SINGER W8910 User Manual

UIHITE

OPERATING MANUAL

EUROFLAIR 8910

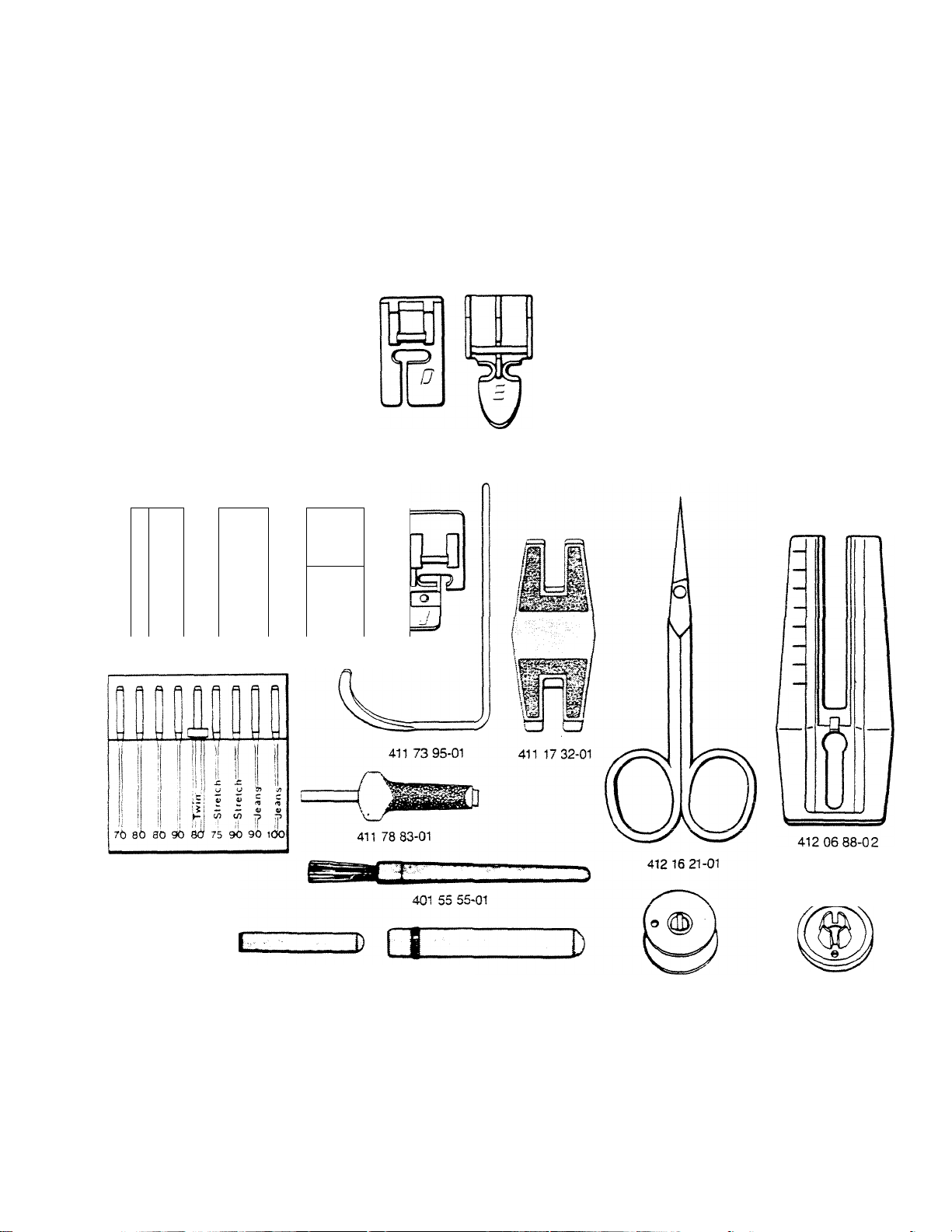

Standard accessories delivered with the machine

412 03 73-01 412 03 74-01 41173 89-01 41173 91-01 41173 93-01 41177 93-01 41185 87-01

f.

--------

f-T...m

^

411 39 25-01

LUJ

fUl

l-T—'

dL

L

412 00 16-01 411 73 99-01 411 85 30-01 411 85 27-01

411 64 14-01

-W

JL

401 53 99-01

412 06 12-01

411 87 78-01

For you and your new sewing machine

This booklet has been prepared to let you know how

to operate this sewing machine and how to make use of

all its sewing possibilities.

You will, for sure, get many pleasant hours with your

new sewing machine and be successful in obtaining many

fine results.

We reserve the right to change the machine equipment

and the assortment of extra accessories without prior

notice, or make modifications in the design or appear

ance of the machine, which do not negatively affect the

function.

Table of contents

Sewing Stitches of personal choice

Joining

Overcasting

Joining and overcasting

Topstitching

Hemming...........................................................

Buttonholes

Clearance plate.................................................

Sewing on buttons

...............................................................

.......................................................

...................................

......................................................

.......................................................

Ordinary/repeated buttonholes, edges, appliqués

adjustment possibilities, corded! Three-step zig-zag

reinforced/keyhole buttonholes. Sewing terry cloth, mending

buttonhole plate, cutting the Stretch stitch, reinforced straight

buttonhole stitch, reinforced zig-zag..................................

............................................

..........

23

..........

23

..........

24

..........

24 pin tucks

..........

25-26 Zig-zag...............................................................

..........

27-31

..........

40 Overcast stitch, overlock

..........

41

Straight stitching

Topstitching, edge stitching.

gathering, sewing in zippers,

Attaching lace, gathering, bound

..............................................

............................................

.................................

Flatlock..............................................................

Pattern cassette.................................................

Bridging stitches, edging. Point

de Paris hemstitch

Programming of decorative stitches

Mirroring, pattern combinations,

cross-stitching

Sewing letters, monograms

..............................

...............

.........

.........

.........

.........

.........

.........

.........

.........

32-35

36-37

38

39

43

44-47

46-47

48-50

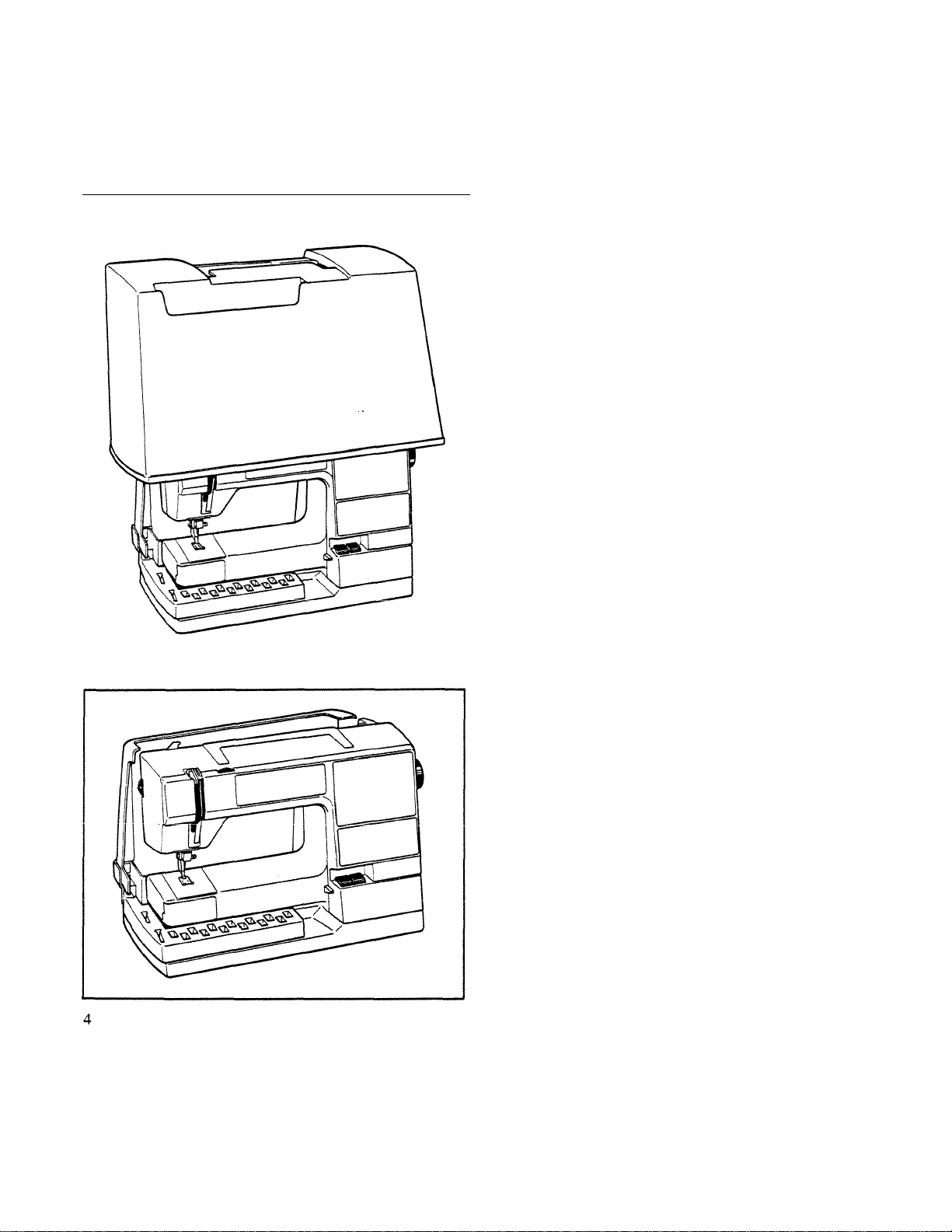

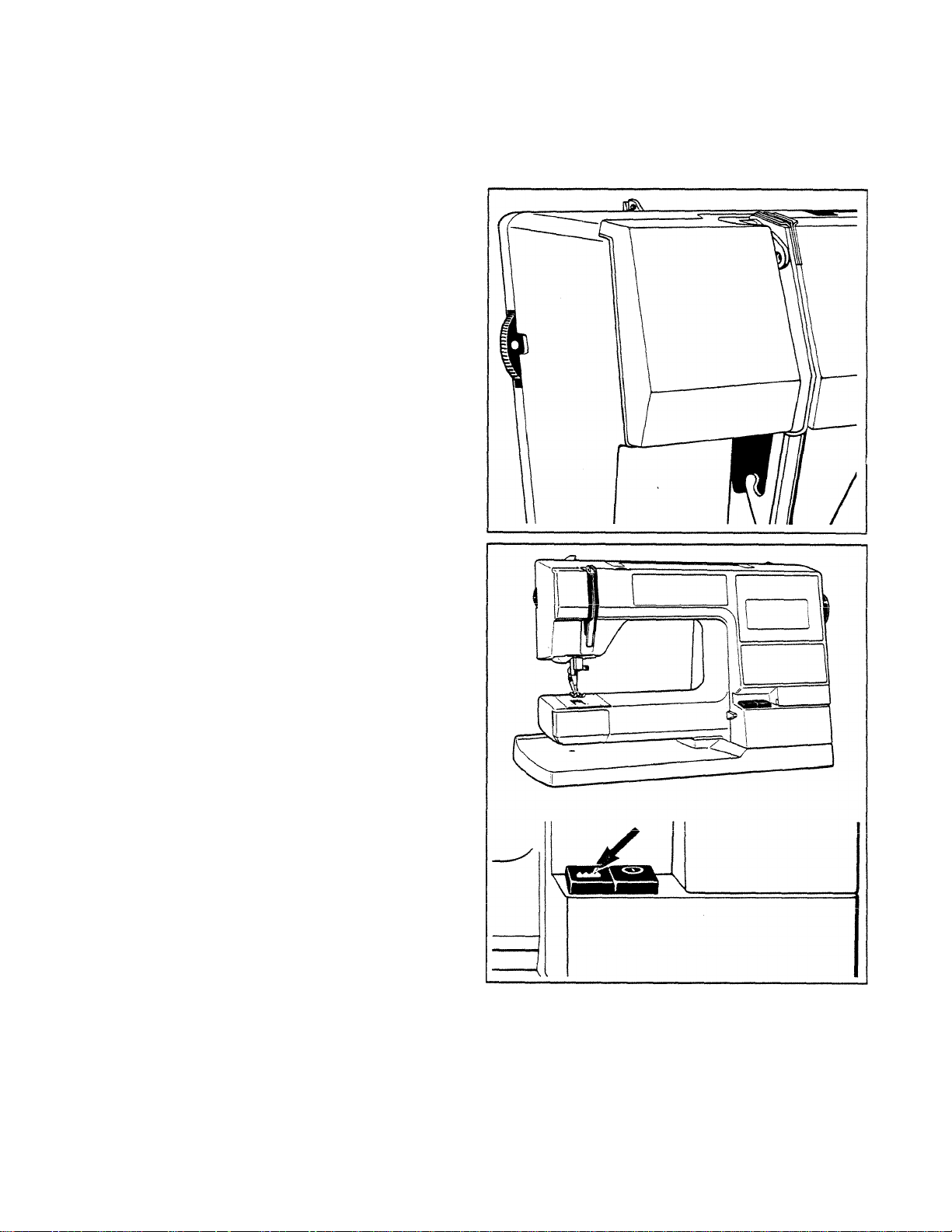

Unpacking and putting away the machine

Unpacking

Place the machine on the table, with the recess for the

handle furthest away from you, and fold down the

handle. Lift off the cover and put it aside. Remove the

extension table and the foot control and sHde the acces

sory box to the left from the machine.

Wipe the machine clean before you start sewing and

be especially careful with the stitch plate and the space

around the needle. The machine is equipped with a

number of presser feet and these are packed in two

plastic bags. Regarding the placing of the accessories,

please refer to page 14 imder “Accessory box”.

Putting the machine away

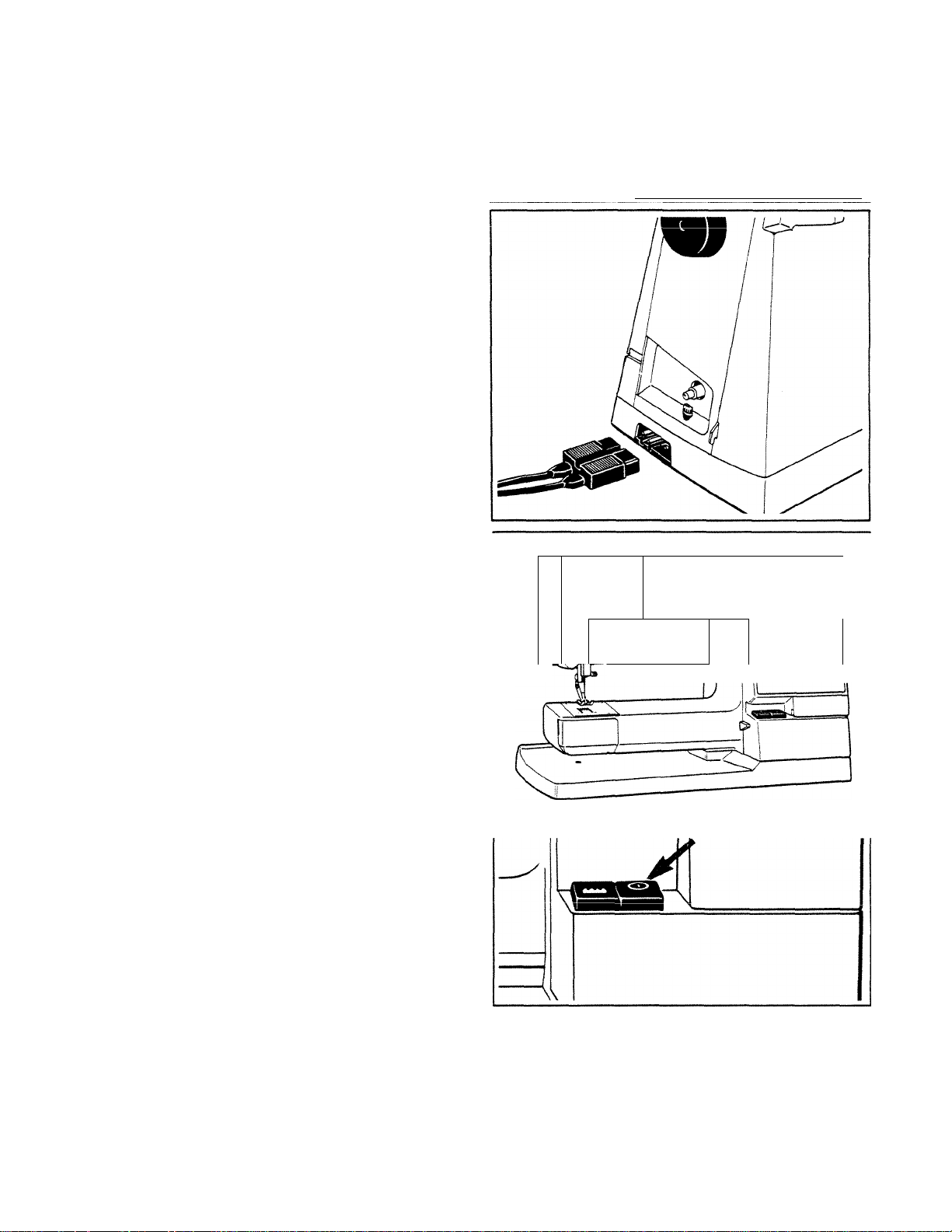

Pull the plugs out of the wall outlet and the socket of

the machine. Wind the cords around your hand, starting

at the foot control and push them into the control com

partment.

Place the control in the rear compartment of the acces

sory box, with the wider end downward. The bottom of

the foot control should be turned toward the machine.

Lower the presser foot. Make sure that all accessories

are correctly placed in the box. Slide the accessory box

into place and put the extension table into the box.

Fold down the handle and put on the cover.

n

_____

V^UllllCV-LXilS LX1& xvjvxx v,v^xxi-iC!i

Remove the cord from the foot control and place the

control under the table. Insert the foot control plug into

the socket on the right side of the machine.

Connecting to the wall outlet

The voltage (V) and frequency (Hz) are indicated

under the base of the machine. Check that these values

correspond to those of the electricity source before con

necting the machine.

Main switch

The light and the machine are turned on by pressing

the main switch. This makes it easy to see that the

machine is ready for sewing.

Speed control and needle stop-right

The speed is controlled by means of the foot control.

Press the foot control down lightly and the machine will

start sewing at the lowest stitch speed. This speed is

suitable for precision sewing and if you wish to manoeuver the fabric by hand.

When you depress the foot control further the

machine will run faster. The needle has full penetration

power all the time.

When you lift your foot from the control the needle

will always stop at its upper position so it is not necessary

to think about the needle position at the start or finish of

a seam. If you wish to turn the fabric when sewing

around a comer for example, it is easy to get the needle

to stop down in the fabric. Just press the foot control

down quickly and release it again.

I I

----II----

mmmm

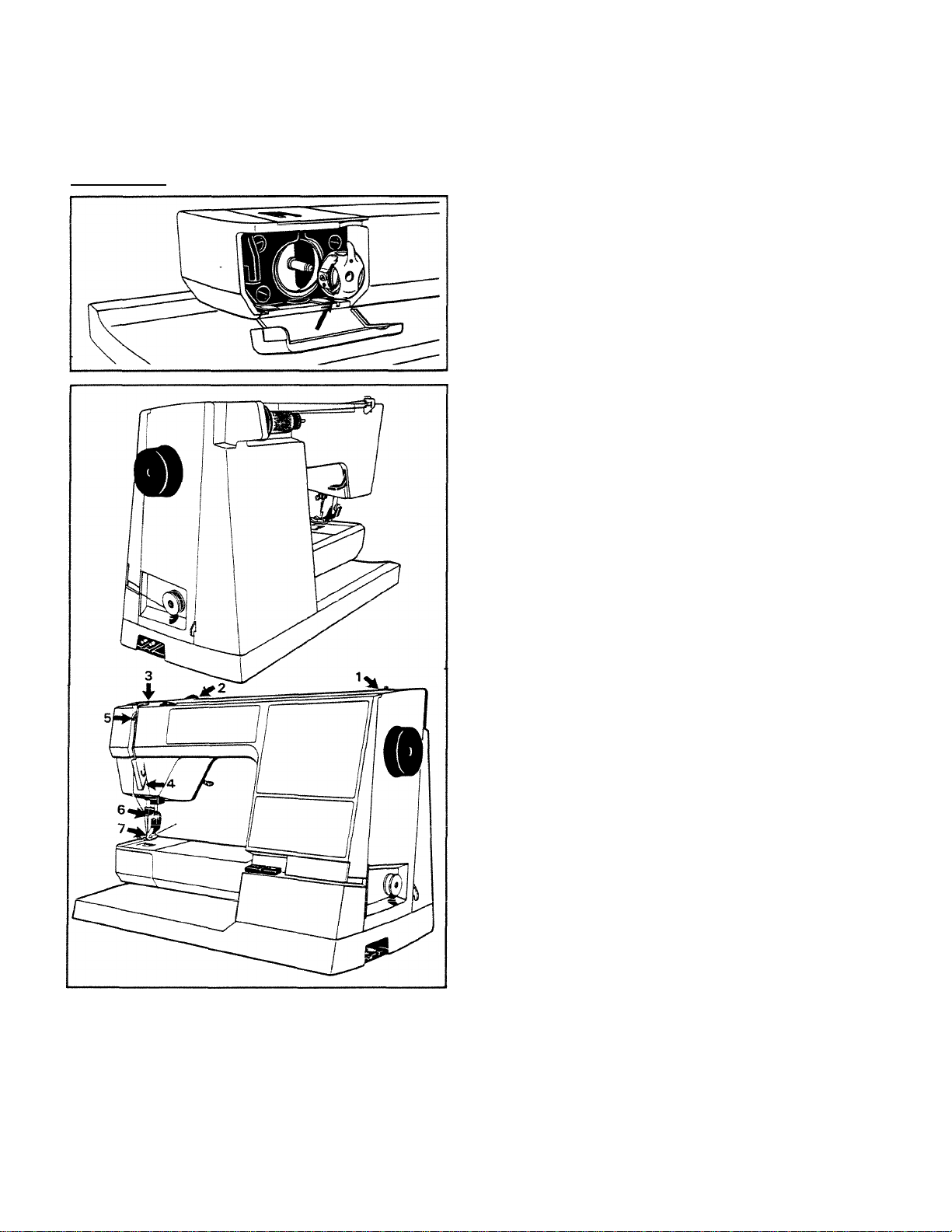

Connecting the machine

Ir^l

■' N

—

^ 1

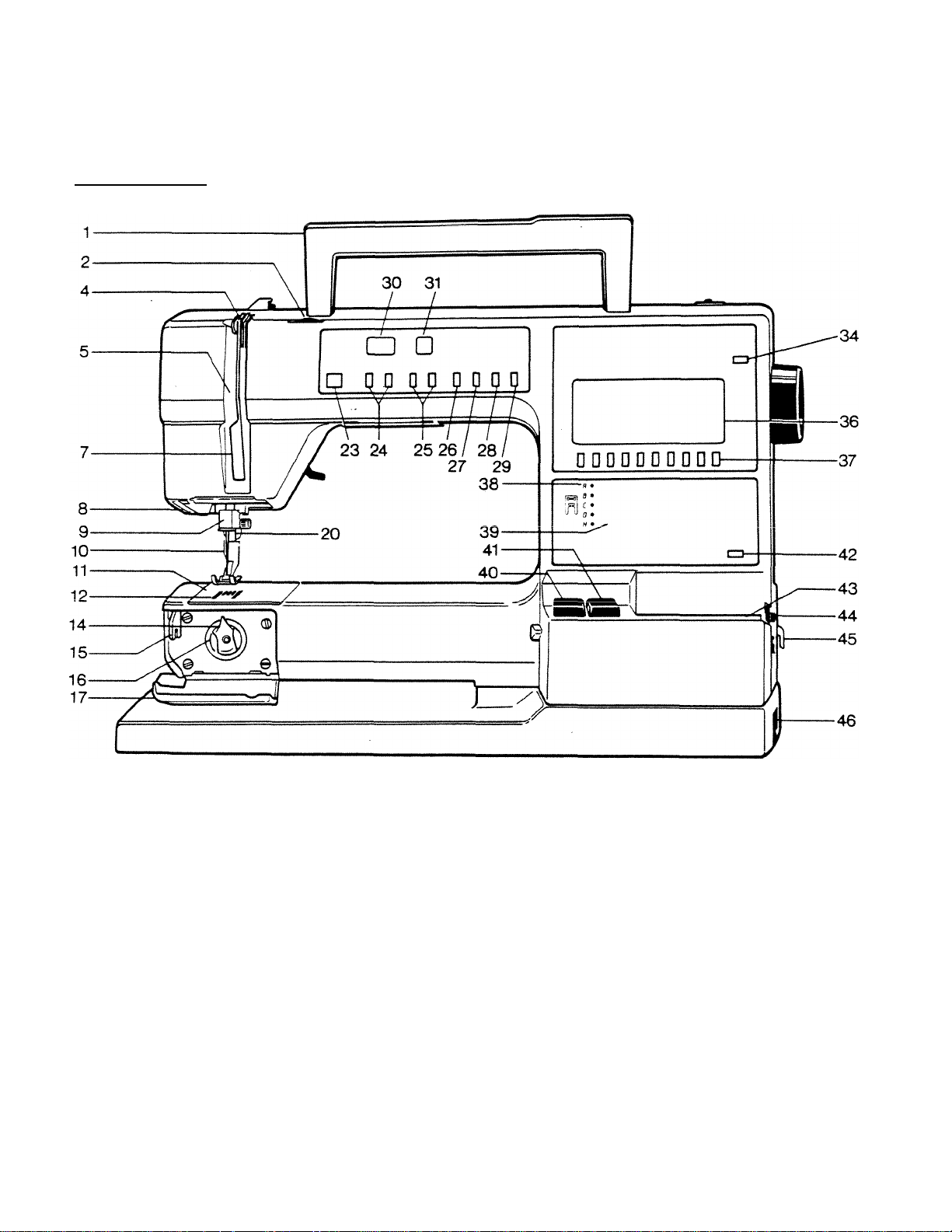

Machine parts

1. Handle

2. Thread tension dial

4. Thread tension discs

5. Thread take-up lever

7. Front thread guide

8. Sewing light

9. Needle bar with needle clamp

10. Presser foot ankle

-IXT_31-

AJL. INCCUIC pi<UC pidkc;

12. Feed dog

14. Bobbin case

15. Thread cutter

16. Shuttle (hook)

17. Door for shuttle (hook)

20. Presser bar

23. Reverse feed button

24. Push-buttons for changing the stitch

length

25. Push-buttons for changing the stitch

width

26. Push-button for mirroring the stitch

pattern

27. Push-button for limiting the stitch wi^

28. Push-button for programming and

repeating

29. Finishing button

30. Stitch length indicator

31. Stitch width indicator

34. Push-button for utility stitch setting

36. Exchangeable cassette

37. Push-buttons for selection of embroidery

38. Recommended presser foot

39. Other recommendations

40. Drop feed switch

41. Main switch

42. Pusii~fcnitton for ssttin^ of fM.?ric

43. Thread guide for bobbin winding

44. Bobbin winding spindle

45. Thread cutter

46. Socket for foot control

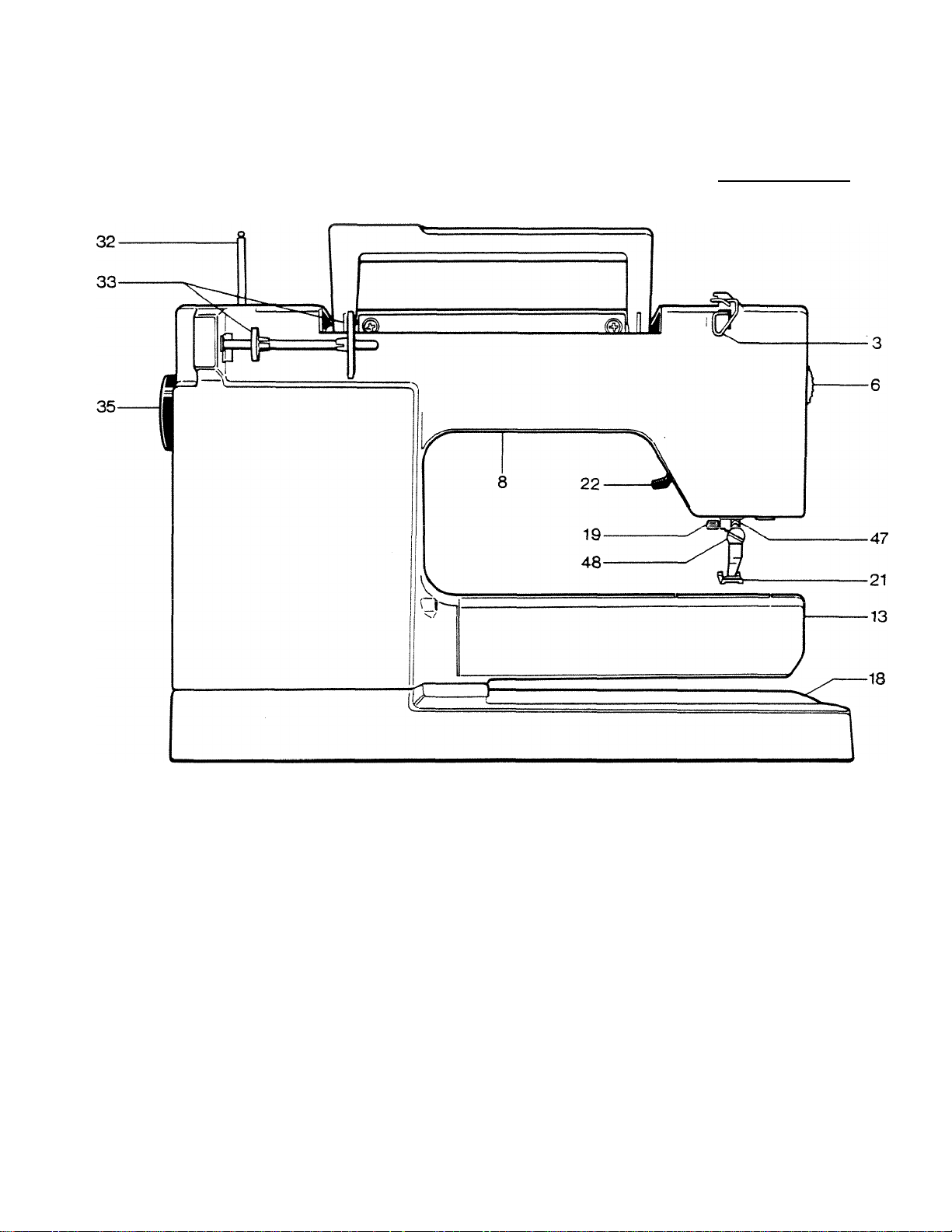

Machine parts

3. Thread guide

6. Presser foot pressure dial

8. Sewing light

A iCCi CIAA4A

18. Base plate

19. Needle clamp screw

21. Presser foot

22. Presser bar lever

32. Extensible thread reel holder

33. Horizontal thread reel holder

35. Handwheel

47. Thread cutter

48. Screw for edge guide

Function

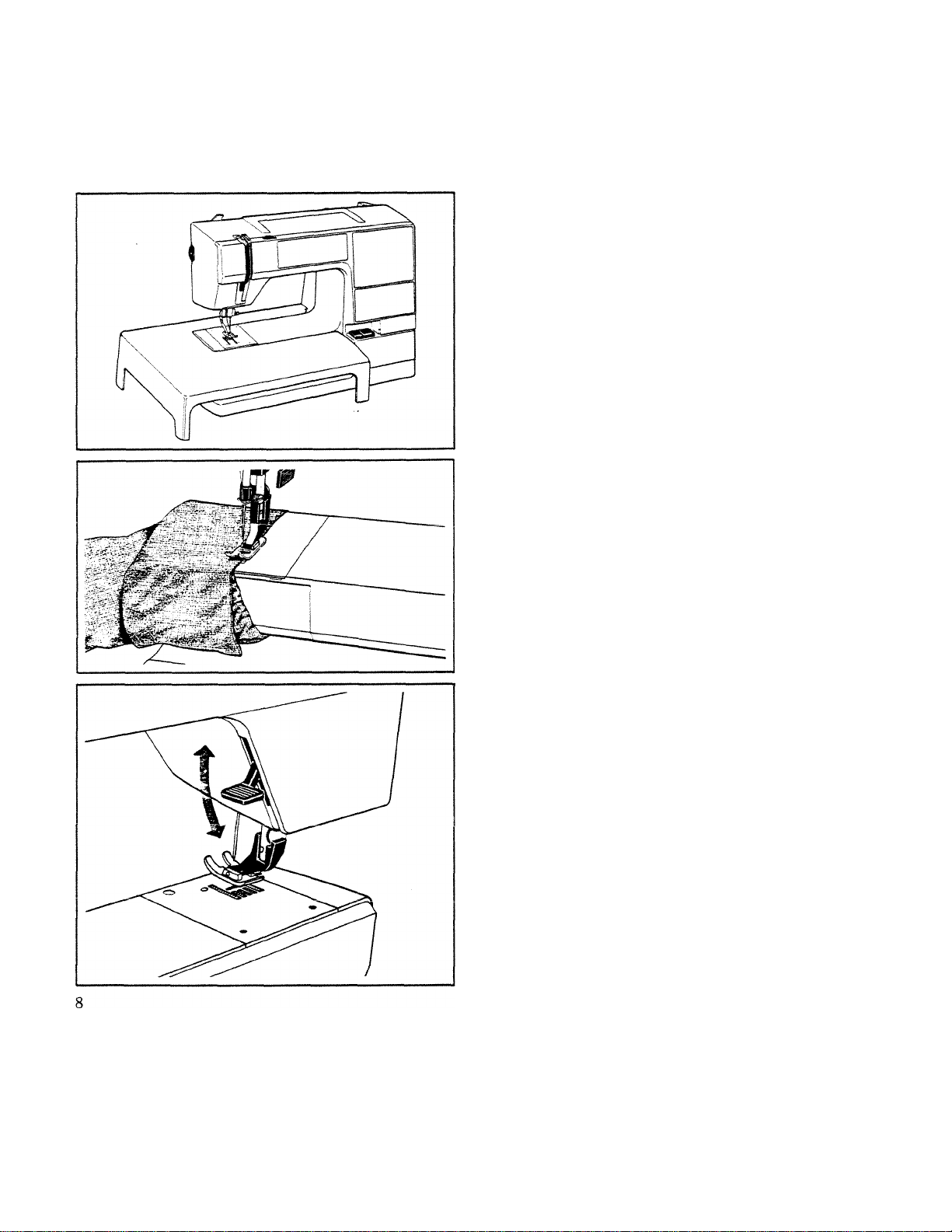

Extension table

When you need a larger working surface, use the

extension table.

Fit the extension table into the holes at the rear of the

free arm. The projections shall fit into the back part of

the recess. Push the table onto the free arm.

When you want to check the amount of thread on the

bobbin, or some similar operation, lift the table to the

front and fold down the shuttle cover.

Free arm

Pant legs and sleeves can be drawn onto the free arm,

making it easy to sew, mend or patch these parts.

The free arm also makes it much easier to attach

collars and cuffs as well as sew children’s clothes, or dam

socks and stockings on the machine.

Presser bar lever

By means of the presser bar lever at the rear of the

machine, the presser foot can be raised and lowered.

When raising, the presser foot wu remain in the raised

position, but the height can be increased by 3 mm by

pushing the presser bar lever upward and holding it in

this position. This is useful when you want to put gar

ments with thick seams under the presser foot.

The presser foot should be lowered while sewing.

Presser foot pressure

The presser foot pressure can be adjusted by means of

the graded dial on the left side of the machine. Adjust

ment will be easier if you lower the presser bar lever

first. Normal pressure is obtained by setting the dial at

the white dot but for some fabrics it may be better to

reduce or increase the pressure. The higher the number

the greater the pressure.

By setting the dial at the symbol iPl the presser

foot pressure is completely released. This setting should

be used when free-hand sewing with the darning foot.

You will find the darning foot under “Extra acces

sories” on page 57.

If you turn the graded dial for the presser foot pressure

to the lowest number, it is possible to darn with presser

foot A. Lower the feed teeth and move the fabric for

ward, backward and sideways by hand.

Function

Lowering the feed teeth

Lower the feed teeth by pressing the push-button

down and raise them by re-pressing the push-button. The

feed teeth will raise when you resume sewing.

The feed teeth should be lowered for a certain type of

darning and when sewing on buttons. It is also easier to

get thick garments under the presser foot if the feed teeth

are not above the level of the stitch plate.

Threading

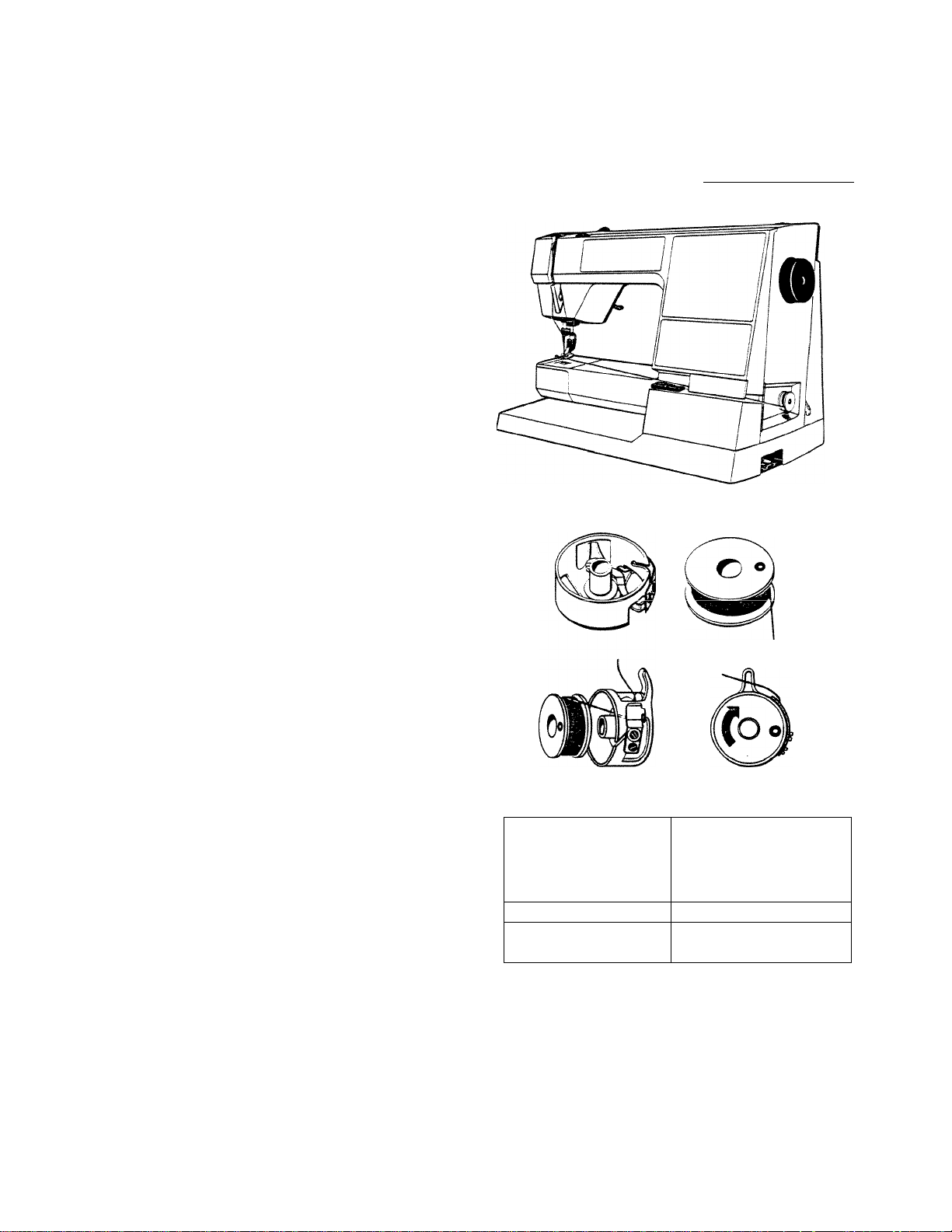

Removing the bobbin case

open the door in front of the shuttle by means of the

small recess on the left side.

Grip the bobbin case with the thumb and index finger

so that the latch is depressed and pull the bobbin case

out. The bobbin will remain in the case as long as the

latch is depressed. When you release the latch, the bob

bin will be released.

Threading the upper thread

Raise the presser foot. Check that the needle is at its

highest position.

The machine is fitted with a horizontal and an exten

sible thread reel holder. As a rule the horizontal holder is

used for ordinary sewing and the smaller disc is placed

outside the thread reel, as illustrated, but if the edge of

the thread reel is uneven, it is advisable to place the

larger disc outside.

The extensible holder is used when sewing with the

twin needle, the small washer, 411 87 78-01, which you

will find in the accessory box is placed under the thread

reel to minimize the friction.

10

Slide the thread into thread guide 2 on the upper arm

and draw it upward. Then draw the thread to the front

between the tension discs 3 and down around thread

guide 4. Continue threading by drawing the thread from

the right into the slot on thread take-up lever 5 and draw

it down to the needle, ensuring that it goes through

thread guide 6.

Thread the needle from the front. Due to the white

color of the presser foot ankle the needle-eye is clearly

seen and the threading of the needle, 7, is easier. Pull the

thread under the presser foot about 15 cm (6") toward

the rear.

Bobbin winding

Turn the empty bobbin until the small round dot on

one side is outward. Slide the bobbin onto the bobbin

spindle, which is located on the right side of the machine.

Raise the presser foot and thread the machine as

described on the previous page, but pull the thread from

the needle through the presser foot and the slot at the

front of the machine. Never run the thread direct from

the eye of the needle because it may result in a bent

needle.

Start from underneath and wind the thread around the

bobbin a few times. Pull the thread backward and insert

it up through the thread cutter until it is cut. Depress the

foot control. The machine will stop automatically when

the bobbin is full. Remove the bobbin and cut the thread

in the thread cutter.

Threading the lower thread

When the bobbin winding is finished, place the bobbin

beside its case with the marking upward. The thread

should run as shown in the figure. Place the bobbin in its

case without turning it around.

Slide the thread into the slot on the edge of the bobbin

case. Pull the thread in under the tension spring. Check

that the bobbin rotates in the direction of the arrow

(clockwise) when the thread is pulled.

The thread must be pulled in the direction of the

spring, otherwise the spring will be overloaded.

Bobbin winding

Insertion of the bobbin case

bJlAW WJkX.1 WUUl Im'V.'XXXXXU UXX^ ^X WJwVoUWXX V/X UXW i./vyw/u/xxx

case and to the right. Put the bobbin case into place.

Press the bobbin case until it clicks to ensure that it fits

properly.

The thread cutter is located to the left of the bobbin

case. Hold the thread end and draw the thread from

underneath and up toward the thread cutter. By doing so

the thread will be cut off and kept in place. Shut the

door.

^

11

Thread tension

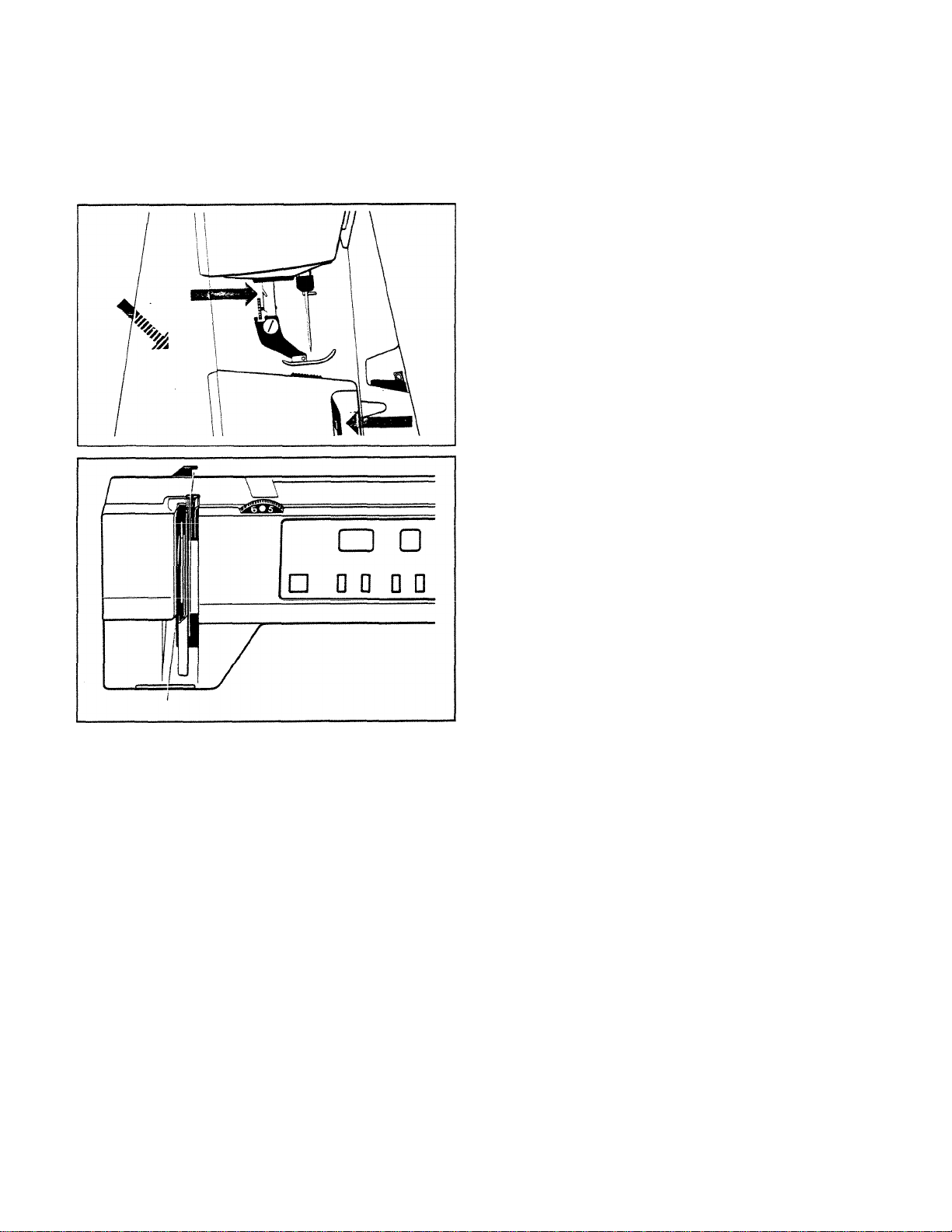

Thread cutters

The notch on the back of the presser bar is the thread

cutter. Threads can easily be cut off when you have

finished sewing.

There is also an additional thread cutter for use when

bobbin winding and one for cutting the bobbin thread

after insertion of the bobbin case. See page 11.

Tension of the upper thread

The dial which regulates the tension of the upper

thread is graduated from 0—10. The higher the number,

the tighter the tension. Normal thread tension is

obtained by setting the dial within the white area. Your

machine has been tested using the thread which accom

panies it and with the thread tension dial within the

white area.

If using a coarser thread, it may be necessary to alter

the thread tension slightly. Also the type of fabric may

require the tension to be adjusted.

When sewing buttonholes and decorative stitches the

thread tension is decreased automatically. When return

ing to regular sewing the normal thread tension is set

again.

12

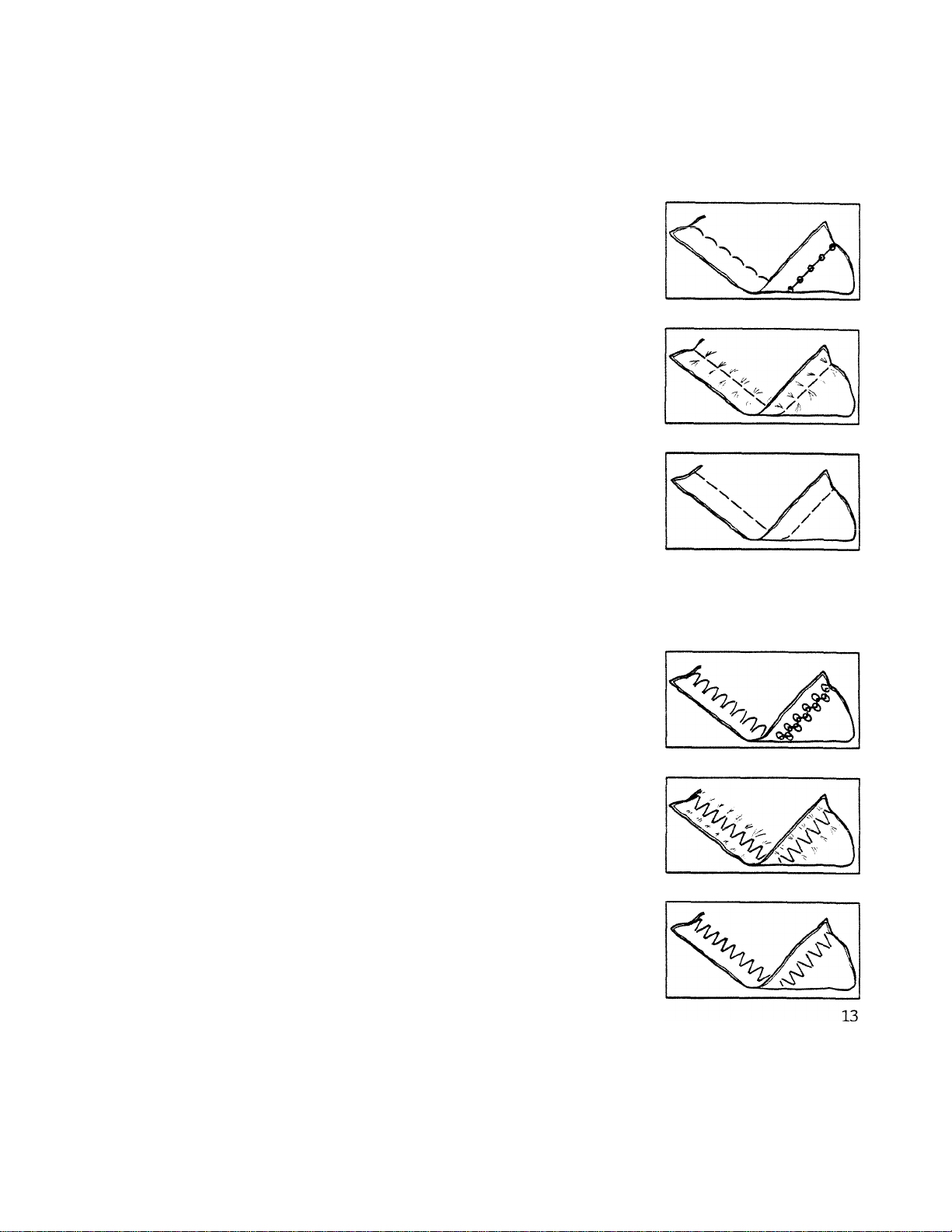

Correct and incorrect thread tension

In order to easily imderstand the importance of correct

thread tension, you can try different thread tensions by

sewing on a scrap of fabric. Begin by using an excessively

loose tension, i.e. set the tension dial near “0”. Look at

the fabric and you will find that the lower thread lies

straight and the upper thread is drawn underneath the

fabric. If, however, you set the dial at the highest

number, the opposite will occur, or the seam may

pucker.

The thread tension is correct when the threads inter

lock in the middle of both layers of fabric.

Please note that even the best quality thread may vary

in thickness. When sewing in fine fabrics, the knot may

sometimes be'visible.

Thread tension

Always check that the thread tension is correct by first

sewing on a scrap of the same fabric, folded double, that

you intend to work with.

If you set the stitch length to less than 1 mm yourself

for sewing close zig-zag stitches, you should also

decrease the thread tension by setting the dial at 4.

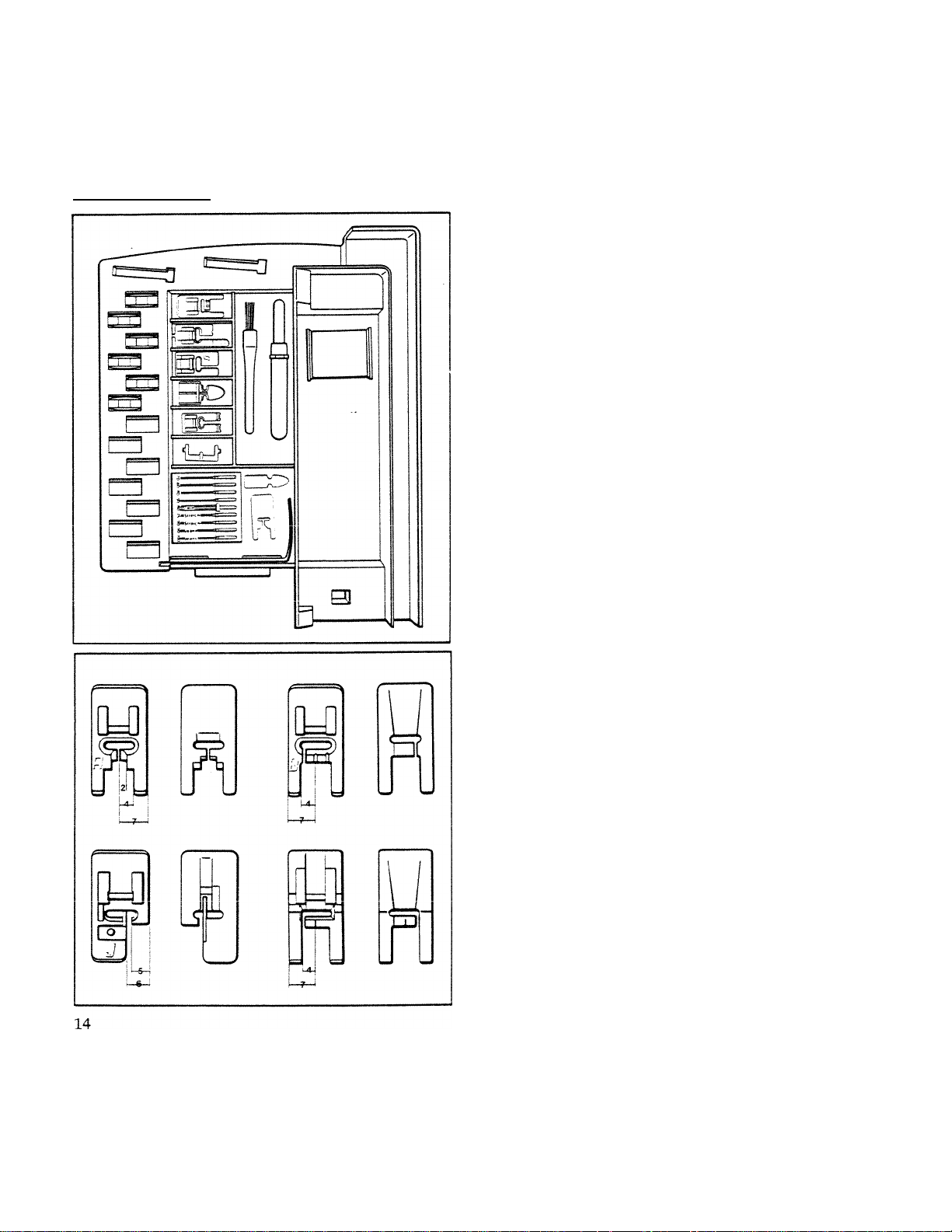

Accessory box

A r*ac'cr*T 7

■1 xvwwaav-fi y ukj^

To obtain the best sewing results you should select the

correct presser foot for the type of sewing you are doing.

The presser feet are marked with letters and the lights on

the lower panel indicate the suitable presser foot for the

type of work you have chosen.

By means of these feet you will be able to carry out

practically all types of sewing work. There are additional

accessories to assist you with special work. These will be

foimd under “Extra accessories” on pages 55—58.

Store the accessories in the accessory box. By placing

them as illustrated, it will be easier for you to remove

and replace the box.

We reserve the right to change the equipment of the

machine and the assortment of extra accessories without

prior notice.

Presser foot A

The presser foot which is fitted on the machine on

delivery is marked A. This foot is used mainly for

straight stitching and zig-zag stitching with a stitch length

longer than 1 mm.

Presser foot B

When sewing close zig-zag stitches with less than 1

mm stitch length; other utihty stitches or decorative

stitches; you should use presser foot B. The bottom of

the foot is designed to give more space for the stitches.

Presser foot J

This foot is used for overcasting, joining and overcast

ing, i.e. stitches which have a stitch width of 5 and 6 mm.

The pin prevents puckering at the edge of the fabric.

Decorative presser foot

Use this foot for decorative stitches. It is completely

transparent, making it possible to match stitch patterns.

Various markings

As you can see from the illustration, the above presser

feet have notches or markings which can be used as

guides when sewing. When straight stitching with the

needle in the center position, you will have a 7 mm (1/4")

seam allowance if you guide the fabric even with the

outer edge of the foot; 4 mm (3/16") at the iimer edge

and 2 mm (3/32") at the innermost notch on presser foot A.

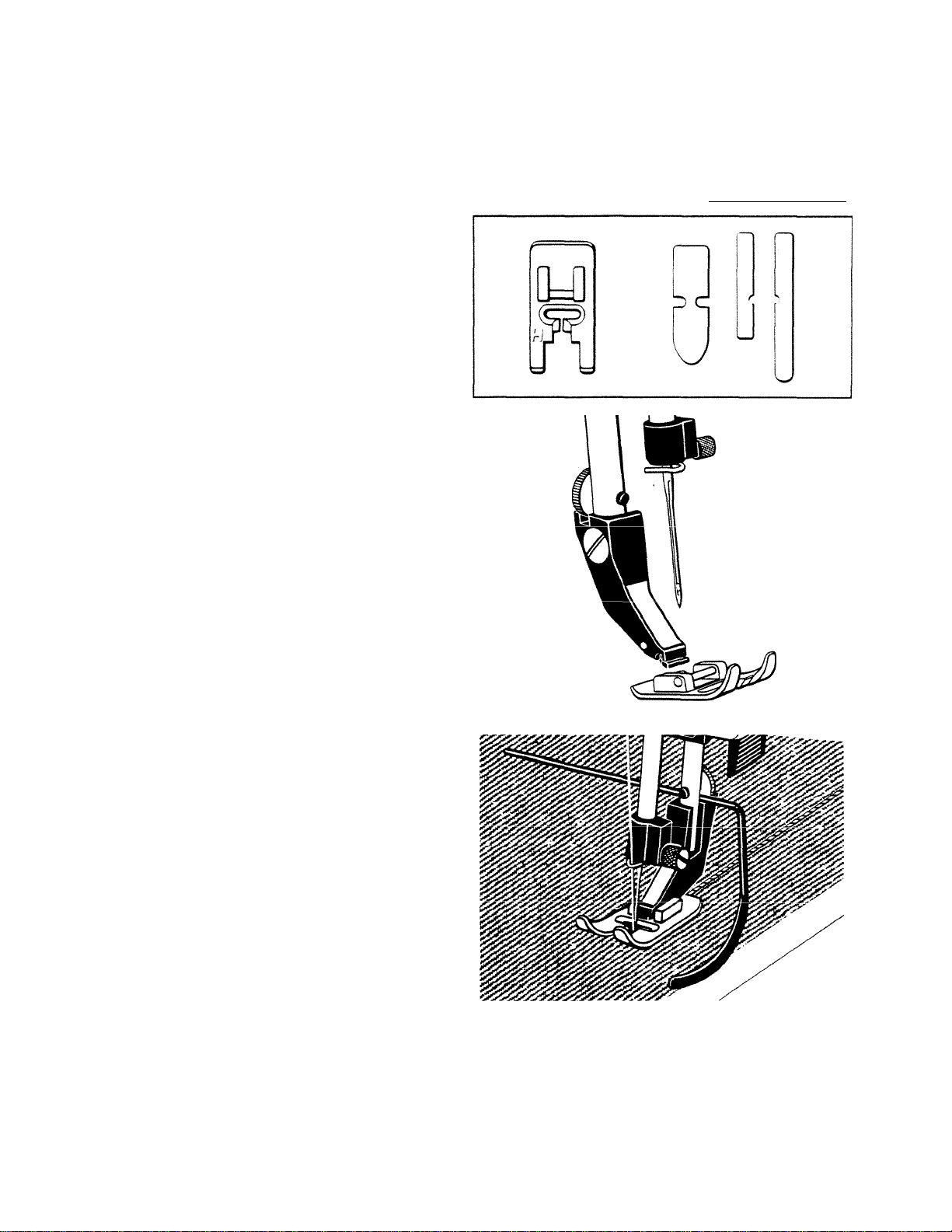

rresser root n, giiae piates

Presser foot H corresponds to presser foot A, with the

exception of the teflon coating underneath. The glide

plates can be adhered to presser feet E and C. Remove

the protective paper and press the self-adhesive side

against the underneath of the presser foot.

Both presser feet may then be used when sewing foam

plastic, vinyl-coated fabric and leather imitations, thus

minimizing the risk of these materials sticking to the

foot.

Changing the presser foot

If you wish to change the presser foot, check that the

needle is at its upper position Remove the presser foot by

drawing it toward you while pressing slightly downward.

Insert the new presser foot in such a way that the

round, horizontal pin fits in between the spring and the

presser foot ankle. Press slightly downward and back

ward and the foot will snap into place.

Accessory box

Edge guide

The stitch place has markings for 1.0,1.5, 2.0,2.5,3.0

and 3.5 cm, to simplify sewing seam allowances. If you

require an even wider seam allowance, use the edge

euide.

First loosen the screw at the rear of the presser bar as

far as it will go. Insert the guide into the groove under

the screw and adjust it to the required seam allowance.

Tighten the screw, using the screwdriver.

15

Accessory box

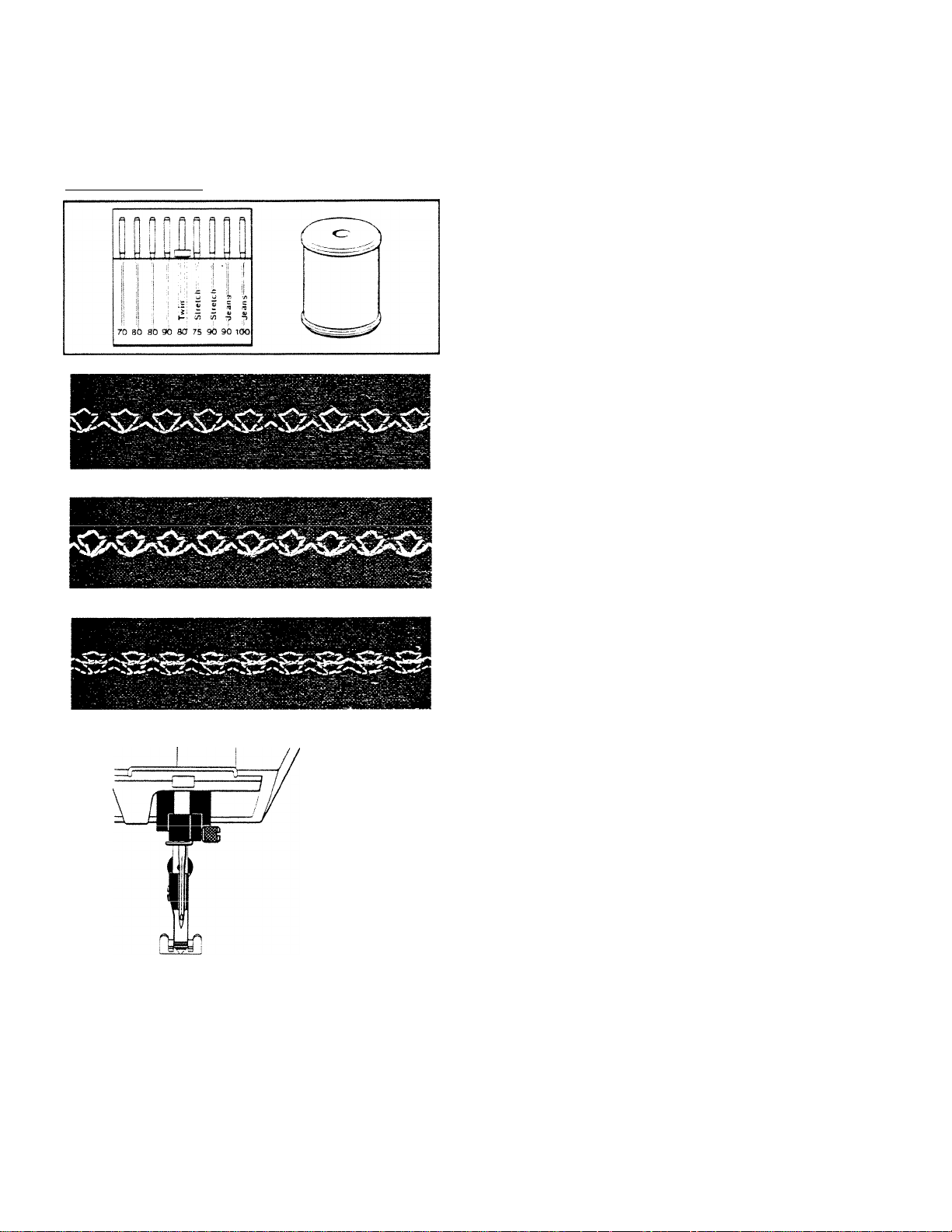

Needle and thread

The machine is delivered with a spool of synthetic

thread, which can be used for all t3rpes of fabrics and

most stitches. Mercerized cotton can also be used.

As a rule it is, however, shghtly coarser and therefore

requires increased thread tension.

Use a finer neddle and thread when sewing lighter

fabrics. Embroidery thread, which is more loosely

twisted and finer, produces more attractive and even

stitches than ordinary thread. It also produces attractive

buttonholes and may even be used for darning.

You can produce a more pronounced seam in thicker

fabrics by using a coarser needle and thread, e.g. synthe

tic buttonhole thread or double upper thread. Metalhc

thread or extra coarse thread which cannot be threaded

through the needle can be wound on the bobbin and used

as the lower thread. Sew on the wrong side of the fabric.

You can also use the twin needle for decorative

stitches. Insert the twin needle, press the | -pushbutton, which limits the stitch width to prevent die

needle from striking the stitch plate.

N.B. After removing the twin needle, press againt the

I -push-button until the light goes out. Increase the

stitch width again if you are going on using the same

stitch with the ordinary needle.

16

Changing the needle

Even if the needles look alike there can be slight

variations which can affect the sewing result. Be sure to

use the right type of needles.

Only a completely undamaged needle will give perfect

sewing results. Therefore, change the needle if you have

the slightest reason to beheve that it is bent or that the

point is damaged. To remove the needle, loosen the

screw in the needle clamp. With the flat side of the shank

away from you, insert the new needle into the needle

socket as far as it will go. Tighten the screw firmly.

Needle design

In most cases the standard needle is the most suitable

and the thickness of the needle should be adapted to the

type of thread and fabric. However, when sewing certain

fabrics, another design of the needle point can produce

better results.

You will find two needles in the needle case with the

description “Stretch” (completely blue). These needles

have rounder tips and should be used when sewing light

elastic fabrics, '^en a needle of this type contacts a

thread in the weave, the thread is pushed aside, without

it being damaged. It is also suitable for sewing corduroy

and soft leather.

If, on the other hand, you are using a rigid fabric, like

denim, sewing will be easier if you use the needle

described “Jeans” (top part blue).

This has a sharper tip, enabling it to pass through thick

seams more easily.

Accessory box

There is a twin needle in the needle case. It consists of

two standard needles, size 80, and is intended to be used

when sewing decorative or raised seams, as described on

pages 16 and 33.

When you use the twin needle, first press the button

marked t . The machine will then automatically

limit the stitch width for all stitches and the twin needle

can be used without any risk of it striking against the

stitch plate.

N.B. After removing the twin needle, press again the

I -push-button until the light goes out. Increase the

stitch width again if you are going on using the same

stitch with the ordinary needle.

Regarding special needles, please refer to “Needle

Assortment” on pages 54 and 55.

n

V

Loading...

Loading...