Page 1

Domestic

SEWING MACHINES

OWNER’S

MANUAl

MODEl 711

iert ullys ,>„

iO<'

SINCE 1868

^o\

^/fnply

Page 2

INDEX

Pages

Accessories

How to Use

Hemmers

33-34

Seam "^¡uge or Cloth Guide 21

Quilting Guide

Attachments

Adjustable Cord and Zipper Foot -35

Attachment Foot

Binder

Edgestitcher 30

Hemmers 39

Rüffler 37

Bobbin

Placing in Shuttle 7

Threading 6

Winding 5

Buttonholes iß

Bound 42

Buttons Sew-On 17

Charts

Needle-Thread-Fabric-Stitching 4

Stitch Length 9

Trouble 25-26-27

18

19

Pages

Darning and Mending

11

Embroidery

Creative

Hoop

14

15

Features and Parts (Front View)

(Back View)

Installation - Head in Cabinet

Head in Portable case

Maintenance and Care

Cleaning and Oiling the Shuttle

45

43

22

23

Needle Setting

Pressure and Feeding of Fabric

Thin and Lightweight Fabrics

11

11

Reverse Sewing

Sewing Preparation

12

Sewing Tips 39-40-41

Straight Stitching . 13

Tension Adjustment 10

Threading-Upper 8

2

3

6

9

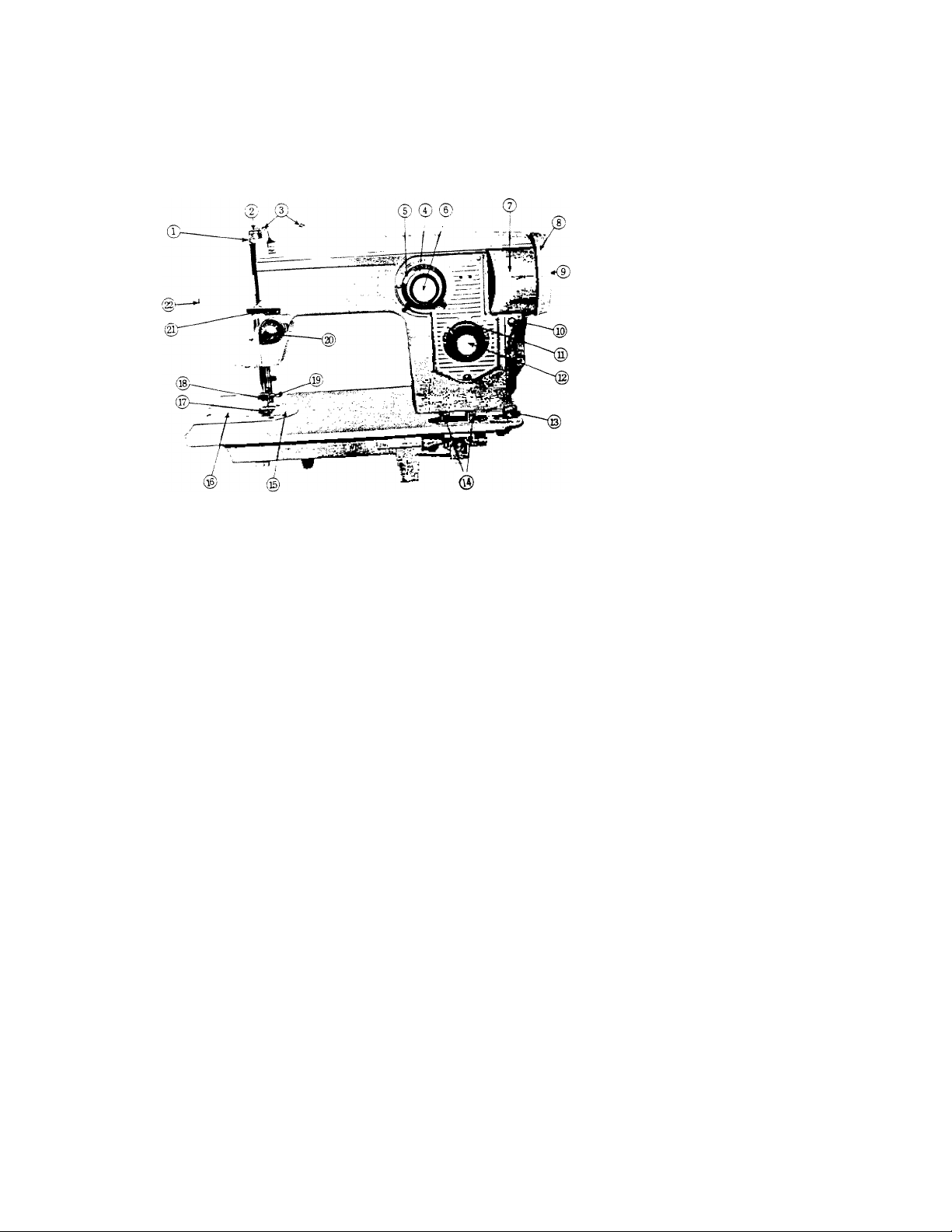

Page 3

FEATURES AND PARTS

(Front View)

Fig. 1

1. Thread Take-up Lever

2. Pressure Release

(Darning)

3. Arm Thread Guides

4. Zigzag Stitch Width Dial

5. Zigzag Stitch Width Lock

6 Stitch Width Control Knob

7 Bobbin Winder Cover

8. Hand Wheel

9. Clutch

10. Cover Release Button

11. Stitch Length Control

12. Push Button Reverse

13. Bobbin Winding Tension

14. Drop Feed Buttons

15. Needle Plate

16. Cover Plate

17. Presser Foot

]_0^ Presser Foot Thumb Screw

19. Needle Clamp

20. Tension Regulator

21. Thread Bar and Guide

22. Sew Lite Switch

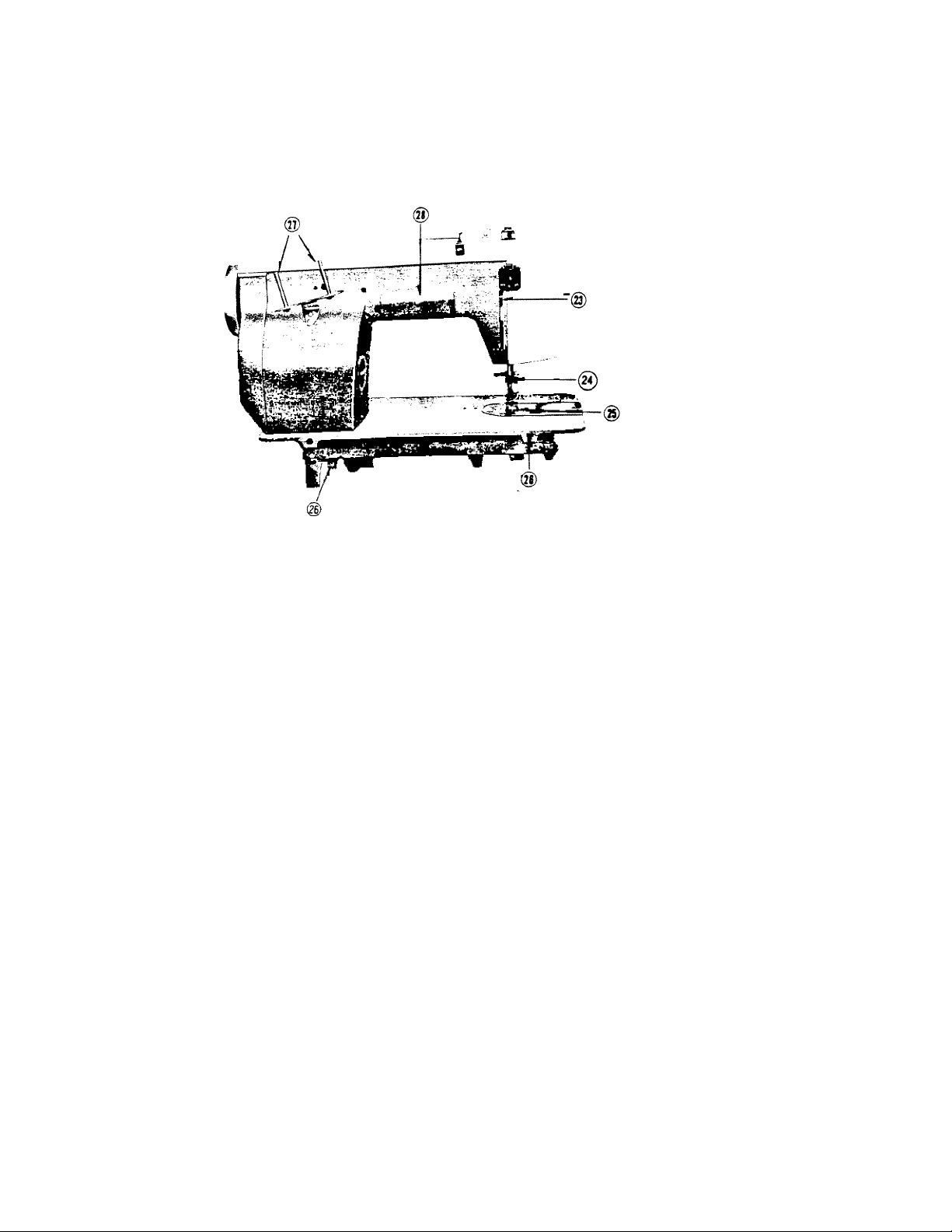

Page 4

Fig. 2

FEATURES AND PARTS

(Back View)

23. Presser Bar Litter

24. Thread Cutter

25. Feed .

26. Head Hinge Mounting

Holes

27. Spool Pins

28. Handle

Page 5

NEEDLE ■ THREAD - FABRIC - STITCHING GUIDE

Fabric

Extremely heavy

tarpaulin, sacking,

canvas duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth.

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn,

dimity, crepe.

handkerchief linen.

plastic film. etc.

Very sheer chiffon.

batiste, lace, organdy,

ninon, net, marquisett etc.

Needle Stitches Cotton Mercerized

Machine

No. Per Inch Thread Thread

6

4

3

2

1

to

8

8

to

10

10

to

12

12

to

14

14

to

0

16

10

to

30

30

to

40

40

to

60

60

to

80

80

to

100

Heavy Duty

Heavy Duty

Heavy Duty

50

50

(Plastic film)

8 to 10

16

00

to

20

100

to

150

5U

Silk

or

Nylon

A

A

h

Page 6

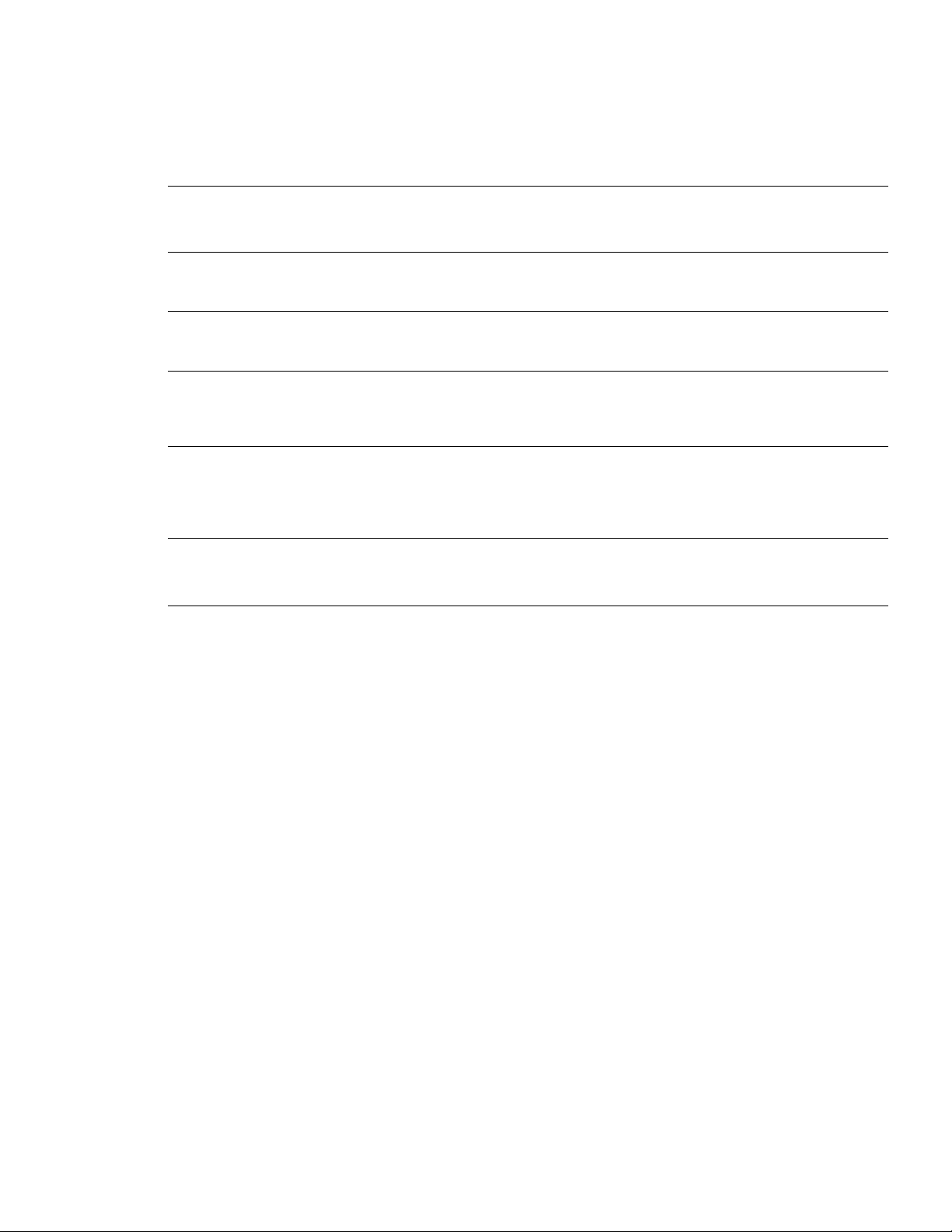

Disengage hand wheel 5, Fig. 3, from the stitching mechanism by turning clutch 6 toward

you or counterclockwise.

of the recessed winder

Lead thread through the upper thread

through a hole in bobbin edge (left flange

and from inside out) and place bobbin B

on spindle of bobbin winder 7, Fig. 4, fitting

the notch bobbin over small pin on spin

dle. Push bobbin winder against hand

wheel. Hold thread end loosely and start

machine slowly.

Bobbin will stop winding when it is

filled. Turn clutch away from you until

sewing mechanism is again engaged so

that needle moves when you turn the hand

wheel.

Break off loose thread end used to

start the winding and thread bobbin as

stated on Page 6.

guide on arm

Push latch 4 (Fig. 4) to spring open cover 3

Place a spool of thread on one of the spool pins.

and down through tension disc 9, Fig. 5, at base of machine. Run end of thread

Fig. 4

Page 7

SETTING THE NEEDLE

^ p Rai3=' the needle bar A to

po J'tuinmg S B

I

(flatside_Jo_2ioru_ n neeaie ^.a-..p

upward as lar as u clamp screw securel^

hole, tightening the ne_ai

with a screw ariver. make one com-

Alter changing the need „heel by

Sï‘'d .»‘'re “nL" thé redte is in the correc,

position.

Fig. 6

THREADING THE BOBBIN CASE

S,ep 1 mustr.ted .n F.g. 8 . »;'"d°“;L°lLor“T.ke“rhe Totb’r be.Lee .humb and

roriiiuro:'::,:. i'- o. tbe bobb.„ =a. .=

s.ep Tr::Tnr:::::^:t - - - --

shown in Fig. 9, and draw

as shown in Fig. 10.

Page 8

SLOT

SLOT

TENSION SPRING

--------------

nd,

ind

as

ing

Fig. 8

Fig. 9

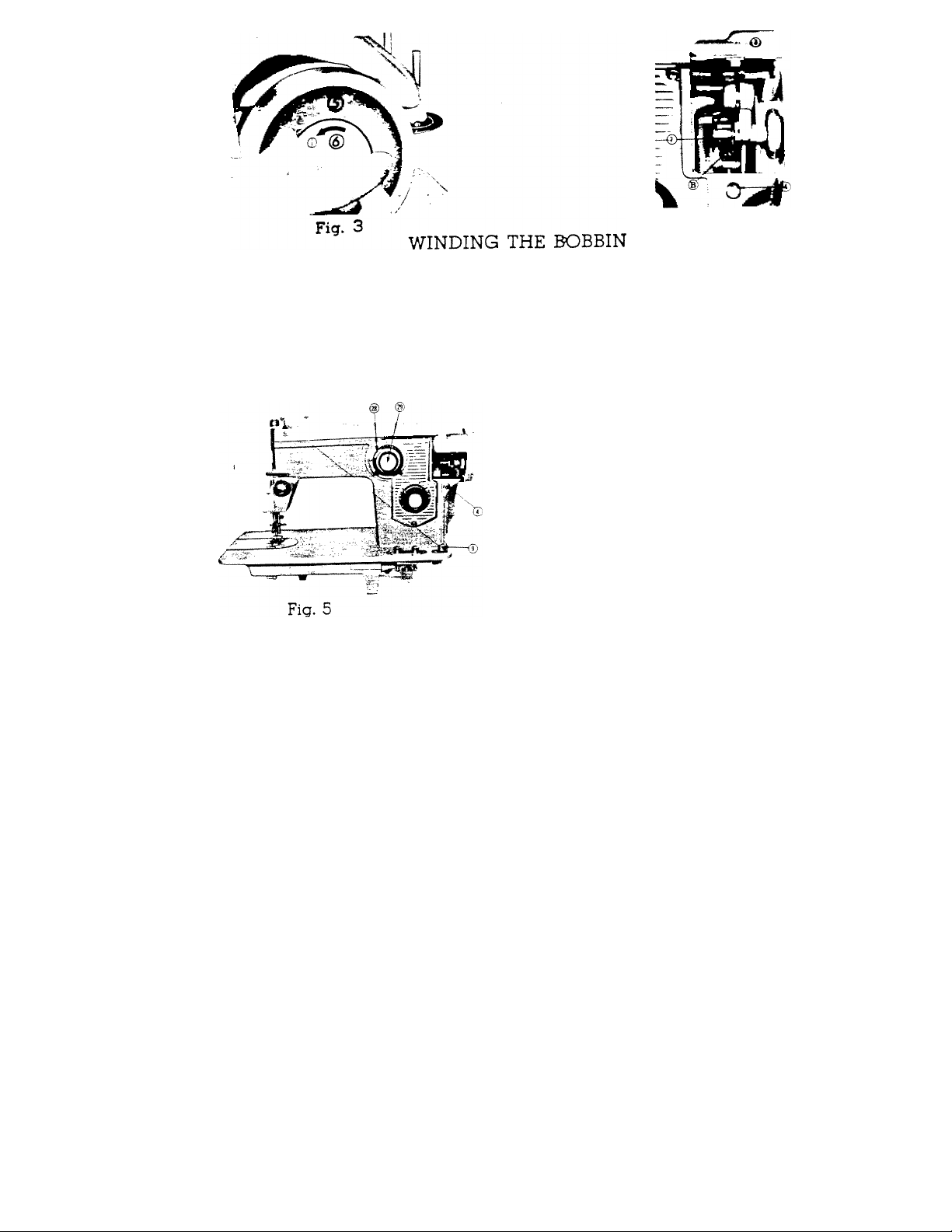

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to highest position, and slide cover plate

to the left. (See 16, Fig. 1) Hold the bobbin case lateh, (D,

Fig. 11) between the thumb and forefinger of the left hand,

with at least three inches of thread running from the top of

the bobbin case to the right. Insert and center the bobbin

case on the stud of the shuttle body, (C). Ee sure the

bobbin case finger, (E), is opposite the shuttle race notch (A).

Press the bobbin case (B) into the shuttle as far as possible

until latch catches on the center post of the shuttle. THEN

release the bobbin case latch, (D). Press bobbin case again

after latch has been released to make sure the bobbin case

is locked securely in place. Close the cover plate.

Fig. 10

Page 9

UPPER THREADING .

Turn the balance wheel toward you to raise

1.

the take-up lever to its highest position.

Place a spool of thread on the spool pin.

2.

Lead the thread through the upper arm thread

3.

Run the thread through the thread guide bar

to the tension discs, then around and be

tween them from right to left.

Draw the thread up through the check spring

and with a slight tug into the hook. 3 (See

insert, Fig. 12) i „k

Pass the thread under the bar and up through

6.

the eye of the take-up lever from right to

Lead thread down under bar, through the

7.

face plate guides and then through the needle

bar guide from tl№ back. RTrHT

Thread needle FROM LEFT TO RIGHT,

8.

drawing it through about 3 or 4 inche^

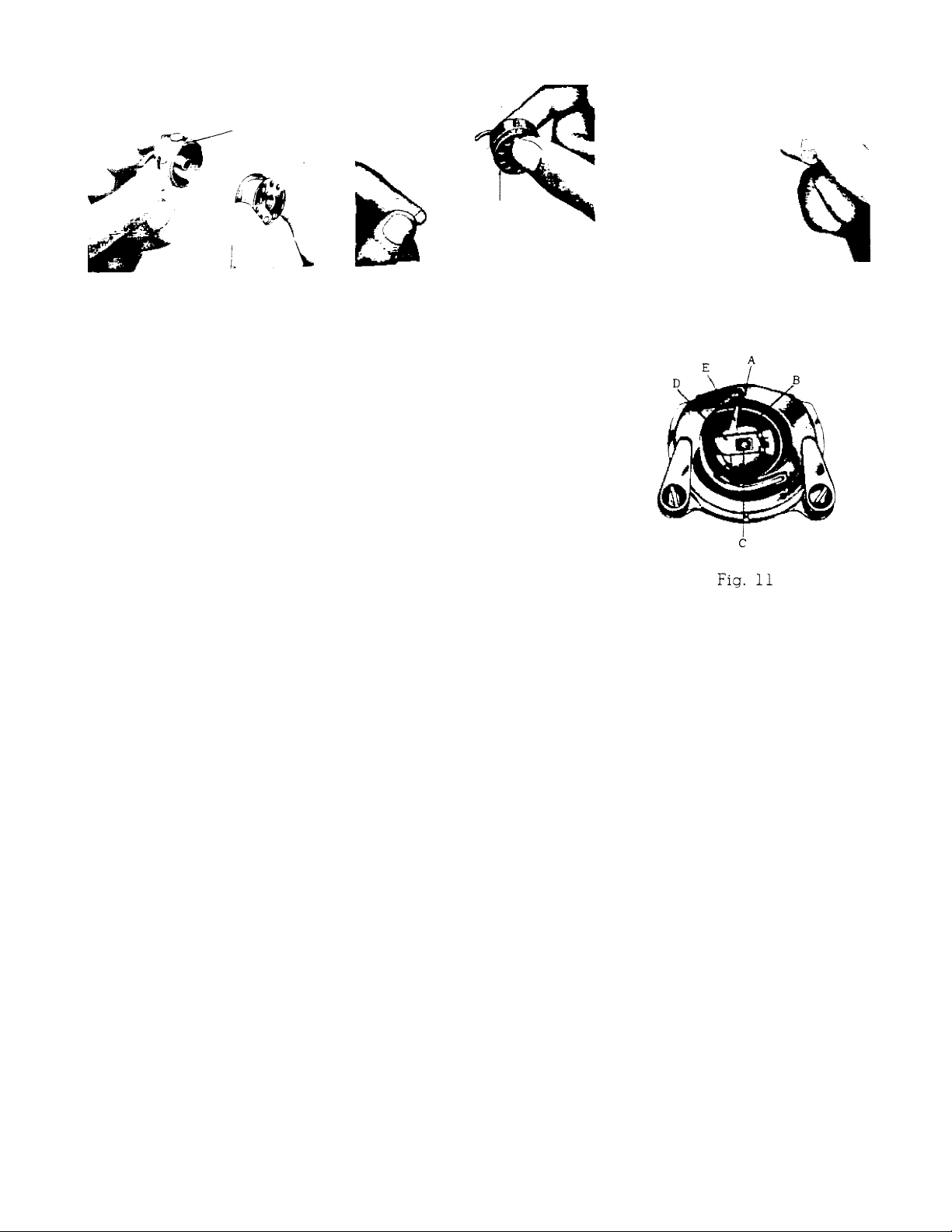

Hold the end of the upper thread loosely and

turn the hand wheel toward you untii the rieedie

goes all the way down and comes back up

A loop (Fig. 13) will be formed over

upper thread which then can be pulled

straight. Place both thread ends under

slot of the presser foot and draw toward

back of the machine, leaving

three or four inches long.

both threads

the

out

the

the

Fig. 12

Page 10

mECK

¡mm

Fig. 14

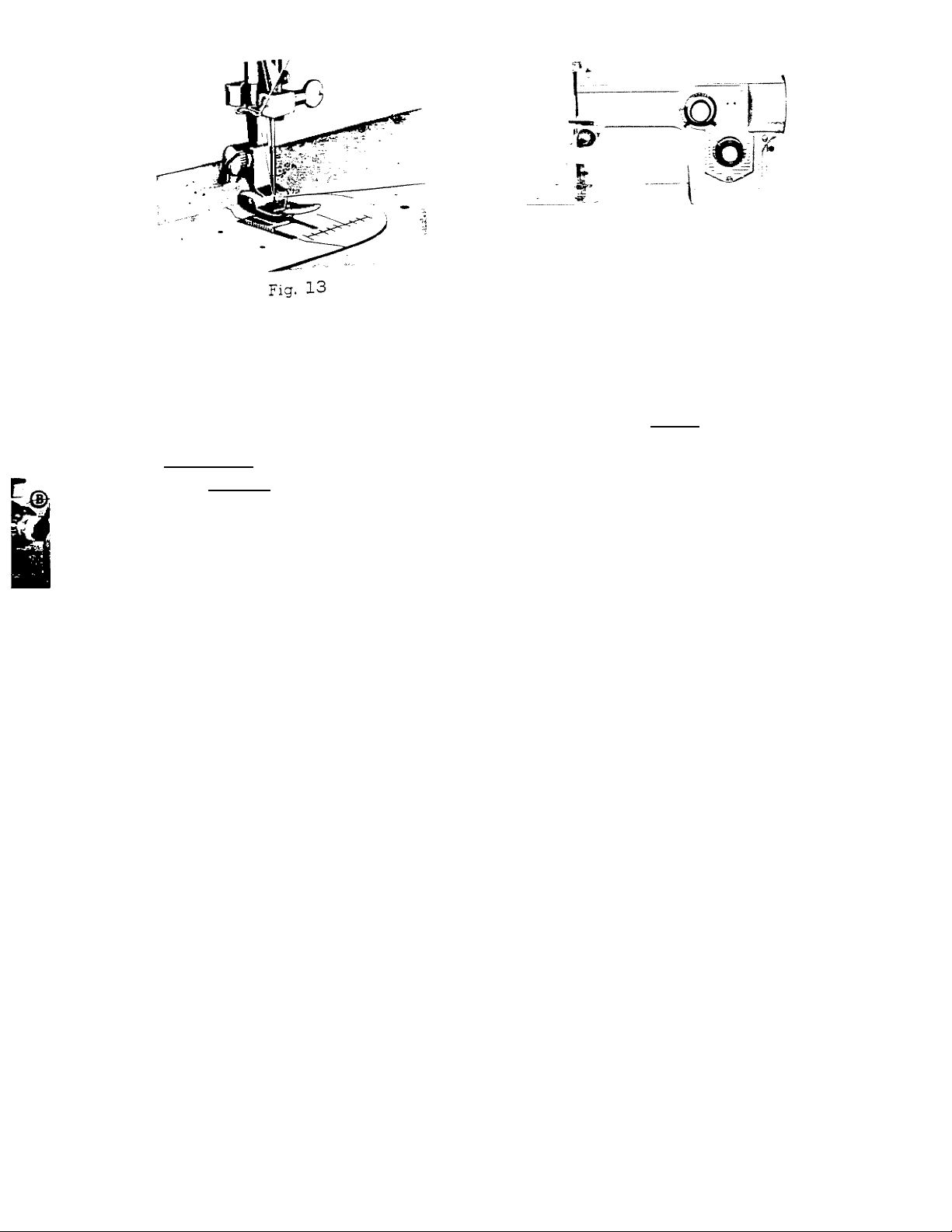

SETTING THE STITCH LENGTH ^

The length o: tne sn.cn is rega y between the markings for a

stitch and 5 IS ;.he the nght to lengthen and to the left to shorten the stitch,

variety of lengths. lurn i e f indicated by the pointer.

The number stitcn length you

. , , , reaulat-ed by the dial, shown in Fig. 14. Near 0 is the shortest

STITCH LENGTH CHART (APPROXIMATE)

___

,, 'r. 2~ 3

Figures on indicator

Number of stitches pei

SEWING IN REVERSE

When you wish to 4ll go The machine will sew backward as long as the

m the button R, Fig. 14, as tar as it win yu

button 13 held in.

, u tn tie the threads at the beginning or end of a seam, press

Page 11

10

ADJUSTING THE TENSIONS

Always adjust the upper tension with- the presses foot down,

as the tension is released when it is raisea. lo increase tne

tension on the upper thread, turn dial (Fig. 15) to the right, or

clockwise; to decrease, turn to the left. The higher the number

on the dial the tighter the tension. Before adjusting lov/er tension

be sure that the machine is threaded properly.

When it is necessary to change the bobbin tension, turn

the small screw (Fig. 17) on side of the bobbin case clockwise to

tighten, counterclockwise to loosen.

Fic. 15

Fig. 16A Fig. 16B

When the upper and under tensions are properly

balanced, a perfect stitch will be formed with both

threads interlocking in fabric (Fig. 16-A).

When the upper tension is too tight, the lower

thread is pulled up over the upper thread which is

lying flat on the fabric (Fig. 16-B).

When the upper tension is too loose, the upper

thread forms loops over the lower thread lying flat

on the fabric (Fig. 16-C).

Fig. 16C

Page 12

12

preparing to sew

Have take-up lever at highest pornt before startxng to sew. Do not try to help the reedxr

by pXg the .s this m.y defied the needle and duse .. to nrean.

KTFVFR run machine without material under presser oo.. v

;^farL?e”.l and th.ada .n

are now ready to begin sewing. By having need The speed of t;'

l^nt r.e^gll:t;\r=rU’'d“„/re P.ednee eneded on the oondol

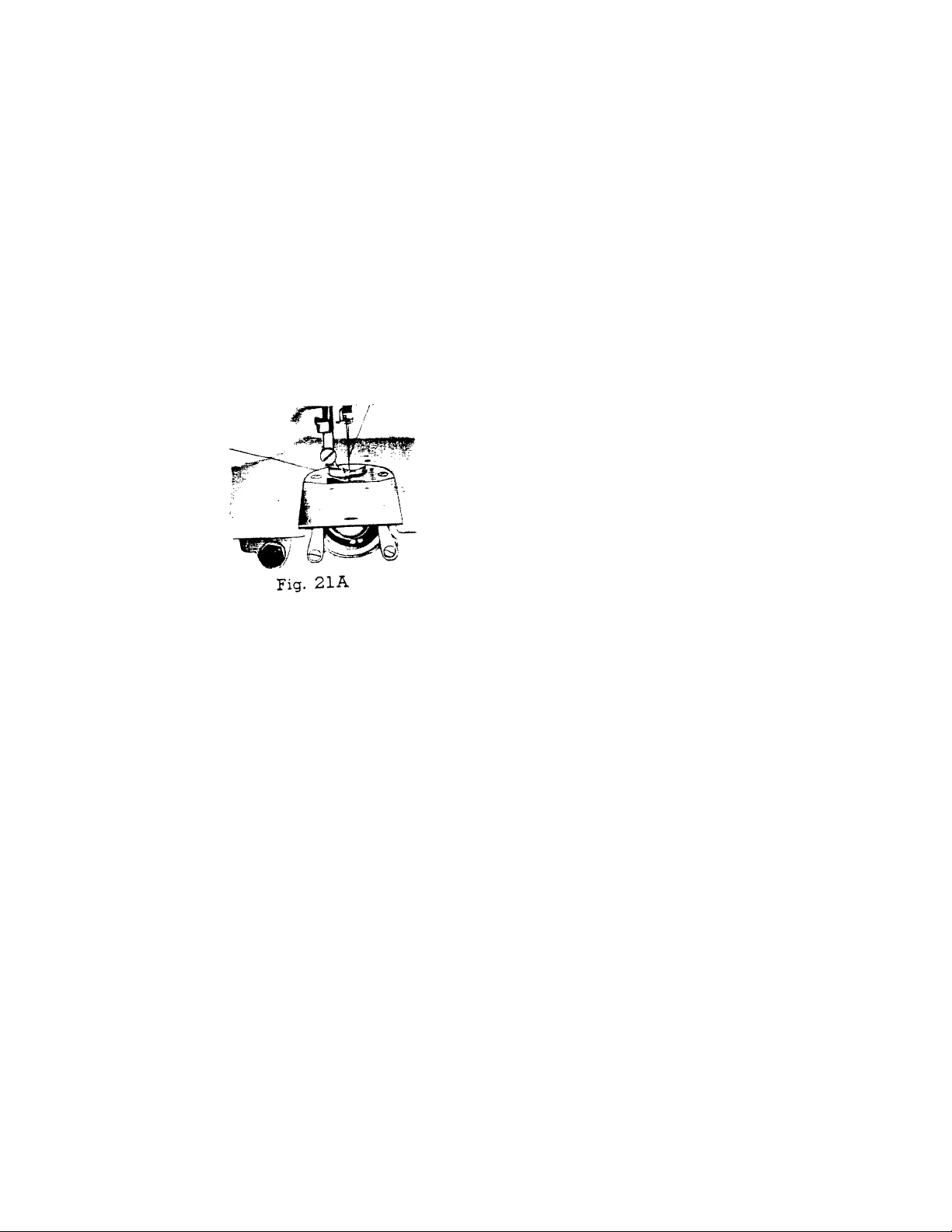

REMOVING THE WORK

llii:

■ 7'

Be sure to stop the machine

when the thread take-up lever

and needle bar are at tne highest

position.

Now raise the presser foot

and draw the fabric back and to

the left (Fig. 21, A and B1 and pass

the threads over the thread cutter.

Pull down slightly, holding

thread in both hands, so as not

to bend the needle. ^

Leave the ends of thread un

der the presser foot.

/■

Fig. 21B

Page 13

STRAIGHT STITCHING

eeding

. You

:essary

of the

ntrol.

eluded in your accessory box. Both

Changing the Presser Foot an

Cl) Presser Foot

(A) Loosen thumb screw

remove zigzag presser oo^

(B) Replace with straight stitch presser foot

(Fig. 22A).

(2) Needle Plate ^

Slide cover plate (lo, iig- ^

(A)

far as possible. „

^ „ -Ur^ldina needle plate (,1b,

Remove screws hoiaing

(B)

Fig. 1) to bed plate.

Remove zigzag needle plate.

(C)

Replace with straight stitch needle plate

(D)

(Fig. 22B).

Be suce to set the -o.-t. -.idtl, and buttonhole

Be sure to set 1x1»=^ °

control knob at 0 or the needle will break in striking

the foot or plate. , -c-- 001 and nress

Grasp outer rim of zigzag dial (A, Fig. 23) and press

down on lock B. Turn dial as far to the left as possible.

Pointer will then be on the zero mark.

Needle Plate:

v

--------—-—

----------

^ ^

V

G

Fig. 22-A

o

O

Fig. 22-B

Fig. 23

Page 14

14

CREATIVE EMBROIDERY

Be sure zigzag presser foot and zig.ag needle plate are in place.

Ihe satin stitch (Fig. 24) which is really just a very short

zigzag stitch and the basis for most embroidery, is obtained

by setting stitch length (see page 9) as near 0 as possible

without stopping the feeding action and lig'ag width at 1,5,

Fig. 23).

To stitch continuously at one width of zigzag stitching

chosen stitch width number.

With the machine set for a short stitch length dif

ferent designs can be made by turning the zigzag width

control knob back and forth between 0 and 5 or any

other combination of widths. Try setting the stop (B,

Fig. 23) at 1 and various other numbers.

Set a rhythm for yourself and then proceed. After

a while you will become quite skillful, varying your de

signs by the speed of the machine, stitch length, and

m.anipulation of the zigzag control knob.

SAMPLES OF CREATIVE EMBROIDERY

Fig. 25

MJIIIIIUUII

niinilfliUi

Fig.

set zigzag width stop iB, Fig. 23'

Uyp il||i jliiiyj mi|ii uji>u mjii iiiuij

A. Sew a few stitches at,5 width, then allow knob

to spring back to 0 for a short period. Count, if necessary,

Fig. 25

to establish a rhythm.

B. Set stop at 2 then move knob slowly back and forth between numbers 2 and 5.

C. Set stop at 1. Gradually move knob from 1 to 5, allowing it to snap back quickly.

D. Set zigzag stitch width stop at 4, stitch length at 1V2- Do a few zigzag stitches, dro

feed for 3 or 4 stitches, then raise it again. By operating the feed knob rhythmically it is n(

necessary to count stitches.

Page 15

inúü'f.

23) to

1 ^

, -dth lock at 5, take 3 or 4 stitches, leave needle m iabnc left of

E. Drop feed, set stitch Continue until flower design is comstitches. Pivot fabric on ^^jth at 0 and taking 3 or 4 stitches in center of design,

píete. Lock threads by s®

embroidering with a hoop

■ follow a stamped design or to

It is easy to Í ^^^^idering or monogram-

work free hand whe

ing. iSee Fig. 26.. r,ng

pressing down

trnt" pL^h^rdCled button down all the

iu

M.

m

■Y-

3s, drop

it is not

way

place under the needle a

I , qpt the stitch width at the size yuu ^

foot. bet tne sum operate the

hoop slowly with both hands. wor

the needle. cHtrhes the fabric is not stretched tight enough or a darning spring

rs needed (see attachments available irom y

V fi. fabric in an embroidery hoop, and

Stretch the fabric m a

speed W.^e »o™, *he^

Should V-dealer illustrated in the back of this book.)

darn or monogram without hoop

If you wish to darn or m 3titch width to suit,

place, release all pressure oi h

and leave feed in sewing position. rnanner,the fabric must be held taut or skipped

When darning or monograming m

stitches will be encountered.

. r^nnoaram without embroidery hoops, leave zigzag presser foot in

Page 16

16

MAKING BUTTONHOLES

mark the beqinning and end of the buttonhole on fabric

with r b.“ng Le o?“.ao?s chalk. Make o„. “»P f

(following directions below) to be sure machine adjustments ar

""T^Replace presser foot with buttonhole foot (Item

which is grooved deeply underneath to prevent piling up of

tlir©3.ci. (S©© 2i7). 1 T u r\

Set stitch width at SVs and stitch length

2.

Lower needle carefully into the mark on fabric ^dicating th

3.

beginning of buttonhole. Stitch to the J^V in

buttonhole, step 1, Fig. 28, stopping machine with needle in

fabric at right side of stitching. T-,ivnt

Lift the presser foot and using the needle as a pi , ^

4.

turn the fabric end for end. , , , ■ . lo I-

Lower presser foot and turn hand wheel ]ust enough

5.

raise needle out of fabric.

raise neeaie oui ui lauxiu. .

Push drop feed button all the way down and ^

6.

zag stitch width knob as far to the right as P°^e ^

and hold. Take five or six stitches to form bar tack ^ ^

s %

T g:

E -S

P g

2

S

T

E $ T-

P

3

S 5 5

T ^ ^

p •/.

P P L

L 5 I

§

E U

Se^eSle^out of fabric, allow stitch width knob to

7.

spring back to stop and return feed 1°_^P P°sifi°^^-

Stitch second side of buttonhole, step 3.

8

.

Stitch bar tack by repeating 5 and 6 above (step ^ fasten bar threads and prevent

9.

Return stitch width to 0 and take two or three *° "Siig careful not to cut the

10.

ravelling. Cut the buttonhole opening with the seam ripper, o y

stitching. V, rar .toft- material place tarlatan or paper, under

If you plan to make buttonholes on sheer or soft materia , p

fabric which can be torn away after stitching.

Fiq. 28

Page 17

SEWING ON BUTTONS

u

C'^ ^

0

M ^ ^

rll

E S|

T I f

E ft

D

revent

it the

under

Remove hinged pressei

1.

See Fig. 29 "DOWN'' all the way. Fig. 33.

Push drop ctoD at 0. Place the button so

2.

ilt'S WtWole.Pomes d.re* ^der the needle, then

3.

gently lower P[®“fjth stop until the needle comes

4.

down ¿Sod, iver the n,ht hand hole in the button,

?OOeWWd‘ wffiel sUwlv by^hand^to

needle enters both

needle, correct ^id ^ the

When needle goes making six or eight stitches,

machine at in the left hole.

6 ToK^the zigzag stitch and prevent ravelling, set the

stitch width at 0, and taxe a ^ ------lUao

“X“„,"bS«Sn thJtwo holes, and sew button to tabrio

FeWvilhrtoothp.ck and wind thread under the button,

forming a sl^^nk to buttons with four

Apply the If a four hole button is to be

holes, hod^ samS procedure as for the two hole button.

Now hh prSsser foot slightly and move fabric to permit

X,- ^ r^resser foot and attach button sewing foot.

=edle in the left hole,

in stitch and prevent r_. ...

I n ^nd take a few stitches in the same hole,

, „ nrav olace a rounded toothpick over the

b lu ^I^afnina two holes. Hooks, snaps, etc., are se%ro

tf fabric S the same procedure as for sewing two hole

buttons.

H:

¡a'”

Fig. 29

bife)

Fig. 32

Fig. 33

Page 18

18

B

1

ACCESSORIES iFig. 34'.

1. Plastic Oiler (Sealed and Filled)

2. Package of Needles (5)

3. Large Screw Driver

4. Small Screw Driver

5. Bobbins (3)

6. Felt Washers (2) (for spool pins)

7. Quilter Guide

8. Cloth Guide

9. Button Sewing Foot Fig. 29

10. Buttonhole Foot

11. Presser Foot for Straight Sewing

12. Narrow Hemmer

13. Thumb Screw

14. Needle Plate for Straight Sewing

(graduated)

Fig. 34

Page 19

HOW TO USE ACCESSORIES

Narrow Hemmer: With needle at its highest position replace regular

presser foot with narrow hemmer (Fig. 35) being sure to tighten it securely

in place. Set decorative stitch dial at manual position, needle positioning

lever center, zigzag stitch width control at OFF for straight stitched hem or

at number 3 for zigzag stitched hem.

For a plain narrow hem make a % inch double fold

for about two inches along edge of fabric. Hold each

end of the two inch fold, slip underneath hemmer. Bring

fold up into the scroll of hemmer, draw fabric forward

to end and fasten with point of needle. Lower presser

bar lifter. Gently pull end of thread as you start stitch

ing (Fig. 35 for straight stitched hem Fig. 37 for zigzag

stitched hem).

Guide material slightly to left and it will take a

double turn through scroll.

The narrow hem provides an excellent finish for

edaes of ruffles or any other dainty work.

Set stitch length control to suit

19

Fig. 37

Page 20

20

LACE TRIMMED HEM

Tn a narrow hem and attach' lace m one stitching

insert lace in the slot next to needle vFig. 38) sew hem as

above guiding lace under needle and hem into scroll Rick

rack may be used in the same way.

LACE EDGE WITH INVISIBLE STITCHING ^

Hold lace 1/8 inch from raw edge on right hand side or

fabric insert both m scroll as for plain narrow hem v Fig. 39,

iJt heiii roll over and sew ш lace. When the stitching is

completed the hem is pressed to the wrong side.

FRENCH SEAM

Place material with right sides facing each °ther and the

too mece of material 1/8 inch irom right hand eage of lower

piLe Insert in hemmer scroll allowing hem to roll over

Ld sew in top fabric making French searn. For wording

effect, use zigzag stitch wide enough to catch both

the narrow rolled hem and

sew with satin stitch. This

can be used for covering

chairs and so forth. Fig. 40.

HEMMING ACROSS

A SEAM

To hem across a seam,

cut the seam folds at an

angle so they will lead into the hemmer gradually^ Press

Sen. Stitch across the seam at the extreme edge to he

together and for added firmness. It may be necessary o

the material slightly when hemming over tne seam. tig. 4l

лО

Fig. ЗУ

Fig. 41

Page 21

quilting guide

V,- miide for making parallel rows of

straight or decorati ^

presser foot^ P>,umb screw from the back and

presser foot fhumb ^¿j^st the curved bar for

bghten screw jFig^4d stitches and

the distance desired b g

set so It previous stitching line, suc-

the guide ride on tn p,g, 45

cessive rows will be an h

^oiative stitching. Attach standard

Fig. 45

SEAM GAUGE OR CLOTH GUIDE

!ss seam,

hold it

to pull

41.

Fig. 46

Use the seam gauge as a guide for f^r^

and even rows of top stitching along edge of fabric.

(Fig^46) 4q^ v/ith accompanying screw

Fasten Gauge (Frg- wuu a ^ Adjust

(Fig.44 ) threaded hole in bed of

to desired width.

Page 22

Fig. 47

CARE AND MAINTENANCE OF

YOUR MACHINE

HOW TO OIL YOUR MACHINE

Use only a good sewing machine oil. Do not use any

common household oils.

Your machine should be oiled occasionally to keep

it operating smoothly How oiten depends on the amount

of sewing you do.

Once a year oil your machine thoroughly as indicated

by the arrows on Figs. 47, 48 and 49

Avoid over-oiling.

Fig. 48

Fig. 49

Page 23

cleaning AND OILING THE SHUTTLE

5ec Fig 5.- anu o.

■ .n mechanism occasionally becomes

The stitch and Imt. This will interfere

clogged with 1°°;® of the machine. Cleaning

the efiicien. op^ safeguard the performance,

and removal of assembly, proceed as follows :

To remove the sh the needle reaches its

Turn the balance hinges,

1.

highest position. Tilt hea

Remove bobbin case. clamps (B) outward

2.

Turn the two snut e

3.

and remove the shuttle race

body ID . shuttle, and shuttle race

Clean the shutt e r

4.

cover by removí g completed, proceed as

"^^"\'^"eplacTthe shuttle assembly:

follows to replace th ^

ows to replace t ^^aches its

1 fVio <rillU.ttl© cLSSSIXlDiy •

Turn the balance

highest position.

-e

..........

- , .'n in race against shuttle driver and adjust into position.

Place shuttle body, v •- fitting pm at lower edge into notch, and lock

2.

Replace shuttle ^^^®J°7lamps '(B), making certain the clamps have been snap

3.

with shuttle race cover clamps, . .,

A . 1. 1 _ t-vr\i

into position.

4.

Pul lilt boU'n^ti'lnto're shuttle, fitting tongue into notch E of race cover.

5.

Fig. 51

____into position

snapped securely

Page 24

ADJUSTING AND CHANGING "V" BELT

Fig. 52

Following are the instructions for adjusting and changing the "V" belt

Open bobbin winder cover door Fig. 52.

(1)

Remove three screws holding rear cover (Fig. 53) by tipping it out at the bottom and

(2)

pivoting around the hand wheel away from the front of the machine.

To adjust "V" belt, loosen screws A, Fig. 54, and move bracket B up to loosen belt and

(3)

down to tighten.

To remove "V" belt:

(4)

(A) Remove top cover.

(B) Loosen clutch C, Fig. 53.

(C) Loosen screws "A" (Fig. 54) and move bracket "B" to its highest position.

(D) Slip belt off motor pulley and then over hand wheel.

(E) Replace "V" belt by slipping it over hand wheel and then over motor pulley.

(F) Adjust as noted under No. 4.

"ig. 53

ng. 54

Page 25

TROUBLE CHART

and

and

If Machine

Binds

Thread or lint in

race% ay

1—With take-up lever in highest position, tilt

head back on hinges and remove bobbin case.

BOBBIN

2— Turn clamps outward and remove race cover.

3— Remove hook.

4— Clean thread and lint from all parts, includ

ing race.

5— Run a drop of oil along rim of hook.

6— Replace hook, then race cover. Snap clamps

into place.

7— Grasp threaded bobbin case by latch and re

place, fitting tongue into notch of race cover.

BOBBIN

NOTCH

RACE COVER CLAMPS

RACE

Page 26

26

Probable Cause

Skipping

Stitches

Irregular

Stitches

Uneven

Stitches

Bent needle

Needle placed j See instruction page No. 6

incorrectly in clamp .

Too fine a needle j See needle and thread chart, page No. 4.

for thread being used ,......................................

Uppsr thread tension

too loose ■

_________—................. 1

Improper threading

Bobbin not wound

evenly

i Pulling or holding

i mAtprial

I

Not enough tension

........................

Discard and replace.

................. ...-

Tighten upper tension.

See threading instruction, page No. 8.

Rewind bobbin. _

Avoid pulling or holding material, just guide it.

Increase tension.

--------—--------

................

........................................

r\n iinner thread

Poor quality thread

Needle too fine for

thread being used

Try different thread.

See needle and thread chart, page No. 4.

..

______________________

Page 27

Correction

Upper Tiiread.

Breaking

Material

Puckering

Improperly tiireaded

Too mucli tension

Starting witli take-up

in incorrect position

Improper setting of

needle

Bent or eye of needle

too sharp

Bent or blunt needle

Tensions too tight

Dull needle

Stitch length too long

Refer to threading instructions see page No. 8

and rethread machine

Loosen tension on upper thread by turning

thread tension knob to lower number

Always start sewing with take-up lever in

highest position

Refer to needle setting instruction see page No. 6

Try a new needle

Discard all blunt or bent needles and replace

with new

See tension adjustment page No. 10

Change needle

Reduce stitch length

________________________________________

Page 28

28

Your sewing machine comes equipped with the basic set of accessories

described earlier in this book.

The following pages illustrate additional time saving attachments that have

been designed specifically for your machine. They are available at modest

cost from your dealer. If your dealer cannot supply you with these items,

ask him to order them for you by part number. Then you will be assured

of receiving the genuine part designed for best performance with your

machine.

If a sewing machine dealer is not available mail your inquiry directly to ;

DOMESTIC SEWING MACHINES

CLEVELAND OHIO 44111

In Canada ;

DOMESTIC SEWING MACHINES

1470 BIRCHMOUNT ROAD

SCARBOROUGH, ONTARIO. CANADA

Page 29

SOME OF THE attachments available for your machine

I .

PART #1403

Rufiler

part #82528

Attachment Foot

part »76553

%

part #76552

PART #4990

Darning Spring

PART #74159

Binder

PART #76551

a « ’

PART 31873

Cording & Zipper Foot

PART #76554

Edgestitcher

' ...... \

r -C— <

Is

%

V4

PART #76550

Page 30

30

ATTACHMENTS

lStitiS5*6aiL.'

Fig. 55

EDGESTITCHER

The edgestitcher is used in mak

ing dainty lace insertions, edgings

and piping. ,

The slots in the edgestitcner

serve as guides in sewing together

various pieces of material. If you

want to sew lace, lace and embroi

dery, or lace and tucked strips togeth

er, place the piece of material that

will be on top in slot 1 (Fig. 56)

and the lower fabric in slot 4. For

instance, if you are sewing lace edg

ing to a finished edge of fabric place

the fabric in slot 1 and the lace in

slot 4 Fig. 57.

Be sure the needle positioning lever i

extreme left hand position

s in trie

ATTACHMENT FOOT

In order to attach the binder, edgestitcher ana

the hemmers, it is necessary to remove the presser

foot and replace it with the attachment foot. Fig. 5o

Mount binder, edgestitcher or hemmers sliding

the attachment to the left as far as possible and

tighten screw

The mounting slot enables you to sew as close

to or as far away from the edge as desired. Just move

the attachment to the correct position before tighten

ing the mounting screw.

Fig. 57

Fig. 56

Page 31

Be sure to cira , as you stitch. Hold the fabric in the left hand and the lace in

,he ieed »'ll thelahr.c overlaps the l.ce shghtly.

the naht, ceing su material in the same manner.

Rick RacK can b _ fabric in slot 4, and the fold of the piping to the left

To trim w>

in slct 3, lor a n

light in slot ^ stitching a French seam.

Slot

‘ 5 ni^y “ „q fiO and 61 for suggestions on how to use the edgestitcher. There are

’ W the lace and material under the needle and back of the edgestitcher so tiia:

narrow piping place fabric in slot 2 and the folded edge of the piping to the

See Fig. 38, by, ou

hundreds of other uses.

1' !Q.

Fig. 58

Fig. 60

Fig. 61

Page 32

32

This attachment folds bias

Slots on scroll of the binde

The open mouth

Dinde- are for corresponding widtns ot commercial ^‘:-

bLd^r scroll IS used for unfolded bias strips cut 15 16 men wiae,

FOLDED BINDING

Cut a point on folded binding, insert in appropriate

slot Draw through slot aud under »>*)>

pin Test stitching to be sure it is on the edg . ]

by sliding binder to right or left.

binding and applies it to the fh!

(Fig. 64')

BINDER

TWO-TONE BINDING (Fig. 65)

Two bindings can be sewn on fabric edge also in one

operation. When two are used, always ^kiP one siz

tween widths, inserting each in correct size slot.

HAND-CUT BIAS BINDING (Fig. 64)

Cut 15'16 inch bias binding fold in half for a couple

of inches. Cut binding d-gonaHy toward end almost o

fold Slip fold into center of binder. Draw bacK imtii

cut opens and binding encircles open end of scroll. Te

stitching to be sure it is on the edge, adjust

and 63 for

suggestions

on how to use

the binder.

There are

hundreds of

other uses.

rat:

Fig. 64

Fig. 63

Page 33

ration.

mq.

THE SET OF HEMMERS

Before attaching any =i the h.mmera^ Be sure

bobbin thread is pulled up. Therr, with hemnrer

P aoe hold top thread loosely and turn handwheel one

toward you, nrakrng a loop under hemmer,

Stasp bobbm thread w.th both hands and shp

horizontally under hemmer toward back, ° ^

thread will catch loop and carry upper thread to back

of hemmer. -

Fold materral to su.t lor two rnohes along edge,

n ,H a- ea-h end of fold. Sl.p fold mto gu.de and ^

nn over Spoon 'Fiq- Go)- ^ ^ ¿-i u-

""P , . a „I „eedle Pull on threads gently as you start stitching,

and fasten witn point Oa neeaie.

^ -L'nld hem m material back of hemmer. Draw forward to ena or hem

Fig. 66

HEMMER SET

You can make a hem 1,'4", 3/8", 5/8" or 7'8" in width, depending upon

which hemmer you use. For a few of the many uses see Fig. 67, 68, 69, 70,

71, and 72.

Page 34

34

HEMMER SET

Fig. 67

Fig. 69

Fig.

Fig. 6i

Fig. 72

Page 35

THE ADJUSTABLE COMINC3

and zipper foot

Fig. 68

Fig. 72

This attacnmen

and insert thumb screw

rslTar^ot to either right or left

of needle^ strip of

CORDING. Loosen thumb

“'0 Tneedle hole. Machine baste

tered in nee no.^lA')

cold m place (F.g- 73-74).

■ „t is used to

Ts^tToot so needle IS cen-

Fig- 74

To sew covered cord to material, reset adjustable

foot so needle stitches closer to cord, and on edge

of base fabric.

SEWING IN ZIPPER

Loosen thumb sore« and sUde loot so needle

enters center oi needle hole. Gu.de metal of mpper

along edge of foot (Fig. 75). Stitching should be

close to Zipper to allow easy opening and o'osing.

idiust to sew from either right or left side, which

ever is more convenient.

Fig. 75

Page 36

Fig. 76

ADJUSTABLE CORDING AND ZIPPER FOOT

Page 37

4

Fig. 80

The ruffler will p^ - ^ another piece of fabric at the same time.

Ruffling can also attachment despite its wide range of use, is simple to nse.

This ® akmq aprons, curtains, pleating a skirt, adding fullness to the bodice o

Use the ruffler lor maKiny f -

a dress and etc.

,, vards of delicate ruffling or precision pleating.

Fig. 81

Page 38

38

RÜFFLER

Fig. 82

Fig. 83

Fig. 85

Page 39

SEWING TIPS

j ■ t hair line finish is particularly desirable for the inside seams of sheer collars

When a allowance that would ordinarily show through is elimmatec

facings, and ^ narrow zigzag stitch.

mg the seam , to line of stitching. Turn and press.

Trim seam auu

EVENLY SPACED BUTTONHOLES

by follow ^

make a row of buttonhbles evenly spaced and accurately stitched, draw the outlines for

t' buhonhLs on one long strip of tissue paper. Fin this pattern to position on the garment

with fabric strips under each marking. Stitch around the outlines then tear paper away.

Page 40

40

SHAPING DARTS IN INTERFACINGS

Fig.

3

c

/¿if

%

Center

" 1'

0

Cut interfacing down center between aart

interfacina

down

Overlap cut edges, matching cart lines. Zigrag _

along marking line from point to wide end o*

Trim both raw edges close to stitching.

center

Cf

ones,

stitcli

aart.

Most fabrics need to be guided only in front of the presses foot as shown at left. Many fil

sheers, crepes, knits, tricots, etc., require support while being stitched. For such fabric use ■

straight stitch throat plate and presses foot and apply gentle tension by holding seam in front a

back of the presses foot as shown at right.

Page 41

filmy

5 the

t and

OVERCASTING WORN EDGES

Zicizag stitch along the worn edges, catching the fabric as

needle swings to the left, and allowing the needle to just

pass over the edge of the fabric on the right (Fig. 93).

PATCHING

Machine baste patch into

place under hole or worn

area which has been cut away.

Then zigzag stitch the patch

into place by overcasting

around edge of hole Tig. 94')-

Fig. 94

STRAIGHT OR THREE CORNERED TEAR

Zigzag stitch along a straight tear catching fabric on left

and right side of tear by swing of needle. Be sure your

tensions are not too tight or puckering will be encountered.

In mending a three cornered tear, zigzag stitch from each

end to center (Fig. 95).

Fig. 95

Page 42

42

PLAIN BOUND BUTTONHOLE

Cut straight or bias strips of fabric 2'

wide and 1" longer than the desired but

tonholes. F lace right sides together over

positions for buttonholes. Mark exact length

of each buttonhole in center of each str p;

place a pin through center of the marking.

Begin to stitch at the pin; marking an oblong

box Vs" above and below the line; V4 across

each end. Run a few stitches beyond start

ing point to reinforce. Viev/ 1. ^

Slash through the center line of the box

to within V4 of each end, then diagonally

into each corner, View 2. 'turn the strip

through the opening, press seams flat across

the ends so the facing will not be visible

from the right side. Fold the strip to meet

in the center of the opening. Paste the folds

together across the opening, View 3.

Turn garment back at each ei d and stitch

across the strip, securing the trie igular slash

ed section to the pleated strip an_l press, View

4. Bring facing of garment to position and

baste around each buttonhole. Insert the

point of a pin through each cor er and slash

through the center and into eac, - comer pin

Turn under the raw edges and slip stitch

the facing to the underside of the buttonhole,

View 5. Press the finished buttonhole, View

6

VIEW X

VIEWS

VIEW5

VIEW4

VIEW 6

Page 43

FOR PORTABLE INSTALLATION

i:ieas^ read these important instructions

.H.^h were written to aid you in placing your

new sewing machine on its portable base.

First remove the nail which holds the loot

control inside the base to avoid damage m

,hipoina. If a small plastic clamp is fastened

the back and not to the top of the parti

tion at one end of the base, remove it, too.

After unpacking the sewing machine unit,

being certain to take out the instruction book,

guarantee and accessory box, lay the unit

face dov7n on a table. You will see two

clamping screws A entering head hinge holes

on the underside of the back.

Cn the base you will find two head hinges

which v/ill fit into holes B. Lower the base

onto tiie sewing machine fitting hinges C into

holes E. lighten screws A securely with a

screw driver.

With machine in sewing position attach

plastic clamp D to top o: partition with screw

provided so that it may be turned across tiie

bed o: the machine, to hold it dowit. ^ v'n

some bases the clamp may be positioned m the

proper spot A

To make the electrical - connection draw

the two wires through the slot in the partition

of the base. Plug the cord labeled "Motor"

into the receptacle marked "Motor" on the

block attached to the outer section of the

base. Then insert the other cord into the

"Light" receptacle.

Place the foot control on the floor, insert

plug into a wall outlet (110-115 volts) and

you are ready to sew. But first read the in

struction book to become familiar with the

threading of the machine, tension adjustments

and all the other features designed to make

sewing a pleasure.

Page 44

Page 45

INSTALLING SEWING HEAD IN CABINET

Loosen both head hinge set screws

until head hinge hole is clear.

OTOR-LIGHt

plugs^

IGHT

^sfr s'iREW

TO clear

HINGE

lift flap

TO LOWER

HEAD INTO

CABINET

HEAD HINGE

HOLES

HEAD HINGES

t««T: STRETCH

A RUBBER BAND

ACROSS THE TWO

HINQES TO HELP

HOLD THEM UP

RIGHT WHILE

MOUNTING THE

SEWING HEAD.

2.

Tilt head hinge fingers up and back

as far as they will go.

3.

Carefully slip head onto head hinges

- - making sure fingers are inserted

as far as they can go into head hinge

holes.

4. Allow the head to rest in its tiltedback position.

5. Tighten both set screws securely with

screw driver.

6. Plug electrical leads into sockets lo

cated inside cabinet. Cord identified

with "motor" tag must be plugged

into socket marked "motor". Un

tagged cord goes to "light" socket.

Page 46

BACK ■

SET SCREW

TO CLEAR

HINGE HOLE

INSTALLING SEWING HEAD IN CABINET

1. Loosen both head hinge set screws

until head hinge hole is clear.

2. Tilt head hinge fingers up and back

as far as they will go.

OTOR-LIGHT

' plugs

IGHT

lift flap

TO LOWER

HEAD INTO

CABINET

HEAD HINGE

HOLES

HEAD HINGES

HINT: STRETCH

JTrUBBER BAND

across the two

HINGES TO HELP

HOLD THEM^UP

RIGHT WHILE

MOUNTING THE

SEWING HEAD.

3. Carefully slip head onto head hinges

- - making sure fingers are inserted

as far as they can go into head hinge

holes.

4. Allow the head to rest in its tiltedback position.

5. Tighten both set screws securely with

screw driver.

6. Plug electrical leads into sockets lo

cated inside cabinet. Cord identified

with "motor'' tag must be plugged

into socket marked "motor". Un

tagged cord goes to "light" socket.

Loading...

Loading...