Page 1

01/30/2008

:^i

- V’ ■

"Í Í ■ ■

0 : <’>i -1'

-■:Щ

:i Щ

■^í k 'lr

Page 2

CONTENTS

Name of each part................................................................

Principal features

How to use selective knob (dial) .............................................

To regulate the stitch length....................................................

Manual operation of zig zag sewing

Automatic operation of zig zag sewing

To wind the bobbin ..............................................'

..............................................................

..................................

.............................

How to remove and replace bobbin case

To thread the bobbin case ...........................................

How to remove the shuttle.........................................

How to insert the needle

Threading the machine

Preparing to sew..................................................

Removing the work .........................................

How to adjust tensions

How to use the automatic darner .............................................f4

.........................................

.........................................

..............................................................

Page

•• 1

.... 2

...........

Drop-feed adjustment

How to embroider with a hoop.

How to use attachments ............................

Narrow hemmer

Quilting guide

Sewing on buttons

Making buttonholes

Gathering

9

■10

Applique........................................

Sewing knitwear.........................

■10

......

11

.......

12

......

12

13

....................................

.....................................

.......................................

.............................

.........................

.......................................

Lighting equipment ■■

Needle-thread-fabric-stitching guide

Check up for smooth sewing

Oiling and cleaning .........................................

Page

■■•14

......

.........

...........16

..............

...............

............

.....................

......................

.........................

...........................

............................

16

16

17

18

19-20

21

22

22

23

•23

■■■24

—25

00

o

o

Page 3

01/30/2008

Page 4

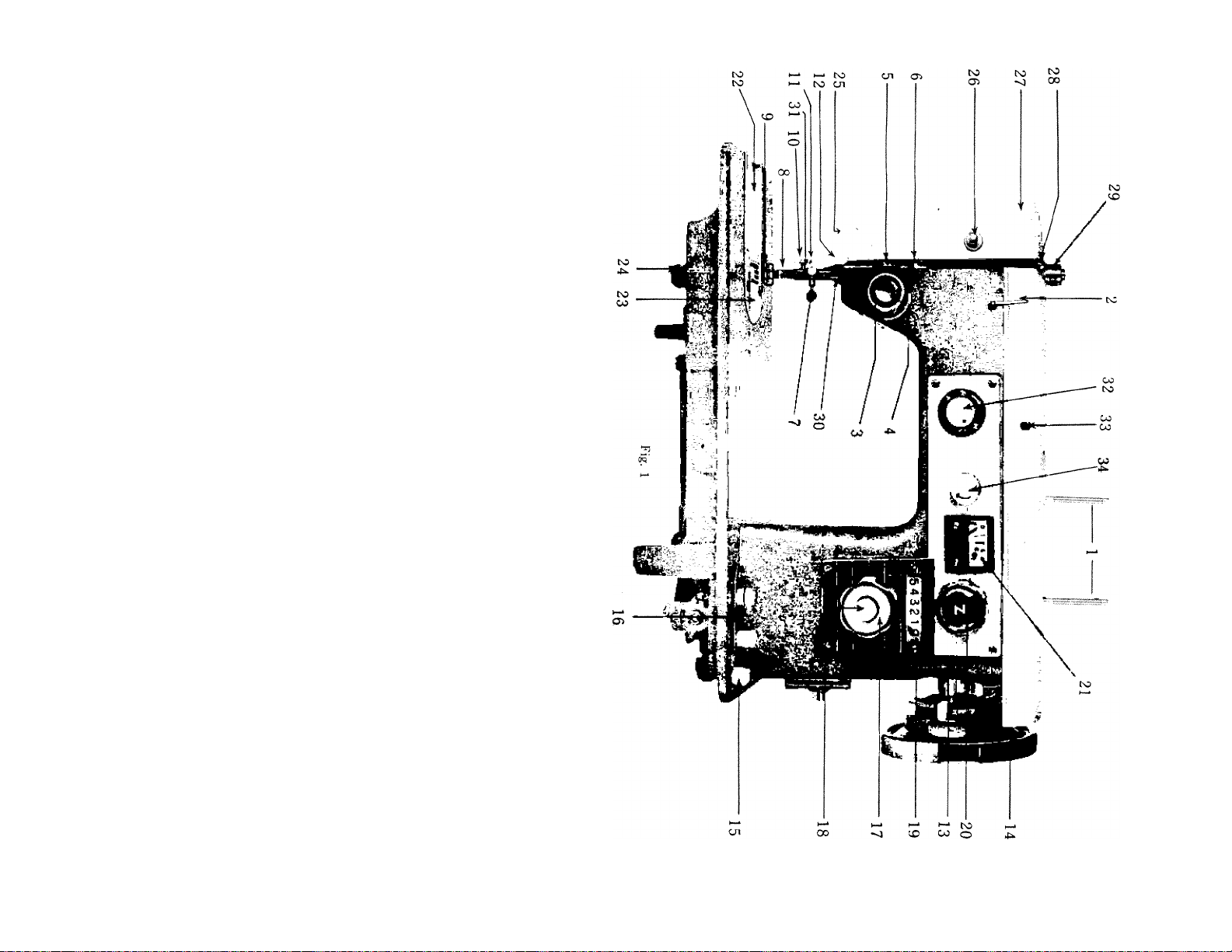

Name of Each Part

Arm spool pin

Thread guide <upper)

.....................................................

..........................................

CJ)

,2)

Thread tension ......................................................(s)

Thread take up spring

Thread guide ¡under)

Thread guide mediate)

Needle Clamp Screw

...........................................

.........................................

.........................................

...........................................

T

5)^

(ji)

,7)

Needle ...................................................................¡D

Presser foot ..........................................................9)

Presser foot clamp screw ....................................,i(j)

Presser bar .............................................................li;

Needle bar thread guide.......................................12)

Automatic bobbin winder

...................................

lis)

Balance wheel........................................................ij

Bobbin winder tension disc

.................................

Drop-feed regulator ¡push button;.......................@

Stitch length regulating knob ...............................ip

Push-button for reverse stitch

Zig Zag stitch length indicator

.............................

...........................

ig)

19)

Zig Zag stitch regulating knob.............................'2}

Zig Zag stitch indicator ......................................2ji

Cover plate (hinge type;

......................................

22)

Needle plate...........................................................(||

Shuttle race

Lamp

Lamp swich

Face plate

Thread take up lever

...........................................................

..................................................................

............................................................

..............................................................

..........................................

A

25)

g)

ig)

Patch-o-matic darner ...........................................§)

Thread cutter ........................................................§)

Needle bar thread guide......................................3i)

is

Selective knob

......................................................

ag

Key-button for Zig Zag disc chamber - (g)

Restrictor knob .....................................................3|

( 1 )

CO

O

O

fN

Page 5

Principal Feahjre«

Restrictor knob

Zig Zag

Stitch indicator

Zig Zag Stitch

regulating knob

Stitch lermtfi

regulatin!^

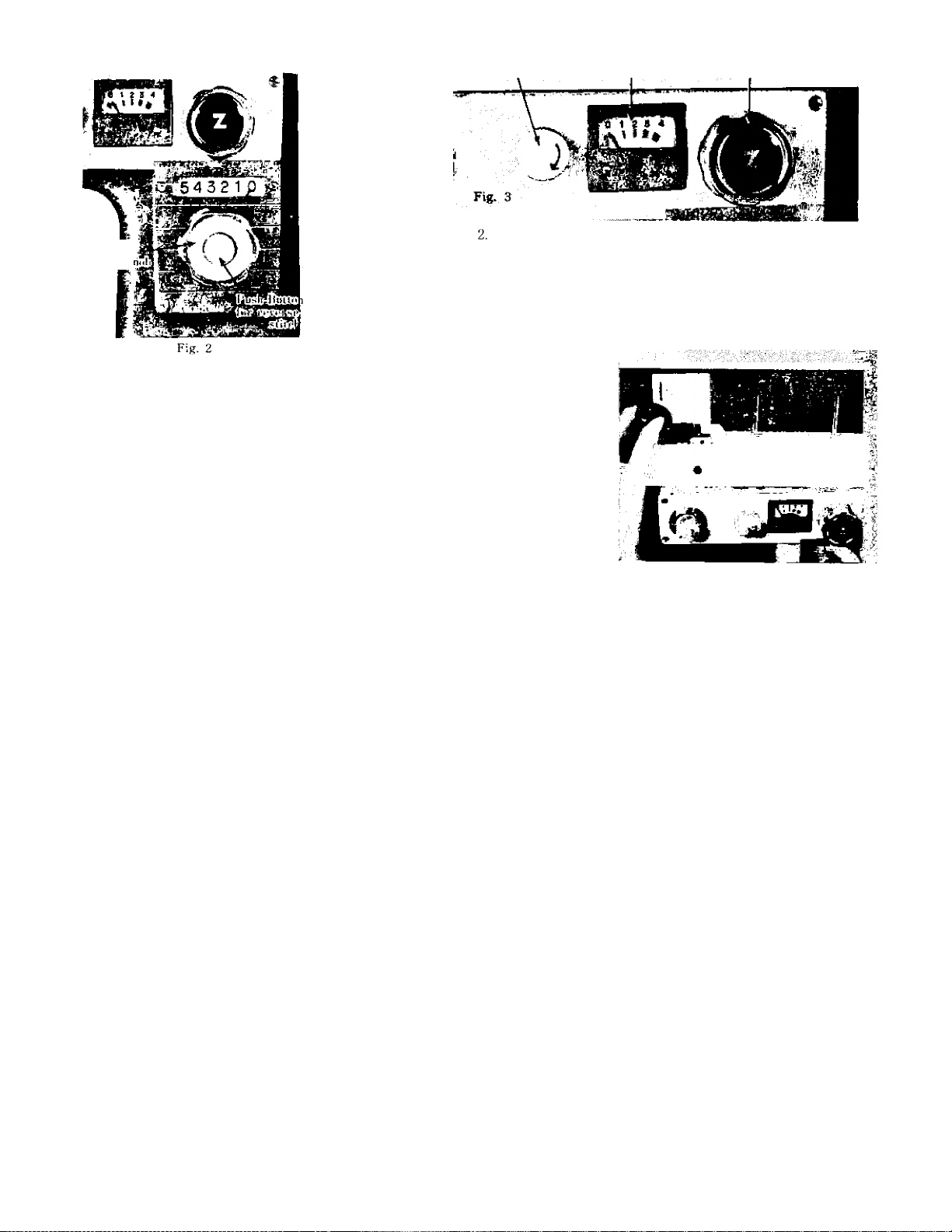

1. Stitch length regulation. The length of the stitch

is controlled by a dial located on the right of the

arm. Turn it right is shorten the stitch and left

to lengthen. The correct stitch length is shown by

numbers in the plastic window just above the

dial. Near zero is the shortest stitch, 5 the long

est. To sew in reverse, just push, the button

marked R in the center of the dial. When the

button is released the machine will automatically

sew forward again (Fig. 2).

3. Decorator discs for automatic sewing. Select

one of 20 discs and insert in the disc chamber

to do embroidery designs automatically (Fig. 4.).

Rotating the Restrictor knob (Fig. 3) in the dire

ction of the arrow on knob, makes it possible to

lock into position any zig zag width from point

0 to 4 on the dial, and is especially desirable in

making buttonholes.

Fig. 4

( 2 )

CO

o

o

Page 6

Fig. 5

5. Patch-o-matic darnen

Provides instantaneous

pressure release on

presser-foot to permit

easy and quick darning

and mending.

Fig. 6

Lighting equipment

Position of sewing light, moun

ted in the face plate, directs a

beam of soft light where it

is needed most, "right on the

material being sewn".

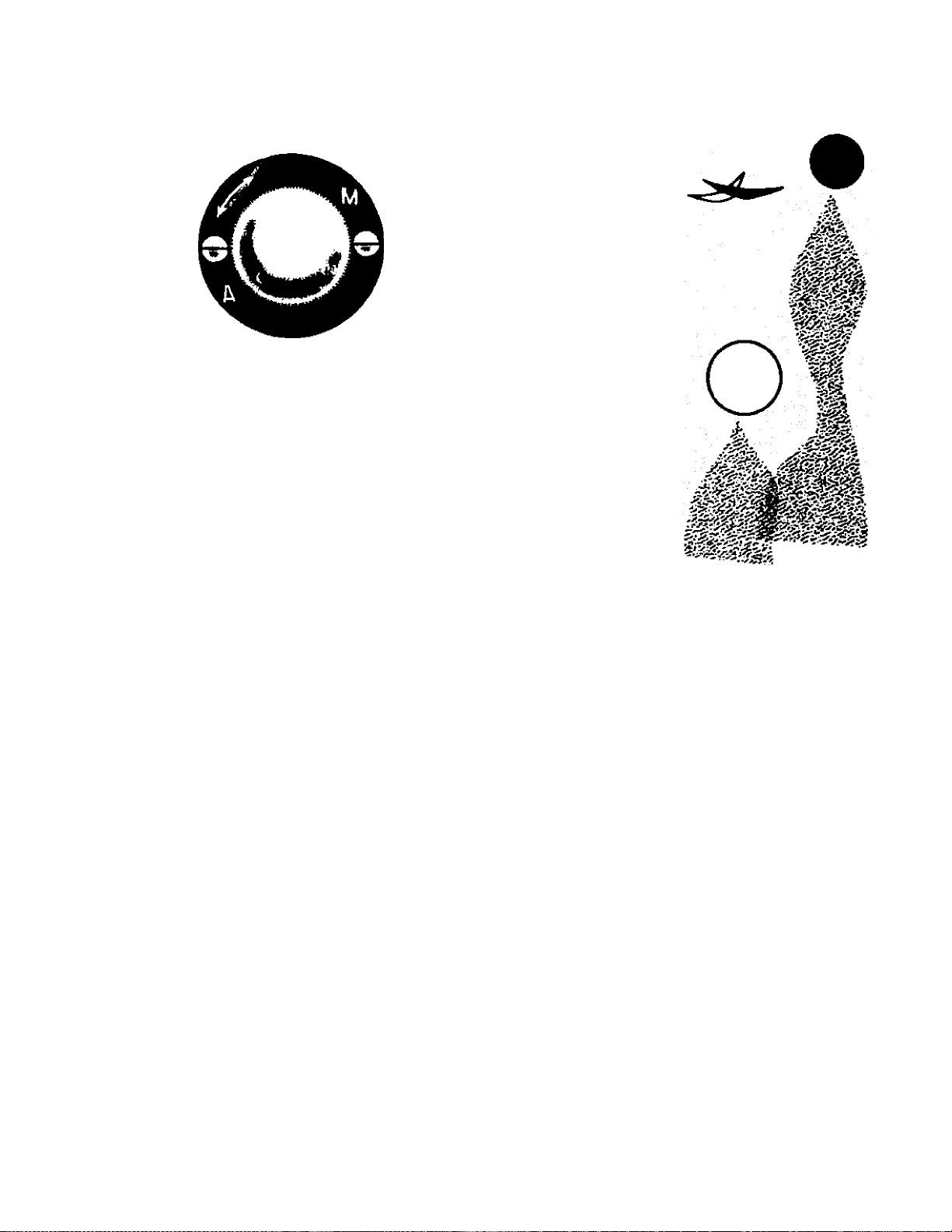

6. Selective knob : Fig.7 Provides

method for instantly switching

from automatic to straight sti

tch sewing without necessity

of removing decorator disc.

Fig. 1:

{ t )

CO

o

o

Page 7

How to Use Selective Knob (Dial)

Fig. 8

Turn hand wheel until needle is out of material.

The selective knob should not be moved at any time

with the needle in the material, which would result

in bent or broken needles. Having inserted a designer

disc in the machine, turn selective knob so that the

red dot is next to "A". Your machine will now sew

the design of the disc, automatically.

By returning the selective knob so that the red dot is

now at "M" the machine will now do regular straight

stitching, without the necessity of removing the disc

first. When sewing, the red dot should always be at

either the "A" or "M" point, never in between.

C 4 )

CO

o

o

rg

Page 8

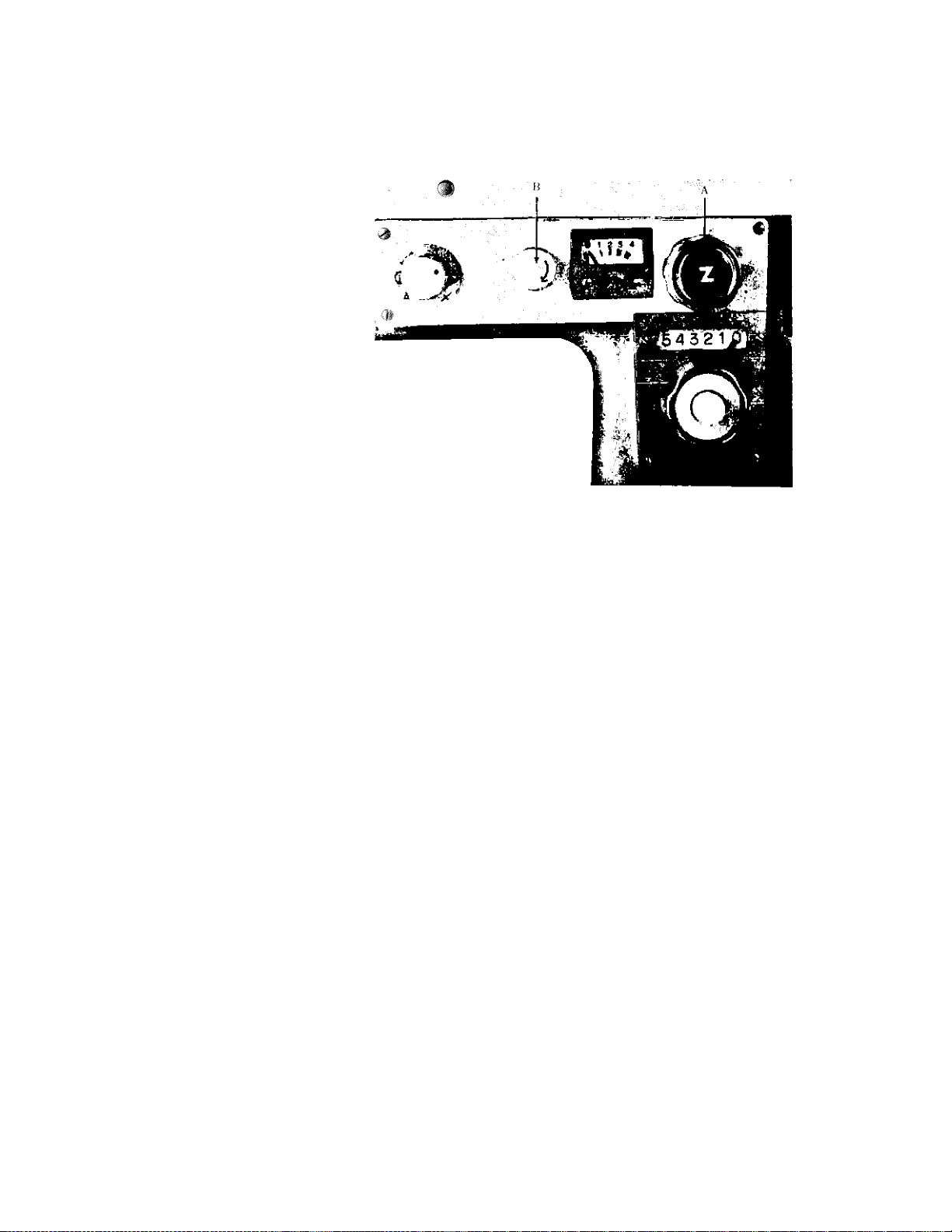

o Regulate the Stitch Length

543^1

w

r-—Tb '|

i mm^

Fig. 9

Figures in the dial

■' Wj

The stitch length is regulated simply by turning the knob shown

in Fig. 9. To lengthen the stitch turn knob to left, to shorten,

return to right. Refer to chart below for approximate number of

stitches per inch obtained at various settings.

1. To sew forward. Turn knob until marker on stitch indicator

points to figure corresponding to the number of stitches per

inch required for the work you are doing.

2. To sew backward. Push the button *R" jn the center of the

stitch length knob and the machine will sew the same length

stitch in reverse. When the button is released the machine

automatically returns to forward stitching. This "backtacking" locks the seams and eliminates tying of threads.

Stitch Length Chart

Numbers of stitches

per inch

(no feeding)

32

( 5 )

16

11

00

o

o

Page 9

Manual Operation of Zi§ Zag Sewing

1) The zig zag regulating knob (A Fig. 10) is used to vary the

stitch width, when you are doing embroidery manually.

Turning this knob back and forth, rhythmically, while the

machine is running, will cause the needle to swing freely

from wide to narrow zig zag widths.

2: The restrictor knob (B Fig. 10) is used to restrict the width of

zig zag stitching. With needle out of material,turn the re

strictor knob in the direction of the arrow. Note that the

pointer in the dial indicates the zig zag width. Turning the

knob back again, will bring the pointer in dial back to "O".

Fij;. 10

C 6 )

00

o

o

Page 10

Automatic Operation of Zig Zag Sewing

Fig. 12

ii #

Fig. 13

Fig. 11

To lose« Decorator Disc

1. Turn restrictor knob ;B Fig. 11) till pointer on dial is

at "O".

2. Press push button < Fig. 13) and cover of disc chamber

will pop open.

3. Turn zig zag knob {A Fig. 11) so that pointer of dial

is at "4", and while holding it at this position, insert a

disc as in figure 13. Make sure that the disc is inserted

properly, by placing disc on spindle, and turning the disc

by hand until the notch on the underside of disc fits

over the small pin on spindle base. When this is done,

you will find that it is not possible to further rotate the

disc by hand.

4. Permit knob "A" to return.

,3. Close the chamber cover.

6. Set selective knob (Fig. 8) with the red dot at "A".

7. Proceed to sew, with complete automaticity.

To remove disc from chamber, first be sure that needle is

out of material, turn zig zag knob (A Fig. 11), till pointer

in dial is at "4". Hold in this position and simply lift disc

straight up and out to remove.

( 7 )

00

o

o

rsj

Page 11

To Wind the Bobbin

Good

No Go od

Fig .1.5

No Go od

Fig. 14

Turn the clutch nut in the center of

the hand wheel toward you to disen

gage the sewing mechanism. Place a

spool of thread on the spool pin, and

slip the thread through the upper arm

thread guide and across to the tension

disc as shown in Fig. 14.

Insert thread through a hole on edge

of bobbin and place bobbin on spindle

of winder. Be sure that the notch in

the bobbin fits over the small pin on

the spindle. Press down on lever mar

ked "push" and set machine in motion.

When the bobbin is fully wound, the

action of the winder stops automati

cally. Remove from spindle and cut

■ ( 8 )

off loose thread end.

If the bobbin winds unevenly (see Fig.

L5), adjust the bobbin winding tension

disc to the right or left by loosening

the screw holding it to the bed of the

machine. Then tighten.

Before starting to sew again, tighten

clutch nut by turning it away from

00

o

o

rsi

Page 12

How (o Remove and Replace Bobbin Cate

Fig. 16

Raise the needle bar to its highest position

and lift up the hinged cover plate. Grasp the

bobbin case by the latch and pull out (see Fig.

16). When the latch is closed, the bobbin

falls out of the case readily.

To replace, hold case by latch and place it

on spindle in center of shuttle race. Press fir

mly before closing latch, making certain that

the tongue of the case fits into notch on the

upper edge of the race cover.

To Thread (he Bobbin Cate

Refer to Figs 17, 18, 19 and 20 to familiarize yourself

with the procedure. Hold the bobbin case in your left

hand with tongue pointing up.

Let about two inches of thread hang free from the bo

bbin, and insert bobbin into case, so that thread will be

rotating counter-clockwise.

Fig. 18

Guide the thread end through the slot on the side of the

case and under the tension spring until it enters the

small notch on the edge of the spring.

( 9 )

00

o

o

Page 13

How to Remove the Shuttle

Fig. 21

i¥hen thread becomes tangled in the hook and shuttle

■ace it is necessary to take the under thread mechanism

ipart and clean it.

:iaise the needle bar to its highest position and tilt the

read back. Remove the bobbin case. Push the screws

>n either side of the race cover to the outside and the

;over can be removed easily. (See Fig. 21), Lift the

rook out.

Brush away all thread and lint from the race, hook and

•ace cover. Then, holding hook by the center pin, place

t in rase so that it fits firmly against driver.

?it cover over pins on each side of the race, with the

rotch at the top. Pull latch screws back over side open,

ngs of the cover.

How to Insert the Needle

Turn hand wheel toward you to raise needle bar to its

highest point. Loosen needle clamp screw and insert

needle with its flat side to the right or toward the screw.

Push needle up as far as it will go, and tighten screw

securely.

Always use the type of needle recommended by the

supplier of your machine. Test on a flat surface to be

sure it is not bent (Fig. 22).

( 10 )

00

О

о

Page 14

Threading the Machine

Fig. 23

Turn the hand balance wheel

: (14) toward you until the

thread take up lever (28) is

raised to its highest position,

i Place a spool of the. thread on

I the spool pin (1) on the top of

I the Machine. (Fig. 23)

' Draw thread through the first

14 ; thread guide pin (2) then

: downward to thread tension

) regulator ( 3) and under the

I same lead the thread from the

I

right to the left between the

I two tension discs. Then pull

upward passing over the thread

I

) take-up spring (4) from right

to left.

Lead thread downward again

around underside of thread

; guide (5) and upward through

); thread guide.

Now draw thread from right

; to left through guide (6) and

i needle clamp screw i 1) right

) above needle. Finally thread

I needle (8) from left to right

- through its eye.

C 11 )

00

o

o

Page 15

Preparing to Sew

Hold the end of the upper thread loosely and revolve

hand wheel toward you slowly until loop of bobbin

thread (Fig. 24) is drawn up through the needle holp.

Draw both threads to the right (Fig. 25

presser foot toward back of machine.

Fig25

1 and under

Fig. 24

Removing the Work

Stop machine w'ith take-up at its highest point. Raise

presser foot. Pull fabric toward back of machine,

keeping thread in presser foot slot to avoid bending the

needle. Hold both threads taut and cut on thread

cutter, leaving machine thread ends about four inches

long. Never operate the machine when it is threaded

unless there is material under the presser foot.

( 12 )

CO

o

o

Page 16

Automatic ZigZag

00

o

o

CM

Page 17

be made with the respective discs. By experimenting with changing the stitch length

and zigzag widths, contless numbers of designs can be made with each disc.

r f

<( )f

00

o

o

fM

o

m

o

Page 18

How to Adjust Tensions

Always adjust the upper tension with the presser foot down,

as the tension is automatically released when it is raised.

To increase the the tension onupper thread, turn dial (Fig. 29)

to the right, or clockwise. To decrease, turn to the left.

The higher the number on the dial the tighter the tension.

Before adjusting lower tension be sure that the machine is

threaded properly. When necessary to change the bobbin te

nsion, turn small screw (Fig. 30) on side of bobbin case clock

wise to tighten, counter-clockwise to loosen.

When the upper and under tensionl are properly balanced, a

perfect stitch will be formed with both threads interlocking in

fabric (Fig. 26).

When the upper tension is too tight, the lower thread is pulled

up over the upper thread which is lying flat on the fabric

(Fig. 27).

When the under tension is too tight, the upper thread forms

loops over the lower thread lying flat on the fabric (Fig 28).

Fig. 26

Fig. 27

Fig. 28

Perfect choin stitch

Ml

Wh

Tension too tight with upper thread

1.

Tension too tight with under thread

wm

M

Hi

m

iBTOl

ff BOeSN TENSION

^AOIUSTMENT SCREW

^

........

■

Fig. 29

Fig. 30

( 13 )

CO

o

o

Page 19

How to Use the Automatic Darner

To release the pressure from the presser foot so that the material can

be moved freely for darning and mending, push the release lever ( B

Fig. 31) and darner will pop up. To return pressure to normal, push

"A" all the way down. For a lesser pressure, when sewing thin mate^

rials, push darner part way down. Test for best pressure on scrap of

fabric.

Drop Feed Adjustment

The height of the feed dogs can be adjusted to suit the fabric or type of work

being done. Push the button on the left (Fig. 32) to "S" position to sew on

thin materials, or all the way down to "E" position for darning or embroil

dering with a hoop. Push button on the right to return feed to *N" or

normal.

Consult the following chart to determine the position of the drop feed

buttons and darner for various types of .sewdng.

Type of Sewing

Sewing thin material

Darning, embroidery with hoop

Sewing thick material

Drop Feed

S ;Silk)

E (Embroidery)

N (Nomai)

Darner Po.sition

Partially down

All the way up

Completely down

Mg. 32

( 14 i

00

o

o

fM

Page 20

( 15 .)

00

о

о

гм

о

го

о

Page 21

How to EmbroiJer with • Hoop

It is easy to follow a stamped design or to work free hand when

embroidering or monogramming. (See Figs. 33 and 34.)

Release the pressure from the foot by turning the burled nut

on the automatic darner in the direction of the arrow, or clock

wise. Push the drop feed button down so that "E" appears

between the two buttons. Stretch the fabric in an embroidery

hoop, and place under the needle after removing the presser

foot. Set the stitch width at the size you prefer and lower the

presser bar lifter. Then operate the machine at a rather high

speed while moving the hoop slowly with both hands. Work

carefully and be sure to keep fingers out of the path of the

needle.

1. Narrow hemmer. With the needle in its highest position

replace regular presser foot with narrow hemmer (Fig. 35).

For a plain narrow hem, make a 1, 8 inch double fold for about

two inches along edge of fabric. Hold each end of the twoinch fold, slip underneath hemmer. Bring fold up into the

scroll of hemmer, draw forward to end and fasten with point

of needle. Lower presser bar lifter. Gently pull ends of thread

as you start stitching.

Guide material slightly to right, and it will automatically take

Fig. 35

a double turn through scroll.

Fig. 33

J2345e7S9

Fig. 34

How to Use Attachmonts

( 16 )

00

o

o

fN

Page 22

Lace Trimmed Hem

To attach lace to hem, insert lace in the slot next to

needle. Sew hem as above, guiding lace under needle

and hem into scroll.

Lacc Edge with Invisible Stitching

Hold lace 1 8 inch from raw edge on right side of

fabric. Insert both in scroll as for plain narrow hem.

Let hem roll over and sew in lace. Press lace out flat

along edge with hem turned up. For a little fullness

in lace, feed it freely under scroll.

French Seam

With right sides together, place top piece of material

1 8 inch inside edge of lower piece.

Insert in hemmer scroll, allowing hem to roll over and

sew in top fabric, making French seam.

Flat Felled Seam

Open out P'ranch seam and insert rolled edge in scroll

of hemmer. Edgestitch to lay seam flat.

2. Quilting Guide. This guide for making parallel

rows of stitching is attached by placing the pronged

holder between the presser foot and the presser foot

clamp screw (Fig. 36). Adjust the curved bar to press

lightly on the faiaric. By letting the guide ride on the

first stitching line, successive rows will be an equal

distance apart. When the bar is attached so that the

curved part is to the right of the needle, it may also

serve as a seam width guide.

( 17 )

Fig. 36

00

o

o

Page 23

3. Sewing on Buttons. Exchange the regular presser foot for the one provided to sew on

buttons. I See Fig 37.) Drop the feed to "E" position. Place button and fabric under

presser foot. Determine the width of the stitch needed to enter each hole of the button

by turning the hand wheel slowly toward you as you adjust the zigzag regulating knob.

Then lock at that width. Take six or seven stitches to fasten the button securely. Then

turn the knob to 0 and take two or three more stitches in one hole to lock the threads.

Repeat' the procedure when sewing on four-hole buttons.

Snaps and hooks may be stitched on in the same manner.

18

Fig. ,37

00

o

o

Page 24

4. Making Buttonholes. Replace the regular presser foot

with the buttonhole foot which is equipped with a measure

ment gauge (Fig 38). Set the stitch lenght near 0 for a very

short stitch. The width of the stitch should be set at 2 or

slightly under for a daintier buttonhole. If a heavier button

hole is required, cord may be strung through the hole in the

foot.

Mark the desired length of buttonhole on the labric or set the

gauge so that the distance between the curved marker and the

needle is equal to that of the buttonhole. Sew the first side

of the buttonhole, stopping the machine with needle in the

material at right side of stitching.

Lift the presser foot, and using the needle as a pivot, turn the

fabric end for end or 180 degrees (see Fig 39). Before lowering

the presser foot make sure that the first row of stitching is

lined up straight. Lower presser foot and turn wheel by hand

just enough to raise needle out of fabric.

Fig. 38

Drop the feed to "E" position and turn zigzag knob to No. 4

width. Take about five or six stitches to make a bar tack.

Stop the machine with the needle out of the fabric, but leave

the presser foot down. Raise the feed to "N" and return stitch

width to 2 or original setting.

Proceed to stitch the second side of the buttonhole. When

you have reached the end of the first row of stitching, stop

the machine again with the needle out of the fabric.

( 19 )

00

o

o

Page 25

Leave the presser foot down, drop the feed to "E" and take five or six stitches to close the buttonhole.

Stop the machine with the needle out of the fabric, but do not raise the foot.

Return stitch width to 0 and take two or three stitches, which will fasten the bar threads and prevent

ravelling.

Cut the buttonhole opening with the seam ripper, being careful not to cut the stitching.

If you plan to make buttonholes on sheer or soft material, place tarlatan or paper, which can be torn

away after stitching, under the fabric. And it is always wise to make several buttonholes on scraps

of fabric before working on the garment.

Fig.

( 20 )

m

00

o

o

Page 26

Fig. 40

6atlieriiif

Simple gathering stitches should be rather long and the upper

thread tension sufficiently light to enable the lower thread to be pulled.

Sew as usual, but preferably stitch two rows.

Use the presser foot as guide. When both rows have been stit

ched, pull the lower thread so as to form gathers in the fabric. (Fig. 40).

CSatliering witib, dkstic tbireadi.'

By using latex thread you can make elastic gathers. Wind the

elastic thread by hand on the bobbin, and use ordinary thread for the

upper thread. The kind of gathering is especially suitable for under

wear, children’s clothes, beach wear, etc. (Fig 41).

Fig. 41

( 21 )

00

o

o

Page 27

Fig. 42

AppKque

Many beautiful and decorative effects are obtained with this "easy

to do operation". Cut out the applique design and simply zig zag

stitch it around the outer, on to the material to which the design is to

be appliqued.

Sewing Knitwear

Use a small stitch (approximately 1 ) and zig zag width at 5.

( 22 )

00

o

o

Page 28

Lighting Equipment

To replace light bulb, open face plate, removing old bulb as in

Fig. 44.

Heedle-Thread-Eahric-Stitching Guide

Fabric

Extremely heavytarpaulin, sacking

canvas, duck, etc

Heavy-upholstery

fabric, ticking.

denim, leatherette, etc

Medium heavydrapery fabric, velveteen,

suiting, felt, terry, etc

Medium-broadcloth,

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc

Sheer-voile, lawn.

dimity, crepe.

handkerchief linen,

plastic film, etc

Very sheer-chiffon.

batiste, lace, organdy,

ninon, net, marquisette, etc

Machine

Needle Stitches Cotton

6 10

4

3 to

2

1 to

0

00

to

8

8

10

10

to

12

12 60

14

14 80

to

16 100

(Plastic film)

8 to 10

16

to

20

100

150

FACE PLATE ,

Mercerized or

Thread N ylon

to

30

30

to

40

40

to

60

to

80

to

to

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk

—

■

A

A

A

LAMP

-

Fig. 44

( 23 )

CO

o

o

r\i

Page 29

Check Up for Smooth Sewing

Although your sewing machine is designed for maximum efficiency, should any of the following difficulties occur

they can be remedied with minor adjustments.

Upper Thread Breaks.

Be sure needle is inserted properly.

Check on correct way to thread machine.

Use correct needle size for thread.

Do not have upper tension too tight.

Lower Thread Breaks

Check correct method of threading bobbin case.

Be sure lower tension is not too tight.

Needle Breaks

Do not tug or pull on the fabric while sewing as this will bend and eventually break the needle.

Skipped Stitches

Do not use a blunt or bent needle.

Insert needle correctly.

Use correct needle size for thread.

Be sure pressure on foot is sufficient when sewing heavy fabrics.

Stitches Loop

Make sure tensions are properly balanced and that machine is threaded correctly.

Machine Binds

Clean thead, dust and lint from hook, shuttle and race. If condition continues, it may be that the machine

is gummy with oil. Apply kerosene to oil holes, run rapidly for a while, and wipe dry. Then lubricate

again with fine sewing machine oil.

( 24 )

00

o

o

rsj

Page 30

Oiling and Cleaning

Bef ore s tar tin g to o il the u pp er p art o f th e mac hin e, tu rn ha nd w he el

unti l ta ke mp is a t it s low e st p oi nt. Ap ply a d rop of oil to p oin ts

indi ca ted b y a rro w s i n F ig s 4 5, 46 a nd 47 .

Fig. 45

To reach the areas requ iri ng oil on th e u nd ers id e

of the mac hi ne iF ig . 46) tilt the head bac k on

its h in ge s.

OIL 8U

Fig. 46

How f req ne ntl y t he m ach in e is us ed de ter mi ne s th e

oili ng req ui rem e nts . M o der at e u se calls fo r o nly an

occ asi on al o ili ng . A fte r a pp lyi ng the oil , ru n th e m a

chin e a t hi gh spe ed so t ha t all par ts w il l be pen et rat ed

bv t he oi l.

Fig. 47

25

00

o

o

Page 31

■ ■■ ' Ч.

A -- " .^jí= ; ■. . _ -i* í .

. '■< .

i 'Kíi-X

^ - ■

ífi w ' ■;- "

'Æ' ■

Ч ■ ‘í ' ' .

■V

■ 4 ' 1 'U w^,

». -1

^--v4Y/*y

,fJíi4ÍLÁ.-* . -Ч*.-

• . ' ■ ' .1"* :

■■ ^r'v.4 Ч V .■•■ J ■ ;•' =ÍvJl'-'‘V ^

■ ^.' ' ' '''

'•

, . . 4. ^

■ '” ‘ ■ * .. ' ' -P* 1

1: r* -- '• -VIJ. *J 4. :í:í

/Л ffci' '*

r^.‘'-“;- - V'"Ч a.V‘--^ ■ '■ ■ J-'',

■ ■>'-■'-

Lj—■■' •' - Lj .

'-Ж

-■i*'.'' ■ -'‘‘í"' ■ ■ '. •■ -•" . ' ■ - . V. Ч ■ * .Г- -; . -Ч. • . ... 3

^ V

Ч-

__________

'-..Л

---------------

-.;ч :■ ■'■ '. ■■■;,.r^’- ■

. ■ ' • ' 1 V Î ■ . ► ’ Ч.- ■ " •■ '

* * . . . . f . . .■ ' ■ ^ - j. ■ V

------

’ ’-\r—. f ■ V-V——r—^

.. -e't _____________■ . Г, ..■j.-_, __•: ■-'■ ■ .. -e.' ! .■>:-' - . V ■■ . . - A. _____________J

------

j*:-—

------------------

r™ —3

, Ч;., >’ 'f cA

00

o

o

ГМ

o

CTi

o

Loading...

Loading...