SINGER W714 User Manual

sewing

I N C E 18 76

machines

OWNER’S MANUAL

SEWING MACHINE

MODEL 714

This booklet has been written for you so that you may use and enjoy fully all

the features built into this machine.

Please read the instructions pertaining to your machine carefully, as a thorough

understanding of how it functions will reward you with many hours of trouble free

creative sewing.

Time-saving attachments, such as rufflers, binders, buttonholers, edgestitchers,

cording feet, and others, to complement the accessories furnished with these models

are available from the store where you purchased your machine.

index

Accessoripj.q

How to Use

Hemmers

Seam Gauge or Cloth n

..............................................

................

.............................

.........................................

...................

Pages

fHiachmentq............................................. 25

Adjustable Cord

..............................

Attachment Foot-- ^ Poot 40

binder

Edgestitcher

Hemmers

Mmd Hem

Bobbin

Winding

buttonhole.q

Bound

BuHoiLs Sew-On......................................

.......................

........

......................... 34

................

.........................................

..............

.......................................

...................................

...................... ............................

......................

.......................................................

.............................

................................ 5

....

18

19

46

■Qharts ■ 21

f«chtS3ht!i™-Söt=hing

trouble

.............................................

.............................

..................

4

9

29-30-31

23

36

34

....

6

~HSSLHilMendinQ • -..

Embroid^ 2

Creative

Hoop

'*22 - Head

Maintenanc

...................

............... ..................................

...................

HeedJe Settf^^ ^B ^Oiting the Shuttle 27

Thin and

Reverse Sewira^

^SHig-Preparation

..............

Eabrics - n

....................................

Sgwing Ting ............................................. 12

-isiabt stitchinrr

..............

'iB

.......;......................

...

iHgadinodwir^- ........................................ 10

.............................

8

11

14

9

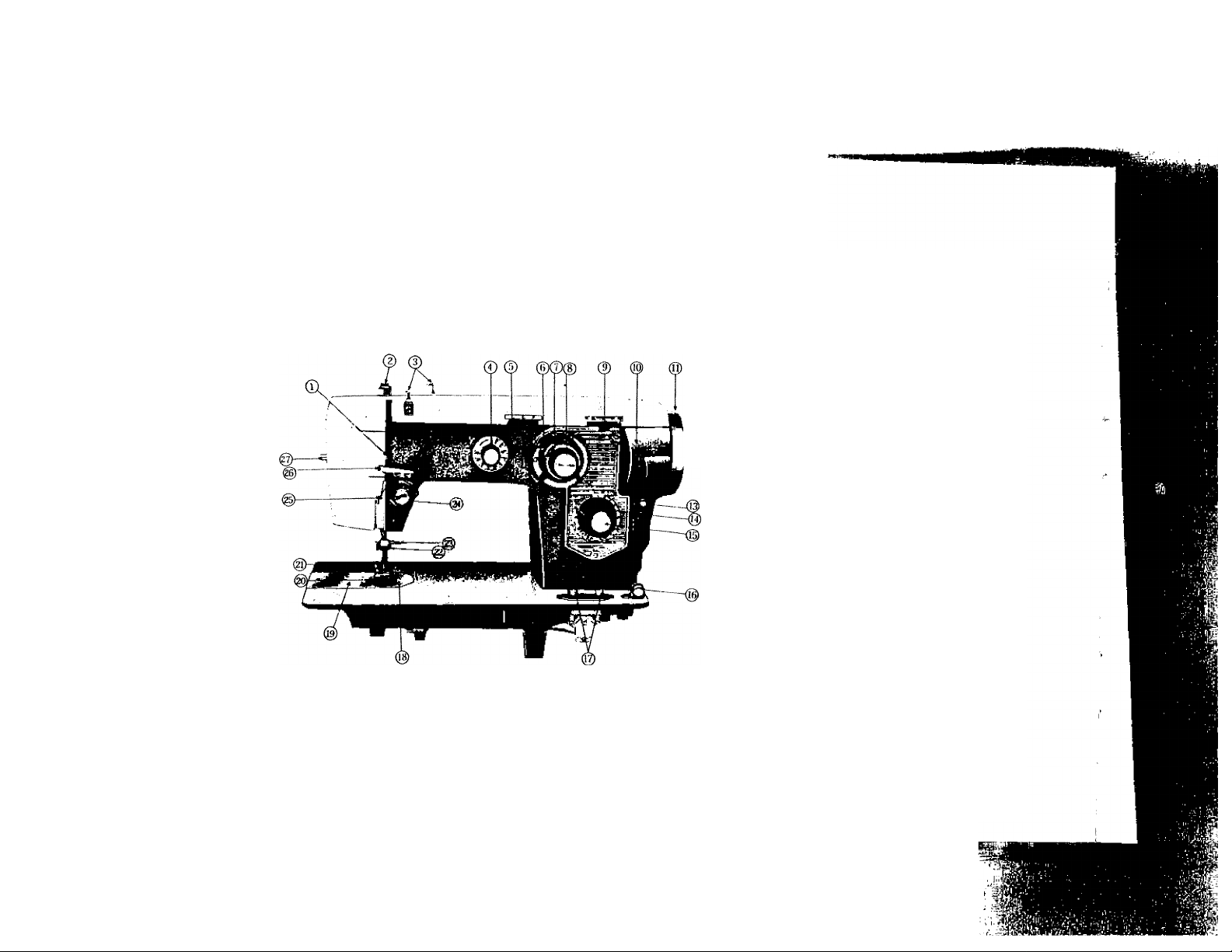

FEATURES AND PARTS

(Front View)

Fig. 1

1. Thread Take-up Lever

2. Pressure Release

(Darning)

3. Arm Thread Guides

4. Decorative Stitch Dial

5. Needle Position Lever

6. Buttonhole Control Knob

7. Zigzag Stitch Width Stop

8. Zigzag Width Control Knob

9. Pattern Selector Lever

10. Bobbin Winder Cover Door

11. Hand Wheel

12. Clutch

13. Cover Release Button

14. Stitch Length Control Knob

15. Push Button Reverse

16. Bobbin Winding Tension

17. Drop Feed Buttons

18. Needle Plate

19. Cover Plate

20. Presser Foot

21. Presser Foot Thumb Screw

22. Thread Cutter

23. Needle Clamp

24. Tension

25. Thread Guide

26. Thread Bar and Face Latch

27. Sew Lite Switch

■ K-

:

Fig. 2

Features and parts

(Back View)

28. Presser Bar Lifter

29. Feed

30. Head Hinge Mounting

Holes

31. Spool Pins

32. Handle

■

- ' I

V::

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

■, ^ Vj-

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen.

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen.

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn.

dimity, crepe.

handkerchief linen,

plastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marquisett etc.

Needle

No.

4

3

2

1

0

00

Machine

Stitches

Per Inch

6

to

8

8

10

10

to

12

12

to

14

14

to

16

(Plastic film)

8 to 10

16

to

20

Cotton

Thread

10

30

3D

to

40

4D

to

60

60

to

80

80

to

100

100^

io

150

Mercerized

Thread

1

Fia.

Fig. 4

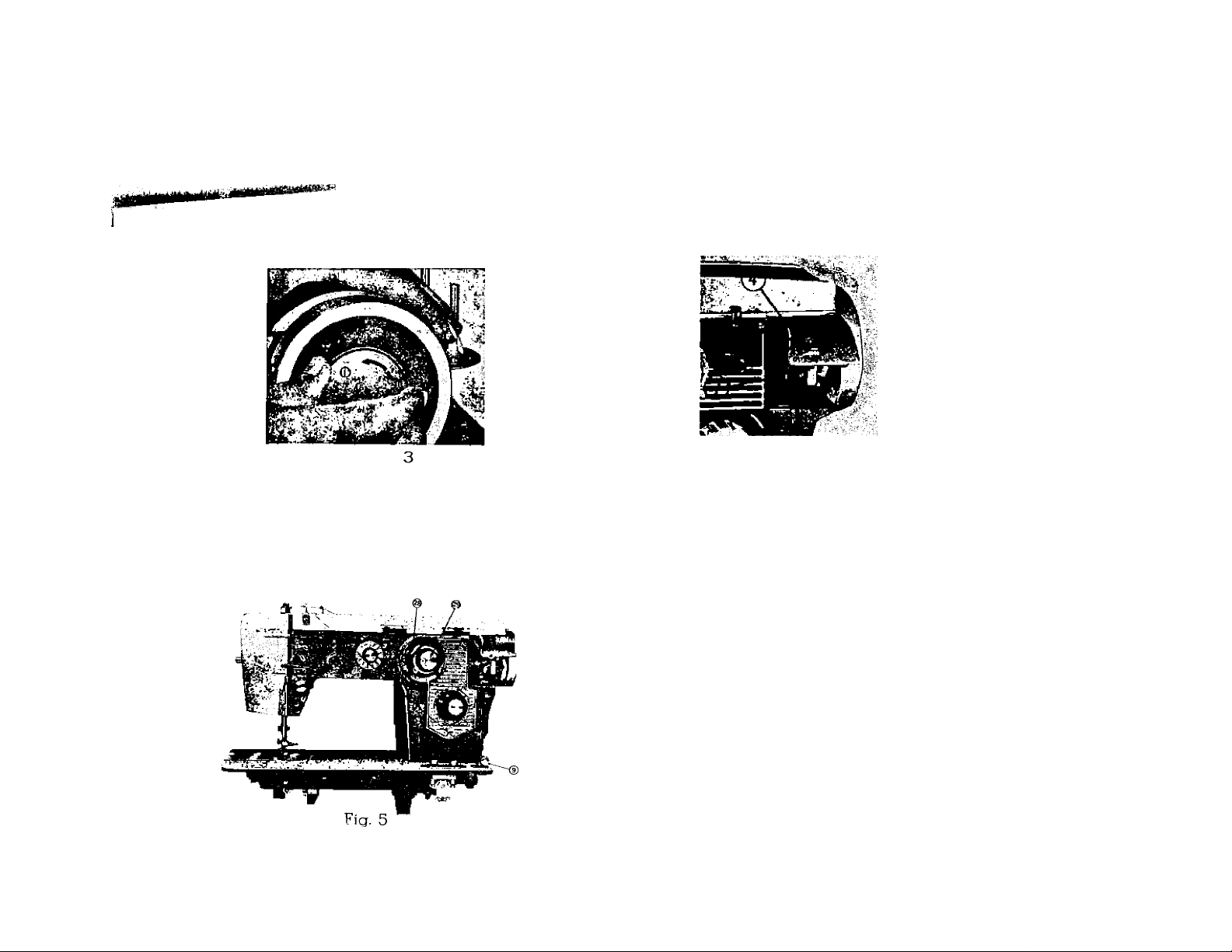

WINDING THE BOBBIN

Disengage hand wheel (5, Fig. 3), from the stitching mechanism by turning clutch (6, Fig. 3)

toward you or counter clockwise.

Push latch (4, Fig. 4) to spring open cover (3, Fig. 4) of the recessed winder.

Place a spool of thread on one of the spool pins. Lead thread through the upper thread

guioe on arm and down through tension disc (9, Fig. 5,) at base of machine. Run end of thread

through a hole in bobbin edge (left flange

and from inside out) and place bobbin

on spindle of bobbin winder (7, Fig.4j fitting

the notch bobbin over small pin on spin

dle. Push bobbin winder against hand

---

(7)

wheel. Hold thread end loosely and start

machine slowly.

Bobbin will stop winding when it is

filled. Turn clutch away from you until

sewing mechanism is again engaged so

that needle moves when you turn the hand

wheel.

Break off loose thread end used to

start the winding and thread bobbin as

stated on Page 6

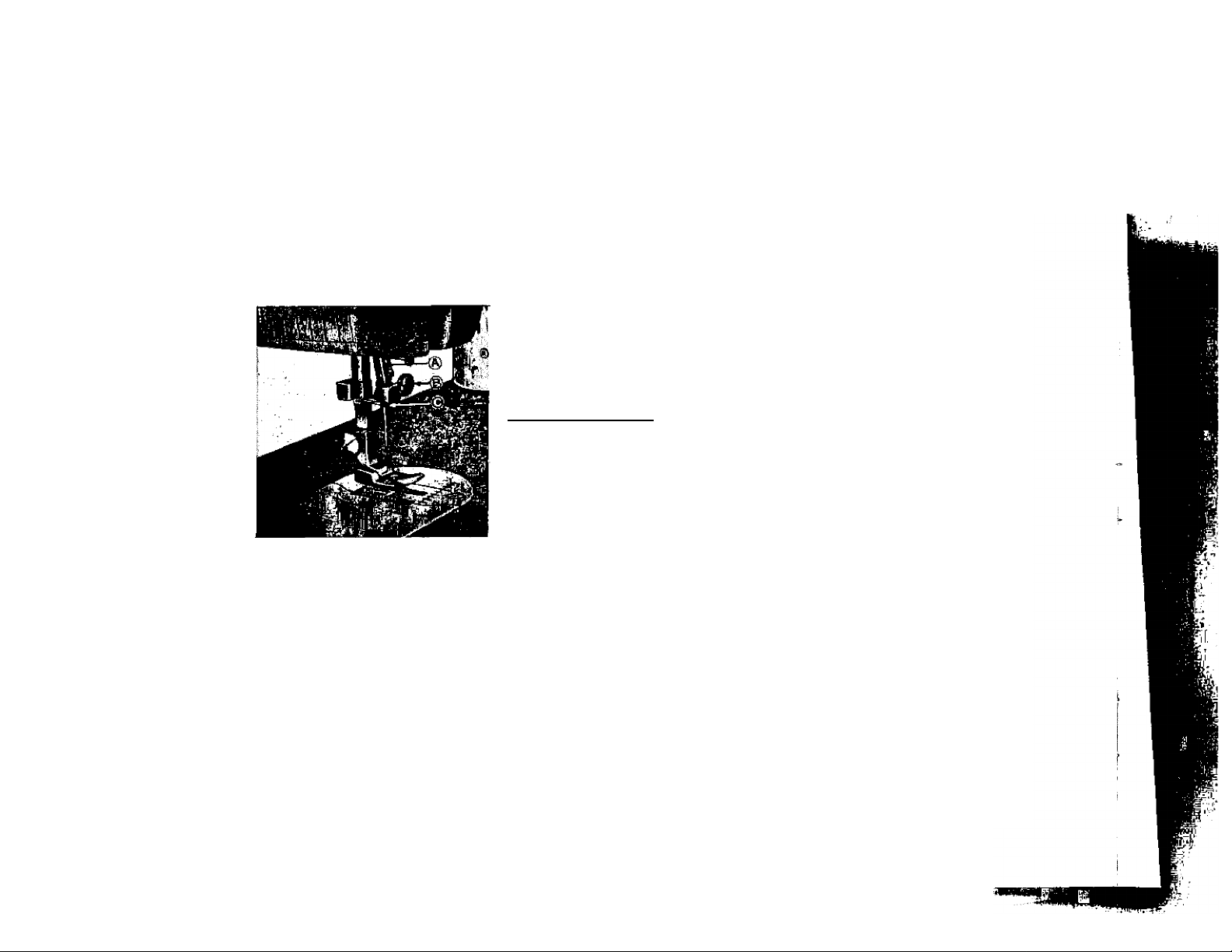

SETTING THE NEEDLE

See Fig. 6. Raise the needle bar A to its highest

point, turning wheel toward you by hand.

Then loosen the needle clamp screw B and the

needle can be inserted into clamp C. Place needle

(flat side to right) in the needle clamp and push it

upward as far as it will go into the needle clamp

hole, tightening the needle clamp screv/ securely

with a screw driver.

After changing the needle make one com

plete revolution of the balance wheel by

hand to be sure the needle is in the correct

position.

Fig. 6

Flat surface

oi needle

shank

/

Fig. 7

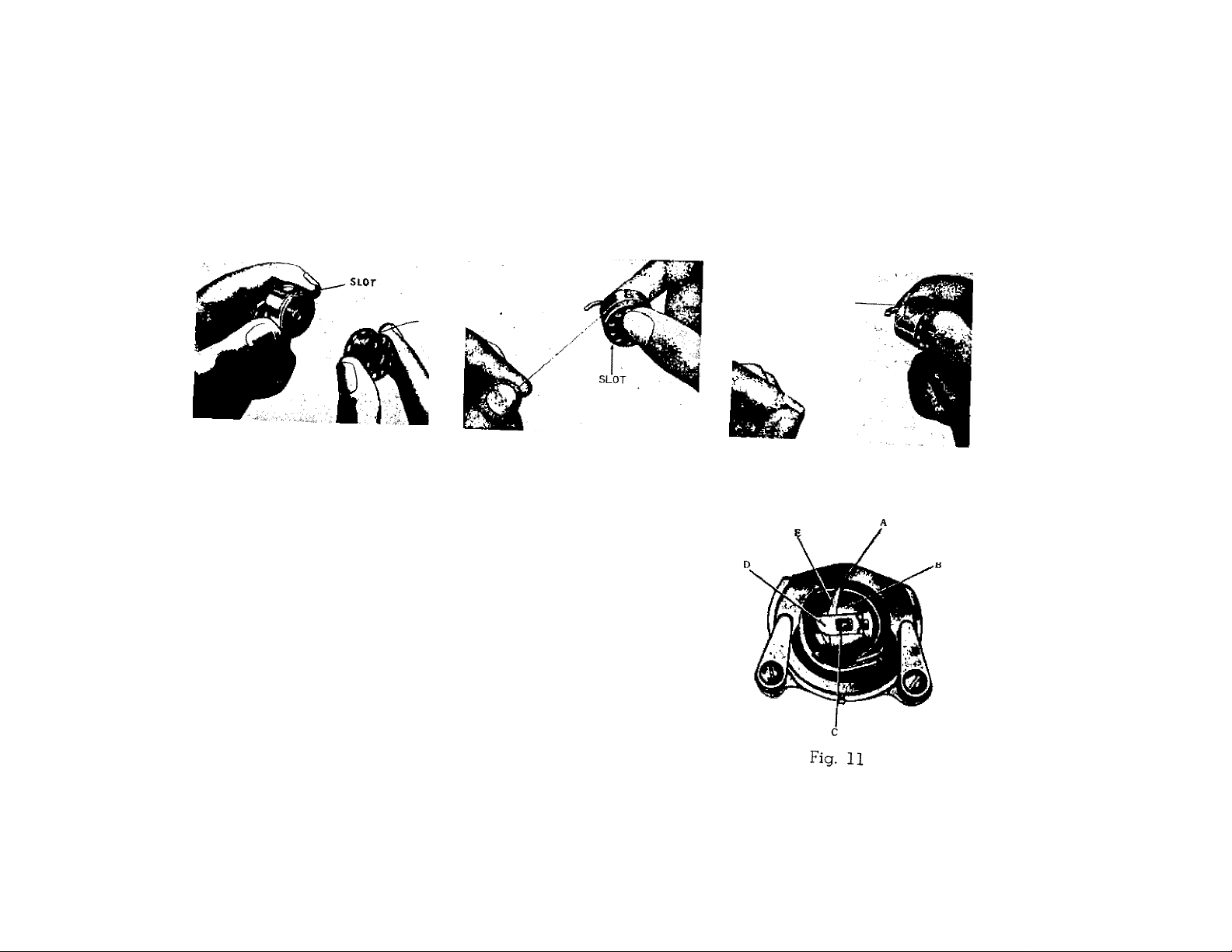

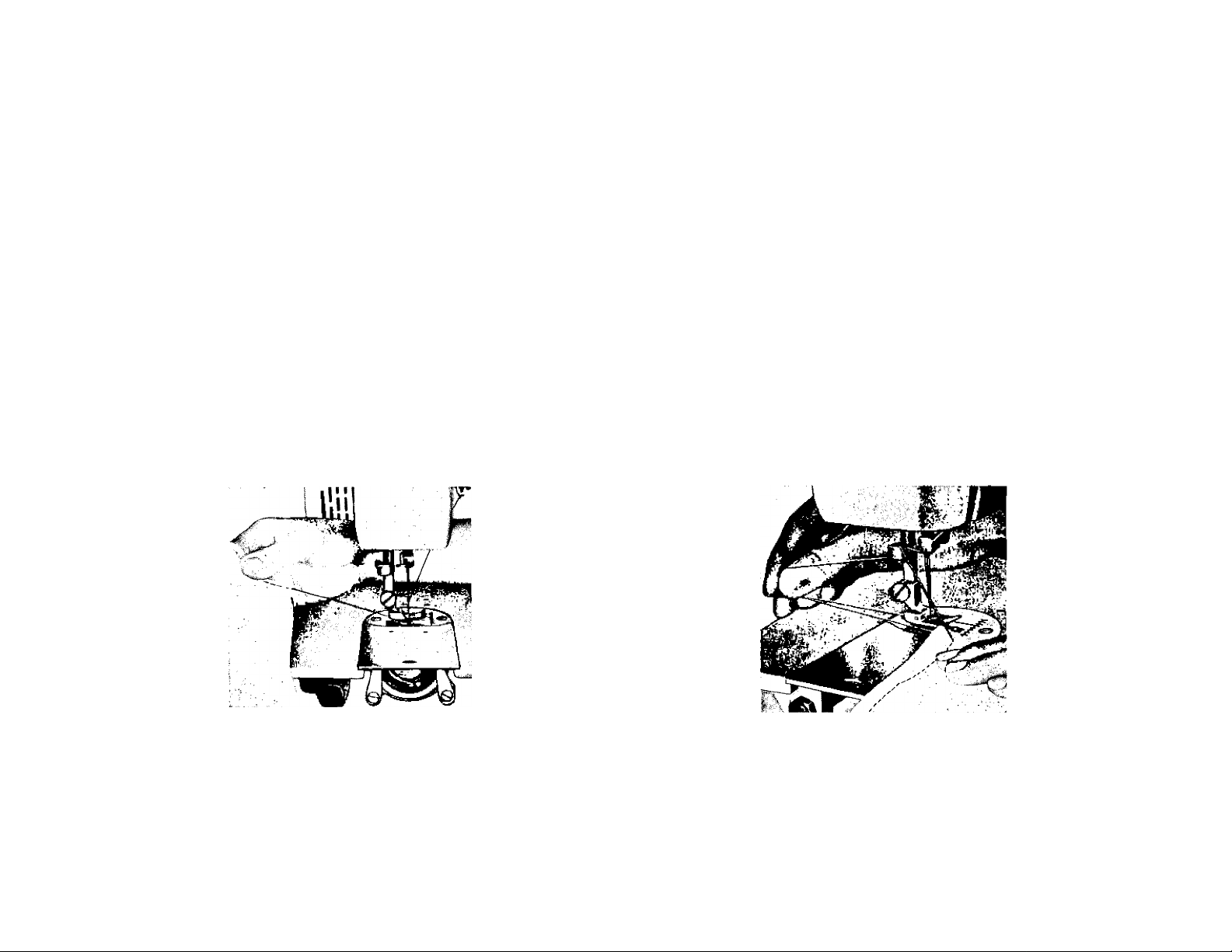

THREADING THE BOBBIN CASE

Step 1 (illustrated in Fig. 8). Hold bobbin case between thumb and forefinger of left hand,

so that the slot in the edge of the bobbin case is on top. Take the bobbin between thumb and

forefinger of right hand so that the thread on top leads from left to right.

Step 2. Insert bobbin into bobbin case, pull the thread into the slot of the bobbin case as

shown in Fig. 9, and draw it under tension spring and into the fork-shaped opening of the spring

as shown in Fig. 10.

TENSION SPRING

Fig. 8

Fig. 9

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to highest position, and slide cover nlate

L n K fbobbin case iXh S

whh at 1 rr"" ® forefinger of the left hand

tT K running from the top of

the bobbin case to the right. Insert and center the bobbin

case on the stud of the shuttle body, (C) Be sure the

PrisifteT hK "■ ‘he shuttle race notch (A)

Press the bobbin case (B) into the shuttle as far as oossible

rdLsi th *be shuttle. THEN

release the bobbin case latch, (D). Press bobbin case aaain

after latch has been released to make sure the bobbin case

IS locked securely in place. Close the cover plate

Fig. 10

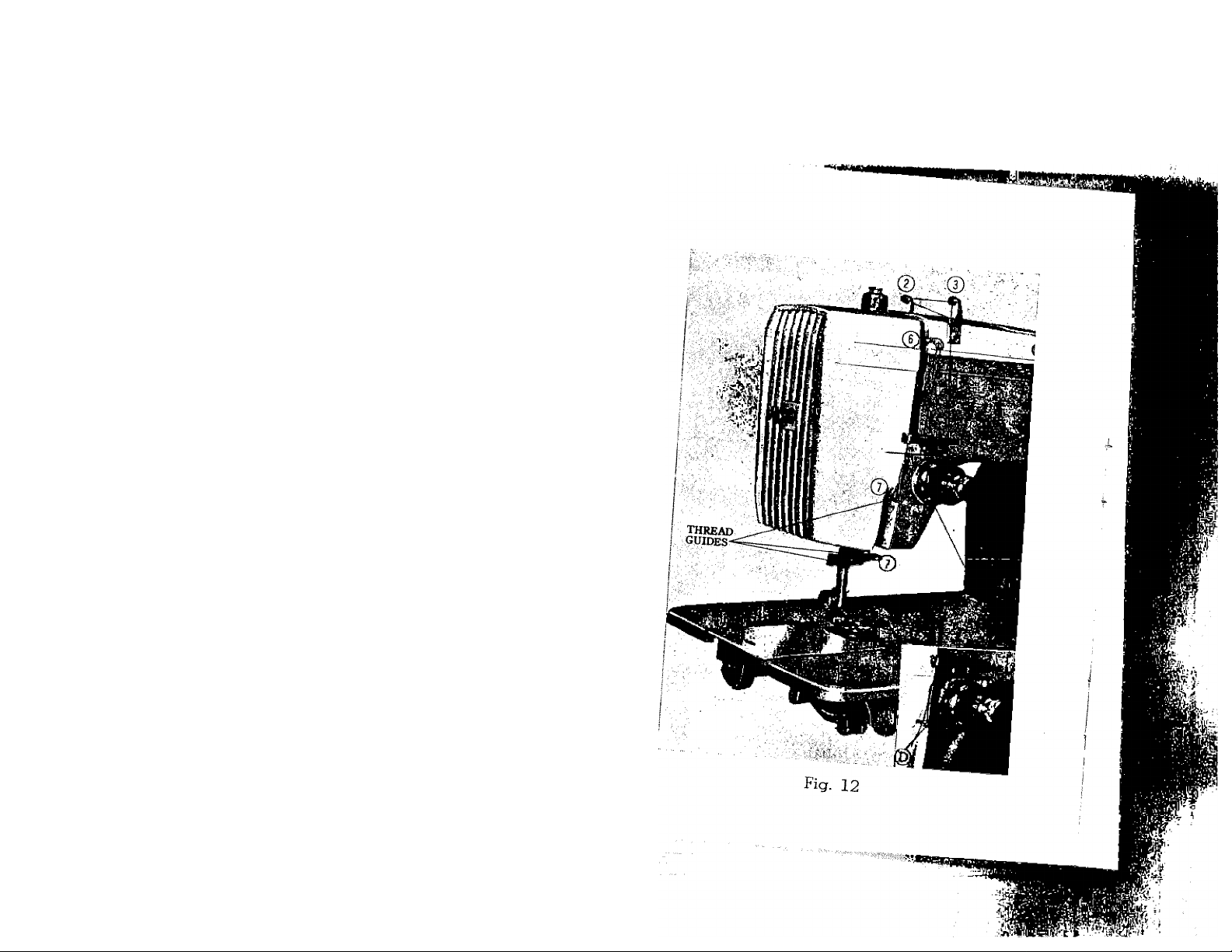

UPPER THREADING

the take^up^IevS

2.

Place a spool oTfh J ^

3.

head the thread through th”

guides. ™® upper arm thread

4.

5.

and with a slight tag^™o*'th'’'’h‘''’"”3

insert, Fig. 12) ^ 11^® hook, (Se©

6.

ftihyi S™t“S£Ji3,^;andup through

left. up lever from right to

face Plate®quidlslnd™ln'’ti'‘'’' the

bar guide from the bacP "®®ble

8.

drawing it through about f © «^GHT,

nold the pnH mf +k d or 4 inohoo

turn the hand wheM toS'’ ^°°s®ly and

goes all the way dowTand^:! "®®dle

A loop (Fig. 1^) ™ comes back up.

upper thread which thin c °ver the

straight. Place both th " out

slot of the presser fool^r^ ¿«ds under the

back of the machine, leati^ T,

three or four inches lonj ^

Fig. 13

Fig. 14

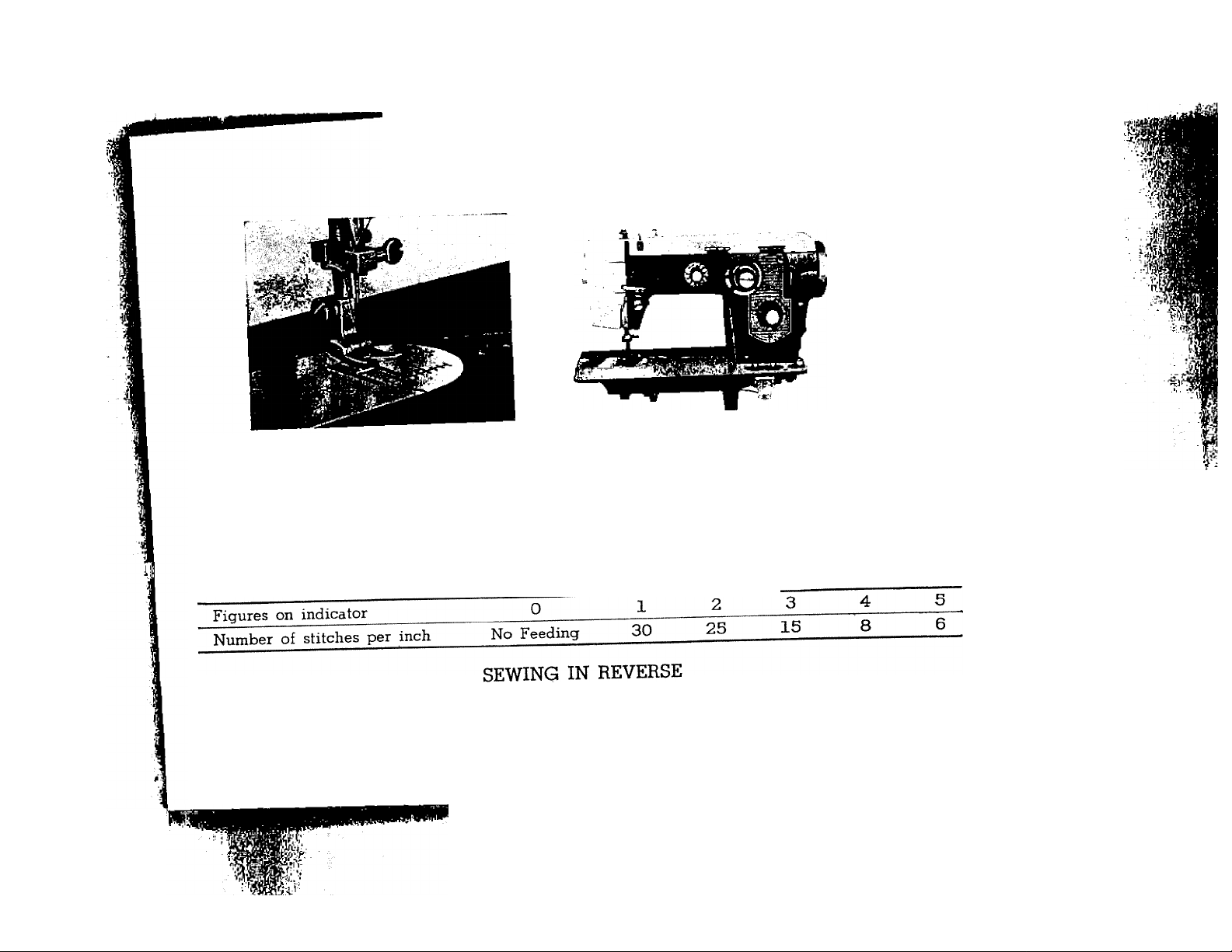

SETTING THE STITCH LENGTH

The length ol the stitch is ^

v“Sy“o1 toSths," 'iTn the d'ial to the r.glt to lengthen and to the left to shoxten the stitch.

The number stitch length you choose is indicated by the pointer.

STITCH LENGTH CHART (APPROXIMATE)

xn th^h“ .rH™lt‘iras’’S?'aTi? Srtctli^ setLch-.i°‘ai tonTii-S^

button is held in.

liPiPffim

HMIMI

10

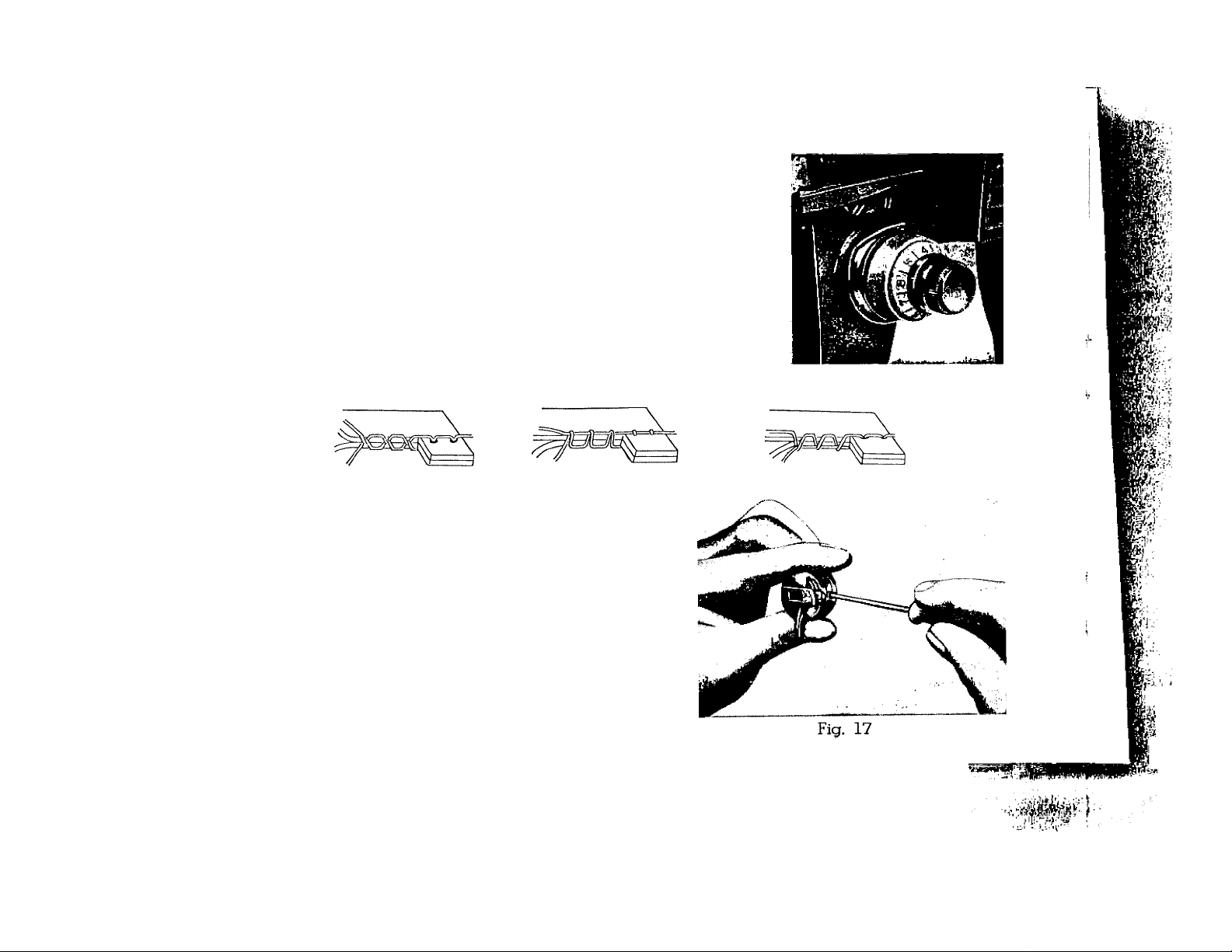

ADJUSTING THE TENSIONS

Always adjust the upper tension with the presser foot down,

as the tension is released when it is raised. To increase the

tension on the upper thread, turn dial (Fig. 15) to the right, or

clockwise; to decrease, turn to the left. The higher the number

on the dial the tighter the tension. Before adjusting lower tension

be sure that the machine is threaded properly.

When it is necessary to change the bobbin tension, turn

the small screw (Fig. 17) on side of the bobbin case clockwise to

tighten, counterclockwise to loosen.

Fig. 15

Fig. 16A Fig. 16B

When the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric (Fig. 16-A).

When the upper tension is too tight, the lower

thread is pulled up over the upper thread which is

lying flat on the fabric (Fig. 16-B).

When the upper tension is too loose, the upper

thread forms loops over the lower thread lying flat

on the fabric (Fig. 16-C).

Fig. 16C

:

Ifebi'

M

11

sewing thin or light weight T’' '*°'“' ‘ “ ®‘’“‘■ "“'•

_ R,E.„ p„3.„„

flimsy material the satisfactnr ?

Release all fL ^ P^'^^sure cap should ^ «« thin

20) aud then pres3 Jo tl s ^^^fway

the feed slightly ^ ® ^^^in to half-wav^ p^g

^ed line. ^ pressing the DOWN button (Fio° 7

^ to the

darning and mending

In order to move the f u •

.t'pir

, pressure cap fi cnmr,i release

on the sn!p loewt'l>^ P-asing

down button (Z It Z i^- P-oas

Fig. 19

^h;ch drops the feed^ejJ If®

plate. To return feed to "^^dle

UP button all the way dLn

Fig. 20

12

PREPARING TO SEW

Have take-up lever at highest point before starting to sew. Do not try to help the feeding

by pulling the material as this may deflect the needle and cause it to break.

NEVER run machine without material under presser foot.

Place material and threads in position under the presser foot and lower the presser foot. You

are now ready to begin sewing. By having the needle at its highest point, it is not necessary

to touch the hand wheel to start the machine. You merely press the control. The speed of the

machine is regulated by increasing or decreasing the amount of pressure exerted on the control.

REMOVING THE WORK

Be sure to stop the machine

when the thread take-up lever

and needle bar are at the highest

position.

Now raise the presser foot

and draw the fabric back and to

the left (Fig. 21, A and B) and pass

the threads over the thread cutter.

Pull down slightly, holding

thread in both hands, so as not

to bend the needle.

Fig. 21A

Leave the ends of thread un

der the presser foot.

Fig. 21B

t"'-

P-

f:

r--'

Loading...

Loading...