Page 1

Domestic

SEWING MACHINES

SINCE 1868

Page 2

.-3

You are now the owner of a new Domestic zigzag sewing machine, the most

versatile machine of its type you can possess. Buttonholes, monogramming, darning,

overcasting and creative embroidery ar% done with ease and speed.

0 ) aid you in obtaining the greatest performance from your machine this

book on its care and use has been written for you. Read the instructions carefully

as a tnorough understanding of your machine will reward you with many hours of

trouble-free creative sewing.

Time-saving attachments such as rufflers, binders, edgestitchers and cord-

.ing feet, to complement the accessories furnished are available from your dealer.

DOMESTIC SEWING MACHINE CO.,

Cleveland, Ohio 44111

DOMES nc SEWING MACHINES

1470 Birchmount Road

Scarborough, Ontario, Canada

INC.

Page 3

INDEX

Pages

Accessories ...................................................... 20

How to Use

Hemmers ................................................. 31

Seam Gauge or Cloth Guide

Quilting Guide

A.ttachments

A.diustable Cord and Zipper Foot 37

Attachment Foot

Binder

Edgestitcher

Hemmers .................................................. 36

Rut tier

Blind Hem

Bobbin

Placing in Shuttle........................................ 7

Threading .................................................. 6

Winding

Buttonholes

Bound........................................................ 44

Buttons Sew - On

Charts

Needle-Thread-Fabric-Stitching..................4

Stitch Length

Trouble .......................................... 27-28-29

..............................................

.....................

........................................

.....................................................

.......................................

........................................................

..............................................

.......................................................

......................................................

.....................................................

......................................................

..............................................

..............................................

21

23

23

30

32

34

32

39

18

16

19

Pages

Darning and Mending....................................... 11

Embroidery

Creative ................................................... 14

Hoop ........................................................ 15

Features and Parts (Front View)

Installation - Head in Cabinet

Head in Portable case •••45

Maintenance and Care

Cleaning and Oiling the Shuttle 25

Needle Setting

Pressure and Feeding of Fabric ....................... 11

Thin and Light weight Fabrics ••• 11

Reverse Sewing

5

9

Sewing Preparation

Sewing Tips .......................................... 41-42-43

Straight Stitching

Tension Adjustment

Threading-Upper

......................................

................................................

..................................................

.........................................

............................................

........................................

..............................................

.......................

(Back View)

..........................

................

6

2

3

47

24

9

12

13

10

8

Page 4

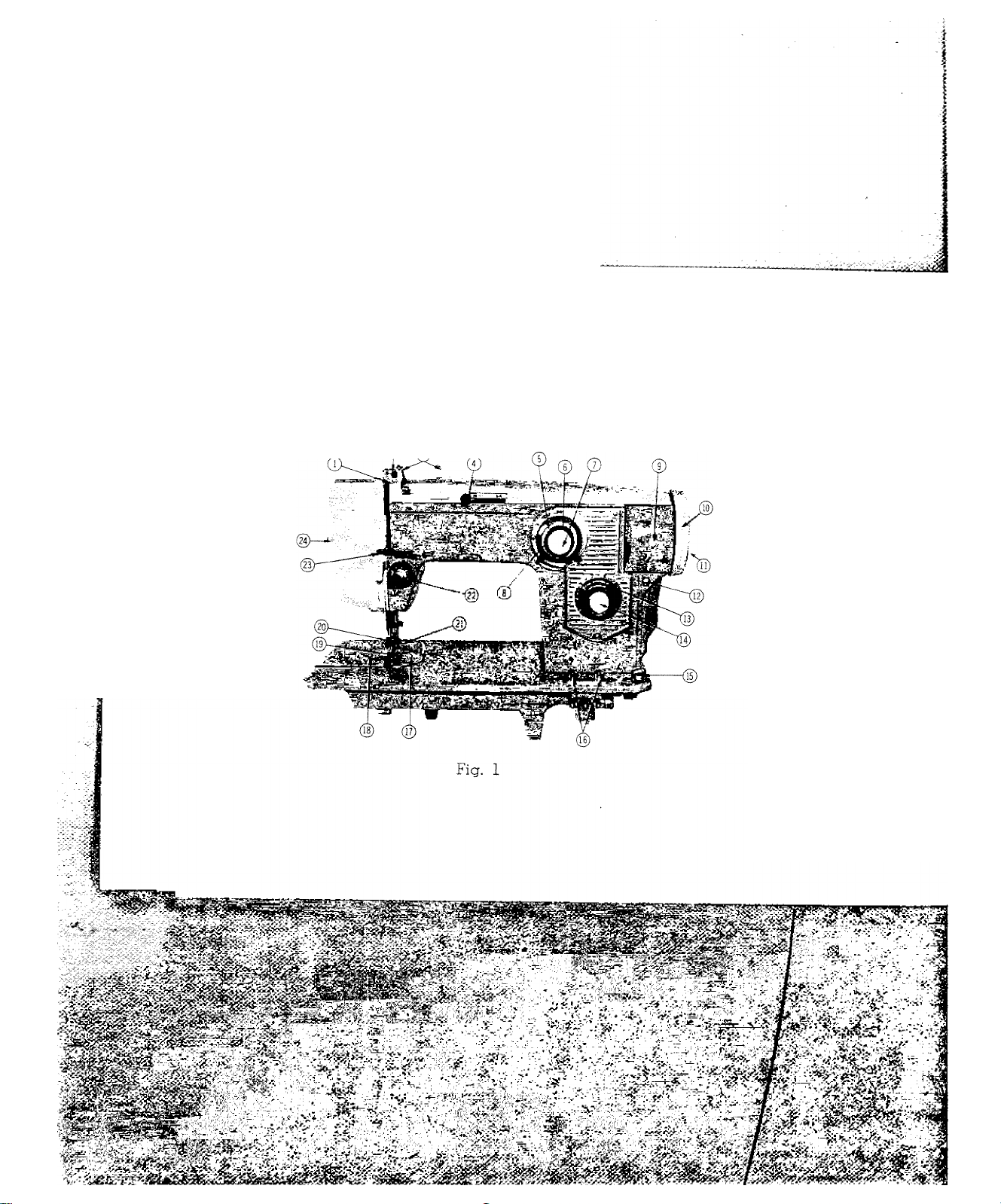

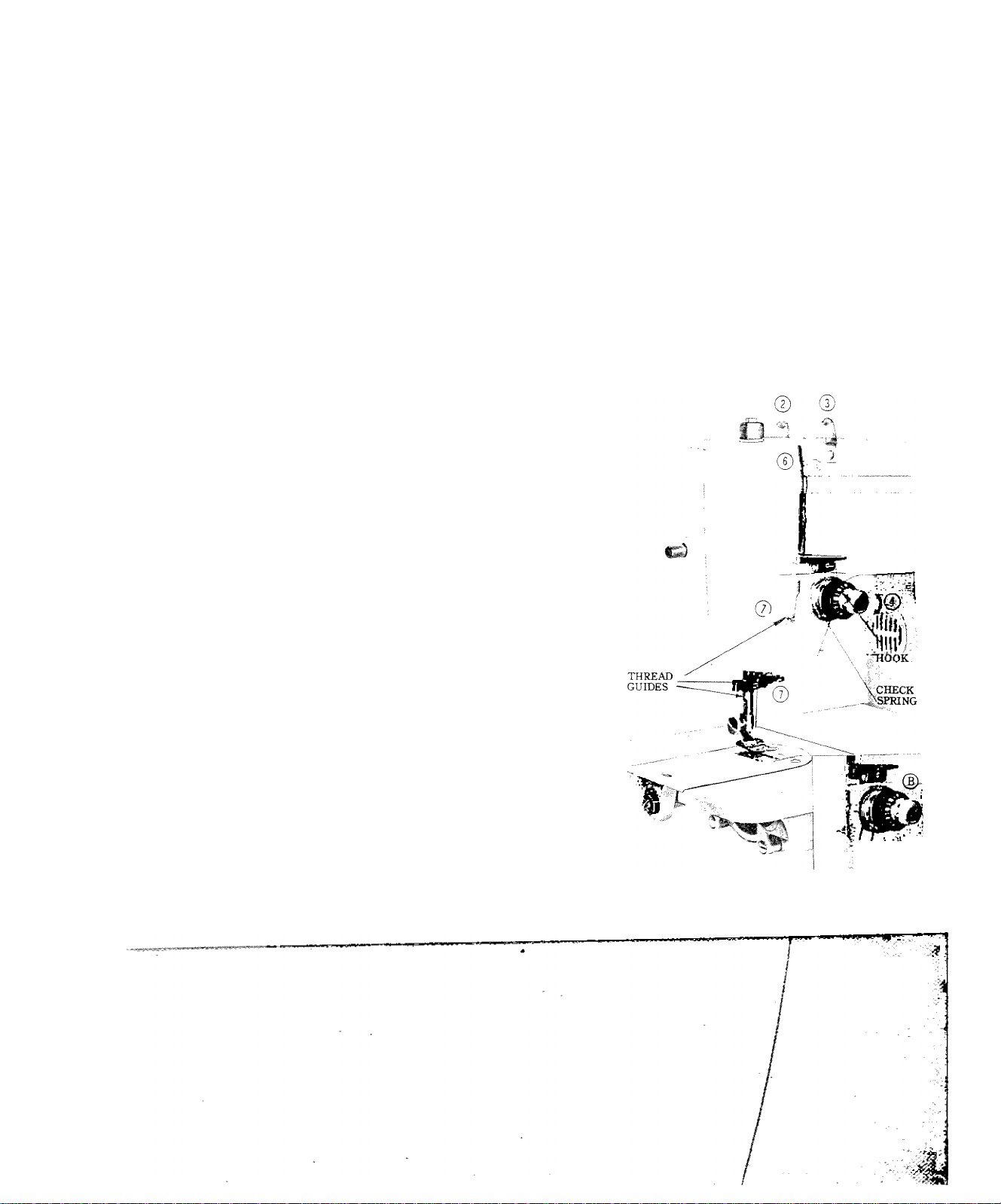

FEATURES AND PARTS

(Front View)

Ф (i) „

1. Thread Take-up Lev-

2. Pressure Release

(Darning)

3. Arm Thread Guides

4. Blind Stitch Lever

5. Zigzag Stitch Width

6. Zigzag Stitch Width

7. Stitch Width Cpntrol

8. Buttonhole Control i

9. Bobbin Winder Cove

1C. Hand Wheel

11. Clutch

12. Cover Release Buttoi

13. Stitch Length Centre

14. Push Button Reverse

15. Bobbin Winding Ten

16. Drop Feed Buttons

17. Needle Plate

18. Cover Plate

19. Presser Foot

20. Presser Foot Thumb

21. Needle Clamp

22. Tension Regulator

23. Thread Bar and Face

24. Sew Lite Switch

Page 5

;CK

,al

Cnot

(ob

Dn

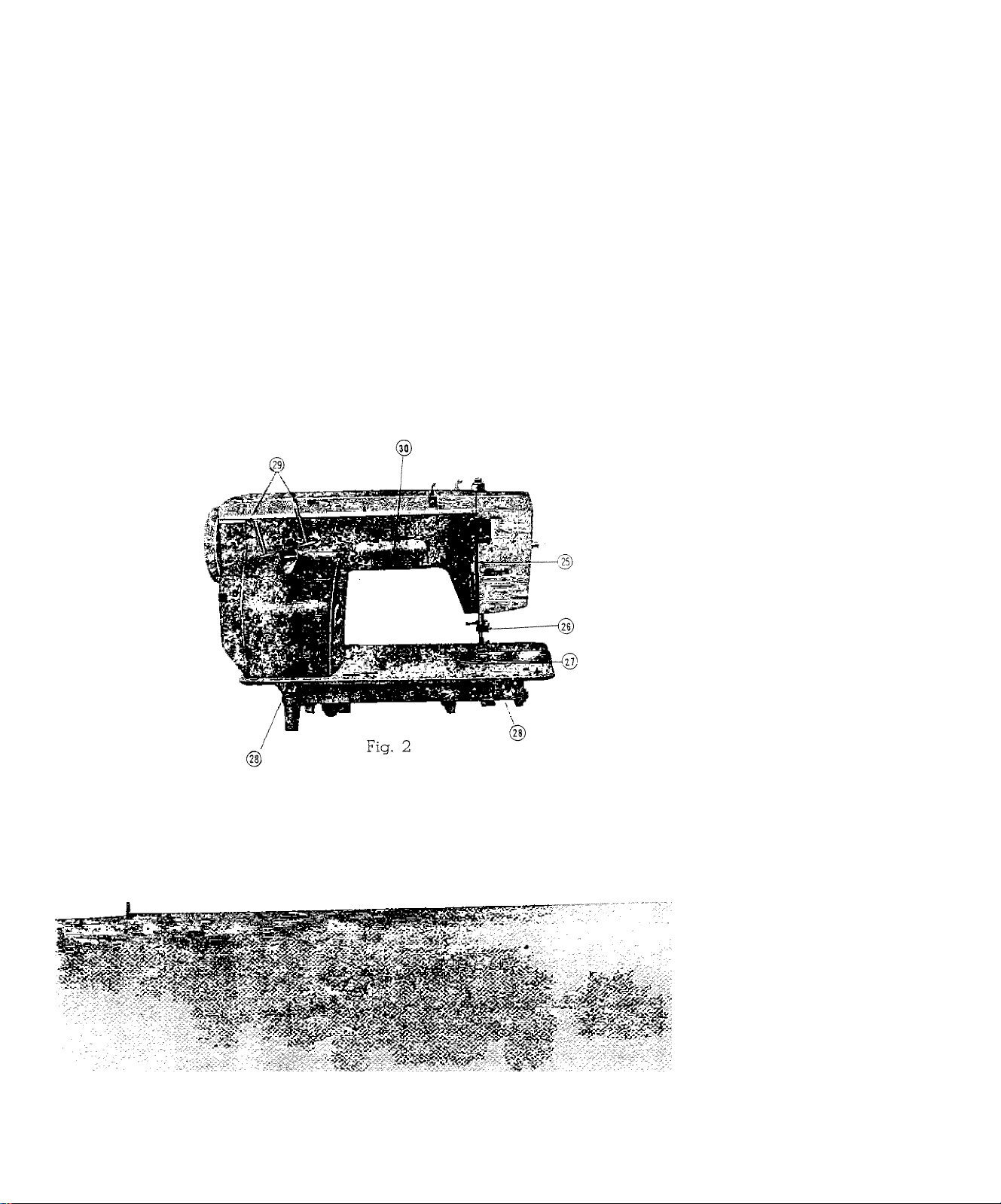

FEATURES AND PARTS

(Back View)

25. Presser Bar Lifter

26. Thread Cutter

27. Feed

28. Head Hinge Mounting

Holes

29. Spool Pins

30. Handle

..atcin

Page 6

4

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

Fabric

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen.

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen.

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn.

dimity, crepe.

handkerchief linen.

olastic film, etc.

Very sheer chiffon.

batiste, lace, organdy.

ninon, net, marguisett etc.

JMeedle

No.

4

3

2

1

u

00

Machine

Stitches

Per Inch

6

to

8

8

to

10

10

to

12

12

to

14

14

to

16

(Plastic film)

8 to 10

16

to

20

Cotton

Thread

10

to

30

30

to

40

40

to

60

60

to

80

80

to

100

100

to

150

Mercerized

Thread

Heavy Duty

Heavy Duty

Heavy Duty

50

50

50

Silk

or

Nylon

- c.

A

A

A

i ■■'A ■-

Page 7

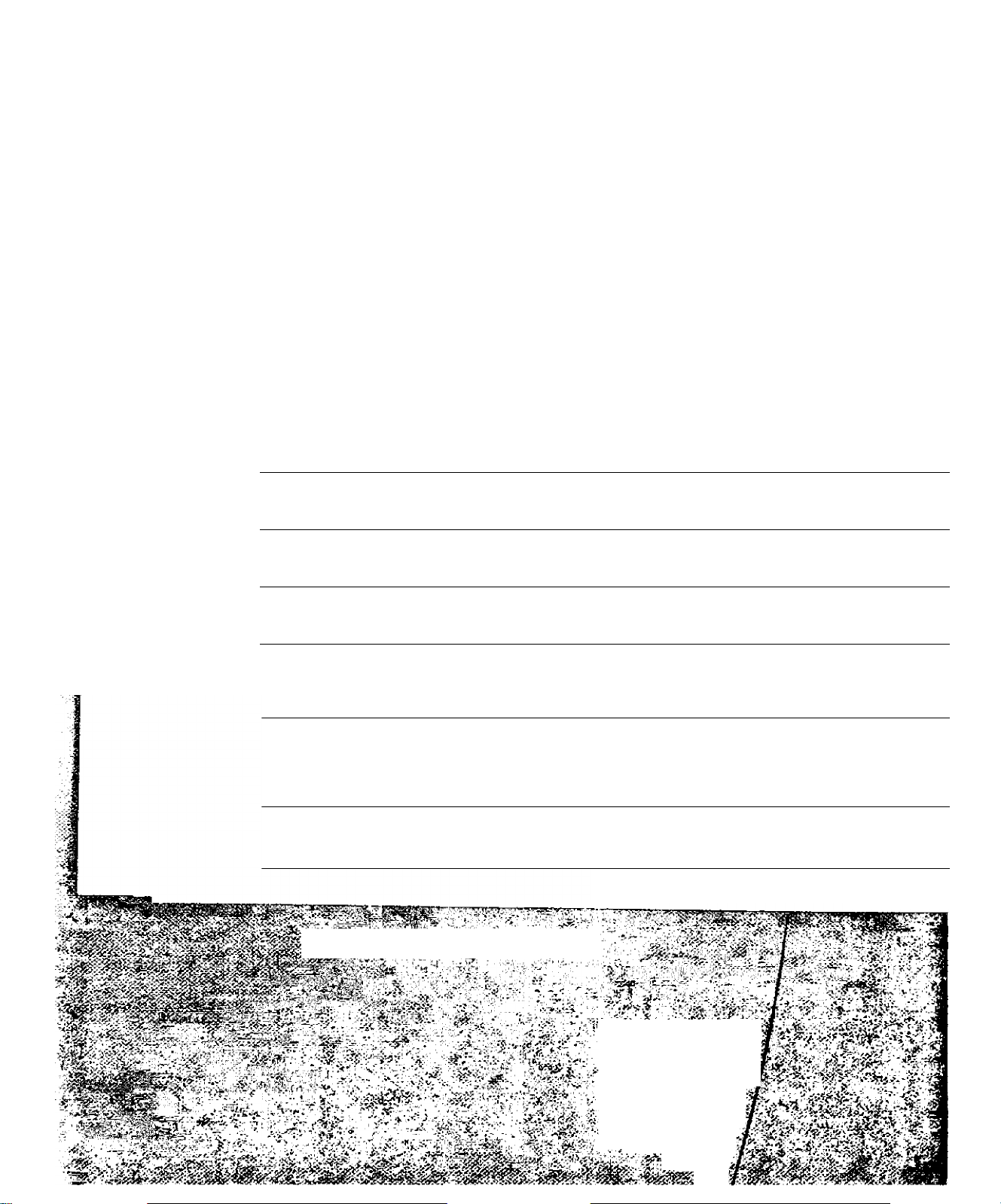

Fig. 3

Disengage hand wheel (5. Fig. 3), from the stitching mechanism by turning clutch (6. Fig- 3)

WINDING THE BOBBIN

ig.

"NSsOD OW tl^Ding cp^ OHuOili^aTSS^SOtyer thread

Place a spool of thread on one of the spool pin . machine. Run end of thread

guide on arm and down through tension disc (9, Fig. bobbin edge (left flange

" and from inside out) and place bobbin

on spindle of bobbin winder !7, Fig.4,J iitting

the notch bobbin over small pm on spm-

Push bobbin winder against hand

v^^^eel. Hold thread end loosely and start

machine slowly. ^

Bobbin will stop winding wnen it is

filled Turn clutch away from you until

sewing mechanism is again engaged so

that needle moves when you turn the han

off loose thread end used to

start the winding and ' *

stated on Page 6.

tiau. —

thread bobbin as

Page 8

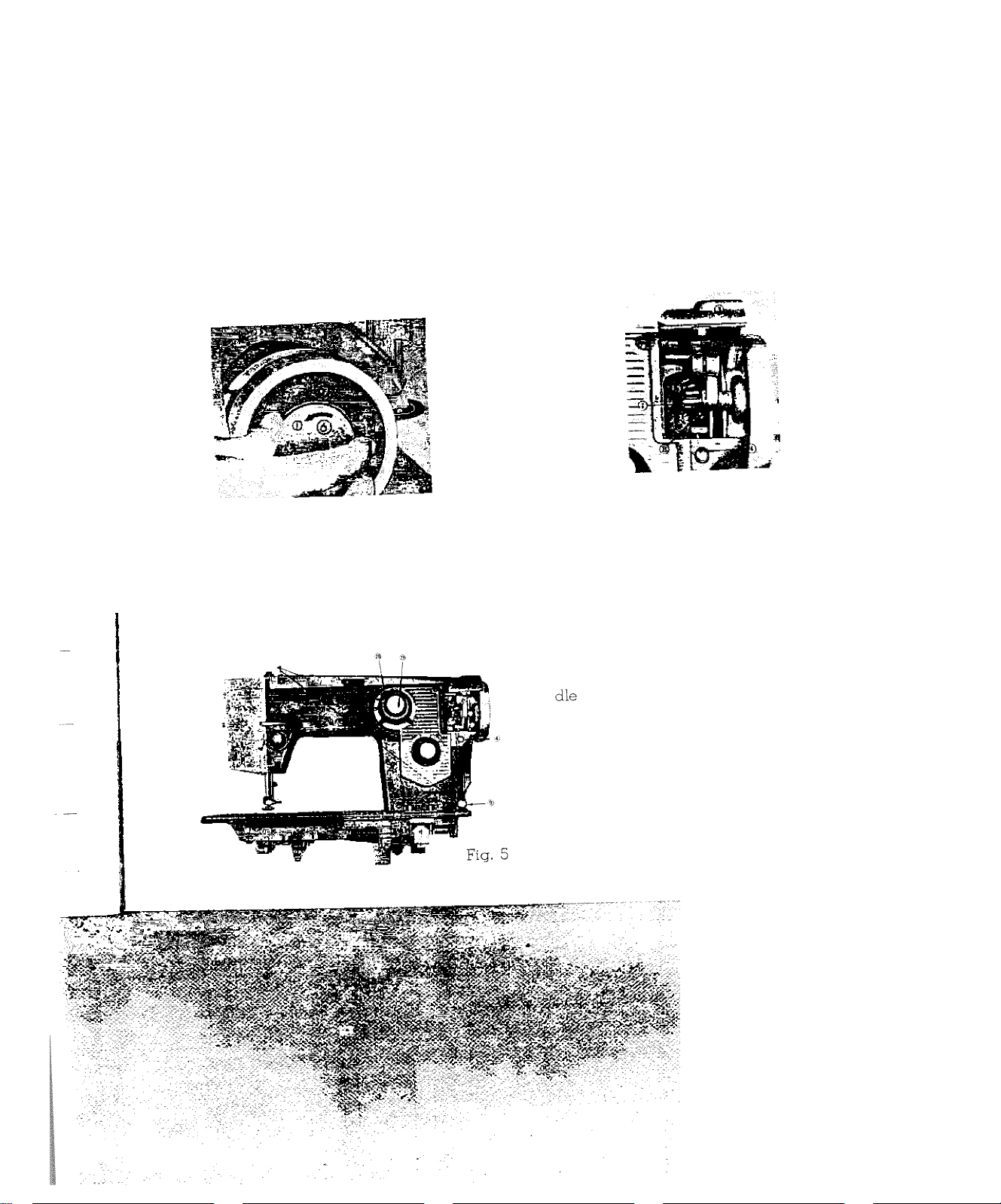

SETTING THE NEEDLE

See Fig. 6. Raise the needle bar A to its highest

point, turning wheel toward you by hand. ■

Then loosen the needle clamp screw B and the

needle can be inserted into clamp C, Place needle

(flat side to rig lit) in the needle clamp and pusii it

far as Tt wm go into the needle clarrip

hole, tightening the needle ciarnp screw securely

with a screw driver.

After changing the needle make one com

plete revolution of the balance wheel by

hand to be sure the needle is in the correct

position.

1

Flat surfa

oE needle

shank

1 /

r

Fig. 7

Fig. 6

THREADING THE BOBBIN CASE

Step 1 illlustrated in Fig. 8). Hold bobbin case between thumb and forefinger of left han

so that the slot in the edge of the bobbin case is on top. Take the bobbin between thumb ai

forefinger of right hand so that the thread on top leads from left to right.

Step 2. Insert bobbin into bobbin case, pull the thread into the slot of the bobbin case ^

shown in Fig. 9, and draw it under tension spring and into the fork-shaped opening of the - sprii

as shown in Fig. 10.

Page 9

UPPER THREADING

'Urn the balance wheel toward you to raise

the take-up lever to its^ hignest posuicn.^

a sDGol ot threaa on tne spooi ,

the Dread througn the upoer arm tnr«aa

Run the thread through the threaa ^guiae oar

to the tension discs, then ^arounO ana oe-

-fteen them from right to mn. ^ ^ ^

Rmw the thread up through thechecK soring

and with a slight tug mto the cook, Dee

-me 'the Dread under the bar and up througn

eye of the take-up lever irom rignt ю

biid Dread down under bar, Drough the

D^e plate guides^and then througn tne neeam

oar guide from the bacic. ^

■mreH needle FROM LmT mGrli,

grawina it Drough about о or ^ e f

1-DD the end of the upper threaa^ ioosetv <md

mm De hand wheel toward you until the rmeam

goes all the way dovrn ana comms cack up^

Д looD Dig. 13) will be tormea over tne

uppe/ thread which then can ce puile^ ou^

straight. Place both Dread enas^ under me

slot of the presses foot ana araw towaD u.e

oack of the machine, leaving both threaas

three or four inches long.

rig.

12

Page 10

Fig. 13 Fig. 14

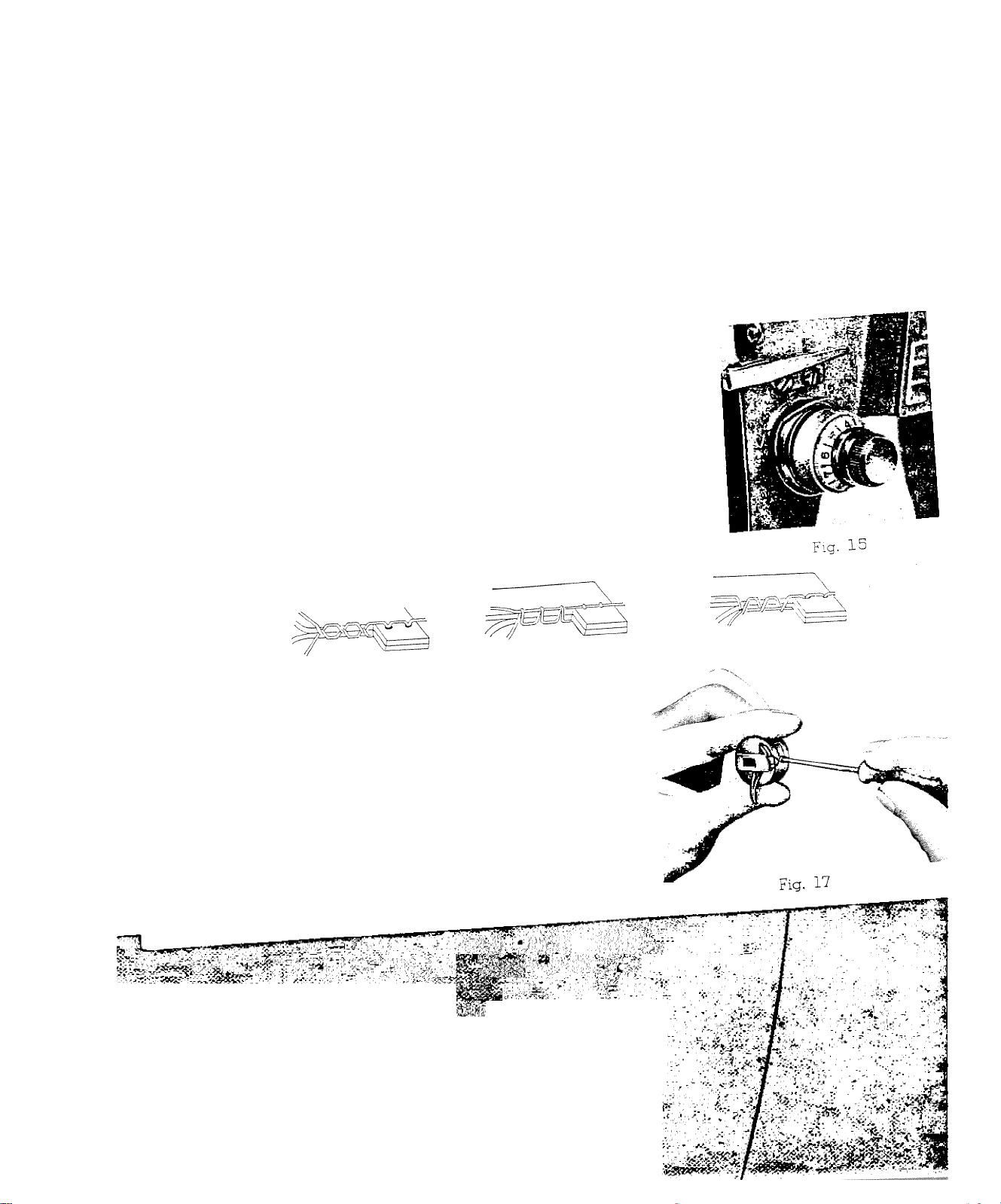

SETTING THE STITCH LENGTH

The length of the stitch is regulated by the dial, shown in Fig. 14. Near 0 is the shortest

stitch and 3 is the longest, but the dial may be set at any spot between the markings for a

variety of lengths. Turn the dial to the right to lengthen and to the left to shorten the stitch.

The number stitch length you choose is indicated by the pointer.

STITCH LENGTH CHART (APPROXIMATE)

Figures on indicator 0

Number of stitches per inch

No Feeding 30

1

2 3 4 5

25

15

8

6

SEWING IN REVERSE

When you wish to sew backward to tie the threads at the beginning or end of a seam, press

in the button R, Fig. 14, as far as it will go. The machine will sew backward as long as the

button is held in.

» V'.

- : if. i

■' ‘"i. N #.■? '

h, -'OFT

»fl'i-Tc'Ch'-

*".4f

Page 11

10 adjusting the tensions

tension with the presses toot down,

always adjust the uppe. ^ ^ increase tne

.3 fre tensron rs released wnen n ^ ,,gnt, or

Cnswn on the upper thread, turn ,,^per

4-,’r-n tiT6 ,

"rSr;n0.o„,

Oil • _

“ ■“ : ,s ihreadea propenT.

be sure that the macnine

When it IS necessary case clocfcwise ю

When it is necessary i

We small screw (Fig. 17) on side ot We b

Og sTnall screw (Fig- IF)

;Jsien, counterclockwise to loosen.

зе macnine u ^ з^.п

1 • ic тНг<^ааеи

Fig. 16A 1

When the upper and und

.-a.apced, a perfe« ddch »-'Ibe .»med

mterlPcUng m fabnc ^

IVKen ihe uppe. 1^-°” ^ „

.3 pulled UP Ue UPP« -Ue.

lyiap Hat on the tabno ' U

When the upper tension

,.,,ead lo.nas loopa ovei ‘»u 1°'-' "

on the fabric (Fig. 16-C).

.-_Рг.:уа ■: - =>-' г; .рсртТ!^

rah under tensions are properly

Ш ,i^sW Г (= ih'.' - -nW ) ■

W-mi now:

lie

■ W.'w , U ..-:

■’' n i,y, ., 1 i-i - . ;, ¡'ti ■,..1

Fig. 16B

.г: ■■'.yf,'--' ^ '-V T' *• Ь|;-''''ч( . '

1, , i''

^ ' _

. s • -‘..л

Fig. 16C

, „rP^ypwo , p.;w,,

.■■ ^':®ti&i,h-..-i.-v *^. '■ -У-аау-рп... л'-. - с- ;-:i ,■ i/ , ь. ,■■.:.■■

-У: УгдаЯ^уУ, ‘

w'-ry y.n-:,: '-. -yh y,„. •'.

Page 12

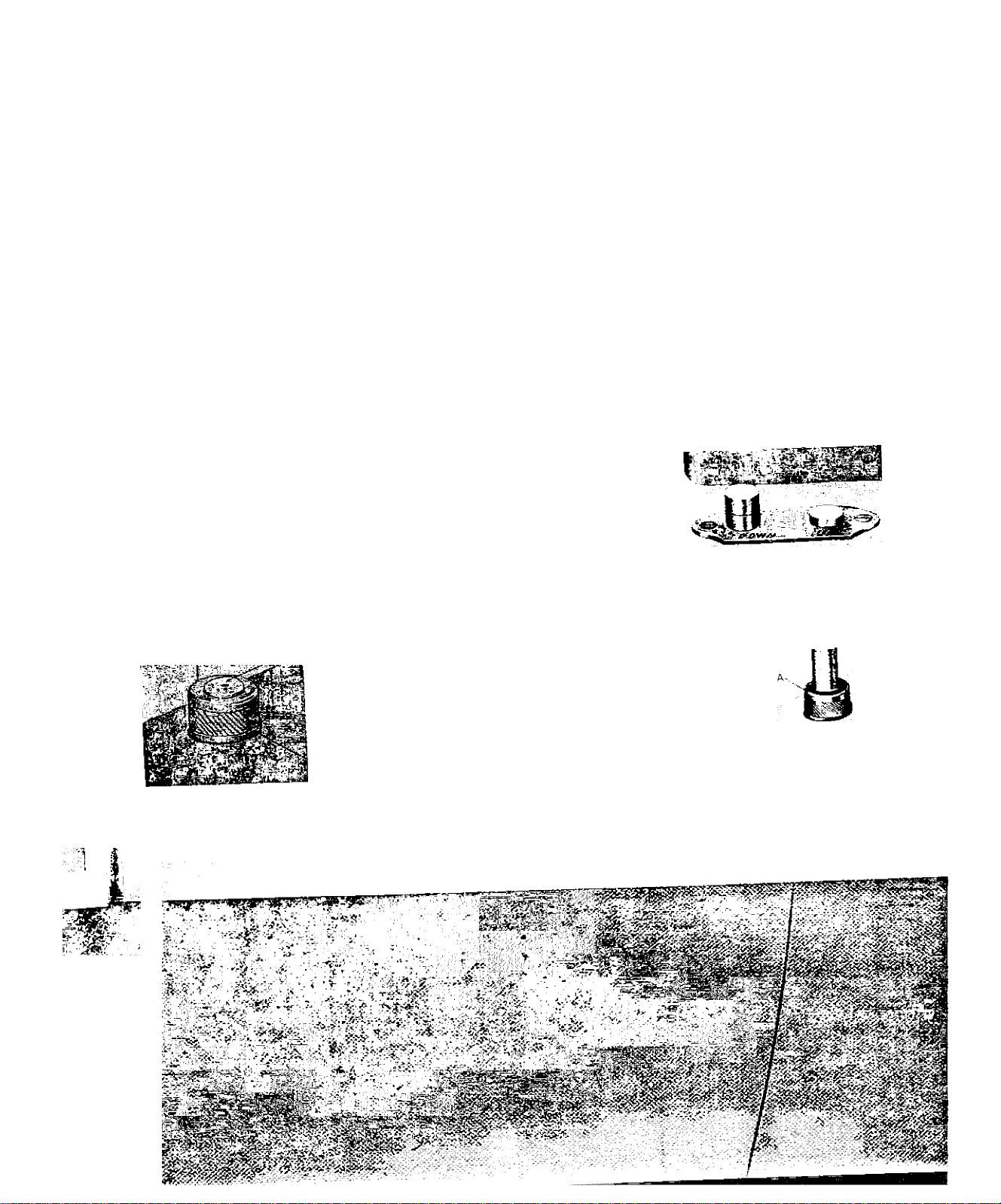

adjusting pressure and feeding of fabric

general SEWINa^Usu^aUy^£or^=.,a^^^

ie mtried UP pressed all the way down, (Fig. 18)

SEWING THIN OR LIGHT WEIGHT FABRICS

When lighter oressure is required to sew satisfactorily on thin

silk or flimsy material, tiie pressure cap should aoou^ Lai ^ay

down. Release all the way by pressing the snap Iock W, F <3

20) and then press cap B down again to nalf-way spo

the feed slightly by pressing the DOWN button vFig. l8y to toe

led line.

■p

ig.

11

18

Fig. 19

DARNING AND MENDING

In order to move the fabric freely in any

direction for darning and mending, release

the pressure cap B completely by pressing

down on the snap lock (A, Fig. 20)- Press

DOWN button (Fig. 18) all the way down,

which drops the feed well below the needle

plate. To return feed to normal, press the

UP button all the way down.

B—

Fig. 20

Page 13

12

PREPARING TO SEW

have take-up lever at highest point before starting to sew. Do not try to help the feeding

by pulling the material as this may deflect the needle and cause it to break.

NEVER run machine without material under presser foot.

Pidce material and threads in position under the presser loot and lower the presser foot. You

are now ready to begin sewing. By having the needle at its highest point, it is not necessary

to touch the hand wheel to start the machine. You merely press the control. The speed of the

machine is regulated by increasing or decreasing the amount of pressure exerted on the control.

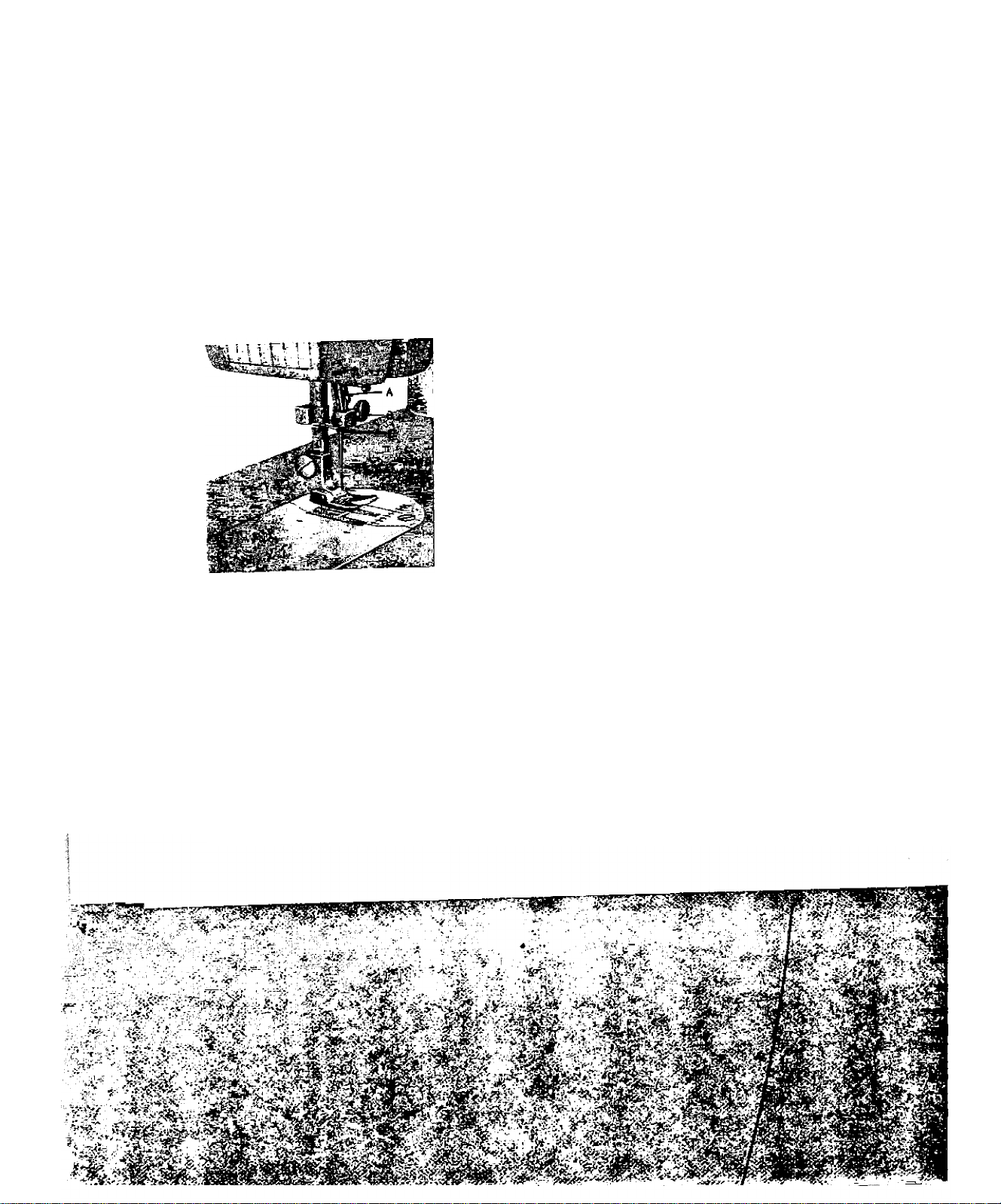

REMOVING THE WORK

Be sure to stop the machine

v/hen the thread take-up lever

and needle bar are at the highest

position.

Now raise the presser foot

and draw the fabric back and to

the left fFig. 21, A and B) and pass

the threads over the thread cutter.

Pull down slightly, holding

thread in both hands, so as not

to bend the needle.

Fig. 21A

Leave the ends of thread un

der the presser foot.

Fig. 21B

Page 14

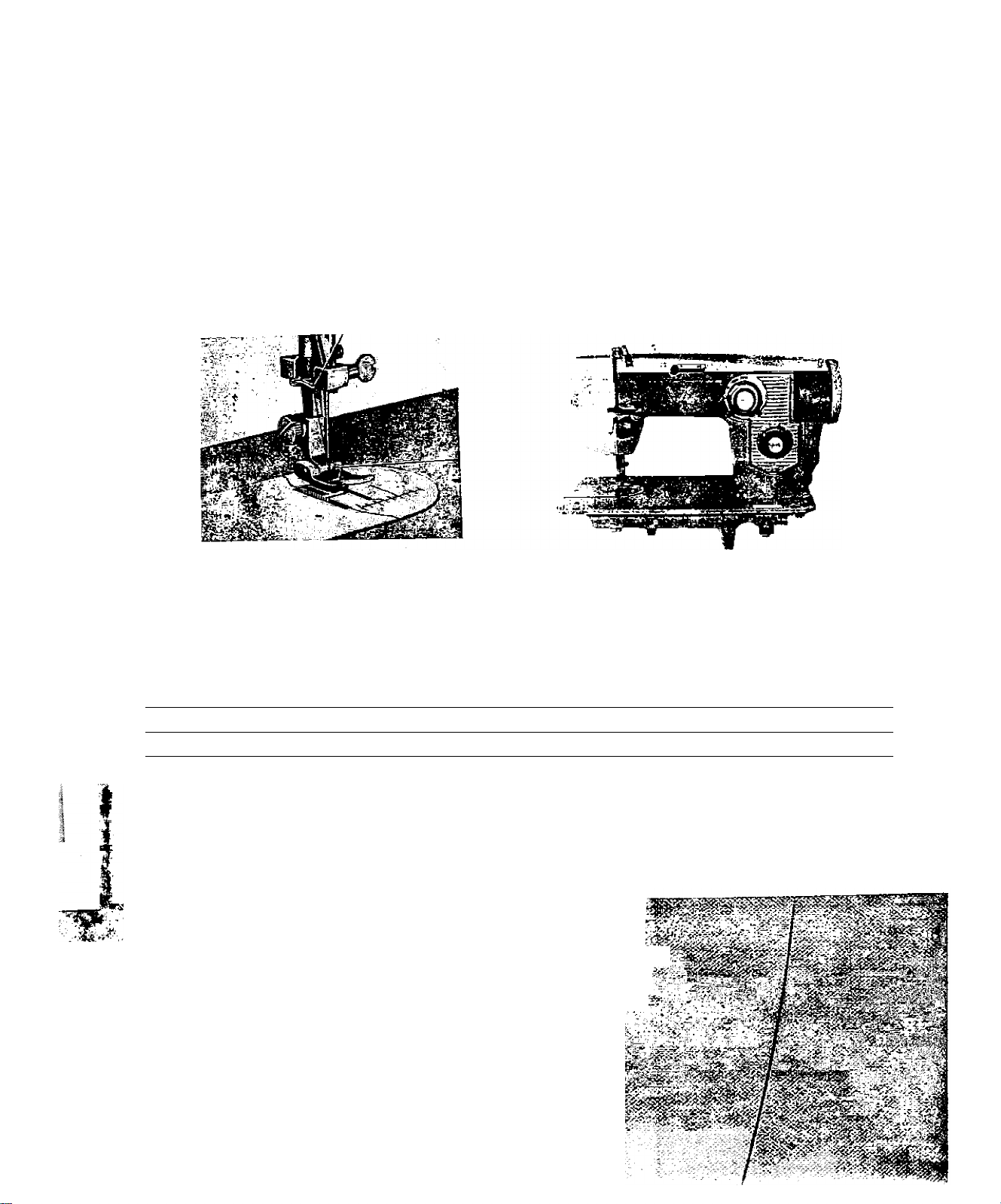

STRAIGHT STITCHING

^ For straight sewing - “ptsl"

rTtnTthHtraTgM stitch needle plate which are in-

bo. Both ha.e narrow needle

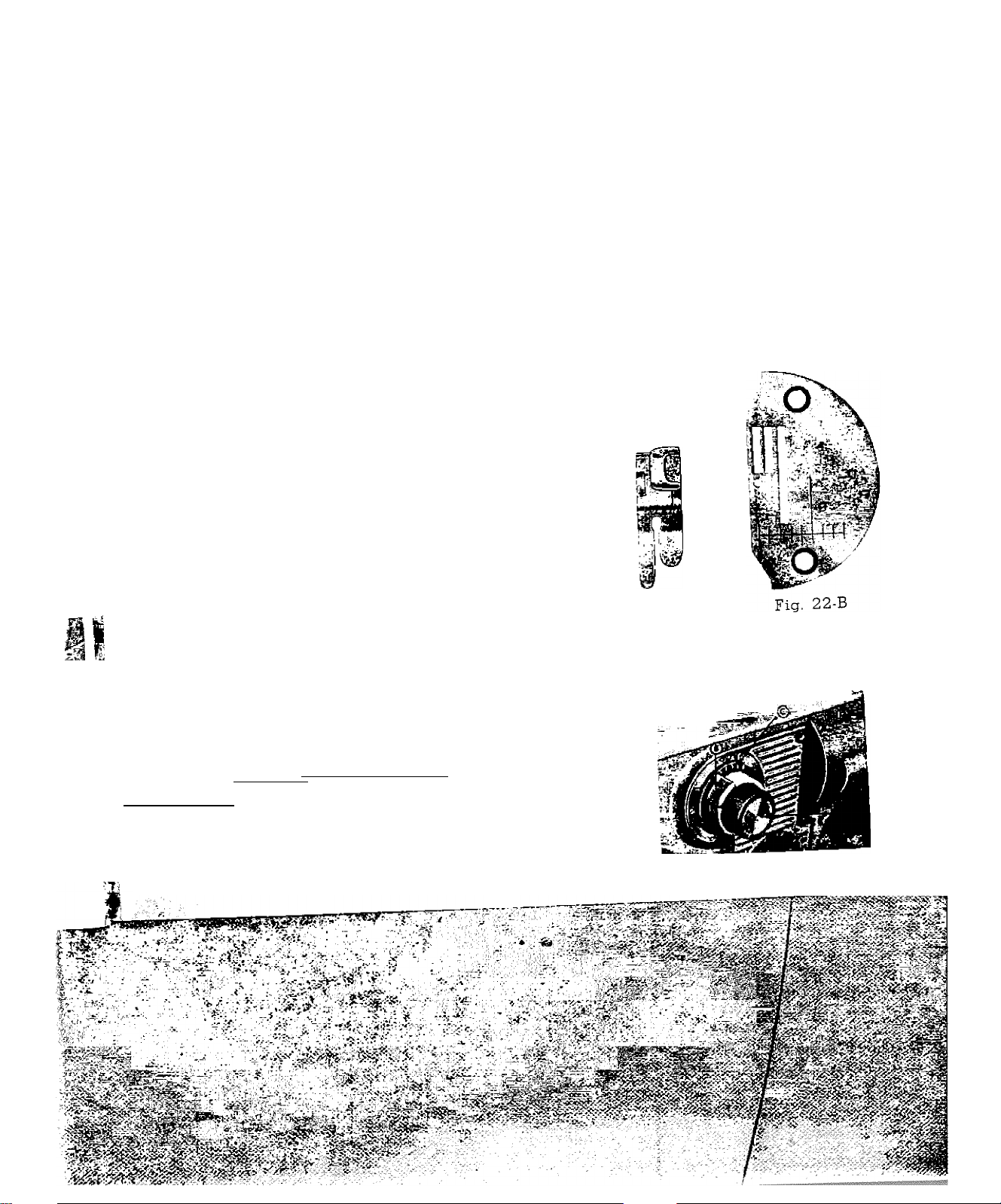

Changing the Presser Foot and Needle Plate :

(1) Presser Foot ,

(A) Loosen thumb screw (18, Fig. )

remove zigzag presser foot.

(B) Replace with straight stitch presser foot

(Fig. 22A).

”(«'* Su“(o,er plate (16. Fi,. 1) to the left a,

far as possible.

(B) Remove screws holding needle plate i ,

Fig. 1) to bed plate.

(C) Remove zigzag needle plate.

(D) Replace with straight stitch needle plate

(Fig. 22B).

1 Be sure to set the sHtch wtdth and buttonhole

i. control knob at 0 or the needle will break in striking

13

Fig. 22-A

ra-WESI

S the foot or plate. ogi nress

i Grasp outer rim of zigzag dial (A, Fig. 1 P

i down on lock B. Turn dial as far to the left as possible.

Pointer will then be on the zero mark.

Fig. 23

Page 15

CREATIVE EMBROIDERY

Fe sure iigzag presser foot and zig.ag needle plate are in place.

ihe satin stitch (Fig. 24) which is really just a ver/ short

zigzag stitch and the basis for most embroidery, is obtained

by setting stitch length (see page 9) as near 0 as possible

without stopping the feeding action and ;ig:ag width at to,

Fig. 23). ,

To stitch continuously at one width of lig ag stitching

chosen stitch width number.

V/ith the machine set for a short stitch length, dif

ferent designs can be made by turning the zigzag width

control knob back and forth between 0 and 5 or

other combination of widths. Try setting the stop iB,

rig. 2o)

a while you will become quite skillful, varying your de

sions by the speed of the machine, stitch length, and

m.anipulation of the zigzag control knob.

at 1 and various other numbers.

3et a rhythm for yourself and then proceed. After

SAMPLES OF CREATIVE EMBROIDERY

iffiSt

Fig. 24

zigzag width stop (B, tig. 23) to

set

MS UM IMi UUil UIM № MM lUM ULU

mmmmmwmmmmm

I

Fig. 25

25

A. Sew a few stitches at, 5 width, then allow knob

to spring back to 0 for a short period. Count, if necessary,

to establish a rhythm. u our

B. Set stoD at 2 then m.ove knob slowly back and forth between numbers 2 and 5.

C. Set stoD at 1. Gradually m.ove knob from 1 to 5, allowing it to snap back quickly.

D. ' Set zigzag stitch width stop at 4, stitch length at 1%. Do a few zigzag stitches, ^ drot

feed for 3 or 4 stitches, then raise it again. By operating the feed knob rhythmically it is no

necessary to count stitches.

^ . ■■ ■ ■" '(: . Ip . :( w z., j 'vi r'v

, ■•f y ^ , .y ■ ■ p.

rig.

Page 16

E. Drop feed, set stttoh w.dth loo. at

SÏÏ“lo“d: bT sTtfno stltcrwfeth'at 0 and ta.tnp 3 or 4 sbtohes tn center o. des.pn,

embroidering with a hoop

It is easy to iollow a stair ped design or to

work free hand when embroidering or rr.onogram^

mg. (See Fig. 26). Pelease the pressure from

the foot by pressing down on the snap lock ring

darner. Push the drop feed button down all the

stretch the fabric in an errbroidery hoop, ana

place umder the needle after removing the presser 26

foot. Set the stitch width at the size you prêter

and lower the presser bar lifter. Then operate the

:3.=:=nu:=a

15

- i-i. ««-• •“ •* - - •'

II Yon wish to dam or monogram w thoal ^Wo.d ^ P

place, release all pressure on presser foot, set stitch leng ,

and leave feed in sewing position. skipped

When darning or monograming m this manner, me laei

stitches will be encountered.

JP!-'.' .f .y.(

ï .-.U^-^'UУ■.Í y ■

%.(■■■-№( tel

■ d-0 : y , _ y,_

•te- y.'hur'f

DARN OR MONOGRAM WITHOUT HOOP

1 pcnbroiderv hoop, leave zigzag presser foot in

W

Page 17

16

BUTTONHOLES

ialini

:

■i

■'t>À

Buttonholes of various lengths can

turning the buttonhole control knob.

To establish the correct length buttonhole required

add Vs inch to the cutting space for bar tacks.

To obtain the length of the cutting space, the opening

through which the button passes is measured by adding

the width "A" and thickness "B" of the button (Fig. 28).

First mark the beginning and end of the buttonhole on

the fabric with a basting line or tailor's chalk. Make one

or two buttonholes on scrap fabric (following directions

below) to be sure the machines adjustments are correct.

(1) Set zigzag stitch width control at 0.

(2) Replace presser foot with special purpose buttonhole

foot. It provides maximum visibility and allows

closely spaced stitches to feed evenly (Fig. 27).

( .-i )

Set stitch length knob 11 (Fig. 1) as near 0 as

possible without stopping the feeding action.

(4)

Set buttonhole control knob (Fig. 30) at 0 and

then to the first buttonhole setting, number 1.

This will set the width of the buttonhole sides.

(5)

.,ower needle carefully into the mark on the

fabric indicating the start of the buttonhole.

Lower presser foot and sew full length of left

be made by just

hg. 21

Fig. 28

c

0

s|l

T||

E||

M

p

I ^

I i

it

n

E ^ ‘

ro "è :

Page 18

( 5) Set buttonhole control at number 2 position for bur tacldng.

Sew four or live stitches, step 2.

(P , Set buttonhole control at number 3 lor rlpht hand side of buttonhole. This will

set the machine to sew m reverse.

Sew right hand side of buttonhole, step 3.

(8 ) Set buttonhole control at number 4 position for oar tack.

Sew four or five stitches, step 4.

(9 ) Set buttonhole control at 0 position and take two or three stitches to fasten ar

tack to prevent ravelling.

(10) Cut the buttonhole opening with seam ripper, being careiul not to cut^ the

stitching.

If you plan to make buttonhcles on sheer or soft material, place tarlalon or paper

17

Mj:

sV

under fabric which can be torn away after stitching.

When making additional buttonholes, be sure to turn the buttonhole oentro. knob

to 0 and back to the number 1

position to put the machine in forward stitching.

:■ [ .;,.v4s>

: ■■■ ■■ t --r "•'V■ ":\r i y

:. V: b- ■ ■■ iM .V iikip .i -w. o... phn

m

Page 19

18

BUND STITCHING

Fig 30

1. Set zigzag siiicn wiae lo

Fig. 1) at 0

Set buttonhole control lever ,

... _de lock (see page 2. 5

. Ipver (see page 2, No.

2

23, Fig. 1) at 0.

3, The bhnd shtch leee. (Hh- 31B) -h be

4. When you wish to

,h to =ew other shloher eKeptmg

the B,H- stitch, the B.H. leve

at M (Fig. 31 A)-

Page 20

o,

>Io.

■5 at

aang

rums

SEWING ON BUTTONS

Remove hinged presser foot and attach button sewing foot.

1.

pSh drtp^ield button "DOWN" all the way (Fig- 36).

2.

S zigzag stitch width stop at 0. Place the button so

3.

that its left hole comes directly under the needle, then

rrentiv lower the presser foot. (Fig. 33) .

M?ve zigzag stitch width stop until the needle comes

4.

down ezmctly over the right hand hole in me button.

CFicf rtt

Turn the hand wheel slowly by hand to oe sure the

needle enters both holes in button without deflecting

needle, correct width if necessary. , , , xu

When needle goes into the center of each hole, r^n the

5.

machine at medium speed, making six or eighi stitches,

stopoing with the needle in the left hole.

To lock the zigzag stitch and prevent ravelling, set the

6.

stitch width at 0, and take a few stitches in the same hole.

If you wish you, may place a rounded toothpick over the

button, between the two holes, and sew button to tabric

in rSQlll&r WSYRemoT© th© toothpick and wind thread under the button,

forming a shank to fasten. x

Apply the above method to sew on buttons with tour

holes, hooks and snaps, etc. If a four hole button is to be

sewn, follow the same procedure as for the two hole button.^

Now lift presser foot slightly and move fabric to permit

stitching the remaining two holes. Hooks, snaps, etc., are sewn

to the fabric with the same procedure as for sewing two hole

buttons.

Fig 33

19

Fig. 32

Fig. 34

Fig. 36

Page 21

20

ACCESSORIES (Fig. 37)

1. Plastic Oiler (Sealed and Filled)

2. Package of Needles (5)

3. Large Screw Driver

4. Small Screw Driver

5. Bobbins (3)

6. Felt Washers (2) (for spool pins)

7. Quilter Guide

8. Cloth Guide

9. Button Sewing Foot(Fig. 32)

10. Prong Type Buttonhole Foot

11. Presser Foot for Straight Sewing

12. Narrow Hemmer

13. Thumb Screw

14. Needle Plate for Straight Sewing

Fig. 37

(graduated)

^ r-'■

T-3

Page 22

HOW TO USE ACCESSORIES

Narrow Hemmer: With needle at its highest position replace regular

presser foot with narrow hemmer (Fig. 38) being sure to tighten it securely

in place. Set A-P lever in the P position and zigzag stitch width con ro

at off for straight stitched hem or at number 3 for zigzag stitched hem.

21

Set stitch length control to suit. .

' For a plain narrow hem make a Vs mch double fold

for about two inches along edge of fabric. Hold each

endtof the two inch fold, slip underneath hemmer. Bring

> fold up into the scroll of hemmer, draw fabric forward

to end and fasten with point of needle. Lower presser

bar^lifter. Gently pull end of thread as you start stitch

ing (Fig. 39 for straight stitched hem and Fig. 40 for

zigzag stitched hem) .

Guide material slightly to left and it will take a

double turn through scroll.

The narrow hem provides an excellent finish for

edges of ruffles or any other dainty work.

Fig. 38

Page 23

22

LACE TRIMMED HEM

To sew a narrow Eem and attaca mce

lacs in the slot next to neecue _,ng. 4.- t;“

abc'/e, guiding lace under needle and hem into .c^on. - ^ ^

race may be used in the same way,

LACE EDGE WITH INVISIBLE STITCHING

Lola lace 1'8 men Corn raw edge on rignt hanc^mae or

wxr- u^seri both in scroll as lor piain narrov/ nem . x ,

ier'Sm'rou over ana sew in lace. When me smcning m

completed the hem is pressed on me wrong sms,

FRENCH SEAM

Place material with right sides lacing each omer and

too oiece of material DC inch trom riant nana sage

1°W2 Insert m hemmer scroll allowing nein m rod one.

mw^'m'top fabric making Frenm seam, ^^-r coming

effeco use zigzag stitch wide enougn to ca.m m..

the narrow roUed asm jcna

sew with satin stitch. This

can be used tor covering

chairs and so icrrn. ucg. cJ

HEMMING ACROSS

A SEAM

To hem across a seam,

cut the seam folds at an _ ^

anqm so then will lead into the hemmer gradually. mess sec

'c

onen. Stitch across the seam at the extreme eage m nold

temether and for added firmness. It may oe necessmy m pi

the material slightly when hemming over me seam. mig. 44;

Fig. 4d

fig. 44

G -tHW -idM" . •

- ' . m.' 'iOe. i....- '■■■y .

• 'd i'' .■■_ -

■ - ,v.;: - i'

PV' ... .-.la “on’

■ ■■}

i

.n,.:ci

Page 24

QUILTING GUIDE

Use this guide for making' parallel rows of

straight or decorative stitching. Attach standard

presser foot. Slip U shaped holder on guide under

presser foot thumb screw from the back and

tighten screw (Fig. 45 ). Adjust the curved bar for

the distance desired between rows of stitches and

set so it presses slightly on the fabric. By letting

the guide ride on the previous stitching line, suc

cessive rows V/'11 be at equal distance apart. (Fig. 43)

Fig. 47

23

Fig. 49

i ig. 43

SEAM GAUGE OR CLOTH GUIDE

Use the seam gauge as a guide for straight seams

and even rows of top stitching along edge of fabric.

(Fig. 49 )

Fasten Gauge (Fig. 46) with accompanying screw

(Fig. 4 7 ) in threaded hole in bed of machine. Adjust

to desired width.

Page 25

..

24

Fig. 51

Fig. 50

CAKE AND MAINTENANCE OF

your machine

HOW TO OIL YOUR do not use any

*' use only a good sewing maohma o.,

common household oils oooasionally to keep

=0” r;aToil yom maoMne thoroughly as indioated

■c, the arrows on Kgs- 50- and 52.

AYoid over oiling.

Fig. 52

Page 26

CLEANING AND OILING THE SHUTTLE

(See Fig. 53 and 54)

The stitch forming mechanism occasionally becomes

clogged with loose threads and lint. This will mterfere

with the efficient operation ot the mmchme. mieaning

and removal of the lint will safeguard the performance.

To remove the shuttle assembly, proceed as tollows :

1. Turn the balance wheel until the needle reaches its

highest position. Tilt head back on its hinges.

2. Remove bobbin case. ^

3. Turn the two shuttle race cover clamps (B) outward

and remove the shuttle race cover (C) and the shuttle

body (D).

4. Clean the shuttle race, the shuttle, and shuttle race

cover by removing all threads, lint, etc.

When the cleaning has been completed, proceed as

follows to replace the shuttle assembly : ^

1. Turn the balance v/heel until the needle reaches its

highest position. ^ _

2 Place shuttle body, (D), in race against shuttle driver and adjust into posi ion.

3. Replace shuttle race cover, (C), fitting pin at lower edge into notch, and lock into position

wth shuttle race cover clamps, (B), making certain the clamps nave been snapped secure y

into position.

4. Put bobbin into bobbin case. ^ ^

5. Put the bobbin case into the shuttle, fitting tongue into notch t ot race cover.

Fig. 54

Page 27

26

adjusting and changing "V" BELT

Fig. 55

Pone»« a.e « « « a« chan,« the 'oeU :

.wing are me .

Open bobbin winder cover door Fig. ■ tipping it out at the bottom and

(1)

ReOove three screws hold« rear o( LOach.ne,

Fig. 56

pivoting around the hand vrheel „.d move bracket B up to loosen belt and

To adjust "V" belt, loosen screws (A, tig. i

(3)

down to tighten.

To remove "V" belt;

(4)

(A) Remove top cover.

(3) Loosen clutch „g„ ^^3 highest position.

(B) Shp^elt off then over motor pulley.

(E) Replace "V" belt by slipping it over nan

(F ) Adjust as noted under No. -•

Fig. 57

Page 28

El.

m

27

TROUBLE CHART

Probable Cause

Thread or lint in

raceway

Correction

1—With take up lever in highest pohtion, tilt

head back on hinges and remove bobbin case.

RACE

CASE

LATCH

BOBBIN

NOTCH

RACE COVER

HOOK CLAMPS

2^Turn clamps outward and remove race cover.

3— Remove hook. , • i j

4— Clean thread and lint from all parts, includ

ing race. , £11

5— Run a drop of oil along rim of hoo£.

5-....-Replace hook, then race cover, bnap damps

into place. ,

7—Qrasp threaded bobbin case by latch and re

place, fitting tongue into notch of race cover.

'.-X'

S -

^'i ■'W*V *

O'

№

i7 ' ’ *’T4

Page 29

;fl

28

Probable Cause

skipping

Stitches

Bent needle

Needle placed

incorrectly in

Too fine a needle

for thread being used

Upper thread tension

too loose

Improper threading

Bobbin not wound

evenly

________

Pulling or holding

material

Not enough tension

on upper thread

_

____

_____

Discard and replace.

See instruction page No. 6.

:ee

Tighten upper tension.

See threading instruction, page No. 8.

Rewind bobbin.

Avoid pulUng or holding material, just guide it-

Increase tension.

needle and thread chart, page No. 4.^

pTTTqualltY thread : Tdt diiierent thread

'U^edle too line for

_ *1 e -1 /1 /S

thread bt

See needle

and thread chart, page No. 4.

Page 30

29

Upper Thread

Breaking

Material

Puckering

———^ i

Probable Cause j

Improperly threaded ^

Too much tension .

Starting with take up ;

in incorrect position

Improper setting of |

needle ■

Bent or eye of needle ^

too sharp

Bent or blunt needle

Tensions too tight

Dull needle

Stitch length too long

Correction

Refer to threading instructions, see page No. b,

and rethread machine.

Loosen tension on upper thread by turning

thread tension knob to lower number.

Always start sewing with takemp lever in

highest position. .

Refer to needle setting instruction, see page No. 6.

Try a new needle.

Discard all blunt or bent needles and replace

with new.

See tension adjustment, page No. 10.

Change needle.

Reduce stitch length.

_____________________________________- .....

,* f^-,»«5r -^11 mw . ■ mW *11 '*!

.-'.V?1+' .

I " ‘ ■

■■■

i ■'

. ."I*,. N *

ykb*

>'5

,-. •: >V ^ tv

Page 31

>1,

I r

I ' i''

30

s equipped witK tke basic set oi access

Y,,, sewiug macbine comes equ PP

described earlier in this book. ^chmerrts that have

Tke following pages illustrate They are available at m

been designed sp 3uppiy yo

^..ianed specifically for your mac -^3^3,

cost from your dealer. H your ! "ur

. illustrate additiorral time savrrrg

INC.

In Canada

' domestic sewing machines

1420 BIRCHMOUNT 5^°“

SCARBOROUGH, ONTARIO. CANADA

Page 32

SOME OF THE ATTACHMENTS AVAILABLE FOR YOUR-MACHINE

31

PART #1873

PART #1403

PART 14990

Darning Spring

Cording & Zipper FOQl

Ruffler

PART #76554

Edgestitcher

PART #82528

Attachment Foot

PART 174159

Binder

Hemmers

l

V4

%

■PART J76S53

PART #76352

PART #76550

: ,•

■ ’-i ' ■■' J.j't ■■ ■-■. V -.'V.-'.. . .■' .

t’-'

1 «r'.«•

X*’ .»‘ O'

>- •

■ - . VV

;>/'.!;■ "-7 d.

: ■p‘ - \

■ ••■''* ■ ■ ^

Page 33

32

Fig. 58

EDGESTITCHER

The edgestitcher is used in mak

ing dainty lace insertions, edgings

and piping.

The slots in the edgestitcher

serve as guides in sewing together

various pieces of material. If you

want to sew lace, lace and embroi

dery, or lace and tucked strips togeth

er, place the piece of material that

will be on top in slot 1 (Fig. 59)

and the lower fabric in slot 4. For

instance, if you are sewing lace edg

ing to a finished edge of fabric,

place the fabric in slot 1 and the

lace in slot 4 (Fig. 60).

ATTACHMENTS

Be sure the needle positioning lever is in the

extreme left hand position.

ATTACHMENT FOOT

In order to attach binder, edgestitcher and the

hemmers, it is necessary to remove the presser foot

and replace it with the attachment foot. (Fig. 58)

Mount binder, edgestitcher or hemmers by

sliding the attachment to the left as possible and

tightening the screw.

The mounting slot enables you to sew as close

to or as far away from the edge as desired. Just move

the attachment to the correct position before tighten

ing the mounting screw.

1

C-''^

't' rfi-:-

; ■ -(Ttílí Wt -

Page 34

Ro <?ure to draw the lace and material under the needle and back of the edgestitcher so that

th*. wiU carry it backward as you stitch. Hold the fabric in the left hand and the lace in

the iSt being sure the fabric overlaps the lace slightly.

Rick-rack can be sewn to the edge of the material in the same manner. ^ ^

To trim with, wid© pipinQ" plo-C© th© fshric in slot 4:, and th© fold of the piping to th© left

in slot 3 for a narrow piping place fabric in slot 2 and the folded eoge of the piping to the

right in slot 3. , . 1 . T- u

■■■■ Slot 5 may be used as a guide m stitching a trench seam.

‘ See Figs. 61, 62, 63, and 64 for suggestions on how to use the edgestitcher

hundred of other uses.

33

There are

Page 35

BINDER

This attachment folds bias binding and applies it to the edge of material in one operation

Tlots on scroll of the binder are for corresponding widths of commercially folded bias bindin

The open mouth of binder scroll is used for unfolded bias strips cut 15116 inch wide,

FOLDED BINDING (Fig. 67)

Cut a point on folded binding, insert in appropriate

slot. Draw through slot and under binder with strong

oin. Test stitching to be sure it is on

ov sliding binder to right or left.

TWO-TONE BINDING

Two bindings can be sewn on fabric edge also in one

ooeration. When two are used, always skip one size bet-.'/esn widths, inserting each in correct size slot.

the edae. Adjust

Fig. 68)

HAND-CUT BIAS BINDING tFig. 67^

Cut 15 16 inch bias binding fold in half tor a couple

or inches. Cut binding diagonally toward end, almost to

Page 36

THE SET OF HEMMERS

■ Before attaching any of the hemmers, be sure

bobbin thread is pulled up. Then, with hemmer in

place,'hold top thread loosely and turn handwheel one

full, turn toward you, making a loop under hemmer.

. Grasp bobbin : thread with both hands and slip

'■ horizontally under hemmer toward back. Bobbin

thread will catch loop and carry upper thread to back

of heramer. .

' _ , Fold material' to suit for two inches along edge,

i 'hold-at each end of Toldr Slip fold into guide and

' , up over spoon. (Fig. 69). Fold hem in material back of hemmer.

-and Fasten with point of "needle. Pull on threads gently as you start stitching

35

’- --S' V

Fig. 69

Draw forward to end of hem

' HEMMER SET

_ g You can make a hem 1/4T 3/8T 5/8" or 7/8" in width, depending upon

, which.bemmer you use. For a few of the many uses see Figs. 70, 71, 72, 73,

74, and 75. / - - ,

•' ■■,■■■'./■'I

Page 37

Page 38

"\g. 71

THE ADJUSTABLE CORDING

AND ZIPPER FOOT

This attachment is used to make

and insert covered cording, and to

sew in zippers. Loosen thumb screw

to sUde, foot to either right or left

— £ «AAf-llo

CC)RDING. Fold bias strip of

fabric over cord. Loosen thumb

screw and :set foot so needle is cen

tered in needle hole. Machine baste

cord' in place , (Fig. 76—77).

37

Fig. 77

To sew covered cord to material, reset adjustable

(qq,. 30 needle stitches closer to cord, and on edge

of base fabric.

SEWING IN ZIPPER

1 oosen thumb screw and slide foot so needle

enters center of needle hole. Guide metal of zipper

along edge of foot (Fig. 78). Stitching should^ be

close to zipper to . allow easy opening and closing.

Adjust to sew from either right or lef. siae, whic ever is more- convenient.

Fig. 78

U*v-i

m

•-1 ' , ' ^. " ■ ■' • ’ ■ ■■■-', ' : •■ w- ■ ■ ■ ■ ' ■ ■

iSiU-

L'-vT-

*

't i J- 'i- -»*'

____

mm

' _ _ ■—_ '

■ -Mi* *1

----

— • •

Page 39

38

ADJQSTABLE CORDING AND

■i.7* I

.

■

Fig. 80

ZIPPER FOOT

Fig. 81

■- : ■ :■' . r- ::;c.i.:;' v '0 i’■

■OA- ‘ '' ■■■'-"^ ;C'—• A-'iAvbA

3..s.-.tri»^d.^f ■- :^‘r-.. •*,/•• -; ■ WWiJ-5ii_ ■ \ Av-.. .'►. k;- 'i\» Vil.ftf'tirhr

,.' ; .■!., ■ ■. .. ... -<£:i

■■ "■ ■■■.■"0;-*'T'-y-’^': '■■ -J-'N.Mi.C‘. ■••' :■ ■Ri

. ; -OOl

Page 40

RÜFFLER

39

The ruffkr will oroduce yards of delicate ruffling or precision Pl^atii^

¿SfÌra -an also' be done and sewn to another piece or laoric at the same time.

Use the rufiler for making aprons, curtains, pieatm^ a snir., a^aOinj

a dress etc.

'P’ig. 8^

/

' /

ig. 82Ä

Fig. 83

Fig. 84

dftly vergarne a,..=hn,eat =eaa.-e y= -¿^5; “ “ydddudds the bodice o£

/0

/n>

■ i.-

•F

> I

hg. 83A

Fig. 84A

'1

n-A-t.- yv : o-d.:-..: . ■ . # ■ i. y -éo-'-rn- ■■ i J ' - ■ . -

. '(

Page 41

Page 42

41

1

'A’l, - hairline finish is particularly desirable for the inside seams of sheer collars,

facin!;"and vok;;, ¡earn allowance that would ordinarily show through is eliminated by folio ina the seam outline with a narrow zigzag stitch.

to seam allowance close to line of stitching. Turn and press.

EVENLY SPACED BUTTONHOLES

SEWING TIPS

To make a row of buttonholes even y spac ^ ^ oattern to position on the garment

the buttonholes on one long strip oi tissue paper, ^ paper away

with fabric strips under each marking. Stitch around the outlines Hen tear paper y

, , 1 accurately stitched, draw the outlines for

■’O'n'c .

'r^-- -

Page 43

SOTER^MATERIALS

Mo.t laoncs need to be^^ded only .n iront

!str!s iïs

back of the presser foot as shown at right. ^

%é

6S

!',' ■■ ,

i::: '

■' i. '. ' ^'-g.''■■•■ ' ._.o ■ r . ■ ''r

- -bid p?;vp V'. o:î:n^

' ..>r d,L-i-b=-, ,b;--.Vi: d ,;t,' "■ ,hv^'-

. -b- •:■;•>'■ ■■v-t.

'..:.b b ' - r nbsfebi#baSi?êf:!№^

-; rb-. O.. « ï?«bîi-,rrobÎiKïÿ¥b&^

r ' '■.;d.,.o y. -, fcn,.:. .a^;5g4b-lS^

• '^:

' r b -.J-): ■

" olM

ï-'*Î''V'Îr^

mm::

... .:. '^b:.

Page 44

OVERCASTING WORN EDGES

1 .-^/-lrтoQ Pritclpirici tin© 3.S

leirnlrow.:; needle .= In.t

el the labdc on ,he «h. (Fid- 96),

PATCHING

Machine baste paten into

place under hole or worn

area which has been cut away.

Then zigzag stitch the paten

into place by overcasting

around edge oi hole iFig. 97].

Fig. 97

STRAIGHT OR THREE CORNERED TEAR

43

- :ilmy

39 tne

' end ■

Zigzag stitch along a strihght tear catching

««rl rifiht Side of tear by swing of needle. Be sure your

tensions are not too tight or puckering will be encounterea.

In mending a three cornered tear, zigzag stitch nom each

end to c»ter CFto*

... .. Vv

.V '

Fig. 98

/

Page 45

44

t3T

Cu^ itraiqht or bias strips of fabric 2"

rvide ana i" longer than the desired but*

tonhcies. г lace right sides together over

ccsitions fcr buttonholes, hlark eracr length

rf aacn budcnncie m center of each str p;

olace a cm thrcugn center or the marking,

oecin to sdrch at the pin; marking an oblong

oca *'s ' aocve ana Peiow the line; tg" across

eacln encl. dun a few stitches beyond start

ing coin: to remtcrce. View 1.

olasn mrcugn the center line of the boo

to within " 1 oi each end, then diagonally

Int-o eacn corner, view 2. hum the strip

mrcugn :h-e opening, press seams flat across

dte erihs sc the racing will not be visible

Ircm the ngnt side. Fold the strip to meet

in the center ot the opening. Haste the folds

together across tne opening. View 3.

Turn garment back at each end and stitcn

across tne strip, securing the triangular slashea section to the pleated strip and press. View

4. Ering facing of garment to position and

caste around each buttonhole. Insert the

ncint of a pin through each corner and slash

thrcugn the center and into each corner pin

turn uncer the raw edges and slip stitch

the lacing to the underside of the buttonhole,

View 3. Hress the finished buttonhole, View

iOUND BUTTONHOLE

о

si

tc

ti,

b<

gi

fa

cl

В

C

or

he

sc

VIEW ЬШ

4Щ;ру4^;4^,|||

' W :•■ ■■ -Ф' ■■ ■ ' '"Aji.- ■iSdiff

-libl"' ' .t'^bil... : d. t.ysti?

.4‘S# -t*:-' -»tfi

Page 46

Page 47

46

PASS

MOTOR-LIGHT

LEADS THROUGH

SLOT IN

PARTITION

"‘‘I'',''' ■■■ :,-^

Page 48

BACK OFF '

SET SCREW

TO CLEAR

HINGE HOLE

47

INSTALLING SEWING HEAD IN CABINET

1.

Loosen both. hmmA Mag« smt screws

O

until head hiag#' hole ^ is clear.

2.

Tilt head hiage, ap and back

as far as they^will go. , /

“CP-L;GJH i

:^t„GGS

-lEAD rnNGE SET

"LAP

TO LC'VER

i-EAD TITO

CABINE

SCREWS

HEAD HINGE

HOLES

HEAD HINGES

HINT: STRETCH

A RUBBER BAND

ACROSS THE TWO

HINGi^S TO Ht-LP

HOLD THEM UP

RIGHT WHILE

MOUNTING THE

SEWING HEAD,

3.

CaieiiiUy sMp head onto head hinges

- - making sure {ingers ace inserted

as far as they can go into head hinge

holes.

4. Allow the head to rest in its tilted*

back position.

5. Tighten both set screws —enrely with

screw driver,

6. Plug electrical leads into sockets lo-

Gated inside cahinot. Cord identiiied

with "motor* tag must be plugged

into socket marked *motor*. Un

tagged cord goes to *Uaht* eodeet

. 'alT-Vu U.S,,:l-Aj

A,;.'

AT, Li ' ■ tí

Loading...

Loading...