SINGER W9951 User Manual

Mi

о и U J о

\У

- г

- X

кй о

■2

iti J

J ч

•2

I-- с

С. 5

ц ш

i:

г

«А

■3

Ф

W

■1

<

V

'U

о

У

J

О

<

c=¿. '

Ò

•sj

Г^^<\ г

ä'3f

, ^ V-

J>-

'Лг-

К-г

\

■Ь--!-''

■ :'. -Í

1 ::•";

!.>•■-*• *j

i.-’v'-*

B'‘^d

m

s

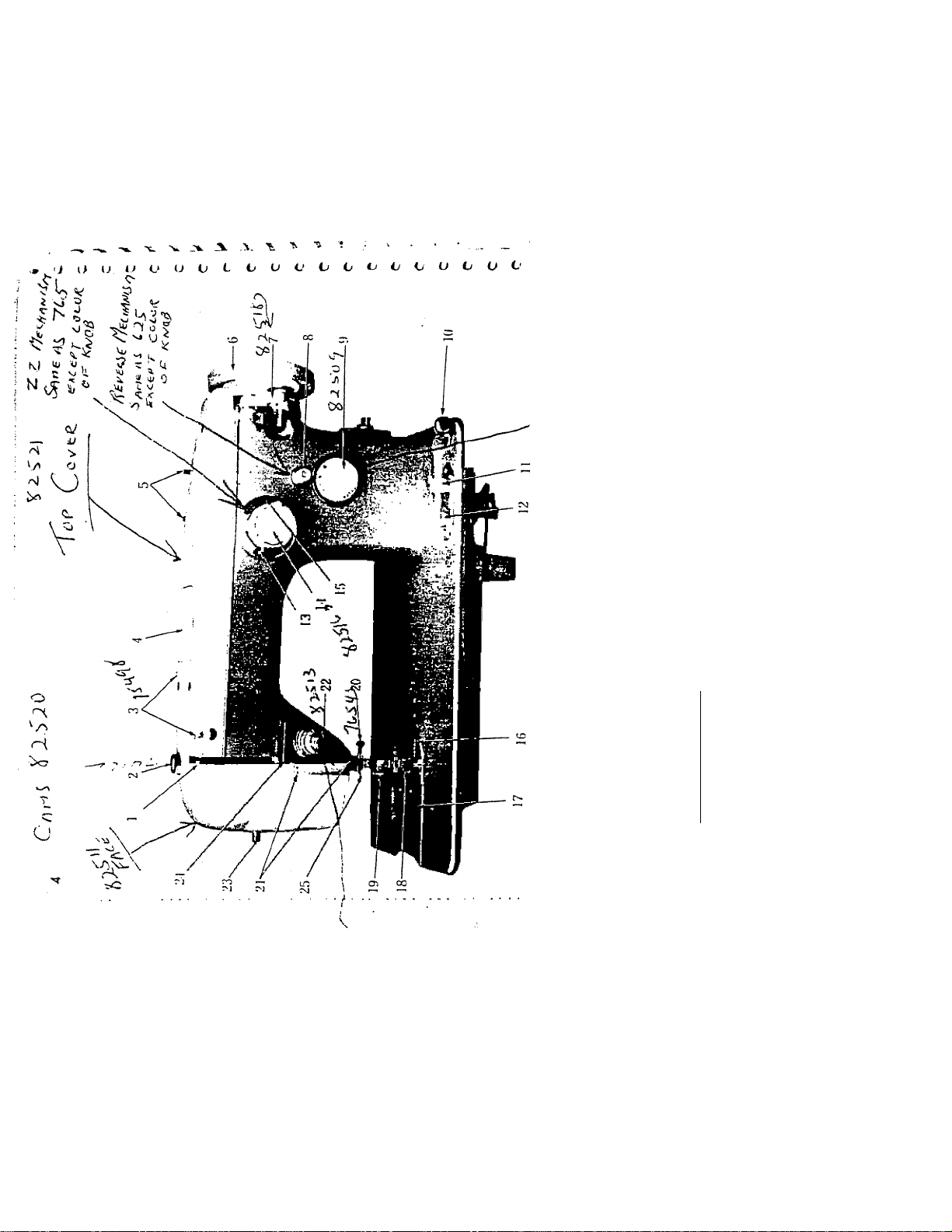

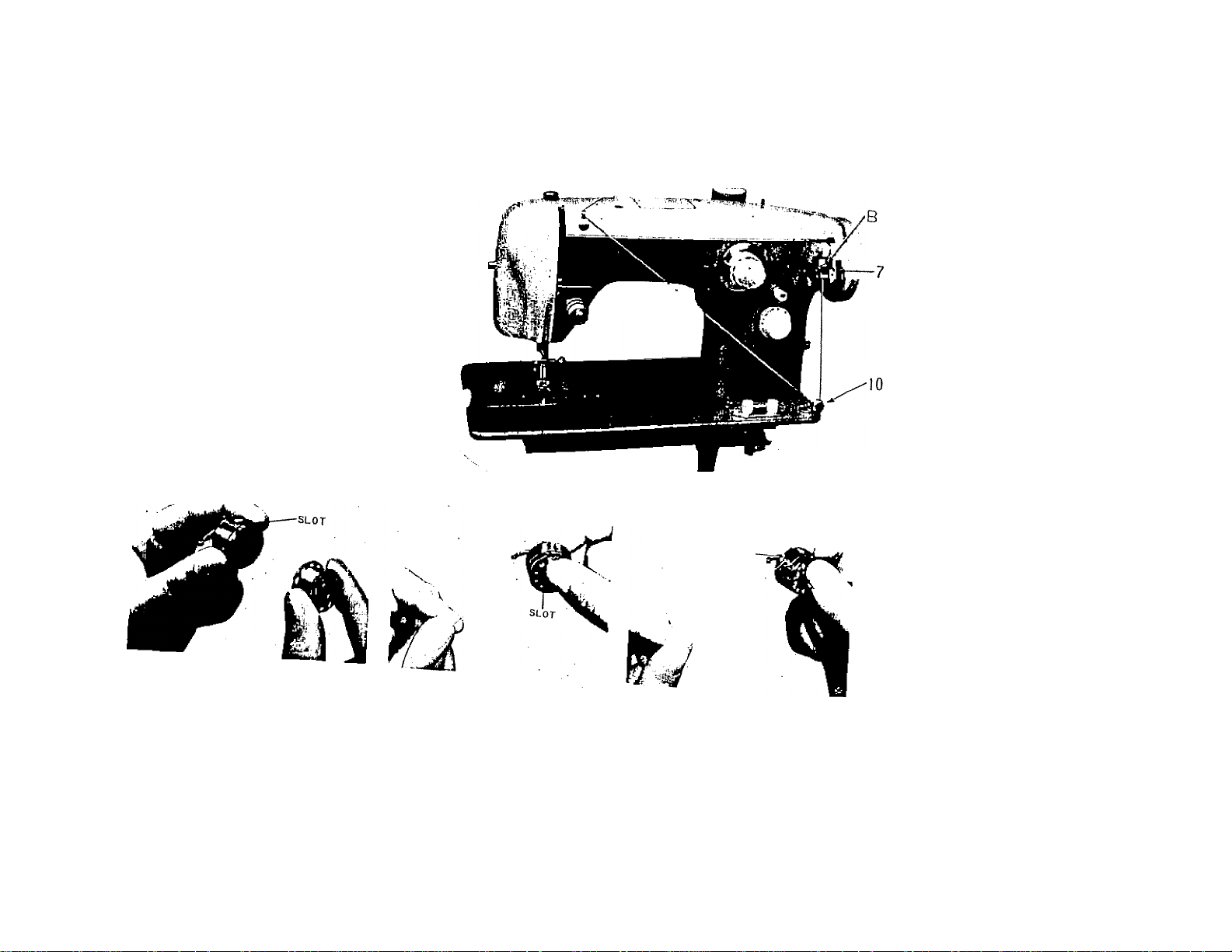

features and parts

(Front view)

1- Take-up lever

14. Stitch width knob ^ X^j I

2. Pressure release-darner

3. Arm thread guides

4.

Cam access door

5.

Spool pins

6. Hand wheel

7- Bobbin winder Y X S') y'

8.

Stitch length dial

^ 9.

Push button reverse I

10.

Bobbin winding tension

11- Feed button "UP"

12. Feed button "DOWN"

13. Width lock

IS- Zigzag width control dial

16. Needle plate-seam guide 5't-’ i 7 ^2 ~2 j

17. Cover plate 7 7S3L

18. Presser foot

19. Attachment and foot thumb screw

20. Needle clamp and screw

21. Thread guides

22. Tension regulator 'S' '2S^i^

23. Light switch

24. Thread guide bar

25. Needle bar thread guide

r

k

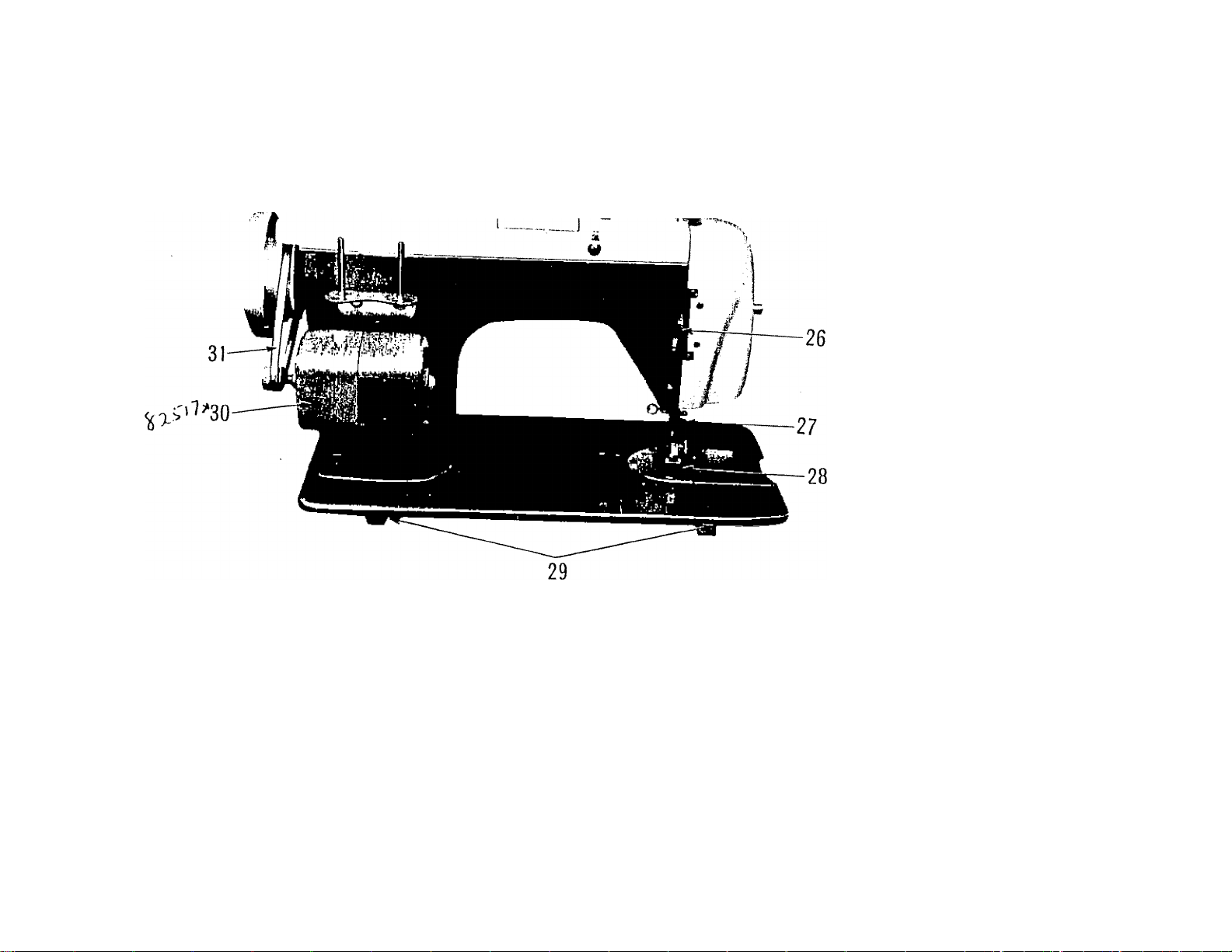

features and parts

(Back view)

c i

: f

: f

: \

r Ì

- I

r I

I

Rg. 2

26. Presser bar lifter

27. Thread cutter

C

28. Feed

29. Head hinge mounting holes

30. Motor -2 !> I 7

31. Belt

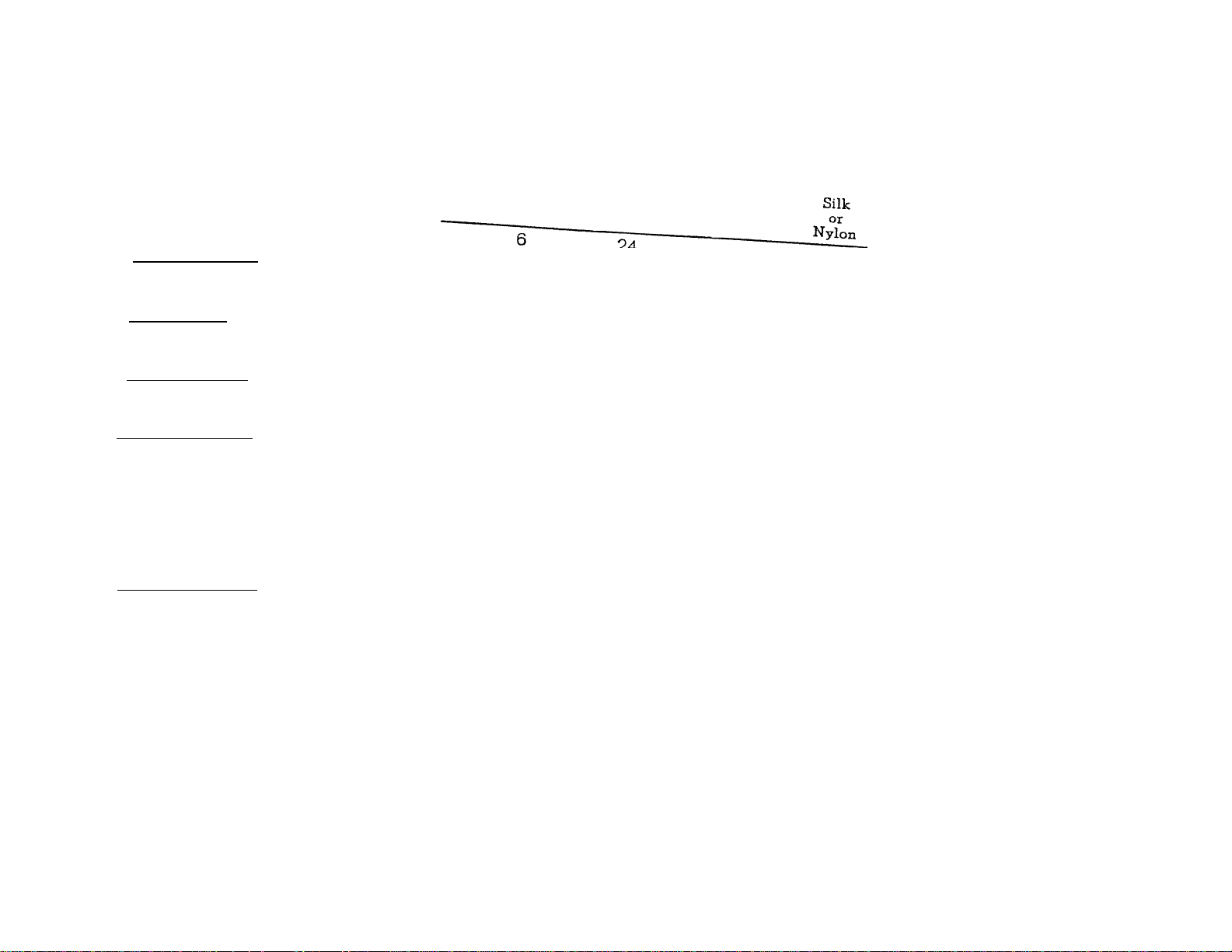

needle • THREAD - FABRIC BTTTr-TJTM/-,

STITCHING GUIDE

Fabric

Extremely Heavy tarpaulin, sacking canvas, duck, etc.'

Heavy upholstery

j brie, ticking,

denim, leatherette

tabric, velveteen

suiting, felt, terry, etc.

gmgham, linen, chintz taffete

^heer wool, shantunrr ^

Sheer voile, lawn,

dimity, crepe,

handkerchief linen

plastic film, etc.

Very sheer chiffon,

oatiste, lace, organdy

_^non, net, marquise^ etc.

Needle

No.

Hachine

Stitches

Per Inch

14

to

16

(Plastic film)

8 to 10

Cotton

Thread

40

to

60

60

to

80

~80

to

100

100

to

150

Mercerized

Thread

Heavy Duty

50

50

50

A

A

A

SETTING THE NEEDLE

See Fig. 3. Raise the needle bar A ifo i.- u j.

point turning wheel toward you by hand

needle^SanXTnseSeTiit^^^ <jlamp screw Band the

(flat side to clamp c. pj^ee needle

eSs, tlgSenlng ^til leldi: Slmo"

with a screw driver ^ securely

Flat surface

oi needle

shank

aiaiiging Iho needle ,„ai,„ „„„

I.anl'r.:\rLlrC

position. »««uie IS m the correct

WINDING THE BOBBIN

mecSSaTrr tohnXIiSSE'l tSi/)

wise. ^ ciurcn D toward you or counterclock-

thrSgh Pj“». thread

the tension disc (10 (Fig 5 ) at the down through

end of thread through a ¿oli fn 1 machine. Run

bobbin B on spindle of bSn winder

bobbin over small pin on spindle Push BeKK^^ “°tch on

/

0 I

Fig. 4

from you until iewing” me?ha!lrsm‘(*“ *‘**'*-‘*' “‘“‘“tt away

needle rnovea „hen you turn the haidXh“”®"'* so that

c-

Break oH loose thread end used to sTart the winding.

c

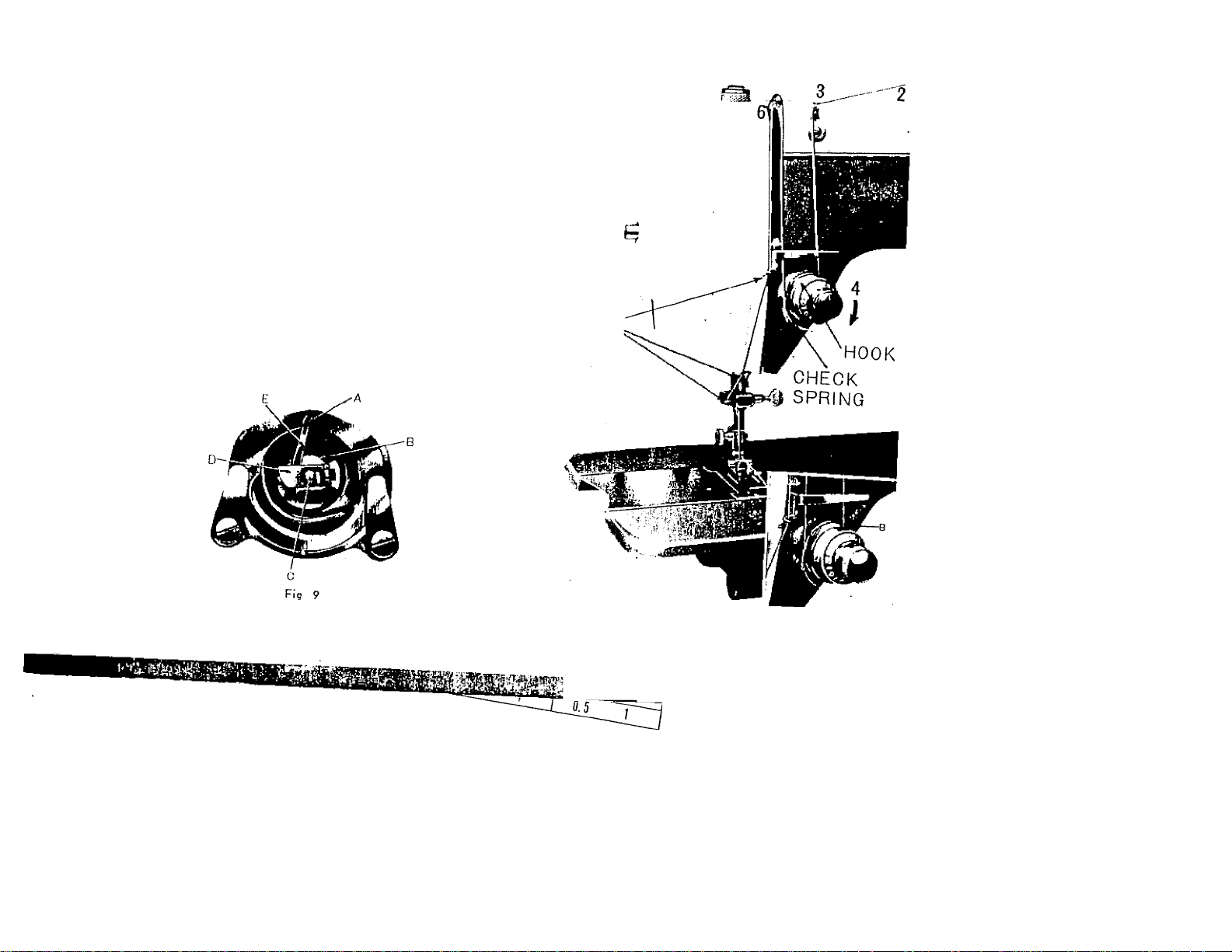

THREADING THE BOBBIN CASE

bobbin^casi betwe^eif th/^b

finger of left hanrl ^ fnnmb and foretbe edge of the bohK°

Take the bobbin K«/“ ^P-

forefinger of riSht^ and

thread on top ;ii the

Step 2. Insert bobbin into bnhK°

pull the thread in+r, +u ^ i oobbin case,

bin case aa™ „ ‘ha b„b;

it Under the tension • and draw

fork-shaped opening^^oTSir"^

shown in Fig. 8. ^ ^ “ spring as

Fig- 5

tension spring-

Fig. 6

Fig. 7

Fig. 8

10

placing bobbin case in shuttle

pg. 9, between the thumb

band, with at least thrf^o^ u of the left

from the top of the bobbin cii?o°th‘^"®^d

and center the bobbin casf ^"s®rt

shuttle body, (C). BeLrefh 'fun® the

(Ej, is opposite thp> shuHT ^ hobbm case finger

the bobb^Soase (S)l^ito P^^ss

sible until latch catches P°b-

shuttle. catcdes on the center post of the

c I

c I

r I*

Press bobbin^ cise “larh\

leased to make sure the bSbin^ ^t®“

eecurely in place. Clos: thfciverpLte.

THREAD

guides

c

c

Fig. 10

»?

I

t"

i

<•

UPPER THREADING

1. Turn the balance „heel toward you to raise the

take-up lever to its highest position

2. PI,« a si^ol of thread on the spool pin,

4. Hun thè thread through the thread guide bar to

e tepsmu discs, then around and between

them from right to left. ^

5. Draw the thread up through the

i^ig- 11

Г.."лг =

.. ... *, a. ,,

7. Lead thread down through the far-« i x .

from the back. ° »“i tbeu through the needle bar guide

8. Thread needle PHOM LEFT TO RIGHT, drawing Ц thr h u

end of .pper thread loosely and turn hand *Гее1 tow 7 ^ ^ “>»

way do^n and comes back up. Д bop will be n ‘be

can be pulled out straight. Place both thread o7 n“™' "‘““b “*en

draw toward the back of the machine, leaving bot^th d' 7

ving both threads three or four inches long

11

12

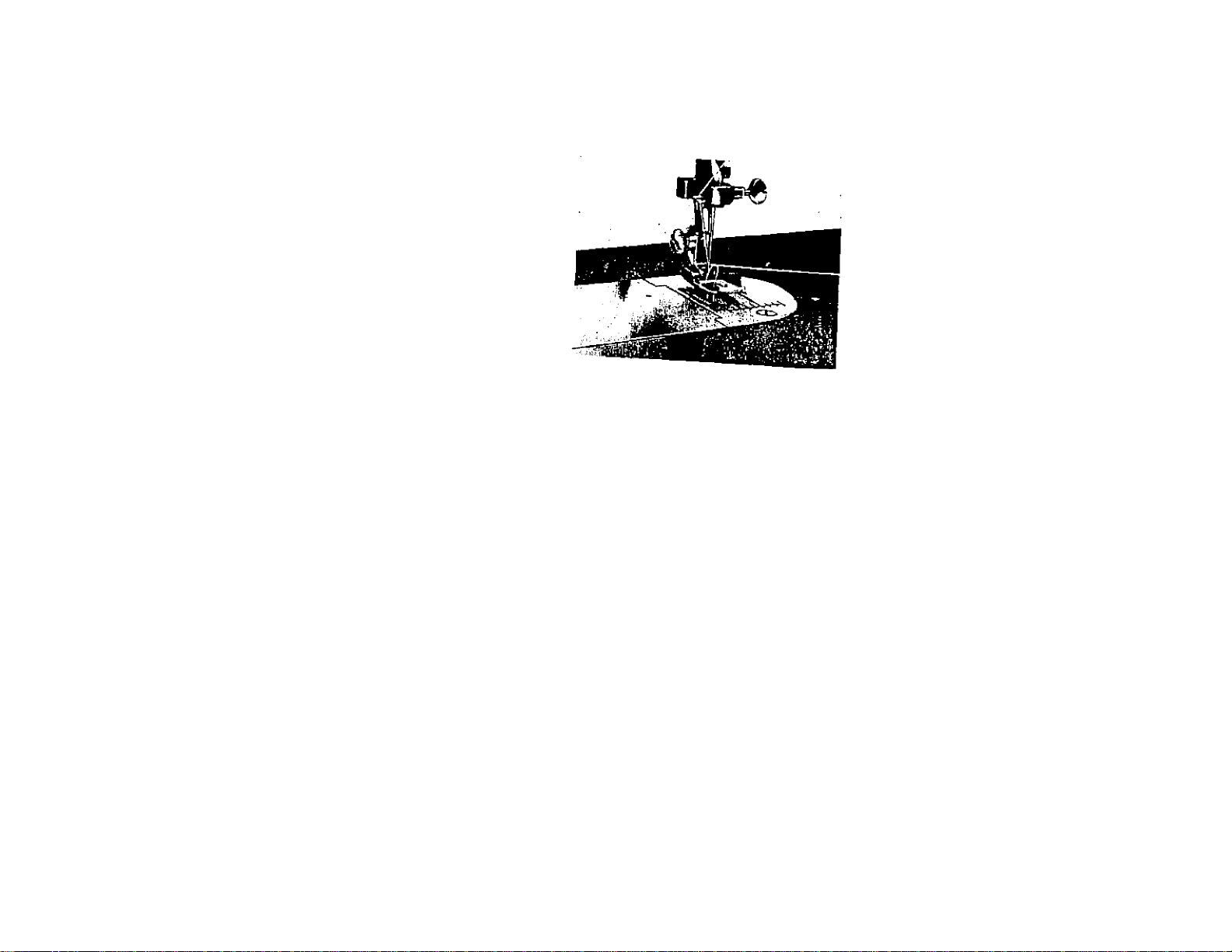

STRAIGHT STITCHING

For straight sewing on fine fabric or very soft

material, you may want to use the straight stitch presser

toot and the straight stitch needle plate which are in

cluded in your accessory box. Both have narrow

needle slots.

Changing the Foot and Plate. To change presser

foot (18, Fig. 1) loosen thumb screw 19 and remove

zigzag foot. Replace with hinged narrow foot and

tighten screw securely.

and lift off with cover plate 17 attached. Turn assembly

wrong side up. Hold needle plate with right hand and

cover plate with left. (Fig. 12)

Press corner of cover plate down slightly and pull

needle plate upward, slipping upper pin needle plate

out ot groove. Then slide lower pin out.

Attach cover plate to straight stitch plate by reversmg the above procedure. Slip pin on lower side of

needle plate into groove on cover plate.

Slic^ upper pin under lip and into groove on cover

plate, rut plates on machine and fasten securely with

needle plate screws.

Be sure to set the stitch width at 0, or the needle

will break in striking the foot or plate.

Grasp outer rim of zigzag dial A, Fig. 13, and

press down on lock B. Turn dial as far to the left as

possible. Pointer will then be on the zero mark

remove screws

Fig- 12

Fig. 13

C i

C ^

c ^

c

c

c

c

c

c

c

c

c

c

c

c

r*.

c

c

c

✓

y-

¡■S'

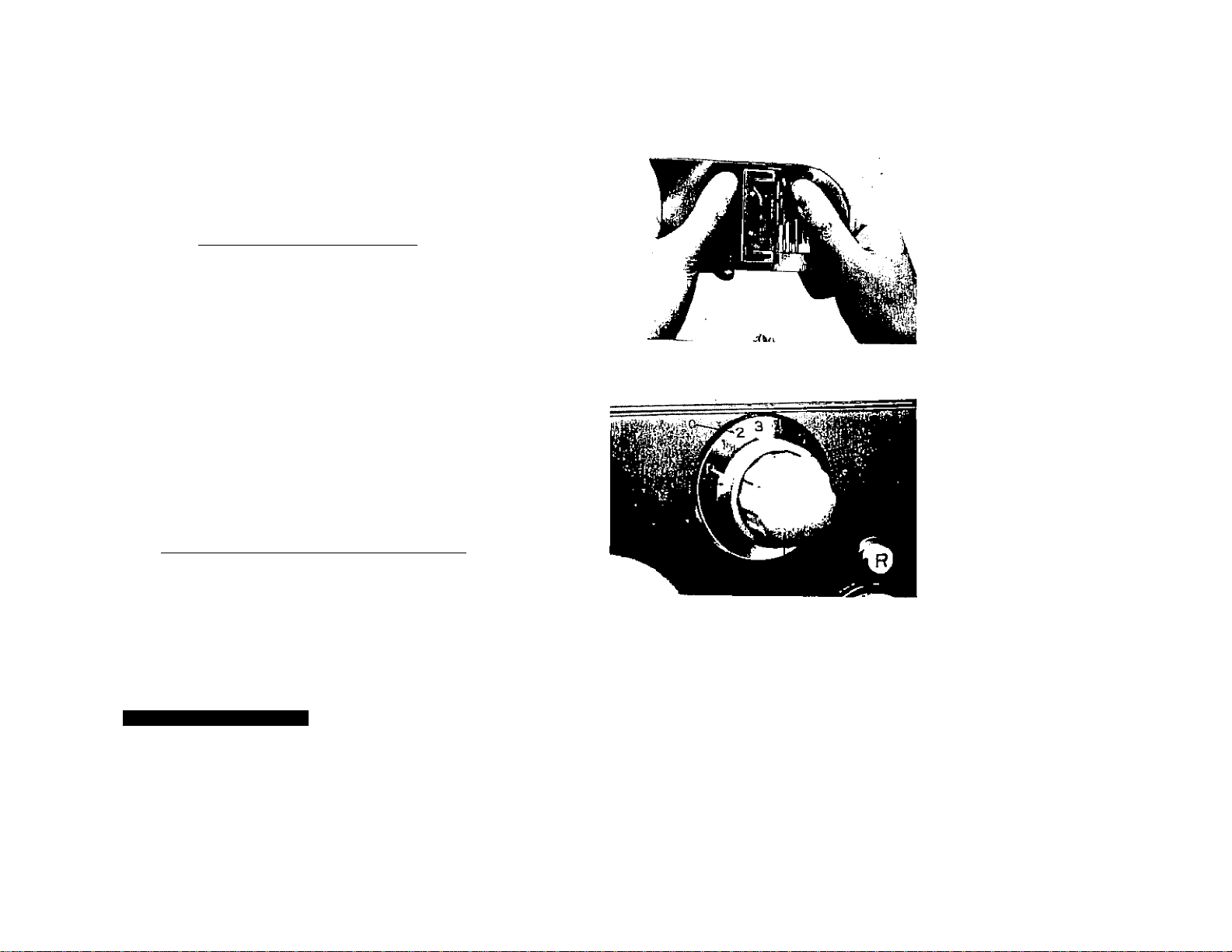

SETTING THE STITCH LENGTH

Fia Ia 'nb«*! by the dial, shown in

J- i ahortest stitch and 5 is the lonaest hnt

the dial may be set at any snot between tT,<n rv. i

variety of lengths. Turn the dSd to tirSght to TenX. ”

to the left to shorten the stitch. The nur^er of ^stitch length

you choose is indicated by the triangular pointer.

STITCH LENGTH CHART (APPROXIMATE)

Figures on indicator ~o 1 2 3

Number of stitches per inch No Feeding 'SQ ' 2S 15 lo'

------4--------

SEWING IN REVERSE

beghSim ore^'^of*a IT threads at the

neginmng or end ot a seam, press m the button F! Firr 1Q

as far as it will go. The machine will sew backw^rAc^l

the button is held in. backward as long as

ADJUSTING THE TENSIONS

Always adjust the upper tension with the oreRRor a

as the tension is automatically released when^it is raised'^^'rii

more.Be the tens on on the upper thread, turn dLl fIo IB)

‘h°al::r"£‘n„” blro^rthe dS fhe?*K;r‘T i

ediuBtina lower tension he sure th.‘t‘l‘;^i\SrrthrS,1

13

5

7

Fig. 14

BcrewiyrsTon'Lidlo^tSrhc^^biiof/“i“' I”*“

counterclockwise to loosen. clockwise to tighten,

Fig. 15

Loading...

Loading...