SINGER W7317 User Manual

c

lEWING MACHINE

a

CONTENTS

Page

Contents .......................................................................................... ^

Name of Each Parts ........................................................................... 2

Special Features ................................................................................ 3

1. Installing Head into Cabinet

2. Attaching Motor to Machine

3. Built-in-Light ........................................................................ 5

4. Winding the Bobbin

5. To Insert and Remove the Bobbin Case

6. Threading the Bobbin Case

7. Placement of the Needle

8. Threading the Machine ....................................................... 11

9. Picking up the Bobbin Thread ............................................ 12

10. Commencing Sewing ........................................................... 12

11. Regulating Thread Tension

12. Regulating the Pressure of the Presser Foot ••• 14

13. Drop-Feed Control

14. Regulating Stitch Length

15. Zig-zag Sewing ..................................................................... 15

.................................................

.....................................

.........................................

..........................

..................................................

.....................................................

................................................

...............................................................

....................................................

6~7

8

10

^

4

13

15

15

Page

16. Cleaning the Snap-Open-Race .......................................... 17

17. Oiling the Machine ................................................................... 18

18. Sewing on Button .................................................................... 19

19. Making Button-Hole ............................................................. 20

20. Darning & Embroidery

21. Quilting ................................................................................ 21

22. Sewing Braids & Raising Applique Stitches ■■■ 21

23. Narrow Hemmer ................................................................... 22

9

24. French Seam (Felling) ......................................................... 23

25. Lace Trimmed Hem

26. Lace Edge With Invisible Stitching

27. Flat Felled Seam .................................................................. 25

28. Cloth Guide .......................................................................... 26

29. Attaching the Zipper Fastener

30; Some Useful Hints ............................................................... 27

31. Causes of Common difficulties

32. Needle and Thread Sizes

(Use 15X1 Needle only)

Parts List

.......................................................

.............................................................

...................................

...........................................

.........................................

...............................

21

24

24

26

28

29

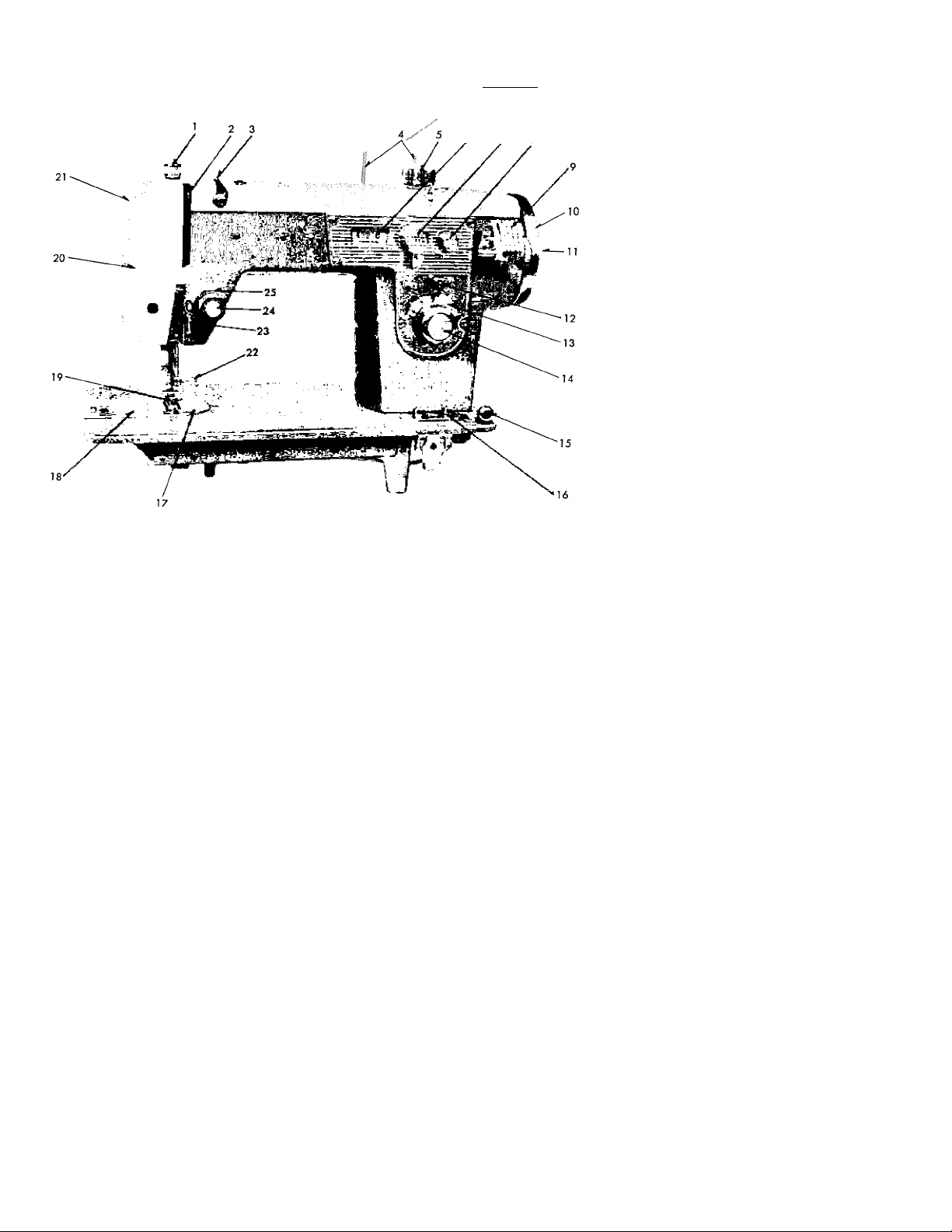

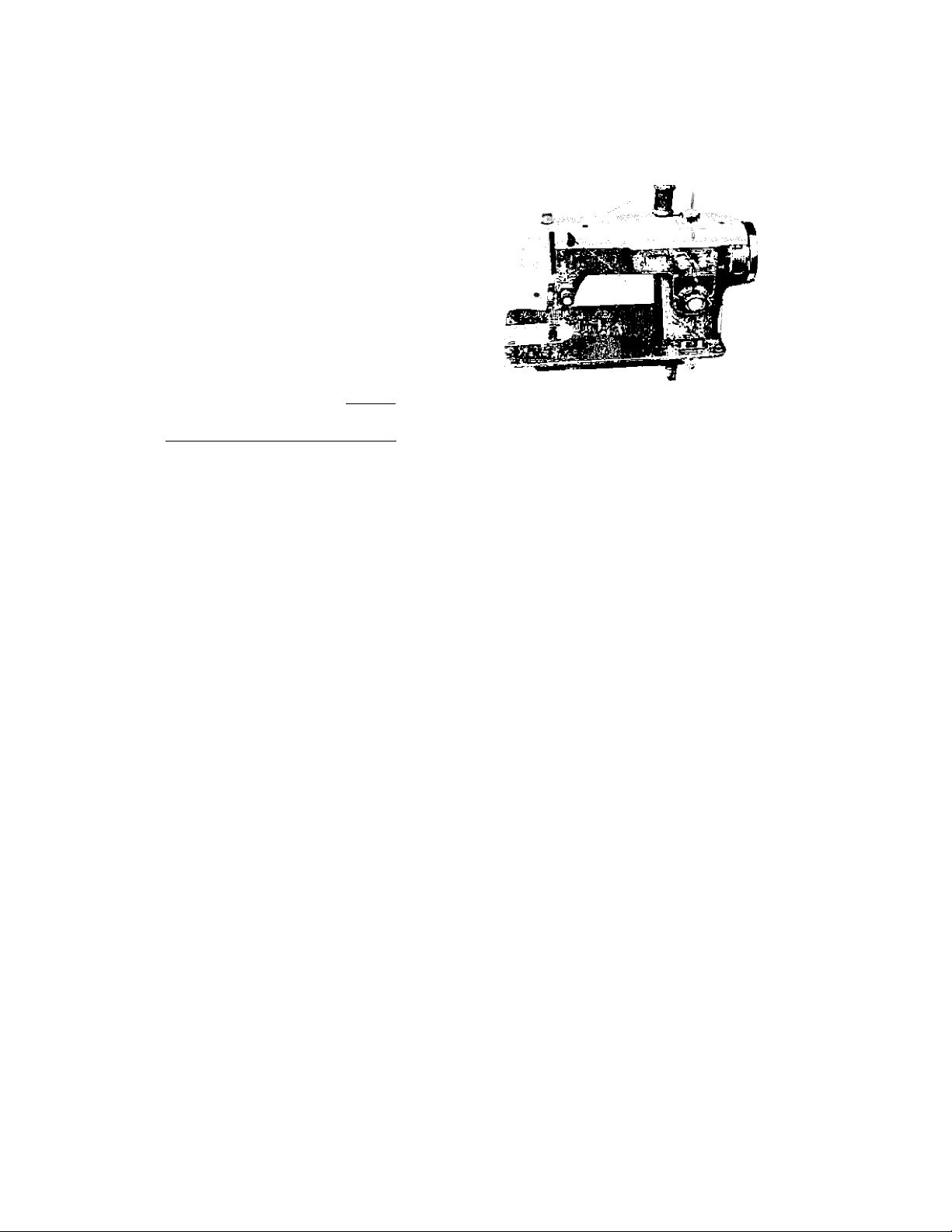

NAME OF EACH PARTS

6

' /1 A

1 /"“

7 8

1. Automatic darner

2. Thread take up lever

3. Upper arm thread guide

4. Spool pins

5. Button hole knob

6. Zig-zag width window

7. Zig-zag width control knob

8. Zig-zag width stopper

9. Bobbin winder

10. Balance wheel

11. Stop motion knob

12. Push button for reverse sewing

13. Stitch length window

14. Stitch length control knob

15. Bobbin winder thread tension guide

16. Push button drop feed

17. Needle plate

18. Slide plate

19. Presser foot for zig-zag sewing

20. Face cover (Built-in-light)

21. Sew-iieht switch

22. Needle clamp

23. Upper thread retaining bar

24. Upper thread tension regulator

25. Check spring

SPECIAL FEATURES

AUTOMATIC DARNIR (PRESSURE RiGULATOR) - enables you to select the exact pressure by pushing

the button according to materials,

STITCH LENGTH CONTROL KNOB - regulates the stitch length by turning the knob. It helps you to select

the stitch size with ease and accuracy.

PUSH-BUTTON FOR REVERSE SEWING - changes to sew reverse stitch from forward by pushing this

button.

AUTOMATIC BOBBIN WINDER - winds your bobbin and stops automatically when bobbin is filled.

NUMBERED UPPER THREAD TENSION REGULATOR - allows the tension of the upper thread to be

easily and accurately adjusted according to thread and material weight.

BUILT-IN-LIGHT - none glare sew-light will be more efficient, light bulb can be changed easily.

BUTTON-HOLE SWING - can be sewn automatically by regulating the knob, without turning the fabrics.

PUSH-BUTTON DROP-FEED - darning & embroidery can be selected easily and accurately.

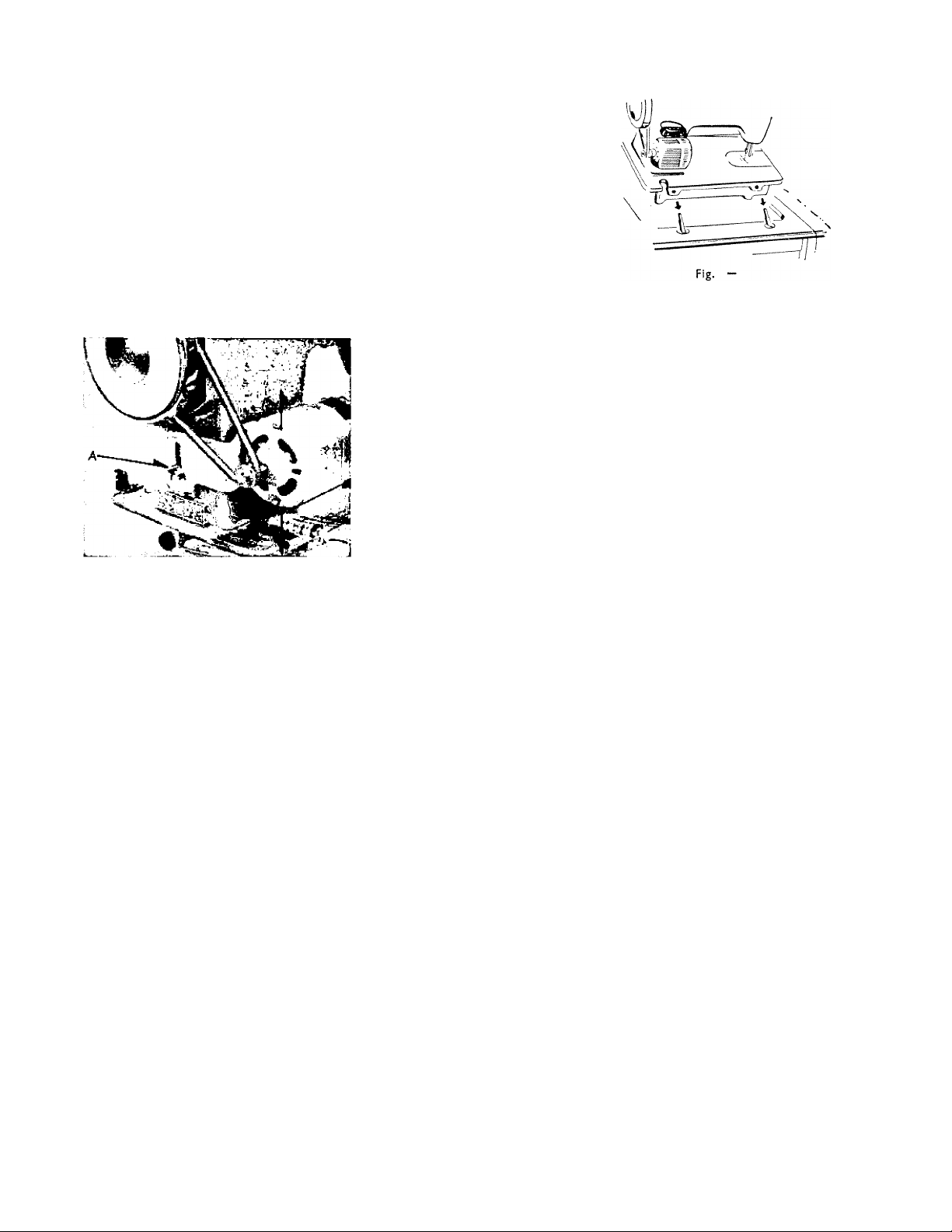

1. INSTALLING HEAD INTO CABINET

1) Loosen the two hinge screws under the holes in the rear edge

of the machine bed ¡Fig. 11.

2! Raise hinge-pins in the cabinet cut-out, slip machine head on

the pins, and tighten hinge screws securely.

2. ATTACHING MOTOR TO MACHINE

1) Place the motor bracket over the tongue of the arm under

the balance wheel, the screw hole in the center of the

tongue can be seen through the slot of the motor bracket

IFig. 2).

2! Then insert the screw and after shifting the motor upward

as far as it will go, tighten the screw.

3) Slip the motor belt into the groove of the balance wheel,

and then slip the belt into the groove of the motor pulley.

4) Adjust the belt tension by loosing the motor bracket fas

tening-screw and let the motor drop downward until the

Fig. 2

Then tighten the motor bracket tastening-screw tightly. NEVER OIL THE MOTOR.

correct belt tension has been reached.

— 4 —

As shown in ¡Fig. 3). lamp is encased in the face

cover. Light is put on when the lamp switch (A)

located on back side of face cover is revolved clockwise,

and when turned further it is put off. When you want

to replace the new bulb, open the face cover and

un-screwes- Electric bulb (15w| is available at any

department stores, electric shops, or your sewing

machine dealers.

Fig. 3-A

Fig. 3-B

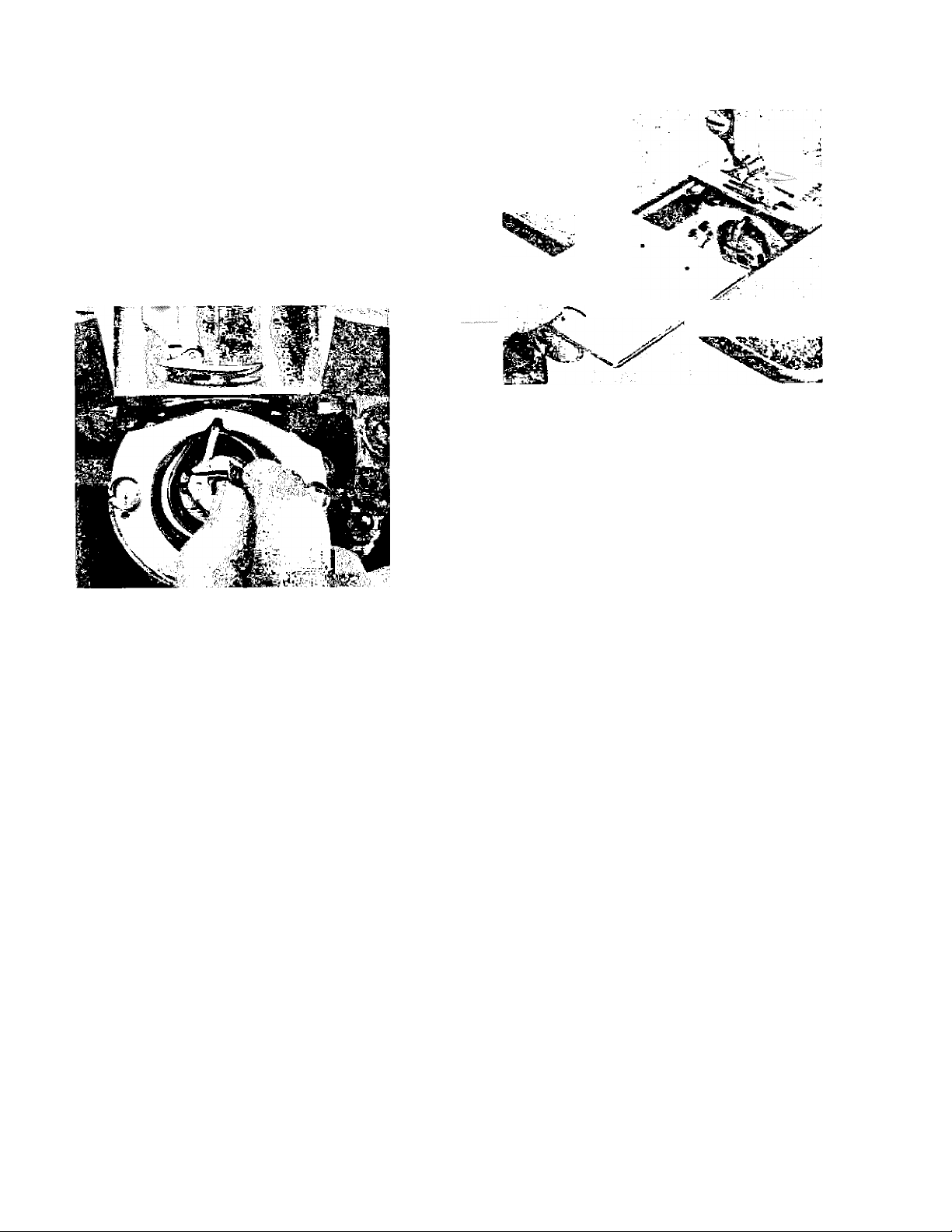

4. WINDING THE BOBBIN

II Hold the balance wheel with your left hand and turn the stop motion knob (A) (Fig. 41 toward you with your right

hand (counter-clockwise!. The balance wheel is now disconnected for the bobbin winding operation.

21 °lace a spool of thread on the spool pin (Fig. 51. Draw the thread from the spool to thread guide' then downward

across the machine from left to right.

31 Pass the thread through the tension device at the |

right corner on the bed. i

4) Now wind the end of thread around an empty

bobbin several times and insert the bobbin on the

bobbin winder spindle.

51 Press the bobbin winder cover until a click is

heard. The bobbin winder release lever is now

touching the spindle of the bobbin. It holds the

bobbin in place.

I

Fig. 4

6) Press vour foot controller or knee controller in

the same manner as in sewing, when the

bobbin is nearly full, it will release automa

tically and stop turning.

Remove the bobbin from the spindle. Hold the

balance wheel firmly with the left hand and

tighten the stop motion knob away Iclockwise!

with right hand.

You may continue sewing while you are

winding bobbin without disconnecting

balance wheel.

Fig. S

5. TO INSERT AND REMOVE

.................... THE BOBBIN CASE

1) Raise the presser bar by lifting the presser bar lifter.

2) Turn the balance wheel toward you until needle bar

comes to its highest position,

3) Pull out slide plate to the left (Fig. 6).

4) With the thumb and forefinger of the left hand, grasp the

5) Allow the end of thread to hang free.

6) Push back the slide plate.

Fig. 7

Fig. 6

bobbin case latch with thread coming from the top, slide

out the case (Fig. 7).

To remove the bobbin case do all the above in reverse

order.

8

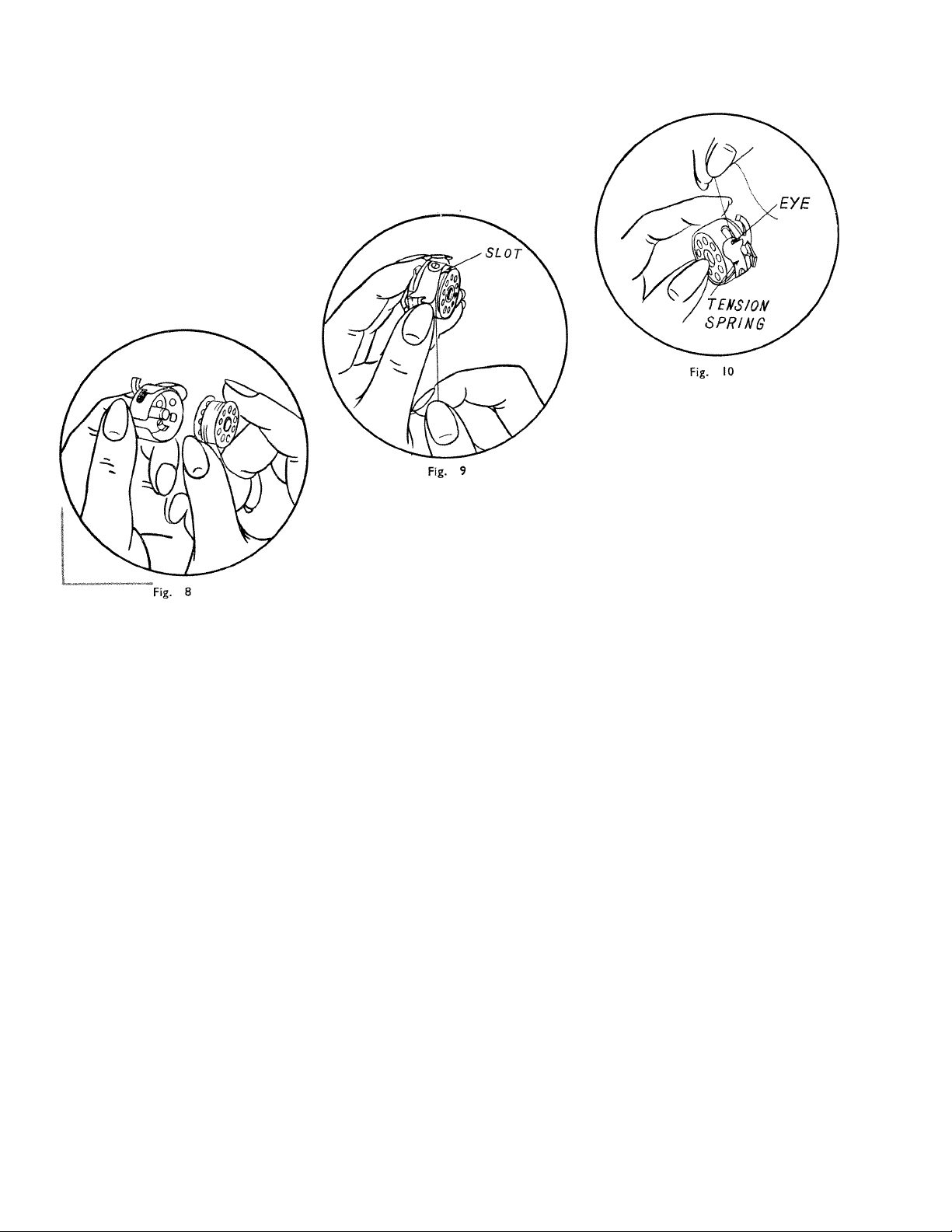

6. THREADING THE BOBBIN CASE

Before threading the bobbin case, study IFig. 8, 9, 10) to get a

general idea as to how it is done.

1) Hold the bobbin case with your left hand and put the bobbin

into the bobbin case with your right hand, leaving about two

inches of the thread end un

wound (Fig. 8). As the bobbin

is being inserted in the bobbin

case, the thread flow in

clockwise.

3) Then pull it through under the tension spring of

the bobbin case IFig. 9) until it enters the delivery

eye (Fig. 10!.

2! While holding the bobbin case

as before, grasp the thread end

with your right hand, and draw

it into the cross slot (Fig. 8).

Loading...

Loading...