHUTTLE IN RACE ASSEMBLY

Raise the needle bar to its highest position.

With the left_ thumb and forefinger, take hold

of the shuttle by the holder post. Turn the

shuttle so that the open ends slide over the

ends of the shuttle driver (E). Gently press in.

Take the race cover in your left hand.

Place ’the race cover over the race assembly

making sure that the two small posts on the

race assembly fit into the small holes on the

race cover. Tighten the both knobs.

Fig. 46

Fig. 45

16

Fig. 47

Page 19

19. OILING THE MACHINE

As in the case with all precision

machinery, it is necessary for maxi

mum efficiency to properly oil and

clean at reasonable intervals. Even

though the machine is not in con

stant use, it is important to oil your .

machine since the oil will dry after

standing over a period of time.

The underside of the machine should

be oiled at the arrow points as shown in

Fig. 48.

NOTE : Before oiling, clean away all

lint or foreign matter. One or two

drops are sufficient at each point.

The machine should be oiled at the

arrow points as shown in Fig. 49. These

parts are accessible by opening the face

plate.

To oil the top parts of your machine,

remove the two screws (A & B) located

at each end of the top cover (C). Remove

top cover and oil the parts located at the

arrow points as in Fig. 50.

NOTE : After you have cleaned and

oiled your machine, it is advisable to

run the machine at high speed so that

the oil will penetrate all moving parts.

CAUTION : After cleaning and oiling

machine, wipe away all excess oil, and

sew on waste material.

20. BUILT IN LIGHT

Fig. 48

Fig. 49

Fig. 50

Your machine is equipped with a built

in sewing light, located inside the face plate.

NOTE ; Face plate is hinged (See

Fig. 51) and opens from left to right.

The sewing light switch is located on

the front of the face plate (See Page 1).

The sewing light is a standard bulb and

can be easily replaced.

17

Fig. 51

Page 20

21. ACCESSORIES

fl:

o

tt "m

Fi . 52

4si

w

I

wm

Button sewing foot

Spool pin felt

Needles (3)

Bobbins (3)

Presser foot for straight stitch

Narrow hemmer

Button hole sewing foot

7

Zipper foot

8

Cloth guide

9

Thumb screw for cloth guide

10

Screw driver

11

Plastic oiler

12

HOW TO USE PRESSER FEET

Your machine is equipped with various specialized feet which will enable you to

do particular jobs with greater efficiency and obtain better results. Whenever you

attach a new foot to the presser bar, make sure you tighten the screw securely with

a screw driver.

18

Page 21

A. PRESSER FOOT FOR STRAIGHT SEWING

When making only straight sewing, it

is necessary to loosen the presser foot

thumb screw and change the presser

foot for zigzag stitch to one for

straight stitch.

CAUTION : Be sure to set the zigzag

indicator at the position of "O”

Fig. 53 A

B. CLOTH GUIDE

Attach cloth guide to the bed of the

machine (See Fig. 53). The cloth guide

will enable you to make a straight stitch

at a uniform distance from the seam.

The cloth guide is adjustable, making it

possible to make a straight stitch at various

distances from the seam.

e, ZIPPER FOOT

Your machine is equipped with an ad

justable zipper foot. Set the zipper foot

on the left side as shown in Fig. 54.

This will allow you to sew on the left

side of zipper without danger of damaging

the zipper or the needle. To sew on the

right side of the zipper, adjust the zipper

foot to the right side by loosening the

screw located on the back of the zipper

foot.

NOTE : When using the zipper foot,

always sew with a straight stitch.

19

Fig. 53

Fie. 54

Page 22

22. BLIND HEMMING

1. Set zigzag indicator on # 4.

2. Set stitch length on largest stitch lo

cated on stitch length indicator plate.

3. Fold the material as shown in Fig. 57A.

4. Turn the fly wheel toward you by

hand until the needle is on the left

side of the zigzag. Place the material

under the presser foot, then adjust the

material until the left side of the fold

is directly under the needle.

5. Make the first stitch by running the

needle through the material by hand,

being very careful to Just barely catch

the folded edge. (See Fig. 57-B) These

stitches should be on the reverse side

of your material. When you open the

folded material, the blind stitch will

be on the front side of your material.

(See. Fig. 57-C)

CAUTION : When making blind hem,

run the machine very slowly. For best

results loosen upper thread tension.

Fig. 57

23. UPP tlQU EING

1. Adjust the machine to a narrow zig

zag stitch.

2. Set the stitch length to smallest stitch.

Baste material on to the article, then

sew around the edges of the material.

21

Fig. 58

Page 23

Fig. 55

?-Thread

BA:

-iD C

2 3 4 5

Fig. 56

Cut

1. Attach buttonhole foot, and set stitch

length indicator on smallest stitch.

(See Page 10)

2. Set zigzag indicator between 1 and

2 and lock into position. (See Paae 12Fig. 32) ^

3. Push “DOWN" button to drop fabric

feeders.

4. Place material under the foot so that

when you start sewnug you will sew

from position A shown in Fig. 56-« !.

Lower the foot on to the material.

Move the zigzag indicator lever until

the zigzag indicator is under * 4 on

the zigzag indicator plate (See Page

11-Fig. 29). Then sew between .A & B

shown in Fig. 56- # 2 and make 4 or 3

stitches.

5. Raise the fabric feeders to up position.

Release zigzag regulating lever so that

the indicator returns to the position

between 1 and 2. ^

6. Sew from A to C shown in Fig. 56- # 3.

With the needle half way through the

material on the left side of the zig

zag stitch (Fig. 56- # 3E), using lire

needle as a pivot, turn the material in

the opposite direction.

7. Lower the fabric feeders as in step # 3.

Turn the fly wheel toward you by

hand until the needle is at its highest

position. Move the zigzag regulating

lever until the indicator is under # 4.

(See step # 4). Sew from C to D as

shown in Fig. 56- # 4. Release zigzag

regulating lever so that the zigzag

indicator returns to the position between

1 and 2.

8. Raise fabric feeders and sew between

D and B as shown in Fig. 56- ^ 5.

CAUTION : Sew between D and B

carefully, being carefull not to overlap

the two sides of the buttonhole.

9. With the ripper, cut the cloth between

the two sides of the buttonhole. (Fig.

56- # 5,

20

Page 24

24. EMBROIDERING AND MONOGRAMMING

!. Release pressure of presser toot. Lower

fabric feeders. Lock zigzag indicator

into posiiion "Z” under the zigzag

indicator plate. Put material into em

broidery hoop, then place under foc-t.

Lower foot, then turn the fly wlicel

toward you. by hand and raise the

lower thread through the material so

that both the upper and lower threads

are on top of your material.

2. Sew' at medium speed. Move niuterial

slowly so that the thread will be close

together as in a satin stitch. With a

little practice you will be able to do

many types of designs and gain a great

deal of pleasure from your machine.

Fig. 59

CAUTION: Work carefully and be sure

to keep fingers out of the path of the

needle.

25. DARNING

1. Release the pressure of the presser

foot. Lower the fabric feeders, and

place the material under the foot and

lower the presser bar.

note : This enables you to move

the material in any direction while

the machine is running.

2. Sew around the areas you desire to

darn. Then move the material back

and forth, sewing out beyond the worn

or open place in the material. Con

tinue until the hole is covered, going

Fig. 6 0

both sideways and forward and back,

note : While darning, run the machine

at medium speed.

Page 25

26. SEWING ON BUTTONS

1. Remove hinged presser foot and attach button sewing foot. (See Fig. 61)

2. Push drop feed button “DOWN” all the way. (Fig. 65).

3. Set zig zag stitch width at 0. Place the button so that its left hole comes

directly under the needle, then gently lower the presser foot. (Fig. 62)

4. Move zig zag stitch width until the needle comes down exactly over the

right hand hole in the button and lock zig zag position. (Fig. 63) Turn the hand wheel

slowly by hand to be sure the needle enters both holes in button without deflecting

needle, correct width if necessary.

5. When needle goes into the center of each hole, run the machine at medium

speed, making six or eight stitches, stopping with the needle in the left hole.

6. To lock the zig zag stitch and prevent ravelling, set the stitch width at 0, and take

a few stitches in the same hole. If you wish you may place a rounded toothpick

over the button, between the two holes, and sew button to fabric in regular way.

Remove the toothpick and wind thread under the button, forming a shank to

fasten.

Apply the above method to sew on buttons with four holes, hooks and snaps,

etc. If a four hole button is to be sewn, follow the same procedure as for the two

hole button.

Now lift presser foot slightly and move fabric to permit stitching the remaining

two holes, Hooks, snaps, etc., are sewn to the fabric with the same procedure as for

sewing two hole buttons.

23

Fig. 62

Fig. 64

Fig. 61

1

• a

DOWN U f*

Fig. 65

Fig. 63

Page 26

91. CAUSES OF COMMON DIFFICULTIES

note : Clean and oil machine at regular intervals.

Machine Makes Noise

1. Thread jammed in race assembly. (Clean and oil shuttle and race assembly )

2. Blunt needle.

3. Needle plate not placed in properly.

4. Slide plate not all the way to the right.

B. BREAKING UPPER THREAD

1. Incorrect threading.

2. Upper thread tension too tight.

3. Lower thread tension too tight.

4. Fautly needle, or needle placed incorrectly.

5. Needle brushing against presser foot or other attachments.

6. Needle eye too small for thread used.

7. Starting the machine suddenly or with a jerk.

8. Starting the machine with the take up lever at its highest point.

9. Presser bar not lowered.

10. Thread jammed in race assembly. (Clean)

C. BREAKING THE LOWER THREAD

1. Incorrect threading of the bobbin case.

2. Lower thread tension too tight.

3. Bobbin wound too full or improperly.

4. Rough edge in hole of needle plate.

BREAKING THE NEEDLE

D.

1. Pulling or holding the fabric while machine is running.

2. Using bent needle.

3. Needle not set in securely. (Tighten needle clamp screw with screw driver)

SKIPPING STITCHES

E.

1. Using bent or blunt needles.

2. Needle inserted incorrectly.

3. Needle threaded improperly.

4. Using wrong size needle. (Length - Use 15X1 needle)

5. Pressure of presser foot insufficient, especially when sewing heavy material.

F. UNEVEN STITCHES

1. Presser foot not resting evenly on material.

- 2. Fabric feeders not high enough.

3. Stitches too short.

4. Pulling or holding the cloth while machine is running.

5. Using too fine a needle with too coarse a thread.

6-. Upper and lower thread tensions not adjusted properly.

Page

9

10

Page 27

I

■щ

ъ

■э

<5

Page 28

51021

1

1

51032

'I

i

A

51050

5

5-1

51968

6

51033

7

8

51031

9

10

51415

11

12

51135

13

14

51116

15

16

51420 Thread tension regulator (unit) 57 51356

17

18

56011

19

51411

20

21

TT

51401

23

24

51061

25

26

56062

27

28

29 132

56041

30

31

32

51440 Bobbin winder (unit) 7 ?77(s

33

34

35

51108

36

37

38 Ilio

39

51800

40

Face plate

Face plate set spring

Washer for 4

703

Set screw for 2 43

112

Lamp assembly 44

Set screw for lamp socket

191

Bulb

Lamp bracket

Set screw for 7

131

Face plate hinge

Set screw for 9

131

Thread guide plate

Thread guide plate set screw

310

Thread loose metal

Thread loose metal hinge screw 54 56234

510

Needle bar crank rod guide^^^3

Set screw for 15 3 70 y

112

445

Set screw for 17

Top cover '7 59 51357

Thread guide for top cover

310

Set screw for 20

170

Top cover set screw 61

Spool pin base (unit)

132 Set screw for 23

Cord set metal

131

Set screw for 25

Cord set metal (2)

1460

Bobbin winder tension bracket

(unit)

Set screw for 28

Machine number plate

680

Lead pin. 1.7

301

Name plate set screw

1455

Bobbin winder rubber ring

162

Set screw for bobbin winder

Fly wheel y^ ~7 7 J

1109

Fly wheel clutch stop washer

Fly wheel clutch

220

Clutch nut set screw

Sewing machine motor

51815

40-1

41

42

51819

51069

45

46

51230

47

51220

48

49 320

51232

50

51 51231

52

53 112

51233 Reverse stitch button

55

56 445

58

60 51360

51359

62

63 704

64 51358

65 690

513.54

66

51353

67

51501

68

69

70

51502

71

51570

71-1

51582

71-2 920

71-3

51583

714 690

72

Plug

Motor setting screw

180

Motor set screw washer

720

V belt for motor

Cord bush

Hinge set screw

270

Feed indicating pin

680

Cover for number plate

Feed regulating device (unit)

Feed regulating device set screw

Stitch length indicator plate

Stitch length control dial knob

703 Washer, 3 x 8 .x 0.5

Set screw for 51

Reverse stitch button spring

Set screw for 55

Zig Zag slide metal ~7 ^ K'J

Set screw for 57

510

Slide metal spring ~7 H 762>

Base plate for Zig Zag indicator

plate

920

Nut for 60

Zig Zag indicator plate

Washer, 4 X 10 x 0.8

Zig Zag lock and release screw

Split pin, 1.0 X 10 7^7/S'

Zig Zag regulating lever

Zig Zag regulating lever knob

Needle plate for Zig Zag stitch

340 Needle plate set screw

Slide plate (unit)Drop feed (unit)

Drop feed connecting rod

Nut for 71-1

Drop feed control button

complete

Split pin for 71-1

131

Set screw for 71-3

Page 29

Page 30

51132 Presser bar spring

51130 Presser bar guide bracket

73

f4

l5

16-

ir

fi

%

470 Set screw for 74 ^

«1131 Presser bar lifter 33 /S

612 Spring pin for 76 33/1*

1133 Thread cutter

732 Presser foot thumb screw

51134 Presser foot for Zig Zag stitch

51150 Presser release (with bushing)

81,

51170 Needle bar supporter (unit)

82

1122 Needle bar

82-1

11 23 Presser bar

82-2

«1175 Presser bar bushing (lov^£i.^:i^i/

82-3

83

84

85

86

87

SS

89

90

91

91-1

92

92-1

92-2

93

94

95

96

97

98

98-1

445 Set screw for presserjla^ushing

444 Set screw for 83

51338 Needle bar connecting rod pin ^

753 Snap ring 3 for 85 33/^

1126 Needle clamp (unit)

Needle (No. 14)

51129 Needle bar thread guide

201 Set screw for needle bar thread

guide

51117 Needle bar crank rod (unit)

51119 Needle bar connecting stud

51111 Thread take-up lever (unit)

51114 Thread take-up lever link pin

51115 Needle bar crank

478 Needle bar crank set screw

• 51106 Thread take-up balance

612 Spring pin 3.5 X 22

51105 Arm shaft bushing

56102 Arm shaft

51301 Zig Zag cam (unit)

51104 Arm shaft screw gear with set 129-1

screw

99

100

101

102

103

104

105

445 Set screw for 98

56600 Worm

444 Set screw for 100

51103 Feed cam

472 Feed cam set screw ■

475 Arm shaft bushing set screw

51107 Fly wheel bushing

106

107

108

109

109-1

110

51201

Spring pin 3.5 X 18

6J2

Set screw for 92-1

445

Forked rod

Forked rod hinge screw

571

970 Nut for 109

Feed connecting slide block

1202

(unit)

110-1 1204

Feed connecting slide block

screw '

111

112

51205

51208

Feed regulater

Feed regulating plate (unit)

113 114 Feed regulating screw

114

51210

115

116

56211

117

51212

118

119

120

120-1

121

51310

121-1 51320

122

123

51321

124

Feed regulating screw spring '

Washer for 107 (STW FM 6.0 x 1.0)

730

Feed regulater spring

Feed regulater hinge pin

Set screw for 117

142

Crank connecting rod

1160

Crank connecting rod hinge screw

581

Nut for 120

980

Zig Zag origin (unit)

Zig Zag origin slide block

Set screw for 121

142

Zig Zag width adjustor 33

Zig Zag width adjustor hinge

570

/

screw 3 70'Z^

125

51322

Zig Zag width adjustor stopper

(1)

126 51323

Zig Zag width adjustor stopper 7^*^

(2)

127

131

Set screw for 126 "7 9 9 ¥7

128 51324 Zig Zag width adjustor spring

129 51330 Vertical shaft link (unit)

51336

130 51337

131

51339

132

51350

133

134

135

56601

Zig Zag width adjustor collar

Needle bar connecting rod 33 fi

Vertical shaft

Zig Zag regulating plate (unit) .

131 Set screw for 132

Set screw for 66

112

Stretch stitch control device

(unit)

135-1

56708

Stretch stitch control stopper

Page 31

135-2

136

137

138

139 131 Set screw for 138

140 56258 Feed change rod pin

141

142

143

144

145 471

146

147

148

149

150

151

152

153 51514

154 444

155

156 51516

157

158

159

160 51518

161

162

162-1

163

164

165

166 1530 Feed rock shaft

167

168

169

170 52533

171

172

56709

56250

56259

481-N

51505

51506

51510

51511

51515

51517

51520

51555

51521

51522

1529

51531

51532 Feed bar

480 Feed bar center screw with

112

1544

Stretch stitch control knob

Set screw for 135

142

Set screw for 135-1

320

Feed change linkage (unit)

S.S. connecting rod

753

Snap ring 3 for 141

Center screw with nut

481

Center screw (without nut)

Set screw for center screw

721

Loose pro tec ter

OscOlating rock shaft -lO

Oscillating shaft crank (unit)^ n

444

Oscillating shaft crank set

screw (L-3.7)

611

Spring pin 3.0 X 16

Lower shaft

Shuttle driver (unit)

Lower shaft stop collar

Set screw for 153

Race connecting rod

Race connecting rod pin

755

Snap ring 5 for 156

126

Race connecting rod pin

set screw

Race guide with screw

Race guide shaft

142

Set screw for 160

Shuttle race (unit)

Race cover complete

Shuttle hook

Bobbin case

Bobbin

Feed rock shaft crank with

screw

nut

Feed dog

Feed dog set screw

Feed lifting rock shaft

ACCESSORIES f

1

1905 Spool pin felt

2

1910 Sewing Needles, No. 14

(3 pee. in a package)

3

1529 Bobbins

4

51924 Pressuer foot for straight sf

5

51925 Narrow hemmer

6

51926 Button hole sewing foot

7

51927 Button sewing foot

8

51928 Zipper foot

9

1942 Cloth guide

1943 Thumb screw for cloth guide

1961 Small screw driver .

12

1962 Large screw driver

13

1965 Plastic oiler

14

1969 Accessory box

Page 32

MEMO

Loading...

Loading...