SINGER W951 User Manual

0 ф

INDEX

Page

INDEX

....................................................................

REFERENCE GUIDE FEATURES AND PARTS

NEEDLE-THREAD-FABRIC-STITCHING GUIDE ... 4

SETTING THE NEEDLE

WINDING THE BOBBIN

TO REMOVE OR REPLACE BOBBIN CASE............................ 7

г

О

ч.

TO THREAD THE BOBBIN CASE....................................... 8

UPPER THREADING..................................................... 9

SETTING THE STITCH LENGTH

STITCH LENGTH CHART (APPROXIMATE)

SEWING IN REVERSE.................................................. 10

PREPARING TO SEW.................................................. 11

REMOVING THE WORK............................................... 11

ADJUSTING THE TENSIONS.......................................... 12

STRAIGHT STITCHING

ADJUSTING PRESSURE AND FEEDING OF

FABRIC.................................................................. 14

SEWING THIN OR LIGHT WEIGHT FABRICS

DARNING AND MENDING

ZIGZAG STITCHING .................................................... is'

NEEDLE POSITION CONTROL

CREATIVE EMBROIDERY.............................................. 16

EMBROIDERY PATTERNS ............................................ 16

SAMPLE EMBROIDERY PATTERNS

TWIN NEEDLES-UPPER THREADING AND

SEWING

BLIND HEMMING....................................................... 20

.................................................................

BUILT IN DECORATIVE STITCH DESIGNS

...........................................

.................................................

.....................................

................................................

.............................................

........................................

..................................

___________

....................

..................

.....................

2-3

5

10

10

13

14

14

15

17

18

19

1

6

BUTTONHOLES ....................................................,21-22

SEWING ON BUTTONS................................................. 23

SEAM GAUGE OR CLOTH GUIDE.................................... 24

NARROW HEMMER

LACE TRIMMED HEM................................................... 26

LACE EDGE WITH INVISIBLE STITCHING

FRENCH SEAM ......................................................... 26

HEMMING ACROSS A SEAM

THE ADJUSTABLE CORDING AND ZIPPER

FOOT.................................................................... 27

SEWING IN A ZIPPER

CARE AND MAINTENANCE OF YOUR

MACHINE................................................................ 28

HOWTOOIL YOUR MACHINE

HOWTO REPLACE THE LIGHT BULB

HOW TO CHANGE THE BELT

ACCESSORIES........................................................... 31

TROUBLE CHART................................................... 32-34

SOME OF THE ATTACHMENTS AVAILABLE

FOR YOUR MACHINE................................................... З6

ATTACHMENT FOOT .................................................

EDGESTITCHER..................................................... 37-38

BINDER

.................................................................

FOLDED BINDING

TWO-TONE BINDING................................................... 39

HAND-CUT BIAS BINDING

THESETOF HEMMERS

HEMMER SET

...................................................

.....................

...........................................

..................................................

..........................................

.................................

.........................................

......................................................

............................................

..................................................

.......................................................

Page

25

26

26

27

29

29

30

37

39

39

39

40

40-41

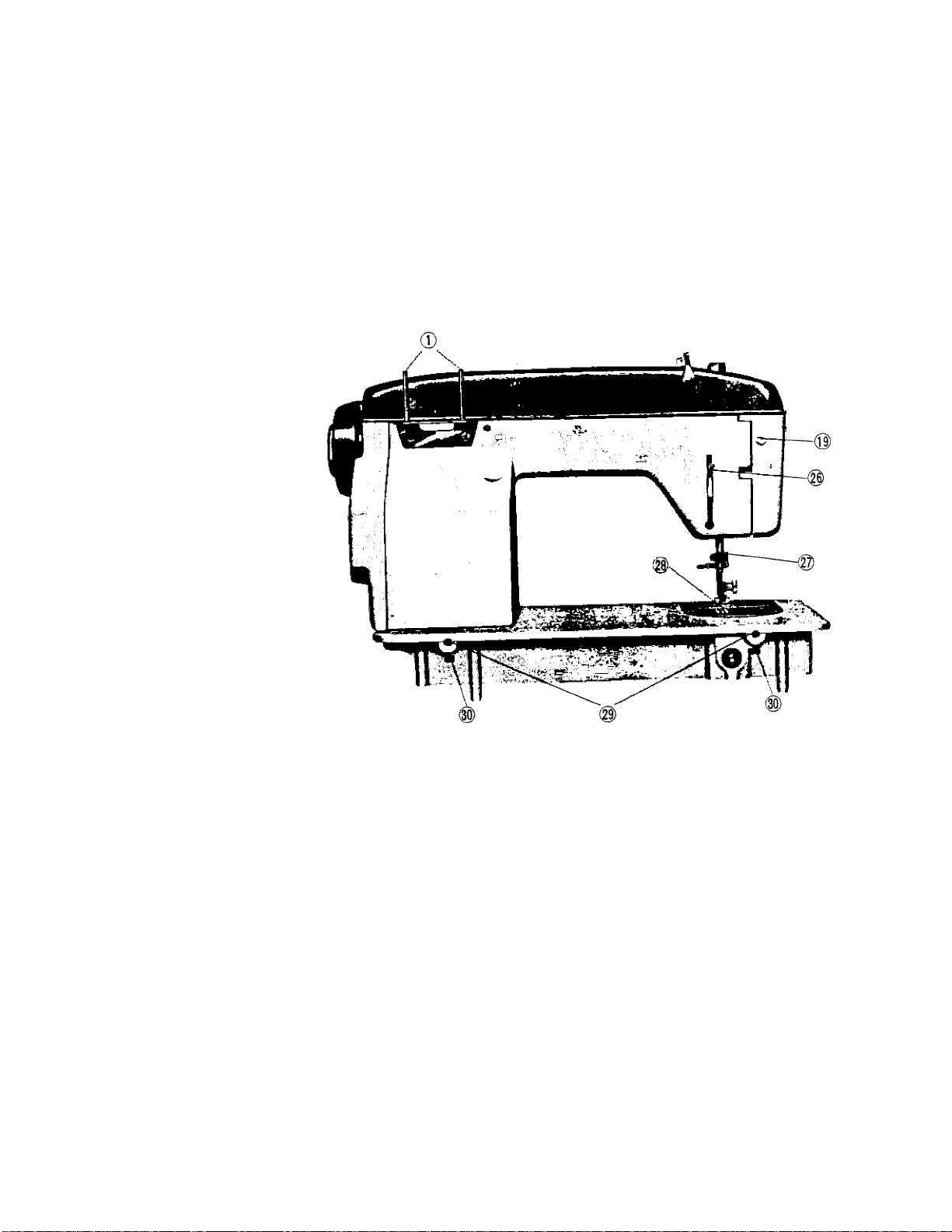

REFERENCE GUIDE FEATURES AND PARTS

\

1. Spool Pins

2. Hand Wheel

3. Stop Motion Knob

4. Stitch Length Dial

5. Reverse Push Button

6. Zigzag Width Lever

7. Stop Lock

8. Fabric Selector

9. Bed

10. Needle Plate

11. Slide Plate

12. Presser Foot

13. Presser Foot Thumb Screw

14. Needle Bar Thread Guide

N1

it

1 . .

A

%

I'S)

l-KD

Fig.1

15. Needle Clamp Screw

16. Arm Thread Guide

17. Thread Tension Dial

18. Face Plate

19. Push Button Light Switch

20. Take-Up Lever

21. Darner

22. Upper Arm Thread Guide

23. Arm-Top Cover

24. Pattern Indicating Board

25. Pattern Selector Dial

26. Presser Bar Lifter

27. Thread Cutter

28. Feed Dog

29. Hinge Holes

30. Hinge Set Screws

31. Needle Position Lever

32. Bobbin Winder Cover

33. Bobbin Winder Tension Disc

Fig. 2

Fig. 2 Features and Parts you should know (Back View)

-3 -

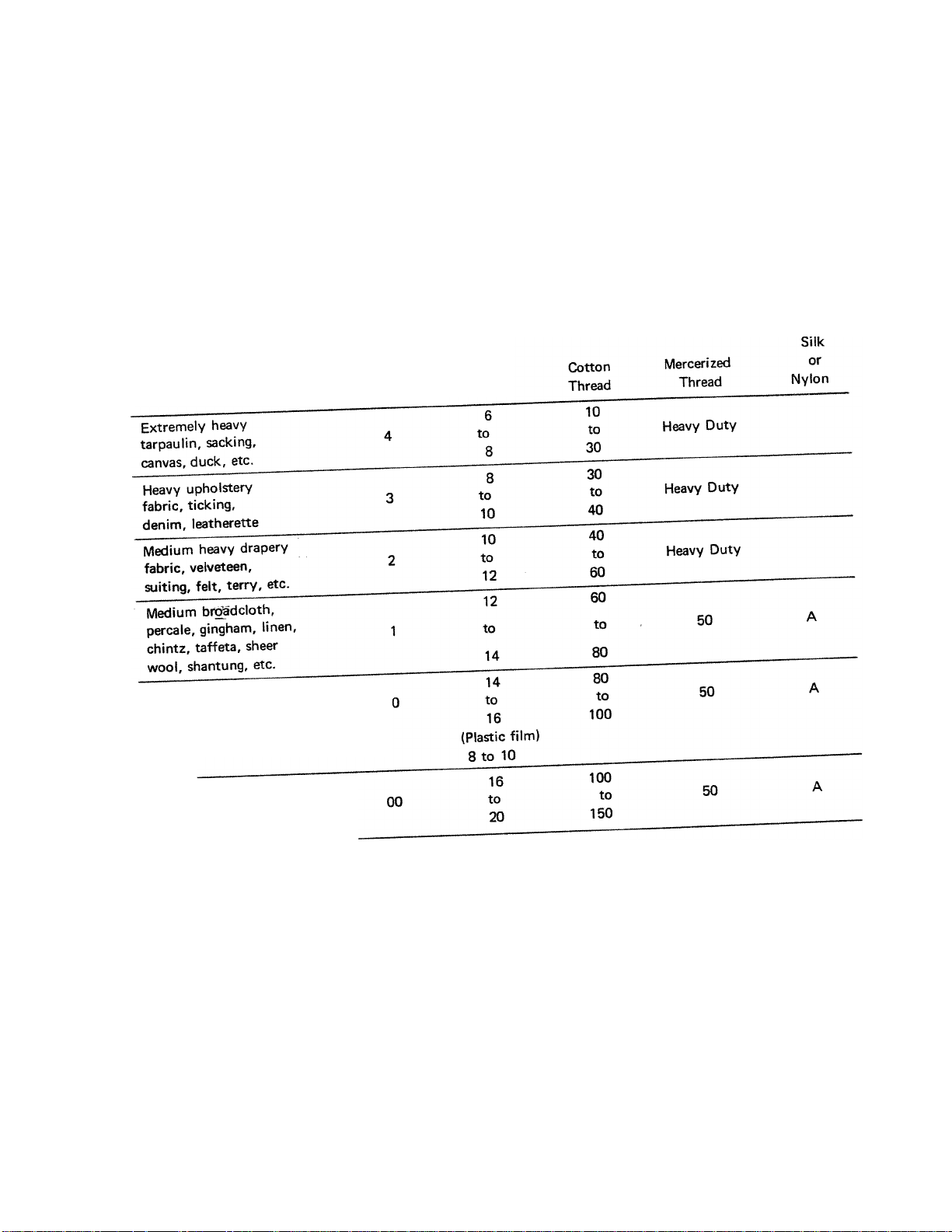

Fabric

Sheer voile, lawn,

dimity, crepe,

handkerchief linen.

Plastic film, etc.

NEEDLE-THREAD-FABRIC-STITCHING GUIDE

Machine

Needle

. . No

Stitches

Per Inch

Very shea" chiffon,

batiste, lace, organdy,

ninon, net, marquisette, etc.

SETTING THE NEEDLE

FLAT

See Fig. 3. Raise the needle bar "A" to its highest

point, turning wheel toward you by hand (Fig. 4).

Then loosen the needle clanrip screw "B" and the

needle can be insert«! into clamp "C". Place needle (flat

Fig. 3

side to back) in the needle clamp and push it upward as far

as it will go into the needle clamp hole, tightening the

ne«ile clamp screw securely.

Aft«- Changing die needle make one «»mplete

revolution of hand wheel by hand to be sure the needle is

in the correct position.

Fig. 4

,, you onoounter an, prob,an,s „i,h your ™d,in. after cbangin, ,be n»<«a such as puckering, skipped stitches, or

needle and thread breakage, check the following: ,

(1) Is the needle up as far as it will go into the clamp?

(2) Is the flat side to the back ?

(3) Is the needle the right size for the thread used ?

(4) Have you tightened the clamp securely ?

(5) Is the needle bent or the point blunt?

SIDE OF

NEEDLE

Fig. 5

WINDING THE BOBBIN

Disengage the hand wheel (Fig. 6) from the stitching mechanism

by turning the stop motion knob toward you or counterclockwise.

Place a spool of thread on one of the spool pins, lead thread through

the upper thread guides on the arm, and down through the tension disc

11 (Fig. 7) at the base of the machine. Run end of thr^d through a

hole in the bobbin edge and place bobbin on spindle B of winder

"4", fitting the notch in bobbin over small pin on spindle. Push bobbin

winder pulley against hand wheel.

Hold thread end loosely and start machine slowly.

Bobbin will be released automatically when it is filled. Break off loose

thread end used to start the winding.

Turn stop motion knob av»ray from you until sewing mechanism is

again engaged so that needle moves when you turn the hand wheel.

If the bobbin winds unevenly, adjust bobbin winding tension disc

11, (Fig. 7) to the right or left by loosening the Kirew. When disc is

in proper position, tighten screw.

Fig. 7

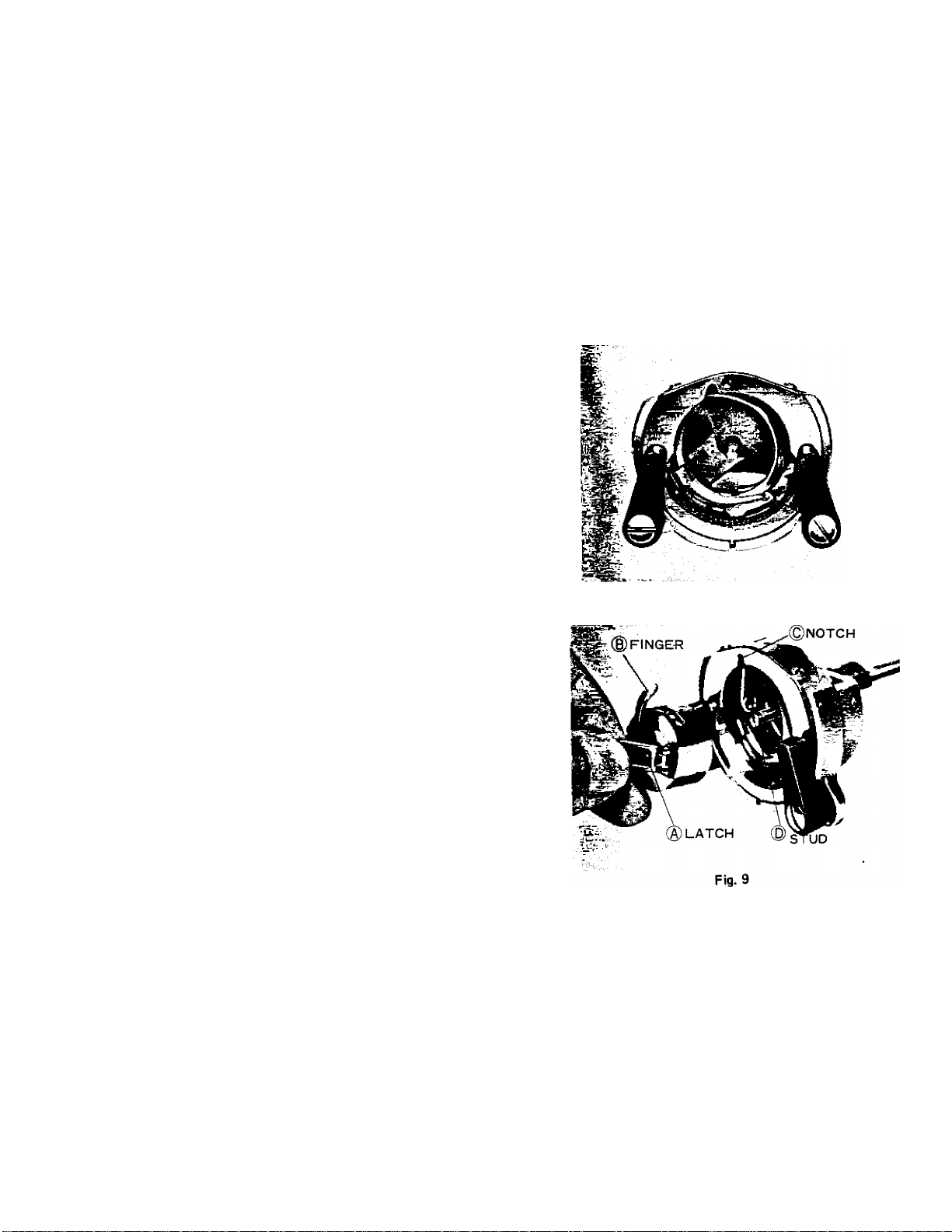

TO REMOVE OR REPLACE BOBBIN CASE

Raise needle to its highest position. The bobbin case cannot

be removed unless the needle is above the needle plate.

Open slide plate II {Fig. 1) by sliding it toward you. Grasp the

bobbin case hinge latch "A" {Fig. 9) between thumb and forefinger.

To remove, pull toward you.

To replace with full bobbin, leave at least three inches of thread

extending from the top of the case to the right.

Insert the bobbin case in the shuttle being aire to center it on

Stud D and that Finger B fits into Notch C {Fig. 9). Pre^ bobbin case

into shuttle as far as possible until latch catches on notch in Stud D.

Then release bobbin case latch A and press bobbin case again

after releasing latch to be sure it is locked securely in place.

Slide cover plate 11 {Fig. 1) into position.

•7 -

Fig. 8

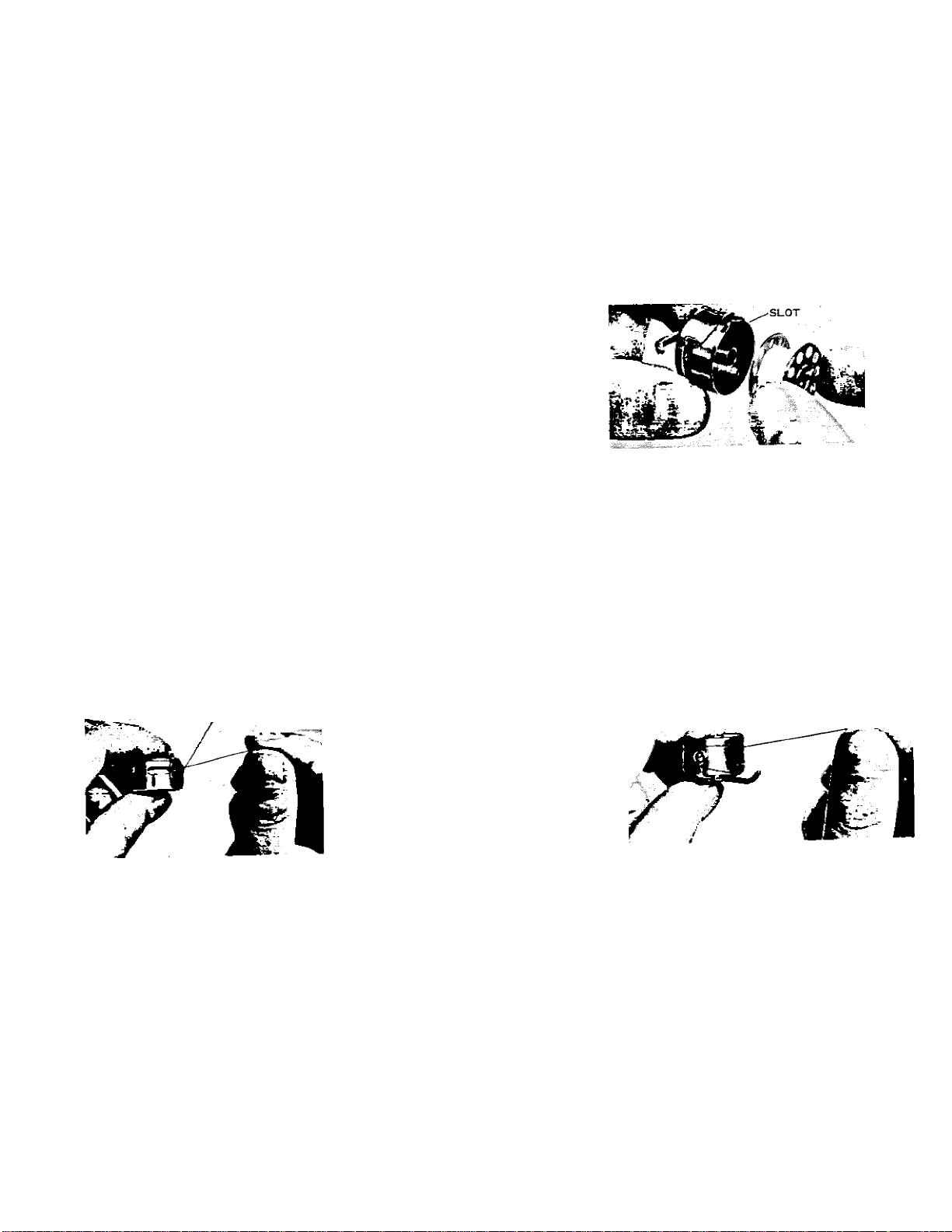

TO THREAD THE BOBBIN CASE

Fig. 10

For best sewing results use only evenly

wound bobbin ”A” (Fig. 10). Do not use

bobbins as illustrated by "B" or "C".

TENSION SCREW

Insert bobbin into the bobbin case. Pull

thread into slot in edge of case (Fig. 13).

and draw it under the tension screw

(Fig. 12).

Fig. 12

-8

Fig. 11

Hold bobbin case between thumb and forefinger of

left hand k) that the slot in the edge of the bobbin

case is on top (Fig. 11).

Take the bobbin between thumb and forefinger of

the right hand so that the thread on the bobbin leads

from left to right and extends about four inches from

the bobbin (Fig. 11).

Fig. 13

iSsii.

UPPER THREADING

(1) Turn hand wheel toward you to raise the take-up lever "E"

{Fig. 14) and needle to their highest positions.

{2j Place spool of thread on spool pin.

(3) Lead thread through rear and front arm thread guides "A"

(4) Down and between tension discs "B" from right to left and up

and over hook "D".

(5) Lead thread up and through take-up eye from right to left.

(6) Down and between thread guide "F".

(7) Into needle bar thread guide "C" and through the needle from

front'to back.

Hold the end of the upper thread loosely, and turn hand wheel toward

you until the needle goes all the way down and comes back up. Loop

{Fig. 15) will be formed over the upper thread which can be pulled out

straight. Place both thread ends under the presser foot and draw

toward the bacjt of the machine, leaving both threads about three or

four inches loog.

Fig. 14

_9 _

Fig. 15

SETTING THE STITCH LENGTH

The length of the stitch is regulated by dial "A Fig. 16. NearO is the

shortest stitch and 4 is the longest, but the dial may be set at any spot

between the markings for a variety of lengths. Turn the dial to the

right to lengthen and to the left to shorten the stitch. The pointer

indicates this number selected.

See chart below for stitches per inch.

STITCH LENGTH CHART (APPROXIMATE)

Fig. 16

Figures on indicator

Number of stitches per inch

0

No Feeding

30

1

2

24

3

12

4

6

SEWING IN REVERSE

When you wish to sew backward to tie the threads at the beginning or end of a seam, press the reverse button "B'

(Fig. 16) in as far as it will go. The machine will sew backward as long as the button is held in.

- 10 -

PREPARING TO SEW

Have take-up lever at highest point before starting to sew. Do not try to help the feeding by pulling the material

as this may deflect the needle and cause it to break.

NEVER run machine without material under presser foot.

Place material and threads in position under the presser foot and lower the presser foot. You are now ready to

begin sewing. By having the needle at its highest point, it is not necesary to touch the hand wheel to start the

machine. You merely press the control. The speed of the machine is regulated by increasing or decreasing the amount

of pressure exerted on the control.

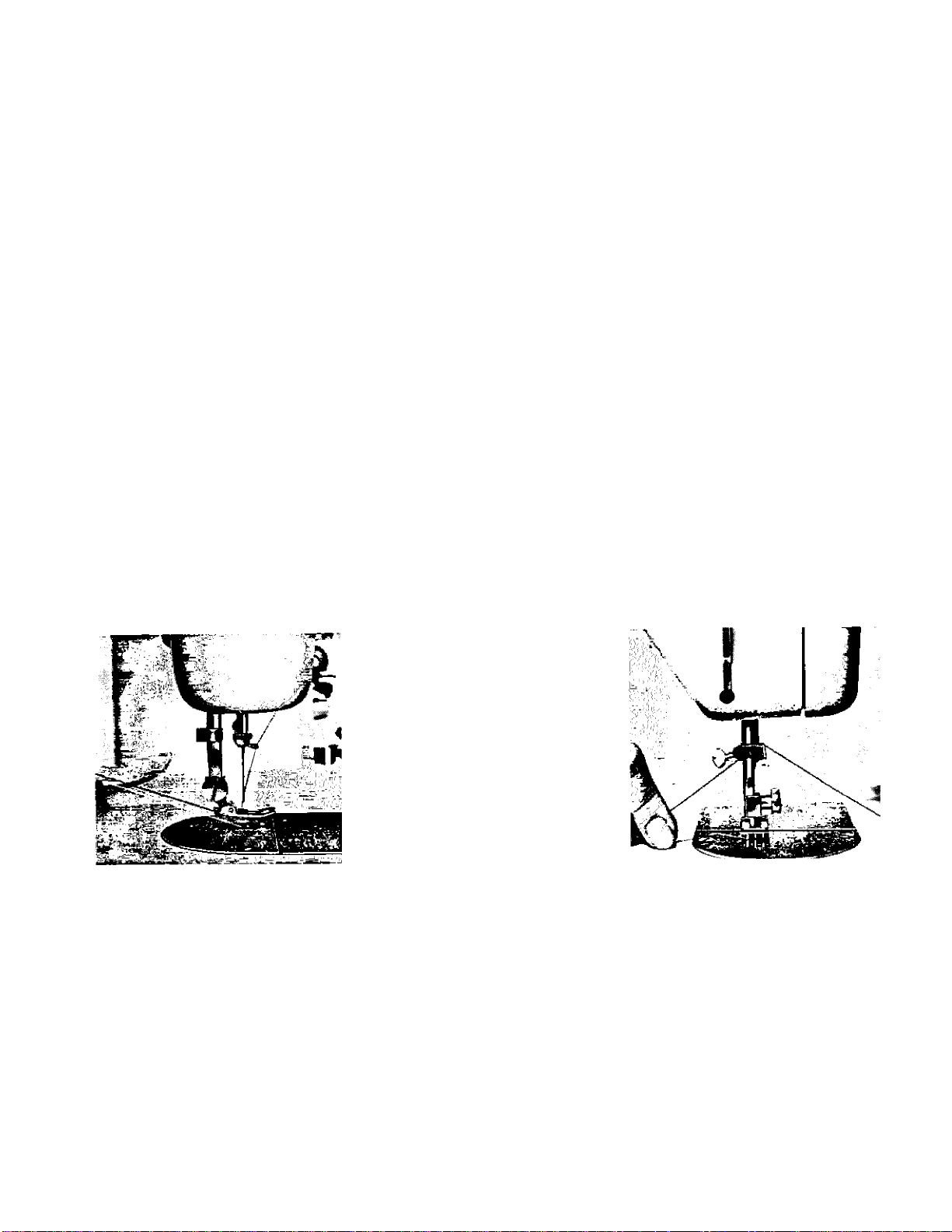

REMOVING THE WORK

Be sure to stop the machine when

the thread take-up lever and needle bar

are at the highest position.

Now raise the presser foot and

draw the fabric back and to the left

{Fig. 17, A and B) and pass the threads

over the thread cutter.

Pull down slightly, holding thread

in both hands, k) as not to bend the

needle.

Leave the ends of thread under the

Fig. 17A

prefer foot.

Fig. 17B

- 11

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down, as the

tension is released when it is raised. To increase the tension on the

upper thread, turn dial “A” (Fig. 18) to the right (clockwise) or to the

left (counterclockwise) to decrease the tension.

Before adjusting lower tension, be sure the machine is threaded

correctly.

When it is necessary to change the bobbin tension, turn the small screw

(Fig. 22) on the side of the bobbin case clockwise to tighten, counter

clockwise to loosen.

Fig. 18

Fig. 19

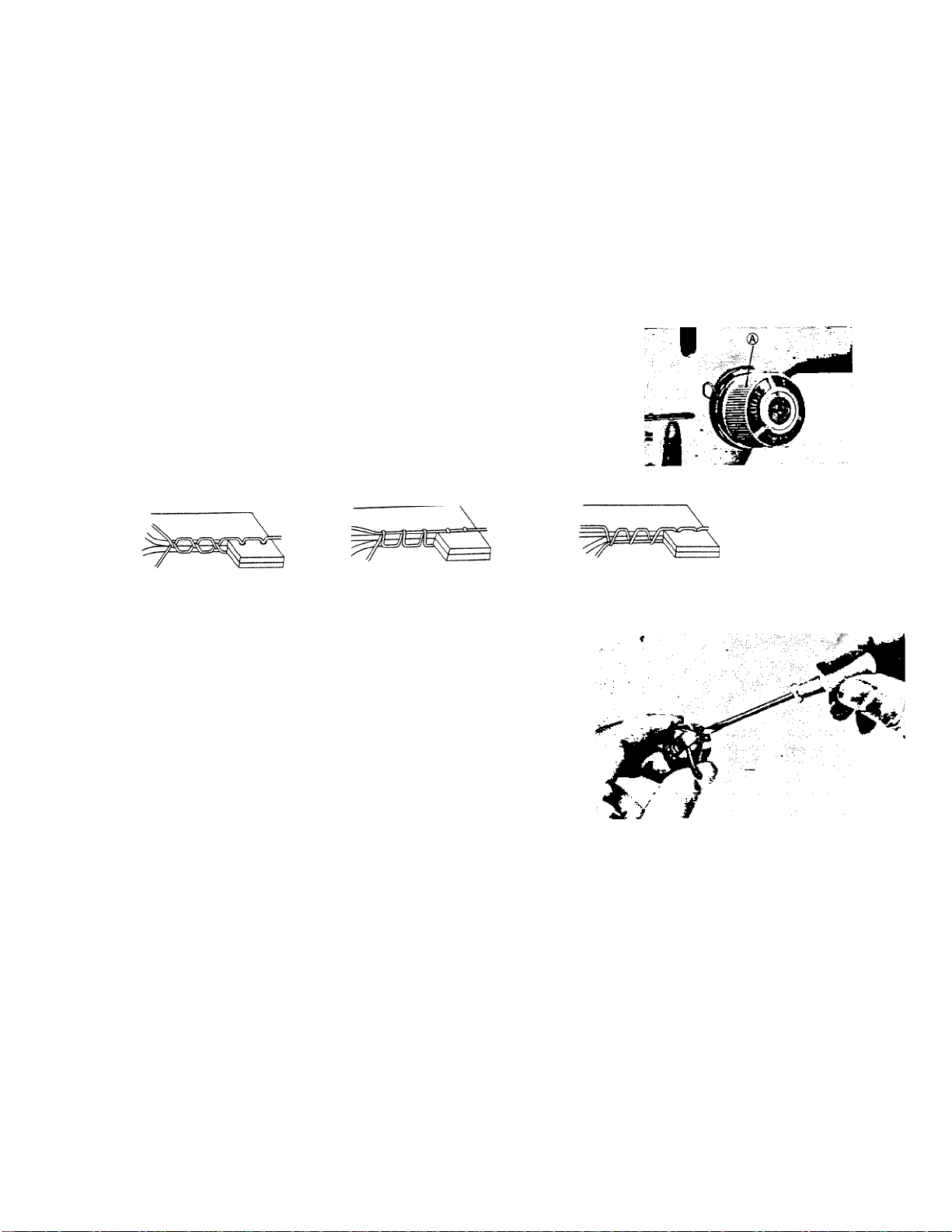

When the upper and lower tensions are properly balanced, a

perfect stitch will be formed with both threads interlocking in fabric

(Fig. 19).

When the upper tension is too tight, the lower thr^d is pull«l up

over the upper thread which is lying flat on the fabric (Fig. 20).

When the uppa" tension is too loose, the upper thread forms

loops over the lower thread lying flat on the fabric (Fig. 21),

Fig. 20

12

Fig. 21

Fig. 22

llk^

==^

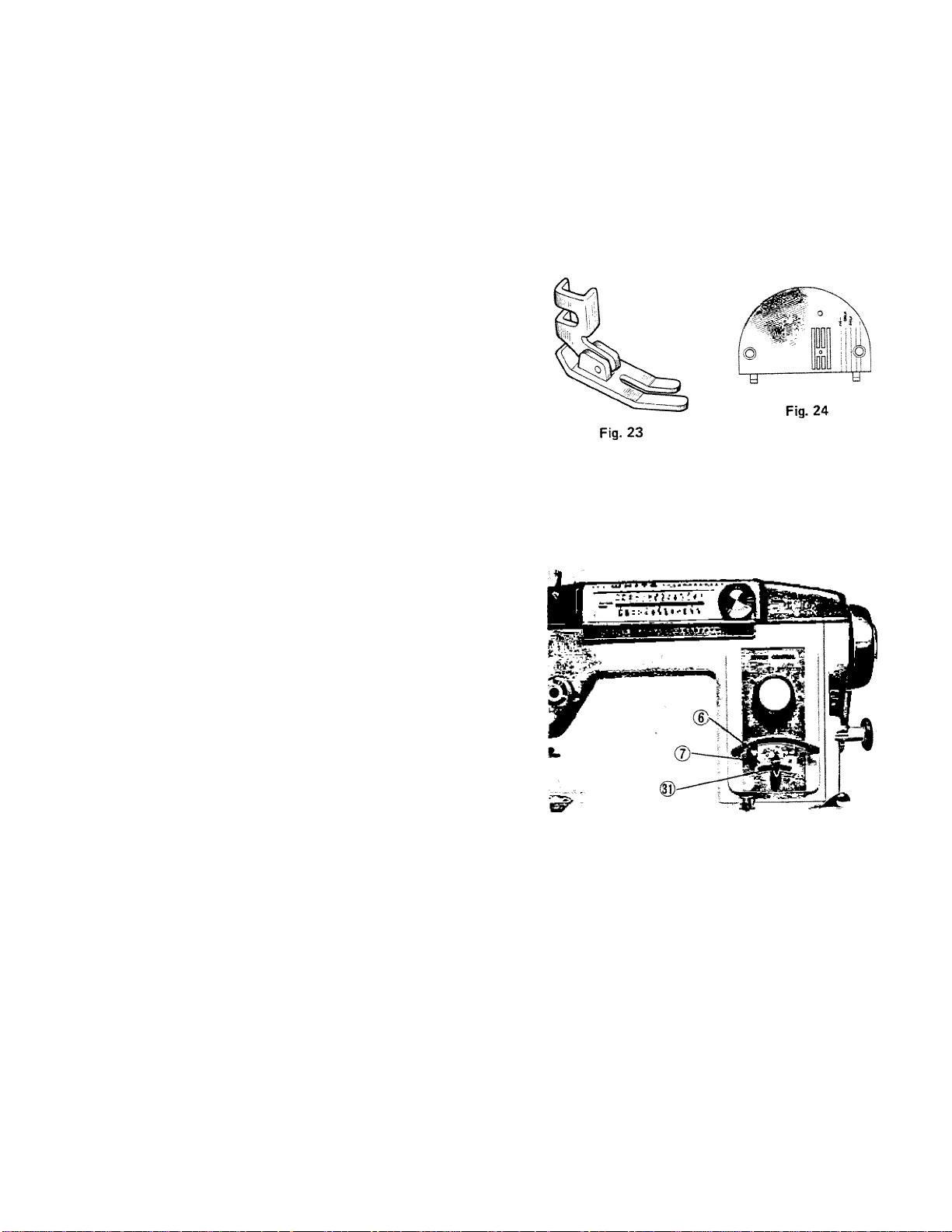

STRAIGHT STITCHING

For straight stitching on fine fabric or very soft material, it is

advisable to use the straight stitch presser foot and the

straight stitch needle plate. Both are included in your

accessory box and have narrow needle slots.

¡1) Change the toot and plate screw 13

(Fig. 1) and remove zigzag foot.

Replace with hinged straight stitch foot and tighten screw

securely (Fig. 23).

To change needle plate remove the two screws holding it in

place and remove.

Replace with straight stitch plate (Fig. 24).

(2) Set neolle position lever "31" (Fig. 25) at "M".

(3) Set zigzag width lever "6" at "0" and lock in position

with locks "7".

(4) Set stitch length control at "1" on desired stitch length.

¡5) Set decorative stitch design control at "M". '

13-

Fig. 25

Loading...

Loading...