Page 1

MODEL 811

Page 2

SEWING MACHINE

Record in space provided below the Serial No.

and Model No. of this appliance.

The Serial No. is located on Base plate

The Model No. is located on Base plate

Serial No

-------------------------------------------------------

Model No. —§_i

Retain these numbers for future reference.

---------------------—.--------------------

-

Page 3

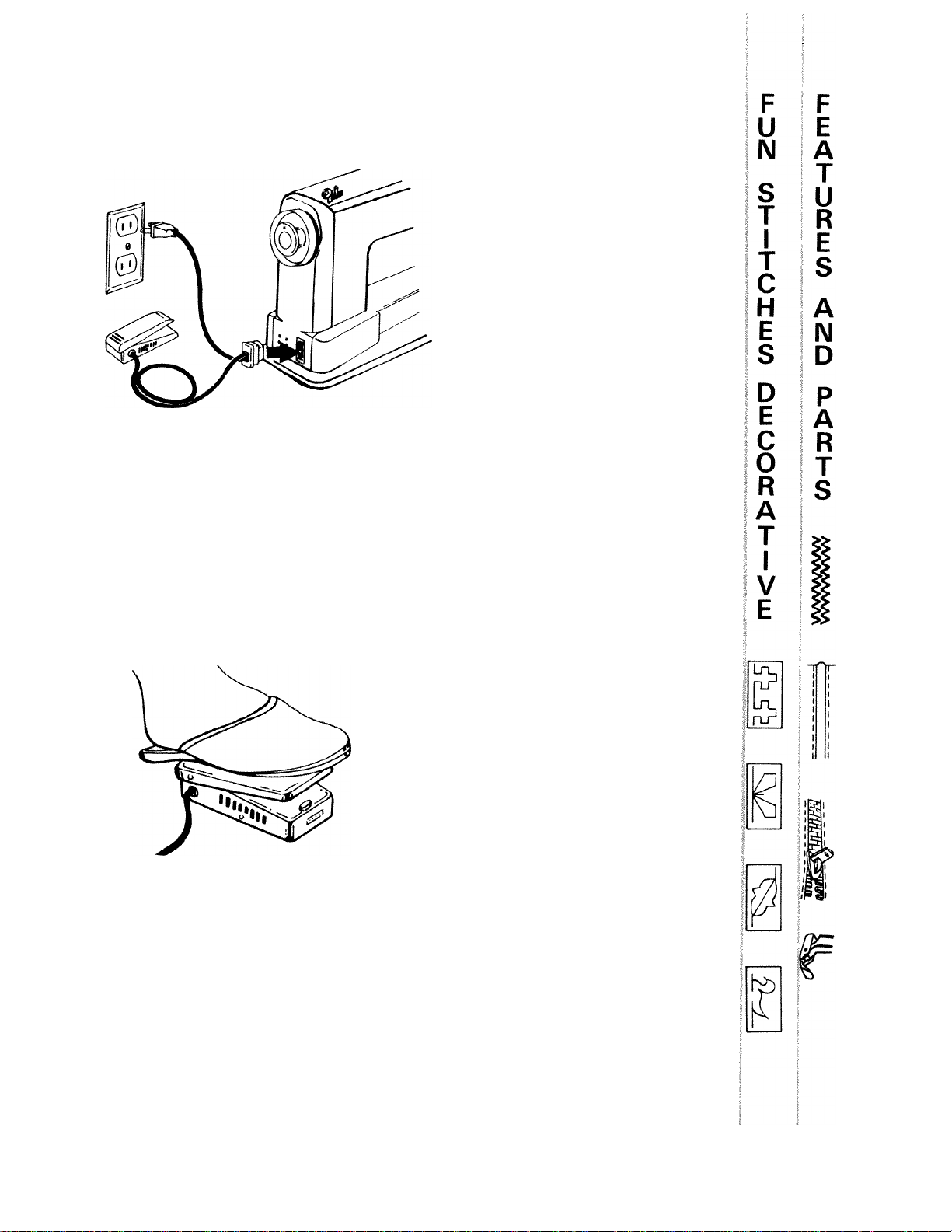

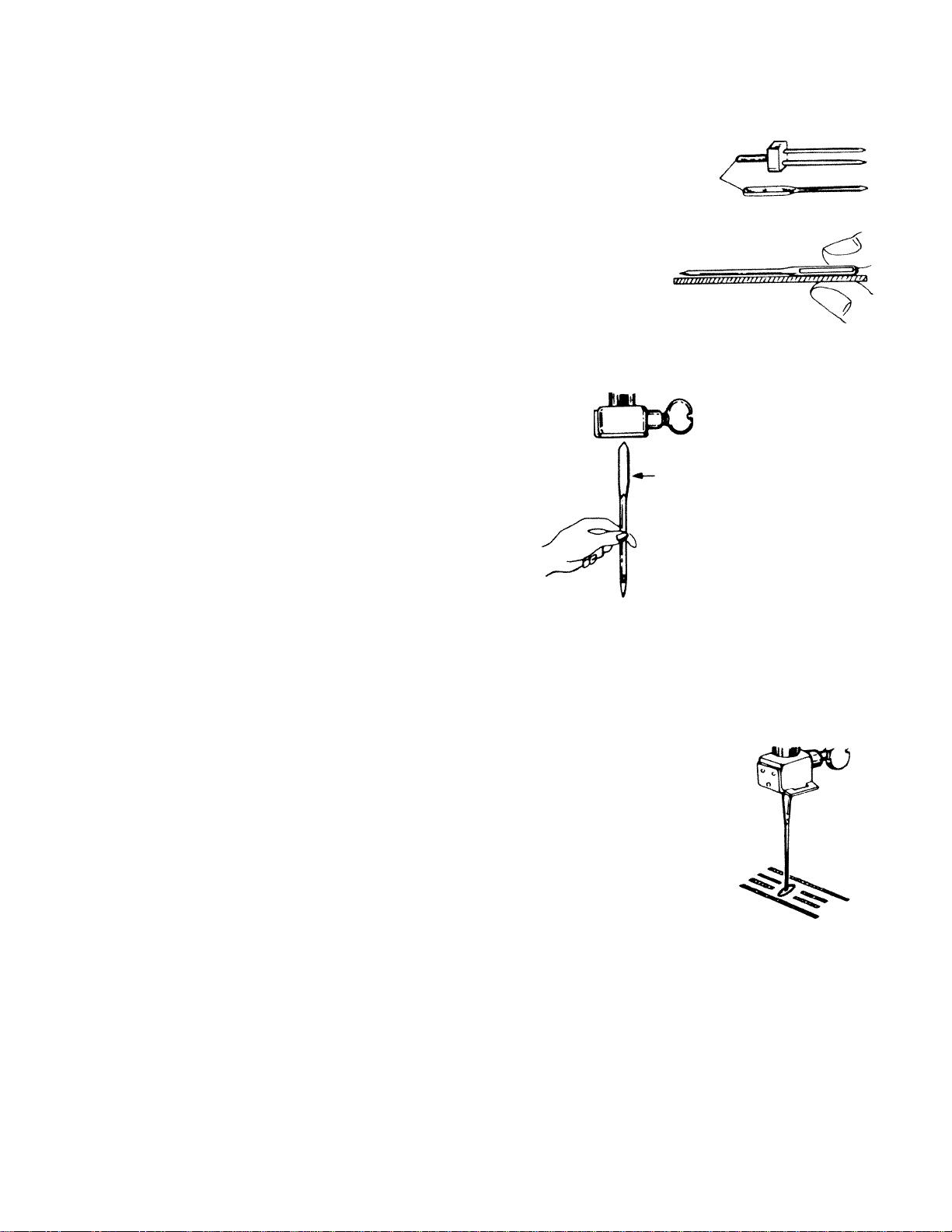

USING THE FOOT CONTROL

TO CONNECT THE FOOT CONTROL WIRES:

• Connect special plug to block on machine as shown in diagram

above.

• Connect outlet plug to electrical outlet.

• When sewing, keep children's hands away from foot control and

wiring.

• After sewing, disconnect plug from electrical outlet.

W

T

T

N

G

A

D

Y

T

O

S

E

I

R

E

B

u

T

T

o

N

H

O

L

E

S

S

T

R

E

T

C

H

U

T

I

IL

I

T

Y

S

T

I

T

C

H

E

S

TO USE THE FOOT PEDAL:

• Begin sewing by turning the hand wheel toward you and apply

gradually increasing pressure to foot pedal.

• Sewing at a constant speed will give best results.

111%

mg

l!!S

ic: I

k

Page 4

Re(

anc

Th(

Th(

Ser

Mo

Ret

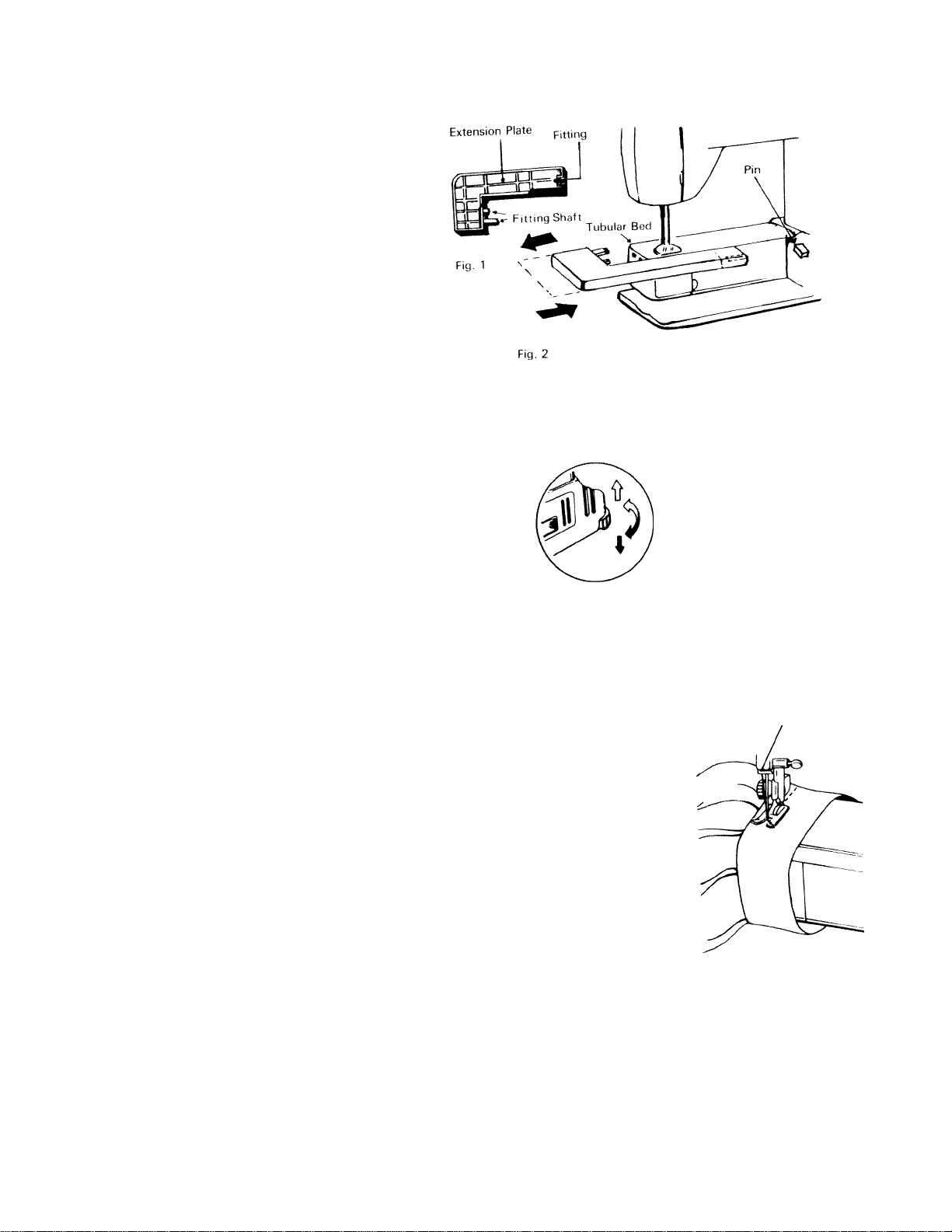

USING THE EXTENSION PLATE

3 ATTACH AND REMOVE THE

remove the extension plate.

LEVELING THE MACHINE ^

Level your sewing machine when you use it on the table or install it

into the cabinet.

UP: Counter Clockwise

DOWN; Clockwise

FREE ARM FEATURES

TUBULAR SEWING , . . ^

• The free arm design simplifies the sewing of tubular items such as

pant cuffs, shirt and blouse cuffs and socks.

Simply position these items over the tubular bed of the machine and

sew.

Page 5

Al IlfcD SEWING

/viti'ii (he uxtension plate is attached

,..u ii.ive.ill the advantages of aflat

I..11 imii* tor sewing flat items,

tiitl for sitwing large tubular

itiHi'. !.u(;h as flared pant legs.

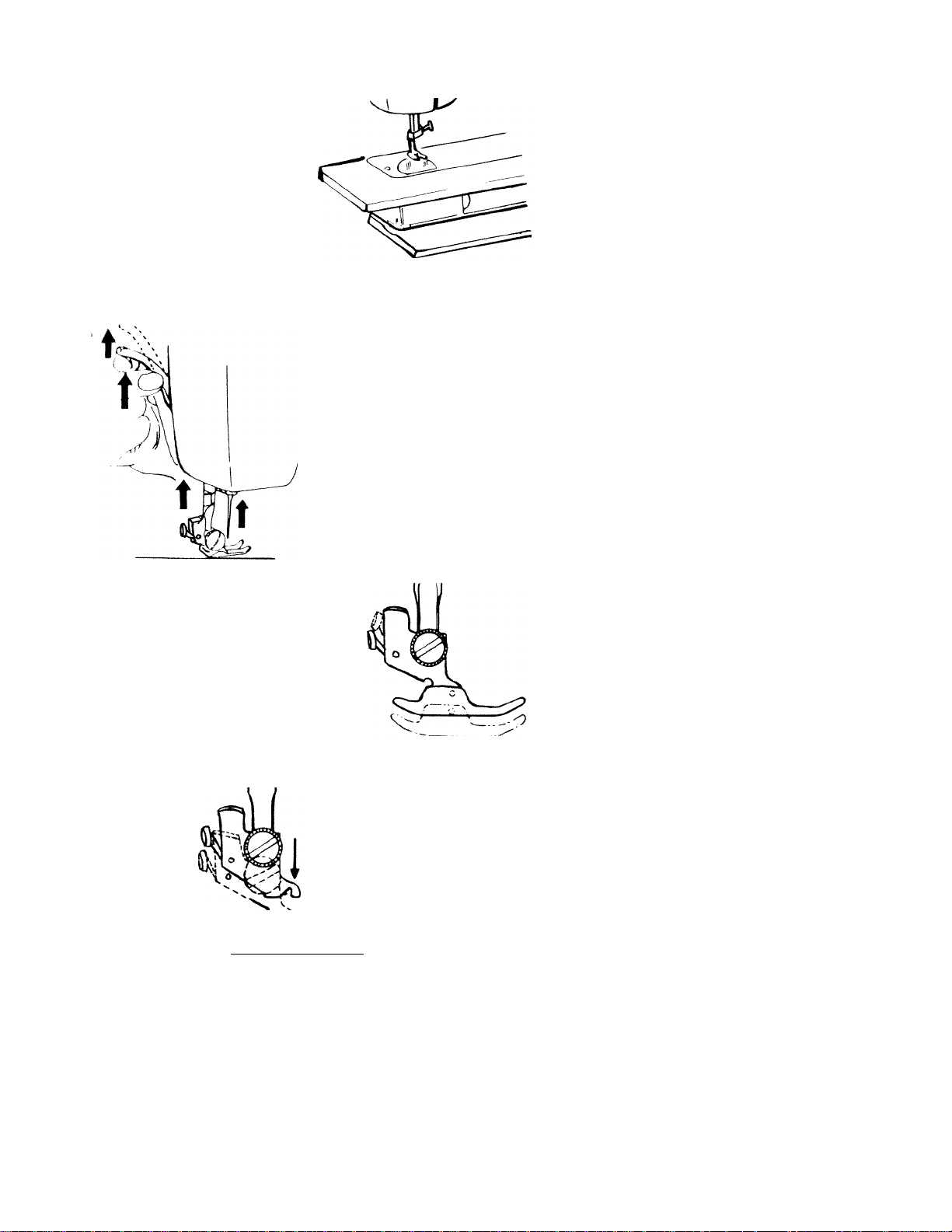

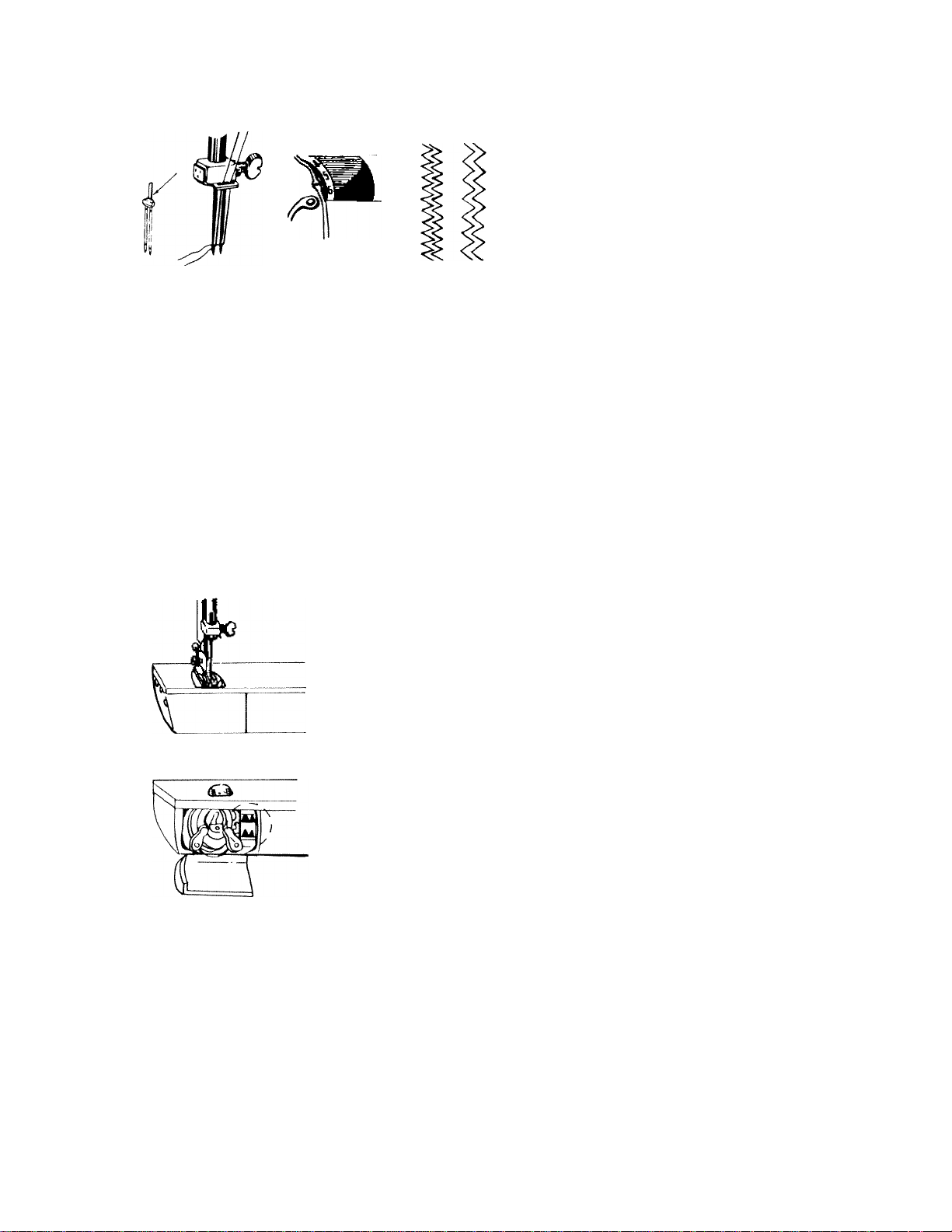

HANGING THE PRESSER FOOT

bed

Raise needle bar to highest

position and raise presser

foot as shown.

The extra lift for heavy fabric

makes it easier to place fabric

under the presser foot.

s

T

R

A

G

H

T

A

N

D

Z

A

G

B

U

S

T

R

T

I

O

N

H

O

L

E

S

E

T

C

H

U

T

I

L

I

T

Y

S

T

I

T

C

H

O REMOVE THE PRESSER FOOT: ■

■ Pri.'ss button on back of presser foot

shank and foot will drop from shank

as shown above.

' It (s not necessary to loosen the thumb

screw to change presser foot.

.

..................................

TO ATTACH THE PRESSER FOOT:

• Align desired presser foot to shank as shown above.

• Lower presser foot lever and shank will automatically attach to foot

as shown above.

iiiÿ

111%

iii^

k

Page 6

Re(

anc

Th(

Th(

Set

Mo

Rel

CHANGING THE NEEDLE

Flat side

Always make sure needle is straight.

To check straightness of needle, lay needle on a flat surface and see

thafneedle is straight and parallel as shown in above diagram.

. Needle

Clamp Screw

- Flat side towards

back of machine

Turn hand wheel toward you to raise needle bar to its highest posi

tion.

Loosen needle clamp screw and insert needle upward as far as it wif

go, making sure flat side of needle is towards back of machine as

shown in the above diagram.

Tighten needle clamp screw with screwdriver.

Follow the same procedure for insertion of twin needle.

To make sure that needle has been inserted correctly, turn hant

wheel toward you and see that needle comes down through thi

center of the needle hole in the needle plate as shown in the abovi

diagram. . .

Stitch selector dial must be set in straight stitch needle positioi

when checking needle alignment.

If skipped stitches occur, needle may be incorrectly inserted.

Page 7

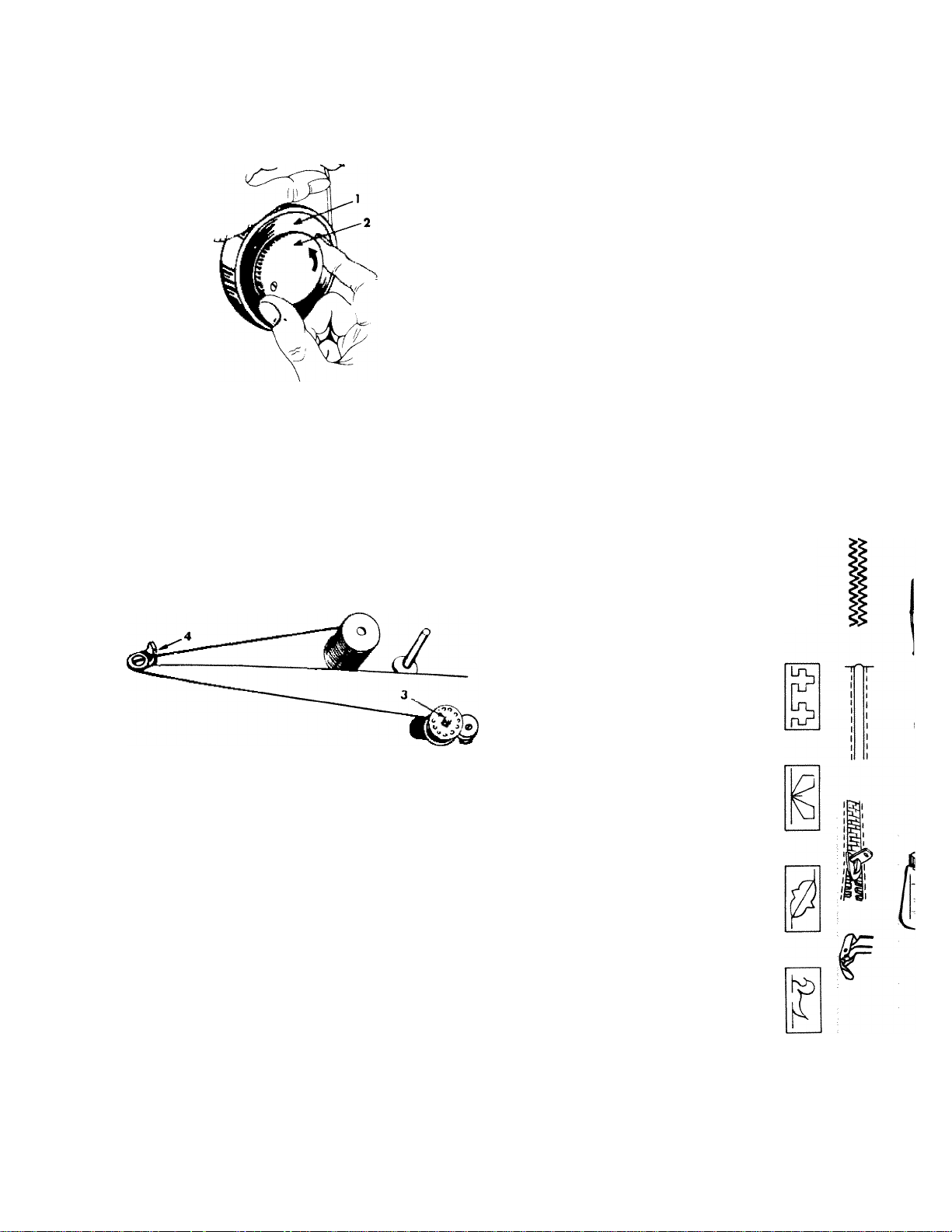

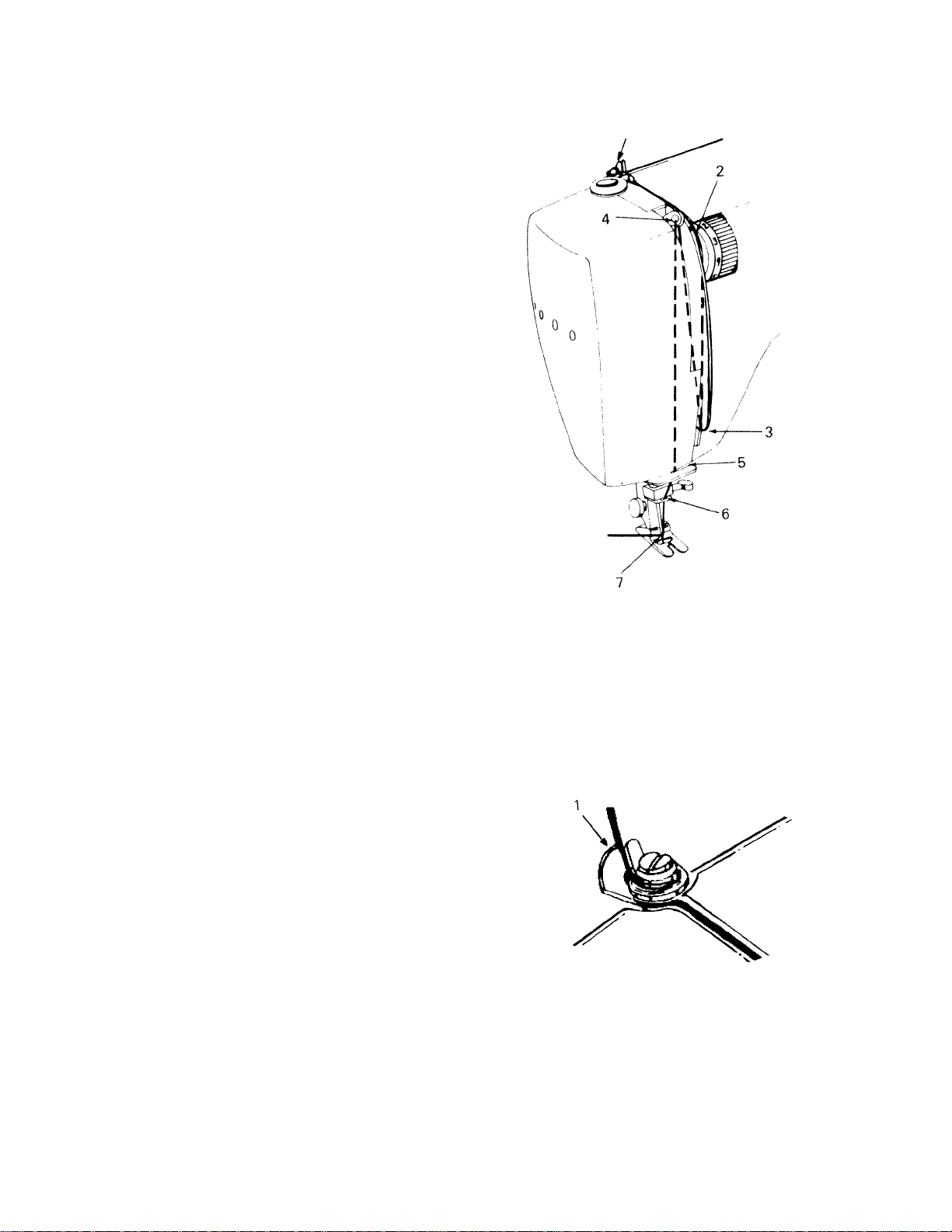

WINDING THE BOBBIN

3 DISENGAGE THE HAND WHEEL:

Hold the hand wheel 11) with left hand, turn clutch

counterclockwise with right hand to disengage as shown.

12)

s

T

R

A

G

H

T

A

N

D

Z

G

Z

A

G

B

U

T

T

I

O

N

H

O

L

E

S

s

T

R

E

T

C

H

U

T

I

L

I

T

I

Y

S

T

I

T

C

H

F

U

N

S

T

I

T

c

H

E

S

D

E

C

0

R

A

T

1

V

E

F

E

A

T

U

R

E

S

A

N

D

P

A

R

T

S

E

S

TO WIND THREAD ONTO BOBBIN:

• Lead thread through spring thread guide (4) and through the hole in

your bobbin from the inside out.

• Place the bobbin onto the bobbin winder shaft (3).

• Push the bobbin winder to the right.

• Hold loose end of thread firmly and turn hand wheel to make thread

tight. Apply gradual pressure on foot pedal until automatic shut off

disengage bobbin winder.

• Cut off loose end of thread.

If

k

Page 8

Re(

anc

Th(

Th(

Sei

Mo

Ret

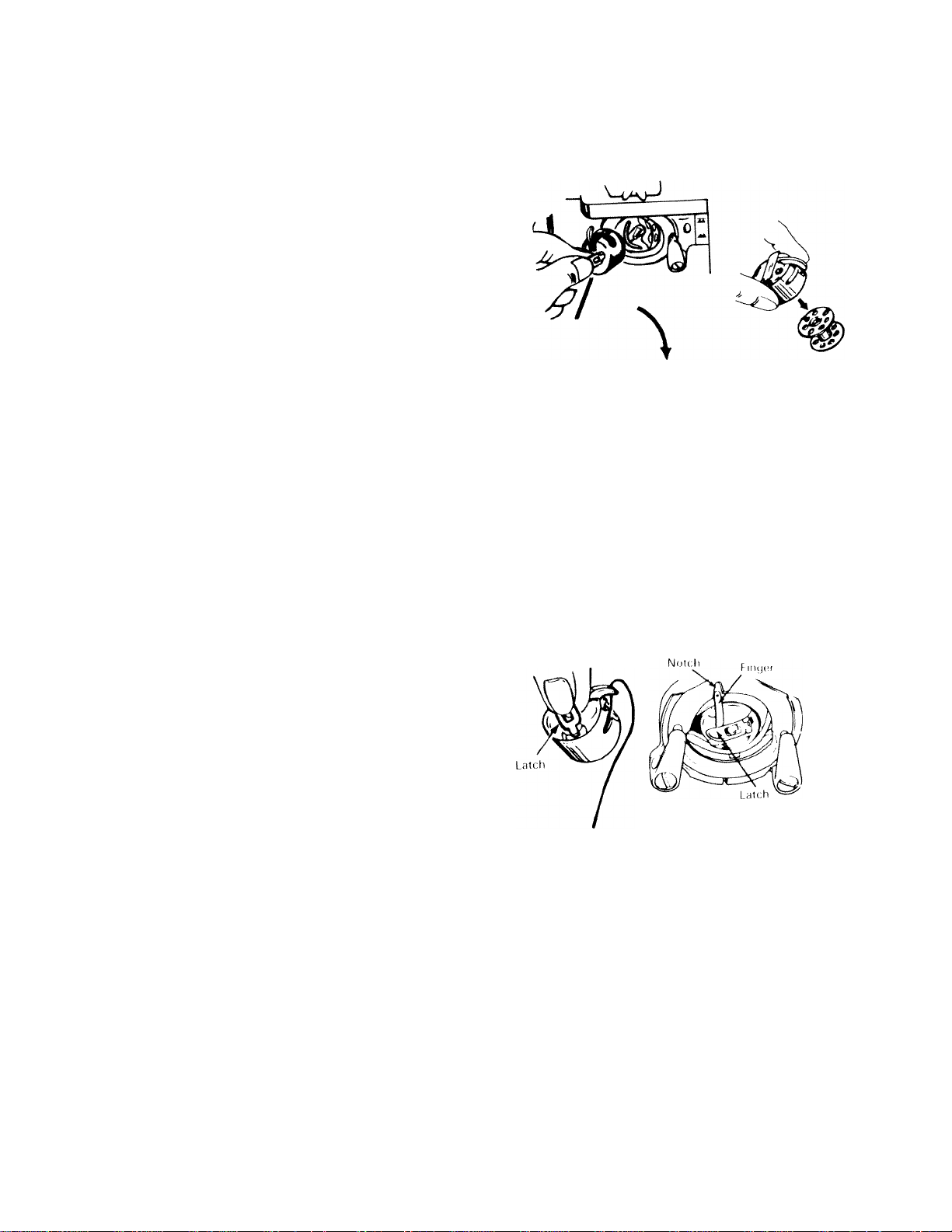

CHANGING THE BOBBIN

TO REMOVE THE BOBBIN FROM BOBBIN CASE:

• Raise needle bar to its highest position. Bobbin case cannot be

removed when needle bar is at low position.

• Open shuttle race cover, pull bobbin case latch with two fingers and

remove bobbin case as shown above.

• Remove bobbin from bobbin case by releasing latch.

TO ATTACH THE BOBBIN CASE:

• Pull thread at least 3 inches from bobbin.

• Thread bobbin as shown on page) 7 ).

• Making sure that needle bar is at its highest position, insert bobbin

case into shuttle race by holding bobbin case latch. Make sure bob

bin case finger is inside shuttle notch. Press bobbin case into shuttle

as far as possible until latch catches on center post of the shuttle.

Page 9

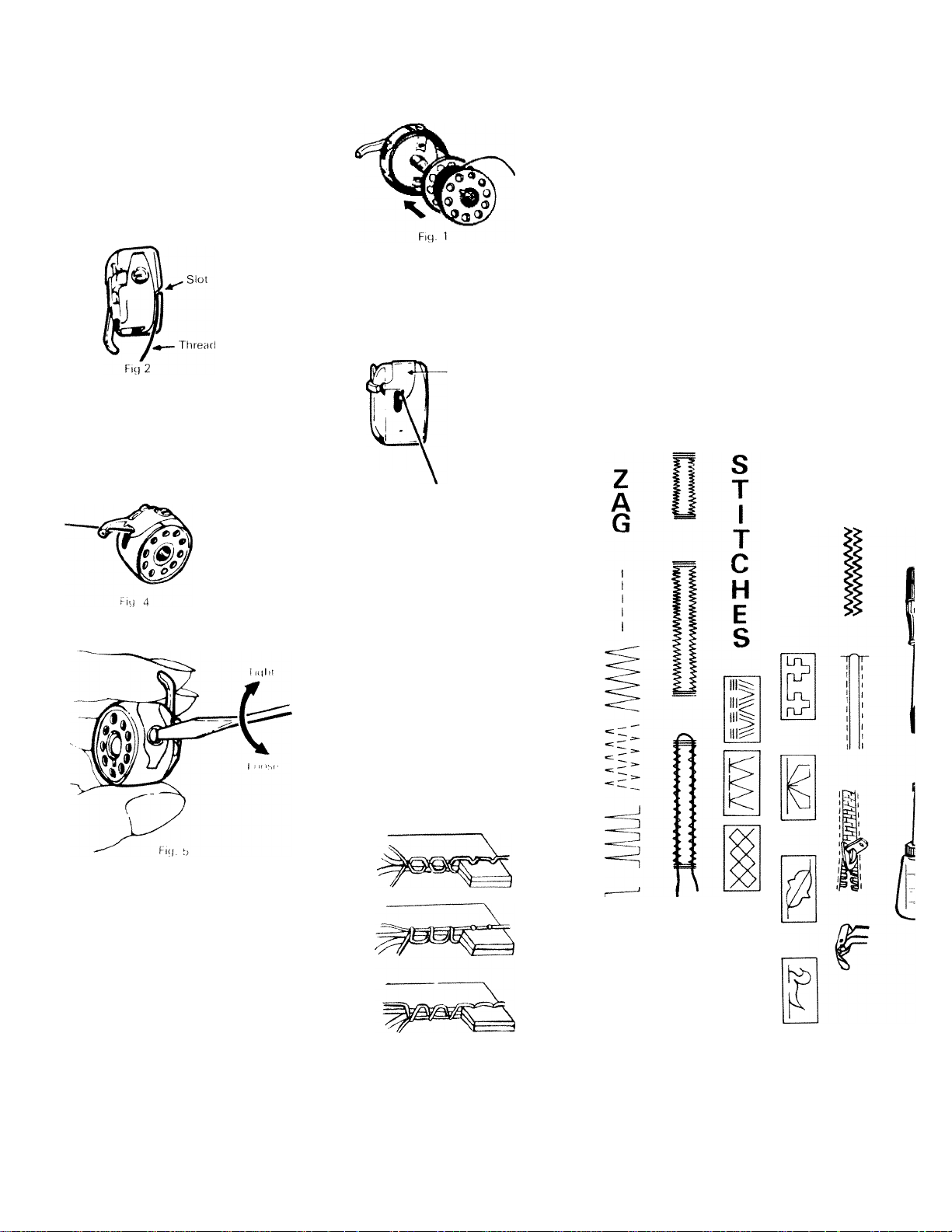

THREADING THE BOBBIN CASE

Pull |[ire;i(l at least 3 inches from bobbin,

hu.uti bobbin in bobbin case so that

ihtu.id will unravel clockwise.

Pull thread into slot of bobbin case

as shown in Fig. 2.

Draw thread under the tension spring and

into the fork'Shaped opening of the spring

• IS sliown in Fig. 3.

Pull thread through hole in bobbin case

finger as sliown in Fig. 4.

(Recommended for /ig/ag sewing only)

}-it). 3

Tensfon Sprint)

s

T

R

A

I

G

H

T

A

N

D

Z

I

G

B

U

T

T

o

N

H

O

L

E

S

S

T

R

E

T

C

H

T

Y

U

T

I

L

I

F

U

N

S

T

I

T

c

H

E

S

D

E

C

0

R

A

T

1

V

E

F

E

A

T

U

R

A

N

D

P

A

R

T

S

P

(

INCORRECT

TOP TENSION TIGHT

BOTTOM TENSION LOOSE

INCORRECT

TOP TENSION LOOSE

BOTTOM TENSION TIGHT

TO ADJUST BOBBIN TENSION.

• Turn screw Oft side of Itobbin

case clockwise to increase!

tension.

• Turn screw on side of bobbin

case counterclockwist! to

decreast! tension.

CORRECT

CT_.

k

Page 10

UPPER THREADING

Rei

anc

Th(

Th(

Set

Mo

Rei

Raise needle bar to its highest position^

SthrSd'through top plate thread guide (1 ) and between tensiot

Puli'tead down a.ound am, thmad guido 13: and up lo take-u,

LOM ‘.hiead through evelet on rake-up lave, from ugh. ro lei, an,

[¡rn’rm^gh laca^ Plata guida (hi, ¿rirn^r'm.o,,,,

Pull thread down through needle elamp gui ^

needle hole from front to rear (7),

Always use the same type of thread on top and bottom as differet

sizes or types of thread will cause tension problems. ,

Example Polyester thread on the bobbin and cotton thread on to

will result in poor tension quality.

8

Page 11

TWIN NEEDLE UPPER THREADING

• Follow threading instruction for single needle with these exception.

• Place thread, matching or contrasting in color, on both spool pins.

• Draw threads through thread guides as normal, but separate the

ilireads at the tension.

• Pass on thread through the left disc and one thread through the right

disc.

• Now treat both threads as one until you reach the needle eyes.

ZIGZAG DIAL: Set at desired width between "O" and "3," if you set

ImI higher than 3, the needle will hit the needle plate and break.

STITCH LENGTH; Set at desired stitch length.

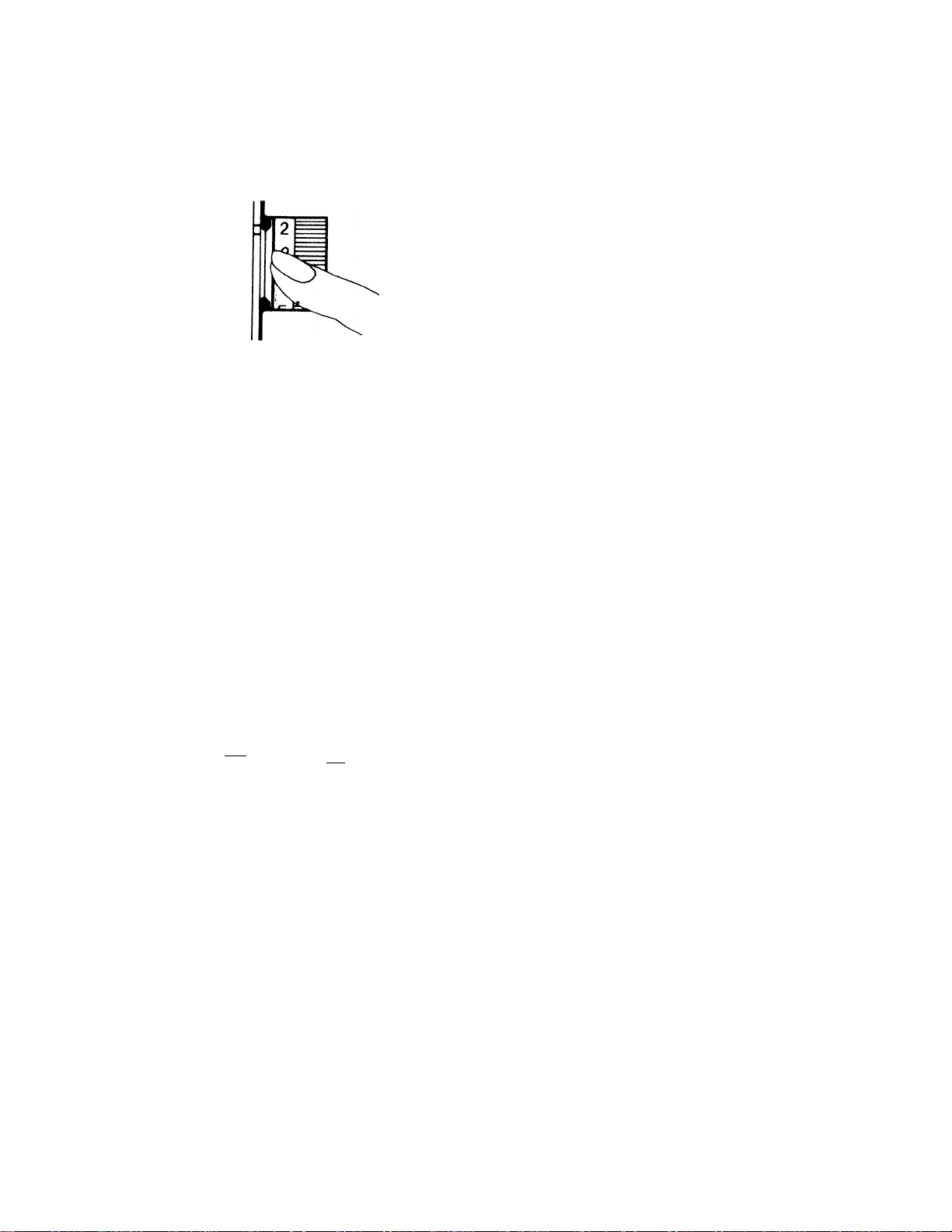

ADJUSTING FEED DOG HEIGHT

s

T

R

A

G

H

T

A

N

D

Z

G

Z

A

G

B

U

T

T

I

O

N

H

O

L

E

S

s

T

R

E

T

C

H

U

T

I

L

I

T

I

Y

S

T

I

T

C

H

F

U

N

S

T

I

c

H

E

S

D

E

C

0

R

A

T

1

V

E

A

T

U

R

A

N

D

P

A

R

T

S

E

S

/

U|)per position of feed dog is used for normal sewing. To raise feed

I log.

I’ress drop feed button " 4A " located under shuttle cover to upper

position.

1

ower position is used for Embroidering, Mending or Sewing on

ihitton. Press drop feed button "HT" to lower position.

ml

' ► *

in;

k

Page 12

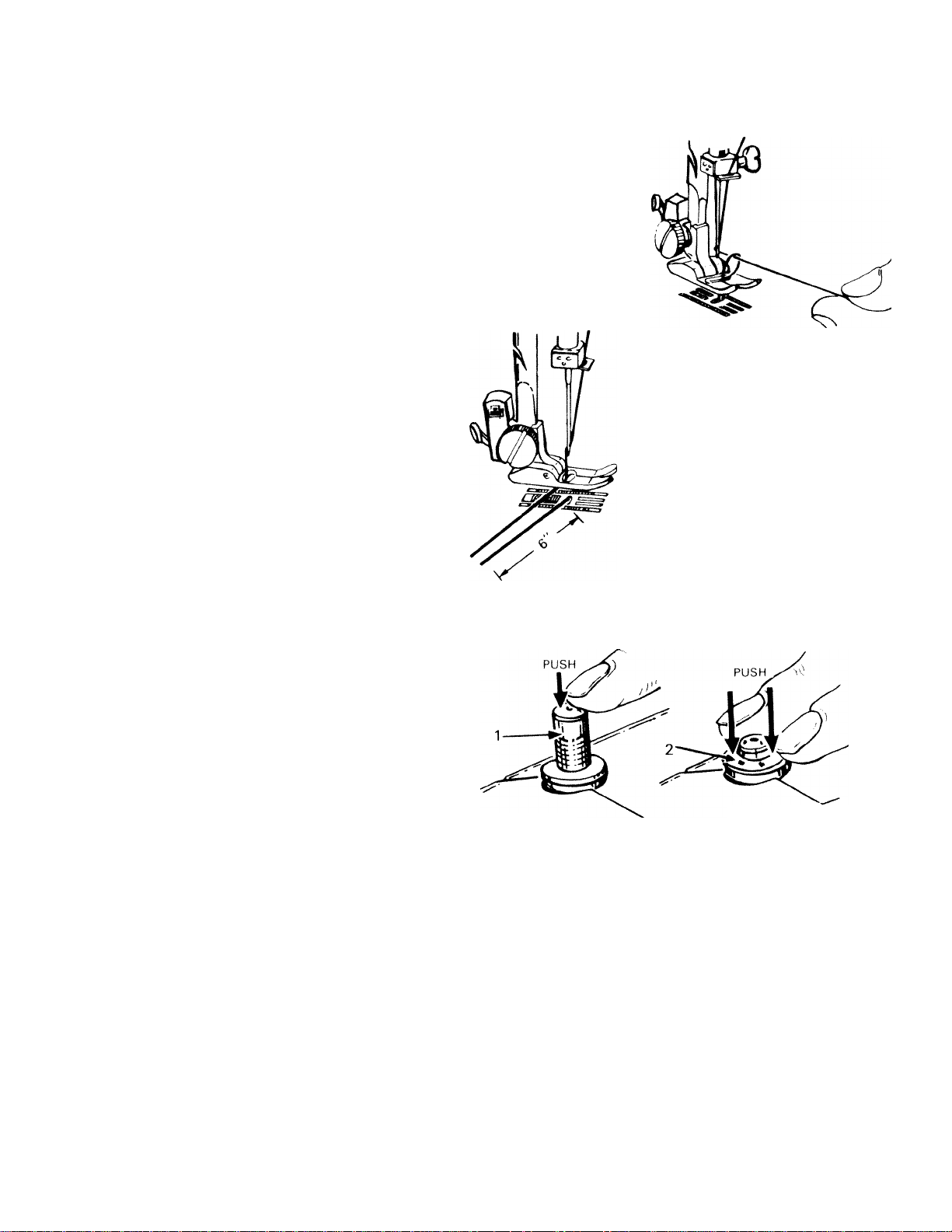

PICKING-UP LOWER BOBBIN THREAD

Raise presser foot.

Holding upper thread, turn

hand wheel toward you

one rotation.

When take-up lever is at its

highest position, pull thread

to pick up loop of lower

bobbin thread.

Pull both upper and lower thread

"to the left of" presser foot ap

proximately 6 inches.

This will prevent jamming.

Re(

anc

Tht

Tht

Sei

Mo

Rel

REGULATING PRESSURE

Fig. 1

The amount of pressure that is applied to the fabric by the press(

foot is adjusted by the pressure cap (1). The upper position gives th

least amount of pressure while the lowest position gives maximui

pressure.

To increase the pressure, push down on the pressure cap to obta

the desired setting. To decrease the pressure, press down on tf

snap lock ring (2) to allow the pressure cap to return to its maximu

height. Then reset to the proper pressure.

Normally the pressure cap will be in the lowest position. If the tc

layer of fabric tends to push out further than the bottom layer

fabric. Pressure should be decreased. This often happens on bull

fabrics, such as wools, and on knits.

Fig. 2

10

Page 13

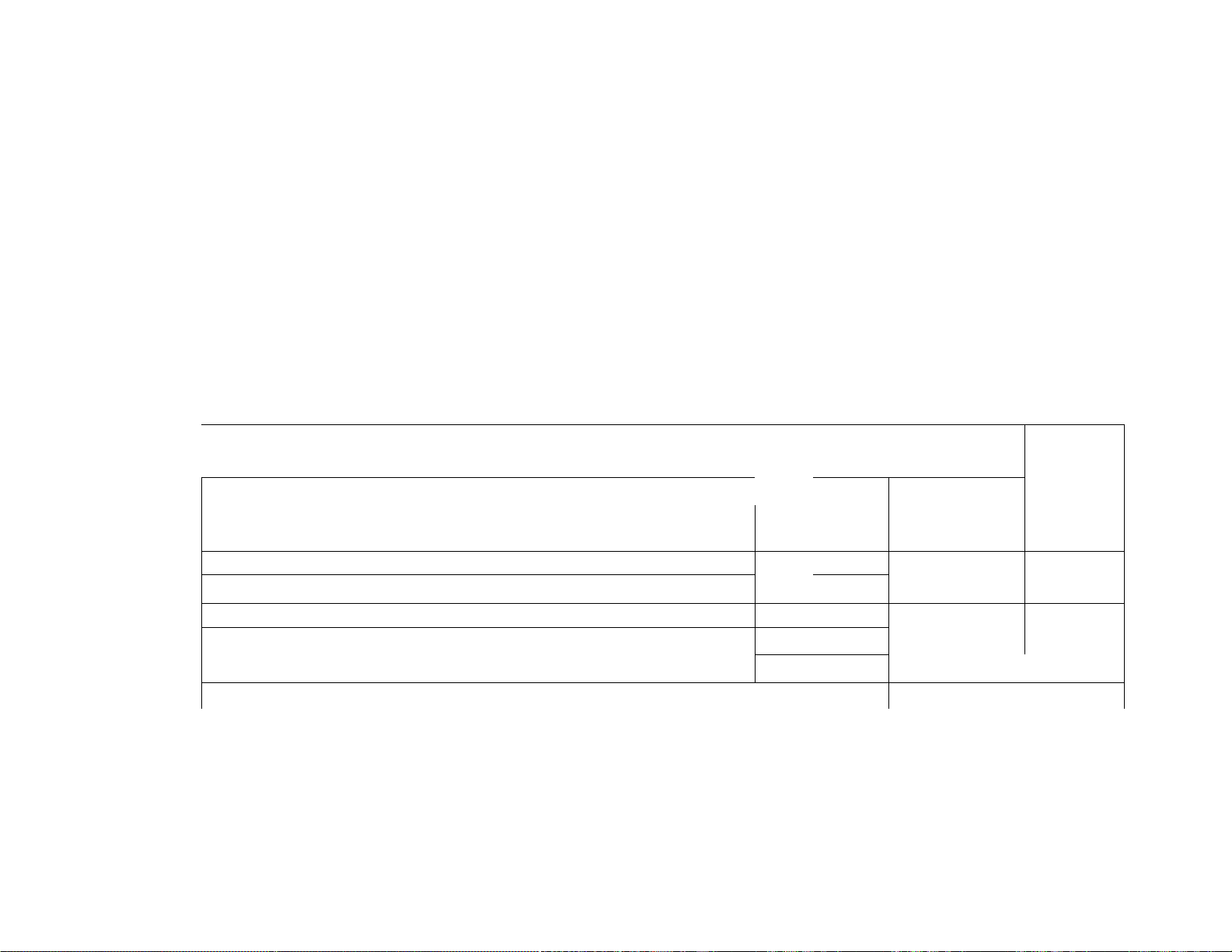

ADJUSTING UPPER TENSION

To increase upper tension, turn upper tension regulator to higher

number.

To decrease upper tension, turn upper tension regulator to a lo

wer number.

Turning tension regulator from ”0" to "9" will increase tension. Nor

mal sewing is performed between "4" and "5".

Note: Normal stitches will be performed on the red zone at 4, 5 and

6 for regular cotton threads.

s

T

R

A

G

H

T

A

N

D

Z

A

G

B

U

T

T

I

O

N

H

O

L

E

S

S

T

R

E

T

C

H

U

T

I

L

I

‘"7*'

Y

S

T

I

T

C

H

E

S

Fi<). 1.

Proper Tension

Fig. 2

Fig- 3

A perfect straight stitch will be formed with both threads interlock

ing in fabric as shown in Fig. 1,

When using the zig zag stitch for embroidery (satin stitching),

decrease upper tension so that top surface will look smooth at the

expense of the bottom surface.

^ №

Upper Thread Tension Too Loose

Upper Thread Tension Too Tight

11

-c/~

.....

g

5

III;

hi

Page 14

33 ^ C/) H H 5

<t) CD IT ^ 5 5

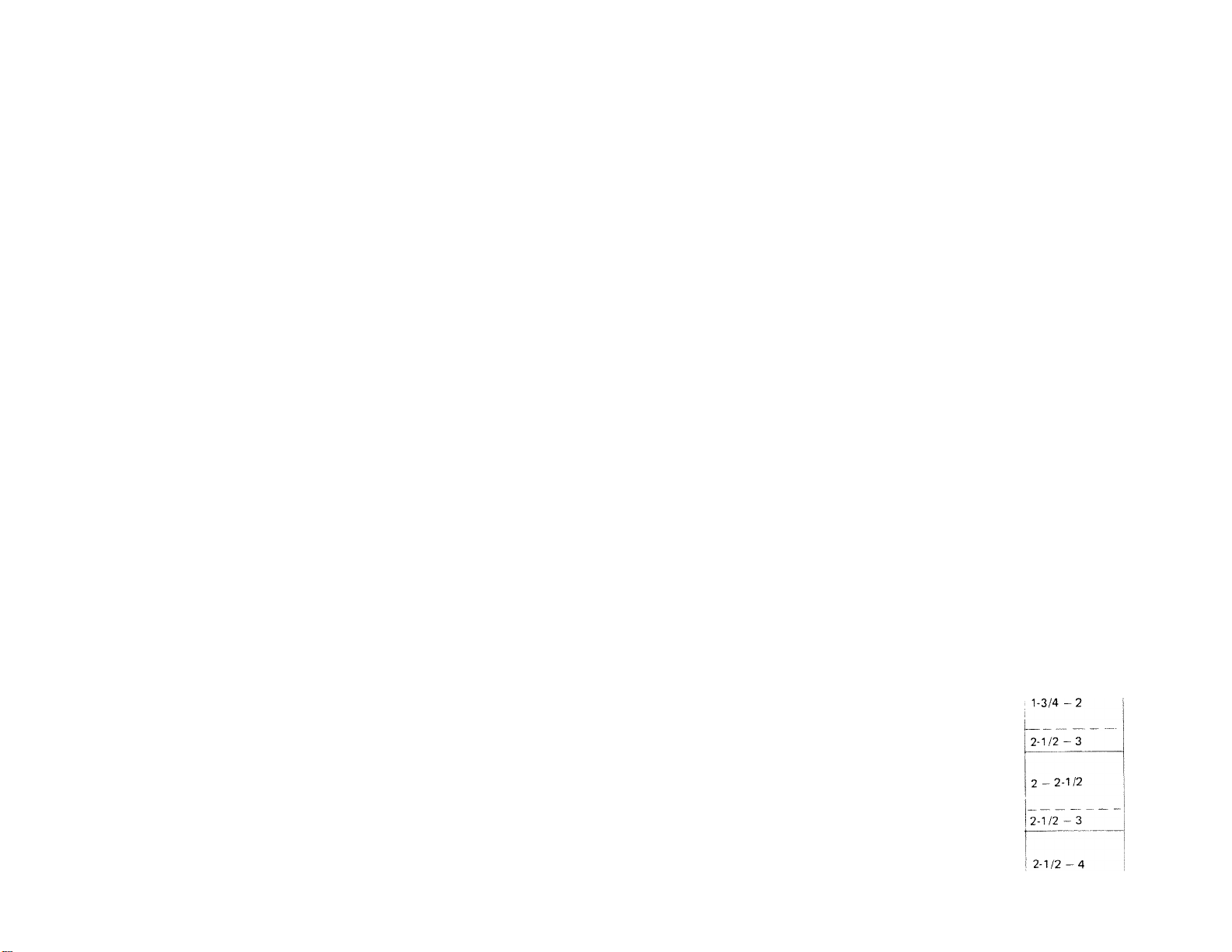

FABRIC, THREAD AND NEEDLE CHART

FABRIC

DELICATE - tulle, chiffon, voile, fine lace, organdy, lawn, crepe, taffeta

Knits — sheer tricot

LIGHTWEIGHT - batiste, organdy, voile, taffeta, silk, crepe, chiffon, velvet

KNITS - tricot, brushed tricot, jerseys, synthetic leathers, power net

LEATHERS — plastic film, vinyls

MEDIUM WEIGHT - gingham, percale, linen, chintz,faille, satin, corduroy, velvet, suitings, wools,

pique, terry _

KNITS - jersey, double knit power net, bathing suits

LEATHERS - vinyls, plastic film

MEDIUM HEAVY ^ gabardine, tweed sailcloth, denim, duck, coatings, wools, drapery. 16

KNITS - double knit, power net

LEATHER — vinyl, rubber backed drapery fabric

HEAVY — overcoatings, canvas, upholstery, awning

KNITS - fake furs, velours, sweater

LEATHERS - vinyls, plastics

light ball point

light ball point

Wedge point

light or medium

Wedge point

! heavy ball point

Wedge point

Wedge point

I

NEEDLE (Long Scarf)

HA X 1

11

14

______

130/705H

Eu ropean

bai jjaq^m t_

100

18 110

heavy ball point

Fine mercerized 60

70

Eu ropean 50 — 70

"A” Silk

Fine Synthetics

80

Fine mercerized 60

European 50 — 70

Fine Synthetics

"A” Silk

Mercerized 50

90

European 30

"A” Silk

Synthetic

Mercerized 50

Heavy Duty Mercerized

j European 30

I

"A" Silk

! Synthetic

Heavy Duty Mercerized

European 30

Synthetic

STITCH

THREAD

LENGTH

1-1/4 - 1-3/4

1- 3/4 ^ 2

2- 1/2 -3

Page 15

ADJUSTING UPPER TENSION

To increase upper tension, turn upper tension regulator to higher

number.

To decrease upper tension, turn upper tension regulator to a lo

wer number.

Turning tension regulator from “0" to "9" will increase tension. Nor

mal sewing is performed between "4" and "5".

Note: Normal stitches will be performed on the red zone at 4, 5 and

6 for regular cotton threads.

s

A

G

H

A

N

D

Z

A

G

T

R

I

T

U

T

T

O

N

H

O

L

E

S

B

S

T

R

E

T

c

H

u

T

L

T

Y

S

T

T

C

H

E

S

F

U

N

F

E

A

T

S

T

I

T

U

R

E

S

c

H

I

E

S

I

D

E

C

0

R

I

A

T

1

V

E

A

N

D

P

A

R

T

S

Fig, 1.

Proper Tension

Fig, 2

Upper Thread Tension Too Loose

......

f

> ... ,......

•>...

4

Fig. 3

A perfect straight stitch will be formed with both threads interlock

ing in fabric as shown in Fig. 1.

When using the zig zag stitch for embroidery (satin stitching),

decrease upper tension so that top surface will look smooth at the

expense of the bottom surface.

^ ^_________

Upper Thread Tension Too Tight

_

11

iii^

111%

iii^

■ i;

k

Page 16

Tn ^ co H ~l ?

£ o ^ ? S' 2 ®

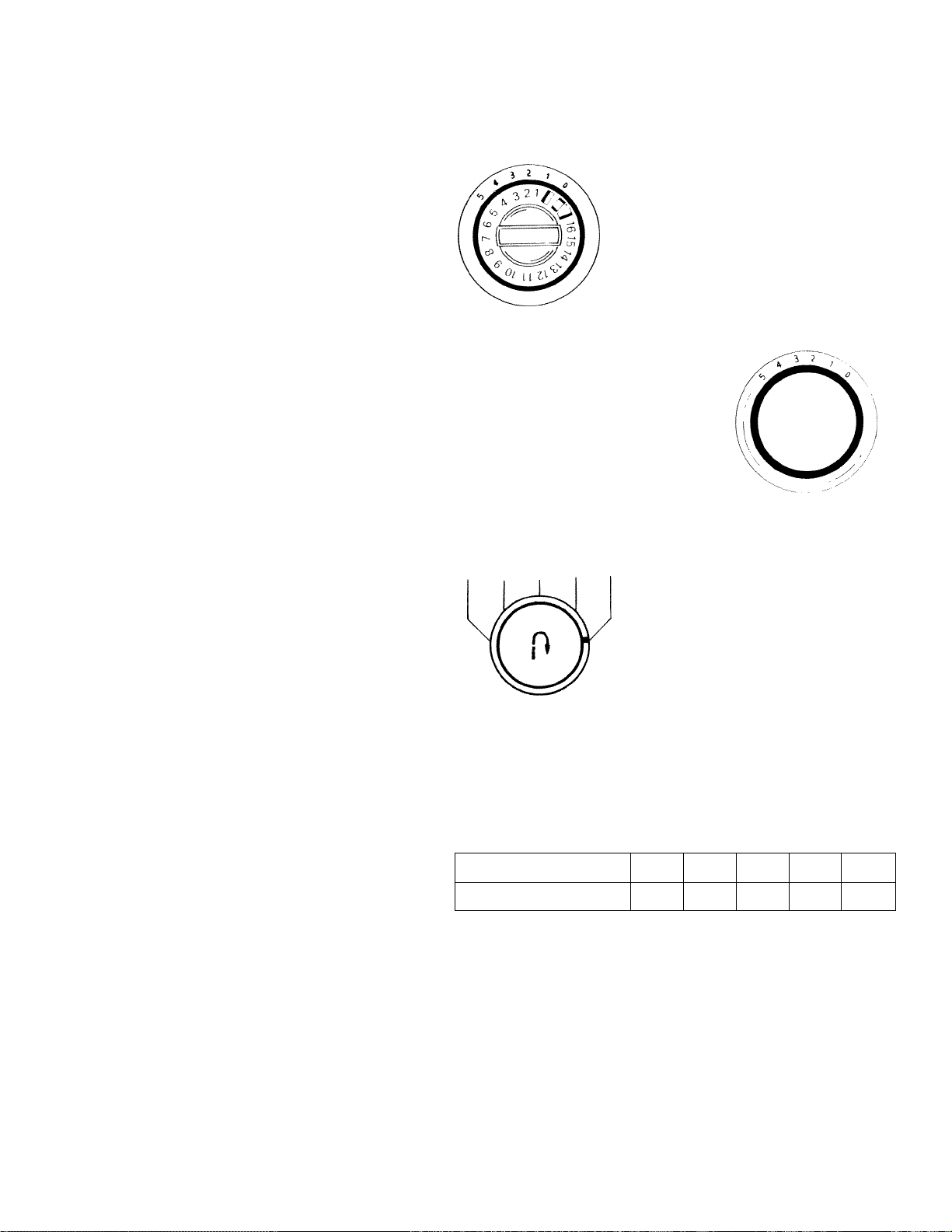

FABRIC, THREAD AND NEEDLE CHART

NJ

FABRIC

DELICATE - tulle, chiffon, voile, fine lace, organdy, lawn, crepe, taffeta

Knits - sheer tricot

LIGHTWEIGHT - batiste, organdy, voile, taffeta, silk, crepe, chiffon, velvet

KNITS — tricot, brushed tricot, jerseys, synthetic leathers, power net

LEATHERS - plastic film, vinyls

MEDIUM WEIGHT - gingham, percale, linen, chintz,faille, satin, corduroy, velvet, suitings, wools

pique, terry

KNITS - jersey, double knit power net, bathing suits

LEATHERS - vinyls, plastic film

MEDIUM HEAVY ^ gabardine, tweed sailcloth, denim, duck, coatings, wools, drapery.

KN ITS - double knit, power net ^ ^

LEATHER - vinyl, rubber backed drapery fabric

HEAVY — overcoatings, canvas, upholstery, awning

KNITS - fake furs, velours, sweater

___________

HA X 1

3

11

14

(Long Scarf)

130/705H

Eu ropean

NEEDLE

light ball point

light ball point

Wedge point

r~Iight or medium

I

_____ balLjsoiriX^

I Wedge point

16

heavy ball point

Wedge point

18 ^ 110

heavy bali point

m/oHnp nnint

THREAD

Fine mercerized 60

70

Eu ropean 50 — 70

A Silk

Fine Synthetics

80

Fine mercerized 60

European 50 — 70

Fine Synthetics

"A" Silk

Mercerized 50

90

"A" Silk

Synthetic

Mercerized 50

I Heavy Duty Mercerized

1 European 30

^ "A" Silk

j Synthetic

I Heavy Duty Mercerized

i European 30 I 2-1 /2 — 4

Synthetic

_____________

STITCH

LENGTH

1-1/4 - 1-3/4

1-3/4 - 2

2-1/2 -3

2-1/2

2 --2-1/2

2-1/2 - 3

Page 17

Point Eye

Shaft

Body

CiO

r^

/ Round

Flat

Short Groove Long Groove

(Flat Side of Needle) (Round Side of Needle)

Regular Sharp All purpose Medium Ball

Needle Needle Point Needle

A A A A A

r

l\l\l\l\l\

I y 'I y 'i \

MT

Long Groove -

Elongated Scarf -

Short Groove-

Eye -

Wedge Point

Needle

0>N O-N OZ> HIO->3JHCn

inr fflZ ^5^ AAA

mmm

P|K |WWWVVVVAAAAAWIAAWV^ ||WWww*yv^

Jr llvHvvvvvwvwviAwwwvwJl wwwimmmJII

\\V/A\V//

C/)miOH-------------------------------------¡(/) <H —r------------------------------------1C lOHm33HO)

rn<----------------------l>30OOmD 0)mIOH

COH30>-0 OZ> cnm30CH>m-n

--------------------------------------------------------------------

0)mr-OIZOHHCD3

1C/) ZCti

Page 18

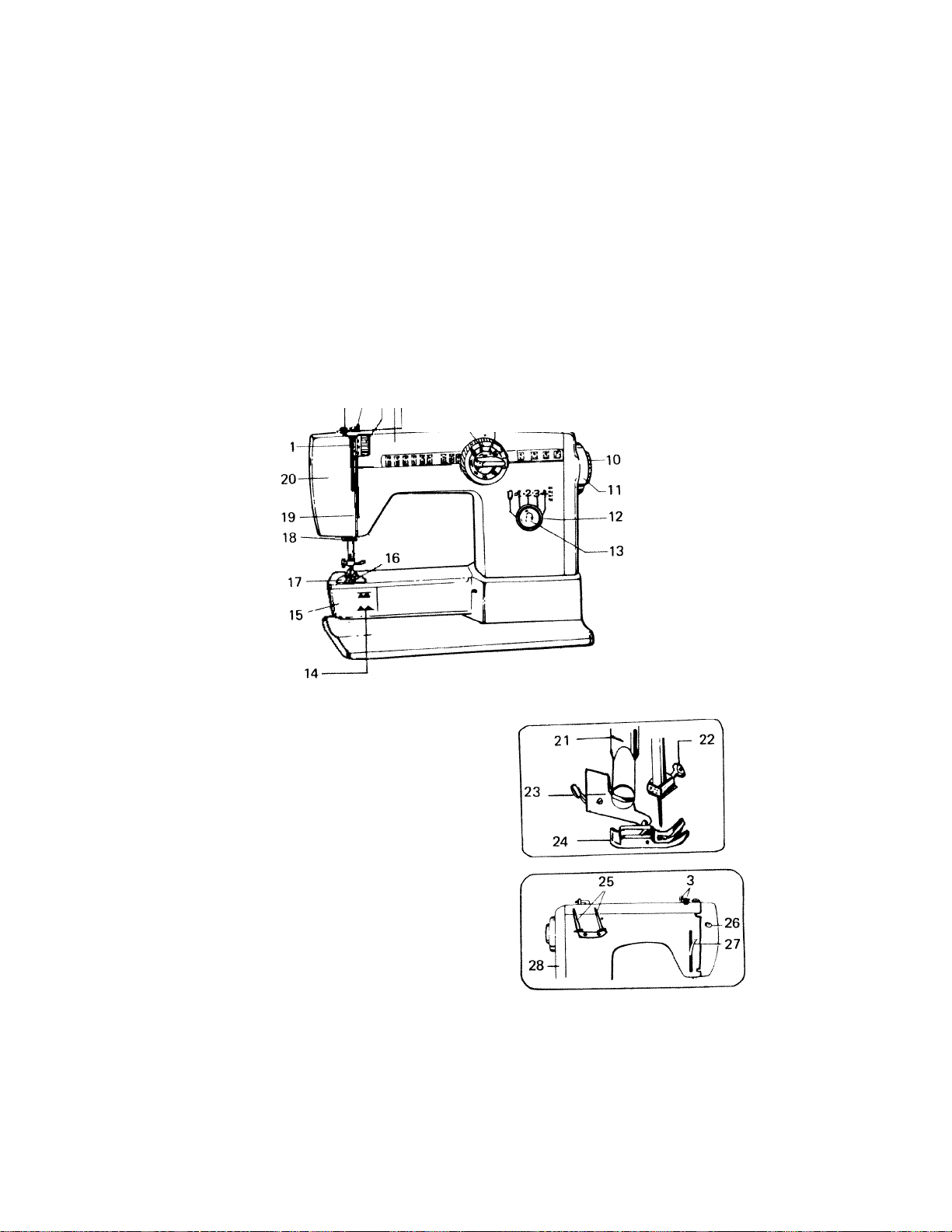

FUNCTIONS OF CONTROLS

NEEDLE POSITION AND PATTERN

SELECTOR DIAL

• Raise needle bar to highest position b'

turning hand wheel toward you.

• Select desired pattern and needle

position.

• Selector dial can be turned either

clockwise or counterclockwise.

ZIGZAG WIDTH CONTROL DIAL

• For wider zigzag stitch, select a higher

number.

• When twin needle is used, zigzag must

be limited between positions "0" and

"3" on the dial (use of twin needle

in position higher than "3" will result

in needle striking needle plate).

Rei

am

Th(

Th(

Sei

Mo

Rei

nr~l 1 2 3 4 111*

STITCH LENGTH CONTROL DIAL

• Numbers on dial denote length of stitches.

• To increase length of stitch, turn dial to higher number.

STITCH LENGTH GUIDE

Numbers on dial

Stitches per inch

0

No Feed 24

1

REVERSE STITCH BUTTON.

• Use for reverse stitching or tacking.

• Keeping button pressed in will allow you to sew reverse stitch

same length as forward stitch.

2

12

3 4

8 6

14

Page 19

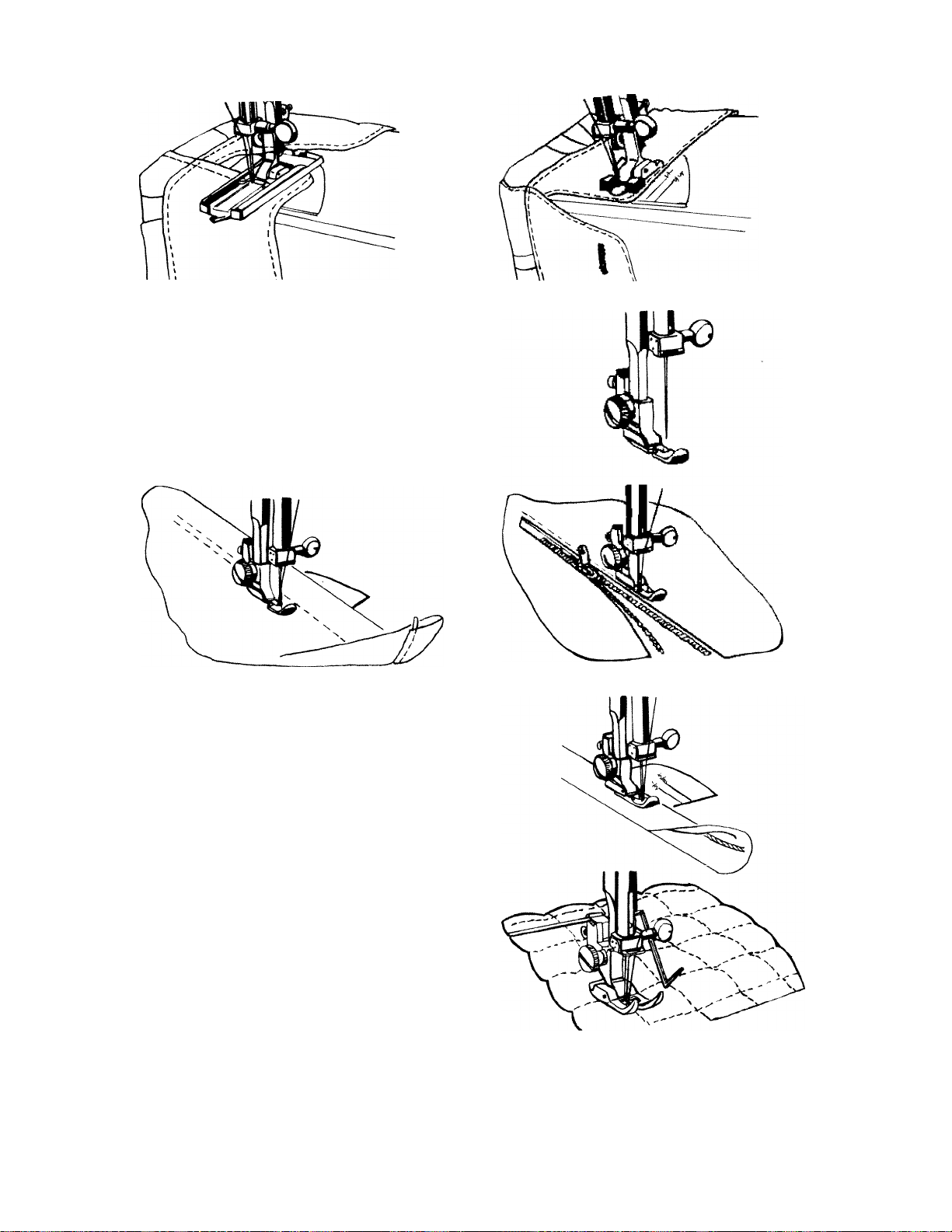

APPLICATIONS OF THE STRAIGHT STITCH

SEAMS

The normal stitch length for most fabrics is 3, but the length chosen

depend on the fabric and area of usage. Usually, heavier fabrics

longer stitches, and lighter weight fabrics require shorter stitches.

For curved seams and bias cut areas use a shorter stitch length to

strength and elasticity to the seam.

Pattern:

.......

Length: 2

Width: 0

Feed Dog:.

Pressure: Normal

Foot: All Purpose

Needle Position: 2

BASTING/TOPSTITCHING

Sewing a seam with a longer stitch is useful for temporary seams prior

to fitting. Basting stitches also may be used when gathering in fullness.

Topstitching can be done very effectively with the long straight stitch.

For a bolder stitch, two threads of the same type can be threaded

through one needle (size 14 or 16). A heavier thread such as buttonhole

twist may be used for topstitching, but be sure to use a larger needleisize

16 or 18). Left needle position may be used for more support of fabric.

Pattern:

Length: 4

Width: 0

Feed Dug:

Pressuie: Nnrmal

Foot: All Put|)Ose

Needle Position: 2 or 1

DARNING

Worn spots or small holes can be darned very easily. Use of an

embroidery hoop is optional depending on the fabric. A fine thread

is recommended so that the fabric and thread will blend together invisibly.

Trim the ragged edges from the area to be darned, Hold the threads to

start, then move the fabric slowly back and forth while running the

machine very fast to fill the area. More professional results will be

attained by moving the fabric in a figure eight pattern while sewing.

After filling in the area lengthwise, reweave with crosswise stitches in the

same manner.

should

require

add

s

T

R

A

G

H

T

A

N

D

Z

A

G

B

U

T*

T

I

o

IM

H

S

T

R

E

c

H

o

L

u

T

I

L

I

T

Y

S

T

I

T

C

H

E

S

I,I

'¡¡S

Pattern: Length: 0

Width: 0

Feed Dog:

Pressure: Darn

Foot: None or All

Purpose

Needle Position: 2

k

15

Page 20

ELASTIC THREAD SHIRRING

Wind elastic thread onto bobbin, as shown, let^

ting the thread pass through your fingers. The

thread should be wound smoothly without stret

ching. Place bobbin in case as usual, being sure

that the elastic is drawn through the tension. Use

regular thread on the top of the machine. Do a

trial run on the chosen fabric to test length of

stitch. Lay a piece of paper under the fabric to

keep it from gathering up as you sew. This will

enable you to sew many parallel rows of stitching

without difficulty. Afterwards tear out the paper

and the fabric will be gathered.

P.ifUif n:

Luntjfh: 3

WidtlrO

FotMt n.ur A.A

F’rcssuM!; Nomiai

Foot: All F’(if|)!)So

NtM-’filtt Position: 2

4

• HOLDING THE FABRIC

For most fabrics, it is not

necessary to hold the fabric in

both front and back. Merely

guide the fabric with one hand

R

a

T

1

from the front.

For the fine delicate fabrics,

such as chiffon, geogrette, and

tricot, the best resits will be at

tained by holding the fabric in

front and back of the needle

without pulling on it.

. TURNING CORNERS

To pivot at a corner, leave the

needle in the fabric while on the

upswing so that the stitch is

almost completed, thus preven

ting the possibility of skipped stit

ches in the corner. Lift the

presser foot and pivot the fabric.

Then, lower the presser foot and

continue sewing.

•

• CURVED SEAMS

On a curved seam use a slightly shorter stitch length than you are using

for the rest of the seams. For example, if length 2 is being used for the

seams, a 1-1/2 stitch length would be preferred for curves. A smaller

stitch length will add strength and elasticity to the seam.

When guiding the fabric, keep your fabric edge on the etched seam

guide line directly across from the needle rather than on the forward part

of the line. The seam guide may be used on an angle as shown.

16

Page 21

• ENDING SEAM/REMOVAL OF FABRIC

Stitch to the edge of the fabric, then press the reverse stitch button and

backstitch for a few stitches to reinforce the end of the seam.

Turn the hand wheel until the take up lever is in its highest position so

that the stitch is completed and the threads will pull freely. Lift the

presser foot and remove the fabric by drawing the threads to the left and

back, keeping them under the foot so as not to bend the needle. Cut the

threads with the thread cutter on the back of the presser bar. Leave the

thread ends three to four inches long.

APPLICATIONS OF THE ZIGZAG STITCH

OVERCASTING

Place the edge of the material underneath the

opening of the sewing foot and guide raw edge

along the center groove of the foot, allowing

stitch to form half on and half off the fabric.

The multiple stitch zigzag is a wiser choice for

most fabrics. See page(21).

Pattern: AAA

Lenght: 2 4

Width: 4-5

Feed Dog:

Pressure: Normal

Foot: All Purpose

Needle Position: 2

B

u

T

T

o

N

H

O

L

E

S

S

T

R

E

T

C

H

U

T

I

L

I

T

Y

S

T

I

T

C

H

E

S

Hip

siS

V

SEAMING KNITS

The narrow zigzag can be used in seams of firm

knits for added strength. After sewing, open

seam and press flat. Tiny zigzag stitches can

hardly be seen and the seam will give when stret^

ched.

Pattern: /Wy

Lenght: 2

Width: 1-2

Feed Dog: A A

Pressure: Normal

Foot: All Purpose

Needle Position: 2

17

k

Page 22

SEWING ON BUTTONS

Zigzag stitching is a very easy and convenient

method of sewing on button without a shank.

Place the button so its left hole comes directly

under the needle, then gently lower the button

sewing foot. Take a stitch in the hole.

Raise the needle and move zigzag width dial to

the right until the needle comes down exactly

over the right hole in the button.

Note: Be sure the needle dears the holes of the

button by moving the hand wheel by hand

before running the machine fast.

Usually 6 to 8 stitches are adequate for securing

a button in place. Stop with the needle in the left

hole. To lock the threads, set the stitch width at

0, and take a few stitches in the left hand hole.

Pattern; A/V\

Lenght: 0

Width; 2 5

Feed Dog; J[S

Pressure; Normal

p

a

Foot; Button Foot

Needle Position; 1

1

1

c

r

FORMING THREAD SHANK ON BUTTON

Buttons sewn on coats or jackets should have

thread shank to make them stand away from th

fabric. To form a thread shank, sew over a pin c

rounded toothpick which can be inserted directI

into the button sewing foot.

After stitching the button to the fabric, remov

work from under the presser foot leaving threat

about six inches from fabric. Remove pin c

toothpick. Pull the threads to back of button an

form a shank between button and fabric b

winding threads tightly around the attaching sti

ches. Pull threads to back of the fabric and the

tie thread ends securely.

18

Page 23

• ENDING SEAM/REMOVAL OF FABRIC

Stitch to the edge of the fabric, then press the reverse stitch button and

backstitch for a few stitches to reinforce the end of the seam.

Turn the hand wheel until the take-up lever is in its highest position so

that the stitch is completed and the threads will pull freely. Lift the

presser foot and remove the fabric by drawing the threads to the left and

back, keeping them under the foot so as not to bend the needle. Cut the

threads with the thread cutter on the back of the presser bar. Leave the

thread ends three to four inches long.

APPLICATIONS OF THE ZIGZAG STITCH

OVERCASTING

Place the edge of the material underneath the

opening of the sewing foot and guide raw edge

along the center groove of the foot, allowing

stitch to form half on and half off the fabric.

The multiple stitch zigzag is a wiser choice for

most fabrics. See page(21).

Pattern: AAA

LeiKjtil: 2 4

Width: 4 5

Feed Dog:

Pressure: Normal

Foot: All Purpose

Needle Position: 2

В

и

т

т

о

N

Н

О

L

Е

S

S

т

R

Е

Т

С

Н

и

Т

I

L

I

Т

Y

S

Т

I

с

н

Е

S

III#

iii^

SEAMING KNITS

The narrow zigzag can be used in seams of firm

knits for added strength. After sewing, open

seam and press flat. Tiny zigzag stitches can

hardly be seen and the seam will give when stret-

"ched.

Patterii: АЛЛ

Lenght: 2

Width: 1-2

Feed Dog: A A

Pressure: Normal

Foot: All Purpose

Needle Position: 2

17

К

Page 24

SEWING ON BUTTONS

Zigzag stitching is a very easy and convenient

method of sewing on button without a shank.

Place the button so its left hole comes directly

under the needle, then gently lower the button

sewing foot. Take a stitch in the hole.

Raise the needle and move zigzag width dial to

the right until the needle comes down exactly

over the right hole in the button.

Note: Be sure the needle dears the holes of the

button by moving the hand wheel by hand

before running the machine fast.

Usually 6 to 8 stitches are adequate for securing

a button in place. Stop with the needle in the left

hole. To lock the threads, set the stitch width at

0, and take a few stitches in the left hand hole.

PatU!fn: A/V\

Lenijht: 0

Wiiltl); 2 5

Fef?d Dog: jBE

Prffssurf;;

p

a

1

1

c

r

Button Font

Nfitfcilu Position: 1

FORMING THREAD SHANK ON BUTTON

Buttons sewn on coats or jackets should have

thread shank to make them stand away from th

fabric. To form a thread shank, sew over a pin c

rounded toothpick which can be inserted directI

into the button sewing foot.

After stitching the button to the fabric, remov

work from under the presser foot leaving thread

about six inches from fabric. Remove pin c

toothpick. Pull the threads to back of button an

form a shank between button and fabric b

winding threads tightly around the attaching sti

ches. Pull threads to back of the fabric and the

tie thread ends securely.

18

Page 25

s

I

SATIN STITCHING

This is useful for decoration such as tapering,

manual designed embroidery, monogramming,

and applique.

The satin stitch, which is a very close zigzag

stitch, is obtained by setting the stitch length as

near to "0" as possible without stopping the

feeding action. The setting will vary for different

fabrics. It may be desirable to loosen the upper

tension slightly to cause the threads to lock

underneath, in order to make the top surface

look especially smooth. For lightweight fabrics,

place paper underneath the fabric while sewing

for best results.

TAPERING/CREATIVE EMBROIDERY

Tapering is done by gradually increasing and

decreasing the stitch width while sewing. By this

method, tapered monograms and other in

teresting designs can be created. For tapered

monograms run the machine fast while turning

the width dial slowly from narrow to wide and

back.

First, learn this stroke by letting the fabric guide

straight. Then, learn to pivot the fabric as you

are tapering by holding the fabric at one point.

Various strokes can be combined to form letters

and designs. Variegated thread can give attrac

tive results.

P,ytlem: AAA

Longhl: '/2 ’/3

Width: 0 5

Fetxi Dog: AA

Prtissiirfo Normal

Foot: All Purpose

vb'

Needle Position: 2,1 or 3

Pattern: /\AA

Length: % ’/3

Width: 15

Feed Dog:

Pressure: Normal

Fool: All Purpose

Needle Position: 2

B

u

T

T

o

N

H

O

L

s

T

R

E

T

c

H

u

T

I

L

I

T

Y

S

T

I

T

c

H

E

S

!!S

F

U

N

S

T

I

T"

c

H

E

S

D

E

C

0

R

A

T

1

V

A

T

U

R

A

N

D

P

A

R

T

S

nCrr

r

<

MANUAL EMBROIDERY DESIGNS

Different designs can be made by turning the

stitch width dial between 0 and 5. By running the

machine at a constant speed and turning the dial

in a definite rhythm, various designs can be

created.

19

Pattern: A/NA

Length: !4 1/3

Width: 0 5

Feed Dog:

Ptssuie: Notmttl

Foot: All Puipo.se

Needle Position: 2, 1 01 3

i a !

k

k

Page 26

PiilK-ni /\ДД

1 О

WkIHi 1 Ь

Frril Г)<«|: ЖЖ

Nni II'

Ne.

FREE HAND MONOGRAMMING

For giving garments and linens a personalized touch, first transfer the design

the right side of the fabric. An embroidery hoop is recommended especiall’j

for soft fabrics and toweling.In order to monogram, you must move the fat

slowly and run the machine rapidly. Monogramming is like writing by movii

the paper under a stationary pen. Guide the fatrric slowly so that ilie zigzag f

close togetlier like a satin stitch, but be careful tltal the stitches do not pile ii|

When guiding from side to side, move fabric slightly faster to avoid a heavy

area.

Practice try foiming loops. Once this is accomplished any lettr-r is easy,

Somrnimes the use of paper or non woven interfacing uii(iei the fabric

may makr; guiding the fabric easier. Tfte ¡taper or interfacing may be torn

cut away iit tlu; completion of the monogram. Wfien iTKtnogramming towe

cellopltane ¡tiaced on tfie top will Itelt) cover loojts and make the monograi

smooth. Pull oi cut away remaining cellofthane when finisht.af.

11 i .c-yy\

h 1

vViiMli 0-1

1 n<0' -A

Pi i?( ' Nidi

\ 1 и ¡1 ,Afi PiM [ n

Ni n -f Ih ■ P; I

St eft 2

ЛЛЛ

'A %

P\jl u ■( lit ■ [ ’( c.ll h >1 I P

APPLIQUE

Applying decorative shaftes of falrnc sciaps to household articles and dotiti

is a very interesting wtiy of trimming an otlirti wise ¡jlam ai tidit. First, h

the design on fabric to (te applicjutid, thiai ¡tin or ttaste it securely in (tktce

garment. With a small straight stitch or narrow zigzag, sew around the

transferreci design. After excess ftilrric is trimmeti away, srtw aiound the

applique with a satin stitcft. For a sntootli curve, sto[) frequently at the insic

edge of the curve to pivot lite fabric slightly. Corners look mudt better wh

the point is stitched by pivoting rather than just turnrrd.

As with all decorative stitches, paper may he used to give more body to tht

fabric wften stitching and can be torn away wlten the ap|)liqiie is completi;

20

Page 27

GATHERING OVER CORD

Ordinary gathering with a basting stitch often

breaks while pulling in fullness. A small zigzag

across a cord such as crochet thread or carpet

thread, gives a much stronger cord for gathering

fullness into fabrics. Once the gathers have been

stitched in place, the cord can be pulled out in

order to eliminate bulk.

fY

Pattern: /SAA

Lengtii: 2

Width: 3

Feed Dog:

Pressure: Normal

Foot: All Purpose

Needle Position: 1

AA

APPLICATIONS OF THE MULTIPLE STITCH ZIGZAG

OVERCASTING

The multiple stitch zigzag is an excellent choice

for overcasting. It keeps the fabric flat and

prevents raveling. For most fabrics, this stitch is

better than the zigzag stitch for overcasting.

The stitch should fall right at the raw edge of the

fabric. Feed the fabric under the presser foot by

guiding the raw edge along the right hand side of

the hole in the presser foot.

Pattern:

Length: ’/4 1J4

Width: 4 5

Feed Dog:

Pressure: Normal

Foot: All Purpose

Pattern Selector: 5

A A

A

IW

A 'iIIil

B

u

T

T

o

N

H

O

L

E

S

s

T

R

E

T

C

H

U

T

T

Y

s

T

I

T

c

H

E

S

iii^

ksA

........

A A A * A R K K JC

V VVV V V V«

<

>

I

Pattern:

Length: ’A 1

Width: 4 5

Feed Dog: A.A.

Pressure: Normal

Foot: All Purpose

Pattern Selector: 5

PATCHING

The multiple stitch zigzag is an excellent stitch

for patching. It is stronger than the zigzag and

the tiny stitches bury into the fabric to make an

almost invisible stitch when using matching

thread.

Place the patch over the right side of the worn or

damaged area. Sew around the patch with the

multiple stitch zigzag letting the last stitch to the

right overcast the edge of the patch. When turn

ing corners leave the needle in the fabric at the

corner. Usually this will be the furthest stitch to

the right or left. In this way, the corners are

doubly stitched and very strong. When the patch

is stitched in place, trim away the excess worn

fabric on the wrong side of the patch.

Note: Try Smocking Stitch for knits.

21

iii^

k

Page 28

PhUciii /V'/'

i l'!U|ttr NiMF 0 ^2

Width 4 h

( IM.(I l)n(,, aA

f’tdSSUH! Ndiintil

( not, Alt h’lUiKibf

P;itK;m Sfilf.’ctor; 5

MENDING A TEAR OR INSTANT DARNING

The multiple stitch zigzag provides a strong an

easy repair for torn garments. It gives an almo;

invisible mend, especially when a fine darnin

thread is used.

To mend a tear, hold the torn edges clos

together and stitch down the middle.

If the tear is guided under the slot in the micid

of the presser foot, stitching will Ire equal c

both sides. If necessary, sew again on either sic

of the first row of stitching making sure tl

needle catches the stitch in the center. With vt:i

worn or frayed falrric, place a ¡liece of ligh

weight interfacing or cotton batiste under tt

tear for reinforcement.

Note: Try Smocking Stitch for knits.

LACE APPLICATIONS

Attaching laces or trims adds a special touch to

lingerie, dresses, or linens. Pin or haste lact;s In

place easitrg or mitering corners where neces

sary.

A straight edged lacr; or braid has a convenitait

line to follow when sewing. Wlien using a

scalloped edged lace follow the design of the

lace for an almost invisilrle application.

Note: Try Multiple Stitch Zigzag, Overlook,

Elastic Edge Stitch, Smocking stitch,

Stretch Overlook or Rick Rack for differ

ent effects.

22

t..|M|lh I

WhIiIf I ?

Pi.-.snn- Ni

(iH,| AM Pm

Nr..(IM' P.mil

AAA

I On,I ^

Page 29

FLUTTER HEM

An unusual way of hemming or finishing edges

of tricot or soft knits is by a flutter edge. Hemm

ing in this manner is just like overcasting an

edge, but the fabric is stretched in back and in

front of the needle as you sew. For best results,

pull the fabric equally, making sure the needle

goes over the edge. When you stop to reposition

your hands, keep the needle in the fabric.

ELASTIC APPLICATION

Applying elastic to lingerie or soft knit fabrics is

easy when using the multiple stitch zigzag. Cut

the elastic 2 inches smaller than your waist

measurement. Overlap the raw ends to form a

circle and stitch with a tiny zigzag to form a box

as shown. Fold the elastic into quarters or eighths

and mark with pins. Do the same with the waist

line of the garment. Place the elastic about 1/2

inch from the top edge of the fabric, matching

the pins. Place under the presser foot and begin

stitching. As you stitch, place the forefinger of

each hand on the fabric at either side of the

presser foot. Pull the fabric out exactly at the

point where the needle is sewing over the elastic

and the fabric. This will ease your fabric and

elastic together as you sew. The amount of ease

Pattern: ,"v v".

Length: % V/2

Width; 4-5

Feed Dog: AA.

Pressure: Noirnal

Foot: All Purpose

Pattern Selector: 5

is dependent on how much you ease the fabric.

In this way you never need to stretch the elastic,

which can be damaged and stretched out of

shape. Trim off excess fabric above elastic near

the stitches.

A/ote: Try Overlock stitch or Smocking stitch for

girdles.

Pattern: /\/V\

Length: %

Width: 4-5

Feed Dog: A.A

Pressure: Normal

Foot: All Purpose

Needle Position: 2

В

и

т

т

о

N

Н

О

L

Е

S

■..

S

т

R

Е

Т

С

Н

и

Т

I

L

I

Т

Y

S

Т

I

Т

С

Н

Е

S

111^

к

F

и

N

S

Т

I

с

н

Е

S

D

Е

С

0

R

А

Т

1

V

Е

А

Т

и

R

А

N

D

Р

А

R

Т

S

Г

(

23

Page 30

UNDERSTITCHING FACINGS

The multiple stitch zigzag is an excellent choice

for understitching and eliminating bulk in facing

seam allowances.

After attaching the facing to the garment, trim

and clip the seam allowance as usual. Press the

seam allowances toward the facing and use the

multiple stitch zigzag close to the seam, stitching

through the facing and the seam allowances.

Using a matching thread, the stitch will blend in

to the fabric and prevent excess bulk. This is

much more successful than a straight stitch for

understitching. It really helps to keep the facings

from rolling.

Note: Try Smocking Stitch for knits.

PitUiirn: /‘v'vT

L urujlit: 1 2

Wtdth: 4 5

FfffMi Dog:

F’fffssuM.*: Nomiul

Foot; Ail Purpose

Pattern Selector: 5

Stei

Ste

/ X

< >

\ /

\/

/\

/ \

< >

\ /

N/

/\

< >

Ч /

\/

/N

Л

о

ж

A V

/ / / / /

/ / / / /

<<<< <

\ \ \ \ N

>>>>>

/ / / / /

<<<<<

\ \ N \ X

>>>>>

/ / / / /

<<<<<

чЧ \ \ X

>»>>

DECORATIVE EFFECTS

As with the irlind hem stitch, the tiiultiple sti

zigzag can be used for many decorative con

nations. If the stitch is pivoted when thr; net

reaches the far left or right of its swing, and

points are carefully matched, a tracery cJiamc

shape results.

On the other hand, if rows of the multiple sti

zigzag are sewn with the points falling direr

under each other, a wavy pattern is produce

Flowers may also be produced. Start in cen

pivot at points shown. Add four more petal

desired.

Partem: ,'VV

Lirngtli: 1

Wiilth: 3 5

Feed Dog:

Pressure: Normal

Foot: All Purpose

Pattern Selector: 5

24

Page 31

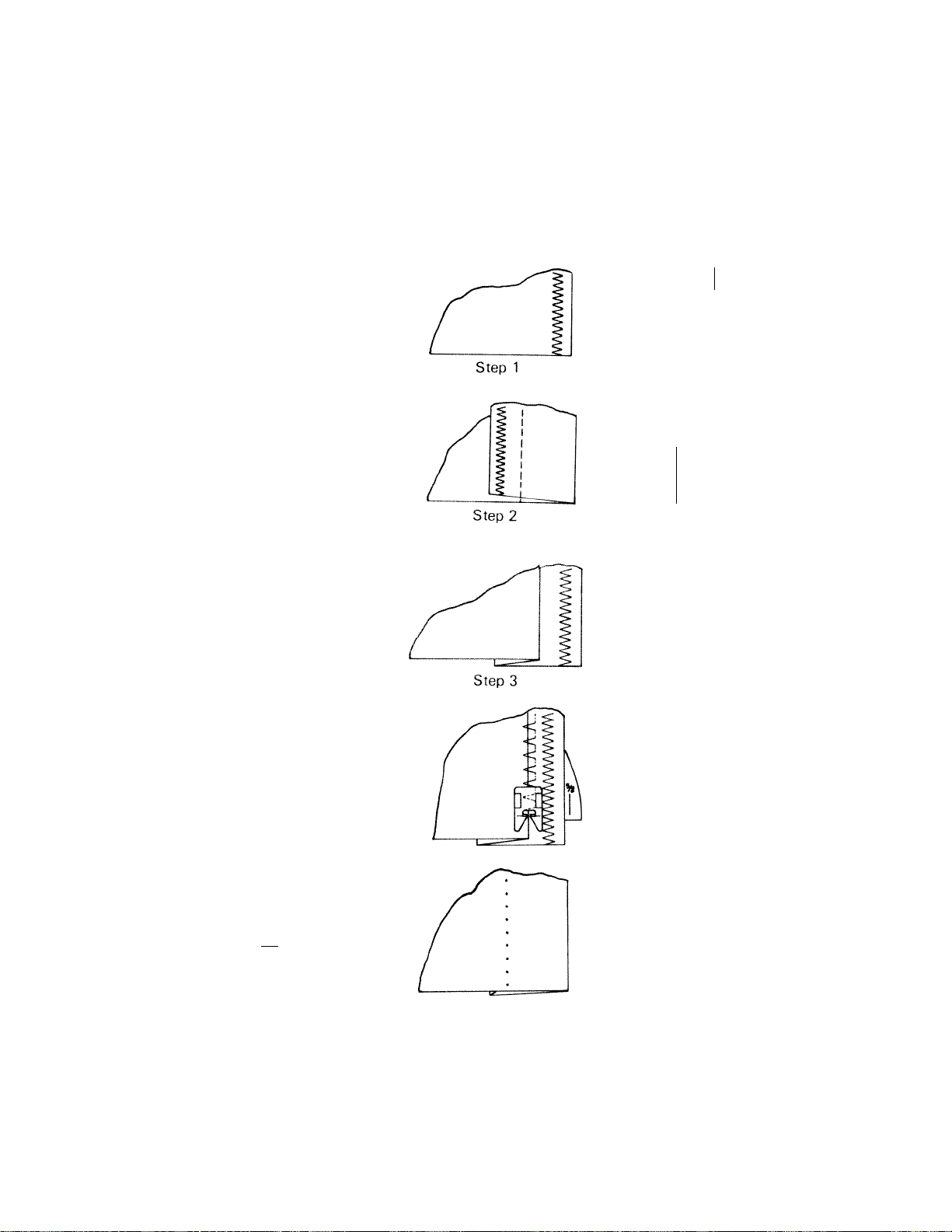

APPLICATIONS OF THE BLIND HEM STITCH

BLIWD HEMMING

The blind hem stitch provides a durable hem

linish that is almost invisible on garments, drapes,

.ind curtains. It is done easily with straight or

slightly curved hems. With a little practice it will

be a very quick and easy hem application and the

tiem will never need repairing.

Procedure:

• Prepare raw edge of hem in desired manner,

such as overcast, 1/4 inch stitched under,

pinked, hem tape, or just plain. (Step 1)

• Fold hem up desired length. Baste or pin 1/2

inch from upper edge. Press in place. (Step 2)

• Fold hem back toward right side of fabric leav

ing about 1/4 inch extended. (Step 3)

• Adjust your stitch width and needle position

so that the zigzag bite of the stitch just slightly

catches the fold of the fabric. The straight

stitches should be formed on the single

thickness of fabric, and the zigzag bite should

catch just barely into the, fold of the fabric at

the left.

• When stitching is completed, remove fabric

from machine and turn to right side. Press

completed hem.

_A__A_

B

u

T

T

0

N

H

0

L

E

S

[|

s

5 T

R

f E

: T

c

H

: 1 1

u

’ T

1

L

1

T

Y

S

T

T

c

H

E

S

F

U

N A

S

: T

1

' ■‘Hj'*

c

H A

E

S

D

E

C

0

R

5 A

F

E

T

U

R

E

S

\

N

D

P

A

R

? T

s

When hemming an A-line skirt, place a machine

h.istmg stitch along the raw edge of the hem. At

ir, ironing board, fold up the hem, matching the

.cums. Ease in the excess fabric by pulling on

hasting thread. Press with steam, then apply

iicrn tape. Baste or pin hem 1/2 inch from taped

• then continue into step 3.

Pattern: _h _ _ A .

Length: 1-2

Width: 3-5

Feed Dog: AA.

Pressure: Normal

Foot: All Purpose

Pattern Selector: 4

25

mg

111%

iii^

k

Page 32

SHELL TUCK

The blind hem stitch gives a very effective and

easy way to make a shell tuck for lingerie, pillow

cases, and decorative finishes. This works well

on knits or on the bias of soft, woven fabrics. A

single folded bias tape may be tucked in this

manner, and then applied under a fold for a

decorative hem on pillowcases or applied with

the facings at the neckline or armhole for a

decorative finish.

Set the upper tension dial to a little bit tighter

position than normal. Fold under the edge where

the shell tuck is to be created. Place the bulk of

the fabric to the right of the needle with the fold

ed edge to the left. Place the fabric so that the

folded edge will be guiding into the center cut

of the foot. The straight stitches will form on the

fabric, and the zigzag bite will swing to the left

off of the folded edge. The shell edge is created

as the needle swings back onto the fabric. The

size of the "shell" can be varied by changing the

stitch length.

DECORATIVE EFFECTS

By sewing two adjacent rows of blind hem i

1—6—1

ching on lace or ribbon attractive decorations

created. The stitch may be pivoted when

<i>

zigzag bite swings to the left and the points n

ched in the second row.

Another variation alternates the zigzag bite;

the center of the straight stitched segment,

stitch may also be pivoted after two straight;

ches to form a snowflake-like pattern

Pattern:

_/\_A_

glh: P2

Width 4 b

Feed

Piossuri!’ Normal

Foot: All Purpose

:x:x;i:xxx

Pattern Selector: 4

TOPSTITCHING EFFECTS

A new kind of topstitching effect can be proc

ed by couching a strand or two of pearl coi

embroidery floss, or yarn with the blind I

stitch. Simply guide the cord through the

groove of the embroidery foot so that the b

hem stitch sews over the cord and not thro

it. The straight stitches of the blind hem st

will bury themselves along the right side of

cord. The sewing thread should match as do

as possible to blend into the fabric.

P<»'«"'- -A_7L

Lriiigtli: 12

Width: 2 4

Feed Dog: A.A.

Pressure: Normal

Foot: All Purpose

Pattern Selector: 4

Pattern: J\_A_

Length: 1’/2-2y2

Widtii: 4 b

Feed Dotj:_JtAPressure: Norma!

Foot: All Purpost!

Pattern Selector; 4

26

Page 33

DECORATIVE STITCHES

-0——

DOOC

applications of the interlock f\J\

INGERIE SEAM

or a very fine, delicate seam in nylon tricot or

;fsey, the interlock is used. Lingerie or tricot

earns should only be about 1/8 inch in finished

vidth.

t your pattern has wide seams, trim them down

u 1/4 inch while cutting out the pattern. Guide

t ie raw edges of the fabric into the center slot of

tie presser foot. On the right, the needle will

iitch over the edge resulting in a finished 1/8

Jttern: JXJXTL

• ■ ngth : 1-1/2

./idth: 4-5

-i!d Onn- A A

•essure: Normal

.int: All Purpose

Littern Selector: 6

nserting lace

I very fine lace insertion can be made with the

iterlock. As in applying lace with the zigzag

titch, follow the straight line or the design of the

1. e. (See page 22). Sew so that the straight

titch of the interlock is on the fabric and the

■ nail zigzag catches into the lace.

Combining rows of decorative stitch patterns is

an easy, inexpensive way to create your own

braids and trims for garments and household

articles. Blending or contrasting colors of thread

may be used to compliment the color of the

fabric. Illustrations will give some of the attrac

tive stitch combinations.

Pattern: As desired

Length: As desired

Width: As desired

Feed Dog: A.A

Pressure: Normal

Foot: All Purpose

Needle Position: 2

PJTJWjmnimimj

B

u

T

T

0

N

H

0

L

E

S

n

Là

S

T

R

E

T

C

H

1 1

u

T

T

Y

s

T

T

c

H

E

S

iii^

iiij

iii^

L

1

1

F

U

F

E

N A

T

S

T

1

T

U

R

E

S

c

H

E

S

D

E

C

0

R

A

N

D

A

T

S

P

R

c

/

F

E

C

F

\

C

L

F

IV

/

C

I-

Pattern: _A_A_ALength:1 —IVa

Width: 2

Feed Dog:j|ulL

Pressure: Normal

Foot: All Purpose

Pattern Selector: 6

njlAiinjmAAaAAAAAAAA

k

27

Page 34

APPLICATIONS OF THE STRETCH BLIND HEM

HEMMING

The stretch blind hem stitch gives a stretcliy,

durable hem finish to knit fabrics. Tlie two tiny

zigzag stitches enable the hem to stretch with

the fabric. It may also prevent woven fabrics

from raveling. Proceed as for the regular blind

hem stitch on page (25).

/AwV\

lrnyih.1-2

VVtiHlr 4-5

fPMTl DiH|: MA.

Plt'SSlIft:. Nmnn-il

Foot AH FHiiptisi-

Pattefn Seiectijc: 7

EDGING

The stretch blind hem stitch can Ite used as an

edging, like the blanket stitdr clone by hand. By

using a fairly short stitch length, die stitches he

very close together. It can be used for over

casting and finishing the edges of tableclotns,

napkins and ruffles. The edge may be turned u|)

about T./2 inch and then overcast with the

stretch blind hem. Cord or pearl cotu.m may Ite

used to give a raisrrd effttcl to itic stiti.lies

Simply place 2 4 strands of pearl cotton or cm

broidery floss unt.lef tfie fool and stitoh over ii.

Fcnir-n,

PatliMU Seitictitf. 7

EYELASH BUTTONHOLE

A unique way of reinforcing buUt)nfi(.)les on

loosely woven fabrics or buttonholes in which

tfre stitches have been accidently cut, is to over

cast them with a short stretcfi blind hem stitch.

Overcast each side of the buttonfiole so the far

right stitch falls into the opening of the Itutton

hole and the small zigzag stitclies covet Hie

previous buttonhole side. On completion of one

side of the buttonhole, pivot the fabric with the

needle at the far right in tfie opening of th.e

buttonhole at the bartack. Sew up the other side

in the same manner,

Pciilftm' aAwV

LciKith: Ti

Widlli: 4 !.)

Fet'd DiMj- .AA.

(deesiiri!: Noim.il

Foot: AH Pu(|)ose

Pattern Selector: 7

28

Page 35

BUTTONHOLES

Various fabrics require various methods of

sewirig buttonholes. Four different methods

are given below, with suggested uses. If you

are in doubt as to which method is best for

your fabric, test the methods in question and

choose the best according to the finished

appearance.

PREPARATION

For the best results, a good quality merceriz

ed cotton thread should be used. Polyester

threads often result in puckered or heavy

unattractive buttonholes. The finer your

fabric is, the finer your cotton thread should

be. An interfacing should be used under the

buttonholes to give body, to strengthen, and

to help them withstand wear. To establish

the correct length of the buttonhole, add the

diameter of the button (A), plus the thick

ness of the button (B), plus 1/8 inch for the

bartacks. The length may be marked on the

garment with a basting stitch, tailors chalk,

or transparent tape, as shown. Another way

to make sure that all buttonholes will be the

same size is to cut a piece of cardboard as

wide as the buttonhole foot and long

enough to make the distance between the

toe of the white slide and the cardboard the

size buttonhole needed. This method works

for buttonholes up to 1-1/8 inches long.

Horizontal buttonholes should extend 1/8

inch beyond the center line of the garment.

Vertical buttonholes are placed so that the

cutting space of the buttonhole is directly on

the center line. Always make a practice

buttonhole on a scrap of the garment fabric

before making any buttonholes on your gar

ment. On your test sample, duplicate the

thickness found in the garment and be sure

to include the interfacing. The test sample

should help determine the length needed for

the button to pass through easily, and the

stitch length for the particular fabric. As with

the satin stitch, the stitches should be close

together, but not so close that they pile up.

Be sure to use the buttonhole foot.

F

U

N

S

T

I

T

c

H

E

S

D

E

C

0

R

A

T

1

V

E

F

E

A

T

U

R

E

S

A

N

D

P

A

R

T

S

29

Center line of Garment

Page 36

fl

--1 j L-i"

Mm)

¡Ri -

Paitorn /V\A

Length:

Width: 4 5

Feed Doy: AA

Pressur: Normal

Foot; Buttonhole

Pattern Selector; D-D-a

PiitfeiH Sclfictof and

ZiQ/ay Width Contiui Ditil

Pallnfn SeltM-!iu and

Ziy/ay Wi(hh Contiiil Dia!

PatUan Sidi-ctn'

itj/ay Witilh Dial

BUILT IN BUTTONHOLER

This buttonhole eliminates the need for

pivoting the fabric. It is used most often on

light and medium woven fabrics.

1. Set the buttonhole control dial at the

(#2) buttonhole picture. Lower the

needle into the mark at the top end of the

buttonhole. Lower the presser foot. A

few stitches will be made for the bartack,

# 2, turn to # 1 than the stitching will sew

the left side in forward.

Stop when the stitching reaches the bot^

tom end of marked buttonhole. At this

position the machine will be sewing in for^

ward.

2. With the needle up, select the (#4) four

buttonhole picture. A few bartack stit

ches will be made, turn to 3 than the stit

ching will sew the right side in reverse.

If using cardboard the white nylon slide

will run into the carboard to prevent sew

ing into the bartack.

3. To lock the stitch, make sure the needle is

out of the fabric. Make sure the pattern

control dial is at straight stitch and take a

few stitches.

4. Score the buttonhole with the back edge

of the seam ripper several times. To pre

vent cutting through the bartack, insert a

straight pin through the bartack. Cut

buttonhole open with the s<jam ripper.

Note: Stitch Width Control should always

be at “0" while sewing this button

hole.

Adjustment of stitch density;

Check the stitch density on a scrap of fabric.

If density is too open or too close, re adjust

by turning stitch length dial.

30

Page 37

TURN-AROUND BUTTONHOLES

It is possible to make small and dainty

buttonholes if you desire or repair damaged

buttonholes. This entails a slight shifting of

the cloth but with some practice, good

buttonholes can be achieved.

1. Mark the length of the buttonhole on the

cloth as shown in figure.

2. Set the needle position to the left and

your stitch length dial near "1/4" or the

density your desire.

3. Choose the desired width of your botton-

hole.

Example: if you want a buttonhole with a

width of # 3 setting on the stitch width

dial, divide this setting in half, or V/z

4. Start at your marked position, sew down

on the left side of buttonhole to the other

end of marking. Leave the needle in the

cloth at the right side of stitches and

rotate your cloth. Lift the presser foot and

slide the bottom of the foot back to the

front.

5. Lower the foot and raise the needle.

Reset your stitch width dial to bartack, in

this case the # 3 setting, set your feed to

▲A sew several stitches.

6. Raise the needle, raise feed to, AA reset

the zigzag width to the initial setting, in

this case #V/z and sew the other side of

buttonhole to your mark, then repeat your

bartack 15).

7. Lock threads by stitching a few stitches at

0 witdh. Cut buttonhole as indicated

previously.

When using this method over a buttonhole

which has already been slit or damaged, be

sure to hold the buttonhole open and allow

the needle to go off the edge of the fabric.

Step 4 is all that may be needed to repair

damaged buttonholes.

Pattern: /\/V\

Length:

Width: 2%-5-2K-5-0

Feed Dog: AA-XZ

Pressure: Normal

Foot: Buttonhole

Needle Position: 1

Step 1 Step 2

Step 3

31

Step 4

Page 38

CORDED BUTTONHOLES

Cording gives a reinforced raised button

hole. It IS excellent for use on bulky, wovei

fabric, oi knits in which the stitching otter

gets buried and makes (tutting difficult. Oi

knits, a cordtHl buttonliole will helji keep th<

fabric from stretching out of shape.

Choose a fujavy cotton crocfiet tfiread o

buttonliole twist to us(! for the cording. Pro

ceed as fot either builtan buttonhok; tpagi

30) or the turnaiound buttonhole (page 31)

having the cord undet the (iresset foot ii

such a way that llie /ig/ag stitcli covers th

cord. When pivoting the buttonhole, als<

swing tlie cord arouncJ to f(,)ll<)w undet th

second side.

At the completion of tlie buttonhole suit) th

excess cord close to the bartack on wovi;

fafincs. For knitted gaim»;nts, always pu

the cords to the wiong side bv using a dan

ing nettdie oi needle thieadta, tind knot th

con) ends liefore dipping

Built in Buttonholoi

(■.Ilonr /VV\

CZl

Wniili 4 ;>

tn,.,, f)o<,

h'il’wSUfd Nidiijd'

! nt M Pu lift mi It sii ■

Pfittc-! f! SdlddiOi U D^[l

Turn-around^Buttonfityle;

P.illi’in /Vd\

Iciujlh

VViflltt 2y>-5-2’A-6-0

Fyi'SsuH*: Nnttii.li

F'ool. F^uUnfiiioln

Nni'illr* F-’osiiin!i. 1

32

Page 39

STRETCH BUTTONHOLES

This buttonhole is used on knit fabrics when

it is desirable to omit interfacing or cording.

This buttonhole will stretch and return to

shape unlike an ordinary zigzag buttonhole.

The v/v\7\. pattern of the stitch makes the

buttonholes nearly invisible when using mat

ching thread. It is excellent to use on jerseys,

double knits, and sweater fabrics.

1. Mark the length of the buttonhole on the

cloth as shown in.

2. Select the overlook stitch (# ii).

3. Set the needle to the left and the stitch

length dial to 4.

4. The width should be set at 2'A .

5. start at the marked position, sew down

the left side of the buttonhole to the other

end of the marking. Leave the needle in

the cloth at the right side of the stitches

and rotate your cloth. Lift the presser foot

and slide the bottom of the foot back.

6. Lower the presser foot and raise the

needle. Reset your stitch width to make a

bartack at width 5. Set your feed dog to

XX sew a few stitches.

7. Raise the needle, raise the feed dog to

XX , reset the width to 2% and sew the

second side of the buttonhole, to the end

of the buttonhole mark, reset the width to

5, the feed dog to XX and sew a few stit

ches for the second bartack.

8. Lock threads by stitching a few stitches at

0 width. Cut the buttonhole as indicated

previously.

Step 1

Step 3

Step 2

/1

J

Step 4

Pattern: tTWV

Length: 4

Width: 2’/r5-2'/j-5-0

Feed Dog: aa-X1^Pressure Normal

Foot: Buttonhole

Pattern Selector: 11

A4-XS

33

Step 5

Step 6

Page 40

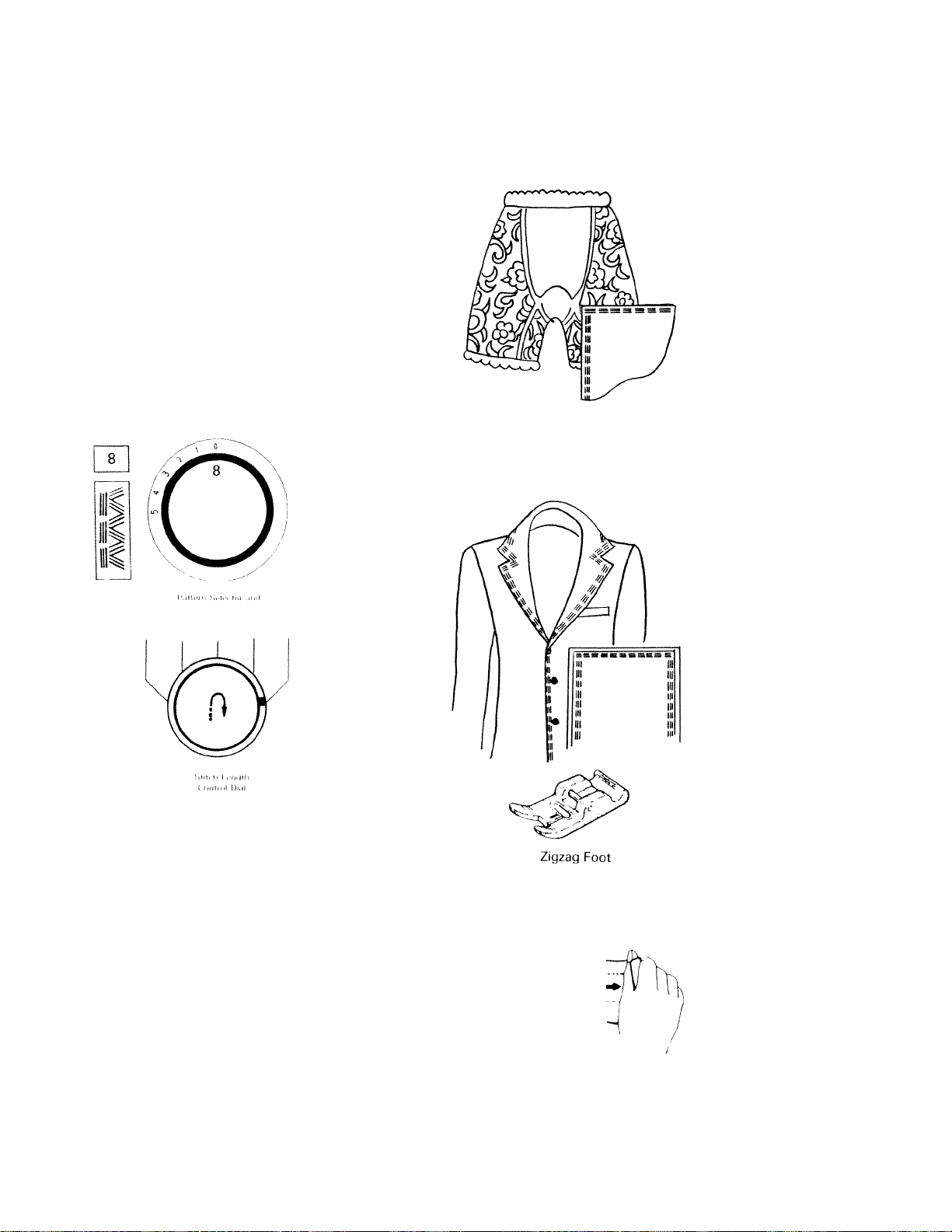

APPLICATIONS OF THE STRAIGHT TRIPLE STRETCH STITCH

SEAMS

This stitch may be used on knits and woven fabrics,

in areas of stress as a reinforcement stitch. It is ex

cellent for curved seams such as armholes and

crotch seams. For active wear such as ski pants and

girdle fabrics which endure a lot of stress in bending

and stretching, this stitch may be used for seaming

throughout the garment.

CAUTION: It is difficult to remove this stitch from

fubni. PreUit garment before using this

stitch.

’ Feed Dog: M J k -

____

Pattern: =

Length: 4

Width: 0

Pressure: Normal

Foot: All Purpose

Pattern Selector: 8

TOPSTITCHING (STRETCH STITCHES)

Because this stitch is heavier than an ordinary

straight stitch, it is ideal for topstitching, particu

larly on knits.

s

T

R

E

T

C

H

U

T

L

T

Y

S

T

T

C

H

F

U

N

F

E

A

T

S

T

U

R

I

T

c

H

I

E

S

I

D

E

C

0

R

I

A

A

N

D

P

A

R

T

S

C

/

F

E

C

F

\

C

L

F

IV

/

C

F

I

IN

E

T

1

V

ori 1

Pal

|tli: 4

I er

III 0

Wl(

Fee

I I )og:

Piessuie: Normal

foul All Purpose

Panelli Selector:8

PROCEDURE;

• The elastic triple straight stitch is used when a

straight line of stitching is desired so that seams

may be pressed open (slacks for example).

• This stitch is especially useful where the tiny

zigzag seam will not hold its shape and the

straight stitch will break.

• Apply this stitch to areas of stress on both

wovens and knits (crotch seam and under arm

for example).

• Use this stitch for tightly fitted garments that

need a lot of stretch, such as ski pants, girdles

and bathing suits.

• If puckering becomes a problem, use the straight

stitch foot.

ifir

Elastic Triple Straight Stitch

Regular Straight Stitch

34

Page 41

APPLICATION OF THE RICK-RACK

TOPSTITCHING/RICK-RACK

A decorative topstitch can be produced with the

rick-rack stitch. Stitch around the structural lines of

the garment for a special effect. Topstitch braid or a

decorative inset to add an additional creative flair.

Pattern: //AW/AW

Length: 4

Width: 4 5

Feed Dog: AA

Pressure: Normal

Foot: All Purpose

Pattern Selector: 8

TAPERING/RICK-RACK

The rick-rack stitch may be tapered to form creative

stems and petals of flowers, embroidered pictures

and wall hangings. As in tapering the zigzag, See

Page (19), slowly turn the stitch width dial from 0

to 5 and back to 0. A group of these tapered rick

rack stitch will from a bouquet-like effect.

Pattern: /Ш М

Length: 4

Width: 0 5 0

Feed Dog: AA.

Pressure: Normal

Foot: All Pirrpose

Pattern Selector: 8

oa 1

The elastic rick-rack stitch is a zigzag line of stit

ching that is desired so that seams may be press

ed open.

Apply this stitch to areas of stress on both

wovens and knits.

Use narrow width of zigzag as a heavy duty triple

stitch for seams.

Use medium and wide widths of zigzag for over

casting edges of seams, facings and hems of

heavier weight fabrics such as terrycloth, and for

attaching elastic. Use also for decorative stit

ching.

3 4 HO

35

Ziy/fjy F-()0!

Elastic Tiiph; Zicj/ay Stitch

/ ' МЛЛЛЛЛл1чЛ^^ЛА^

AAA^ZN/y''

/Recjular Ziyzaq SiiicFt /

Guide your fabric from the front.

Do not pull or push as it will

cause poor stitching.

^ ' I /

hv

Page 42

APPLICATION STRETCH OVERLOCK

On fabrics that are bulkier or heavier, tf^e stretch

overlock is a better choice than the overlock. In all

methods proceed as you would for the overlook,

see page (37), except feed the fabric with the bulk

to the right. The stitch is less dense and will prevent

soft stretchy knits from rippling.

Pattern: yyv

Length: 4

Width: 4 5

Feed Dog:

Pressure: Normal

Foot: All Purpose

Pattern Selector: 9

APPLICATIONS SMOCKING STITCH

This stitch is very versatile and can be corded or

used as a topstitch as other reverse stitch patterns.

vw

F

U

N

S

T

I

T

c

H

E

S

F

E

A

T

U

R

E

S

A

N

D

SEAMING SMOCKING STITCH

The smocking stitch can be used to seam fine

gauze type fabrics or bulky sweater knits, this

results in less bulk for a finished 1/4 inch seam.

Follow the directions for overlook seam on Page

(37).

Pattern:

Length: 4

Width: 4-5

Feed Poo: AA

Pressure: Normal

Foot: All Purpose

Pattern Selector: 10

ELASTIC THREAD SHIRRING

Cuffs and bodices of little girls dresses can be shir^

red easily with the smocking stitch. Place the right

side of the garment down on the bed of the

machine. Place two strands of elastic thread under

the foot. Stretch the elastic thread while sewing

with the smocking stitch to gather cuffs or bodice

for a feminine effect.

PROCEDURE:

• The smocking stitch is a very useful special ultra

stretch stitch.

• Lingerie or tricot seams should only be about 1/8

inch finished width.

• Fagoting can be achieved by joining the folded

edge of two piece of fabric together with a gap

between them. Use a sheer flesh colored piece of

fabric underneath to make the fagoting much

stronger and prettier.

• Do the fagoting with a piece of paper underneath

and remove the paper by hand washing.

Paitern Selector and

Zigzag Width Control Dial

Overlap seam

Paper

D

E

C

0

R

A

T

1

V

E

P

A

R

T

S

36

Page 43

APPLICATIONS OVERLOOK STITCH

SEAMING OVERLOOK STITCH

This stitch gives a finished 1/4 inch seam in one

step. For knits, it gives strength and elasticity to the

seams and prevents the curling of the fabric that

often occurs with 5/8 inch opened seams. It is most

applicable to soft, thin knits such as nylon or

acetate knits, but may be used on other fabrics as

well. Always make test seams with this stitch.

For woven fabric, the overlock stitch gives strength

and prevents raveling. It can tte used on woven

goods to replace flat felled or French seams.

For patterns with 1/4 inch seams. Place the raw

edge of the fabric under the presser foot so that as

the needle swings to tfit; right, it comes down at the

raw edge. This will result in an raiclosed seam

allowance.

For patterns witli 5/8 inch t

The seam allowances ntay

either before or cfior c.iwi

sewing, proceed as aturvt

seam wllfi the raw edgr' ot tire falrnc on the etcherl

guide line "1/2" (Any time you use the full widtii of

a particular stitcli, you shouiri retidjust the raw edge

of the fabric 1/8 inch to the left.) Afterward, trim

the excess fabric near the stitching. This metliod is

actually easier than thrr overedge metfiod for fabrics

that curl.

Note: On soft, loose knits, the fabric may seem to

wave or ripple. If this occurs, reduce the

pressure. (Page 10 ).

■ams:

:■ trimmed to 1/4 inch

■j. If irimmmg before

wise, sew tire

tool: ли РшПиы;

p.illcrm SiiUicloi I'

HEMSTITCHING EFFECT

By using a very large needle and a fine thread an

openwork effect can Ire attained winch is beautiful

for sewing tfie hems into tafrleclrrths, napkins,

placemats, handkerchiefs, etc. Use a large needle,

size 18 or 20, and a fine cotton thread. Tighten the

upper tension slightly, until the stitch looks bott(;r

on the underside tfian on top. (You will be sewing

with your fabric faci! side down.)

Turn u,. 1 inch then turn up 1 inch again to form a

hem of a double tliickness of fabric. The bulk in cor

ners can be eliminated by trimming away tfie ex

cess, as shown, after having folded the fabric orr all

sides. Stitch from the wrong side, so that the

straight stitch forms on the single layer and tfie

zigzag bites on the double layer. Stitch all the way

to the edge of the fabric along all sides.

37

x:

H

о u

c

.£

T

t

inch

1

i

A"

inch

1

3

D.

3

О

!l

Page 44

TOPSTITCHIIMG OVERLOOK

The overlook stitch can be used to topstitch non

raveling fabrics such as felt or leather into place for

appliques or pockets.

Stitch so that the straight part of the stitch is form

ed over the edge of the leather, and only the zigzag

part holds it in place.

Pattern: ZyVS

Length: 4

Width: 3-5

Feed Dog: AA

Pressure: Normal

Foot: All Purpose

Pattern Selector: 11

f'tilloin St'IncIct cimi

/iti/at) Widlfi Didl

OfT

PROCEDURE:

• Overlock stitching is used for sewing overlapping

seams, decorative hems, binding and edges on

woven and elastic fabrics.

• To sew an overlapping seam, place one piece of

fabric 1 cm over the other piece and sew the

flatlock stitch over the fabric edge on the right

side.

• You can produce a decorative hem by folding a

single hem on the wrong side and sewing the

flatlock from the right side.

• Use knit trim or bias binding when binding

curved edges, like round necks and armhols.

38

Page 45

APPLICATIONS ULTRA STRETCH

JL JL

SEAMING ULTRA STRETCH

On most knits, a 1/4 inch finished seam, such as

stitch and overcast or the overlook stitch, is more

desirable than a 5/8 inch opened seam allowance.

These stitches can create a neater, more profes

sional finish, eliminate bulky seams, prevent curl

ing, permit the garment to "give" under stress, and

at the same time they cut down on the amount of

work involved in making a garment. If ever in doubt

as to which of the two stitches to use, test both on

the particular fabric in question and choose accor

ding to their performance.

The stitch and overcast stitch is excellent for

stretch fabrics such as sweater knits, bathing suit

knits, and cotton knits. It has the greatest strength

and elasticity of all.

For patterns with 1/4 inch seam allowances: Feed

the fabric such that the needle goes over the raw

edge of the fabric when it swings to the right.

For patterns with 5/8 inch sgam allowajices: Feed

the raw edge of the fabric along the etched guide

line "1/2", then trim away the excess fabric close

to the stitching.

Pattum: AL

LtMKph: 4

WuSth- 4 1)

FfHui D(ur

Piassuu*' Nutmal

Fof)i; A!! iAuptisi.’

Patttfm SflaciDf VJ

e

r-'

k""

..

P.itttni) Soli-i

Ziii/.U) Width la

PROCEDURE:

• Overlock stitching is used for seaming and

finishing the cut edge of knit fabrics, all in one

operation.

• This overlook stitch is especially good for stretch

fabrics such as double knit and jersey and will

give a firm, neat edge finish.

39

Zlgгag Foot

Overcasting

Page 46

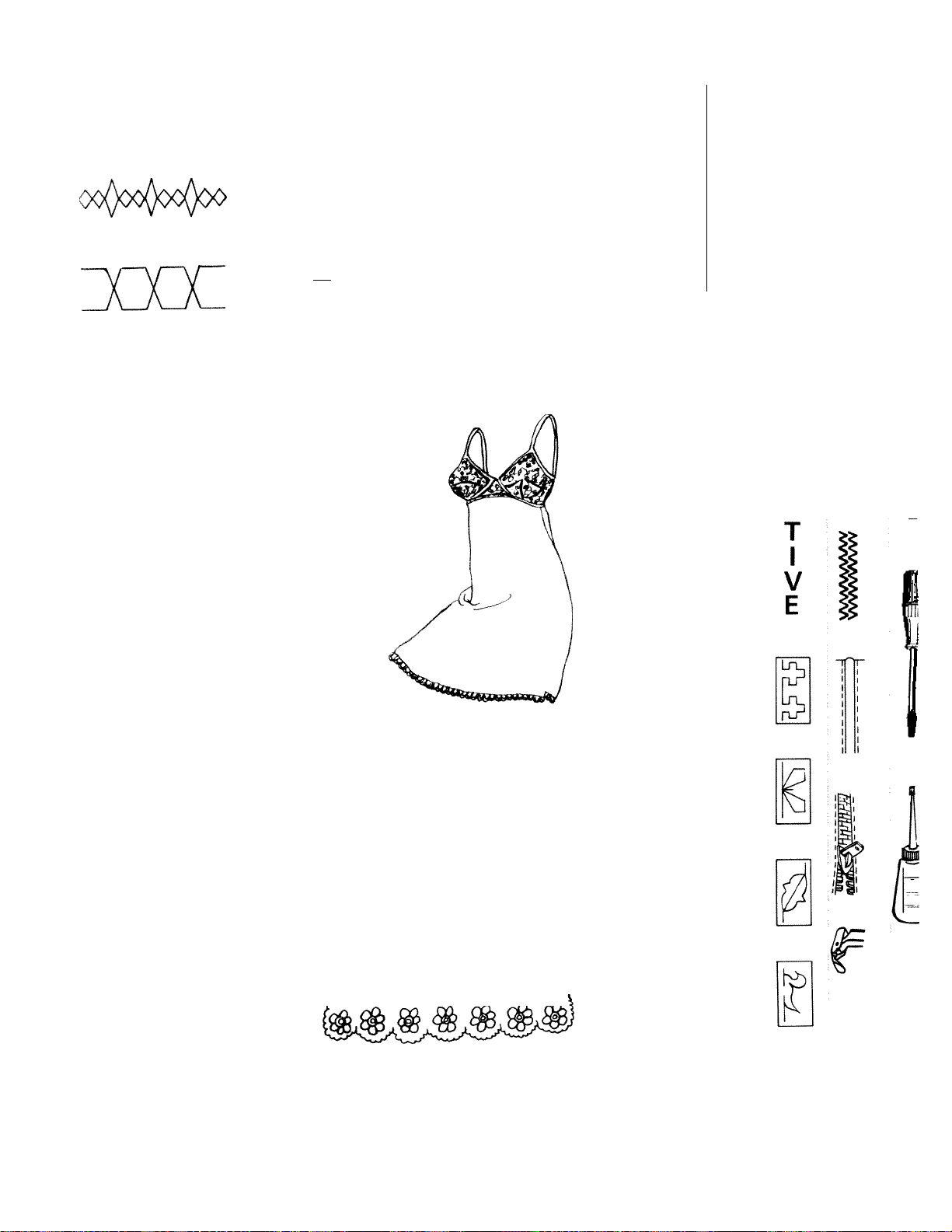

APPLICATIONS OF THE DECORATIVE FUN PATTERNS

DECORATIVE EFFECTS

The reverse stitch patterns produce duck swiss

cross, leaf and butterfly designs for use on house

hold linens and children clothes. These reverse