Page 1

Page 2

1. CONTENTS

1. Contents.............................................................................................................................................................1

2. Description of machine..................................................................................................................................2—3

3. Winding the bobbin.............................................................................................................................................4

4. Threading the bobbin case................................................................................................................................. 5

5. Inserting and removing the bobbin case..............................................................................................................6

6. Threading the machine.......................................................................................................................................7

7. Setting the needle...............................................................................................................................................7

8. Preparing to sew.................................................................................................................................................8

9. Starting to sew....................................................................................................................................................8

10. Regulating the thread tension.............................................................................................................................9

11. Regulating the stitch length..............................................................................................................................10

12. Regulating the drop feed..................................................................................................................................10

13. Regulating width of zigzag stitch...................................................................................................................11

14. Regulating length of zigzag stitch.................................................................................................................. 11

15. List of zigzag patterns.......................................................................................................................................12

16. Oiling.................................................................................................................................................................13

17. Cleaning the shuttle race..................................................................................................................................14

18. How to make buttonholes.........................................................................................................................15—16

19. Darning embroidering and monogramming.......................................................................................................17

20. Button sewing...................................................................................................................................................18

21. Narrow hemming..............................................................................................................................................19

22. Zipper sewing...................................................................................................................................................20

23. Felling

24. Cloth guide.......................................................................................................................................................21

25. Quilting.............................................................................................................................................................21

26. Some useful sewing hints.................................................................................................................................22

27. Cause of common difficulties........................................................................................................................... 23

28. Needle and thread sizes...................................................................................................................................24

..............................................................................................................................................................20

Page 3

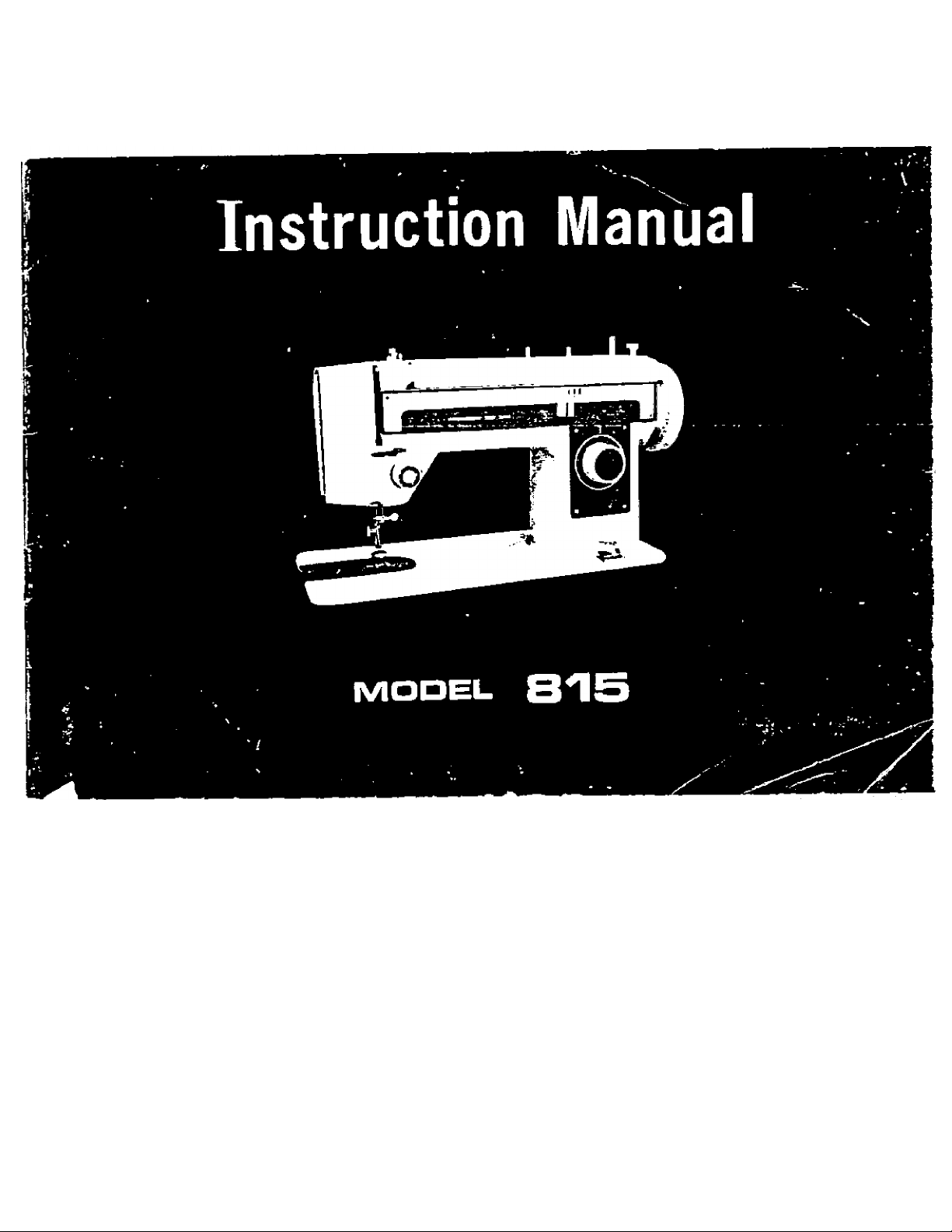

2. DESCRIPTION OF MACHINE

16 17 18

7 6 3

19 20 21 22

Page 4

1 .Balance Wheel

2.Stitch Length Control Knob

3. Reverse Push Button

4. Drop Feed Knob

5. Dial Tension

6. Needle Clamp

7. Needle Plate

8.Slide Plate

9,Presser Foot

10. Presser Foot Clamp Screw

11. Needle Bar Thread Guide

12. Lower Thread Guide

13. Horizontal Thread Guide

14. Face Plate

15. Light Switch (Rear side)

16. Thread Guide

17. Tension Bracket

18. Top Plate

19.Spool Pin

20. Zig-Zag Width Lever

21. Bobbin Winder

22. Bobbin Winder Stopper

- 3

Page 5

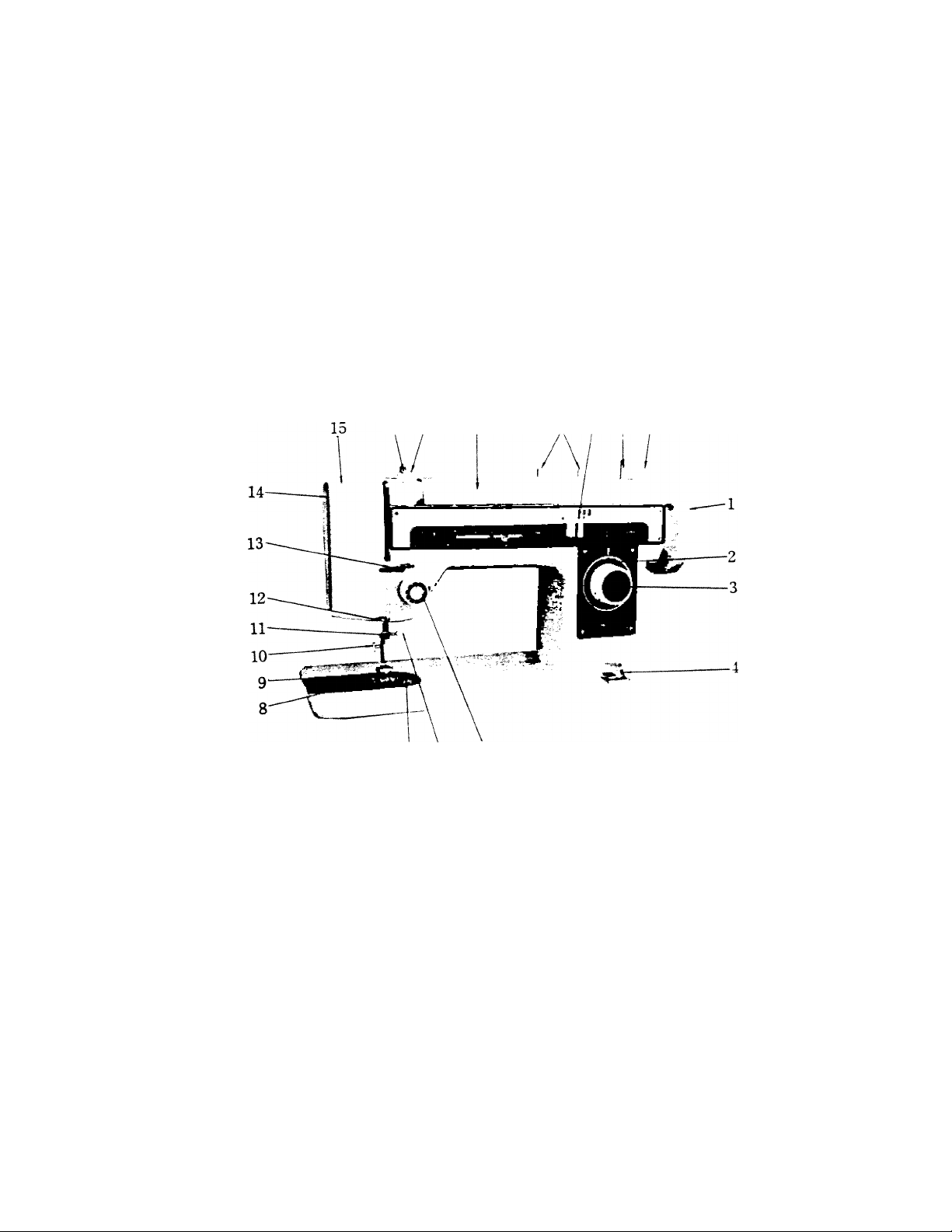

3. WINDING THE BOBBIN

1. To wind the bobbin, the balance wheel must be disconnected from the stitching mechanism. Hold the

balance wheel with your left hand and turn the stop motion knob (Fig, 1) towards you with your right

hand. This will permit the balance wheel to turn freely while the needle bar remains motionless. The

balance wheel is now disconnected for the bobbin winding operation.

2. Place a spool of thread on the spool pin. Draw thread from the spool through tension bracket from back to

front (Fig. 2).

3. Now wind the end of the thread around empty bobbin seven or eight times and place the threaded bobbin

on the spindle of the bobbin winder.

4. And push the bobbin winder from left to right.

5. Now manipulate your foot control in the same manner as in sewing and when the bobbin is completely

full it will release automatically and stop turning. Detach bobbin from spindle. Hold balance wheel firmly

with left hand and with the right hand turn stop motion knob, away from you until if cannot be moved

any further and the needle bar moves with the turning of the balance wheel.

Fig 2

Page 6

Fig 4

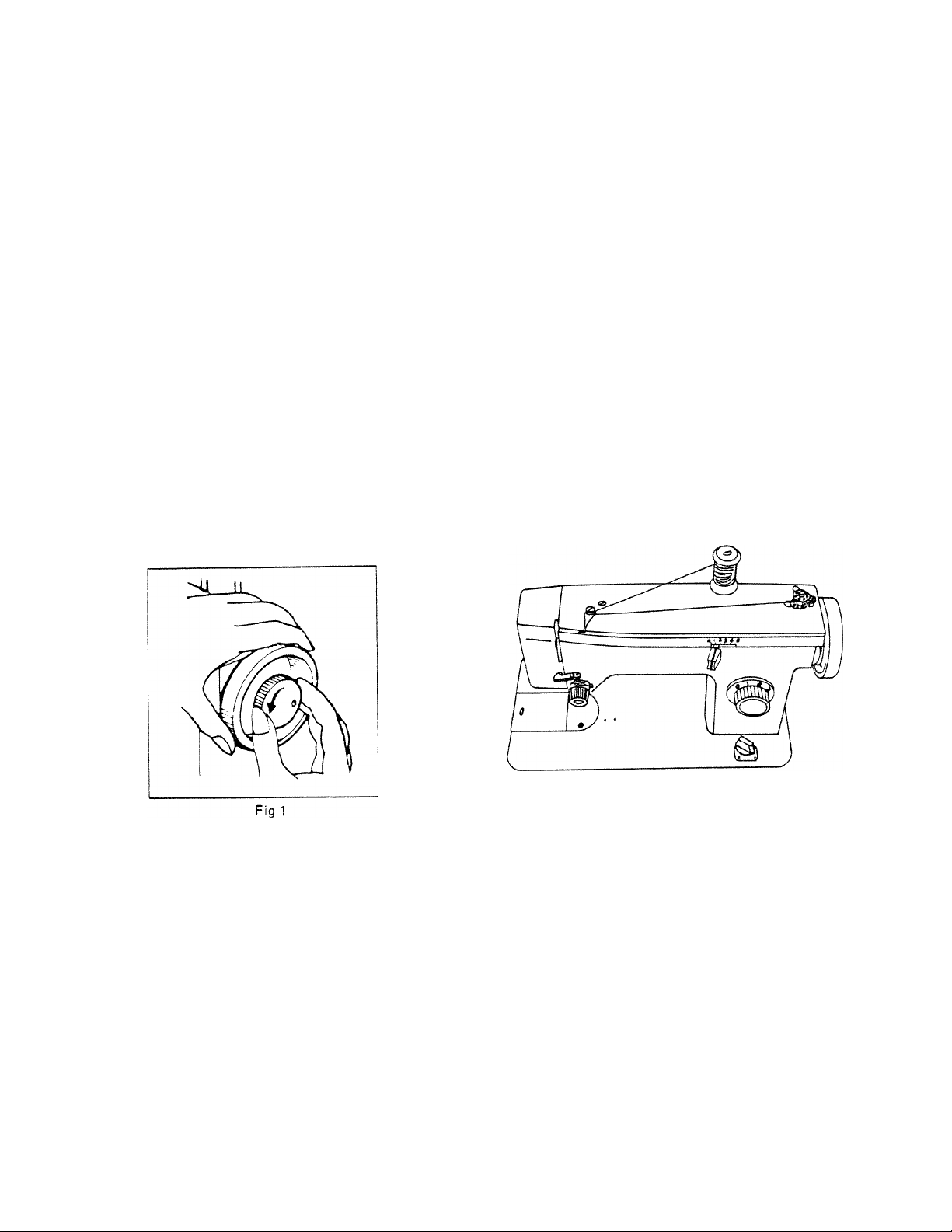

4. THREADING THE BOBBIN CASE

Before threading the bobbin case, study Fig. 3, 4 and 5 to get a general idea

as to how it is done.

1. Hold the bobbin case with your left hand and put the bobbin into the

bobbin case with your right hand, leaving about two inches of the thread

end unwound (Fig. 3). As the bobbin is being inserted in the bobbin case,

the thread flow, you will note, is clockwise.

2. While holding the bobbin case as before, grasp the thread and with your

right hand and guide it into the cross slot (Fig. 4).

3. Then pull it through under the tension spring of the bobbin case until it

enters the delivery eye (Fig. 5).

Page 7

5. INSERTING AND REMOVING THE BOBBIN CASE

1. Raise the presser bar by lifting the presser bar lifter.

2. Raise the needle bar to its highest position by turning the balance wheel towards you.

3. Pull out slide plate IFig. 6).

4. After threading the bobbin case, hold its latch (Fig. 7) between the thumb and forefinger of the left hand, with its

position finger opposite the notch at the top of the shuttle race and replace it on the centre stud of the shuttle

(Fig 7).

5. Then release the latch and press the bobbin case back until the latch catches the groove near the end of the stud.

6. Allow the end of the thread to hang free.

7. Push back slide plate. To remove the bobbin case do all the above in reverse order.

(f i J

Fig 6

. Fig 7

6 -

Page 8

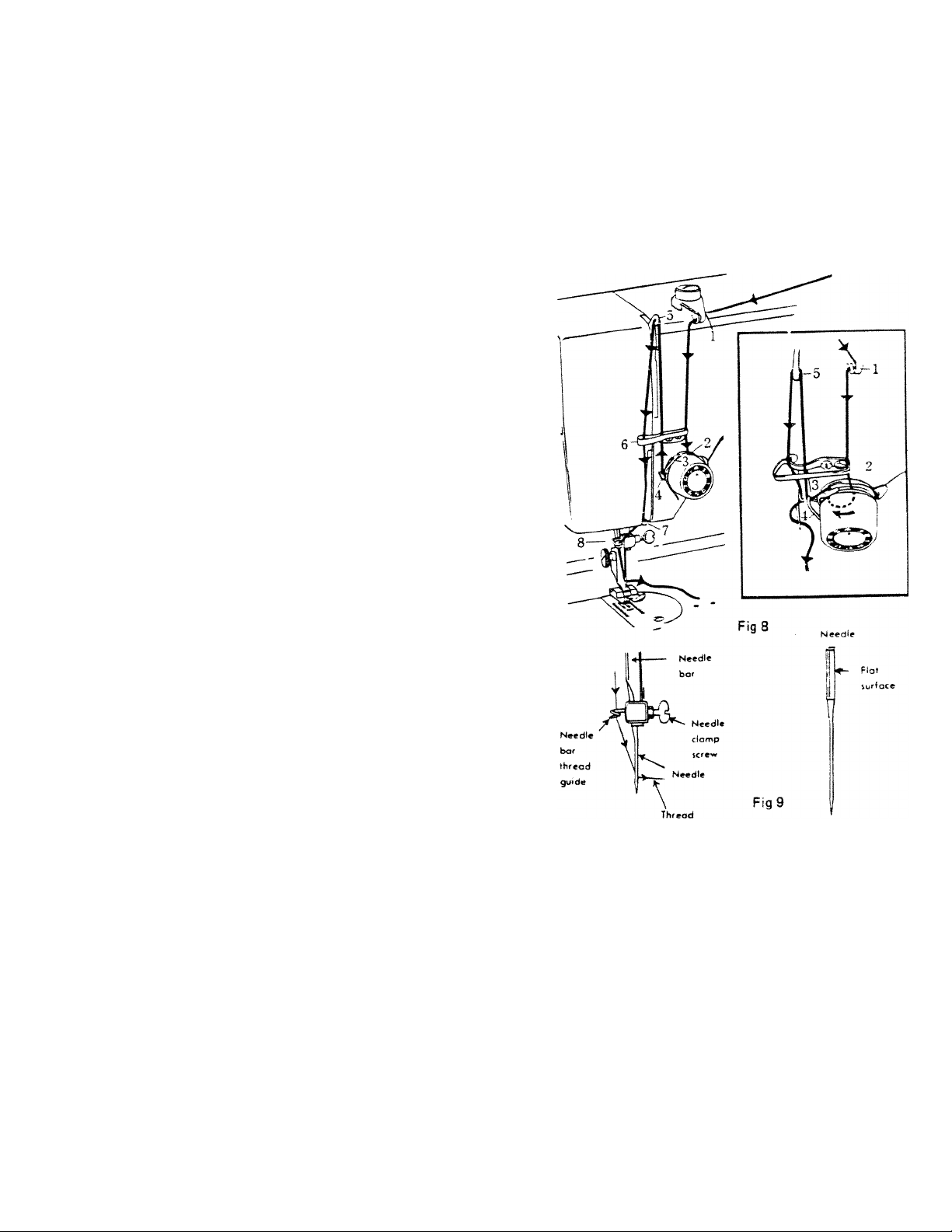

6. THREADING THE MACHINE

Place a spool of thread on spool pin and raise the take-up

lever to its highest point Refer to(Fig. 8).

Pull thread through slot of upper thread guide (1) down

through tension discusi2)up into thread check spring (3) and

(4) and on up into the eye of the take-up lever (5) from right

to left.

Return thread through middle thread guide ¡6) down through

lower guide (7j and into needle bar thread guide (8).

Thread needle from left to right, pulling about four inches

of thread through needle.

7. SETTING THE NEEDLE

1. Turn the balance wheel towards you, raising needle bar

to its highest position, and loosen the needle clamp screw.

2. Hold the needle in the left hand with the point down

and insert the needle up into the needle clamp as far

as it will go with its flat surface to the right then retight

en the clamp screw (Fig. 9).

Page 9

8. PREPARING TO SEW

1. Hold the end of the upper-thread with the left hand, leaving it

slack from the hand to the nee'dle.

2, Turn the balance wheel towards you to lef the needle bar to its

highest position.

3 Pull the thread you are holding, and the lower thread will be brought

up with it through the hole in the needle plate, as shown (Fig. 10).

4, Place both ends of the upper and lower thread under and to the back

of the Dresser foot fFig. 11).

9. STARTING TO SEW

1 Place the fabric to be sewn beneath the presser foot.

2. Lower the presser foot by lowering the presser bar lifter.

3. Start sewing by slowly turning the balance wheel towards you while

gradually working the foot control,

always turn balance wheel towards YOU!

Page 10

10. REGULATING THE THREAD TENSION

For ordinary stitching the tension of the upper

and lower threads should be equal so as to lock

both threads in the center of the material (Fig.

13). If one tension is stronger than the other,

imperfect stitching will result. Fine materials

require a light tension, while heavy materials

require more tension to obtain -a perfect stitch.

TO INCREASE the tension, turn the thread

tension dial (Fig. 12) clockwise.

TO LESSEN the tension, turn the thread tension

dial in the opposite direction. (When regulat

ing the tension always have the presser foot

down).

As all machines are correctly adjusted before leaving the factory and

readjusted before the dealer delivers them to you, the lower tension

seldom requires to be altered, but, if this becomes necessary, tighten

the screw holding the tension spring on the outside of the bobbin case

for more tension, or loosen the screw slightly for lesser tension (Fig. 14).

Fig 12

Correct Stitch

Needle Thread Tension too strong

Needle Thread Tension too weak

Fig 13

Page 11

1. REGULATING THE STITCH LENGTH

The length of the stitch can be changed with the stitch length dial (Fig. 15). In

order to set machine at a certain length of stitch, turn the stitch length dial until

the indicator is facmg the selected number on the scale. The length of the stitch is

variable from 0-5. The normal stitch lenght is 2.

a Regulate the length of the stitch as for forward sewing.

b. Push reverse stitch button located in the centre of the stitch length dial (Fig.

15) as far as it wiM go. The machine will remain sewing in reverse while the

reverse stitch button is depressed. When released the machine resumes forward

sewing with the same stitch length.

12. REGULATING THE DROP FEED

The DROP FEED is located on the bed of the machine (Fig 16).It regulates the

height of the feed dog for sewing normal material, for darning and embroidering.

1. For darning, embroidering and monogramming, turn the knob to left

"DOWN" place and the feed mechanism will be lowered under the level of

theneedle plate, so that the material can be moved freely.

2. For normal sewing turn the knob to the right UP place.

Fig 15

■10-

Page 12

13. REGULATING WIDTH OF ZIGZAG STITCH

Fig 17

The width of zigzag stitch is regulated by the zigzag lever. By pushing the zigzag lever to right, the width of the

zigzag stitch will increase accordingly. And by pushing the zigzag lever to left, the width of the zigzag stitch will

decrease accordingly. If at "0" position, there will be a straight stitch.

14. REGULATING LENGTH OF ZIGZAG STITCH

The stitch length dial regulates the length of the zigzag stitch for zigzag sewing in the same manner as for straight

sewing. In order to produce the "Satin Stitch" which is the closest zigzag stitch, set the stitch length dial close

to 0.

11

Page 13

15. LIST OF ZIG ZAG PATTERNS

Patterns

—

1

2

/vw

3

mm

4

5

Stitch

Length

5

5

0.5-2

0.5-2

How to move zig zag lever or needle position lever

Lock, zig zag lever at

Lock zig zag lever at (B).

Lock zig zag lever Î5).

Move zig zag lever from (0) to (5) at even speed

Restât^and oscillatetV\-ft\-iV\and rest.

...........

(0).

12-

Page 14

16. OILING

To see that your machine is always in smooth running condition, you must keep it oiled at all times.

No grease is required, just a drop of oil is sufficient at each time of oiling. Points to be oiled are il

lustrated in Fig. 18 & 19 by arrow marks. To oil your machine thoroughly, open top^ plate and turn

the machine over to get to parts underneath the bed.

After oiling, run the machine at high speed for a few minutes to let the oil penetrate to all parts.

13-

Page 15

17. CLEANING THE SHUTTLE RACE

When the thread is tangled in the race or lint gets into the

space between the shuttle and shuttle-race, this will cause

abrupt heavy running or complete stoppage of the machine.

When this occurs

1. Raise the needle bar to its highest position and take the

bobbin case out.

2. Pull the KNOBS (A) on both side of shuttle race (Fig. 20

& 21) aside, then take out the outside ring and the shuttle

body with your fingers.

3. After shuttle race and bobbin case have been cleaned, put

all of them back in reverse order.

Fig 21

Fig 20

■14^

Page 16

18. HOW TO MAKE BUTTONHOLES

1. Set zig-zag width between markings 1 and 2.

2. Raise the presser foot and turn the balance wheel towards you to bring needle to its highest position. Replace

regular presser foot with special buttonhole foot shown on Fig. 22. Tighten thumb screw.

3. Set stitch length to obtain closely spaced forward stitches. Best length of stitch for buttonholes is when

indicator is placed between markings 0 and 1 on dial. Adjust length of stitch, if necessary, to get best possible

appearance of buttonhole.

4. Slightly tighten needle thread tension, turning thread tension to the right. If appearance of buttonhole should

not prove satisfactory, slightly vary tension until the desired results are obtained.

NOTE: It IS suggested that you make one or two sample buttonholes

on a clipping of fabric, same as your garment, to test adjustments

of machine and to make corrections, if needed. Also mark with

pencil or chalk the position and exact length of buttonhole on

garment. Adjust gauge on bottonhole presser foot (Fig 22) to

correspond to the desired length of the buttonhole. To determine

this adjustment, measure size of button and add approximately

3/16" to 1/4". The distance from the needle or the machine to

the front of the gauge should equal this measurement. The actual

sewing of the buttonhole should be done in this sequence.

— 1 5 —

Page 17

5. Place start of buttonhole under needle and have its face you. Let down presser foot and

begin sewing. Stop when first row of stitches reaches the gauge.

6. Turn handwheel toward you until needle makes another right hand stitch. Leave needle

in material, (Fig. 22-A)

7. Raise presser foot slightly and turn garment clockwise around the needle. (Fig.22-B)

Lower presser foot and turn handwheel toward you until needle is above material.

8. Setting zigzag width lever to the Tightest position. Make 3 to 4 stitches to sew

closing bar and stop machine with needle out of materiaj. The adjacent diagram (Fig.

22-C) shows the buttonhole as far as it has progressed up tonow.

9. Resetting zigzag width lever between markings 1 and 2. (to its original setting). Now

sew a second line of purl stitches making sure that the already sewn row passes through

the right-hand groove at the underside of the buttonhole presser foot. Stop machine

with needle out of material. The almost finished buttonhole will look like this (Fig.22-D).

10. Setting zigzag width lever again and repeat operation described in paragraph 8

above this finishes the buttonhole. If desired, lock stitchirtg by sewing a few stitches

with zigzag width lever returned to its normal position, so the indicator points at "0

and turn the drop feed knob to left "down! Insert Buttonhole Cutter at one end of

buttonhole and carefully cut material between the two rows of stitching. Avoid cutting

of stitching to assure strong and lasting buttonholes, to make reinforced buttonholes

introduce gimp of proper size into the samll hole right in front of the halfmoon-shapeded

stitch hole of the buttonhole presser foot. Sew over gimp as machine makes buttonholes

leave thread tension much the same as for ordinary sewing. Purl stitch buttonholes

require a tight tension of the needle thread. For better appearance, use needle thread of

the next heavier size.

Page 18

19. DARNING EMBROIDERING AND MONOGRAMMING

Lower the feed by turning drop feed knob to "DOWN" thus permitting the work to be moved by hand

in any direction desired. Also remove presser foot andiowerfoot lifting lever and your machine is ready for

embroidering and darning. Both will be done most successfully when material is stretched on an embroidery

hoop.

Hold the hoop closely on the machine base with both hands and press the material with index finger on

the vicinity of the needle. This will help in holding down the material and will prevent the machine from

skipping stitches. Manipulate work carefully and be sure to keep finger out of path of needle to avoid injury.

Adjust thread tensions for best appearance of embroidery work and slightly decrease the upper thread

tension to avoid the lower thread from being pulled up.

■17-

Page 19

20. BUTTON SEWING

Turn balance wheel towards you to get needle to .ts highest pos.tion.

Raise presser bar and replace regular presser foot, with button sewing

‘oot as shown in Fig. 23- Drop the feed dog as required for darning

and embro.denng. Upper and lower thread tensions remain the same

as for ordinary sewing.

Place material or garment together with button under the presser

foot so that holes in button line up with oblong hole in presser foot.

.Adiust width of zigzag stitch to permit needle to pass through center

Fig 23

of holes In button. ■ u •

Before sewing with power, turn the balance wneei uy a

the center of the holes m button.lf the needle hit the button it will break.

Then sew five to six stitches to attach button.

When attaching four-hole buttons first sew one set of two holes, then stitch into second set of two holes an

lock thread with two or three plain stitches in last hole.

K r rh, balance wheel by hand towards you to make sure that needle will stitch in

18-

Page 20

21. NARROW HEMMING

Turn balance wheel towards you until needle reaches its

highest point. Raise presser bar and remove the regular presser

foot. Attach hemmer foot (Fig. 24).

1. Fold over edge of material approximately H" wide, then

fold it over again in the same way for a length of about

2”. Insert this folded end from beneath into spiral formed

opening (scroll) of hemmer foot. Move material back

and forth until the hem forms itself in the scroll.

2. Pull material towards you until the beginning of the hem

is just below the needle.

3. Lower presser foot and begin to sew. Guide material

into hemmer foot while sewing (Fig.24).

NOTE: Do not crowd material into scroll and do not leave scroll only partly filled by material, feed just enough

material into the hemmer foot to fill out the scroll.

Instead of a straight stitch, you can also use a zigzag stitch for this hemming operation. Be sure however,

to adjust the width of the zigzag stitch to be as wide as the hem itself. Using a very long stitch and tight

tensions will produce a shell stitch.

19-

Page 21

22. ZIPPER SEWING

1 Release the thumb screw on rear side of foot. Lower needle into the

side notch of the foot and check position of the foot to avoid needle

strike the foot. Fasten thumb screw to the lock make sure that the foot

is in DOSitlOn. , . ,,

2. Fold edge of the material by %" and place zipper under the folded portion

of the material where you wish to attach the zipper.

3 Stitch close to the edge of the zipper foot along zipper teeth.

_

__

4' To sew on the opposite side of the zipper, loosen thumb screw and slide

tne foot over and sew in the same way.

23. FELLING

Us-the hemmer foot for doing felling and proceed in the following manner

V Lav two pieces of cloth one on too of the other with their RIGHT sides facing

each other. The right edge of the bottom piece must extend about ¡^inch beyon

the right edge of the top piece. See Fig. 26

2 Sew both pieces of cloth together using the hemmer foot like a regular presser

'oot. Use the right edge of long toe of hemmer foot to guide the bottom piece

of material while the left edge of the same toe serves as a gu 1 de for the top piece

of material. Fig. 26 shows this aetaii.

3. Open and spread out material and put back on machine nght sides downward.

Make sewn edges of material stand up.

Fold over the edges to the left and insert them into the scroll of the hemmer foot.

Sew as you would do ordinary hemming. Use left edge of long toe of hemmer

-Out as guide, having original seam run alongside of it (Fig. 27!

Fig 25

TOP PI CCE

BOTTOM PUCE-

Fig 26

flPST

FOID

20-

Fig 27

Page 22

24. CLOTH GUIDE

The cloth guide (Fig. 28) serves as a guide for straight stitching

when making wide hems, deep tucks or seam widths which are

greater than presser foot allows.

It is attached to machine as illustrated.

25. QUILTING

The quilter (Fig. 29) will enable you to sew equidistant lines on

padded fabrics without the necessity of marking them in advance.

1. To attach the quilter to the presser bar of the machine,

loosen the presser foot thumb screw and place the quilter

astride the presser foot. The quilter must be on top of the

presser foot when secured on the presser bar.

2. Adjust the width guide of the quilter to the desired width

and drop guide on material.

3. Sew with the quilter width guide following the previous

stitches as- in Fig. 29.

■21-

Fig 29

Page 23

26. SOME USEFUL SEWING HINTS

TO TURN CORNERS:

1 Stop the machine while the neeoie IS 5UI

2', ,h, pr.«.r foo, and ,„.n th, fabnc using .h. n..dl. as a P»«.

3. Lower the presser foot and resume sewing.

TO SEW ELASTIC FABRICS: , Hoths e^c it is advisable to sew them with reduced upper

,h..ad ,.ns.on o,ne™.s. .b. .b.aad will break wb.n .b. sawn ma.anals ar.

TO SEW VERY THIN CLOTH: newspaper or any other thin

wnan sawing »ry <b.n Co.b wbinb .and. .0 ga.b.r as VbslriU

p,p.r und.rn...b ,ba n.a.eri.1 an= saw w.,b .b. sbor.as, sb.cb possibla. Tbrs „

rr.ra .b. ..nsiPb o. -b. uPPar .braad and anspinv .ba iongas. sb.ab puss,b,a,

2. Tbe so.cbas pray .ban ba aasily ranso-.d bv pulb"S "b« I»”«' 'b'»»“TO KEEP YOUR MACHINE IN PERFECT CONDITION: machine

iuf\t:c.r iww j/.loan Ho not over-oil macnme.

,. K..P an mo-ing parts P< >ba macbina cpns.an.ly orlad and cl.an. Dp no

2. Always turn handwheel toward you.

3. Do not run machine without cloth. machine is designed to feed

4. When sewing, do not pull the material otherwise you wHl bend the nee .

1 ■ u.iq tKp nppdiG IS Still ths mstGnsl.

SUCK .I.S..C ma..s.ais as ¡.rs.vs, bias cu, do. . ^ ^

the material automatically-

5. Do not operate machine when the presser bar lifter is raised.

-22-

Page 24

27. CAUSE OF COMMON DIFFICULTIES

BREAKING OF THE UPPER THREAD;

1. Incorrect threading

3. Faulty needle or needle set incorrectly

4. Needle brushing against presser foot or other attachments

5. Needle eye too small for thread used 6. Starting the machine suddenly or with a jerk

7. Starting the machine with the take up lever at its lowest position

BREAKING OF THE LOWER THREAD:

1. Incorrect threading of the bobbin case 2. Lower thread tension too tight

2. Upper thread tension too tight

3. Bobbin being wound too fully or too loose

4. Rough edge of hole in needle plate caused by improper needle action

BREAKING OF THE NEEDLE:

1. Pulling the fabric while machine is running, thus causing, the needle to strike the needle plate

2. Using bent needle

SKIPPING STITCHES:

1. Using bent or blunt needles 2. Needle inserted incorrectly

3. Needle threaded incorrectly 4, Using wrong size needle

5. Pressure on presser foot insufficient, especially when sewing heavy material

UNEVEN STITCHES:

1. Presser foot not resting evenly on material

3. Using too short a stitch

5. Using too fine a needle with to coarse a thread

Feed dog not being high enough

Pulling the cloth while the machine is running

6. Thread out of tension or check spring

Page 25

18. NEEDLE AND THREAD SIZES

Sizes & Grades of

Needles

11

¡Medium-Fine)

i (Medium)

I

16

1 (Light-Heavy)

i

19

I (Heavy)

i

14

18

(Medium-Heavy)

(Extra-Heavy)

Type of Fabric

and

Work to be Done

Medium, light-weight and summertime fabrics.

For house dresses, children's dresses, washable cotton

dresses, aprons, curtains.

Dress silks and cottons, light weight woolens, draperies,

fabric furnishing.

For general household sewing, fine men's shirts, smocks,

window draperies and fabric decorations.

Heavy cretonne, madras, muslin, brocades and puilts.

For men's work'shirts, sturdy smocks and aprons, heavy

auiltinq and fabric furnishings.

Heavy woven coating, light weight canvas, bed ticking,

upholstery and awning materials, slipcover fabrics.

For work or sports uniforms, suits made of strong linen

or cotton fabrics, awnings, slip covers and mattresses.

Heavy woven suiting, coating, duck, ticking, drilling,

canvas and sacking. For heavy wash uniforms, bedding

supolies for hospitals, hotels and camps.

For bags, canvas coarse cloths and heavy goods.

....................................................

....................................................

......

SI7E OF THREAD

Cotton

80

to

100

60

to

80

40

to

60

30

to

40

10

to

30

Very

Coarse

Silk 1

Twist

A & B

Twist

Twist

Twist

r-

----------

Twist

0

C

D

E

Linen

■■ ' " "i

60 1

to

80

40

to

60

24-

Page 26

Loading...

Loading...