Page 1

STRUCTION BOOK

IN

Page 2

foreword

Your sewing machine is the product

of mony years of research and

developmer.t in the field of house

hold sewing machines. It is the

ultimate in efficiency, quality and

design, yet its moving and wearing

parts, such as needles, bobbins,

bobbin cases hooks, etc., are

standard and interchangeable with

parts immediately available at

sewing machine stores the world

over.

This precision sewing head, simpli

fied and many labor saving extras,

is the result of our constant effort,

and each machine is built the most

exacting specifications under our

rigid quality control program.

The furniture and attachments are

made by affiliated factories under

our main factory while complete

units are assembled and recheck

ed by our specialists in our factory

strictly.

FMEWORD

Page 3

Note:

Use standard 15 x 1-needles

available at any sewing ma

chine store.

J

-

Fig. 1

To replace the needle, raise the needle

bar to its highest point by turning the

balance wheel (Rg. 3) TOWARD YOU

by hand. Loosen the needle clamp screw

(A) on the right hand side and the needle

damp will open, allowing the old needle

to fall out.

Remove the old needle and slide the

new needle up (FLAT SIDE TOWARD

THE BALANCE WHEEL) as far as it will

go, when the needle hits the stop it is

in position correctly. Now fasten the

needle clamp securely. For best results

change needles frequently.

needles and thread

Never use a bent needle, nor one with a

blunt point, since this causes imperfect

stitches and may cause the needle to

break. Unless the needle is in CLEAR

TO THE STOP, FLAT SIDE TOWARD

THE BALANCE WHEEL, the machine will

be out of time, and skipped or imperfect

stitches will result and needles may break.

The size of the needle should conform

to the size of the thread and both should

be suitable to the material. Use a needle

sufficiently large to permit the thread to

pass freely through the eye. In general

sewing, use the same size thread in the

bobbin as is used on top.

Page 4

, Fig. 2

Important:

In the following operations

the needle must always be

above the surface of the

machine.

Raise the needle by turning

the balance wheel TOWARD

YOU by hand.

TO REMOVE THE BOBBIN CASE

Open the window for removing bobbin case

located in the left side of the Oil Re

ceptacle. With left thumb and forefinger

open the latch (A) and hold securely as you

withdraw the bobbin case from around the

holder post (D).

On releasing the latch and turning the

bobbin case downward, the bobbin case

drop out.

TO INSERT THE BOBBIN CASE

After winding a fresh bobbin and threading

the bobbin case (see pagas 8, 9, 10 and

11), hold the case latch with left thumb

and forefinger, (as explained above) to

prevent the bobbin from falling out.

Keeping protruding finger (B) topside to

ward the delivery eye (C), press the

bobbin case around the holder post until

the finger (B) enters the delivery eye and

the latch mechanism catches the groove

near the end of the stud. This operation

is easy NEVER FORCE IT. Three or

four inches of the thread hanging free

from the bobbin case will be brought up

through the needle plate stitch hole as

shown on page 12.

Page 5

Fig. 3

Fig. 4

NOTE: This machine uses standard 15

class bobbins available at all sewing

stores. The bobbin can be wound

while machine is in operation by not

releasing the stop motion knob as de

scribed in below paragraph. Therefore

needle and bobbin winder will operate

at the same time.

Holding the balance wheel with the left hand,

turn the stop motion knob toward you. This

will permit tne balance wheel to turn freely

while the needle bar remains motionless.

Place a spool of thread on the spool (A).

Pass the thread through the tension disc (B)

at right corner of the base of the machine.

Now wind the end of the thread around an

empyt bobbin seven or eight times and place

the threaded bobbin on the spindle ‘(C) of

t^’e bobbin winder. Press the bobbin into

the spindle with the left hand, making sure

that the PIN on the spindle fits into the

SLOT in the bobbin. Push the bobbin winder

lever (D) down until the small rubber wheel

presses against the hub of the balance wheel

and the clasp (E} falls between the sides of

the bobbin, holding it in position. Turn the

balance wheel toward you and proceed to

operate the rheostat control, as in sewing,

when the bobbin is full, it will release auto

matically and stop turning. Break off the

thread and detach the bobbin from the spindle.

Hold balance wheel firmly with left hand and

with right hand turn the stop motion knob

away from you until the machine is tight and

the needle bar moves with the turning of

the balance wheel.

Page 6

Fig. 5

Fig. 6

10

Fig. 7

Hold the bobbin case between the

left thumb and forefinger with the

slot up. With 5 or 6 inches of

thread trailing in the palm, hold

the bobbin between the thumb

and two fingers of the right hand.

(Fig. 5)

Insert the bobbin into bobbin case

and pull the trailing thread into the

slot, down and to the left until it

enters the delivery eye under the

tension spring. (Fig. 6)

There should be a slight tension oil

the thread as it is pulled through

the delivery eye and the bobbin

should unwind freely. The tension

may be increased by turning the

tension screw to the RIGHT and

decreased by turning the screw to

the LEFT. (Fig. 7)

11

Page 7

Fig. 8-A

1. Place a spool of thread on spool pin (A)

and lead the thread through the notched

thread guide (A) on the face plate.

2. Run the thread through the tension discs

(C) FROM BACK TO FRONT.

3. Draw the thread up over the tension bar

(D) and through the wire check spring (E).

4. Now take the thread up through the eye

of the take-up lever (F) and down through

the thread gui des (G and H).

5s Thread the needle from left to right, pull

ing about six inches of thread through the

eye of the needle (1).

1. Place a spool of thread on spool pin (A)

and pass the thread to the left through

thread guide (.B).

2. Lead down from right to left between

tension discs (C).

3. Draw the thread up into the take-up spring

(E) until the thread enters the retaining

fork (D).

4. Now pass the thread through the hole of

thread take-up lever (F), and down to the

guide (G) on face plate.

5. Then lead into the wire guide (H) on the

needle clamp and thread the needle from

right to left, drawing about six inches of

thread through the eve of the needle Cn,

13

Page 8

Fig. 9

14

Thread machine

Pick up bobbin thread as follows;

Holding the loose end of the

needle thread in your left hand,

turn the balance wheel toward you

by hand until the needle moves

down and up again to its highest

point. Pull the needle thread

gently and the bobbin thread will

come up with it through the needle

hole (Fig. 9). If the bobbin thread

does not rise, check to see if at

lest 3 or 4 inches of bobbin thread

is hanging loosely from the bobbin

THEN PLACE BOTH ENDS OF

THE THREAD BACK BETWEEN

THE TWO PRESSER FOOT TOES

(A) (Fig. 9).

15

Page 9

Fig. 10

With the needle raised and the

threads drawn back, at least 4

inches through the toes of the

presser foot, place the material to

be sewn beneath the presser foot,

and lower the presser foot lever

as far as it will go. Insert needle

into material by turning the balance

wheel TOWARD YOU from top

down, by hand. Regulate stitch to

desired size (see page 21 ) and start

sewing.

Do not try to help the feeding of

the work by pulling the material,

as this may bend the needle and

cause it to blunt or break. As the

machine feeds without any assist

ance, it is sufficient merely to guide

the fabric gently, by hand in the

direction you want it be sewn.

To Remove the Work

Stop the machine by releasing the

pressure on the rheostat control

and stopping the balance wheel

with the right hand. Raise the

needle to its highest point and

raise the presser foot by lifting

the presser foot lever with either

hand. Now draw the sewn

fabric back and to the left about

eight inches and break or cut the

trailing threads.

Page 10

NON-

JAMMIHG

FEATURE

Fig- ITi

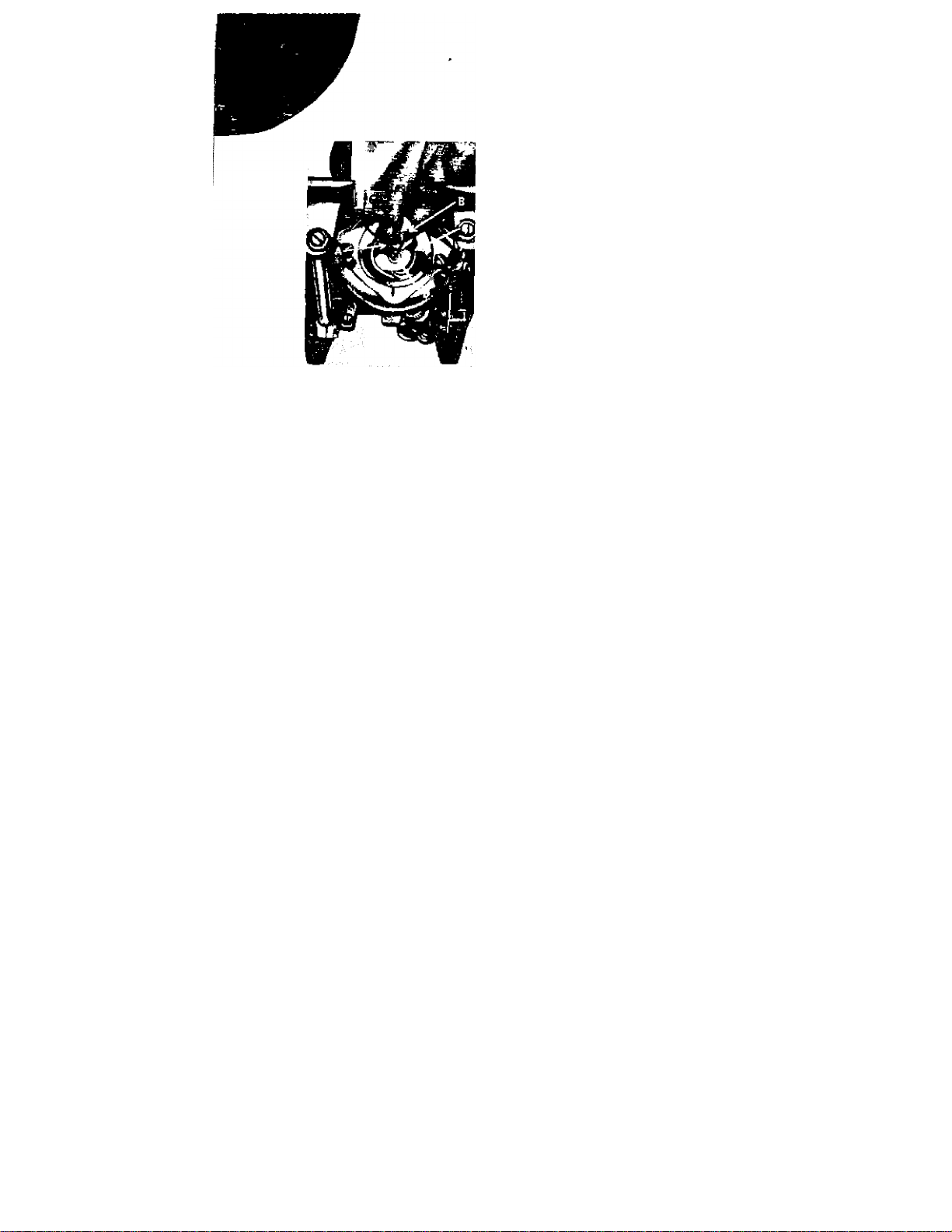

One of the outstanding engineering innovations incorporated in this machine eliminates,

for all practical purposes, the age old problem

of jamming.

Other round bobbin, oscillating machines tend

to jam, or freeze, when thread is impropetly

introduced into the race assembly. This

nitroduction of alien thread is usually the

result of sewing without material tn the ma

chine or of turning the balance wheel back

wards while the machine is threaded.

Should this happen while you are using your

machine, the thread will simply break and,

by the action of a scientifically cut hook.

18

the thread will be swept out of the race and

the machine freed almost instantly. The ma

chine may seem to become stiff for a

moment. Do not be afraid to free the ma

chine by turning the balance wheel TOWARD

YOU by hand.

Your dealer will be happy to show you the

operation of the precision engineered single

screw race assembly and to explain the action

of the cut hook in preventing jamming.

OTHER EXCLUSIVE FEATURES

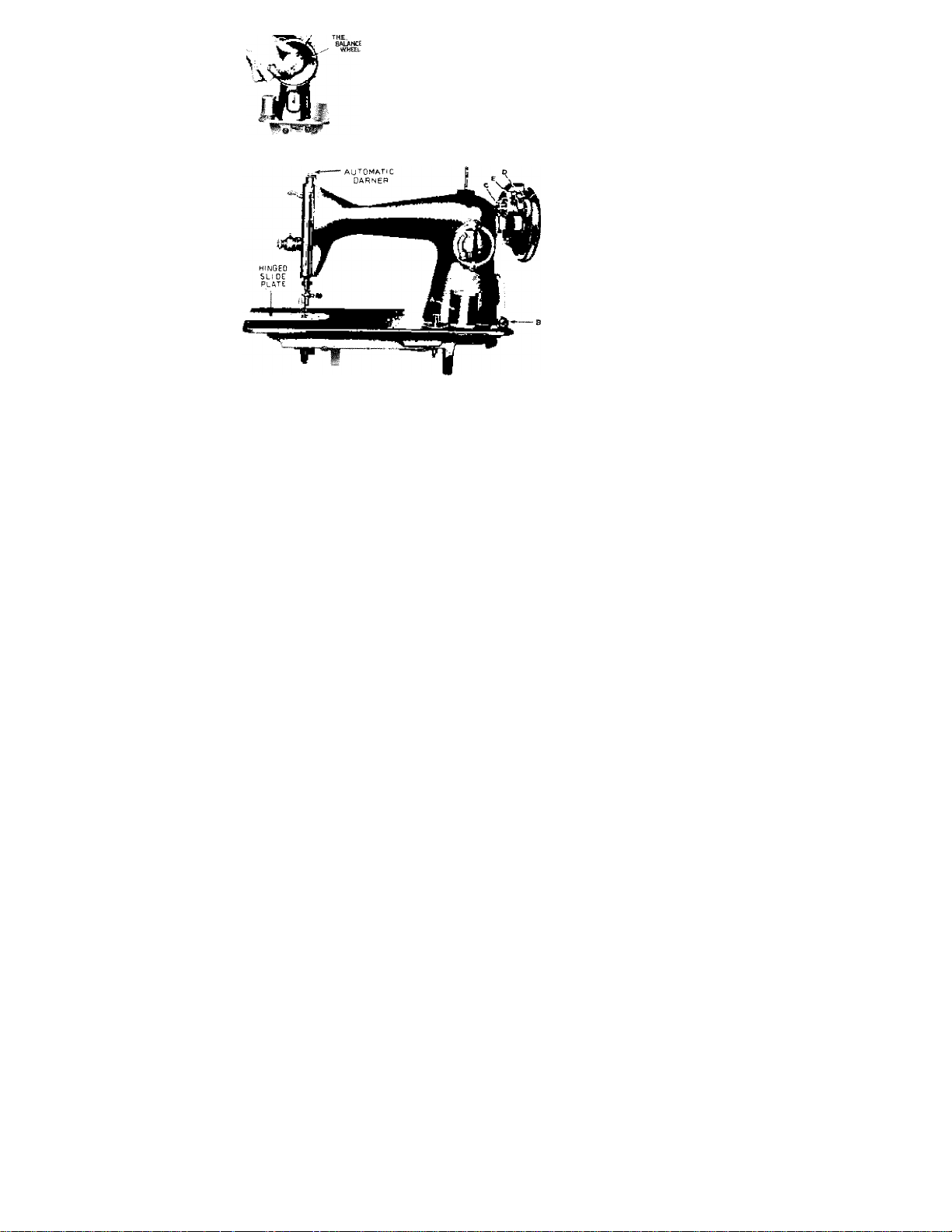

Automatic Darner i A new design with a

self adjusting spring loading mechanism. By

pressing the release spring the pressure bar

foot is relieved so that you may darn, mend,

embroider or monogram. (Fig. 4, page 8.)

Deck Drop Feed : By turning this device

to DOWN position the machine can be made to stop

tV feeding automatically and

f * ; t;,g material guided by hand.

Used with the automatic

darner, this will make darn

ing, monogramming, etc. much easier. The

special, exclusive adjustment for SILK makes

it possible to sew this fine material without

snagging.

Hinged Slide Plate: This exclusive improve

ment makes it possible to reach the bobbin

case easily by giving you much more hand

room than in any other machine. (Fig. 4, page

19

Page 11

Fig. 12

20

Your machine can be adjusted to

sew from 7 to 30 stitches to the

inch, forward or reverse, as desired.

To adjust the stitch length, move

the lever (A) to the center, or

neutral position. Loosen thumb

screw (B) and move it up. When

the thumb screw is in its lowest

position, a 7 will appear in one of

the two windows at the right. As

it is moved up, toward the top,

the numbers 1 2, 1 5, 20 and 30 will

appear in the windows. These

numbers indicate the number of

stitches per inch, 7 being largest

and 30 the smallest stitch practical

for home sewing.

As the desired stitch setting ap

pears, tighten thumb screw, thus

automatically locking the adjusting

plate.

To sew FORWARD, pull lever (A)

down as far as it will go. To sew

REVERSE, push lever (A) up as

far as it will go. You can sew the

same size stitch forward or reverse,

by merely flicking lever (A) down

or up.

Never sew in the neutral

position (0-Fig. 12)

21

Page 12

For perfect stitching, the tension

on the upper and under threads

should be equal, and just sufficient“

ly strong to lock both threads in

the center of the work (A)

(A,) Fig. 13

If the tension on the needle thread

is too tight, or if that on the

bobbin thread is too loose, the

needle thread will lie straight along

the upper surface of the material,

making an imperfect stitch (B).

Fig. U

If the tension of the bobbin thread

is too tight, or if that on the nee

dle thread is too loose, the bobbin

thread will lie straight along the

under side of the material, making

an imperfect stitch (C).

Regufating the Neecife Tension: Minor

imperfections in the stitch can usually

be corrected by varying the needle

tension only.

To increase the tension, turn the thumb nut

(diagram) clockwise; to lessen the tension,

turn the nut in the opposite direction. The

tension adjust from 0 to 9 in one 360 turn,

with 0 being the lightest tension and 9

being the tightest. All adjusttr.ents should

be made gradually, not abruptly, and the

required tension setting will vary with the

size of thread being used. A little practice

will make instant tensio.n adjustments possible.

All adjustments should be made while the

presser foot is down since an automatic

release does not permit adjustments to be

made when the foot is up. If a perfect

stitch cannot be obtained by adjusting the

needle thread tension, it may be necessary

to adjust the bobbin thread tension as ex

plained on page 10, Fig. 7. This mach.ine is

correctly adjusted before leaving the factory

and checked and readjusted before the dealer

delivers it to you.

A careful regulation ot the tensions on this

machine will assure you of the finest seams

that mechanical design will produce.

23

Page 13

Pig. 16

A sewing machine never needs

grease. All moving parts which

come in contact with others, must

be covered with a film of oil, and

should not be allowed to become

dry. Oil, when necessary, should

be applied at the points indicated

by the arrows in Fig. 16, a drop

of oil being sufficient at any one

place. Oil should be applied

freely at all contact points on the

underside of the machine. A few

drops of oil in the bobbin race

will help your machine to run

freely.

When oiling, insert the oil can

nozzle well into oil holes.

After oiling, run the m.achine

rapidly for a fe w minutes, so that

the oil may penetiate into the

bearings. For the proper care of

your machine oil -frequently.

Neglecting to do this tends to

shorten the life of the machine,

and may cause trouble and an

noyance.

Page 14

SEWING MACHINE PARTS

-■¿■i ■ 1 «& ■

a 115

Page 15

1 Main Shaft

2 Thread Take Up Cam

3 Stud Screw ar^d Nut for Thread

Take Up Cam

4 Thread Take Up Cam Screw

5 Main Shaft Bearing

6 Main Shaft Bearing Set Screw

7 Counter Balance

g Counter Balance Set Screw

9 Feed Cam

10 Feed Cam Set Screw

11 Balance Wheel Bushing

12 Washer for Stop Motion Screw

1 3 Clamp Stop Motion Clamp Screw

14 Stop Screw for Clamp Screw

15 Cap for Thread Take Up Lever

Hoie

16 Taper Pin for Balance Wheel

Bushing

17 Thread Take Up Lever Stud

Screw

18 Thread Take Up Lever Assembly

19 Darner

20 Presser Bar Spring Bracket

21 Presser Spring

22 Presser Bar

23 Presser Foot

24 Presser Foot Thumb Screw

25 Oil Cap for Needle Bar

26 Needle Bar

27 Needle Clamp

28 Needle

29 Needle Bar Thread Guide

30 Thread Cutter

iCey NO.

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

56

57

58

r'arts rvame

Set Screw for Needia Bar Thread

Guide

Taper Pin for Lower Shaft Crank

Needle Bar Bearing

Needle Bar Connecting Link

Needle Bar Stud

Forked Connecting Rod

Peed Forked Connecting Hinge

Screw with Nbit

Crank Rod

Rock Washer

Slide Block for Feed Regulator

Stude Screw for Feed Regulator

Slide Block

Feed Regulator

Set Screw for Hinged Stud

Screw

Hinged Stud Screw for Feed

Regulator

Crank Rod Taper Screw with Nut

Set Screw for Lower Shaft Crank

Lower Shaft Crank

Lower Shaft

Shuttle Driver with Spring

Presser Bar Lifter Pin

Piesser Bar Lifter

Set screw tor Presser Bar Liiter

Pin

Slide Roller and Stud for Drop

Feed Bracket

Peed Bar

> Feed Dog

Feed Dog Set Screw

Toper Center Screw for Feed Bor

Taper Center Screw with r,ut

Key No

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

90

Parts Name

Oscillating Rock Shaft

Lower Shaft Crank Slide Block

Horizontal Feed Rock Shaft

Vertical Feed Rock Shaft

Drop Feed Connecting Rod

Drop Feed Plate

Drop Feed Bracket Assembly

Drop Feed Plate Screw

Drop Feed Knob

Drop Feed Rod Bearing

Cutter Pin

Hinge Stud for Drop Feed Con

necting Rod

Drop Feed Rod Spring

Drop Feed Knob Rod

Shuttle Race

Shuttle Hook

Bobbin Case

Bobbin

Shuttle Race Screw

Needle Plate

Slide Plate Spring

Slide Plate

Spring Screw

Needle Plate Set Screw

Face Plate Assembly

Face Plate Screw

Upper Thread Tension Knob

Tension Dial

Cap Washer for Tension Dial

Upper Thread Tension Spring

Cap for Tension Dial

Thr«i"d W/--!-

Thread Take Up Spring

92

Tension Stude

93

Tension Release Pm

94

Arm Slide Plate

95

Arm Slide Plate Screw

96

Stitch Dial Plate

97

Limitting Plate for Feed Regula

98

tion

Stitch Dial Lever and Nut

99

Stitch Dial Plate Screw

100

Balance Wheel

101

Fixing Screw and Washer

102

Limitting Plate

Washer for Fixing Screw

103

Ball Oiler for Bobbin Winder

104

Bobbin Winder Assembly

105

Bobbin Winder Set Screw

106

Name Plate Screw

107

Tag P’*'^

108

Head Set Screw for Head Hinge

109

Bobbin Winder Rubber Wheel

no

Cord Bushing

111

Bobbin Winder Tension Bracket

112

Assembly

Set Screw for Bobbin Wmder

113

Tension Bracket

V Belt ,

114

Dial Tension for Bobbin wmder

115

Accessories Box

116

Oiler

117

118

119

120

121

122 Spool Pin

)23 Needle

124 Oil

For

Felt

Bobbin

Driver (Large)

Driver (Small)

Page 16

Loading...

Loading...