Page 1

Page 2

[ftam]

«nd Parts ................................................

Windir>o the Bobbin

yw>er Threading...................................

Sotting the Needle

Threading the Bobbin Case

Stitch Ungth Chart ....................................

Sewing in Reverse

Adjusting the Tensions......................................... It

Adiusting Pressure and Feed ...................................... \ f

General Sewing ............................................ 15

Light Weight Fabrics

Darning and Mending......................................................... jf

Preparit^ to sew

Se*novir^ the Work

Straight Stitchhig ........................................................ 11

Changing of Needle Plate

Sotting Needle Position

Twin Needle

Sewif>g on Buttons

Stretch Stitch —

Multiple Zigzag stitch - 29

.....................................

....................................... ..................

.......................... ................................

........................................

...................................... ....................

............................ ...........................................

^^eative En*roidery^^- -

...............

..........

................................................

...................................

...................................

.................................................

25-26

..................................................... 27

.........................

....................

'

i n , f

.............

»

’ ?

®’’®

] °

I N

D E X

[Item]

Blind Stitch Hem........................................

Manual Opeiation

How to use Accessories

Narrow Hemmer

Lace Trimmed Hem

Seam Gauge or Cloth Guide..........................................

Care and Mamtenance of your Machine It

How to replace the light bub ~ .........

Trouble Chart

Attachments ............................................................... 39-41

Attachment Foot

Edgestitcher

Binder

.............................................

Hemmer.......................................................................... A6

Rüffler ..............................................

Sewing in Zipper

! Portable Case

To Assemble Le^ on Cabinets

^talli^ Sewing Head ni Cabmet

..................................... ........................

..............................

....................

............ ............................. ..............

..................................................................

.............................

.................................................................

.......................................................

Corcfcig and Zipper Foot U

®nd Changmg "V” Belt

.............. ............................

Shuttle........................................ tt

..!...............................^3

.........................................

........................................

..................-.............

....................

........................ 33

;;;;;;

.................

........................

A4

a4.4s

A7 -48

49-50

..........

54

55

58

...

||

Page 3

f

® d) ® @ ®(D

Fig. 1

Igi

Page 4

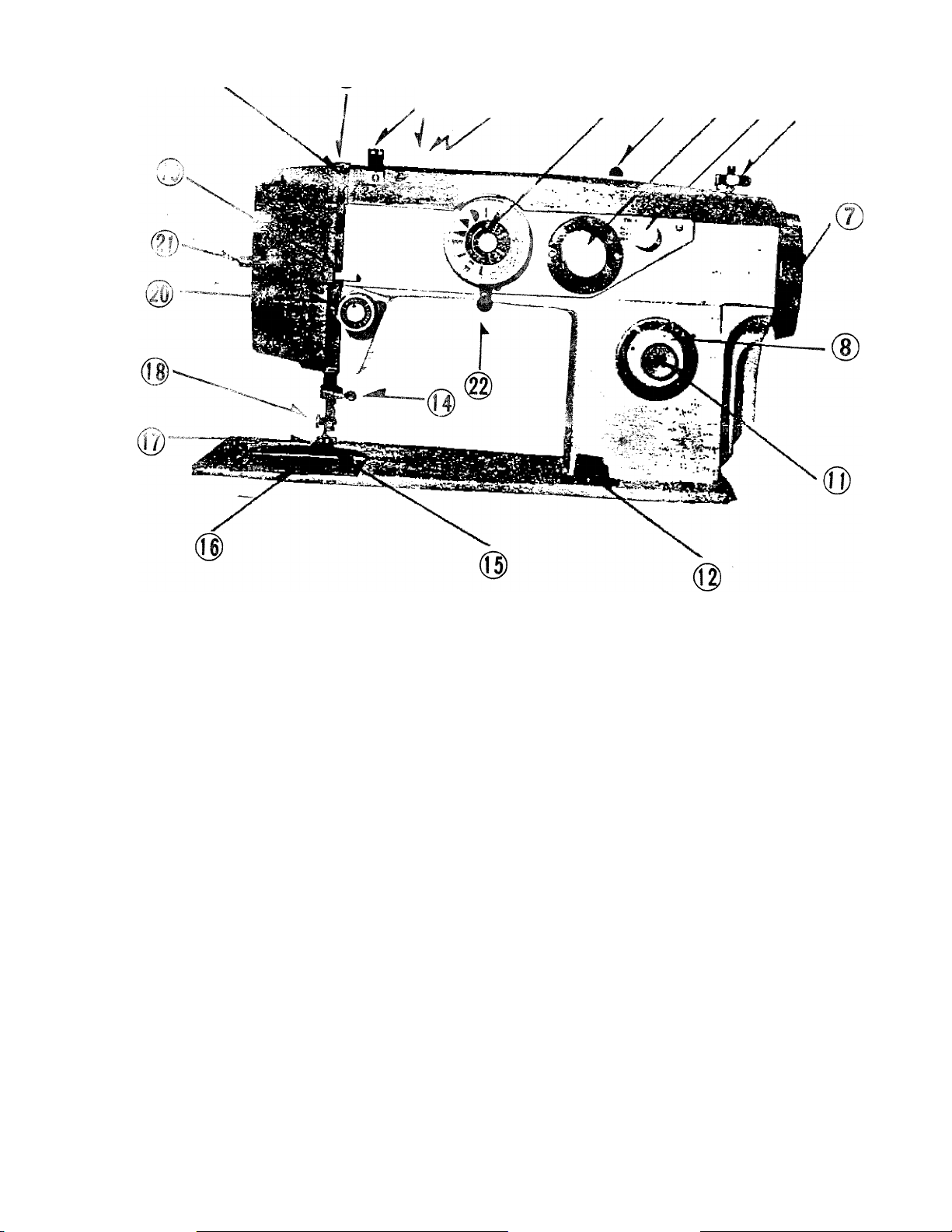

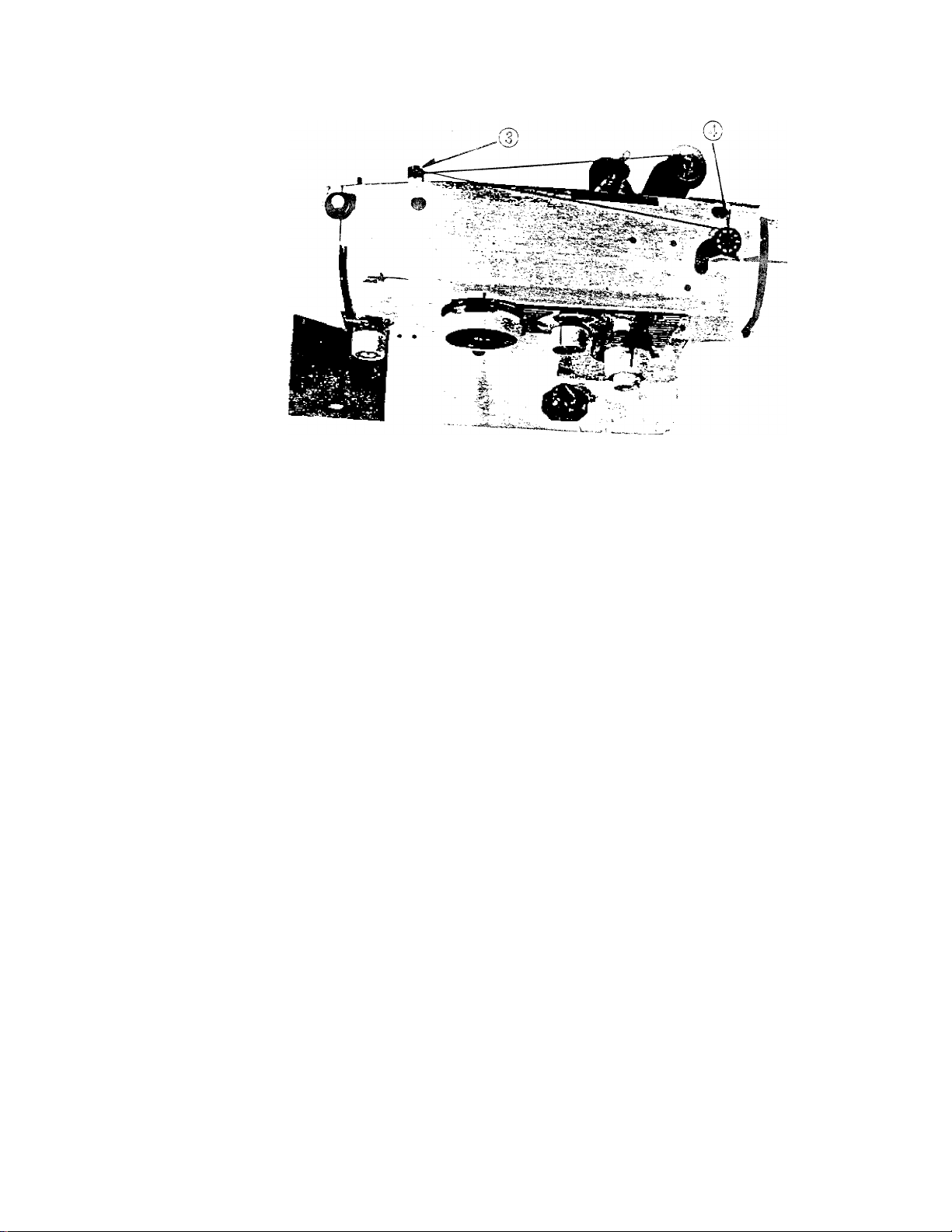

FEATURES AND PARTS

(Front View)

CD Take up Lever

® Pressure Release (Darning)

(D Arm Thread Guides

® Zigzag Stitch Width Control

d) Needle Position Control'

(©Pattern Selector Dial

® Hand Wheel

CD Stitch Length Control

(© Bobbin Winder

® Bobbin Winder Tension (Fig. 2)

(Q)Push Button Rovers®

(©Drop Feed Control

©Reverse Stitch Adjustment Lever

(©Needle Clamp Screw

® Needle Plate

©Cover Plate

(©Presser Foot

©Attachment and Foot Thumb Screw

® Thread Guide

© Tension

@Sew Lite Switch

© Stretch Lever

Page 5

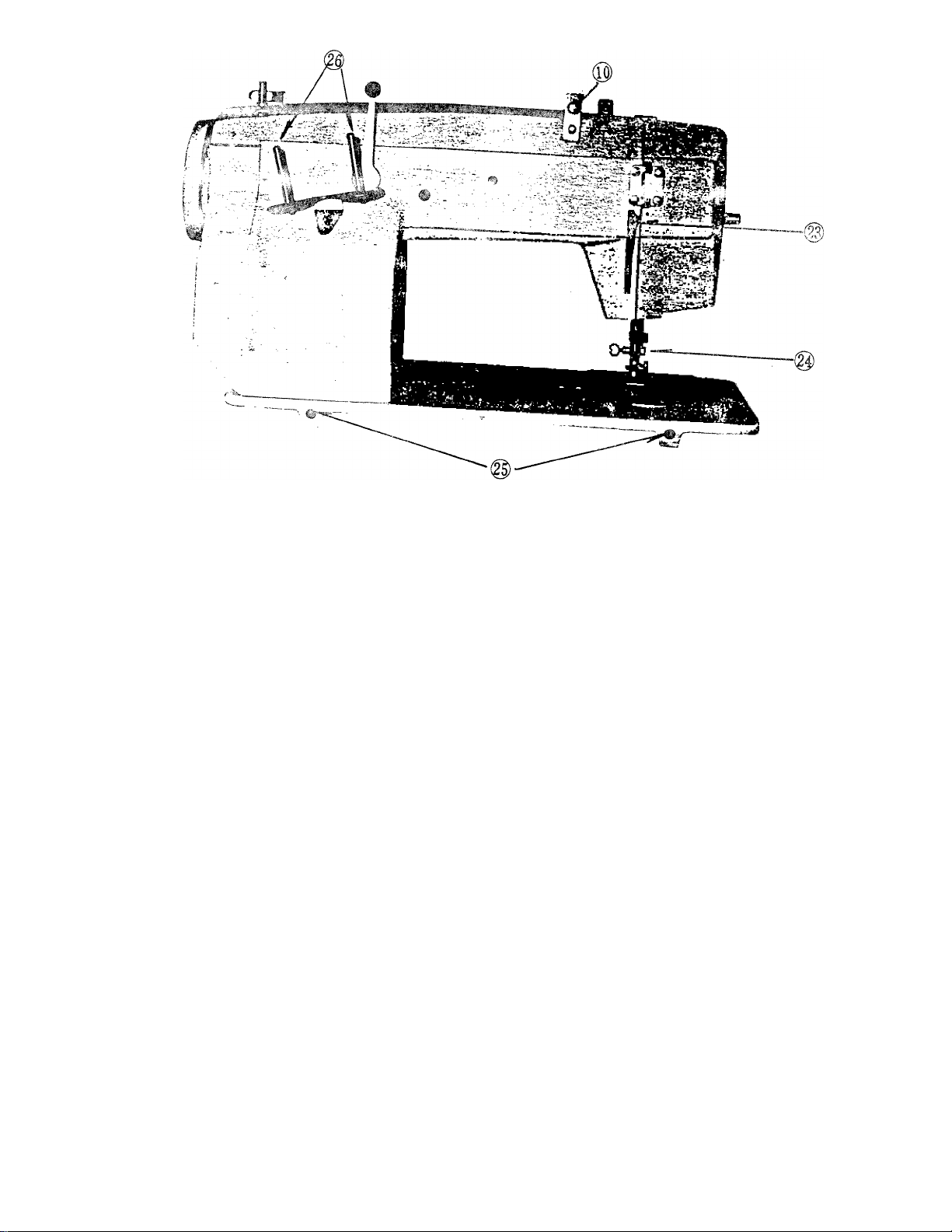

©Bobbin Winder Tension

©Presser Bar Lifter

©Thread Cutter

Fig. 2

©Head Hinge Mounting Holes

©Spool Pins

Page 6

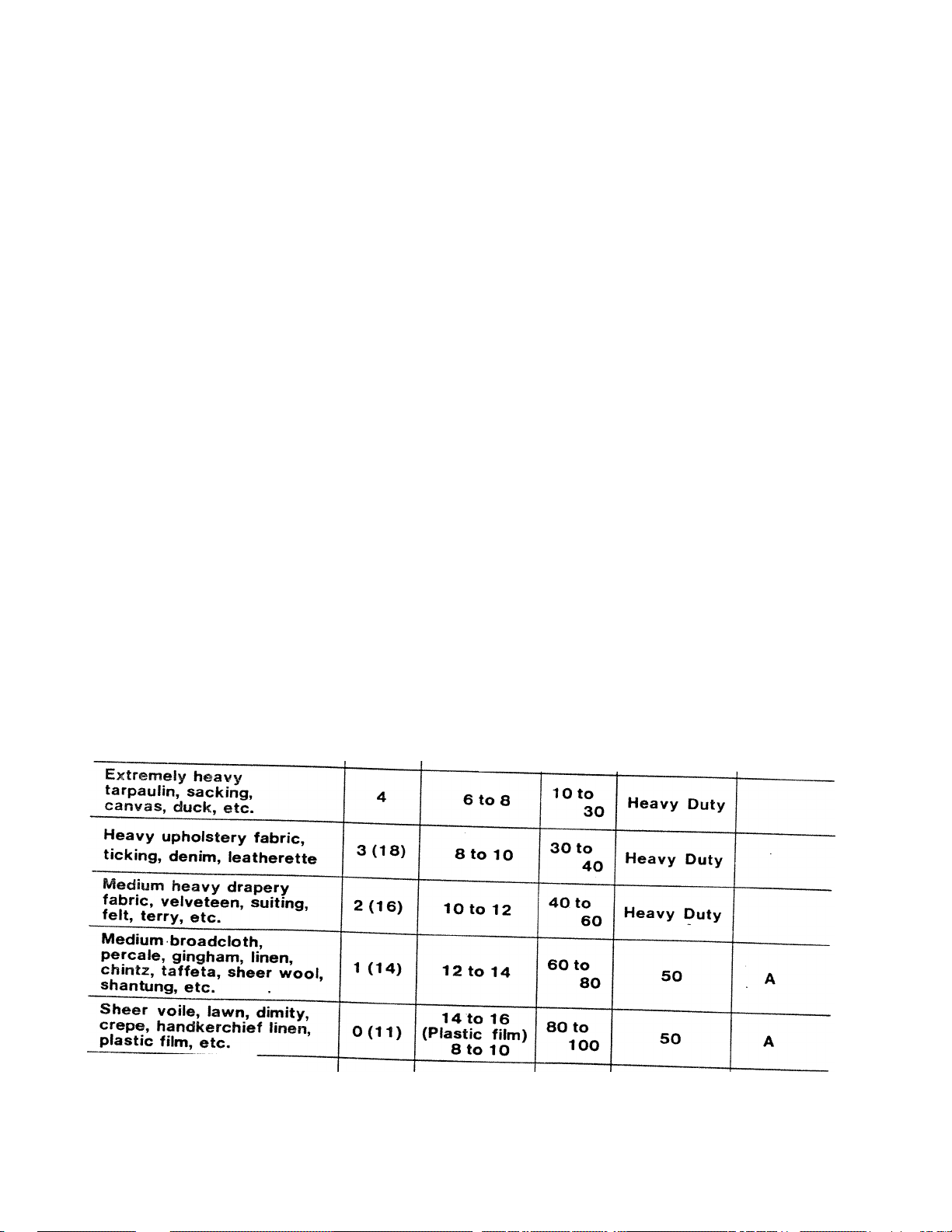

needle-thread-fabric-stitching guide

Fabric

Very sheer chiffon,

batiste, lace, organdy,

ninon, net, iharquisette,

etc.

Needle

No

00

Machine

Stitches

Per Inch

16 to 20

Cotton

Thread

100 to

ISO 50

Mercerized

Thread

Silk or

Nylon

Page 7

Fig.3

• íSo-í? ^?е*ги

í:#í/ í;

í ti l 1

Page 8

WINDING THE BOBBIN

Fig. 4

Disengage the hand wheel (1, Fig. 4) from the stitching mechanism by turning the

clutch (2, Fig. 4) toward you or counter clockwise. Place a spool of thread on one of

the spool pins and lead thread through the arm thread guide (3, Fig. 3). Run end of

thread through a hole in the bobbin edge and place bobbin on spindle of bobbin winder

(4, Fig. 3) fitting the notch on bobbin over small pin on spindle. Push bobbin winder

(5, Fig. 3) to the right, and hold thread end loosely then start machine slowly.

Bobbin will stop winding when it is filled. Turn clutch away from you until sewing

rn-chanlsn is again erigaged so that needle moves when you turn the hand wheel.

Break off loose thread end used to start the winding.

Page 9

Fig. 6

Page 10

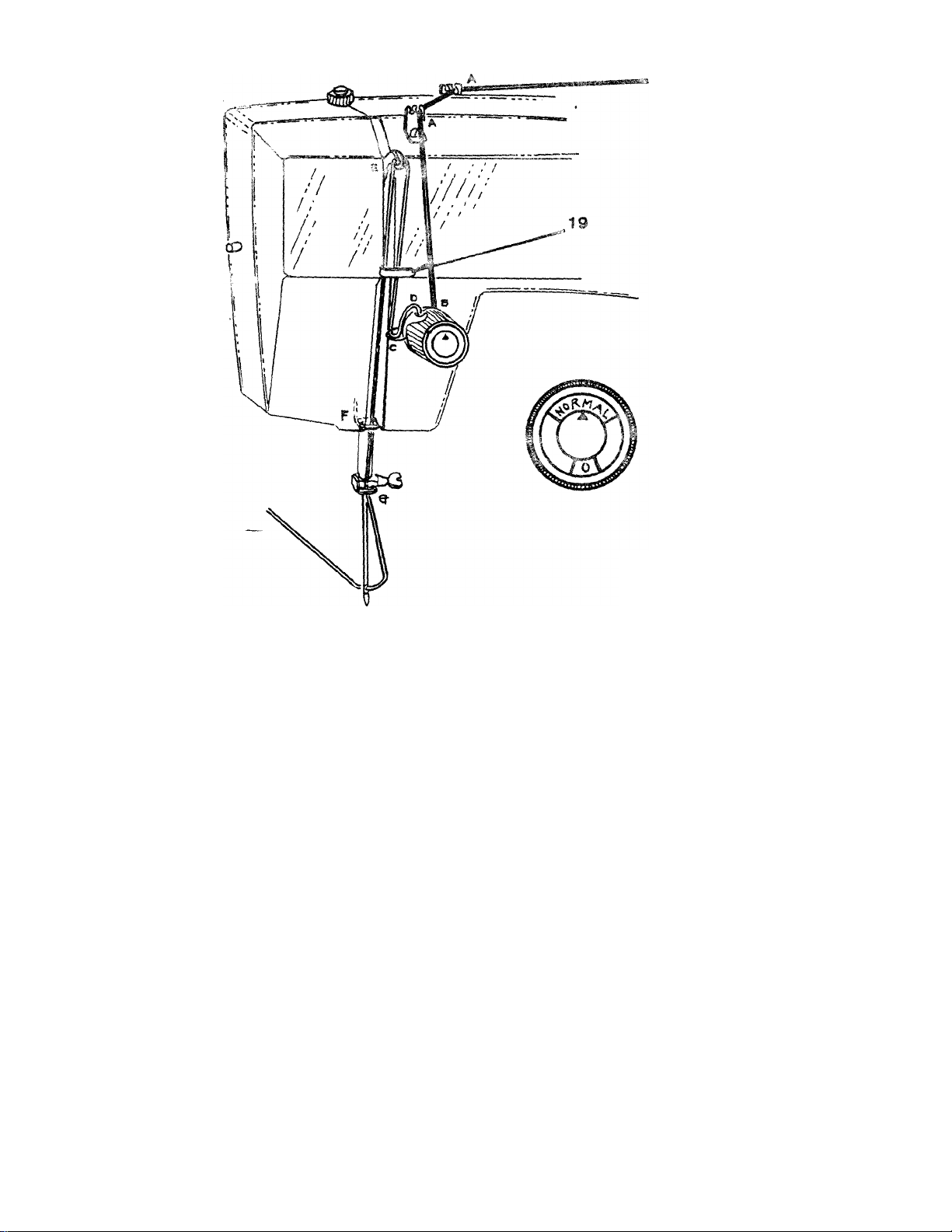

UPPER THREADING

1. Turn the hand wheel toward you to raise the

take-up lever to its highest position.

2. Place a spool of thread on the spool pin.

3. Lead the thread through the upper arm thread

guides.

4. Down and between tension discs from right to

Left.

5. Draw the thread up through the check spring

and with a slight tug into the hook, (See insert

Fig. 6 ) ’

6. Then up through the eye of the take-up lever

from right to left.

7. Lead thread down, through the thread guide 19

and face plate guides then through the needle

bar guide.

8. Thread needle FROM front to back, drawing it

through about 3 or 4 inches. Hold the end of

the upper thread loosely and turn the hand wheel

toward you until the needle goes all the way

down and comes back up. A loop (Fig. 7 ) will

be formed over the upper thread which then

can be pulled out straight. Place both thread

ends under the presser foot and draw toward

of the machine, leaving both threads

^ thr#e'VOr^*four:*inches.,'long. ■ ■

Fig. 7

Page 11

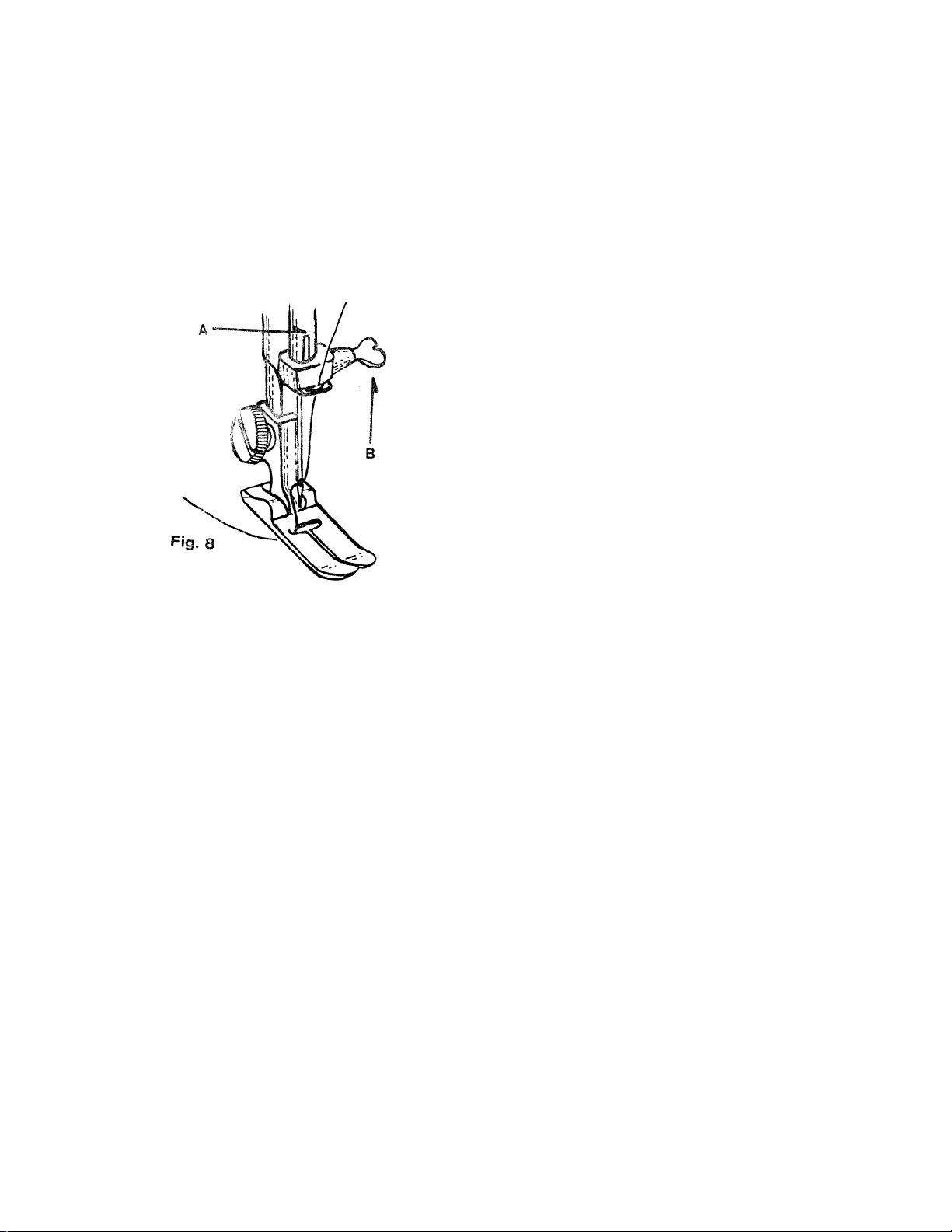

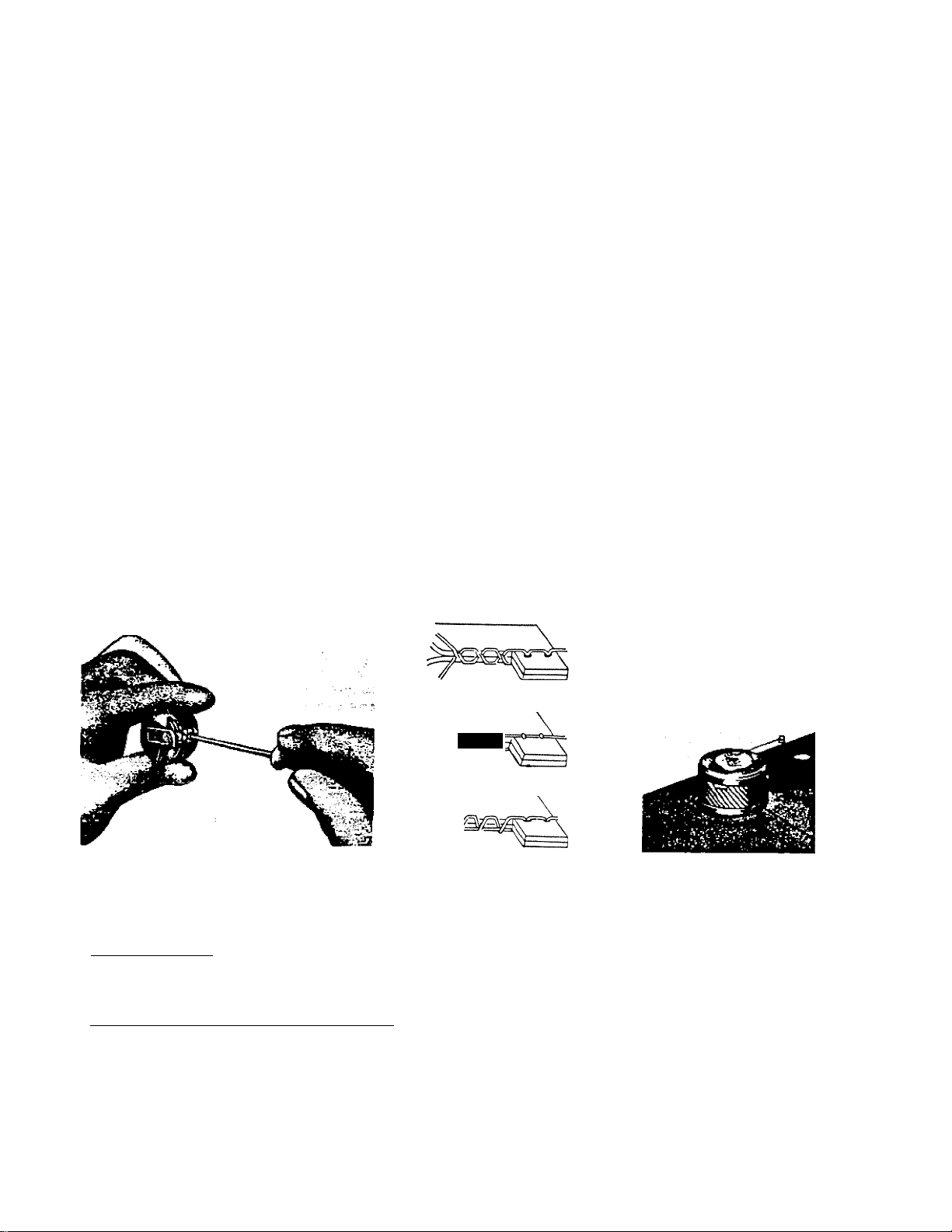

SETTIMG THE

See Fig. 8. Raise the needle bar (A) to it«s ^

you fay hand. Loosen needle clamp screw (B) and^t^" ’ ^

NEEDLE

Fig. 8-A

«ee.. c=.p.eihec^;.;

V y

Page 12

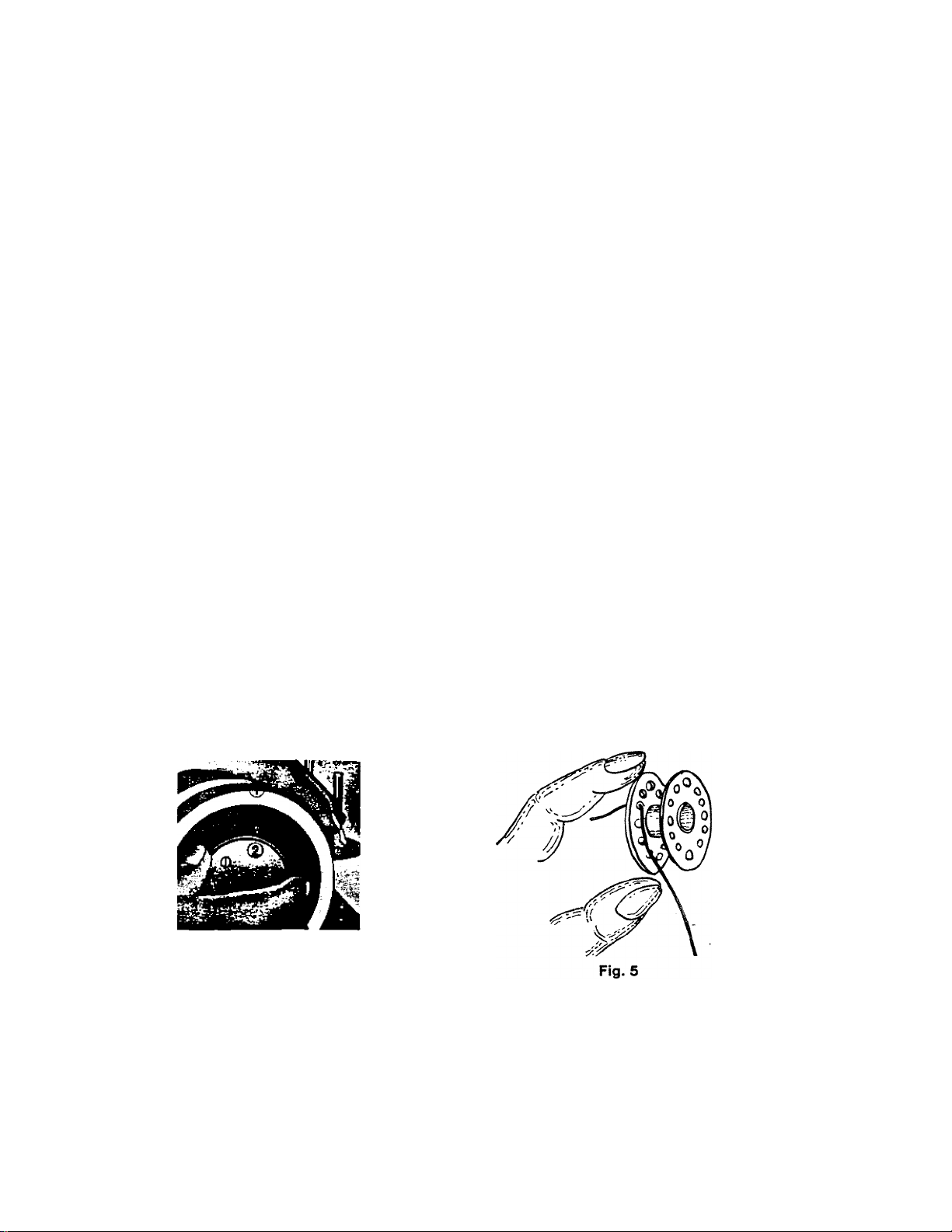

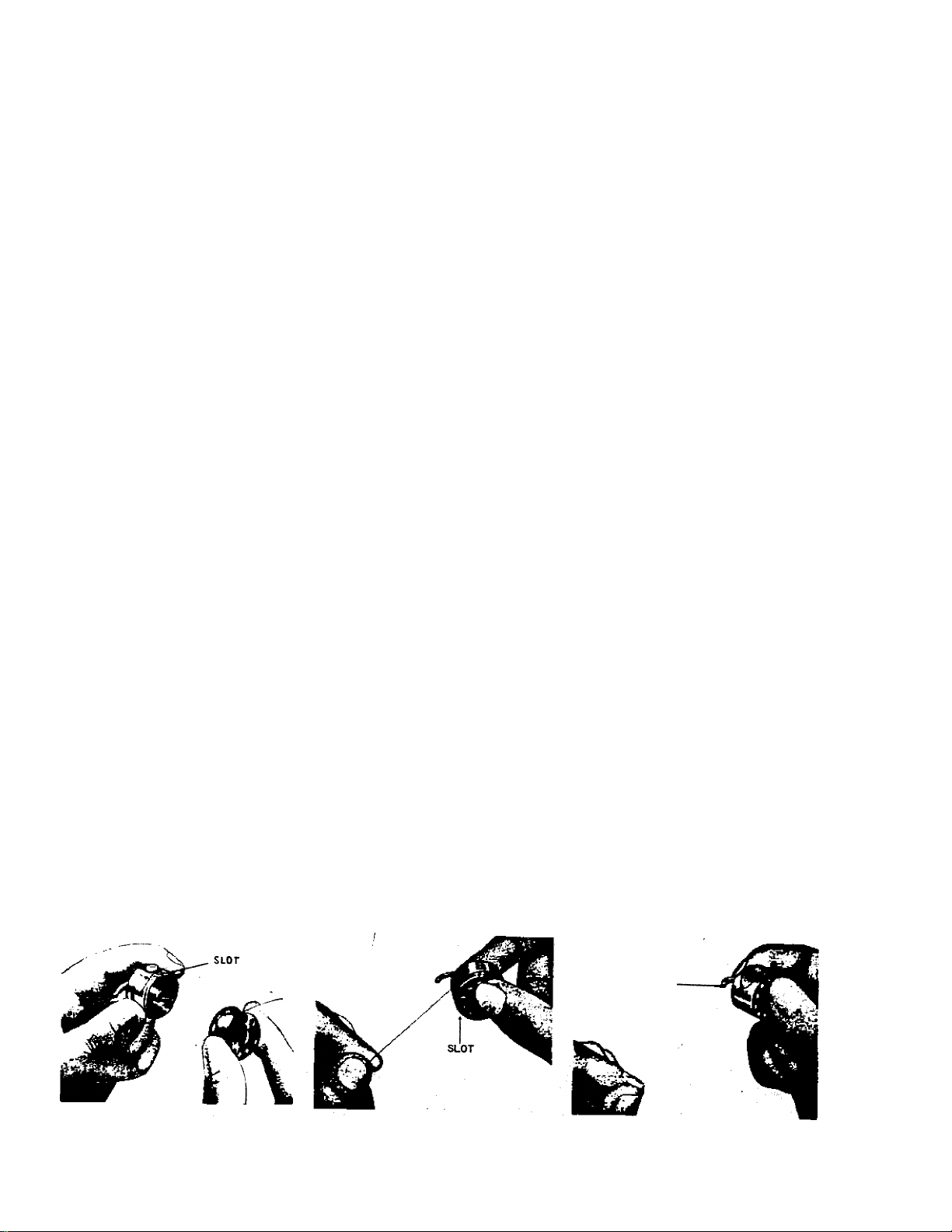

THREADING THE BOBBIN CASE

Step 1 (illustrated in Fig. 9). Hold bobbin case between thumb and forefinger of left

hand, so that the slot In the edge of the bobbin case is on top, take the bobbin between

thumb and forefinger of right hand so that the thread on top leads from left to right.

Step 2 Insert bobbin into bobbin case, pull the thread into the slot of the bobbin case

as shown in Fig. 10, and draw it under the tension spring and into the fork-shaped open

ing of the spring as shown in Fig. 11.

TENSION SPRC-

11

Fig. 10

Fig. 11

Page 13

'PIJ\CJMG BOBBIN

Fig. 12

Raise needle bar to highest

„ , , powiuof), and (ifi hinaed

cover plate. (See 16 Fig. l ) Hold th»

latch (D io) ^ ^ bobbin case

of the left hand, with at least three inches of thread

un«l rtT®

11 latch catches on the center post of the shuttle,

en release the bobbin case latch, (D). Press bob

bin case again after latch has been released to make

suf-s the bobbin case is locked securely.

Close the cover plate.

ch (D Fig. 12), between the thumb and forefinger

running from the top of the bobbin case to the right

Insert and center the bobbin case on the stud of the

s uttle body, (C). Be sure the bobbin case finger (E)

opposite the shuttle race notch; (A). Press the

5 *5,^ .

Page 14

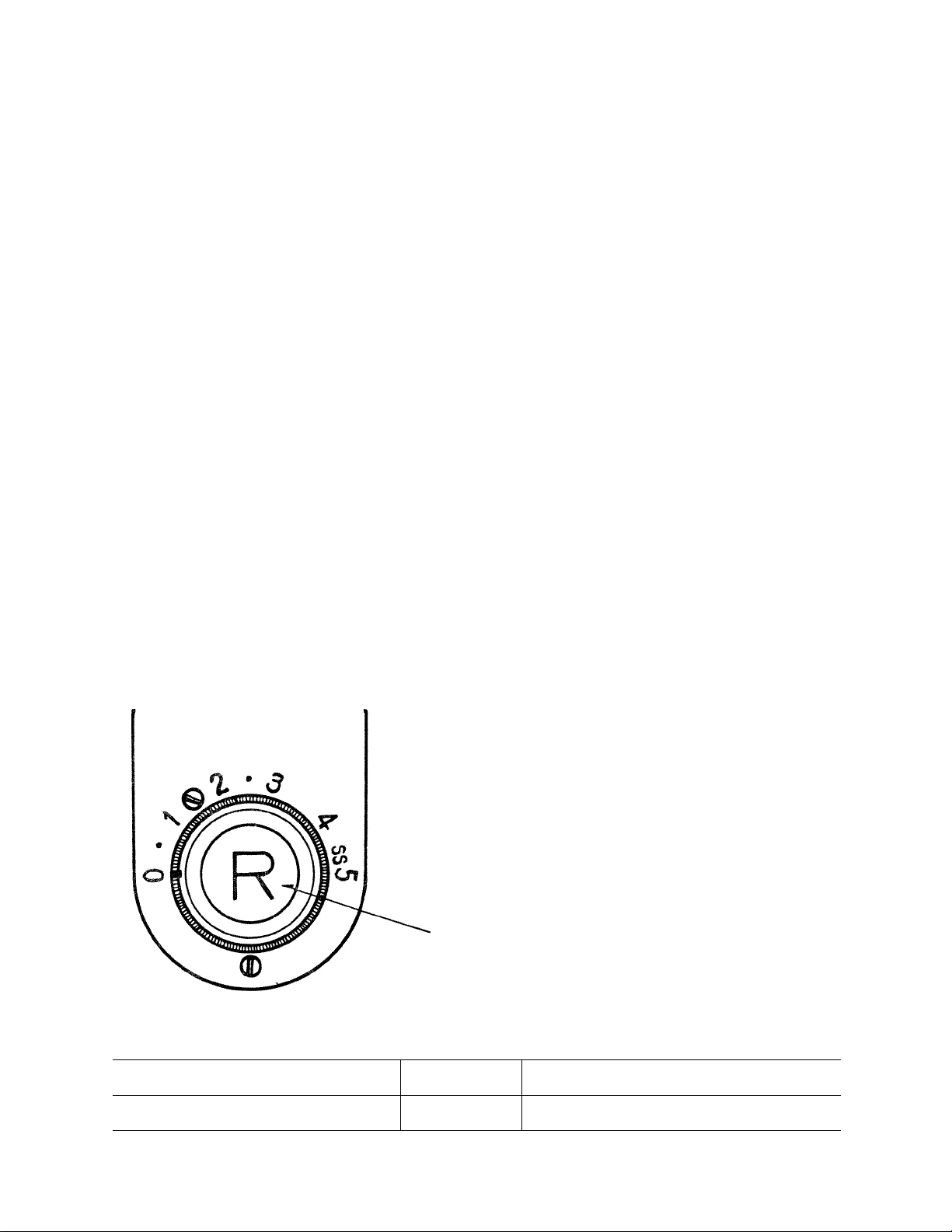

SETTING THE STITCH LENGTH

Fig. 13-A

STITCH LENGTH CHART (Approximate)

13

The length of the stitch is regulated by the dial shown

in Fig. 13-A. Near O is the shortest stitch and 5 is

the longest, but the control may be set at any spot

between the markings for a variety of lengths. Turn

the dial to the right to lengthen and to the left to

shorten the stitch. The number stitch length you

choose appears over the indicator.

Figures on indicator

Number of stitches per inch

O

No Feeding

1

30 25

2

3 4

15

8

5

6

Page 15

aiEVERSE

17 j

-press In the button (A Fig *!* ‘«reads at the beginning or end of

,o„« „ ,He -■■■ -.7.

^ i ii s-4 ' .-^ a®s3 ^..

r

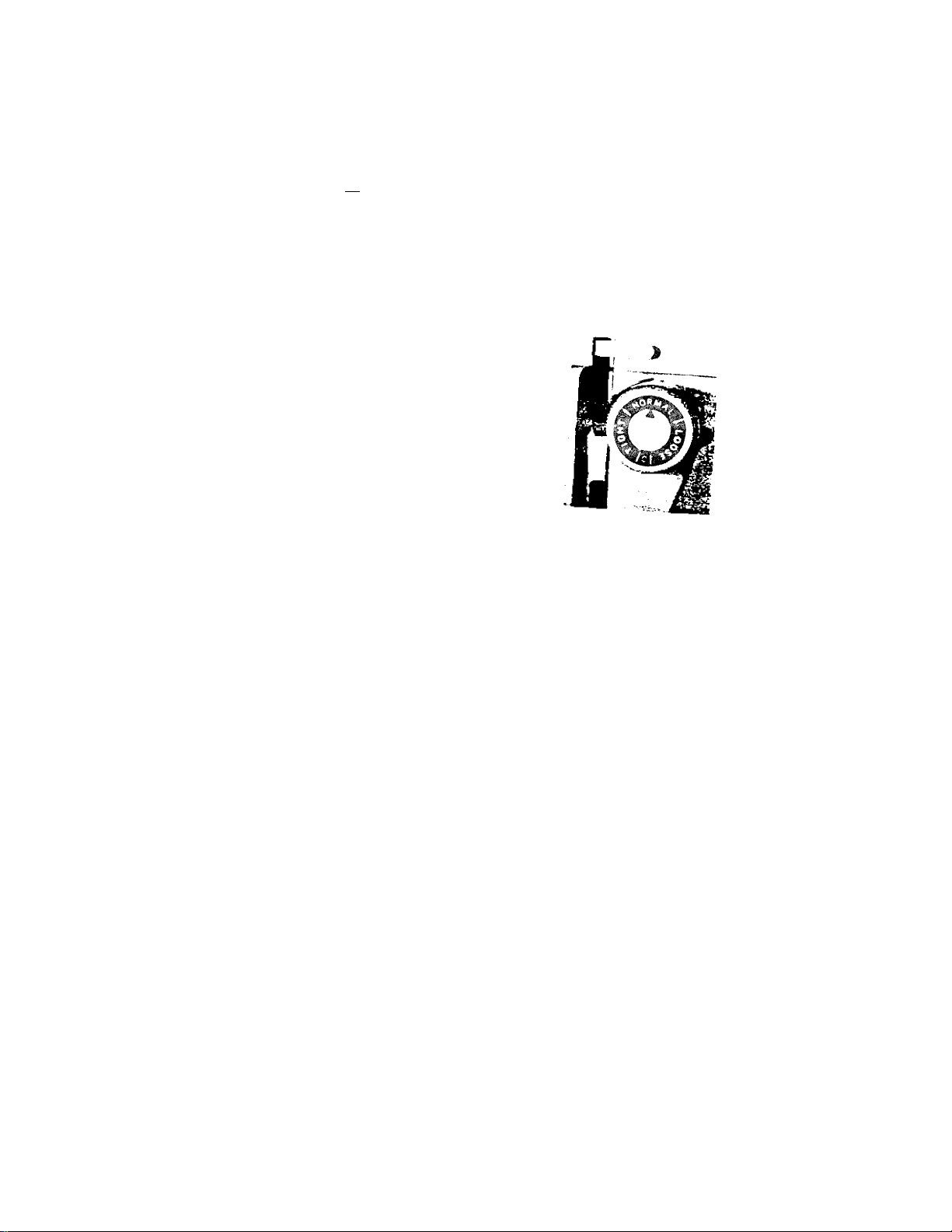

‘ ^ yrtfe TENSIONS

When h is ™in,d^?Гn"г«sПhe“oпeto' nn " "’* “ '•'=“=»«

right, io decrease, turn to the left. d'st (Fig. 13) to tii®

5»9fr)r*i * . '

Chine „ 'Hreaded p,„;e;rWh'’e'™:;^;“:

the bobbin tension, turn emaiieereri” ,1^

of the bobbin case clockwiaa to tinhten °"

Clockwise to loosen. ^

Ptei fPCii Siitcri will be formed with k„»L

'-'hsions are properiv beianced a

iocklnsin fabric (Fig «"»•«c inter-

ZlVTu^ZTtT"

on" ba fab^ ? g """" "

too ioosa, the uppJr thread , "

lower thread lying flat on the Xte 1 "r"

" «’food

Fig-13

irs-P»'

r*' :7pi-' v7ppi-;77: /=;!--

- , ^ ^

Page 16

Fig. 15

Fig. 16

15

Fig. 14

Fig. 17

ADJUSTING PRESSURE AND FEEDING OF FABRIC

General Sewing. Usually for normal sewing the pressure bar cap or

darner release, (B, Fig. 18) is at its lowest position and the drop

feed knob is turned to. "High” position, Fig. 19.

Sewing Thin or Light Weight Fabrics. When lighter pressure is re

quired to sew satisfactorily on thin silk or flimsy material, the pres

sure cap should be about halfway down. Release ail the way by

pressing the snap lock, (A, Fig. 20), and then press cap (B) down

again to halfway spot. Lower the feed slightly by turning the black

i&i on t’:S Itnols to "Low” position. " ' ' ^ ^ ^ ^

Fig. 18

Fig. 19

Page 17

-¿EHESJE!LM!EE!!5S: order to raova -’ad?’/' 5'-..'^,^.

rection for darning, and mending relea*'- »-.*

'limMM hw "«'"ii. reiea*,,^ ,...j proseure cap S eoic-

>.«tely by pressing down on the snap look, (A, Fig. 20).

2 urn tho KnoIlD to ”DOWKI”

.....

° ""i'*' drops the feed „ell

be_ the needle plate. To return feed to normal, return knob to

■ PREPAHI^^fn TO SEW

Have take-up lever at highest point before starting to sew Do nor

tie 'I T T *his may’deflect

the needle and cause it to break. ^ aeTiect

-dar the presser foot. Fig. 20

-V« »re pr:dor dr“' -d

Turn the hand wheel toward you until the neowiaa ■ a ■ .

ready to begin sewing. By having the neeHi ♦ ■ ^ '** highest point. You are now

touch the hand wheeT to start the mach’ '** Po«nt, it is not necessary to

.Ha maohina Is raguls.sd b;Tnorer„g “,1:7: 1'“ T f'”"''"'

the control. ® ^"’ount of pressure exerted on

. tit

11

is

»

?

-i

Page 18

REMOVING THE WORK

Be sure to stop the machine when the thread take-up lever and needle bar are at the

highest position. Now raise the presser foot and draw the fabric back and to the left.

Fig. 21-A and B, and pass the threads over the thread cutter. Pull down slightly, holding

thread in both hands, so as not to bend the needle. Leave the ends of thread under the

presser foot.

17

-it

Fig. 21-A

.•Sirica«

Fig. 21-B

Page 19

“CUING

For straight aarving an fine fabric

or verv aaft 'Ti-naria!, it Is advis*

abie to use the straight stitch press

a- ard tho straight stitch nee

dle plate %vhich arelncJatJsdin your

^uccassoiy box. Boih have narrow

nsedie slots. '

Fig. 23

CHANGE

C1 ) Presser Foot

(A) Loosen thumb screw (18, Fig. 1 ) and remove zigzag presser foot.

U3) Replace with straight stitch presser foot (Fig. 23).

(A) Slitia covBr plate (16, Fig. 1 ) to the front as far as possibis.

(B) Remove screws holding needle plate (15, Fig. 1 ) to bed plate.

(C) Remove zigzag needle plate.

(D) Replace with straight stitch needle plate (Fig. 22-B).

AS FOLLOWS

Page 20

When using the straight stitch needle oíate anH k .

setting hef«r» * P'®*® ^°o‘- be sure to make the following

setting before starting to sew or the needle uuiii ■ x -i • ”

o,3tg ® needle will bre^k in striking the foot or needle

Set Your Machine as Follows

(1 ) Needle posititon control "A” Fig. 24 at C

(center).

(2) Decorative stitch dial "B” for straight

stitching.

(3) Zigzag width control "C” at "O”.

(^i- ) Stretch stitch control "D” at "M”.

(5) Stitch length control "E” at suit material

being sewn. .

See page 13 for stitches per inch.

19

Fig. 24

Page 21

ad

SETTIMG NEEDLE POSITION

The needle bar should be at its highest point edier, adin-;

isaring the fabric or bending the needle. ' ' position to avoid

Select needle position by canlml, 5 big. 25-A.

eT if^icatas bin right hand position - "C” center and

L. left.

- ^ne position is where most of your work will be

T.N

Clone.

zra igiii stitcliing.

Stretch stitching.

Designs.

H undreds of other uses.

The Isft and right hand position can be used for :

''-■•■-»ai siiiCn (coraing and so forth)

a c C! «■£. i i V e cJ os igns.

Hundreds of other uses.

The left hand positio^is best for sewing on buttons.

T.N

Page 22

TWIN NEEDLES-UPPER THREADING AND SEWING

1. Be sure zigzag needle plate and presser foot are in place.

2. Set needle position control 5 Fig.-25B at twin needle position. This will set a stop

to preeent the zigzag width control moving beyond the number 3 position.

3. Follow threading instructions for single needle with these exceptions:

a. Place two spools of thread, matching or contrasting in color, one on each spoo

b. Lead both threads through arm thread guides.

c. Bring threads down and around tension discs with one thread passing between the

back discs and the other between the front discs.

Now treat both threads as one until you reach the needle eye.

d. Pass one thread through each needle eye (Fig. 26).

4. The maximum zigzag stitch width that can be sewn when ♦

needle is at the number 3 setting of the zigzag width 000 1^® "

Any pos,„on above the number 3 position will break the twin needle.

21

" - ^s“:

n-eximum zigzag Width. ™ndle sew,ng except for the

Page 23

C^EATIWF FiiSROIDERY (fis. -»3)

’ ■” siiiciie^ at 5 width then allow knob to spring back to O for a short

-e'ind. Count, if necessary, to establish a rhythm.

B Set zigzag width control at the second line then move the control slowly back and

........

'oan the Stop and Number 5.

" ''Vidth at the first line. Gradually move the control from the Stop to 5

allowing it to snap back quickly.

"D” Set zigzag width at 5, stitch length at 2. Sew a few zigzag stitches. Drop feed (F,

Fig. 24) for 3 or 4 stitches then raise it again. By operating the drop feed knob

rhythmically it is not necessary to count stitches.

hanging the needle position and varying the movement of the controls, hun-

drada af designs can be produced. ■ ’

Set drop feed knob at Down position and lock zigzag width control at the number

5 position. Take 3 or 4 stitches, leave needle in fabric and pivot fabri c on needle

to make next ^isy petal. Continue until flower design is completed. Lock threads

by setting stitch width at O and sewing 3 or 4 stitches in center of design.

^ I

Page 24

CREATIVE EMBROIDERY

Be sure aig^eag press«, foot and »iga=ag needle plate are in place.

1. Set decorative stitch control (B, Fig. 24)at “M”

position.

2. Set needle position control at “L” position.

3. With the zigzag width control (C, Fig. 24) set at the Number 5 and stitch length

control (E, Fig. 24) as near 0 as possible without stopping the feeding action, a satin

stitch is produced (Fig. 27)

4. With the machine set fora short stitch length, different designs can be made by

turning the zigzag width control back and forth between 0 apd 5 or any other

combinations of widths. Try setting the zigzag width control at (C, Fig. 24) the

first line and the various other lines.

Set a rhythm for yourself and then proceed.

After awhile you will become quite skillful, vary

ing your designs by the speed of the machine,

stitch length and manipulation of the zigzag

width control.

'im'ftlumli

fllll Mk

Fig. 27

23

Fig. 28

Page 25

WITH A HOOP

.i i. aasy io ioliow a stamped design or to

'«crk free hand when embroidering or mono-

(See Fig.i.y) Belease the pressure

from the foot by pressing down the snap lock

on the darner. Turn the drop feed knob to

position (See Fig. 29).

•■itratcn iii3 fsbris in an embroidery hoop, and '

place under the needle after removing the

presser foot. Set the stitch width at the size

you prefer and lower the presser bar lifter.

I hen operate the machine at a rather high

speed while moving the hoop slowly with

.join hands. Work carefully and be sure to keen #■

J j ,Up «itchs. “he ,11 T"

ipring i.j iiaadeci imu atiachments available from"” • tlarning

this book). available from yourdealer illuatratad in the back of

Fig. 29

ofWp;

' ^•„.tr

■T’.

..............

Page 26

BUTTONHOLES

Various widths and lengths can be made automatically by

turning the dial (C, Fig. 24)

To establish the correct length buttonhole required add >^inch

to the cutting space for bar tacks.

To obtain the length of the cutting space, the opening through

which the button passes, is measured by adding the width (A)

and thickness (B) of the button (Fig. 32).

The width of the buttonhole sides are governed by the material

used. Set zigzag stitch width control on number 5 for thick

material and a lower number for thin material.

Mark the beginning and end of the buttonhole on fabric with a

basting line or tailor’s chalk. Make one on scrap fabric

following directions below to be sure machine adjustments are

corrrect.

1. Replace presser foot with special purpose buttonhole foot

This provides maximum visibility and allows closely spaced

stitches to feed evenly (Fig. 31 ).

2. Set needle in left position

3.Set zigzag stitch width control (C, Fig. 24) to suit material

being sewn or width of buttonhole desired (number 5 for the

widest buttonhole).

4. Set stitch length control (E, Fig. 24) as close to O as possible

without stopping the feeding action.

5. Set stretch stitch control at manual position.

25

Fig. 30

Page 27

ß.

Set decorative stitch dial (A, Fig. 34) to sew the left

side (Step 1). Lower needle carefully into mark on

fabric indicating the end of the buttonhole. Lower

presser foot and sew entire length of buttonhole

(Forward feeding).

7.

'With needle out of the cloth, set decorative stitch

dial for лаг tacK (Step 2). Sew 4 or 5 stitches.

- .-'/lii! needle nf cloth, set decorativa stitch dial

to sew right side of the buttonhole (Step 3). This

WÜJ reverse the feeding motion.

9. With needle out of the cloth, set decorative stitch

dial for bar tack (Step 4). Sew 4 or 5 stitches.

10. If the stitch density on the buttonhole sides are

different adjust by moving lever ("B” Fig. 34) to

either hie right ( —) or left (+).

- II,. iije 3'ijtch density on the right hand side

of the fciitionhole move lever "B” to the right (—).

To increase the feeding move "B” to the left ( +).

PLEASE NOTE:

If

you

plan

to make buttonhole, on .hoar or soft

material,

can b« torn

piaeo tarlatan or paper under fabric which

away after stitching.

|f

s s:

T 3

p ^

I

У

2 ,

g $

г ^ ?

P i i?

3

f *

it

li

Fig. 33

Fig. 34

•r"' , .'y nf :■ ' „

Page 28

SEWING ON BUTTONS

1. Remove pressor foot and replace \with special purpose button sewing

foot (Fig. 36)

2. Turn drop feed knob to “DN” position (Fig. 35).

3. Set zigzag width control at "0”

4. Set needle position control at “L” and decorative stitch dial at “M”

Place the button so that its left hole comes directly under the presser

foot. .

5. Set the zigzag width control to produce a zigzag stitch until the

needle enters the right hand hole of the button. Turn the balance

wheel slowly by hand to be sure the needle clears both holes in the

button. Correct width if necessary.

6. When needle goes into the center of each hole, run the machine at

a medium speed, making five or six stitches, stopping with the needle

in the left hole.

7. To-lock the zigzag stitch and prevent ravelling,

set the zigzag stitch width control to O (remem

bering its original setting) and take a few stitches

in the same hole. If you wish, you may place a

rounded toothpick over the button between the

• two holes, and sew button to fabric in the regular

way. Remove the toothpick and wind thread under

Fig. 35 button fonming a shank to fasten.

27

Fig. 38

Page 29

STRETCH STITCH

k k k k k k ^ !

AA/WWV

wvVVW\^.x

VywV\AAA^

i Y \

-----—--

■ "X- ^

When sewing at

ever

---

-------------

.

y ^ >

(22,

---------

Fig.

1 ) n “SS” position with red indicator on top

Needle | Stitch

Po^Ai;osi| Lan^ih

———j------------—^------

j If

LCR

"

H

n

//

//

//

//

"

» ,,

the stretch stitching, be sure

0.5-5

"

n

u

n

0.5-3

//

//

//

Zigzag

I u

1 -5

-----------

p -i 'w ',..2 '...' -'? s'a «

"

//

//

//

//

//

//

//

//

Stretch

Paiiarns

#Mm\

—irw |^I„II

to

set

the

Needle

Position

C

LCR

--------------

LCR

„

„

"

stretch

cover.

Stitch

5

5

//

//

Zigzag

w

1 dth

0

1 —*>

1 ~*5

//

,fSi '

i* ci' fi .rSt .*?

Page 30

MULTIPLE ZIGZAG STITCH

29

A A ^ ^

^ V V V V

. A A A A A

V V V V V V \

Fig. 40

A. Use zigzag needle plate and presser foot.

B. Set stitch length control to suit-Number 5 for the widest width

C. Set decorative stitch dial at multiple zigzag stitch.

D. Set zigzag width control at Number 5 for widest stitch.

USE:

When replacing worn blanket bindings for both a

decorative and durable finish. Fig. 41.

When overcasting an edge to prevent fraying.

When applying elastic waist bands to skirts and

dresses b® sure to stretch the elastic as It is

applied to Insure fullness required in the garment.

_________

sewing a zigzag stitch on soft or sheer

41 materlaljt wiir: prevent: puckering;. ^ ^ ^ ^

Th©r© of OtHor uses mrlitr*K will

which will become apparent as you use the machine.

Page 31

«jpi

"3i

Jse standard zigzag foot (Fig. 42).

•• ?arK-th control at number 3 or 4.

Needle position control at “Center" position.

Zigzaci stitch width to suit materia! being sewn.

The lower the rrirmber, the smaller the sidewise stitch,

rjiii'icj Siiicn tianis provide a durable hem finish that is

almost invisible and comparable to hand sewing.

Prepare the garment in the same manner as for hand

hemming.

Step 1. (Fig. 43).Jf hem with folded edge is used make first fold % deep.

Step 2. Turn hem to the depth desired and baste %" from upper edge. Press in place.

Step 3. Fold hem back toward right side of garment leaving K’ extended.

Step 4. Place material under presser foot, sew with stitch length set to suit material

being sewn and make a side wise stitch about every %" of an inch of sewing.

HEM

Page 32

MANUAL OPERATION

Be sure standard zigzag presser foot and zigzag needle

plate are in place and machine is set for manual oper

ation. Use for:

OVERCASTING WORN EDGES

Zigzag stitch along the worn edges, catching the fabric

as the needle swings to the left, and allowing the needle

to just pass over the edge of the fabric on the right

(Fig. 45).

PATCHING

Machine bastes patch into place by placing fabric under

hole or worn area which has been cut away. Then

zigzag stitch the patch into place by overcasting around

edge of hole.

APPLIQUE

Fig. 44-Baste design to fabric and zigzag stitch follow

ing the shape of the design outlining it entirely and

remove excess material on the outer edge by trimming

it away after stitching.

Fig. 46-Baste design to fabric and overcast a zigzag

stitch around the design outlining it entirely.

Hundred of others uses will become apparent as you

continue to use the machine. Try the mulitple zigzag

stitch for these operations. Also, for beist result set

opsecl control slower when sewing;around(contours and

faster for straight lines.

31

Fig. 46

'fsS

Page 33

TO 3J3E ^CCSSSO^ISS

HARROW HEMMEfi: With needle at its highest position

;foot with narrow hemmer (Fig.

47) being sure to tighten It securely in place. Set

•^attorn -seiector dial at manual position, needle pos

itioning control center, zigzag stitch width control at

on -{ Qf siraigjii siiiched hem or at number 3 for zigzag

stitched hem. Set stitch length control to suit.

For a plain narrow hem make a % inch double fold for

about two Inches along edge of fabric. Hold each end

of the two inch fold and slip underneath hemmer. Bring

fold up into the scroll of HEMMER, draw fabric forward

to end and fasten with needle point. Lower presser

'-''-S’-i'- -Oiiiry ; ijl! snd of thread as you start stitching

(Fig. 4S for straight stitched hem Fig. 49 for zigzag

stitched hem).

Guide material slightly to left and it will take a double

turn through scroll.^

The narrow hem provides an excellent finish for edges

of ruffles or any other dainty work .

Fig. 48

Fig. 49

:Tf4Fn,Vv 7

TrT; ^ tr •T p

SIJ-I '

Page 34

LACE TRIMMED HEM

¡¡ЛегГТае! '^‘=® *" Stitching,

insert lace in the slot next to needle (Fia 51) S«w ham

as above, guiding lace under needle and®hem’info

Rickrack may be used in the same way.

LACE EDGE WITH INVISIBLE STITCHING

Hold lace ^ inch from raw edge on right hand side of

plain narrow hem (Fig

is iomoleid tha Г®' l®<=e When the stitching

IS completed, the hem is pressed to the wrong side

FRENCH SEAM ’

Place material with right sides facing each other and the

piece of material M inch from right hand edge of lower

piece. Insert in hemmer scroll allowing hem to roll over and

sew in top fabric making French seam. For cording effect

use zigzag stitch wide enough to catch both edges of the’

narrow rolled hem and sew with satin stitch. This can

chairs and so forth (Fig. 53).

HEMMING ACROSS A SEAM

To hem across a seam, cut the seam

folds at an angle so they will lead

the hemmer gradually. Press seam

open. Stitch across the seam at the ex

treme e^e to hold it I together and for

added firmness. It may be necessary

Fig. SO

to pull the material slightly when hem

ming over the seam (Fig. so).

33

Fig. 51

Fig. 52

Fig. 53

Page 35

Use this guide for making parallel rows of straight or

decorative stitching. Attach standard presser foot.

Slip U shaped holder on guide under presser foot

thumb the back and tighten screw (Fig.

58) . Adjust the curved bar for the distance desired

between rows of stitches and set so it presses sligh-

•¡.si3|.;.3_ gy letting the guide ride on the

previous stitching line, successive rows will be an

equal distance apart (Fig. 58).

Fig. 56

SEAM GAUGE OR CLOTH GUIDE

Use the seam gauge as a guide for straight seams

and even rows of top stitching along edge of fabric

(Fig. 57).

Fasten Gauge (Fig. 55) with accompanying screw (Fig.

56) in threaded hole in bed of machine. Adjust to desired

width.

Fig. 54

Fig. 58

Page 36

CLEANING AND OILING THE SHUTTLE

(See Fig. 59 and 60)

The stitch forming mechanism occasionally becomes clogged with loose threads and

Imt. This will interfere with the efficient operation of the machine. Cleaning and

removal of the lint will safeguard the performance. To remove the shuttle assembly

proceed as follows:

1. Turn the balance wheel until the needle reaches Its highest position. Tilt head

back on its hinges.

2. Remove bobbin case (A), Fig. 59

3. Turn the two shuttle race cover clamps (B) outward and remove the shuttle

race cover (C) and shuttle body (D).

A C D B

35

Fig. 59

Fig. 60

Page 37

■u-.T?. • .»" "'"’ """" «"* •» »«« o, =h„„,e

assembly: ' ''■"’ ' “'” “***"^ ‘■= to replace the shuttle

2. PlacVlhuti body'^^C^) aqa' position.

-. .¡.piece shuttle ra« co;»,?^) m“t!"° *•«““ '"'“ Po-iMoo;

into position^ with shuttle race c’o»er"Lm"ps°* (B)"*" '"*° '°<=K

have beer, snapped securely into position ’ “'“"tP»

4. Put bobbin into bobbin case.

CARE AND MAINTENANCE OF YOUR MACHIwir

HOW TO Oil, YOUR MACHINE

Vour machine should be oiled occasionally to

Keep ,t operating smoothly, how often depends

on the amount of sewing you do.

Before oiling the upper part of the sewing unit

at points indicated by arrows in (Fig. 6l) turn

hand wheel toward you until the take-up lever

IS at its lowest point.

MACHINE

Fig. 61

Page 38

To Oil mechanism under bed of machine, tip the head back on its hinges and oil all

moving parts indicated by arrows Figures 62 & 63 and red spots on machine.

Fig. 63

HOW TO REPLACE THE LIGHT BULB

37

Fig. 62

Open Face (Fig. 62). Unscrew bulb and insert new one.

For long life and correct size, be sure it is a genuine

iWhitespaft. :k.^ ^ ,

Page 39

¿i4^wiSi^SCi^lES

(4)

(D

m

@

(I) Ptastic Oiler (sealed and filled).

^ Package of Needles (5 Straight)

® Large Screw Driver. '

® Small Screw DTTver.

(D Quitter Guide.

(6)Cloth Guide.

(J) Button Sewing Foot.

® Buttonhole Foot.

® dF

T

(ID

®Presser Foot for Straight Sewing.

Qj) Narrow Hemmer.

(©Twin Needles.

(0) Thumb Screw.

©Felt Washers(2) (for spool pins)

©Bobbins (3). ^

©Needle Plate for Straight Sewing.

Page 40

TROUBLE CHART

39

T rouble

If Machine

Binds

Probable Cause

Thread or lint in

raceway

Correction

-With take-up lever in highest position, tilt

head back on hinges and remove bobbin case.

LINT CLEANER

RACE

RACE COVER

HOOK

CLAMPS

2 —Turn clamps outward and remove race cover.

3—Remove hook.

4 —Clean thread and lint from all parts, includ

ing race.

5 —Run a drop of oil along rim of hook.

6—Replace shuttle, then race cover.

Snap clamps into place.

^ Grasp threaded bobbin case by latch and

replace, fitting tongue into notch of race

^ coveri;"'^^ ^ ^

Page 41

Irragula

• stitches

Uneven

stitches

Pulling or holding

material

Needle too fine for

thread being used

Avoid pulling or holding material, Just guide it.

See needle and thread chart, page 5.

Page 42

41

T rouble Probable Cause

Upper

Improperly threaded

thread

breaking

Too much tension

Starting with take up

in incorrect position

Improper setting of

needle

Bent or eye of needle

too sharp

1 Bent or blunt needle

______________L________________________

Material

Tensions too tight

puckering

Dull needle

S tf t c h 1 ength too long

Correction

Refer to threading instructions, see page 8

and rethread machine.

Loosen tension on upper thread by turning

thread tension knob to lower number.

Always start sewing with take up lever in

highest position.

Refer to needle setting instructions, see page 10.

Try a new needle.

Discard all blunt or bent needles and replace

with new.

See tensions adjustment, page 14.

Change needle.

Reduce stitch length.

Page 43

Your sewing machine comes equiop^d with th« h ■ '

series described earlier in this bol

i he following pages illustrate additional time Savina attacK ,

tea, have been designed specifically for your maebine Tb

available at modes, cos, from your dealer. If you: ealercYnn":

-. ..PC' you with these items, ask him to order them for vo k

designed for best oerf receiving the genuine part

gnea for best performance with your machine. .

i

Page 44

SOMK OF THE ATTACHMENTS AVAILABLE FOR YOUR

43

PART # 1403

Rufflar

PART #82528

Aflachment Foot

Fig 71

PART #4990

Darning Spring

PART #74159

Hemmers

Binder

MACHINE

PART #1873

Cording & Zipper Foot

PART #76554

Edgestitcher

K

PART #76553

K

PART #76552

%

PART #76551

Needle position control must be in the left position when using these attachments.

PART #76550

Page 45

Sr."’“i •' “•

fabric overlaps iL iice slightly.

Rick Rack can be sewn to the edoA nf th«

-45

the folded edge of the piping The Mghmio '" °'°' =

r '■r^3,tr. '::rrTi:;£r \T

Slot 5 may be used as a quide in ctitr'Hinn c

See Figs. 67 70 for suggestions

on how to use the edgestitcher.

There are hundreds of other uses.

Fig. 70

Page 46

s!||

Of commercial folded bias bindhia Tht «« ^®'’ corresponding widths

for unfolded bias strfprcut

FOLOEO BINDING (Fig. 73 ) ®'

Cut a point on folded binding, insert In appropriate

slot. Draw through slot and under binder with strong

pm. Test stitching to be sure it is on the edge

Adjust by sliding binder to right or left "

TWO-TOME 31MOING (Fig. 73) ’

I WO bindings can be sewn on fabric edge also in one

operation. When two are used, always skip one size

^erw^n -wiaiiis, inserting each in correct size slot

HAND-CUT BIAS BINDING (Fig. 74) ‘

* binding fold in half for a couole

of inches. Cut binding (diagonally toward end

almost to fold). Slip fold into center of binder’

.-■law until cut opens and binding encircles

opens end of scroll. Test stitching to be sure

IS on the edge. Aajust if necessary.

See Fig. 71 and 72 for suggestions on how to

Fig. 73

use the binder. There are hundreds of other uses.

Fig. 71

Pig.

Fig. 74

Page 47

THE SET OF HEMMERS

Before attaching any of the hemmers, be sure

bobbin thread is pulled up. Then, with hemmer in

place, hold top thread loosely and turn hand wheel

one full turn toward you, making a loop under

hemmer. Grasp bobbin thread with both hands

and slip horizontally under hemmer toward back.

Bobbin thread will catch loop and carry upper

thread to back of hemmer.

47

Fold material to suit for two inches along edge,

hold at each end of fold. Slip fold into guide and

up over spoon (Fig. 75). Fold hem in material back of hemmer.

Draw forward to end of hem and fasten with point of needle.

Pull on threads gently as you start stitching.

HEMMER SET

You can make a hem 1/4”, 3/8”, 5/8”, or 7/8 in width, depending upon

which hemmer you use. For a few of the many uses see Figs. 84—89.

Fig. 75

Page 48

rltìifeil

Ш ЩШШфк^ШШ 0

т

Fig. 76

Fig. 78

Fig. 77

Fig. 80

Fig- 81

Page 49

Fig- 83 pig^ 84

the bodice of a dre^s^etl C“«-tams. pleating a skirt, adding fullness to

49

Fig. 83-A

Page 50

ATTACHMENT FOOT

hemmers, it is*nícelsLy''to%’n?ov^e^t^^^^

^uirb^rndt;,* rd^e^^tch^^^hTm"* tooTr^g^^

at.acH.e„. to ,ha ,s„ as ,ar as

The mounting slot enable«! ♦

/ ^

Fig. 64

or as far away from the edge as destred

the attachment to the correct posmnnh r

ening the mounting screw ^ * before tight-

EDGESTITCHER

¡he edgestitcher is used in

making dainty lace insertions,

6‘CJ'C|ings and pipings,

j ns slots m tho odgesticher

seive as guides in sewing

together various pieces of

material. If you want to sew

lace, lace and embroidery,

or lace and tuckeB" strips

together, place the piece of

_ a . -------------

material that will be on too in slot 1 n ’^'9- 66

For instance, if you are sewing lace edoino^ lower fabric in slot 4.

Pliica the fabric in slot 1 and the iact r slo° 4 TCtt)

------

Wl I IM. 015 r-»

Fig. 65

¡3®

' '' ' ‘ -■

s-n- ^

i

Page 51

THE ADJUSTABLE CORDING AND ZIPPER FOOT

This attachment is used to make and insert

covered cording and to sew in zippers.

Loosen thumb screw to slide foot to either

right or left of needle.

CORDING. Fold bias strip of fabric over

cord. Loosen thumb screw and set foot so

needle is centered in needle hole. Machine

bastes cord in place (Fig. 91).

To sew covered cord to material, reset

adjustable foot so needle stitches closer to

cord, and on edge of base fabric.

Fig. 90 Fig. 91

SEWING IN ZIPPER

Loosen thumb screw and slide foot so needle enters

center of needle hole. Guide metal of zipper along

edge of foot (Fig. 92). Stitching should be close to

zipper to allow easy opening and closing. Adjust to

sew from either r ight or left side, whichever is more

convenient.

51

Fig. 92

Page 52

ROFFLER

Fig. 89

Fig. 88

l'îfryrtVy* *

Page 53

1

ADJUSTABLE

Fig. 93

CORDING AND ZIPPER FOOT

Fig. 95

Page 54

«yFFLSH

1

Fig. 89

à

Page 55

THE ADJUSTABLE CORDING AND ZIPPER FOOT

This attachment is used to make and insert

covered cording and to sew in zippers.

Loosen thun^ screw to slide foot to either

right or left of needle.

CORDING. Fold bias strip of fabric over

cord. Loosen thumb screw and set foot so

needle is centered in needle hole. Machine

bastes cord in place(Fig. 91).

To sew covered cord to material, reset

adjustable foot so needle stitches closer to

cord, and on edge of base fabric.

Fig. 90 Fig. 91

SEWING IN ZIPPER

Loosen thumb screw and slide foot so needle enters

center of needle hole. Guide metal of zipper along

edge of foot (Fig. 92). Stitching should be close to

zipper to allow easy opening and closing. Adjust to

sow from either r Ight or left side, whichever is more

converiient.

51

Fl^:92

Page 56

TO ASSEMBLE LEGS ON

See Fig. 98

1. Place cabinet body upside down on

smooth level surface (use packing

material as cushion to prevent

marking top. )

2. Slip leg into position between corner

blocks and down as far as it will go

W.th stud mtlng into Slot or hols in

metal bracket.

3. Add wing nut and tighten securely.

CABINETS

WING NUT

STUC

CABINET

BODY

Fig. 98

PASS

MOTOB-UGHT

LEADS THROUGH

_SLOT m

PARTITION

alternate

BRACKET

Fig. 97

TYPE OF

CORNER

Page 57

INSTALLING SEWING HEAD IN CABINET

1. Back off both head hinge set screws

until head hinge hole Is clear.

2. Tilt head hinge tongues up and back

as far as they will go.

3. Carefully slip head onto head hinges

- - making sure tongues are inserted

as far as they can go into head

hinge holes.

4. Allow the head to rest In its tilted-

back position.

5. Tighten both set screws securely

with screw driver.

6. Plug electrical leads into sockets

located inside cabinet. Cord identi

fied with“iTiPtor” tag must be plugged

into sockot marked “motor"

Untagged cord goes to “light”

socket.

.....................

, , ,

See Fig. 99

BACK OFF

SET SCREW

TO CLEAR

HINGE

LIFT FLAP

TO LOWER

HEAD INTO

CABINET

Fig. 99

HEAD HINGE

HOLES

HEAD HINGES

HINT: STRETCH

A RUBBER BAND

ACROSS THE TWO

HINGES TO HELP

HOLD THEM UP

RIGHT WHILE

MOUNTING THE

SEWING HEAD.

55

Page 58

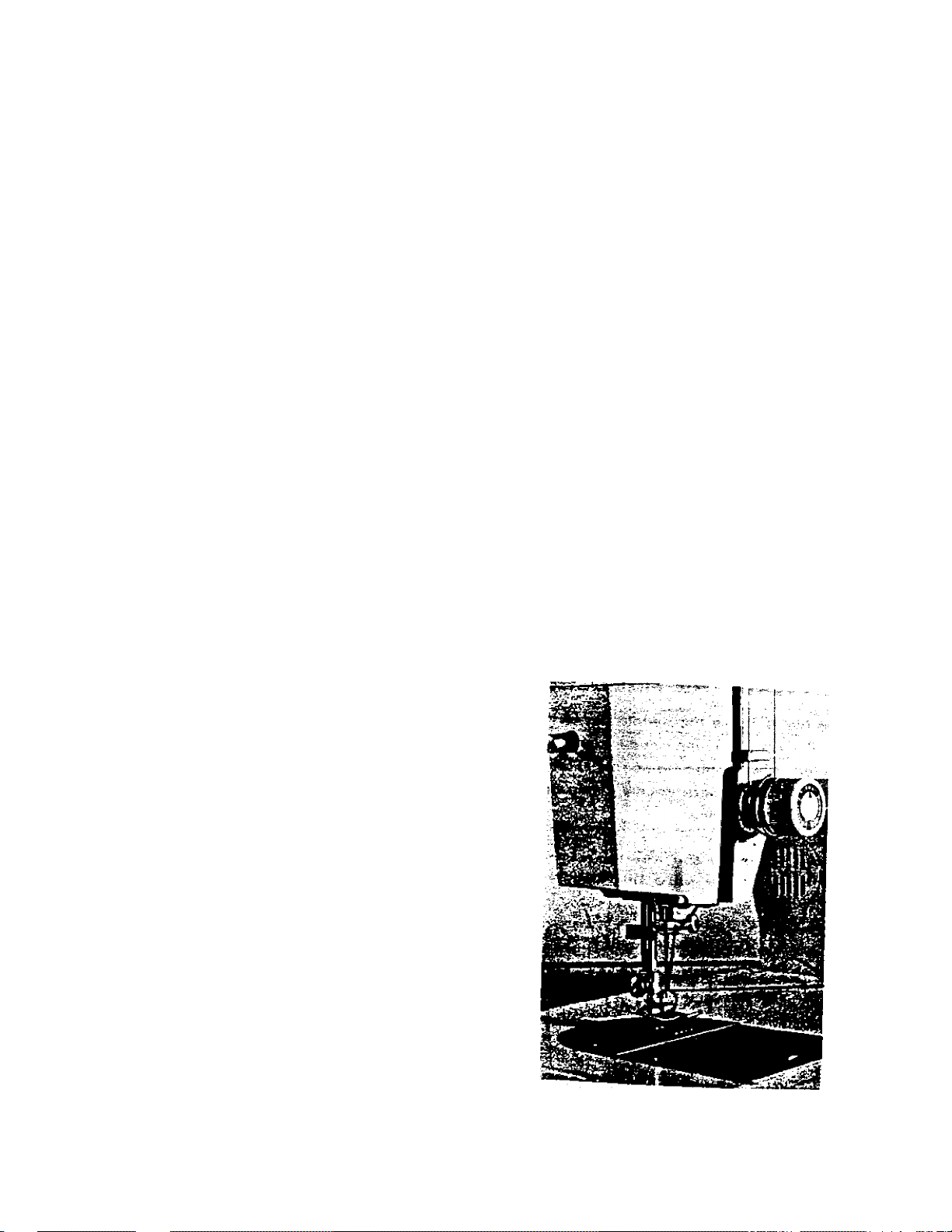

INSTALL!NO SEWINO HEAD IN PORTABLE CASE

Please read these important instructions which were written to aid you in

placing your new sewing machines in its portable case.

First, remove the foot control which is fastened inside the base to avoid

damage in shipping. After unpacking the sewing machine unit, being

certain to take out the Instruction book, guarantee and accessory box,

lay the unit face down on a table. You will see two clamping screws A

entering head hinge holes B on the underside of the back.

On the base you will find two head hinges C which will fit into holes B.

Lov^er the base onto the sewing machine fitting hinges C into holes B.

Tighten screws A securely with a screw driver. -

To make the electrical connection draw the two wires through the slot In the

partition of the base. Plug the cord labeled “Motor” Into the receptacle marked

“Motor” on the block attached to the outer section of the base.

Then insert the other cord into the “Light” receptacle.

Place the foot control on the floor. Insert plug Into a wall outlet (110-115

volts) and you are ready to sew. But first read the instruction book to

become familiar with the threading of the machine, tension adjustments and

all the other features designed to make sewing a pleasure.

53

See Fig. 96 and 97 (RS4)

Loading...

Loading...