Page 1

How to use

and care Sor your

мЬаЖ?. ^

Page 2

Parts Indentification

Principle Parts

Accessories ............................................................

Installing Machine Head onto portable case

or cabinet and Connecting Machine . .

......................................................

PAGE

4

6

I

I

■

Selection of Needles and Threads

Needle-Thread-Fabric-Stitching Guide

Changing Needle......................................................................................................................................... iq

Changing Needle Plate ........................................................................................................................... iq

Selection of Presser Foot............................................................................................................................ it

Winding Bobbin ........................................................................................................................................ 12

Upper Threading.............................................................................................................. ..................' 13

Threading Bobbin Case............................................................................................................................ 14

Placing Bobbin Case in Shuttle ...............................................................................................................14

Selection of Stitch

Stitch Length Control.........................................................................................................

Reverse Button ............................................................................................................

Stitch Width Control................................................................................................................

Relating Stitch Length to Stitch Width

Stretch Stitch Control Ring ...........................................................................................................

Stitch Pattern Selector......................................................................................................................

Automatic Reverse Stitch Tuner.................................................. ,0

Controls ..................................

Adjusting Thread Tensions............................................................................................................ig

Adjusting Pressure on Fabric and Feed Dog Height...........................................................19

Sewing Light.......................................................................................................’

Preparing to Sew .....................................................................................................................

Guiding Fabric..................................................................................................

Turning Corners........................................................................................................................! ' ' ! . o-.

Curved Seams.............................................................................................. ii'

Sewing Across Heavy Seams

Removing the Work .

..................................................................... . g

.............................................

.....................................................................

' ! !

..............

! ^ ' ic

....................

.9

..

20

21

21

22

22

22

15

15

16

Straight Stitch

Seams......................................................................................................................................................

Basting/Topstitching.............................................................................................................■ „3

Darning........................................................................................................

Cording/Sewing on Zipper ...........................................................................................................

Quilting.......................................................................................................................................

Zigzag Stitch

Overcasting ..........................................................................................

.

.. .. .. . .. .. .. .22

.........................

24

25

Page 3

„ . ^ . PAGE

Sewing Knits.............................................................................................................................

Sewing on Buttons

With a Thread Shank................................................................................

Satin Stitching........................................................................

Built-in Embroidery and Utility Stitches . . . . ! . . . . . ^ ' ' ' ' '

Twin Needle Sewing................................................ • ■ ■ 27

Freehand Monogramming............................................................................

Applique/Patching

................................

............................................................................................................................

.................................................................................¿ o

............................................................

................................

Lace Application..................................................................................... '.

Sewing Tips

Shaping Dart in Interfacings...........................■ ^ ^ ^ ^ ^ ^ ^ 3Q

Multiple Zigzag Stitch...........................................................................................

Buttonholes ................................................

Preparation .....................................................................................

Built-In Buttonhole .....................................................................

Corded Buttonhole

Blind Hem Stitch ...................................................................

Straight Stretch Stitch ..................................................................................................................................

Topstitching

Ultra-Stretch Stitch .............................................................................................

Rick-Rack Stretch

Pine-Leaf Stretch ..................................

Special Ultra-Stretches........................................................................................................ 35

Elastic Application

Overlook Application

Oiling Machine

Cleaning and Oiling Shuttle Area . ^ ^

Adjusting Bobbin Winder

Adjusting and Changing Motor Belt .... ...............................................................................fn

Problem and Remedies

................................................................. .......................................................................

.................................................................... .....................................................

............................................................

........................................................

............................

..................................................................................................................

..............................................

.......................

...................................................................................................

...........................................................................................41

.......................................................................

............................................................................

„„

...........................................................................................

- ~ -

......................................................................

...................................................

.

.............................................................

............................

^2

.

.

.

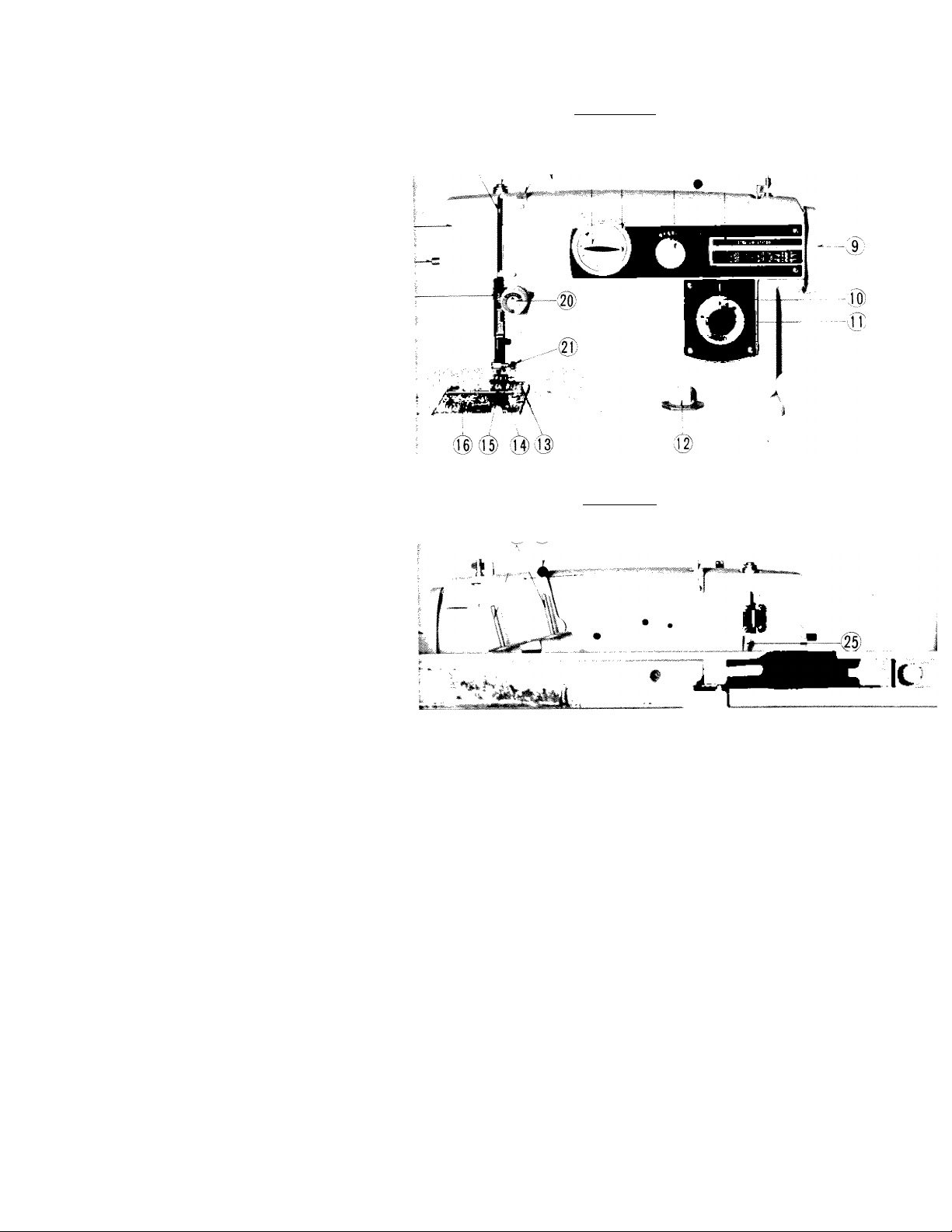

Page 4

3ENTIFICATI0N

.E PARTS

0 (D (3) (4) 15,

FRONT VIEW

BACK VIEW

® (2| i24)

Page 5

1. Take-up

2. Pressure Control

3. Top Thread Guides

4. Stitch Pattern Selector

5. Stretch Stitch Control

6. Stitch Width Control

7. Stretch Stitch Pattern

Marking

8. Bobbin Winder

9. Hand Wheel

10. Stitch Length Control

11. Reverse Button

12. Feed Dog Height

Control

13. Needle Plate

14. Presser Foot

15. Feed Dog

16. Slide Plate

17. Check Spring

18. Light Switch

19. Face Plate

20. Tension Dial

21. Needle Clamp

22. Spool Pins

23. Automatic Reverse

Stitch Tuner

Allways at its highest position when beginning or end

ing sewing.

For regulating the pressure on fabric.

For leading thread to Tension Control for sewing.

For selecting the stitch pattern and buttonholing steps.

For changing ordinary stitch to triple back-and forth

stitch (stretch stitch).

For setting stitch width.

Cro^-reference by number between- ordinary stitch

patterns and stretch stitch patterns performed with

stretch stitch control ring at "SS".

For winding thread on bobbin.

For the control of the up and down movement of the

needle.

For selecting stitch length between no feeding and max

to about 6 stitches per inch.

For easy backtacking to lock thread ends by pushing the

button.

For regulating feed dog height for various materials and

types of sewing.

With guide lines for sewing accuracy.

For holding fabric when sewing.

Diamond point to move fabric accurately.

For opening an access to bobbin and bobbin case.

For automatic precise adjustment of flow of upper

thread.

For turning on or off the light inside face cover.

Hinge-open type for replacemerit of light bulb and

oiling.

For regulating the amount of tension on upper thread.

For holding needle in place in the slot of needle bar.

For holding spools, preventing over-spin of spools.

For adjustments for the buttonhole reverse stitch den

sity and the evenness df the back-and-forth stitch lengths

of stretch stitch.

24. Bobbin Winder

Tension Disc

25. Presser Foot Lever

26. Thread Cutter

27. Thumb Screw

28. Head Hinge Holes

29. Clutch-nut

For providing proper tension on thread when bobbin

winding.

For lifting or lowering presser bar and presser foot.

For convenience to cut both upper and lower threads

after sewing.

For tightening presser foot in place on presser bar.

For installation of machine head onto portable case or

cabinet.

For the releasing movement of the needle bar in order

to wind bobbin.

Page 6

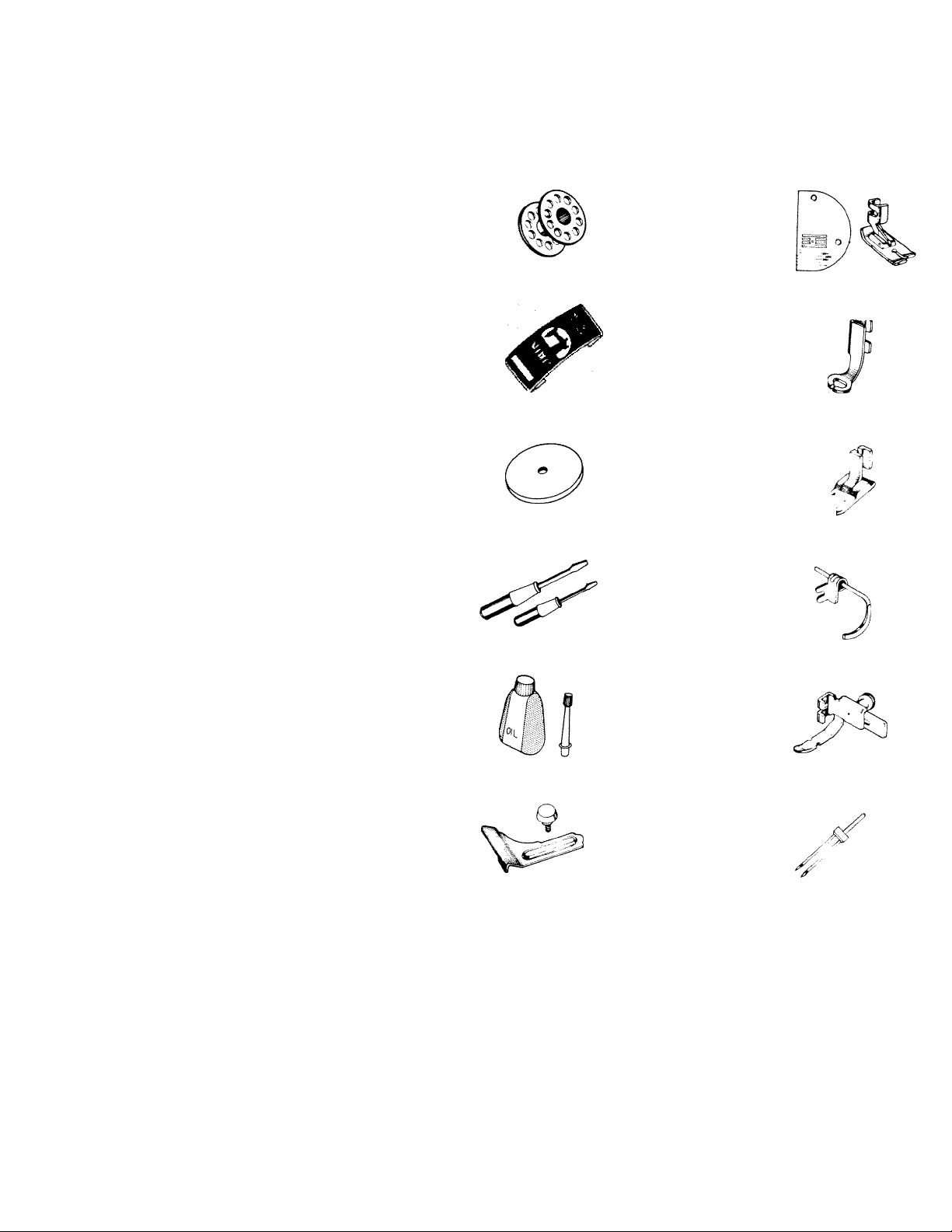

ACCESSORIES

Your new sewing machine comes equipped with the following set of accessories to

make your sewing easier.

METAL BOBBINS

I

I

For your spare bob

bins wound with

various color threads.

A PACK OF NEEDLES

For spares. Regular

assortment of sizes

#11, #14 and #16

regular needles and

size #11 ball point

needle.

SPOOL CUSHIONS

Place two felt Spool

Cushions on spool

pins to reduce

sound of spool spin

ning.

SCREW DRIVERS

Small one for use on

bobbin thread ten

sion adjustment.

Large one for use on

thumb screw, needle

clamp, etc.

For straight stitch

ing on very sheer

soft or very light

weight stretchy ma

terials where extra

control is needed.

BUTTON FOOT

For holding buttons

in place for stitch

ing.

BUTTONHOLE FOOT

Use for buttonhol

ing. Do not use

when normal sew

ing.

quilting guide

Helps make parallel

rows of stitching.

OILER

Containing machine

oil, use as oiler.

CLOTH GUIDE WITH SCREW

Aid in creating

straight seams.

CORDING AND ZIPPER FOOT

For stitching very

close to the edge

of a cord or zipper.

TWIN NEEDLE

For twin parallel

sewing.

Page 7

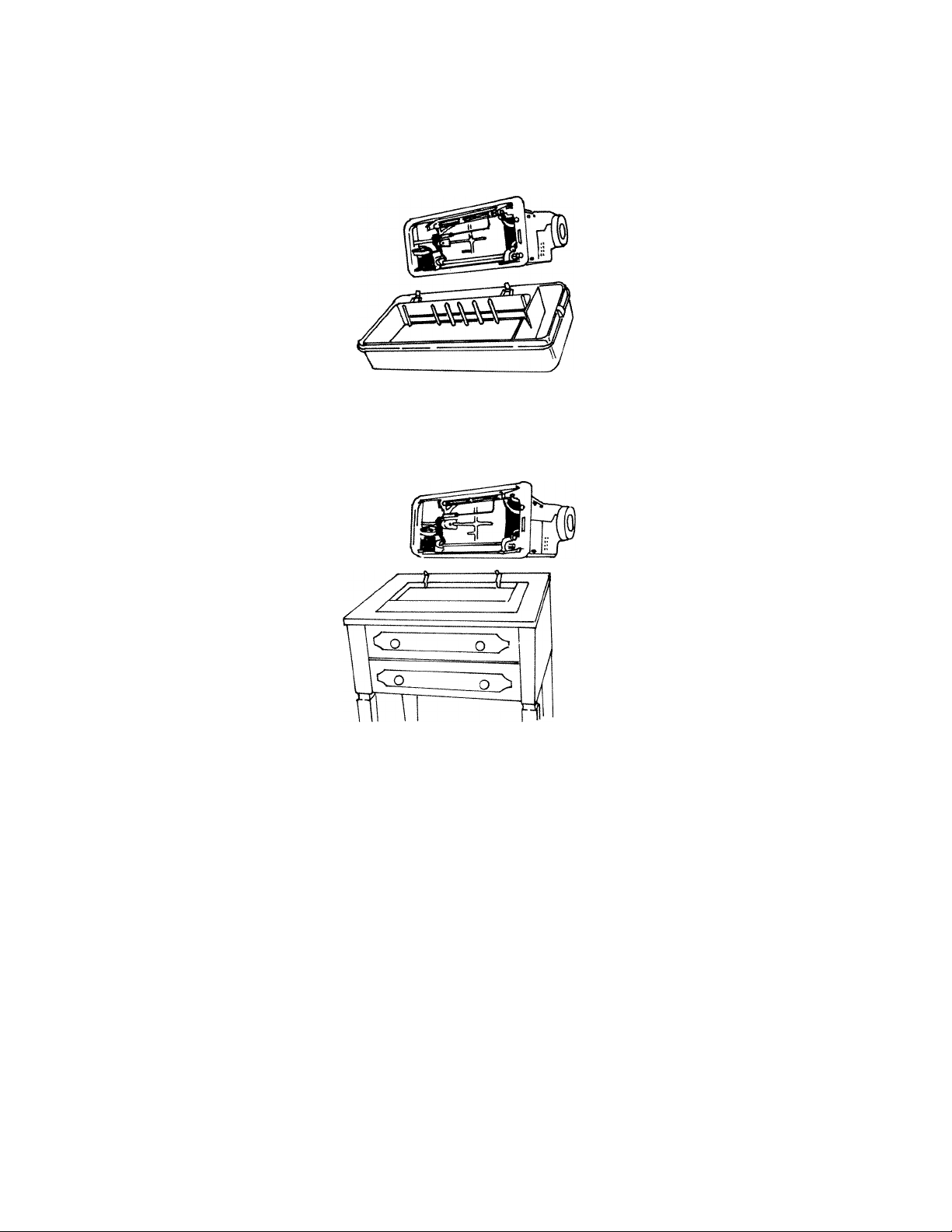

INSTALLING MACHINE HEAD ONTO PORTABLE CASE

OR CABINET-AND CONNECTING MACHINE

Loosen both head hinge set screws

on the back of machine bed plate

until head hinge holes are clear.

Tilt head hinge pins up and back

as far as they will go.

Carefully slip machine head ontp

hinges — making sure the head

hinge pins are inserted as far as

they can go into head hinge holes.

Allow machine head to rest in its

tilted back position.

Tighten both set screws securely

with screwdriver.

Plug electrical leads from machine

head into sockets located inside

cabinet or portable case. Cord

identified with "motor" tag must

be plugged into socket marked

"motor". Untagged cord goes to

“light" socket.

Insert plug into a wall outlet of

110-115 Volts.

Page 8

I

■

I Se-

SELECTION OF NEEDLES AND THREADS

The needle ^nd thread you choose depends

upon the fabric you are stitching. The correct

selection of needle and thread is very important

to avoid damaging the fabrics of light weight,

or tightly woven fabrics, and to prevent skip

ped stitches when sewing on very sheer or

stretchy fabrics or needle breakage when stitch

ing heavy or stiff fabrics. For best results, sewing

machine needles should be replaced when they

become even slightly dull or bent or at the com

pletion of every other garment.

A regular needle is suggested for use with

woven fabrics. Needles, style 15 x 1, of the

range in size from 8 to 20 are used on this

machine. The lower number indicates the finer

needle. The most commonly used sizes are 11

and 14.

A ball point needle is recommended for use

with tricots, jerseys, lingeries and power nets.

Unlike sharp pointed needles, which pierce

fibers of knit fabrics destroying elasticity,the

ball point needle slips between fibers without

damage to fabric and skipped stitches.

A wedge point needle is recommended for use

with leather and leather-look vinyls. A wedge

cutting point pierces leather more easily than

ordinary sewing machine needles, resulting in

more satisfactory stitching.

REGULAR

SHARP NEEDLE

BALL POINT

NEEDLE

FLAT

Although it is recommended to use a ball point

needle for knit fabrics, when sewing on very

stretchy fabrics of knits, the placement of a thin

paper below the fabric and the use of a finer

needle are suggested to prevent skip stitches.

Always use the same type and size of thread

in both needle and bobbin. Use good

quality thread without knots for best stitches.

8

WEDGE POINT

NEEDLE

Page 9

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette.

Medium heavy drapery

fabric, velveteen,

aiiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn,

dimity, crepe,

handkerchief linen.

Plastic film, etc.

Very sheer chiffon,

batiste, lace, organdy,

nylon net, marquisette, etc.

14

11

18

16

18

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

(plastic film)

8 to 10

16

to

20

Heavy Duty

Heavy Duty

Heavy Duty

50

50

60

O

o

o

Page 10

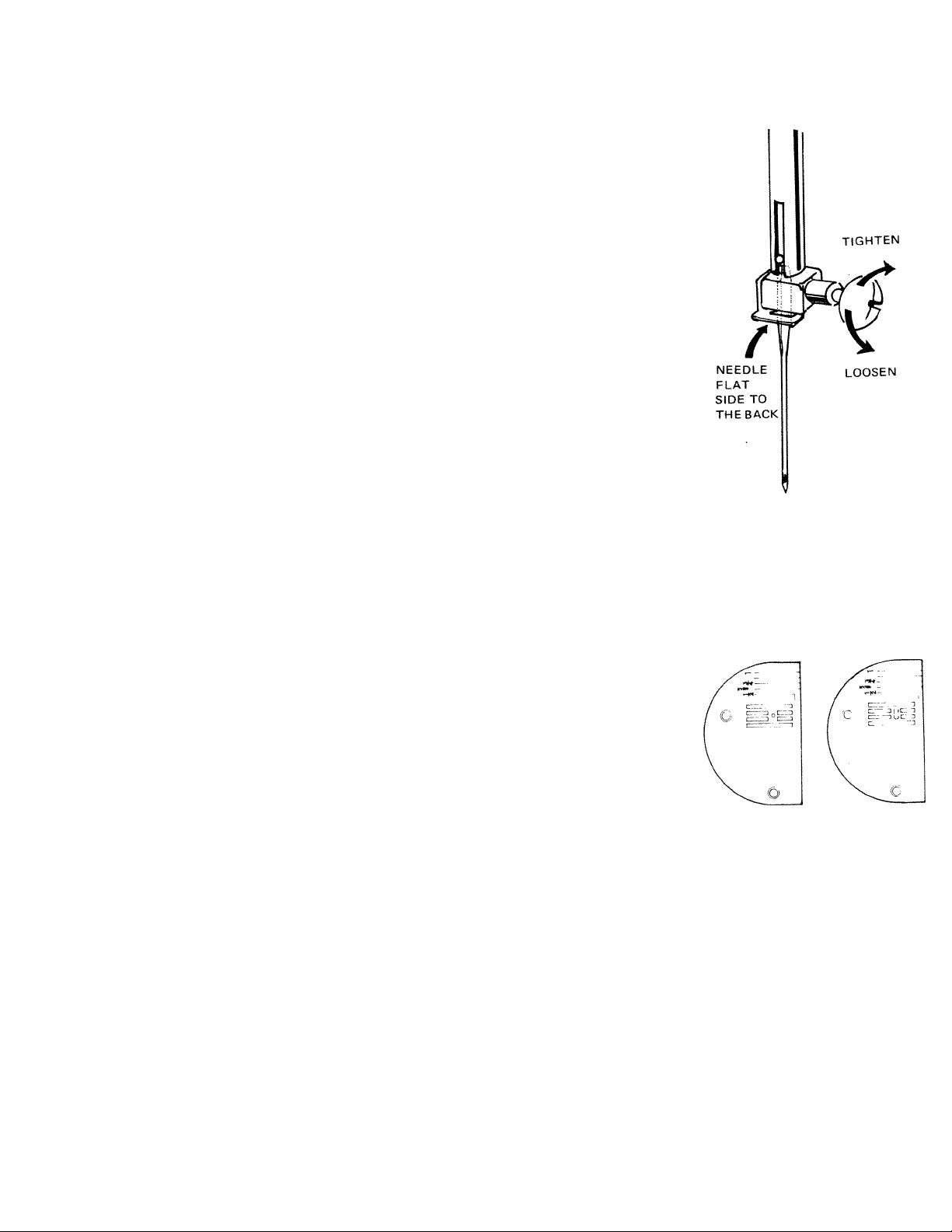

CHANGING NEEDLE

Always change the needle after every

other garment especially when sewing on

polyester and nylon fabrics which dull

needles much faster. When needles are

dull or bent, they damage both your

fabric and the machine. A general rule

when placing sewing machine needles is

that the flat side of the needle is placed

to the back of the machine, when the

bobbin is put in from the front. If the

needle is inserted incorrectly, the stitches

will not form.

To change the needle

1. Raise the needle bar to its highest

position by turning the hand wheel

toward you.

2. Loosen needle clamp to remove the

needle.

3. Place needle (flat side to the back and

long groova to thefront)in the needle

clamp and push it upward as far as it

will go, tighten needle clamp.

4. After changing the needle, make one

complete Uirn of the hand wheel by

hand to be sure the needle is clearing

the needle plate.

I

I

■

CHANGING NEEDLE PLATE

Although an all-purpose, utility needle

plate is fixed on your machine, for

straight sewing on fine fabric or soft or

very stretchy fabric, you may want to use

the straight stitch needle plate together

with the straight stitch foot, both of

which are included in your accessory box.

To change the needle plate, simply slide

the slide plate as far forward as possible.

Remove the two screws holding the

plate in place. Lift the needle plate and

replace.

The needle plate is removed for cleaning

the lint which may pile up between

needle plate and feed dogs.

STRAIGHT STITCH

NEEDLE PLATE

UTILITY

NEEDLE PLATE

Page 11

SELECTION OF PRESSER FOOT

Straight Stitch Foot

This has only a narrow hole to accom

modate only straight stitching. It may be

used on sheer or soft fabrics for more

control. When using this foot, the Stitch

Width should be 0 to avoid hittinq^th^

joot and breaking the needleT ~

Buttonhole Foot

This foot has a groove underneath, to

allow the narrow satin stitch or button

hole to form evenly. However, if skipstitch occurs on sheer fabrics with this

foot, it may be necessary to use thin

paper underneath.

Cording or Zipper Foot, and Button Foot

Use for sewing very close to the edge of a

cord or zipper, and sewing on buttons

respectively.

CHANGING FOOT

Use the large screwdriver to loosen thumb

^rew. Turn the screw backward until the

foot becomes loose. Then, lift up on

presser foot lever until it is in its highest

position in order to remove the foot.

R^eplace with desired foot and tighten

thumb screw securely.

Page 12

I

I

■

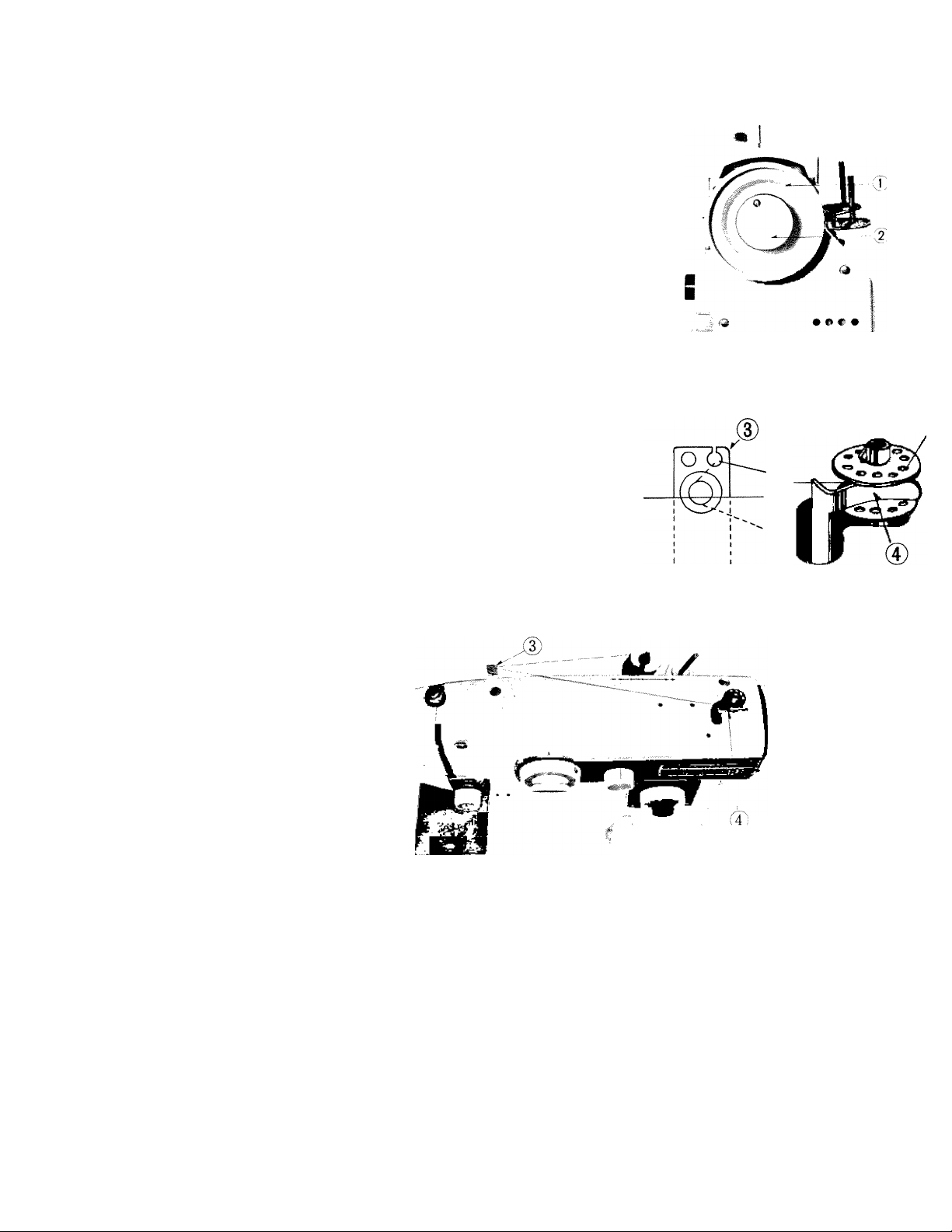

WINDING BOBBIN

Disengage the hand wheel (1) from

the stitching mechanism by turning

the clutch nut (2) toward you or

counter-clockwise.

Place a spool of thread on one of

the spool pins and lead thread

through the rear Top Thread Guide

(3) after winding around Bobbin

Winder Tension Disc.

Run the end of thread through a

hole in the bobbin edge and place

bobbin on spindle of bobbin winder

(4) fitting the notch on bobbin over

small spring on spindle.

Push bobbin winder latch (4), and

hold the thread end loosely then

start machine slowly, and bobbin

winder latch will be released to

stop winding when bobbin is full.

Turn clutch nut away from you

until sewing mechanism is again

engaged so that needle moves when

you turn the hand wheel.

Break off loose thread end used to

start the winding and cut other

thread end. Then remove bobbin

from bobbin winder.

I-

12

%■

Page 13

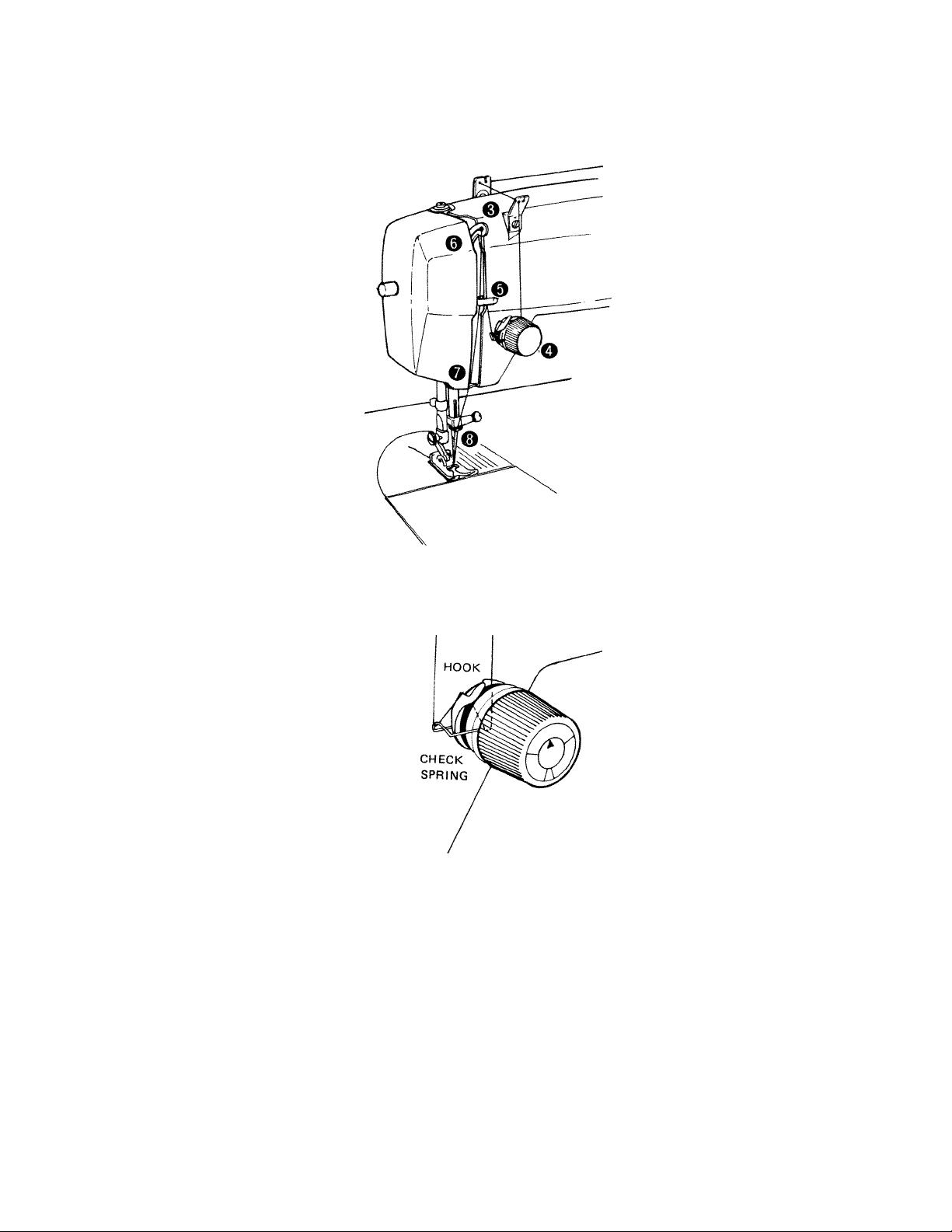

UPPER THREADING

1. Turn the hand wheel toward

you to raise the take-up lever

to its highest position.

2. Place a spool of thread on the

spool pin.

3. Lead the thread through the

top thread guides.

4. Down and between the tension

discs, from right to left.

5. Draw the thread up through the

check-spring and with a slight

tug into the hook.

6. Up behind the front thread

guard and through the eye of

take-up lever from right to left.

7. Lead thread down through the

thread guide at the bottom of

the threading slot after drawing

thread behind the front thread

guard then, through the needle

bar thread guide.

8. Thread the needle FROM

FRONT TO BACK, drawing it

through about 3 or 4 inches.

Hold the end of the upper

thread loosely and turn the hand

wheel toward you until the

needle goes all the way down

end comes back up. A thread

loop will form over the upper

thread which then can be pulled

out straight. Place both thread

ends under presser foot and

draw toward the back of the

machine, leaving both threads

three or four inches long.

In case of twin needle sewing, place

two spools of thread, matching or

contrasting in color, one on each

spool pin, lead both threads

through top thread guides, bring

threads down and pass one thread

between the back discs and the

other between the front discs, then

treat both thread as one until

threading each thread through each

needle eye of twin needle.

I

Page 14

THREADING BOBBIN CASE

. Hold bobbin case be

tween thumb and fore

finger of left hand, so

that the slot in the edge

of the bobbin case is on

top. Take the bobbin

between thumb and fore

finger of right hand so

that the thread on top

leads from left to right

Insert bobbin into bob

bin case, pull the thread

into the slot of the

bobbin case and draw it

under tension spring and

into the fork-shaped

opening of the spring.

I

I

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to its highest position, and slide plate

forward. Hold the bobbin case latch (D) between the

thumb and forefinger of the left hand, with at least three

inches of thread running from the top of the bobbin

case. Insert and center the bobbin case on the stud of

the shuttle body (C). Be sure the bobbin case finger (E)

is opposite the shuttle race notch (A). Press the bobbin

case (B) into the shuttle as far as possible until the latch

catches on the center post of the shuttle. Then release

the bobbin case latch (D). Press the bobbin case again

after the latch has been released to make sure the bobbin

case is locked securely in place. Close the slide plate.

Page 15

i

SELECTION OF STITCH:

STITCH LENGTH CONTROL

'“»-d feeding

•ra“nd'te'ti tar “"'™l

stitch is available At 5 is thp°i tittonhole, the shortest

pet inch on ord'r,a" f.taif '“"¿f, ' ^ stitches

set at any desired spot ta ween 0 a„d 5 T "" “'

length exrpnt ^ ^ ® for a variety of

forth stitching) the roVtro^ sh^'^ri h^ back-andthe control to 'the right to h“

lengthen the stitch. ^

poihter abo»e"the conToh Pv 'he

fta’h «chi'„7t taerrotal«"* 7“"

Stretch stitch length on trouble-free

stretch stitlh c<^^troi «"‘th

control at''5' the stitch length

reverse button

-d-'« at the beginning or end of a seam

sews in reverse at approximately the sLe stitch fe machine

machine will sew backward as long as the button is hX in.' The

Cross reference table between numeral on th ,

P«-- mch ' the control and number of actual stitches

NumersI on the control

Number of stitches per inch (approx.

No Feeding 3q

0 1

25

2

3

4

15

8

15

Page 16

I

I

STITCH WIDTH CONTROL

This control controls the side sewing of the needle for various width of stitches. At 0,

the straight stitch line results in ordinary sewing. Also, the widest special stitch

patterns as per those shown on the stitch pattern selector are made with this control at

5.

The narrow special stitch patterns including buttonhole are made with this control at

the less number, and with this control at 0, only straight sewing is made regardless the

selection of stitch patterns.

With the control at any other point than "0", ordinary straight stitch varies to zigzag

stitches. At 1, the needle takes a harrow swing resulting in narrow column of stitching

and, at 5, the needle takes a large swing respiting in a wide column of stitches.

In case of twin needle sewing, this control

should be set less than Number 3, other

wise needle hits needle plate.

RELATING STITCH LENGTH TO

STITCH WIDTH

When the stitch width control is set at

one particular width (such as 5j, the

stitch length control will now control how

close those stitches come together. At

length 0, the fabric does not move,

resulting in a bar of stitches formed one

on top of the other, as is used in button

sewing. At red bar mark or near 0, the

feed pulls the fabric through slowly,

resulting in a dense column of stitches

called a satin stitch. At length 5, a very

long open zigzag results.

VI. .-j-'-'

4$

'; " , r" ■

. . •.

• ■ • ■

V'' ^ _'''<V

:,

■ 3

■■

= V- '3. .r

'« ■ ''

■. .

' 3'

. .

' ' ' ' ' '

■■■■"jV . ■■

':^3"VV

-'1

Page 17

STRETCH STITCH CONTROL RING

Selection between ordinary stitching and triple auto

matic back-and-forth stitching called stretch stitch is

made by the stretch stitch control ring. With the

control ring to the left at mark "M", ordinary sewing

is performed. With the control ring to the left at the

mark "SS", your machine automatically performs the

stretch stitch with the repetition of two forward and

one backward stitch combination.

A reinforced seam of stretch stitch that will stretch

considerably more than the fabric used is the most

wanted feature in a sewing machine today.

Its uses are almost unlimited and the more you use

your machine the more it will become apparent to you.

When stretch stitching, the stitch length control should

be always set at 5.

STITCH PATTERN SELECTOR

In addition to ordinary straight and zigzag stitches, three consecutive buttonholing-

step stitches, 2 embroidery stitches, blind stitch and blind stretch stitch, 8 different

kinds of utility forward stitches, 9 special stretch stitches and straight and Rick-Rack

stretches as shown on the Stretch Stitch Patterns Marking can be selected by this

selector. This selector can be turned only to the right, except for it's buttonhole step

selection range where the selector can be turned to both directions.

For regular stitch patterns, set the pattern selector at the selected pattern position

and the stretch stitch control ring at "M".

The regular stitch patterns selected by the selector are turned to the stretch stitch

patterns shown on Stretch Stitch Pattern Marking under same cross-reference number

patterns on the selector, simply by setting stretch stitch control ring

All regular stitches and blind stretch stitch are made by forward sewing at an op

tional forward stitch length selected by

stitch length control. All stretch stitches

are made at the fixed stretch stitch length

with the stitch length control at 5 and the

stretch control ring at "SS". To balance

forward and reverse stitch length in stretch

stitching and buttonholding, adjust the

Automatic Reverse Stitch Tuner. With the

selector at buttonhole step (2-4 ), your

machine does not feed fabric for barrack

ing the buttonhole ends and, with it at

buttonhole step (3), it feeds fabric in

reverse to sew the right buttonhole edge

with the preset reverse satin stitch length

automatically, regardless the setting of

stitch length control.

17

Page 18

I

I

AUTOMATIC REVERSE STITCH TUNER

Your buttonhole and stretch stitches are preset and tested to sew on most materials

certain fine materials may require a slight adjustment to balance forward and reverst

stitch lengths of buttonhole and stretch stitches.

We have provided a special tuner for this purpose on the back of the arm. Shifting this

tuner to the right j+) to increase the density of reverse stitch of buttonhole and shorter

reverse stitch of stretch and to the left { -) to expand the density of reverse stitch o1

buttonhole and stretch stitch.

CONTROLS:

ADJUSTING THREAD TENSIONS

Always adjust the upper thread

tension with the presser foot down,

as the tension is released when it is

raised. To increase the tension on

the upper thread, turn tension

control to the right. To decrease,

turn to the left. Before adjusting

the tension be sure that the

machine is threaded properly.

It is seldom required to adjust

the bobbin thread tension,

however, when necessary to change

bobbin thread tension, turn small

screw on side of the bobbin case

clockwise to tighten , counterclock

wise to loosen.

When both tensions are properly

balanced, a perfect stitch will be

formed with both threads interlock

ing in fabric (A).

When the upper tension is too tight,

the bobbin thread is pulled up over

the upper thread which is lying fiat

on the fabric (B).

When the upper tension is too

loose, the upper thread forms loops

over the bobbin thread lying flat on

the fabric (C).

When the upper and bobbin thread

tensions are balanced but fabric is

puckered in sewing direction on

sheer fabrics, both tensions are too

tight. Loosen both tensions evenly.

it is recommended to adjust the

tension balance under medium

stitch length, in case of satin

stitching for buttonholes and em

broidery slightly loosen the upper

thread tension.

18

1

Page 19

ADJUSTING PRESSURE ON FABRIC AND FEED DOG HEIGHT

• GENERAL SEWING

Usually for normal sewing, except for sewing on

very heavy and bulky fabrics and very stretchy

knit fabrics, the center pin (B) of the pressure

control be at its lowest position, also, the feed

dog height control be turned to the right, "High"

position, except for sewing on very sheer fabrics.

For below exceptional fabrics, refer to table.

To reduce half the pressure, press the outer ring

(A) of the pressure control, then press the center

pm (B) down again to halfway. To reduce half

the feed dog height, turn the feed dog height

control to LOW" position.

Ordinary fabric of less elasticity

Heavy and bulky fabrics

Medium weight fabrics

Light weight soft fabrics

Very stretchy fabrics and knits:

Heavy and bulky ones

Medium weight ones

Light weight and sheer ones

Half

Full

Full

Full

Half

Half

High

High

Low

High

High

Low

• MENDING AND DARNING:

dog height cohtrol T ® ''"S «1- Toth the feed

heed,eo,ate. To tetoto Sd iS"h'Tghr“ lito'S ^

19

Page 20

SEWING LIGHT

The sewing light is located in face cover directly over the

needle so as to better illuminate the stitching area.

Turn the light on and off by pushing the switch

on face cover.

To replace bulb, turn light off and open face cover to

the left. Unscrew bulb as you do a conventional light

bulb. Place new bulb in socket and screw in place.

I

I

20

Page 21

I SECTIOW

PREPARING TO SEW

Have take-up lever at highest position before starting to sew. Pinning may be used

as a time saver instead of hand basting. It is possible to sew over pins when placed at

right angles to the edge of fabric with the pin head at the raw edge, but for best

results It IS recommended that the pins be removed as you approach the presser foot

bewing over pins can result in damaged needles. '

Place material and threads under presser foot and lower the presser foot. Lower the

needle by turning hand wheel by hand to check if the needle will pierce the stitching

The sew^ You are now ready to begin sewing. Press the speed control

If nro!!, ^ machine running is regulated by increasing or decreasing the amount

of pressure exerted on the control. Never run machine without material under

|Ji Cobv^r TOOT.

GUIDING FABRIC

The scale is etched with every 1/8 inch distance measured from the center of needle

plate. Let the edge of fabric follow the line selected for the seam, and let your eyes

follow the etched line you selected for the seam, not the needle, during sewing To

help you guide the fabric, place cloth guide attachment securing it by the extra

ncTd bedplate. Cloth guide and extra thumb screw are

included m your accessory box. ^ v aic

°n°d caisLTt to break material as this may deflect the needle

TURNtNG CORNERS

fabric, then lower the presser foot and continue sewing.

Lift the presser foot, turn the

21

Page 22

CURVED SEAMS

Use slightly shorter stitch length

than that of the rest of the seams.

On the part where elasticity is

required on the seam, sew by

stretch stitch. The cloth guide may

be used on angle as shown.

SEWING ACROSS HEAVY

SEAMS

When approaching heavy seam,

hold the fabric upward on an angle

so that the heavy seam falls under

the front curved sled of presser

foot.

I

I

REMOVING THE WORK

Be sure to stop the machine when

the thread take-up lever or needle

is at the highest position.

Now raise the presser foot and draw

the fabric back and to the left

and pass the threads over the

thread cutter.

Pull down slightly, holding thread

in both hands, so as not to bend the

needle .

Leave the ends of threads under

the presser foot.

22

Page 23

SfcCTIOM V

Pattern;^; (I)

Length: 2-3

Width; 0

Feed Dog; High

Pressure: Full

Foot; Straight Stitch or

All Purpose

Stretch Control: M

Pattern: (D

Length :4_5

Width: 0

Feed Dog: High

Pressure: Full

Foot: Straight Stitch

Stretch Control: M

STRAIGHT STITCH:

SEAMS

The normal stitch length for most fabrics

should depend on the fabric and area of

usage. Usually, heavier fabrics require

onger stitches, and lighter weight fabrics

require shorter stitches. For curved seams

lennth R ® stitch

control

BASTIIMG/TOPSTITCHING

uspfid^ / ® longer stitch is

useful for temporary seams prior to

fitting. Basting stitches also may be used

when gathering in fullness.

sTitih '°tig straight stitch. For a bolder

stitch, tvvo threads of the same type can

or ifii 14

or ifa). A heavier thread such as

^ttonhole twist may be used for

topstitching, but be sure to use a larger

needle {size 16 or 18 ) ^

'tery effectively

Pattern:^!

Length:0

Width: 0

Feed Dog; Down

Pressure; 0

Foot: All Purpose, or

Stretch Control; IVI

darning

Worn spots or small holes can be darned

very easily. Use of an embroidery hoop is

optional depending on the fabric. Лпе

thread IS recommended so that the fabric

and thread will blend together.

darned. Hold the threads to start then

move the fabric slowly backwards and

forwards while running the machine very

wnl hP Z Professional results

ill be attained by moving the fabric in

a figure eight pattern while sewing After

b ling m the area lengthwise, reweave

wdh crosswise stitches in the same

Page 24

CORDING/SEWING IN ZIPPER

• INSERT CORDING

(Aj Fold bias strip of fabric over

cord. Loosen the adjusting

screw on the back of cording/

zipper foot and set the foot to

the left of needle.

(B) Sandwich the welting between

two layers of fabric with right

sides together. Stitch a second

time with cording/zipper foot

to the right of needle so that

the needle stitches close to the

cord through all thicknesses.

• ZIPPERS

Swing the foot to left or right of

the needle as needed so that the

foot sews very close to zipper teeth.

I

I

QUILTING

Parallel straight lines are easy to

sew with the quilting guide. To

attach the guide, loosen thumb

screw and slip the U-shaped holder

of the guide between presser foot

and thumb screw. Tighten the

thumb screw securely. Adjust the

curved bar to the desired distance

from the needle. Sew the first line

of stitching as desired, then, for the

succeeding rows let the guide

follow along the previous stitch

line. A straight stitch, zigzag, or any

other stitch may be used.

24

Page 25

Pattern: (()

Length: 1^3

Width: 5

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

ZIGZAG STITCH:

OVERCASTING

Place the edge of the material urxierneath

the opening of the sewing foot and guide

raw edge along the center slot of the foot

a lowing stitch to form half on and half

on the fabric.

The multiple stitch zigzag is a wiser

choice for most fabrics.

See page 30.

Pattern; <1 (|)

Length: 1-3

Width: 1

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

Pattern:^,' (|)

Length; 0

Width: 2—5

Feed Dog: Down

Pressure; Full

Foot; Button Foot

Stretch Control: M

SEWING KNITS

of firm knits for added strength After

sewing, open seam and press flat. Tiny

zigzag stitches can hardly be seen and the

seam will give when stretched

Generally on knits, however, try the

yearns

SEWING ON BUTTON

Place the button so that the holes of

button are positioned in same distance

from the center straight stitch needle

position respectively.

Turn hand wheel by hand until needle

point lowers close to the face of button.

Turn stitch width control until the needle

comes just above a hole of button

Turn hand wheel slowly by hand to check

If the needle comes just above another

hole of button after clearing the first

ole of button. If necessary, readjust

the button position below button foot

and repeat above checking and adjust

ment of stitch width.

Note; Be sure the needle clears the holes

of the button by moving the hand wheel

by hand before running the machine

fast.

Usual 6 to 8 stitches are adequate for

securing a button in place.

To lock the threads, set the stitch width

at 0 readjust the button position to that

a hole of button is just below the needle

and take a few stitches in the hole. '

See

25

Page 26

SEWING ON BUTTON

WITH A THREAD SHANK

Buttons sewn on coats or jackets should

have a thread shank to make them stand

away from the fabric. To form a thread

shank, sew over a pin or rounded tooth

pick, as shown on page 25.

After stitching the button to the tabric,

remove work from under the presser foot

leaving threads about six inches from

fabric. Remove pin or toothpick. Pull the

threads to back of button and form a

shank between button and fabric by

winding threads tightly around the attach

ing stitches. Pull threads to back of the

fabric and tie thread ends securely.

SATIN STITCHING

This is useful for decoration such as

tapering, manual designed embroidery,

monogramming and applique.

The satin stitch, which is really just a

very close zigzag stitch, is obtained by

setting the stitch length as near to "0"

as possible without stopping the feeding

action or at the red bar marked "button

I

I

hole". The setting will vary for different

fabrics. It may be desirable to loosen the

upper tension slightly to cause the

threads to lock underneath in order to

make the top surface look especially

smooth. For lightweight fabrics, place a

paper underneath the fabric for best

results.

Pattern; < 1 (I)

Length: % or "Buttonhole"

Width: 1-5

Feed Dog: High

Pressure: Full

Foot; All Purpose

Stretch Control: IVI

26

Page 27

BUILT-IN EMBROIDERY

and utility stitches

The most popular two kinds of utility

embroidery stitch patterns can be made

by simply selecting with stitch pattern

selector, in addition to 10 kinds of utility

forward stitches and those complex stitch

patterns of back-and-forth feeding action

with stretch stitch control as "SS ".

TWIN NEEDLE SEWING

Attractive parallel straight stitch effects

and decorative zigzag patterns can be

easily made by sewing with the twin-

needle, and they are very effective for

various kinds of garment finish sewing

such as top stitching, border sewing, etc.

Except buttonhole stitches, all built-in

special stitch patterns can be applied with

the twin needle sewing.

In case of twin needle sewing, the stitch

width control should be at less number

than 3 or white number.

The use of color-matched or contrasted

two threads will result in a more attrac

tive finish.

Pattern: Other than buttonhole stitches

Length; 1—5

Width: Less than 3

Foot: All-purpose

27

Page 28

FREEHAND MONOGRAMMING

For giving garments and linens a per

sonalized touch, first transfer the design

to the right side of the fabric. An

embroidery hoop is recommended es

pecially for soft fabrics and toweling.

In order to monogram, you must move

the fabric slowly and run the machine

rapidly. Monogramming is like writing by

moving the paper under a stationary pen.

Guide the fabric slowly so that the zigzag

falls close together like a satin stitch, but

be careful that the stitches do not pile up.

When guiding from side to side, move

fabric slightly faster to avoid a heavy

pile up of thread.

Practice by forming loops. Once this is

accomplished any letter is easy.

Sometimes the use of paper or non-woven

interfacing under the fabric may make

guiding the fabric easier. The paper or

interfacing may be torn or cut away at

the completion of the monogram.When

monogramming towels, plastic film plac

ed on the top will help cover loops and

make the monogram smooth. Pull or cut

away remaining plastic film when finish

ed.

Pattern: ' '

Length:0

Width: 1-5

Feed Dog: Down

Pressure: 0

Foot: All Purpose or

Darning Spring of

White special

attachment

Stretch Control: M

I

I

APPLIQUE/PATCHING

Applying decorative shapes of fabric

scraps to household articles and clothing

is a very interesting way of trimming an

otherwise plain article. First, trace the

design on fabric to be appliqued or

patched,then pin or baste it securely in

place on garment. With a small straight

stitch or narrow zigzag, sew around the

transferred design or patch.

After excess fabric is trimmed away, sew

around the applique or patch with a satin

stitch or short length zigzag stitch. For a

smooth curve, stop frequently at the

inside edge of the curve to pivot the

fabric slightly. Corners look much better

when the point is stitched by pivoting

rather than just turned.

As with all decorative stitches, paper may

be used to give more body to the fabric

when stitching and can be torn away

when the applique is completed.

Step 1

Pattern:^.' ID

Length: 1

Width: 0-2

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

Step 2

Pattern; '''

Length: %—

Width: 2-5

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

Page 29

gathering over a cord

Ordinary gathering with a basting stitch

often breaks while pulling in fullness A

small zigzag across a cord such as crochet

thread or carpet thread, gives a much

stronger cord for gathering fullness into

fabrics^ Once the gathers have been

stitched in place, the cord can be pulled

out in order to eliminate bulk.

Pattern:^;

Length; 2 '

Width: 2-3

Feed Dog: High

Pressure; Full

Foot: All Purpose

Stretch Control; M

LACE APPLICATION

Attaching laces or trims adds a special

touch to lingerie, dresses, or linens. Pin or

baste lace in place easing or mitering

corners where neccesssry.

A straight edged lace or braid has a

convenient line to follow when sewing.

When using a scalloped edged lace follow

the design of the lace for an almost

invisible application.

Pattern:^/ ID

Length: ’A~1

Width; 1—3

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

FLUTTER HEM

edges of tricot or soft knits is by a flutter

edge. Hemming m this manner is just like

overcashng an edge, but the fabric is

stretched in back and in front of the

fte fabric equally, making sure the nee^dle

goes over the edge. When you stop to

Pattern:^/ Ш

Length; %—Я

Width: 4—5

Feed Dog: High

Pressure: Full

Foot; All Purpose

Stretch Control: IM

29

Page 30

SEWING TIPS

When a dainty hair line finish is

particularly desirable for the inside seams

of sheer collars, facings, and yokes, seam

allowance that would ordinarily show

through is eliminated by following the

seam outline with a narrow zigzag stitch.

Trim seam allowance close to line of

stitching. Turn and press.

Pattern: <I (I)

Length: 54—1

Width: ’/2-2

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

SHAPING DARTS IN

INTERFACINGS

Cut interfacing down center between dart

lines. Overlap cut edges, matching dart

lines. Zigzag stitch along marking line

from point to wide end of dart. Trim

both raw edges close to stitching.

Pattern:^! (|)

Length: ’/2—1

Width: ’/2-1

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

I

I

MULTIPLE ZIGZAG STITCH

The multiple zigzag stitch can be used for

hundreds of various kinds of sewing applications,

such as replacing worn blanket bindings for both

a decorative and durable finish, overcasting an

edge to prevent fraying, applying elastic waist

bands to skirts and dresses, sewing a zigzag stitch

on soft or sheer material preventing puckering,

etc.

Just sew like ordinary zigzag stitching.

30

„ (Cl

Pattern:

Stitch Length: 4—5

Width; 3-5

Feed Dog: High

Pressure; Full

Foot: All Puroose

Stretch Control: IVI

Page 31

BUTTONHOLES

b'lTOntolei“”'"9

PREPARATION

SHrirri”'""»'“'"

Horizontal bu,°,o„Mer‘taulde°f^^^^^

O acad"“' L'tlr“ bottonho":!”"

Sea o'rtrirTi"'"' -

OF GARMENT

OF GARMENT

Always make a practice buttonhole on a scran of thp

M- oe sure to use the buttonhole foot.

31

Page 32

BUILT-IN BUTTONHOLE

This buttonhole eliminates the needle for pivoting the

fabric. It is used most often on light and medium woven

fabric. The narrowest buttonhole is made with stitch

width control at 3 and the widest one is done with it

at 5. The stitch length control should be at "BUTTON^

HOLE” or near 0 not to without stop feeding action.

With stitch width at your desired position between 3

and 5, a buttonhole can be made by simply turning

stitch pattern selector from buttonhole position 1 to

those 2, 3 and 4 in sequence on the stitch pattern

selector panel.

1. Set stitch pattern selector at buttonhole (1). Lower

needle into the mark at the top left end of button

hole. Lower buttonhole foot and sew on the left side

of buttonhole until you reach the bottom end of

■ buttonhole.

2. Turn pattern selector to buttonhole (2-4) and take

just a few stitch to bartack the bottom end of button

hole.

3. With needle up, turn the pattern selector to the

buttonhole (3) to sew on the right side of buttonhole.

Your machine is preset to balance both forward and

reverse stitches on most materials, but certain fine

materials may require a slight adjustment to balance

of them. If the stitch density in this step is rougher

than of the left side of buttonhole, shift automatic

reverse stitch tuner to the right {+) and if it is heavier

than left side one, shift it to the left (—).

I

I

■

4. With the needle out of the cloth, turn again to the

buttonhole (4) position and complete the buttonhole

by bartacking just a few stitch on the top end of

buttonhole.

5. To lock the stitch, make sure the needle is out of the

fabric and set the pattern selector at ordinary sewing

position, the stitch width control at 0, and feed dog

height down. Then take a few stitches.

6. To prevent cutting through the bartack insert a

straight pin through the bartack and cut buttonhole

open.

Pattern: |]-D-[]-0

Length: Buttonhole

Width: 3-5

Feed Dog: High-Dovun

Pressure: Full

Foot: Buttonhole Foot

Stretch Stitch: IW

32

Page 33

Pattern: (II

Length: Buttonhole

Width: 5-2-2-5-2-0

Foot: Buttonhole Foot

Stretch Control: M

For best buttonhole finish it ic e, ,

»r„i:r;rr:,roVr;"F-'°-

stitch density hes, suited to your t-b“

CORDED BUTTONHOLE

e°:e1tem“r“ “ ™ised buttonhole I, is

in wS

makes cutting difficult O^n k?t

»e.rnrou”l^n-:

£:no,e.:“r.„r?o\n?s:LrSeed

r-p^r sr:f

the zigzag stitch covers the cord^'^ ^

excei cor7c?'°" buttonhole snip the

fabrics Tor knZT '-°ven

cords tn th garments, always pull the

33

Page 34

BLIND HEM STITCH

The blind hem stitch provides a durable hem

finish that is almost invisible on garments,

drapes, and curtains. It is done easily with

straight or slightly curved hems. With a little

practice it will be a very quick and easy hem

application and the hem will never need

repairing.

Procedure:

(1 (Prepare raw edge of hem in desired manner,

such as overcast, 1/4 inch stitched under

pinked, hem tape, or just plain. (Step 1 j

(2) Fold hem up desired length. Baste or pin 1/2

inch from upper edge. Press in place. (Step 2)

(3) Fold hem back toward right side of fabric

leaving about 1/4 inch extended. (Step 3)

(4) Guide the fold of the fabric into the center

cut of the presser foot so that the zigzag bite

of the stitch comes Just slightly to the left of

the center cut of the presser foot. The straight

or narrow zigzag stitches should be formed on

the single thickness of fabric, and the zigzag

wide bite should catch just barely into the

fold of the fabric at the left.

(BjWhen stitching is completed, remove fabric

from machine and turn to right side. Press

completed hem.

When hemming an A-line skirt, place a machine

basting stitch along the raw edge of the hem. At

an ironing board, fold up the hem, matching the

seams. Ease in the excess fabric by pulling on

I

I

basting thread. Press with steam, then apply hem

tape. Baste or pin hem 1/2" from taped edge,

then continue into step 3.

STEP 1

STEP 2

STEP 3

Pattern: (H) or .

Length: 2-3

Width: 3-5

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

34

STEP 5

STEP 4

Page 35

STRAIGHT STRETCH STITCH:

This stitch may be used on knits and wovens in areas of

h shtch. It is excellent for curved

stress ntn . endure a lot of

for « stretching, this stitch may be used

ordina^^ing. ^ - for

Tdfusfbrn ^'¡'‘^hing is not same

adjust by automatic reverse stitch tuner In case of Innno'

.‘ntrr Si ,17 fIT

un^rb 'tht'k'"'"

fatric ?re-fho rmLfb T" from

■ e tit garment before using this stitch

• TOPSTITCHING

ULTRA-STRETCH STITCH:

Pattern: (|)

Length: 5

Width: 0

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: SS

bathingTuh knte, andto«oTknh?7t'iaitVe'X^^^

nits. It has the greatest strength and elasticity of all

• rick-rack stretch

is most common utility ultrastretch of a triple '

than regulaTzigzin more elasticity ;

• pine-leaf stretch

This is the combined stitch of straight stretch and

,ngte sideward „„ches, ussfu heLing

knits and stretchy fabrics.

• SPECIAL ULTRA-STRETCH STITCHES

These are very useful ultra-stretch stitches caL

Pa^rnw' l Stretch

attern Marking for various purpose.

Pattern: ^

Length: 5 ’

Width: 2-5

Feed Dog: High

Pressure: Full

Foot: All purpose

Stretch Control: SS

Pattern: ^ (Jj or (h:

Length: 5 ^

Width: 2-5

Feed Dog: High _

Pressure: Full-Half

Foot: All purpose

Stretch Control: SS

Pattern:

Special stitches

Length: 5

Width; 2-5

Feed Dog: High

Pressure; Full

Foot: All Purpose

Stretch Control: SS

ill

35

Page 36

APPLICATIONS:

I

I

On most knits, an about 3/16 inch finished

seam, such as pine-leaf or special ultra

stretch stitches are more desirable than a

5/8 inch opened seam allowance. These

stitches can create a neater, more

professional finish, eliminate bulky

seams, prevent curling, permit the gar

ment to "give" under stress, and at the

same time they cut down on the amount

of work involved in making a garment. If

ever in doubt as to which of those

stitches to use, test them on the particular

fabric in question and choose according

to their performance.

Its uses are almost unlimited and the

more you use your machine the more it

will become apparent to you

ELASTIC APPLICATION

Fold fabric over the elastic and stitch

elastic and fabric at one time, using

smocking, pine-leaf, or other ultra-stretch

stitch. The double layer of fabric next to

the elastic should be stitched with the

one-side of ultra-stretch seam and the

elastic should be caught by another side.

Note;

The stitch length control should

be always at number 5 when

stretch stitching, otherwise the

machine will be noisy and the

material may feed in reverse only

or with uneven forward and reverse

stitch length.

36

Page 37

OVERLOOK APPLICATION

(B)

(A)

Special ultra-stretch stitches are also

usable for overlock stitching on

woven and knit fabrics.

(A) Place the raw edge of the fabric under the

presser foot so that as the needle swings to

the right, it comes down at the raw edge.

This will result in an enclosed

allowance.

(B)

The seam allowances may be trimmed to 1/4

inch either before or after sewing. If

Rimming before sewing, proceed as above.

Otherwise, sew the seam with the raw edge

of the fabric on the etched guide line 1/2"

(Any time you use the full width of a

pyticular stitch, you should readjust the raw

edge of the fabric 1/8 inch to the left )

Afterward, trim the excess fabric near the

stitching. This method is actually easier than

the overedge method for fabrics that curl.

Note: On soft, loose knits, the fabric may

seem to wave or ripple. If this occurs, reduce

the pressure on fabric.

very

both

seam

37

Page 38

OILING MACHINE

Use only a good sewing machine

oil, do not use any common

household oils.

Your machine should be oiled

occasionally to keep it operating

smoothly. How often depends on

the amount of sewing you do.

Once a year oil your machine

thoroughly as indicated by the

arrows on illustrations.

Avoid o\/er oiling.

I

I

38

Page 39

CLEANING AND OILING

THE SHUTTLE AREA

The stitch forming mechanism occasional

ly becomes clogged with loose threads

and lint. This will interfere with the

efficient operation of the machine.

Cleaning and removal of the lint will

safeguard the performance.

To remove the shuttle assembly, proceed

as follows:

1. Turn hand wheel until the needle

reaches its highest position. Tilt head

back on its hinges.

2.

Remove bobbin case (A).

3.

Turn the two shuttle race cover clamps

(f| outward and remove the shuttle

race cover (C) and the shuttle body

(E) and the lint cleaner (D).

4. Clean the shuttle race, the shuttle, and

shuttle race cover by removing all

threads, lint, etc.

When the cleaning has been completed

tie assembly:

1. Turn hand wheel until the needle reaches its highest position.

2. Place lint cleaner (D) to shuttle driver and shuttle body (E)

against shuttle driver and adjust into position.

3.

Replace shuttle race cover (C), fitting pin at lower edge into notch, and lock

into position with shuttle race cover clamps, (f|, making certain the clamps have

been snapped securely Into position.

Put bobbin (B) into bobbin case (A).

:a)

(B)

(C) (D) (E)

proceed as follows to replace the shut-

race (F)

39

Page 40

adjusting bobbin winder

It mav be sometime required to adjust

the level of rear top thread guide to

conform with the level of bobbin winder,

especially, when thread winds unevenly

on bobbin.

If the thread winds unevenly on bobbin

as shown (AS, loosen set screw of rear top

thread guide and move the thread guide

up slightly. If the thread winds as shown

(B), move the thread guide down slightly.

15~o

Q

Co

O

(B)

adjusting and changing

MOTOR BELT

Following are the instructions for adjust

ing and changing the motor belt:

Remove four screws holding rear

(1

cover by tipping it out at the bottorn

and pivoting around the hand wheel

away from the front of the machine.

To adjust motor belt, loosen screws

(2S

(A)and move bracket (B)up to loosen

belt and down to tighten.

(3) To remove motor belt:

• Remove top cover.

I

I

I

• Loosen clutch (C).

• Loosen screws (A) and move

bracket (B) to its highest posi-

• Slip belt off motor pulley and

then over hand wheel.

• Replace motor belt by slipping it

over hand wheel and then over

motor pulley.

• Adjust as noted under No. 2.

40

Page 41

PROBLEM AND REMEDIES

If Machine

Binds

Skipping

Stitches

Irregular

Stitches

Uneven

Stitches

Upper Thread

Breaking

Material

Pu ckering

Machine noisy

& material will

not feed in

stretch stitching.

Thread or lint in race

way.

Bent needle.

Needle placed incor

rectly in clamp.

Too fine a needle for

thread being used.

Too stretchy fabric.

Upper thread tension

too loose.

Improper threading.

Bobbin not wound

evenly.

Pulling or holding

material.

Not enough tension

on upper thread.

Poor quality thread.

Needle too fine for

thread being used.

Improperly threaded.

Too much tension.

Starting with take-up

in incorrect position.

Improper setting of

needle.

Bent or eye of needle

too sharp.

Bent or blunt needle.

Tensions too tight.

Dull needle.

Stitch length too long.

Stitch length control

is set at other than

Number 5.

Clean and oil machine the shuttle

area. (See page 39.)

Replace to new needle. (See page 10.)

Place needle correctly. (See page 10.)

Replace needle or thread to conform

each other. (See page 9.)

Place a paper beneath fabric, or use

Ball Point needle.

Tighten upper tension.

See threading instruction, page 13.

Adjust bobbin winder. (See page40 )

Avoid pulling or holding material. Just

guide it.

Increase tension.

Try different thread.

See needle and thread chart, page 9.

Refer to threading instructions, see

page 13, and rethread machine.

Loosen upper thread tension.

(See page 18.)

Always start sewing with take-up lever

in highest position.

Refer to needle setting instruction, see

page 10. '

Try a new needle.

Discard all blunt or bent needles and

replace with new.

See tension adjustment, page 18.

Change needle.

Reduce stitch length.

Set stitch length control at Number 5

Improper

feeding

Lint in feed dog.

Remove needle plate and clean lint from

feed dog.

41

Loading...

Loading...